Valorization of Face Masks Produced during COVID-19 Pandemic through Hydrothermal Carbonization (HTC): A Preliminary Study

Abstract

1. Introduction

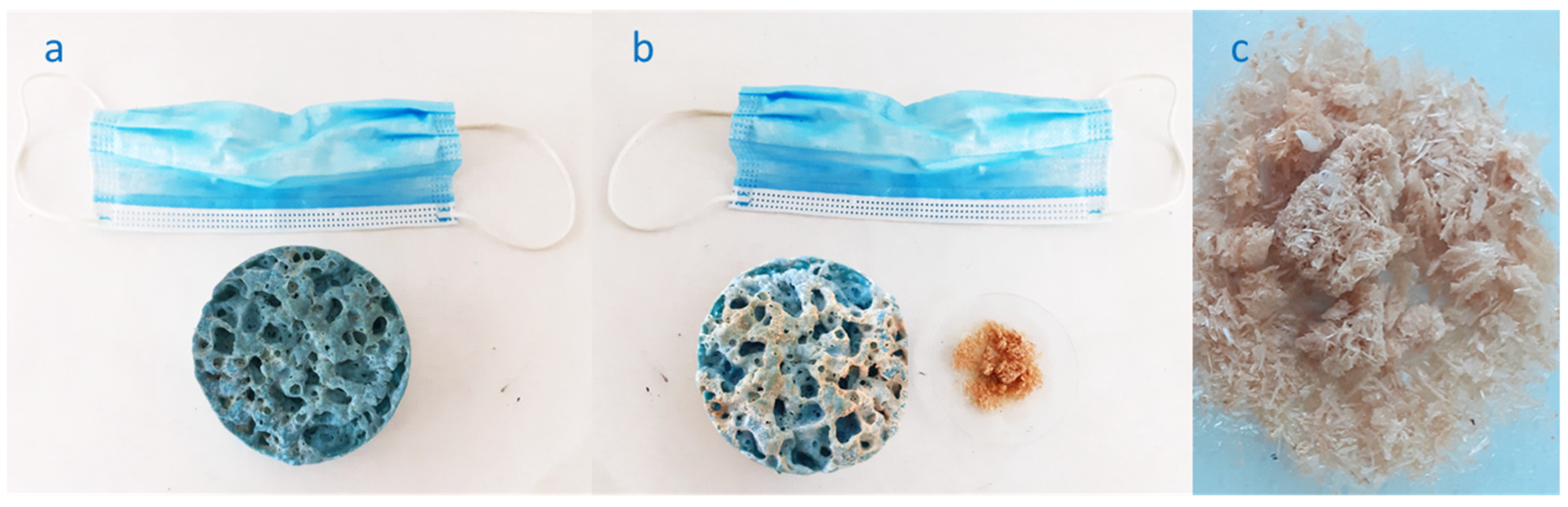

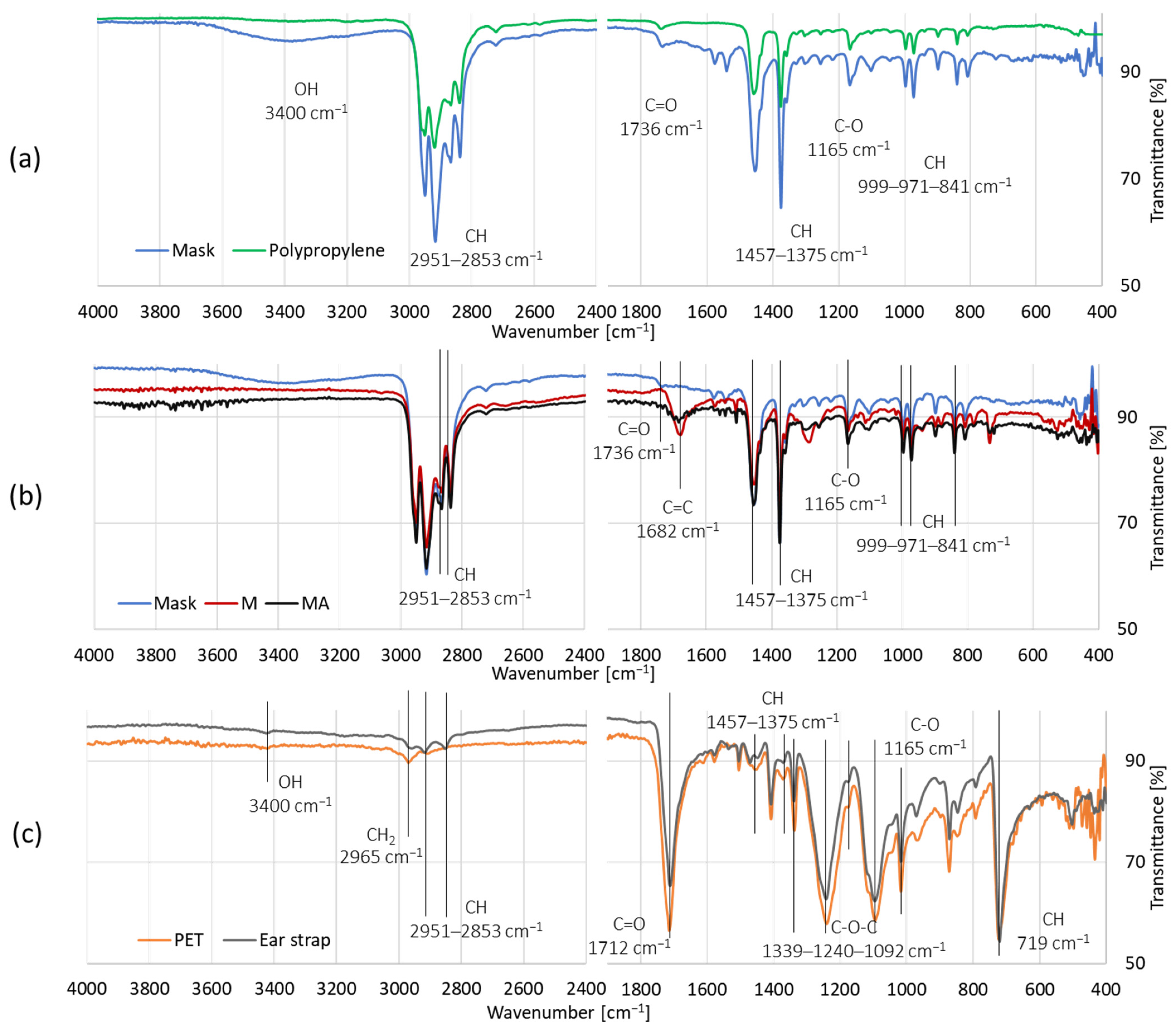

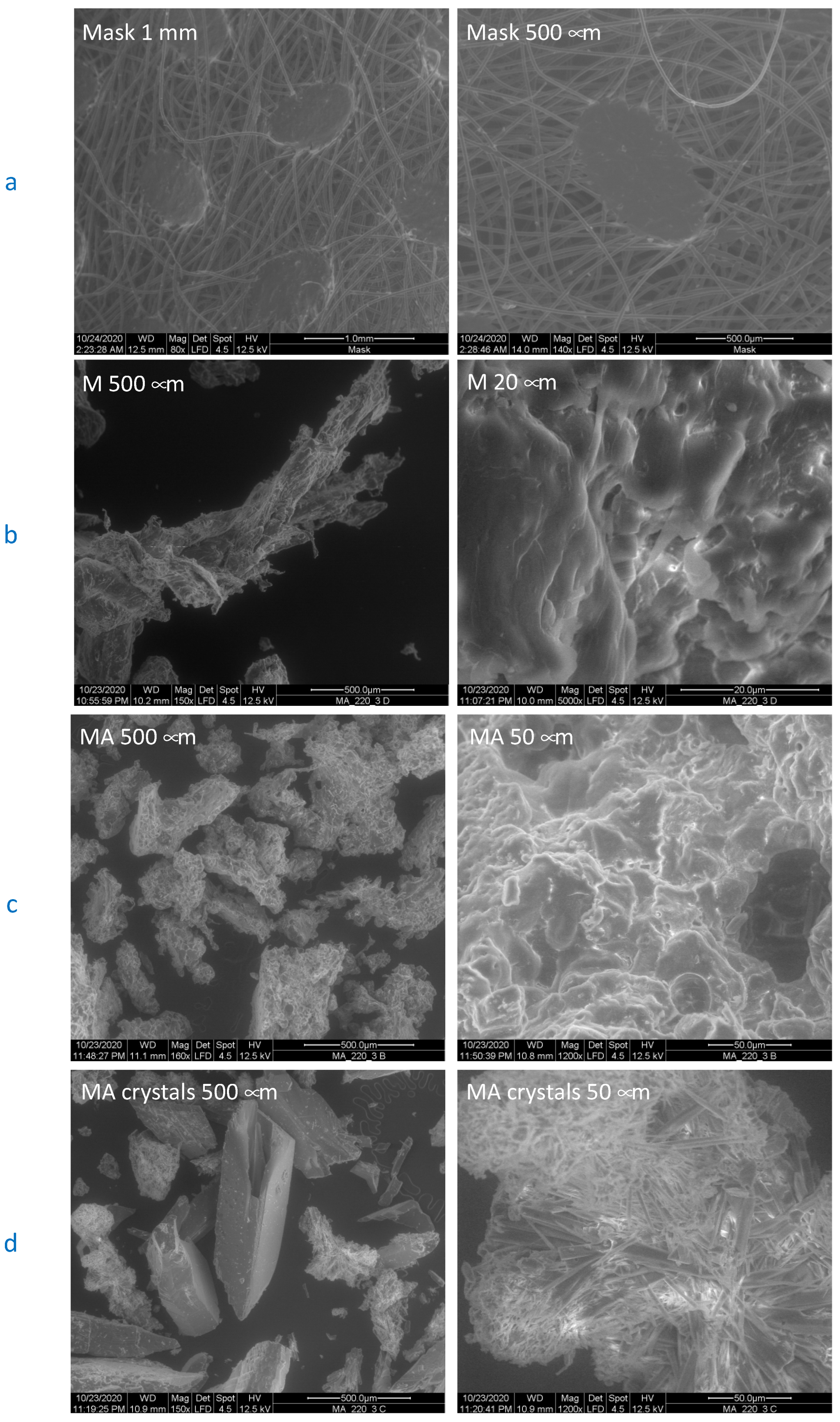

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of Variance |

| ARG | Antibiotic Resistance Gene |

| BET | Brunauer–Emmett–Teller |

| EC | Electrical Conductivity |

| FTIR | Fourier Transform Infrared Spectroscopy |

| HC | Hydrochar |

| HHV | Higher Heating Value |

| HTC | Hydrothermal Carbonization |

| IC | Inorganic Carbon |

| M | Hydrochar from surgical masks |

| MA | Hydrochar from surgical masks in presence of acetic acid |

