Methanol Vehicles in China: A Review from a Policy Perspective

Abstract

1. Introduction

2. Rationale for Deploying Methanol Vehicles in China

2.1. Energy Security

2.2. Economic Benefit

2.3. Environmental Impact

2.4. Green Methanol Vehicle Technology

2.4.1. Fuel Technology

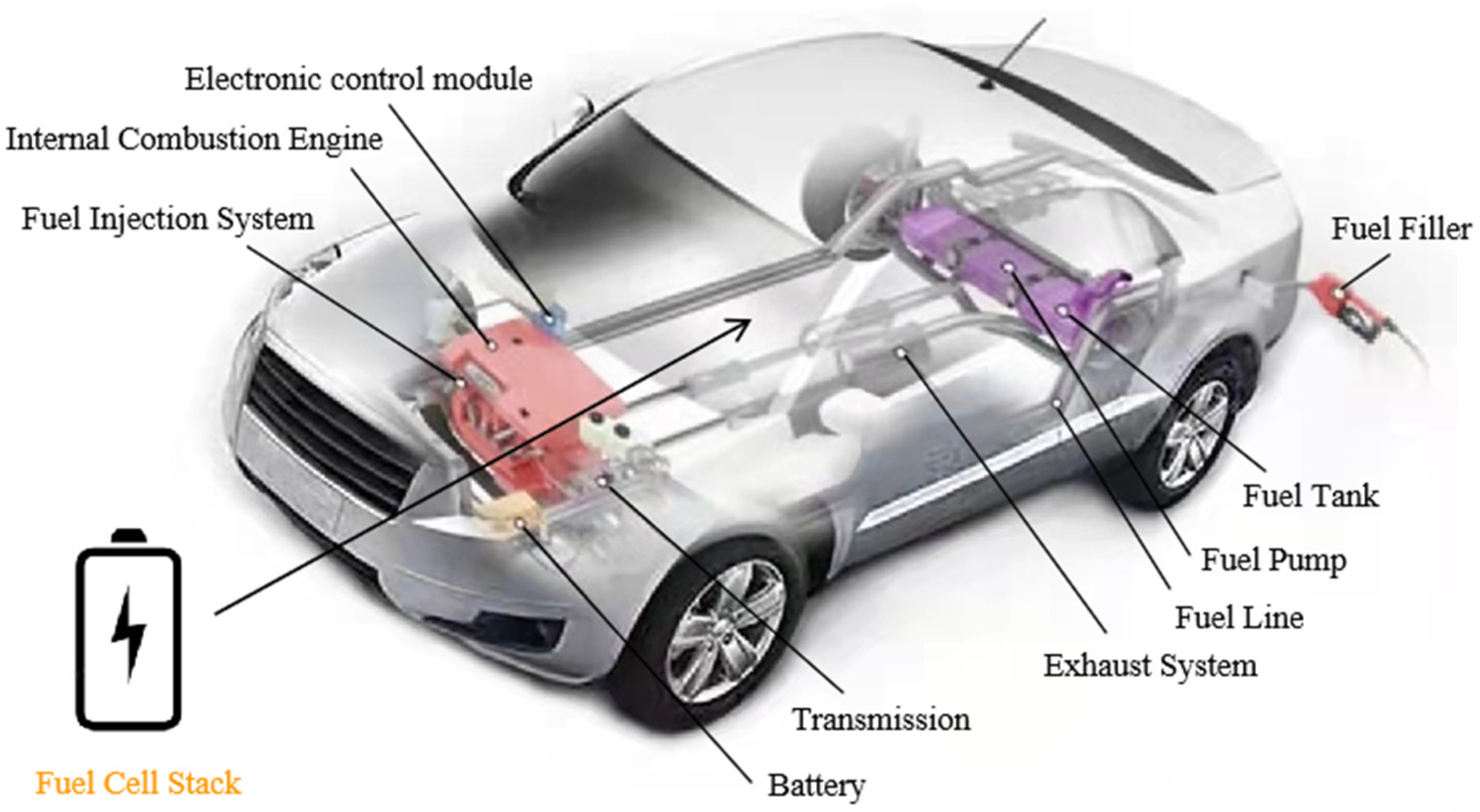

2.4.2. Vehicle Technology

3. Policy Review for Deploying Methanol Vehicles in China

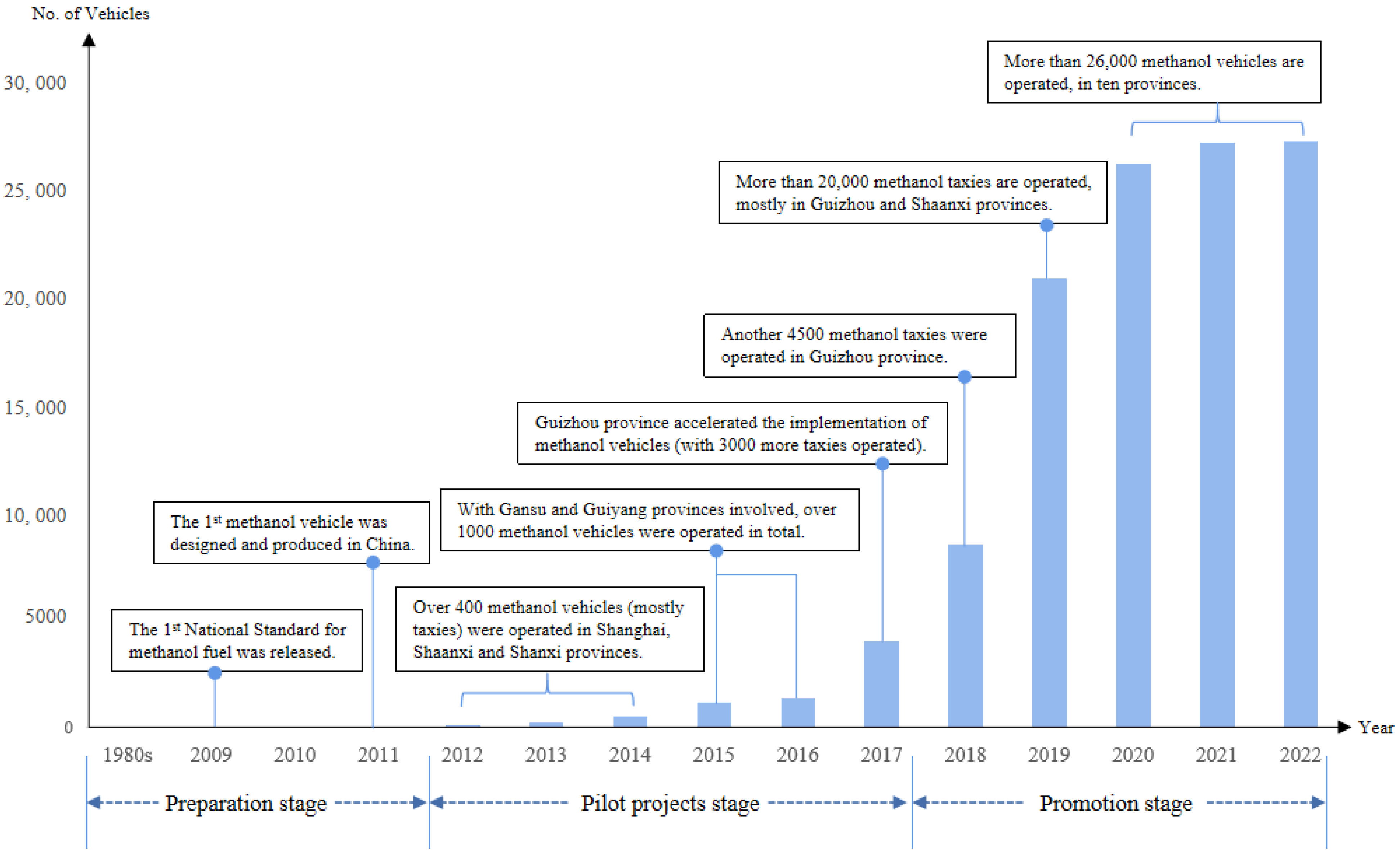

3.1. The Preparation Stage (1980s–2011)

3.1.1. National Level

3.1.2. Provincial Level

3.2. The Pilot Project Stage (2012–2018)

3.2.1. National Level

3.2.2. Provincial Level

3.3. The Promotion Stage (2018 Onward)

3.3.1. National Level

- Technology development is a priority for the application of methanol vehicles. In addition to methanol vehicles, the government also encourages the development of methanol fuel-cell electric vehicles in response to the further deployment of electric vehicles.

- Regarding methanol fuel and fuelling stations, the “Guidance” encourages the production of methanol through multiple pathways and the expansion of fuelling stations; it also emphasizes the importance of meeting national standards and local energy conditions.

- The central government aims to regulate the methanol automotive industry by standardizing methanol fuels, methanol vehicles, and fuelling stations.

- Considering local conditions and safety issues, the implementation of methanol vehicles is encouraged in pilot provinces, not nationwide, at present. Subsidies are mentioned for the first time, although the amount is not clarified.

- The regulations for methanol vehicles and vehicular emissions are strict.

- The provincial governments have the right to formulate additional policies for methanol vehicles. However, as the “Guidance” prohibits the use of low-proportion methanol and “methanolized” conventional vehicles, only dedicated methanol vehicles (M100) are encouraged.

3.3.2. Provincial Level

4. Challenges of Further Deploying Methanol Vehicles in China

5. Conclusions and Policy Implications

- Green methanol fuel has environmental and economic advantages and can respond to the call of the national “carbon neutral” policy, so it is recommended to further promote its use.

- Different measures are taken depending on the region. For economically developed regions with high carbon emissions, pilot projects for green methanol taxi fleets could be led by the government, thus opening up new research areas to promote the conversion of CO2 to methanol or biomass to methanol vehicle fuel.

- Improve the economy of methanol vehicles. It suggested that the government can introduce relevant policies to subsidize the preparation of methanol fuel and the production of methanol vehicles, to reduce the cost of methanol vehicles and thus further encourage related industrial fields to innovate the key core technologies.

- Support research on key processes and equipment technologies for capturing carbon dioxide to prepare methanol. Carry out basic research on the application of methanol fuel power and thermal combustion engineering.

- For regions with large straw production and abundant biomass resources reserves, bio-methanol fuel can be further developed, thus expanding the scale of bio-methanol vehicles. In this way, the production cost can be effectively reduced according to the regional situation, and the economic advantages of methanol vehicles can be fully utilized.

- Incorporating the carbon-capture portion of the fuel cycle into carbon trading for CO2-to-methanol vehicles to reduce the cost of preparing CO2-to-methanol, such as by allowing companies to purchase or provide subsidies.

