The Role of Renewable-Derived Plastics in the Analysis of Waste Management Schemes: A Time-Dependent Carbon Cycle Assessment

Abstract

:1. Introduction

2. Methodology

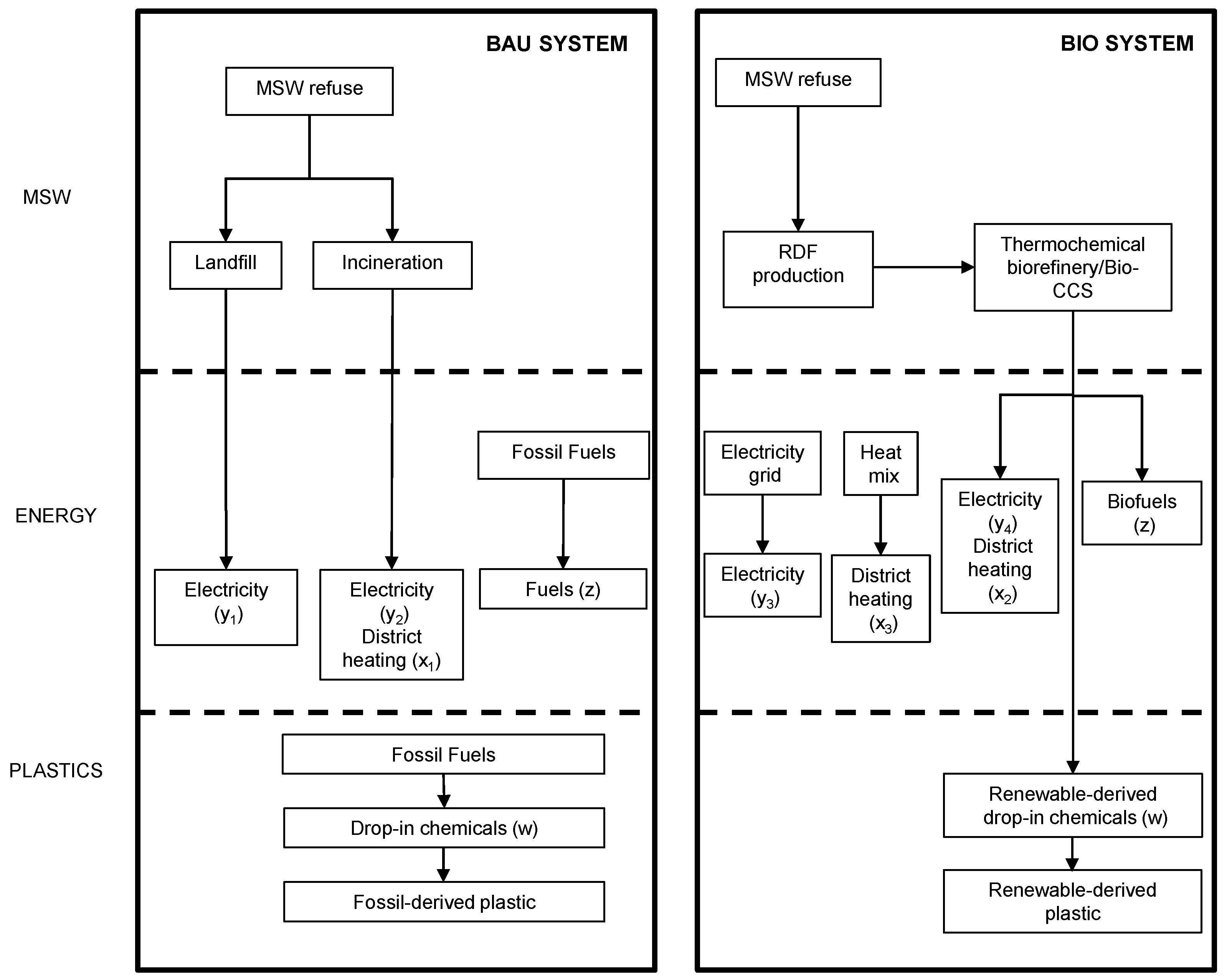

2.1. Definition of the Systems

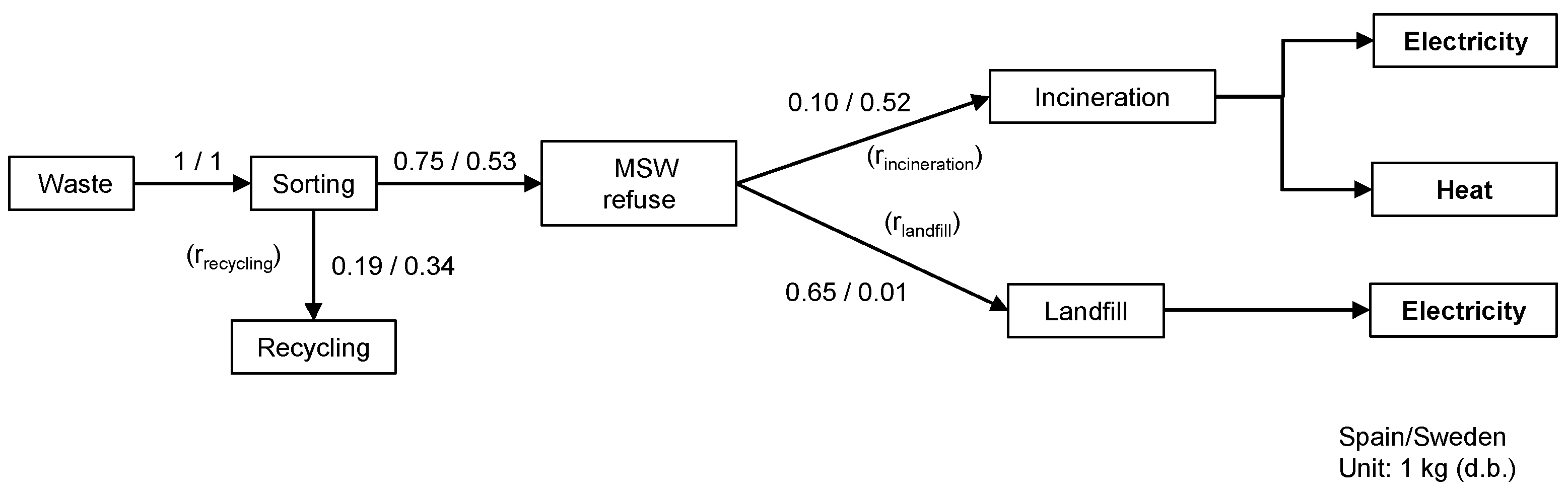

2.1.1. Modelling of the BAU System

2.1.2. Modelling of the BIO System

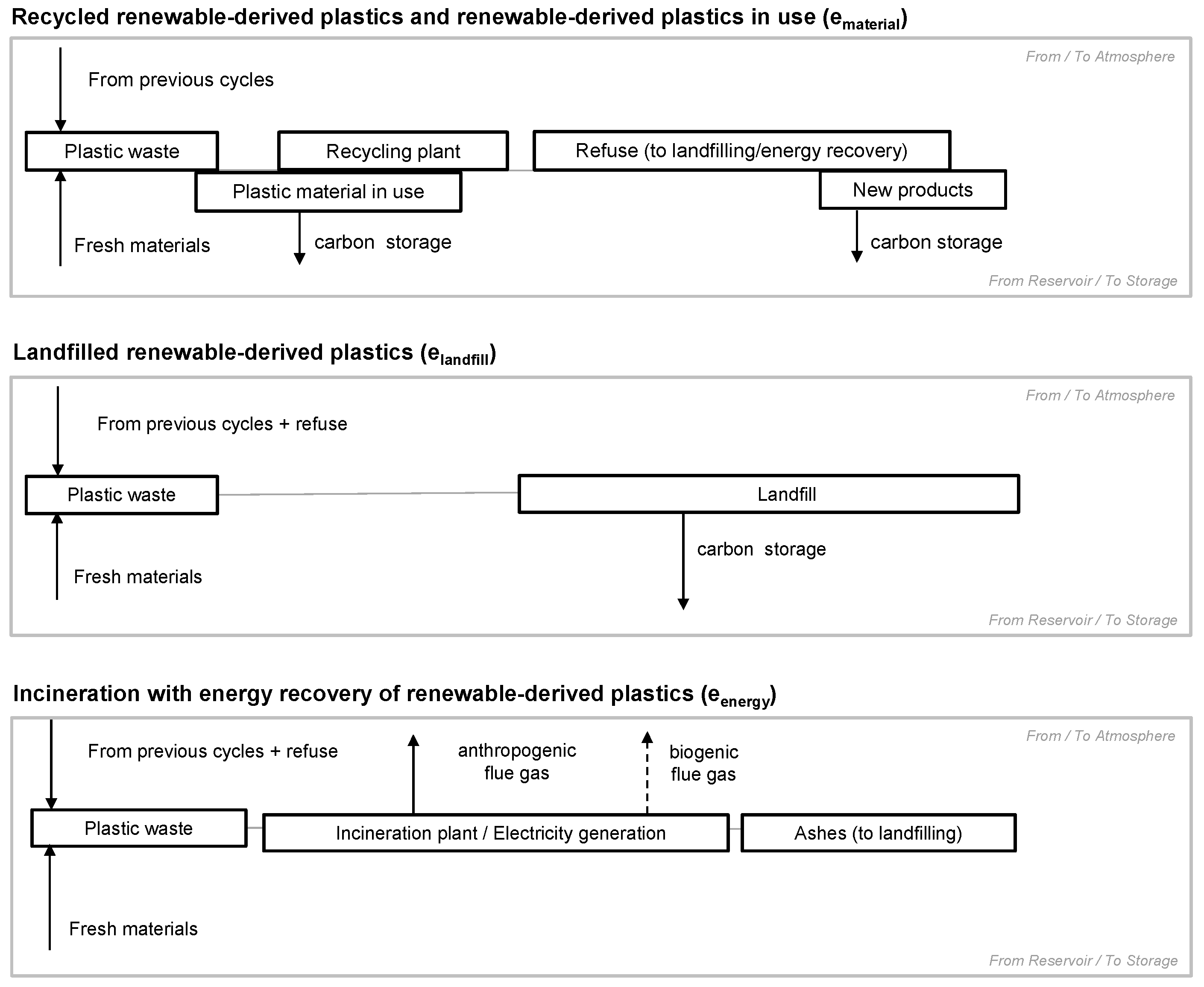

2.2. Assessment of GHG Emissions

2.2.1. Static Scenario (Differential GHG Impact)