| PC | Polycarbonate |

| PE | Polyethylene |

| PET | Polyethylene Terephthalate |

| PP | Polypropylene |

| PPE | Personal Protective Equipment |

| PS | Polystyrene |

| PTFE | Polytetrafluoroethylene |

| PVC | Polyvinyl Chloride |

| PW | Process Water |

| PXRD | Powder X-ray Diffraction |

| SEM | Scanning Electron Microscopy |

| TC | Total Carbon |

| TGA | Thermogravimetric Analysis |

| TOC | Total Organic Carbon |

| TPA | Terephthalic Acid |

| XRD | X-ray Diffraction |

References

- World Health Organization; The United Nations Children’s Fund (UNICEF). Water, Sanitation, Hygiene, and Waste Management for the COVID-19 Virus: Interim Guidance; World Health Organization: Geneva, Switzerland, 2020.

- Dharmaraj, S.; Ashokkumar, V.; Pandiyan, R.; Halimatul Munawaroh, H.S.; Chew, K.W.; Chen, W.-H.; Ngamcharussrivichai, C. Pyrolysis: An Effective Technique for Degradation of COVID-19 Medical Wastes. Chemosphere 2021, 275, 130092. [Google Scholar] [CrossRef]

- Liang, Y.; Song, Q.; Wu, N.; Li, J.; Zhong, Y.; Zeng, W. Repercussions of COVID-19 Pandemic on Solid Waste Generation and Management Strategies. Front. Environ. Sci. Eng. 2021, 15, 115. [Google Scholar] [CrossRef]

- Yousef, S.; Eimontas, J.; Striūgas, N.; Abdelnaby, M.A. Pyrolysis Kinetic Behaviour and TG-FTIR-GC–MS Analysis of Coronavirus Face Masks. J. Anal. Appl. Pyrolysis 2021, 156, 105118. [Google Scholar] [CrossRef]