- In coal-rich regions, make full use of regional advantages to continue to develop and promote coal-to-methanol vehicles. Thus, the benefits will be maximized, and the economy of coal-to-methanol vehicles will be further improved.

- Combine the planning of the coal chemical industry and other related industries in coal-rich areas, make full use of the existing and proposed methanol storage, as well as the fuel transfer infrastructure, build a methanol fuel transmission and distribution system with coal-rich areas as the core and radiating to surrounding cities, and expand the deployment area of existing coal-to-methanol vehicles.

- Advance the construction of methanol fuel stations. Relying on the planning and layout of existing gas stations, form a supply system with a reasonable layout to meet demand and encourage existing gas stations to increase the filling function of methanol fuel for vehicles through transformation.

- China is a vast country and can diversify into methanol vehicles. For example, in coal-rich areas, coal-based methanol vehicles should be developed vigorously; in natural gas-rich areas, natural gas-based methanol vehicles should be developed; and for areas with developed coal chemical infrastructure, the preparation of coal-based methanol fuel can be increased.

- Strengthen publicity and promotion. Popularize the knowledge of methanol fuel and methanol vehicles, publicize, and promote the importance of the application of methanol vehicles for energy conservation and emission reduction, and improve the public’s awareness and acceptance of methanol vehicles.

- Establish a methanol vehicle data industry platform, and improve the service system of methanol vehicle financing, insurance, leasing, logistics, after-sales service, second-hand car-trading. Promote the innovation of various methanol vehicle business models such as financial leasing and methanol fuel-filling systems. Obtain feedback information to improve relevant technologies and scientifically adjust the output.

- The development of methanol vehicles should have a more comprehensive plan, while the implementation should be further increased to better contribute to the national goal of ‘carbon neutrality’. Before reaching the carbon peak, priority should be given to the development of bio-methanol vehicles and coal-to-methanol vehicles from the economic and environmental perspectives, considering the resource situation of each Chinese province. In addition, a next step could also be to vigorously develop the core technology of green methanol fuel, thus promoting the development of CO2-based methanol vehicles. However, this should also be comprehensively prepared to consider methanol fuel cell electric vehicles in the development scope according to the development situation and make reserves for other technical routes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AEV | Alternative energy vehicles |

| DIIT | Department of Industry and Information Technology |

| EV | Electric Vehicle |

| GICEV | Gasoline Internal Combustion Engine Vehicle |

| ICE | Internal Combustion Engine |

| IRENA | International Renewable Energy Agency |

| M100-Bio-V | Methanol vehicle using neat biomass methanol as fuel |

| M100-CO2-V | Methanol vehicle using neat CO2-to-methanol as fuel |

| M100-Coal-V | Methanol vehicle using neat coal-to-methanol as fuel |

| MIIT | Ministry of Industry and Information Technology of China |

| NDRC | National Development and Reform Commission |

| SETC | China’s State Economic and Trade Commission |

| SSTC | China’s State Scientific and Technological Commission |

Appendix A

| Year | Policy and Big Event |

|---|---|

| 2009 | Before launching methanol vehicle pilot projects, MIIT entrusted Beijing Institute of Technology to test methanol vehicles’ emissions, and the results were compared with gasoline vehicles. |