2.2.2. Time-Dependent Emissions (Differential Climate Impact)

3. Results and Discussion

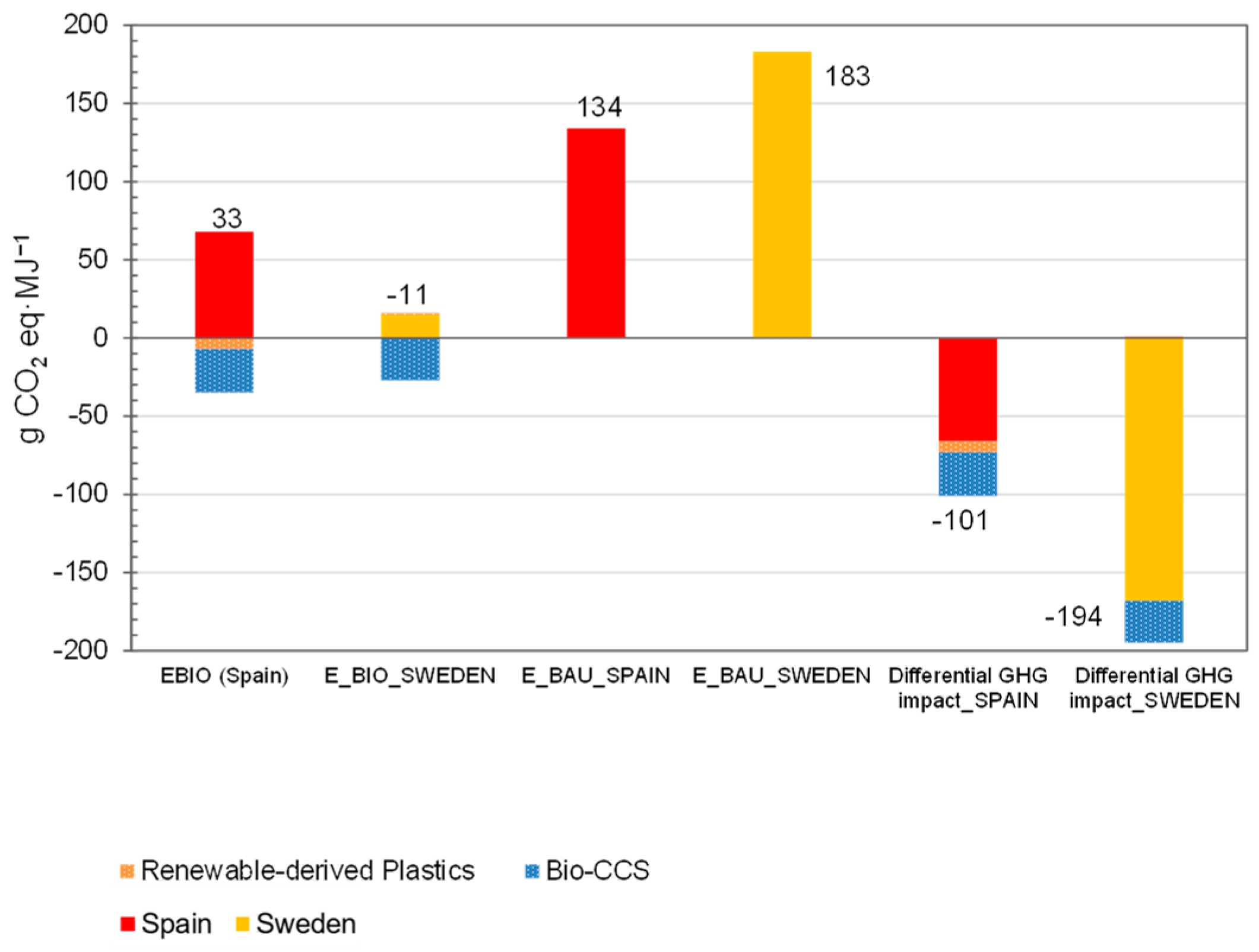

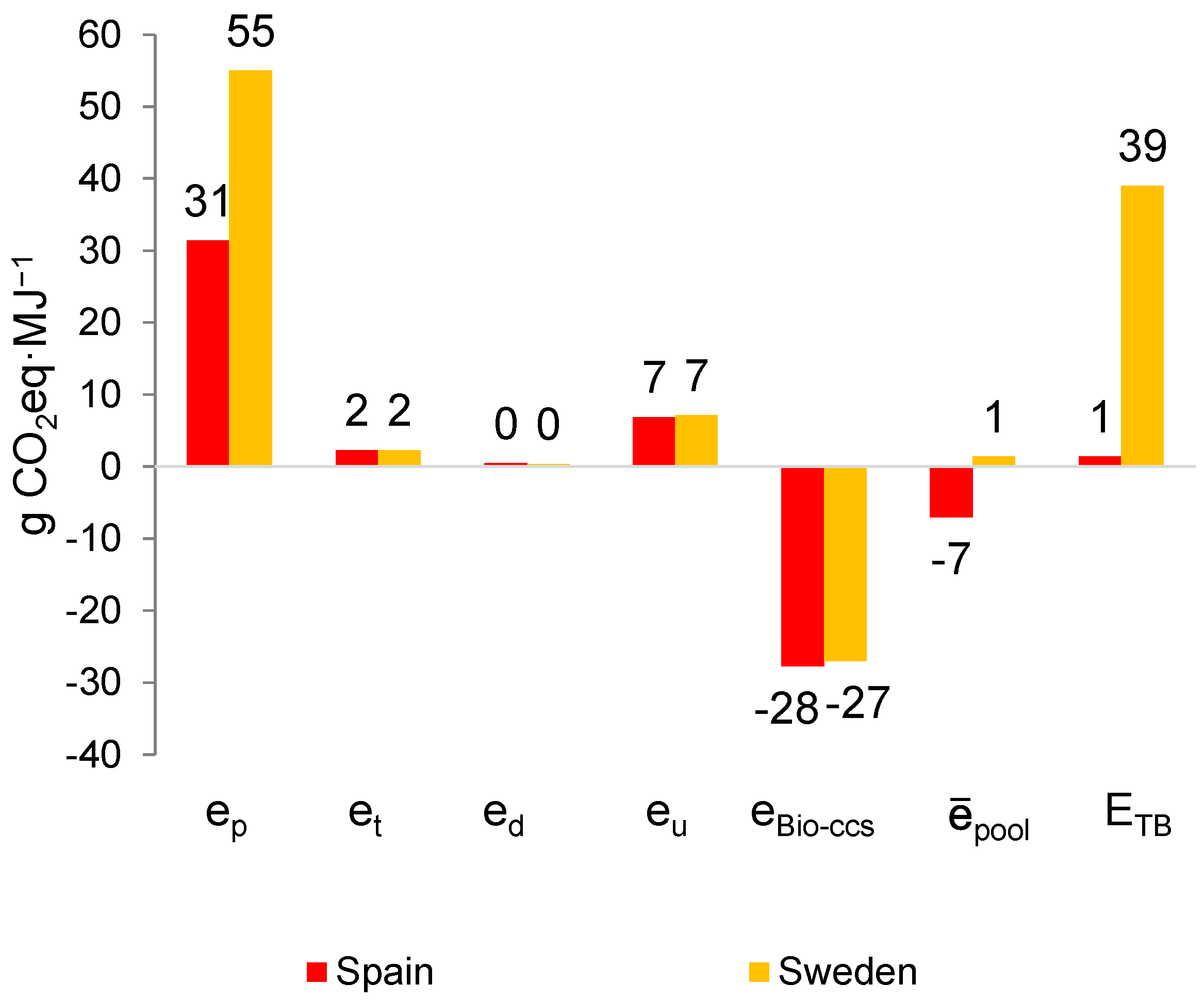

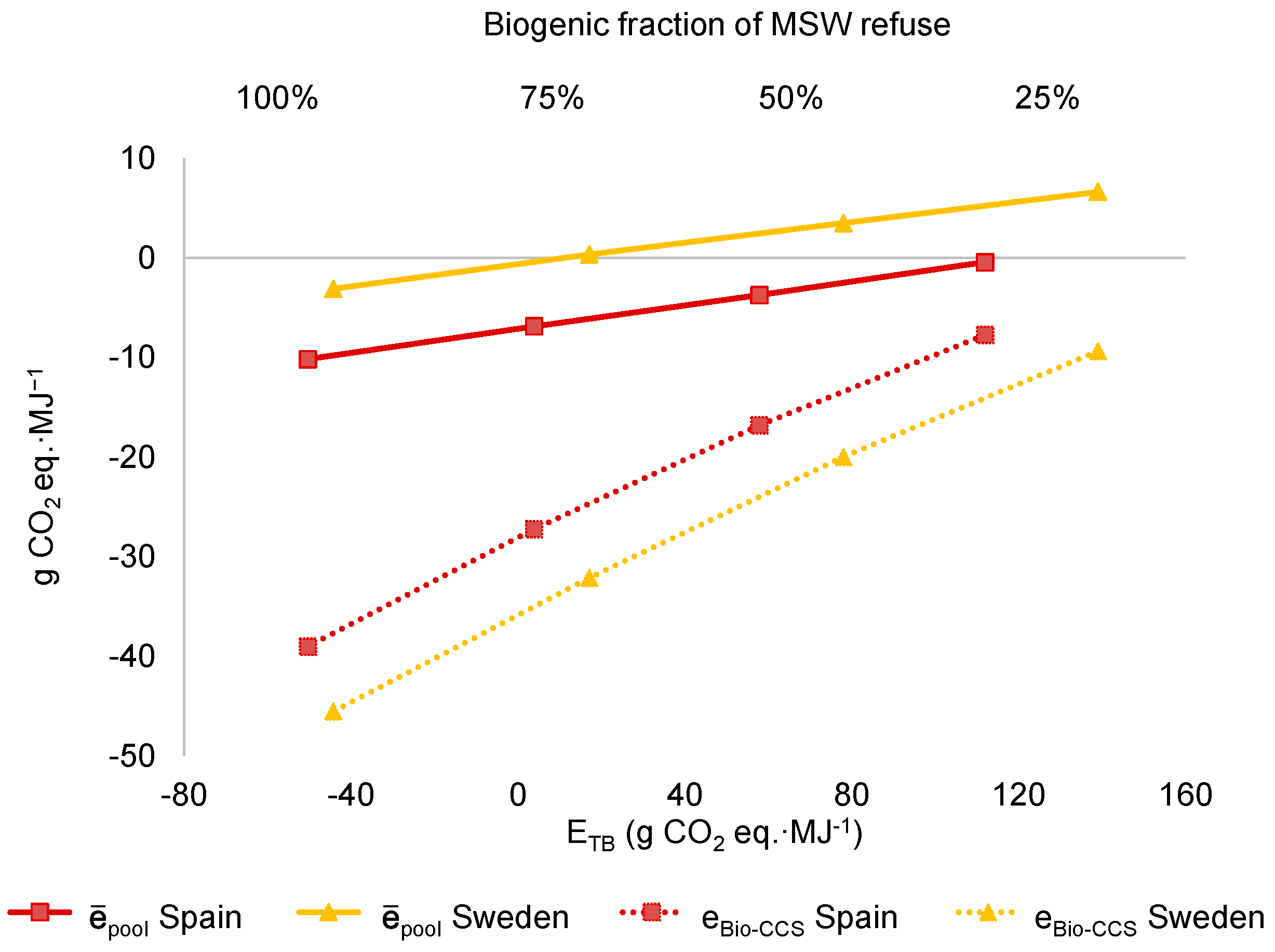

3.1. Differential GHG Impact

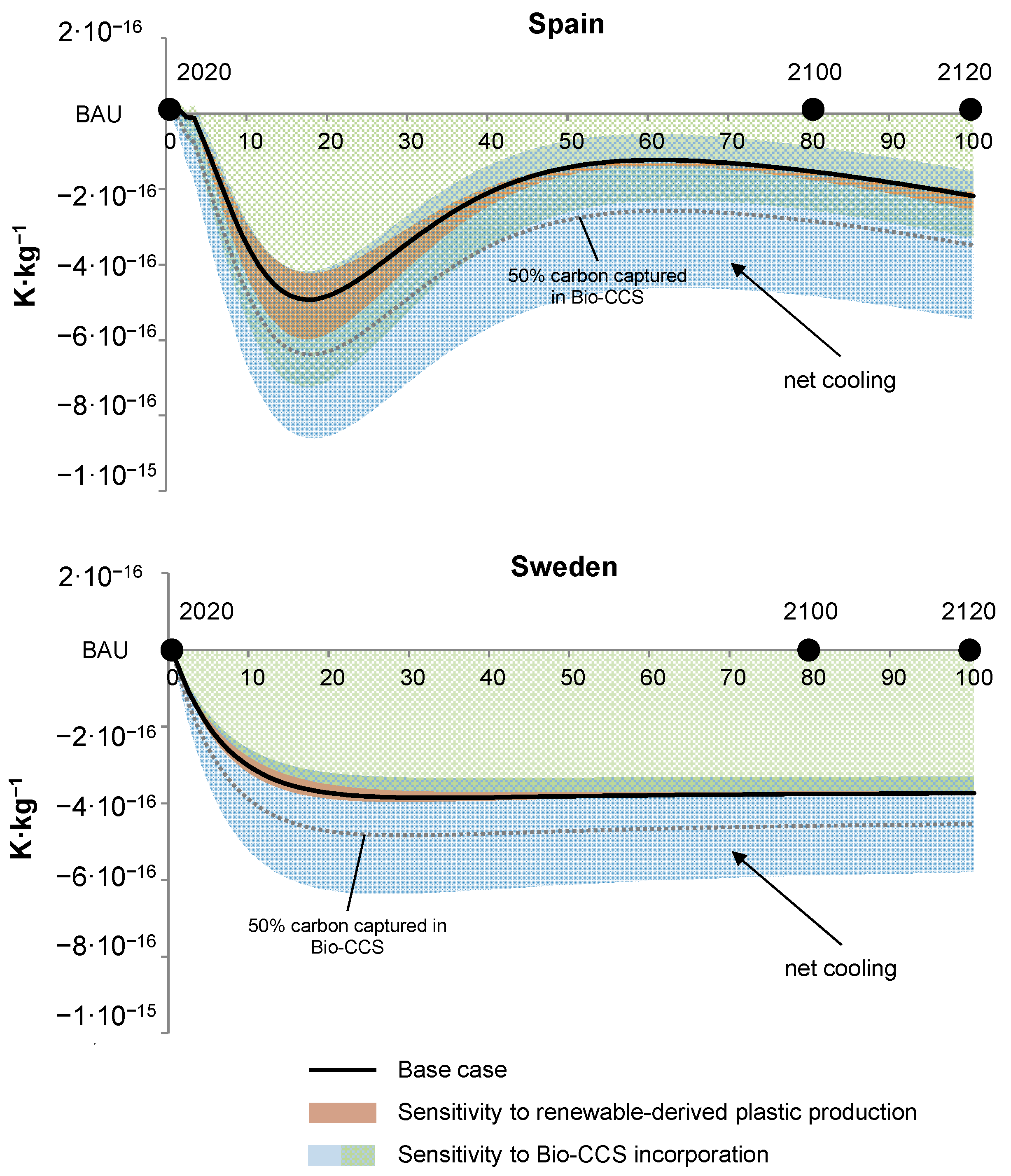

3.2. Differential Climate Impact (DCI)

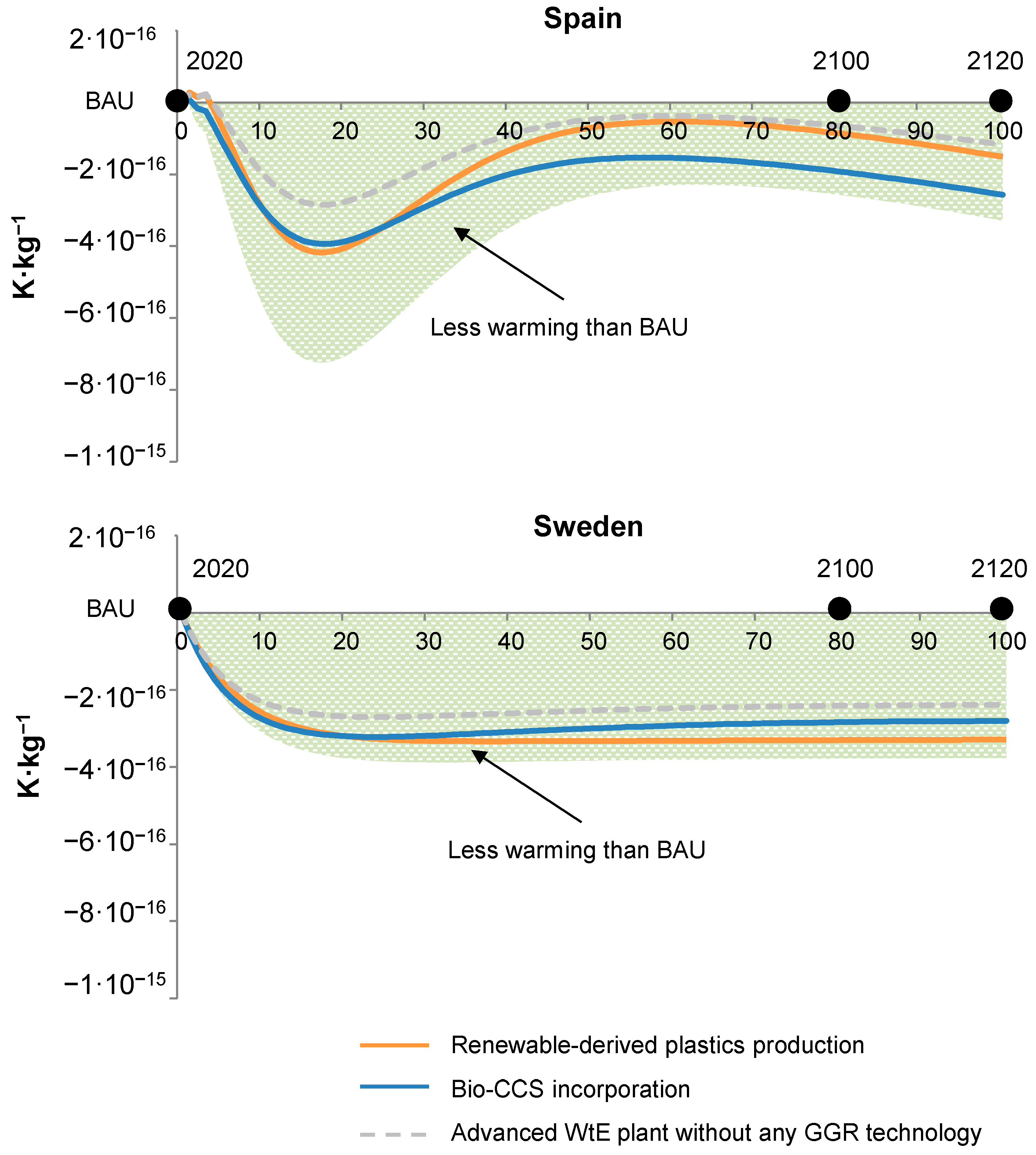

3.3. Renewable-Derived Plastics Versus Bio-CCS

3.4. Climate Change Mitigation Potential of Renewable-Derived Plastics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Symbols