- Crespo, C.; Ibarz, G.; Sáenz, C.; Gonzalez, P.; Roche, S. Study of Recycling Potential of FFP2 Face Masks and Characterization of the Plastic Mix-Material Obtained. A Way of Reducing Waste in Times of COVID-19. Waste Biomass Valor. 2021, 12, 6423–6432. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.P.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 Pandemic Repercussions on the Use and Management of Plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Patrício Silva, A.L.; Prata, J.C.; Duarte, A.C.; Barcelò, D.; Rocha-Santos, T. An Urgent Call to Think Globally and Act Locally on Landfill Disposable Plastics under and after COVID-19 Pandemic: Pollution Prevention and Technological (Bio) Remediation Solutions. Chem. Eng. J. 2021, 426, 131201. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of Potential Applications of Hydrochar Derived from Hydrothermal Carbonization of Biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Brillard, A.; Kehrli, D.; Douguet, O.; Gautier, K.; Tschamber, V.; Bueno, M.-A.; Brilhac, J.-F. Pyrolysis and Combustion of Community Masks: Thermogravimetric Analyses, Characterizations, Gaseous Emissions, and Kinetic Modeling. Fuel 2021, 306, 121644. [Google Scholar] [CrossRef]

- Duangchan, A.; Samart, C. Tertiary Recycling of PVC-Containing Plastic Waste by Copyrolysis with Cattle Manure. Waste Manag. 2008, 28, 2415–2421. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Eui Lee, M.; Kim, S.-S.; Joh, H.-I.; Lee, S. Efficient Upcycling of Polypropylene-Based Waste Disposable Masks into Hard Carbons for Anodes in Sodium Ion Batteries. J. Ind. Eng. Chem. 2022, 105, 268–277. [Google Scholar] [CrossRef]

- Ro, K.S.; Hunt, P.G.; Jackson, M.A.; Compton, D.L.; Yates, S.R.; Cantrell, K.; Chang, S. Co-Pyrolysis of Swine Manure with Agricultural Plastic Waste: Laboratory-Scale Study. Waste Manag. 2014, 34, 1520–1528. [Google Scholar] [CrossRef]

- Adolfsson, K.H.; Lin, C.; Hakkarainen, M. Microwave Assisted Hydrothermal Carbonization and Solid State Postmodification of Carbonized Polypropylene. ACS Sustain. Chem. Eng. 2018, 6, 11105–11114. [Google Scholar] [CrossRef]

- Ducey, T.F.; Collins, J.C.; Ro, K.S.; Woodbury, B.L.; Griffin, D.D. Hydrothermal Carbonization of Livestock Mortality for the Reduction of Pathogens and Microbially-Derived DNA. Front. Environ. Sci. Eng. 2017, 11, 9. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal Carbonization of Biomass: A Summary and Discussion of Chemical Mechanisms for Process Engineering. Biofuels Bioprod. Bioref. 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.-M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal Carbonization of Biomass Residuals: A Comparative Review of the Chemistry, Processes and Applications of Wet and Dry Pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Shen, Y. A Review on Hydrothermal Carbonization of Biomass and Plastic Wastes to Energy Products. Biomass Bioenergy 2020, 134, 105479. [Google Scholar] [CrossRef]

- Poerschmann, J.; Weiner, B.; Woszidlo, S.; Koehler, R.; Kopinke, F.-D. Hydrothermal Carbonization of Poly(Vinyl Chloride). Chemosphere 2015, 119, 682–689. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, S.; Ge, S.; Chen, X.; Ge, X.; Chen, M. Hydrothermal Carbonization of Medical Wastes and Lignocellulosic Biomass for Solid Fuel Production from Lab-Scale to Pilot-Scale. Energy 2017, 118, 312–323. [Google Scholar] [CrossRef]

- Yao, Z.; Ma, X. Characteristics of Co-Hydrothermal Carbonization on Polyvinyl Chloride Wastes with Bamboo. Bioresour. Technol. 2018, 247, 302–309. [Google Scholar] [CrossRef]

- Xu, Z.; Bai, X. Microplastic Degradation in Sewage Sludge by Hydrothermal Carbonization: Efficiency and Mechanisms. Chemosphere 2022, 297, 134203. [Google Scholar] [CrossRef]

- Wei, Y.; Fakudze, S.; Zhang, Y.; Ma, R.; Shang, Q.; Chen, J.; Liu, C.; Chu, Q. Co-Hydrothermal Carbonization of Pomelo Peel and PVC for Production of Hydrochar Pellets with Enhanced Fuel Properties and Dechlorination. Energy 2022, 239, 122350. [Google Scholar] [CrossRef]