| Fuel methanol (M100) and methanol-added gasoline for motor vehicles (M85) standards were established, the first standards for fuel methanol and methanol-added gasoline in China. | |

| 2010 | A panel formed by MIIT evaluated alcohol ether fuel and methanol vehicles in the provinces of Shanxi, Shaanxi and Shanghai as the first stage of selecting potential pilot cities. |

| 2012 | The “Key Points of Industrial Energy Conservation and Integrated Utilization”, which was issued by MIIT, proposed the development of methanol vehicle pilot projects in Shanxi, Shanghai and Shaanxi. |

| MIIT released the “Notice on Methanol Vehicle Pilot Projects” and the “Technical Requirement for Methanol Vehicles” as standards for pilot projects in Shanxi, Shaanxi and Shanghai. | |

| Geely Holding Group designed and produced a model of methanol vehicle, which was the first methanol vehicle made by the Chinese automobile industry. | |

| The “Suggestions on Strengthening the Energy Saving and Emission Reduction of the Internal Combustion Engine Industry” was released by General Office of the State Council for promoting petrol/methanol dual fuel vehicles and diesel/methanol dual fuel load-carrying vehicles. | |

| 2013 | The “Data Collection and Management for Methanol Vehicle Pilot Projects” was issued by MIIT. It describes data collection including data on methanol vehicle, engine, emissions, impacts on the environment and human health, fuel specification, and fuel stations. |

| Methanol vehicle pilot projects in Shanxi and Shaanxi provinces (six cities in total) were officially launched. Over 400 methanol vehicles (taxies) were operated. | |

| Shanxi Automobile Holding Group designed and produced a model of a methanol/diesel dual-fuel truck. | |

| 2014 | Provincial standards for methanol-added gasoline were applied in Zhejiang and other 13 provinces. |

| Shanxi government released the “Policies for Accelerating New Energy Automobile Industry”, which categorized electric, methanol and gas vehicles as new energy vehicles. | |

| 2015 | The “Development of Methanol Fuel and Methanol Vehicles in China”, which describes the advantages and barriers of implementing methanol fuel and vehicles in China, was provided. |

| The “Regulation of Constructing Methanol Fuel Station” and the “Safely Using Methanol Fuel” were issued to guide and regulate the construction of methanol filling stations in pilot projects. | |

| Geely Holding Group launched a methanol vehicle test project in Iceland, which was organized and supported by Reykjavik Municipal Government. | |

| 2016 | Methanol Vehicle Development Forum and Exhibition was held in Jiangsu province. International issues including the development of methanol vehicle technology, the construction of filling stations, environmental impact, methanol fuel and vehicle were discussed during the forum. |

| 2017 | MIIT, National Development and Reform Commission, Ministry of Science and Technology held a Panel Conference in Beijing to discuss the future of methanol vehicles in China. The panel suggested constantly promoting methanol vehicles in China. |

| 2018 | The 3rd methanol vehicle development conference was held in Kunshan. Stakeholders from methanol, automobile manufacturing and parts industry participated and displayed their products. Vehicle technology and development trends were discussed. |

| 2019 | The “Guidance of Developing Methanol Vehicles Applications in Some Parts of China” was released by the central government. Detailed regulations for the further implementation of methanol vehicles were listed. |

| 2020 | The Ministry of Ecology and Environment issued the Measurement Method of Non-conventional Pollutants from Methanol Vehicles (Draft for Comments), which strictly stipulates relevant emission parameters. |

| 2020 | The Ministry of Industry and Information Technology issued the “Notice on Adjusting the Requirements for the Access of Methanol Automobile Products”. |

| 2021 | The Ministry of Ecology and Environment officially opened the declaration port for methanol vehicles, and methanol vehicles were included in the unified management of the national automobile industry. |

| 2021 | In the “14th Five Year” Industrial Green Development Plan, “promoting the promotion of alternative fuel vehicles such as methanol vehicles” was included in the “green product and energy-saving and environmental protection equipment supply project”, and “carbon dioxide coupling methanol” was included in the “green low-carbon technology promotion and application project”. |

| 2021 | According to the plan of the Department of Industry and Information Technology of Shanxi Province, by the end of 2021, Shanxi will have an annual production capacity of 150,000 methanol cars, promote 5000 M100 methanol cars in taxis, online car hailing and other fields in key cities such as Taiyuan, and build more than 100 methanol filling stations, strive to promote and apply more than 20,000 M100 methanol vehicles by the end of 2022, and build more than 200 methanol filling stations. |

| 2022 | The Fourteenth Five Year Plan for Scientific and Technological Innovation in the Transportation Field proposes promoting the application of new energy and clean energy, research and develop new energy transportation equipment. |

| 2022 | Guizhou Province issued Several Policies and Measures to Support the Promotion and Application of Methanol Vehicles in the Province (QFGY (2002) No. 172). |

References

- Shao, Y.; Qiao, H.; Wang, S. What determines China’s crude oil importing trade patterns? Empirical evidences from 55 countries between 1992 and 2015. Energy Policy 2017, 109, 854–862. [Google Scholar] [CrossRef]

- Ji, Q.; Zhang, H.Y.; Zhang, D. The impact of OPEC on East Asian oil import security: A multidimensional analysis. Energy Policy 2019, 126, 99–107. [Google Scholar] [CrossRef]

- Rehman, O.U.; Ali, Y. Optimality study of China’s crude oil imports through China Pakistan economic corridor using fuzzy TOPSIS and Cost-Benefit analysis. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102246. [Google Scholar] [CrossRef]

- Sahu, B.K. Wind Energy Developments and policies in China: A short review. Renew. Sustain. Energy Rev. 2018, 81, 1393–1405. [Google Scholar] [CrossRef]

- China National Petroleum Corporation. Oil and Gas Imports in 2018. Economics and Technology Research Institute. 2019. Available online: https://etri.cnpc.com.cn/en/ (accessed on 10 December 2020).