| ed | emissions from products distribution (g CO2 eq. MJ−1) |

| eenergy | emissions from energy recovery of plastics (g CO2 eq. MJ−1) |

| elandfill | biogenic carbon storage in landfilled plastics (g CO2 eq. MJ−1) |

| ematerial | biogenic carbon storage in recycled plastics and plastics still in use (g CO2 eq. MJ−1) |

| emix | emission factor from electricity grid mix (g CO2 eq. MJ−1) |

| ep | emissions from processing (g CO2 eq. MJ−1) |

| epool | biogenic carbon storage in plastics (g CO2 eq. MJ−1) |

| ept | emissions from pretreatment (g CO2 eq. MJ−1) |

| et | emissions from feedstock transport (g CO2 eq. MJ−1) |

| eu | emissions from the use (g CO2 eq. MJ−1) |

| renergy | fraction of plastics waste going to energy recovery (%) |

| rincineration | fraction of MSW refuse going to incineration (%) |

| rlandfill | fraction of MSW refuse/plastic waste going to landfill (%) |

| rrecycling | fraction of plastics waste going to recycling (%) |

| wi | MJ of chemicals per MJ of final product mix (i = 1 BAU system, i = 2 BIO system) (%) |

| xi | MJ of heat per MJ of final product mix (i = 1 BAU system; i = 2 biorefinery, i = 3 heat mix in BIO system) (%) |

| yi | MJ of electricity per MJ of final product mix (i = 1 landfill, i = 2 incineration in BAU system; i = 3 electricity grid, i = 4 biorefinery in BIO system) (%) |

| zi | MJ of biofuel production per MJ of final product mix (i = 1 fossil fuels in BAU system; i = 2 biorefinery in BIO system) (%) |