- Poerschmann, J.; Weiner, B.; Wedwitschka, H.; Baskyr, I.; Koehler, R.; Kopinke, F.-D. Characterization of Biocoals and Dissolved Organic Matter Phases Obtained upon Hydrothermal Carbonization of Brewer’s Spent Grain. Bioresour. Technol. 2014, 164, 162–169. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, H.; Sikarwar, V.S.; Zhao, M.; Park, A.-H.A.; Fennell, P.S.; Shen, L.; Fan, L.-S. Biomass-Based Chemical Looping Technologies: The Good, the Bad and the Future. Energy Environ. Sci. 2017, 10, 1885–1910. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.-X. Bio-Based Polymers with Performance-Advantaged Properties. Nat. Rev. Mater. 2021, 7, 83–103. [Google Scholar] [CrossRef]

- Huang, Y.W.; Chen, M.Q.; Li, Q.H.; Xing, W. A Critical Evaluation on Chemical Exergy and Its Correlation with High Heating Value for Single and Multi-Component Typical Plastic Wastes. Energy 2018, 156, 548–554. [Google Scholar] [CrossRef]

- Linstrom, P. NIST Chemistry WebBook, NIST Standard Reference Database 69. J. Phys. Chem. Ref. Data Monogr. 1998, 9, 1–1951. [Google Scholar]

- Ali, L.; Kuttiyathil, M.S.; Altarawneh, M. Catalytic Upgrading of the Polymeric Constituents in COVID-19 Masks. J. Environ. Chem. Eng. 2022, 10, 106978. [Google Scholar] [CrossRef]

- Krylova, V.; Dukštienė, N. Synthesis and Characterization of Ag2S Layers Formed on Polypropylene. J. Chem. 2013, 2013, 987879. [Google Scholar] [CrossRef]

- Stuart, B. Infrared Spectroscopy: Fundamentals and Applications; Analytical techniques in the sciences; J. Wiley: Chichester, UK; Hoboken, NJ, USA, 2004; ISBN 978-0-470-85427-3. [Google Scholar]

- Chiu, F.-C.; Chu, P.-H. Characterization of Solution-Mixed Polypropylene/Clay Nanocomposites without Compatibilizers. J Polym Res 2006, 13, 73–78. [Google Scholar] [CrossRef]

- Ravichandran, S.A.; Rajan, V.P.; Aravind, P.V.; Seenivasan, A.; Prakash, D.G.; Ramakrishnan, K. Characterization of Terephthalic Acid Monomer Recycled from Post-Consumer PET Polymer Bottles. Macromol. Symp. 2016, 361, 30–33. [Google Scholar] [CrossRef]

- van Leeuwen, P.W.N.M. Catalysis, Homogeneous. In Encyclopedia of Physical Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003; pp. 457–490. ISBN 978-0-12-227410-7. [Google Scholar]

- Zhou, J.-H.; Shen, G.-Z.; Zhu, J.; Yuan, W.-K. Terephthalic Acid Hydropurification over Pd/C Catalyst. In Studies in Surface Science and Catalysis; Elsevier: Amsterdam, The Netherlands, 2006; Volume 159, pp. 293–296. ISBN 978-0-444-51733-3. [Google Scholar]

- Cosimbescu, L.; Merkel, D.R.; Darsell, J.; Petrossian, G. Simple But Tricky: Investigations of Terephthalic Acid Purity Obtained from Mixed PET Waste. Ind. Eng. Chem. Res. 2021, 60, 12792–12797. [Google Scholar] [CrossRef]

- Kang, M.J.; Yu, H.J.; Jegal, J.; Kim, H.S.; Cha, H.G. Depolymerization of PET into Terephthalic Acid in Neutral Media Catalyzed by the ZSM-5 Acidic Catalyst. Chem. Eng. J. 2020, 398, 125655. [Google Scholar] [CrossRef]

- Lee, H.L.; Chiu, C.W.; Lee, T. Engineering Terephthalic Acid Product from Recycling of PET Bottles Waste for Downstream Operations. Chem. Eng. J. Adv. 2021, 5, 100079. [Google Scholar] [CrossRef]

- Kambo, H.S.; Minaret, J.; Dutta, A. Process Water from the Hydrothermal Carbonization of Biomass: A Waste or a Valuable Product? Biomass Valor. 2018, 9, 1181–1189. [Google Scholar] [CrossRef]