- Lin, B.; Wang, T. Forecasting natural gas supply in China: Production peak and import trends. Energy Policy 2012, 49, 225–233. [Google Scholar] [CrossRef]

- Zhang, Z.X. The overseas acquisitions and equity oil shares of Chinese national oil companies: A threat to the West but a boost to China’s energy security? Energy Policy 2012, 48, 698–701. [Google Scholar] [CrossRef]

- Wang, J.; Feng, L.; Zhao, L.; Snowden, S. China’s natural gas: Resources, production and its impacts. Energy Policy 2013, 55, 690–698. [Google Scholar] [CrossRef]

- Shen, J.; Luo, C. Overall Review of renewable energy subsidy policies in China—Contradictions of intentions and effects. Renew. Sustain. Energy Rev. 2015, 41, 1478–1488. [Google Scholar] [CrossRef]

- Huang, Y.; Yi, Q.; Kang, J.-X.; Zhang, Y.-G.; Li, W.-Y.; Feng, J.; Xie, K.-C. Investigation and optimization analysis on deployment of China coal chemical industry under carbon emission constraints. Appl. Energy 2019, 254, 113684. [Google Scholar] [CrossRef]

- Li, C.; Negnevitsky, M.; Wang, X.; Yue, W.L.; Zou, X. Multi-criteria analysis of policies for implementing clean energy vehicles in China. Energy Policy 2019, 129, 826–840. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Mustafi, N.N. Real-world automotive emissions: Monitoring methodologies, and control measures. Renew. Sustain. Energy Rev. 2021, 137, 110624. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, K.; Dong, X.; Shahbaz, M. How renewable energy alleviate energy poverty? A global analysis. Renew. Energy 2022, 186, 299–311. [Google Scholar] [CrossRef]

- Hao, H.; Liu, Z.; Zhao, F.; Du, J.; Chen, Y. Coal-derived alternative fuels for vehicle use in China: A review. J. Clean. Prod. 2017, 141, 774–790. [Google Scholar] [CrossRef]

- Xian, Y.; Wang, Q.; Fan, W.; Da, Y.; Fan, J.-L. The impact of different incentive policies on new energy vehicle demand in China’s gigantic cities. Energy Policy 2022, 168, 113137. [Google Scholar] [CrossRef]

- Shih, C.F.; Zhang, T.; Li, J.; Bai, C. Powering the future with liquid sunshine. Joule 2018, 2, 1925–1949. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y. An overview of methanol as an internal combustion engine fuel. Renew. Sustain. Energy Rev. 2015, 52, 477–493. [Google Scholar] [CrossRef]

- Svanberg, M.; Ellis, J.; Lundgren, J.; Landälv, I. Renewable methanol as a fuel for the shipping industry. Renew. Sustain. Energy Rev. 2018, 94, 1217–1228. [Google Scholar] [CrossRef]

- IRENA, 2021. Innovation Outlook Renewable Methanol. Available online: https://irena.org/-/media/Files/IRENA/Agency/Publication/2021/Jan/IRENA_Innovation_Renewable_Methanol_2021.pdf (accessed on 23 June 2022). (In Chinese).

- Kumabe, K.; Fujimoto, S.; Yanagida, T.; Ogata, M.; Fukuda, T.; Yabe, A.; Minowa, T. Environmental and economic analysis of methanol production process via biomass gasification. Fuel 2008, 87, 1422–1427. [Google Scholar] [CrossRef]

- Olah, G.A.; Mathew, T.; Goeppert, A.; Prakash, G.K.S. Difference and Significance of Regenerative Versus Renewable Carbon Fuels and Products. Top. Catal. 2018, 61, 522–529. [Google Scholar] [CrossRef]

- Yang, S.; Li, B.; Zheng, J.; Kankala, R.K. Biomass-to-Methanol by dual-stage entrained flow gasification: Design and techno-economic analysis based on system modeling. J. Clean. Prod. 2018, 205, 364–374. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2018, 70, 43–88. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M. A Study of Variable Cell Spacings to the Heat Transfer Efficiency of Air-Cooling Battery Thermal Management System. Appl. Sci. 2021, 11, 11155. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H.; Li, C. Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles. Sustainability 2022, 14, 4975. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Li, C. An up-to-date review on the design improvement and optimization of the liquid-cooling battery thermal management system for electric vehicles. Appl. Therm. Eng. 2023, 219, 119626. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Li, C.; Zhang, H.; Cheng, Y. A High-Performance Vortex Adjustment Design for an Air-Cooling Battery Thermal Management System in Electric Vehicles. Batteries 2023, 9, 208. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Yu, E.; Rao, R.; Xie, J. Review of electric vehicle policies in China: Content summary and effect analysis. Renew. Sustain. Energy Rev. 2017, 70, 698–714. [Google Scholar] [CrossRef]

- Zhang, L.; Qin, Q. China’s new energy vehicle policies: Evolution, comparison and recommendation. Transp. Res. Part A Policy Pract. 2018, 110, 57–72. [Google Scholar] [CrossRef]

- Li, C.; Negnevitsky, M.; Wang, X. Review of methanol vehicle policies in China: Current status and future implications. Energy Procedia 2019, 160, 324–331. [Google Scholar] [CrossRef]

- Liu, S.; Clemente, E.R.C.; Hu, T.; Wei, Y. Study of spark ignition engine fueled with methanol/gasoline fuel blends. Appl. Therm. Eng. 2007, 27, 1904–1910. [Google Scholar] [CrossRef]

- Su, L.W.; Li, X.R.; Sun, Z.Y. The consumption, production and transportation of methanol in China: A review. Energy Policy 2013, 63, 130–138. [Google Scholar] [CrossRef]

- Xie, F.; Li, X.; Su, Y.; Hong, W.; Jiang, B.; Han, L. Influence of air and EGR dilutions on improving performance of a high compression ratio spark-ignition engine fueled with methanol at light load. Appl. Therm. Eng. 2016, 94, 559–567. [Google Scholar] [CrossRef]

- Nguyen, D.K.; Sileghem, L.; Verhelst, S. Exploring the potential of reformed-exhaust gas recirculation (R-EGR) for increased efficiency of methanol fueled SI engines. Fuel 2019, 236, 778–791. [Google Scholar] [CrossRef]

- Qin, Z.; Zhai, G.; Wu, X.; Yu, Y.; Zhang, Z. Carbon footprint evaluation of coal-to-methanol chain with the hierarchical attribution management and life cycle assessment. Energy Convers. Manag. 2016, 124, 168–179. [Google Scholar] [CrossRef]

- Wu, W.; Pai, C.T.; Viswanathan, K.; Chang, J.S. Comparative life cycle assessment and economic analysis of methanol/hydrogen production processes for fuel cell vehicles. J. Clean. Prod. 2021, 300, 126959. [Google Scholar] [CrossRef]

- Al-Qahtani, A.; González-Garay, A.; Bernardi, A.; Galán-Martín, Á.; Pozo, C.; Mac Dowell, N.; Chachuat, B.; Gozalez, G. Electricity grid decarbonisation or green methanol fuel? A life-cycle modelling and analysis of today’s transportation-power nexus. Appl. Energy 2020, 265, 114718. [Google Scholar] [CrossRef]

- Butera, G.; Gadsbøll, R.Ø.; Ravenni, G.; Ahrenfeldt, J.; Henriksen, U.B.; Clausen, L.R. Thermodynamic analysis of methanol synthesis combining straw gasification and electrolysis via the low temperature circulating fluid bed gasifier and a char bed gas cleaning unit. Energy 2020, 199, 117405. [Google Scholar] [CrossRef]

- Nugroho, Y.K.; Zhu, L.; Heavey, C. Building an agent-based techno-economic assessment coupled with life cycle assessment of biomass to methanol supply chains. Appl. Energy 2022, 309, 118449. [Google Scholar] [CrossRef]

- Chinese Academy of Sciences Headquarters. Thousand-Ton Scale Demonstration of Solar Fuel Synthesis Starts Operation in Lanzhou, China. 2020. Available online: https://www.eurekalert.org/news-releases/621503 (accessed on 15 April 2022).