Abbreviations

| AGTP | Absolute Global surface Temperature change Potential |

| AGWP | Absolute Global Warming Potential |

| BAU | Business as usual |

| BIO | Bioenergy |

| Bio-CCS | Carbon capture and storage in bioenergy |

| DCI | Differential Climate Impact |

| DME | Dimethyl ether |

| e | Carbon flows |

| EBIO/BAU | GHG impact of the BIO or BAU system |

| EF | Emission factor (fossil comparator) |

| EPA | U.S. Environmental Protection Agency |

| ETB | Global GHG balance of the thermochemical biorefinery |

| GGR | Greenhouse gases removal |

| GHG | Greenhouse gases |

| HDPE | High-density poly-ethylene |

| IPCC | Intergovernmental Panel on Climate Change |

| LCA | Life cycle assessment |

| LDPE | Low-density poly-ethylene |

| LHV | Lower heating value |

| MA | Methyl acetate |

| MSW | Municipal solid waste |

| PP | Polypropylene |

| PVC | Poly vinyl chloride |

| RDF | Refuse derived fuel |

| SM | Supplementary Material |

References

- IPCC. Climate Change 2022: Mitigation of Climate Change: Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Shukla, P.R., Skea, J., Reisinger, A., Slade, R., Fradera, R., Pathak, M., Khourdajie, A.A., Belkacemi, M., van Diemen, R., Hasija, A., et al., Eds.; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Fuss, S.; Canadell, J.G.; Peters, G.P.; Tavoni, M.; Andrew, R.M.; Ciais, P.; Jackson, R.B.; Jones, C.D.; Kraxner, F.; Nakicenovic, N.; et al. Betting on negative emissions. Nat. Clim. Chang. 2014, 4, 850–853. [Google Scholar] [CrossRef]

- Kerner, C.; Thaller, A.; Brudermann, T. Carbon dioxide removal to combat climate change? An expert survey on perception and support. Environ. Res. Commun. 2023, 5, 041003. [Google Scholar]

- The Fact. Plastics Europe. 2017. Available online: https://www.plasticseurope.org/download_file/force/1055/181 (accessed on 1 February 2023).

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Karan, H.; Funk, C.; Grabert, M.; Oey, M.; Hankamer, B. Green bioplastics as part of a circular bioeconomy. Trends Plant Sci. 2019, 24, 237–249. [Google Scholar] [CrossRef] [PubMed]

- Cañete Vela, I.; Berdugo Vilches, T.; Berndes, G.; Johnsson, F.; Thunman, H. Co-recycling of natural and synthetic carbon materials for a sustainable circular economy. J. Clean. Prod. 2022, 365, 132674. [Google Scholar] [CrossRef]

- Clark, J.H. From waste to wealth using green chemistry: The way to long term stability. Curr. Opin. Green Sustain. Chem. 2017, 8, 10–13. [Google Scholar] [CrossRef]

- Sustainable Biomass in the Chemical Industry. Dutch Sustainable Biomass Commission. 2012. Available online: http://www.corbey.nl/files/media_base/original/199.pdf (accessed on 1 February 2023).

- Sigurjonsson, H.Æ.; Elmegaard, B.; Clausen, L.R.; Ahrenfeldt, J. Climate effect of an integrated wheat production and bioenergy system with low temperature circulating fluidized bed gasifier. Appl. Energy 2015, 160, 511–520. [Google Scholar] [CrossRef] [Green Version]

- McLaren, D. A comparative global assessment of potential negative emissions technologies. Process Saf. Environ. Prot. 2012, 90, 489–500. [Google Scholar] [CrossRef]

- Shackley, S.; Sohi, S.; Brownsort, P.; Carter, S.; Cook, J.; Cunningham, C.; Ganut, J.; Hammond, J.; Ibarrola, R.; Mašek, O.; et al. An Assessment of the Benefits and Issues Associated with the Application of Biochar to Soil; Department for Environment, Food and Rural Affairs, UK Government: London, UK, 2010.

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- Nessi, S.; Sinkko, T.; Bulgheroni, C.; Garbarino, E.; Garcia-Gutierrez, P.; Giuntoli, J.; Konti, A.; Orveillon, G.; Sanye Mengual, E.; Tonini, D.; et al. Life Cycle Assessment (LCA) of Alternative Feedstocks for Plastics Production; EUR 31085 EN; Publications Office of the European Union: Luxembourg, 2022; ISBN 978-92-76-52958-3. [Google Scholar] [CrossRef]

- Nessi, S.; Sinkko, T.; Bulgheroni, C.; Garcia-Gutierrez, P.; Giuntoli, J.; Konti, A.; Sanye Mengual, E.; Tonini, D.; Pant, R.; Marelli, L.; et al. Life Cycle Assessment (LCA) of Alternative Feedstocks for Plastics Production; EUR 30725 EN; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-38145-7. [Google Scholar] [CrossRef]

- Chen, L.; Pelton, R.E.O.; Smith, T.M. Comparative life cycle assessment of fossil and bio-based polyethylene terephthalate (PET) bottles. J. Clean. Prod. 2016, 137, 667–676. [Google Scholar] [CrossRef] [Green Version]

- Grabowski, A.; Selke, S.E.M.; Auras, R.; Patel, M.K.; Narayan, R. Life cycle inventory data quality issues for bioplastics feedstocks. Int. J. Life Cycle Assess. 2015, 20, 584–596. [Google Scholar] [CrossRef]

- Aracil, C.; Haro, P.; Giuntoli, J.; Ollero, P. Proving the climate benefit in the production of biofuels from municipal solid waste refuse in Europe. J. Clean. Prod. 2017, 142, 2887–2900. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics Europe: Plastics—The Facts 2022. An Analysis of European Latest Plastics Production, Demand, Conversion and End-of-Life Management. 2022. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/ (accessed on 1 February 2023).