- Alhnidi, M.-J.; Wüst, D.; Funke, A.; Hang, L.; Kruse, A. Fate of Nitrogen, Phosphate, and Potassium during Hydrothermal Carbonization and the Potential for Nutrient Recovery. ACS Sustain. Chem. Eng. 2020, 8, 15507–15516. [Google Scholar] [CrossRef]

- Crossley, O.P.; Thorpe, R.B.; Peus, D.; Lee, J. Phosphorus Recovery from Process Waste Water Made by the Hydrothermal Carbonisation of Spent Coffee Grounds. Bioresour. Technol. 2020, 301, 122664. [Google Scholar] [CrossRef] [PubMed]

- Farru, G.; Cappai, G.; Carucci, A.; De Gioannis, G.; Asunis, F.; Milia, S.; Muntoni, A.; Perra, M.; Serpe, A. A Cascade Biorefinery for Grape Marc: Recovery of Materials and Energy through Thermochemical and Biochemical Processes. Sci. Total Environ. 2022, 846, 157464. [Google Scholar] [CrossRef] [PubMed]

- Farru, G.; Asquer, C.; Cappai, G.; De Gioannis, G.; Melis, E.; Milia, S.; Muntoni, A.; Piredda, M.; Scano, E.A. Hydrothermal Carbonization of Hemp Digestate: Influence of Operating Parameters. Biomass Conv. Bioref. 2022, 1–12. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.; Peng, X.; Lin, Y.; Wang, J.; Zheng, C. Effects of Aqueous Phase Recirculation in Hydrothermal Carbonization of Sweet Potato Waste. Bioresour. Technol. 2018, 267, 167–174. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Olszewski, M.P.; Wang, X.; Pfersich, J.; Sebastian, V.; Manyà, J.; Hedin, N.; Kruse, A. Assessment of the Effects of Process Water Recirculation on the Surface Chemistry and Morphology of Hydrochar. Renew. Energy 2020, 155, 1173–1180. [Google Scholar] [CrossRef]