- Shanxi Economic Paper. Jinzhong: Strive to Build a National Methanol Economic Demonstration Zone. 2022. Available online: http://epaper.sxrb.com/shtml/sxjjrb/20220627/770137.shtml (accessed on 15 November 2022). (In Chinese).

- Ward, P.F.; Teague, J.M. Fifteen years of fuel methanol distribution. In Proceedings of the 11th International Symposium on Alcohol Fuels, Sun City, South Africa, 14–17 April 1996; Available online: https://listserver.energy.ca.gov/papers/CEC-999-1996-017.PDF (accessed on 13 August 2022).

- Solomon, B.D.; Barnes, J.R.; Halvorsen, K.E. Grain and cellulosic ethanol: History, economics, and energy policy. Biomass Bioenergy 2007, 31, 416–425. [Google Scholar] [CrossRef]

- Klein, T. Methaol: A Future-Proof Fuel. Methanol Institute. 2020. Available online: https://www.methanol.org/wp-content/uploads/2020/03/Future-Fuel-Strategies-Methanol-Automotive-Fuel-Primer.pdf (accessed on 20 March 2021).

- Dolan, G. Methanol transportation fuels: A look back and a look forward. In Proceedings of the International Symposium on Alcohol Fuels, San Diego, CA, USA, 26–28 September 2005; Available online: http://fuel-future.com/pdf/Meth.transport.fuels.pdf (accessed on 5 July 2022).

- Bromberg, L.; Cheng, W.K. Methanol as an Alternative Transportation Fuel in the US: Options for Sustainable and/or Energy-Secure Transportation; Sloan Automotive Laboratory, Massachusetts Institute of Technology: Cambridge, MA, USA, 2010. Available online: https://afdc.energy.gov/files/pdfs/mit_methanol_white_paper.pdf (accessed on 11 May 2021).

- Nichols, R.J. The Methanol Story: A Sustainable Fuel for the Future. 2003. Available online: http://nopr.niscair.res.in/handle/123456789/17582 (accessed on 14 December 2019).

- Dankner, G. Methanol as a Fuel Alternative. Washington Methanol Policy Forum. 2017. Available online: http://www.methanol.org/wp-content/uploads/2017/06/Dor-Methanol-Economy-June-2017.pdf (accessed on 12 January 2020).

- Ministry of Industry and Information Technology. Methanol Vehicle Development Forum. Methanol Vehicle Pilot Project Briefing Report No.19. 2016. Available online: http://www.ciceia.org.cn/upfile/uploadfile/20170106/14836813418363279.pdf (accessed on 17 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Methanol Vehicle Pilot Projects Passed Inspection. Methanol Vehicle Pilot Project Briefing Report No.24. 2018. Available online: http://www.ciceia.org.cn/upfile/uploadfile/20180918/15372564534482771.pdf (accessed on 13 December 2019). (In Chinese)

- Ministry of Industry and Information Technology. Guidance of Developing Methanol Vehicles Applications in Some Parts of China. 2019. Available online: http://www.miit.gov.cn/n1146295/n1652858/n1652930/n3757016/c6684042/content.html (accessed on 25 March 2020). (In Chinese)

- Nematchoua, M.K. Analysis and comparison of potential resources and new energy policy of Madagascar Island; A review. Renew. Energy 2021, 171, 747–763. [Google Scholar] [CrossRef]

- Lo, K. A critical review of China’s rapidly developing renewable energy and Energy Efficiency Policies. Renew. Sustain. Energy Rev. 2014, 29, 508–516. [Google Scholar] [CrossRef]

- Wang, J.; Dong, Y.; Wu, J.; Mu, R.; Jiang, H. Coal production forecast and low carbon policies in China. Energy Policy 2011, 39, 5970–5979. [Google Scholar] [CrossRef]

- Huang, H.; Yan, Z. Present situation and future prospect of hydropower in China. Renew. Sust. Energ. Rev. 2009, 13, 1652–1656. [Google Scholar] [CrossRef]

- Yang, C.J.; Jackson, R.B. China’s growing methanol economy and its implications for energy and the environment. Energy Policy 2012, 41, 878–884. [Google Scholar] [CrossRef]

- Wu, K. China’s energy security: Oil and gas. Energy Policy 2014, 73, 4–11. [Google Scholar] [CrossRef]

- BP Statistical Review of World Energy 2019. 2019. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2019-full-report.pdf (accessed on 12 February 2020).

- Ming, Z.; Ximei, L.; Na, L.; Song, X. Overall Review of Renewable Energy Tariff Policy in China: Evolution, implementation, problems and countermeasures. Renew. Sustain. Energy Rev. 2013, 25, 260–271. [Google Scholar] [CrossRef]

- The State Council of China. Notice of the General Office of the State Council on Issuing the Program of Action for the Energy Development Strategy (2014–2020). 2014. Available online: http://www.gov.cn/zhengce/content/2014-11/19/content_9222.htm (accessed on 10 November 2021). (In Chinese)

- Tang, X.; Snowden, S.; McLellan, B.C.; Höök, M. Clean coal use in China: Challenges and policy implications. Energy Policy 2015, 87, 517–523. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Y.; Zhang, F.; Di, W.; Zhang, Y. Clean coal technologies in China based on methanol platform. Catal. Today 2017, 298, 61–68. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Statistics Regarding Energy Consumption and Methanol Feedstocks in China. 2019. Available online: http://www.stats.gov.cn/ (accessed on 15 November 2020). (In Chinese)

- Zhao, K. A Brief Review of China’s Methanol Vehicle Pilot and Policy. Methanol Institute. 2019. Available online: https://www.methanol.org/wp-content/uploads/2019/03/A-Brief-Review-of-Chinas-Methanol-Vehicle-Pilot-and-Policy-20-March-2019.pdf (accessed on 20 November 2020).