- European Commission. An EU action plan for the circular economy. Com European Commission, Joint Research Centre & Institute for Environment and Sustainability. In International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- European Union. COMMISSION DECISION of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council (2014/955/EU). Off. J. Eur. Union 2014, 7, 44–86. [Google Scholar]

- Fischer, C.; Gentil, E.; Ryberg, M.; Reichel, A. Managing Municipal Solid Waste—A Review of Achievements in 32 European Countries. EEA Report No 2/2013; European Environment Agency: Copenhagen, Denmark, 2013. [Google Scholar]

- European Compost Network. Organic Resources and Biological Treatment (Spanish Report). 2010. Available online: https://www.compostnetwork.info/download/no-012010-eu-working-document-sludge-biowaste/?ind=1478255578910&filename=101021_ECN_bio-sludge-working-doc_comments2.pdf&wpdmdl=141&refresh=6477288655c491685530758 (accessed on 1 February 2023).

- Vandecasteele, C.; Billen, P.; Verbinnen, B.; Caneghem, J. How to choose between recycling, incineration and landfill in a LCA perspective. In Proceedings of the WasteEng International Conference on Engineering for Waste and Biomass Valorisation, Albi, France, 23–26 May 2016. [Google Scholar]

- Penman, J.; Gytarsky, M.; Hiraishi, T.; Irving, W.; Krug, T. IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Giuntoli, J.; Agostini, A.; Robert Edwards, L.M. European Commission EUR 27215 EN—Joint Research Centre—Institute for Energy and Transport. In Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar]

- Sandén, B.; Pettersson, K.; Systems Perspectives on Biorefineries. Chalmers University of Technology. 2013. Available online: https://publications.lib.chalmers.se/records/fulltext/182212/local_182212.pdf (accessed on 1 February 2023).

- Haro, P.; Aracil, C.; Vidal-Barrero, F.; Ollero, P. Rewarding of extra-avoided GHG emissions in thermochemical biorefineries incorporating bio-CCS. Appl. Energy 2015, 157, 255–266. [Google Scholar] [CrossRef]

- Haro, P.; Ollero, P.; Villanueva Perales, A.L.; Gómez-Barea, A. Thermochemical biorefinery based on dimethyl ether as intermediate: Technoeconomic assessment. Appl. Energy 2013, 102, 950–961. [Google Scholar] [CrossRef]

- The European Plastics Industry. Plastics—The Facts 2013 An Analysis of European Latest Plastics Production, Demand and Waste Data Plast; Association Plastics Manufactures: Brussels, Belgium, 2013. [Google Scholar]

- EC. Eurostat Database Eurostat Commission Online Statistics Database. 2017. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 1 February 2023).

- Gaudreault, C.; Miner, R. Temporal aspects in evaluating the greenhouse gas mitigation benefits of using residues from forest products manufacturing facilities for energy production. J. Ind. Ecol. 2015, 19, 994–1007. [Google Scholar] [CrossRef]

- Ministry of Agriculture Food and Environment, Government of Spain. State Framework Plan for Waste Management; Ministry of Agriculture Food and Environment: Madrid, Spain, 2015; pp. 2015–2020.

- Cherubini, F.; Bargigli, S.; Ulgiati, S. Life cycle assessment of urban waste management: Energy performances and environmental impacts. The case of Rome, Italy. Waste Manag. 2008, 28, 2552–2564. [Google Scholar] [CrossRef]

- Clausen, A.; Pretz, T. The relevance of framework conditions for modelling GHG emissions from rMSW treatment systems in EU. Waste Biomass Valoriz. 2016, 7, 175–191. [Google Scholar] [CrossRef]

- Fiorentino, G.; Ripa, M.; Protano, G.; Hornsby, C.; Ulgiati, S. Life cycle assessment of mixed municipal solid waste: Multi-input versus multi-output perspective. Waste Manag. 2015, 46, 599–611. [Google Scholar] [CrossRef]

- Chen, C.; Rubin, E.S. CO2 control technology effects on IGCC plant performance and cost. Energy Policy 2009, 37, 915–924. [Google Scholar] [CrossRef]

- Oreggioni, G.D.; Singh, B.; Cherubini, F.; Guest, G.; Lausselet, C.; Luberti, M.; Ahn, H.; Strømman, A.H. Environmental assessment of biomass gasification combined heat and power plants with absorptive and adsorptive carbon capture units in Norway. Int. J. Greenh. Gas Control 2017, 57, 162–172. [Google Scholar] [CrossRef]

- Smith, P.; Davis, S.J.; Creutzig, F.; Fuss, S.; Minx, J.; Gabrielle, B.; Kato, E.; Jackson, R.B.; Cowie, A.; Kriegler, E.; et al. Biophysical and economic limits to negative CO2 emissions. Nat. Clim. Chang. 2016, 6, 42–50. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency. Technology Roadmap: Carbon Capture and Storage; OECD Publishing: Prais, France, 2013. [Google Scholar]

- Shields, L.; Dias, D.; Bain, J.; Mudgal, S.; Johansson, L.; Lyons, L.; Bowyer, C.; Dolley, P.; Faninger, T. Plastic Waste in the Environment—Final Report. European Commission- DG Environment. 2011. Available online: https://op.europa.eu/en/publication-detail/-/publication/fd4f120a-bf98-403b-a22e-ca4d7b280da8 (accessed on 1 February 2023).

- Fridahl, M. Socio-political prioritization of bioenergy with carbon capture and storage. Energy Policy 2017, 104, 89–99. [Google Scholar] [CrossRef] [Green Version]

- Clark, W.C. (Ed.) Carbon Dioxide Review; Oxford University Press: New York, NY, USA, 1982; p. 467. [Google Scholar]

- Jones, F.C.; Blomqvist, E.W.; Bisaillon, M.; Lindberg, D.K.; Hupa, M. Determination of fossil carbon content in swedish waste fuel by four different methods. Waste Manag. Res. 2013, 31, 1052–1061. [Google Scholar] [CrossRef]

- Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 98/70/EC Relating to the Quality of Petrol and Diesel Fuels and Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32015L1513&qid=1685526497364 (accessed on 1 February 2023).

- Plastics Europe. Plastics Europe: Plastics-The Facts 2015. An Analysis of European Latest Plastics Production, Demand and Waste Data. 2015. Available online: http://www.plasticseurope.org/Document/plastics-the-facts-2015.aspx (accessed on 1 February 2023).