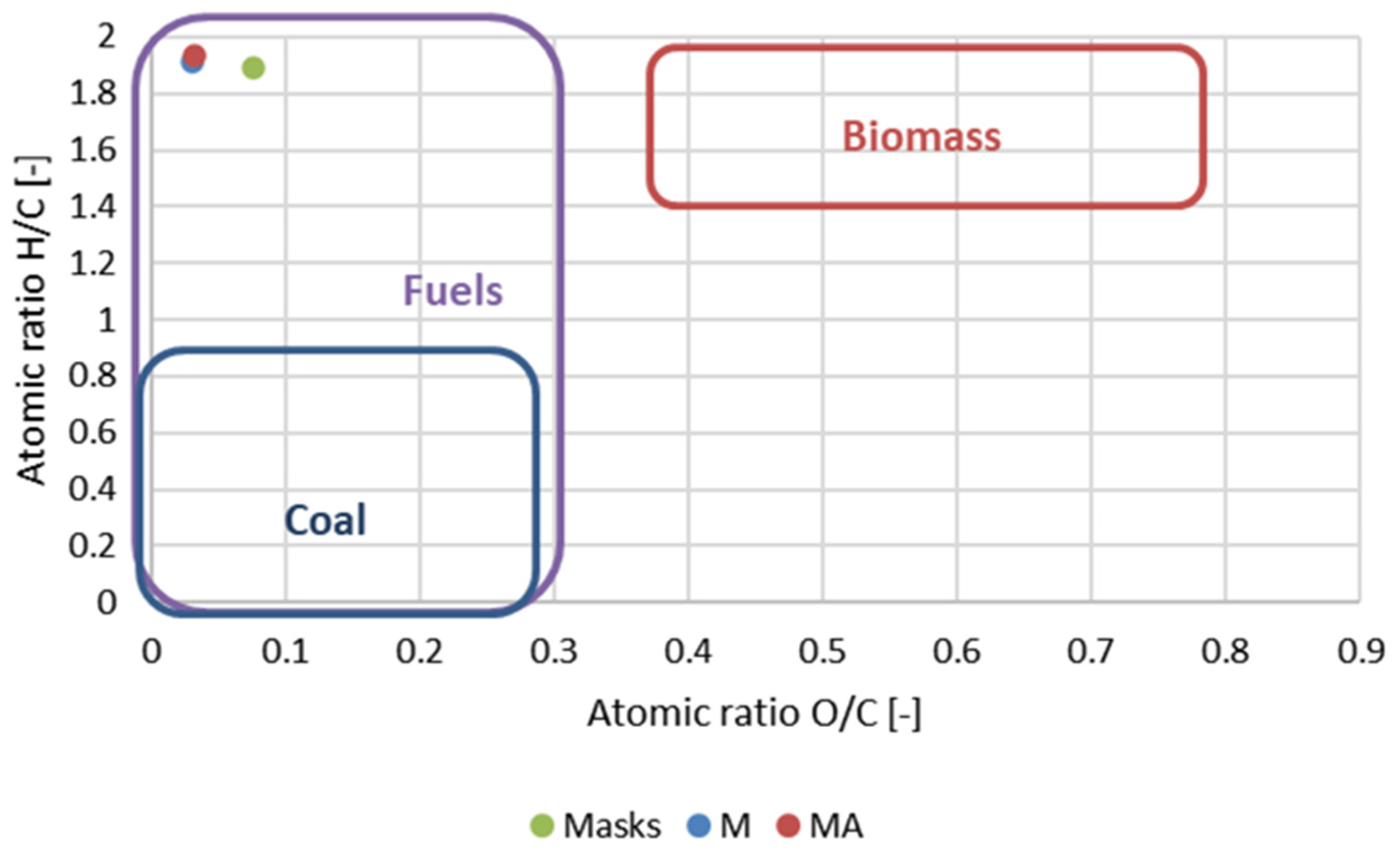

| Sample | Ash [%] | C [%] | H [%] | N [%] | O [%] | H/C [-] | O/C [-] | HHV [MJ/kg] | LHV [MJ/kg] | Energy Yield [-] |

|---|---|---|---|---|---|---|---|---|---|---|

| Masks | 1.92 (0.04) | 76.21 (0.89) | 12.02 (0.53) | 2.08 (0.20) | 7.77 (1.22) | 1.892 | 0.077 | 43.12 (0.51) | 40.48 | - |

| M | 0.21 (0.02) | 82.99 (1.14) | 13.22 (0.35) | 0.17 (0.03) | 3.41 (1.47) | 1.911 | 0.031 | 45.29 (0.21) | 42.41 | 0.94 |

| MA | 0.59 (0.04) | 82.41 (0.09) | 13.31 (0.19) | 0.17 (0.04) | 3.68 (0.26) | 1.938 | 0.032 | 45.33 (0.17) | 42.41 | 0.88 |