- National Bureau of Statistics. Statistics Regarding the Price of Different Types of Vehicle Fuel in China (2014–2022). Available online: http://www.stats.gov.cn/ (accessed on 2 December 2022). (In Chinese)

- Li, X.; Zhen, X.; Wang, Y.; Tian, Z. Numerical comparative study on performance and emissions characteristics fueled with methanol, ethanol and methane in high compression spark ignition engine. Energy 2022, 254, 124374. [Google Scholar] [CrossRef]

- Li, J.; Jiao, J.; Xu, Y.; Chen, C. Impact of the latent topics of policy documents on the promotion of New Energy Vehicles: Empirical evidence from Chinese cities. Sustain. Prod. Consum. 2021, 28, 637–647. [Google Scholar] [CrossRef]

- Vancoillie, J.; Demuynck, J.; Sileghem, L.; Van De Ginste, M.; Verhelst, S.; Brabant, L.; Van Hoorebeke, L. The potential of methanol as a fuel for flex-fuel and dedicated spark-ignition engines. Appl. Energy 2013, 102, 140–149. [Google Scholar] [CrossRef]

- Jiao, J.; Li, J.; Bai, Y. Ethanol as a vehicle fuel in China: A review from the perspectives of raw material resource, vehicle, and infrastructure. J. Clean. Prod. 2018, 180, 832–845. [Google Scholar] [CrossRef]

- Pan, W.; Yao, C.; Han, G.; Wei, H.; Wang, Q. The impact of intake air temperature on performance and exhaust emissions of a diesel methanol dual fuel engine. Fuel 2015, 162, 101–110. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Comparative life cycle assessment of hydrogen, methanol and electric vehicles from well to wheel. Int. J. Hydrog. Energy 2017, 42, 3767–3777. [Google Scholar] [CrossRef]

- Cui, C.; Li, X.; Sui, H.; Sun, J. Optimization of coal-based methanol distillation scheme using process superstructure method to maximize energy efficiency. Energy 2017, 119, 110–120. [Google Scholar] [CrossRef]

- Li, C.; Yue, W.; Zou, X. Study on the Optimal Subsidy Policy for the Development of Methanol Vehicle in China. Eastern Asia Society for Transportation Studies. 2017. Available online: https://www.researchgate.net/publication/324329525_Study_on_the_Optimal_Subsidy_Policy_for_the_Development_of_Methanol_Vehicle_in_China (accessed on 16 November 2022).

- Wang, X.; Ge, Y.; Liu, L.; Peng, Z.; Hao, L.; Yin, H.; Ding, Y.; Wang, J. Evaluation on toxic reduction and fuel economy of a gasoline direct injection-(GDI-) powered passenger car fueled with methanol–gasoline blends with various substitution ratios. Appl. Energy 2015, 157, 134–143. [Google Scholar] [CrossRef]

- Department of Industry and Information Technology of Shanxi Province. Methanol Vehicle and Efficient and Clean Utilization of Coal. 2016. Available online: http://gxt.shanxi.gov.cn/SearchDefaults.aspx?pid=1_22_40_43494.xtj&sword=%E7%94%B2%E9%86%87%E6%B1%BD%E8%BD%A6&type=1 (accessed on 14 November 2019). (In Chinese)

- Liu, Y.; Li, G.; Chen, Z.; Shen, Y.; Zhang, H.; Wang, S.; Qi, J.; Zhu, Z.; Wang, Y.; Gao, J. Comprehensive analysis of environmental impacts and energy consumption of biomass-to-methanol and coal-to-methanol via life cycle assessment. Energy 2020, 204, 117961. [Google Scholar] [CrossRef]

- Liu, X.; Hong, H.; Zhang, H.; Cao, Y.; Qu, W.; Jin, H. Solar methanol by hybridizing natural gas chemical looping reforming with solar heat. Appl. Energy 2020, 277, 115521. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, C.; Gao, P.; Wang, H.; Li, X.; Zhong, L.; Wei, W.; Sun, Y. A review of the catalytic hydrogenation of carbon dioxide into value-added hydrocarbons. Catal. Sci. Technol. 2017, 7, 4580–4598. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Wang, G.; McLellan, B.; Liu, X.F.; Wang, L. A review of photovoltaic poverty alleviation projects in China: Current status, Challenge and policy recommendations. Renew. Sustain. Energy Rev. 2018, 94, 214–223. [Google Scholar] [CrossRef]

- Nyári, J.; Magdeldin, M.; Larmi, M.; Järvinen, M.; Santasalo-Aarnio, A. Techno-economic barriers of an industrial-scale methanol CCU-plant. J. CO2 Util. 2020, 39, 101166. [Google Scholar] [CrossRef]

- Khojasteh-Salkuyeh, Y.; Ashrafi, O.; Mostafavi, E.; Navarri, P. CO2 utilization for methanol production; part i: Process design and life cycle ghg assessment of different pathways. J. CO2 Util. 2021, 50, 101608. [Google Scholar] [CrossRef]

- Liu, X.; Sun, X.; Zheng, H.; Huang, D. Do policy incentives drive electric vehicle adoption? Evidence from China. Transp. Res. Part A Policy Pract. 2021, 150, 49–62. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Ghorbani, B.; Shahsavari, A.; Zaitsev, A. Conversion and storage of solar energy in the forms of liquid fuel and electricity in a hybrid energy storage system using methanol and phase change materials. Energy Convers. Manag. 2020, 209, 112669. [Google Scholar] [CrossRef]

- Cui, X.; Kær, S.K.; Nielsen, M.P. Energy analysis and surrogate modeling for the green methanol production under dynamic operating conditions. Fuel 2022, 307, 121924. [Google Scholar] [CrossRef]

- Harris, K.; Grim, R.G.; Huang, Z.; Tao, L. A comparative techno-economic analysis of renewable methanol synthesis from biomass and CO2: Opportunities and barriers to commercialization. Appl. Energy 2021, 303, 117637. [Google Scholar] [CrossRef]

- Zhao, X.; Yin, M.; Ma, L.; Liang, L.; Liu, C.; Liao, J.; Lu, T.; Xing, W. Recent advances in catalysts for direct methanol fuel cells. Energy Environ. Sci. 2011, 4, 2736–2753. [Google Scholar] [CrossRef]

- Verma, S.; Mishra, S.; Gaur, A.; Chowdhury, S.; Mohapatra, S.; Dwivedi, G.; Verma, P. A comprehensive review on energy storage in hybrid electric vehicle. J. Traffic Transp. Eng. 2021, 8, 17. [Google Scholar] [CrossRef]

- Department of Industry and Information Technology of Shanxi Province. Why It Is Difficult to Promote Methanol Fuel in the Past 30 Years? 2014. Available online: http://gxt.shanxi.gov.cn/SearchDefaults.aspx?pid=1_22_42_26775.xtj&sword=%E7%94%B2%E9%86%87%E7%87%83%E6%96%99&type=1 (accessed on 14 November 2019). (In Chinese)

- China Standardization Administration Committee. Fuel Methanol for Motor Vehicles; Methanol-added Gasoline for Motor Vehicles (M85). 2009. Available online: http://www.china-nengyuan.com/tech/73471.html (accessed on 15 November 2019). (In Chinese).