- Haro, P.; Aracil, C.; Vidal-Barrero, F.; Ollero, P. Balance and saving of GHG emissions in thermochemical biorefineries. Appl. Energy 2015, 147, 444–455. [Google Scholar] [CrossRef]

- Panepinto, D.; Tedesco, V.; Brizio, E.; Genon, G. Environmental performances and energy efficiency for MSW gasification treatment. Waste Biomass Valorization 2015, 6, 123–135. [Google Scholar] [CrossRef]

- Karmakar, M.K.; Chandra, P.; Chatterjee, P.K. A review on the fuel gas cleaning technologies in gasification process. J. Environ. Chem. Eng. 2015, 3, 689–702. [Google Scholar]

- Chalmers University of Technology. Systems Perspectives on Biorefineries (Goteborg, Sweden). 2014. Available online: https://www.chalmers.se/en/areas-of-advance/energy/Documents/SystemsPerspectiveson/Systems_Perspectives_on_Biorefineries_2014_v3.1b.pdf (accessed on 1 February 2023).

- IPCC. IPCC Fifth Assessment Report (AR5); IPCC: Geneva, Switzerland, 2013; pp. 10–12. [Google Scholar]

- Giuntoli, J.; Caserini, S.; Marelli, L.; Baxter, D.; Agostini, A. Domestic heating from forest logging residues: Environmental risks and benefits. J. Clean. Prod. 2015, 99, 206–216. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2014: Mitigation of Climate Change. 2014. Available online: http://www.ipcc.ch/report/ar5/wg3/ (accessed on 1 February 2023).

- Arena, U.; Di Gregorio, F.; De Troia, G.; Saponaro, A. A techno-economic evaluation of a small-scale fluidized bed gasifier for solid recovered fuel. Fuel Process. Technol. 2015, 131, 69–77. [Google Scholar] [CrossRef]

- COM 2016 Proposal for a Directive of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1485356116722&uri=CELEX:52016PC0767 (accessed on 1 February 2023).

- EPA. Framework for Assessing Biogenic CO2 EMIssions from Stationary Sources; Environmental Protection Agency: Washington, DC, USA, 2014. Available online: http://www.epa.gov/climatechange/downloads/Framework-for-Assessing-Biogenic-CO2-Emissions.pdf (accessed on 1 February 2023).

- Haro, P.; Villanueva Perales, A.L.; Arjona, R.; Ollero, P. Thermochemical biorefineries with multiproduction using a platform chemical. Biofuels Bioprod. Biorefin. 2014, 8, 155–170. [Google Scholar] [CrossRef] [Green Version]

- Onel, O.; Niziolek, A.M.; Hasan, M.M.F.; Floudas, C.A. Municipal solid waste to liquid transportation fuels—Part I: Mathematical modeling of a municipal solid waste gasifier. Comput. Chem. Eng. 2014, 71, 636–647. [Google Scholar] [CrossRef]

- European Parliament. Directive 2003/71/EC Euratom 2001. 2004, pp. 20–30. Available online: https://www.europarl.europa.eu/doceo/document/TA-5-2004-03-30_EN.html?redirect (accessed on 1 February 2023).

- Patel, C.; Lettieri, P.; Germanà, A. Techno-economic performance analysis and environmental impact assessment of small to medium scale SRF combustion plants for energy production in the UK. Process Saf. Environ. Prot. 2012, 90, 255–262. [Google Scholar] [CrossRef]

- Final Reports—Energy Recovery from Renewable Content of Waste: Incentives and Methodology for Analysing Biogenic Content of Mixed Waste Topic 1—Policy Support. 2012. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjGxNa7_bL_AhWKplYBHe_YACwQFnoECBoQAQ&url=https%3A%2F%2Fwww.parliament.nsw.gov.au%2Flcdocs%2Fother%2F10967%2FAnswers%2520to%2520questions%2520on%2520notice%2520-%2520Dr%2520El%2520Hanandeh.pdf&usg=AOvVaw1_qa4jJ3HXzi7qQe5jZdEK (accessed on 1 February 2023).

- Yassin, L.; Lettieri, P.; Simons, S.; Castillo-Castillo, A.; Leach, M.; Ryu, C.; Swithenbank, J.; Sharifi, V.N. From incineration to advanced fluid-bed gasification of waste. In Proceedings of the Institution of Civil Engineers-Waste and Resource Management; Thomas Telford Ltd.: London, UK, 2009; Volume 162, pp. 169–177. [Google Scholar]

| System | Share (LHV Basis) | Spain | Sweden |

|---|---|---|---|

| BAU/BIO | Drop-in chemicals (w) | 24% | 13% |

| Fuels (z) | 23% | 12% | |

| BAU | Heat to district heating—Incineration (x1) | 0 | 54% |

| Electricity to grid—Landfill (y1) | 14% | 0 | |

| Electricity to grid—Incineration (y2) | 39% | 21% | |

| BIO | Heat from district heating (x3) | 0 | 44% |

| Heat to district heating—Biorefinery (x2) | 0 | 10% | |

| Electricity from the grid (y3) | 40% | 13% | |

| Electricity to grid—Biorefinery (y4) | 13% | 8% |

| Gt of Biogenic Carbon Removed (ppm Reduction), Annually a | Gt of Biogenic Carbon Removed (ppm Reduction), until 2050 a | |

|---|---|---|

| Europe (all plastic production is renewable-based, only landfill is considered for waste disposal) | 0.05 (0.02) | 1.5 (0.7) |

| World (all plastic production is renewable-based, only landfill is considered for waste disposal) | 0.27 (0.12) | 8.0 (3.8) |

| All new plastic materials are renewable-based (the amount of plastic waste in landfills from now on until 2050) | - | 5.6 (2.6) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aracil, C.; Villanueva Perales, Á.L.; Giuntoli, J.; Cristóbal, J.; Haro, P. The Role of Renewable-Derived Plastics in the Analysis of Waste Management Schemes: A Time-Dependent Carbon Cycle Assessment. Sustainability 2023, 15, 9292. https://doi.org/10.3390/su15129292

Aracil C, Villanueva Perales ÁL, Giuntoli J, Cristóbal J, Haro P. The Role of Renewable-Derived Plastics in the Analysis of Waste Management Schemes: A Time-Dependent Carbon Cycle Assessment. Sustainability. 2023; 15(12):9292. https://doi.org/10.3390/su15129292

Chicago/Turabian StyleAracil, Cristina, Ángel L. Villanueva Perales, Jacopo Giuntoli, Jorge Cristóbal, and Pedro Haro. 2023. "The Role of Renewable-Derived Plastics in the Analysis of Waste Management Schemes: A Time-Dependent Carbon Cycle Assessment" Sustainability 15, no. 12: 9292. https://doi.org/10.3390/su15129292