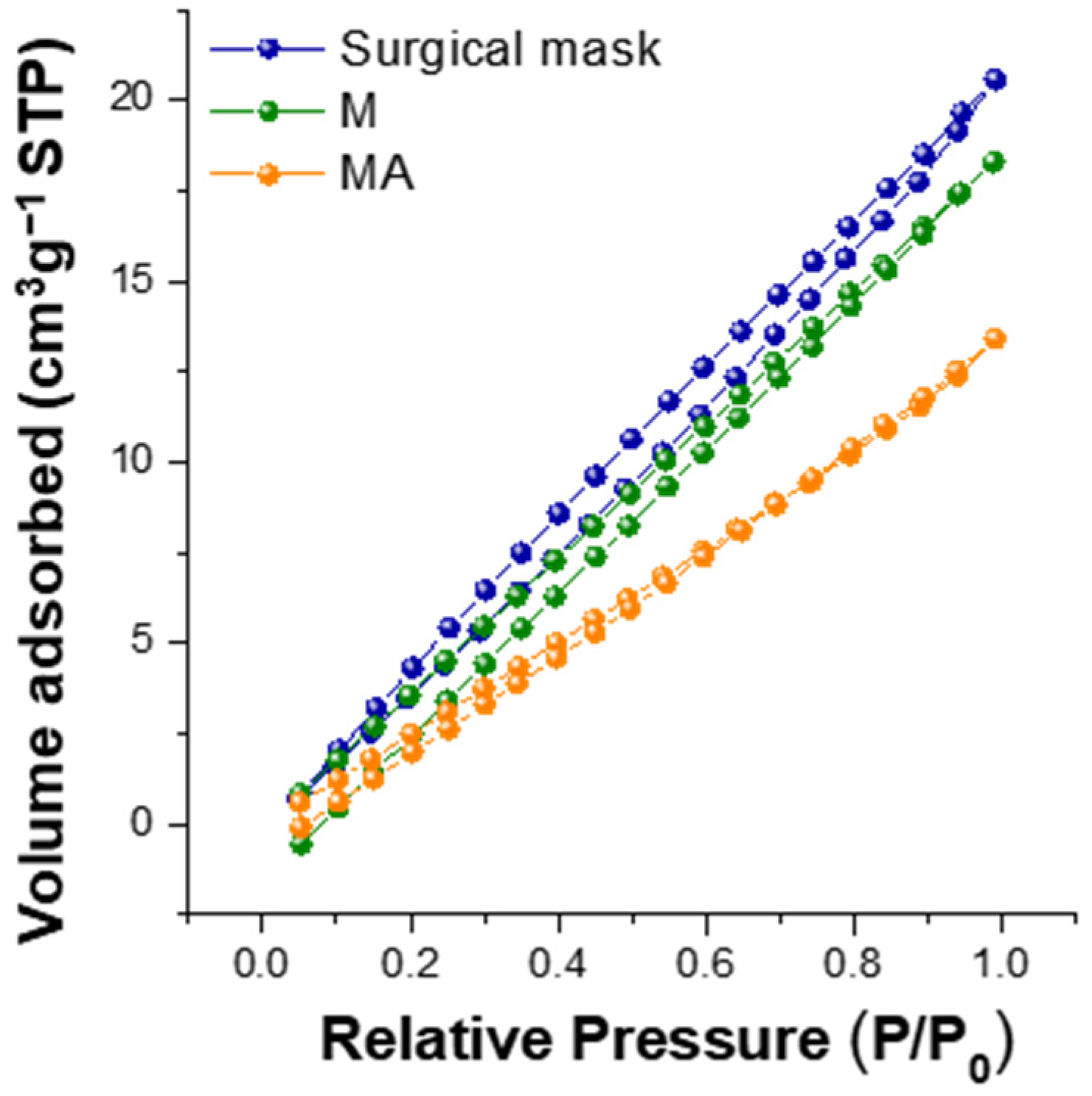

| Sample | Surface Area [m2/g] | Micro-Mesoporous Volume [cm3/g] |

|---|---|---|

| Surgical mask | 44.0 | 0.03 |

| M | 37.7 | 0.03 |

| MA | 24.5 | 0.02 |

| Sample | pH | Electrical Conductivity [mS/cm] | TOC [g/L] | TC [g/L] | IC [g/L] |

|---|---|---|---|---|---|

| Before HTC treatment | |||||

| M | 6.11 | 0.02 | 0.00 | 0.01 | 0.01 |

| MA | 2.58 | 1.51 | 20.49 | 20.50 | 0.01 |

| After HTC treatment | |||||

| M | 3.82 | 0.51 | 2.65 | 2.67 | 0.02 |

| MA | 2.70 | 2.57 | 26.58 | 26.75 | 0.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farru, G.; Libra, J.A.; Ro, K.S.; Cannas, C.; Cara, C.; Muntoni, A.; Piredda, M.; Cappai, G. Valorization of Face Masks Produced during COVID-19 Pandemic through Hydrothermal Carbonization (HTC): A Preliminary Study. Sustainability 2023, 15, 9382. https://doi.org/10.3390/su15129382

Farru G, Libra JA, Ro KS, Cannas C, Cara C, Muntoni A, Piredda M, Cappai G. Valorization of Face Masks Produced during COVID-19 Pandemic through Hydrothermal Carbonization (HTC): A Preliminary Study. Sustainability. 2023; 15(12):9382. https://doi.org/10.3390/su15129382

Chicago/Turabian StyleFarru, Gianluigi, Judy A. Libra, Kyoung S. Ro, Carla Cannas, Claudio Cara, Aldo Muntoni, Martina Piredda, and Giovanna Cappai. 2023. "Valorization of Face Masks Produced during COVID-19 Pandemic through Hydrothermal Carbonization (HTC): A Preliminary Study" Sustainability 15, no. 12: 9382. https://doi.org/10.3390/su15129382

APA StyleFarru, G., Libra, J. A., Ro, K. S., Cannas, C., Cara, C., Muntoni, A., Piredda, M., & Cappai, G. (2023). Valorization of Face Masks Produced during COVID-19 Pandemic through Hydrothermal Carbonization (HTC): A Preliminary Study. Sustainability, 15(12), 9382. https://doi.org/10.3390/su15129382