- GB/T 23799-2021; Methanol Gasoline (M85) for Motor Vehicles. China Standardization Administration Committee: Beijing, China, 2021. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=26B4B0DCD219ED7F426C9DF26C7E4054 (accessed on 26 October 2022).

- Faberi, S.; Paolucci, L.; Ricci, A.; Velte, D.; Jiménez, I. Methanol: A Future Transport Fuel Based on Hydrogen and Carbon Dioxide. STOA Science and Technology Options Assessment. 2014. Available online: http://www.europarl.europa.eu/RegData/etudes/etudes/join/2014/527377/IPOL-JOIN_ET%282014%29527377_EN.pdf (accessed on 18 December 2022).

- Shanxi Provincial Government. Notification on Deploying Methanol Vehicle and Methanol Fuel. 2014. Available online: http://www.shanxi.gov.cn/sxszfxxgk/sxsrmzfzcbm/sxszfbgt/flfg_7203/bgtgfxwj_7206/200507/t20050728_160591.shtml (accessed on 16 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Key Points of Industrial Energy Conservation and Integrated Utilization. 2012. Available online: http://www.miit.gov.cn/n1146295/n1146592/n3917132/n4061768/n4061770/n4061771/n4061773/c4066830/content.html (accessed on 16 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Notification on Methanol Vehicle Pilot Projects. 2012. Available online: http://www.ciceia.org.cn/mptdc/news.asp?vid=1224 (accessed on 16 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Data Collection and Management for Methanol Vehicle Pilot Projects. 2013. Available online: http://www.miit.gov.cn/n1146295/n1146592/n3917132/n4061768/n4061770/n4061771/n4061773/c4067864/content.html (accessed on 16 November 2019). (In Chinese)

- The State Council of China. Opinions on Strengthening Energy Conservation and Emission Reduction in Internal Combustion Engine Industry. 2013. Available online: http://www.gov.cn/zwgk/2013-02/17/content_2333161.htm (accessed on 15 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Construction Station and Safety Specifications for Methanol Fuels and Vehicles. Methanol Vehicle Pilot Project Briefing Report No.13. 2015. Available online: http://www.ciceia.org.cn/back/newsmanage/edit/uploadfile/20151221104619857.pdf (accessed on 16 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Ministry of Industry and Information Technology Answers Questions from Reporters on the Pilot Work of Methanol Vehicles. 2012. Available online: http://www.gov.cn/govweb/gzdt/2012-02/29/content_2079545.htm (accessed on 13 May 2022). (In Chinese)

- Shanxi Provincial Government. Guides for Accelerating the Development and Implementation of New Energy Vehicle Industry in Shanxi Province. 2014. Available online: http://www.shanxi.gov.cn/sxszfxxgk/sxsrmzfzcbm/sxszfbgt/flfg_7203/bgtgfxwj_7206/201411/t20141112_161402.shtml (accessed on 18 November 2019). (In Chinese)

- Department of Industry and Information Technology of Shanxi Province. Incentive Policy for New Energy Vehicles in Shanxi Province. 2015. Available online: http://gxt.shanxi.gov.cn/SearchDefaults.aspx?pid=_369_38216.xtj&sword=%E6%96%B0%E8%83%BD%E6%BA%90%E6%B1%BD%E8%BD%A6%E8%A1%A5%E8%B4%B4&type=1 (accessed on 16 November 2019). (In Chinese)

- Industry and Information Technology Department of Shaanxi Provincial. Notice on Printing and Distributing the Key Points of Working Plan for the Preparation of Pilot Operation of Methanol Vehicles. 2012. Available online: http://gxt.shaanxi.gov.cn/gxtwj/18407.jhtml (accessed on 4 June 2022).

- Department of Industry and Information Technology of Guizhou Province. MIIT Agreed to Launch the Methanol Vehicle Pilot Project in Guizhou. 2014. Available online: http://gxt.guizhou.gov.cn/jxdt/wndt/201611/t20161107_1307799.html (accessed on 19 November 2019). (In Chinese)

- Department of Industry and Information Technology of Guizhou Province. Guiyang Applied for Launching the Methanol Vehicle Pilot Project. 2014. Available online: http://gxt.guizhou.gov.cn/jxdt/dsdt/201611/t20161107_1308968.html (accessed on 19 November 2019). (In Chinese)

- Ministry of Industry and Information Technology. Overview on Methanol Vehicle Pilot Projects in Shanghai, Guizhou, Gansu Provinces. Methanol Vehicle Pilot Project Briefing Report No.12. 2015. Available online: http://www.ciceia.org.cn/back/newsmanage/edit/uploadfile/20151030173942240.pdf (accessed on 19 November 2019). (In Chinese)

- Ministry of Ecology and Environment of the People’s Republic of China. Measurement Methods for Non-Regulated Emissions from Methanol Fuelled Vehicles. Standard No. HJ 1137–2020. 2020. Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqydywrwpfbz/202011/t20201113_807830.shtml (accessed on 5 May 2022). (In Chinese)

- Ministry of Industry and Information Technology. “14th Five Year” Industrial Green Development Plan. 2021. Available online: http://www.gov.cn/zhengce/zhengceku/202112/03/5655701/files/4c8e11241e1046ee9159ab7dcad9ed44.pdf (accessed on 7 July 2022). (In Chinese)

- People’s Government of Guizhou Province. The Fourteenth Five Year Plan for National Economic and Social Development of Guizhou Province and the Outline of Vision Goals for 2035. 2021. Available online: http://fgw.guizhou.gov.cn/zwgk/xxgkml/ghjh/202102/t20210224_66840750.html (accessed on 13 June 2022). (In Chinese)

- Ministry of Industry and Information Technology. Announcement of the Ministry of Industry and Information Technology of the People’s Republic of China. Road Motor Vehicle Manufacturers and Products (the 361st Batch). No.21. 2022. Available online: https://wap.miit.gov.cn/zwgk/zcwj/wjfb/gg/art/2022/art_164da9ff3ddd4641a7ea1a199369e589.html (accessed on 20 November 2022). (In Chinese)

- Municipal Government of Xi’an. Policies for Deploying Methanol Vehicles in Xi’an. 2018. Available online: http://xatzw.xa.gov.cn/index.php/article/articledetail/article_id/1193 (accessed on 20 November 2019). (In Chinese)

- People’s Government of Guizhou Province. Notice on the Establishment of Guizhou Provincial Leading Group for the Development of Methanol Automobile Industry. No.66. 2018. Available online: https://www.guizhou.gov.cn/zwgk/zfgb/gzszfgb/201804/t20180428_70523364.html (accessed on 20 November 2020). (In Chinese)

- Guizhou Provincial Development and Reform Commission. Notice on Printing and Issuing Several Policies and Measures to Support the Promotion and Application of Methanol Vehicles in the Province. No. 172. 2022. Available online: http://www.ch3oh.net/view/20509 (accessed on 8 July 2022). (In Chinese)

- Municipal Government of Guiyang. Policies for Deploying Methanol Vehicles in Guiyang. 2018. Available online: http://www.guiyang.gov.cn/zfxxgk/gsgg/qsxgg/20181212/i1875343.html (accessed on 20 November 2019). (In Chinese)

- Department of Industry and Information Technology of Shanxi Province. Notice on Printing and Distributing the Implementation Plan for Accelerating the Development of Methanol Automobile Industry and the Promotion and Application in the Province. 2020. Available online: http://gxt.shanxi.gov.cn/zcwj/wjfb/202110/t20211016_2642146.shtml (accessed on 19 April 2021). (In Chinese)

- Municipal Government of Jinzhong. Notice on Printing and Distributing the Work Plan of Jinzhong City for Accelerating the Promotion and Application of Methanol Vehicles (2021–2023). No. 26. 2021. Available online: https://www.sxjz.gov.cn/zwgk/fdzdgknr/zfwj/szfbgt43zfbgs/content_161134 (accessed on 27 December 2022). (In Chinese)

- Ministry of Industry and Information Technology. Reply to Recommendation No. 2276 of the Fifth Session of the Thirteenth National People’s Congress 2022. Available online: https://www.miit.gov.cn/zwgk/jytafwgk/art/2022/art_9b4f735de4d740348015cd9c4403b29b.html (accessed on 25 December 2022). (In Chinese)

- National Energy Administration of China. Coal Clean and Efficient Utilization Action Plan (2015–2020). 2015. Available online: http://ynb.nea.gov.cn/front/article/102203.html (accessed on 21 November 2019). (In Chinese)

- Brandt, A.R.; Farrell, A.E. Scraping the bottom of the barrel: Greenhouse gas emission consequences of a transition to low-quality and synthetic petroleum resources. Clim. Chang. 2007, 84, 241. [Google Scholar] [CrossRef]

- Zhu, L.; Cheung, C.S.; Zhang, W.G.; Huang, Z. Influence of methanol–biodiesel blends on the particulate emissions of a direct injection diesel engine. Aerosol Sci. Technol. 2010, 44, 362–369. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Li, C.; Jia, T.; Wang, H.; Wang, X.; Negnevitsky, M.; Hu, Y.-J.; Zhao, G.; Wang, L. Assessing the prospect of deploying green methanol vehicles in China from energy, environmental and economic perspectives. Energy 2023, 125967. [Google Scholar] [CrossRef]

- Li, C.; Bai, H.; Lu, Y.; Bian, J.; Dong, Y.; Xu, H. Life-cycle assessment for coal-based methanol production in China. J. Clean. Prod. 2018, 188, 1004–1017. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, P. Focus on bioenergy industry development and energy security in China. Renew. Sustain. Energy Rev. 2014, 32, 302–312. [Google Scholar] [CrossRef]

| Geely Emgrand Methanol Vehicle | Geely Emgrand Methanol/Electric Hybrid Vehicle | Geely Emgrand Conventional Vehicle | |

|---|---|---|---|

| Maximum power (KW) | 95 | 97 | 93 |

| Methanol consumption (L/100 km) | 14 | 9.2 | / |

| Gasoline consumption (L/100 km) | / | / | 5.82 |

| Province | City | Start Year | Inspect Year | No. of Vehicle | No. Station | Mile (1000 km) |

|---|---|---|---|---|---|---|

| Shanxi | Jinzhong | 2013 | 2016 | 300 | 6 | 21,290 |

| Changzhi | 2014 | 2017 | 96 | 1 | 24,100 | |

| Shaanxi | Yulin | 2014 | 2017 | 5 | 1 | 415 |

| Xi’an | 2014 | 2017 | 20 | 1 | - | |

| Baoji | 2013 | 2017 | 215 | 2 | - | |

| Hanzhong | 2015 | 2018 | 20 | 1 | 287 | |

| Gansu | Lanzhou | 2015 | 2017 | 150 | 1 | - |

| Pingliang | 2015 | 2017 | 50 | 2 | 24,432 | |

| Guizhou | Guiyang | 2015 | 2017 | 300 | 7 | 72,090 |

| Shanghai | Shanghai | 2013 | 2017 | 56 | 1 | 5572 |

| Vehicle Type | VOC | CO | NOx | SOx | CH4 | Dust | CO2 |

|---|---|---|---|---|---|---|---|

| M100-Coal-V | 85.20 | 631.9 | 115.1 | 124.3 | 69.07 | 74.82 | 281,700 |

| M100-CO2-V | 83.40 | 631.6 | 140.0 | 105.5 | 29.23 | 40.45 | −24,160 |

| M100-Bio-V | 84.45 | 633.6 | 69.80 | 100.9 | 45.19 | 31.71 | 74,630 |

| GICEV | 125.5 | 1128 | 177.2 | 130.2 | 214.6 | 36.35 | 151,600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Jia, T.; Wang, S.; Wang, X.; Negnevitsky, M.; Wang, H.; Hu, Y.; Xu, W.; Zhou, N.; Zhao, G. Methanol Vehicles in China: A Review from a Policy Perspective. Sustainability 2023, 15, 9201. https://doi.org/10.3390/su15129201

Li C, Jia T, Wang S, Wang X, Negnevitsky M, Wang H, Hu Y, Xu W, Zhou N, Zhao G. Methanol Vehicles in China: A Review from a Policy Perspective. Sustainability. 2023; 15(12):9201. https://doi.org/10.3390/su15129201

Chicago/Turabian StyleLi, Chengjiang, Tingwen Jia, Shiyuan Wang, Xiaolin Wang, Michael Negnevitsky, Honglei Wang, Yujie Hu, Weibin Xu, Na Zhou, and Gang Zhao. 2023. "Methanol Vehicles in China: A Review from a Policy Perspective" Sustainability 15, no. 12: 9201. https://doi.org/10.3390/su15129201

APA StyleLi, C., Jia, T., Wang, S., Wang, X., Negnevitsky, M., Wang, H., Hu, Y., Xu, W., Zhou, N., & Zhao, G. (2023). Methanol Vehicles in China: A Review from a Policy Perspective. Sustainability, 15(12), 9201. https://doi.org/10.3390/su15129201