Mechanical and Sensory Properties of Pulse Gels in the Development of New Plant Based Food

Abstract

:1. Introduction

2. Materials and Methods

2.1. Gels Composition and Preparation

2.2. Mechanical Properties of Pulse Gels

2.2.1. Texture Profile Analysis

2.2.2. Compression up to Rupture

2.2.3. Resistance to Penetration

2.2.4. Cutting Test

2.3. Sensory Evaluation

2.3.1. Composition and Preparation of Gels

2.3.2. Procedure

2.4. Data Analysis

3. Results and Discussion

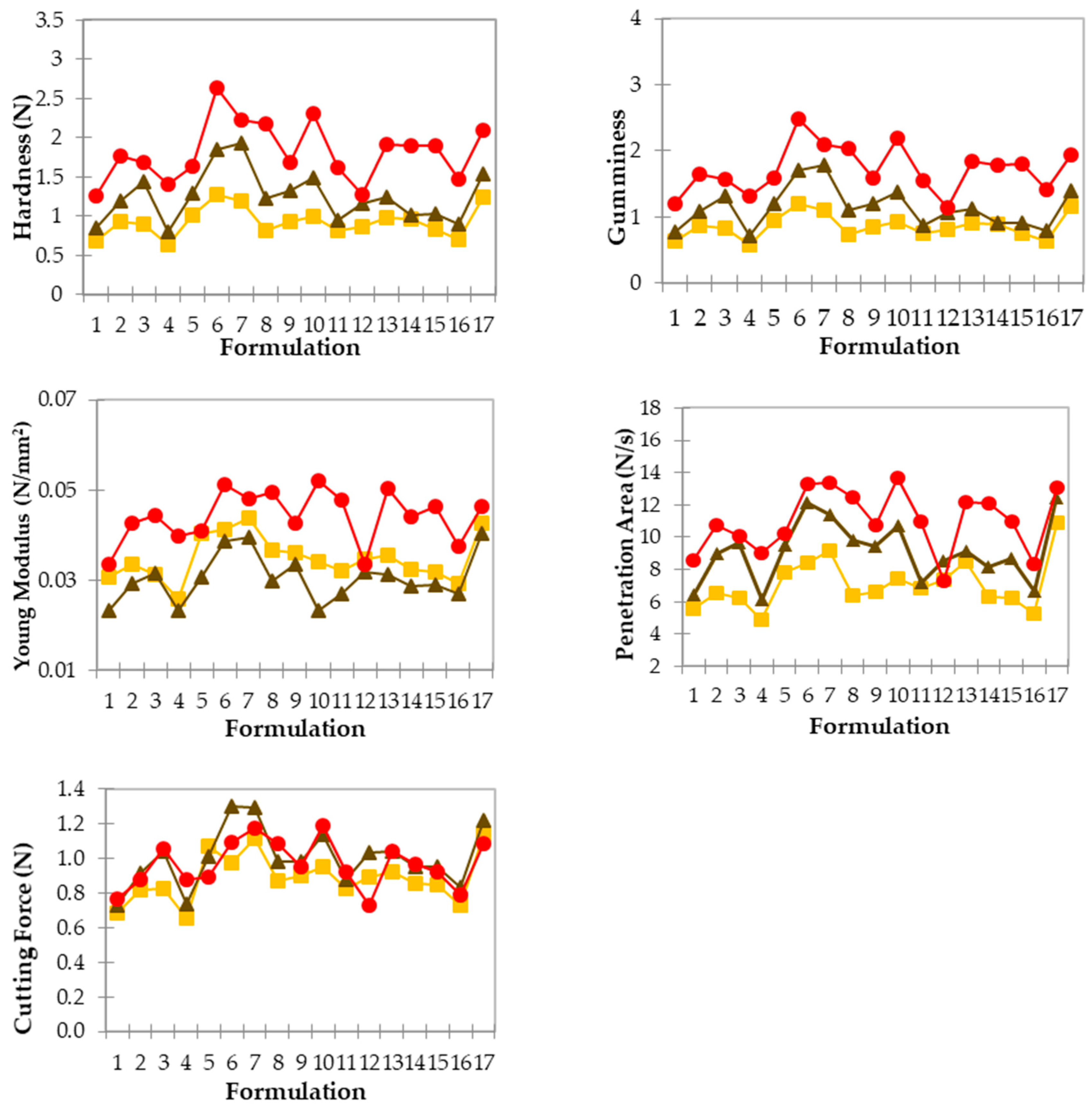

3.1. Mechanical Properties of Pulse Gels

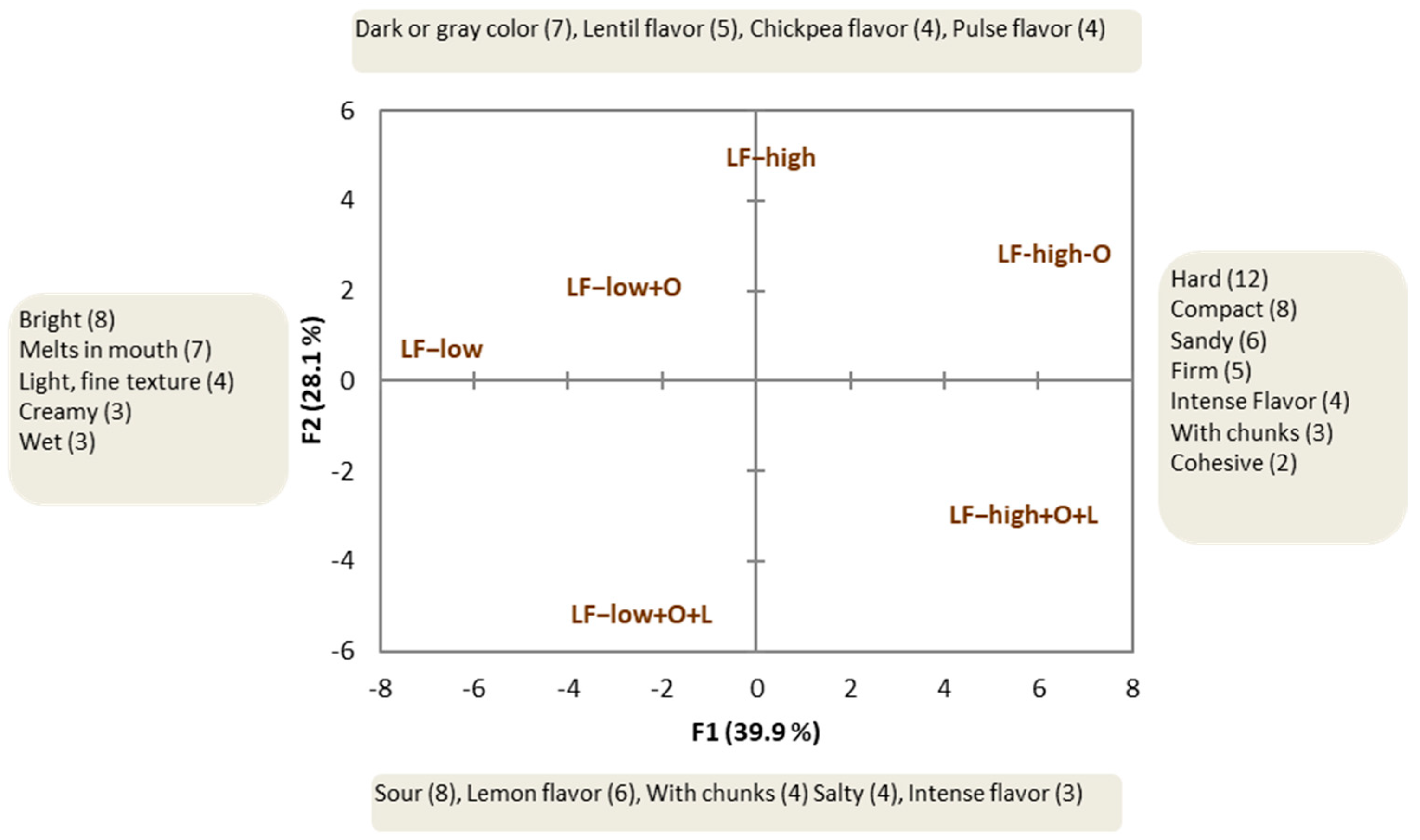

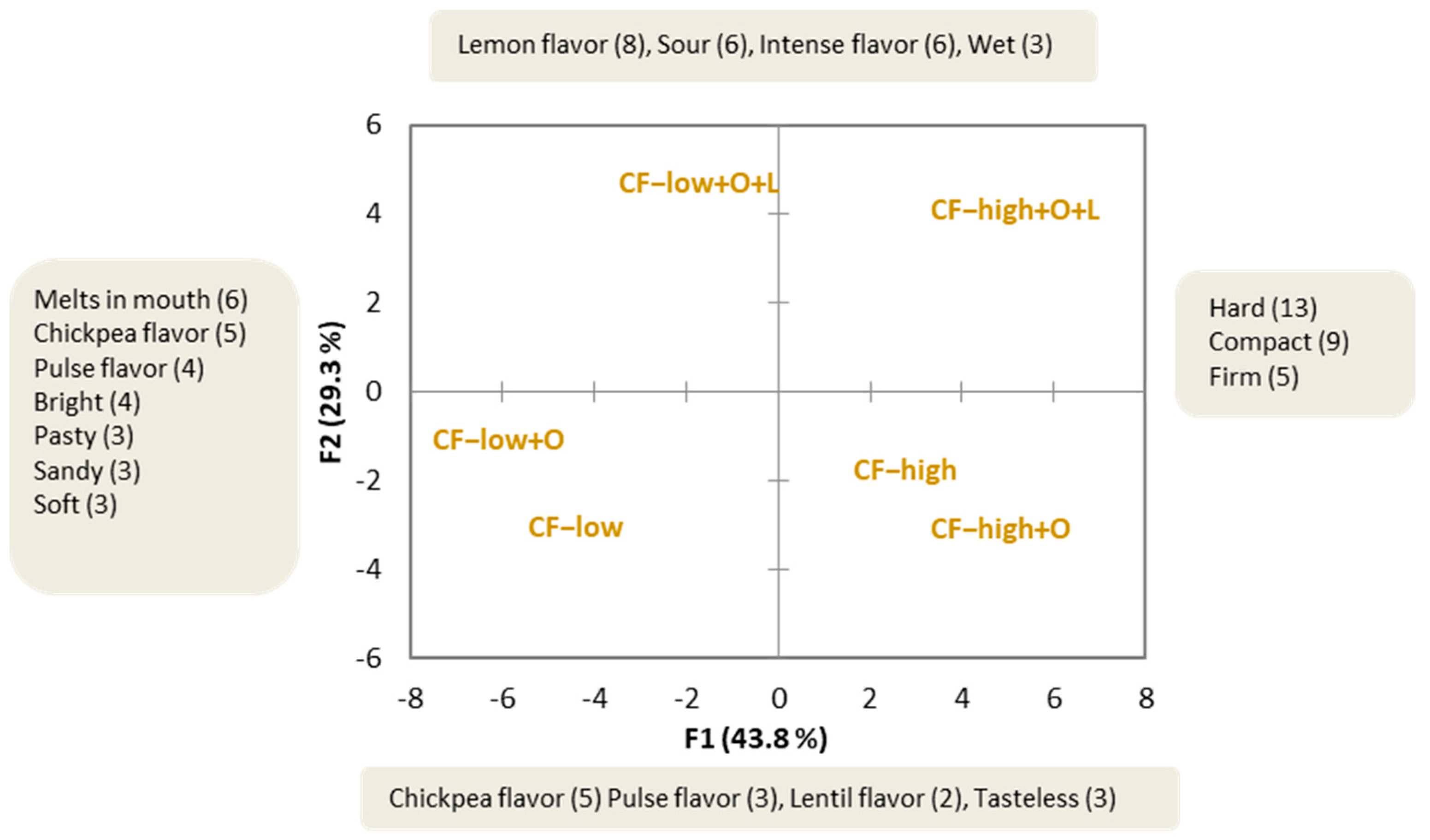

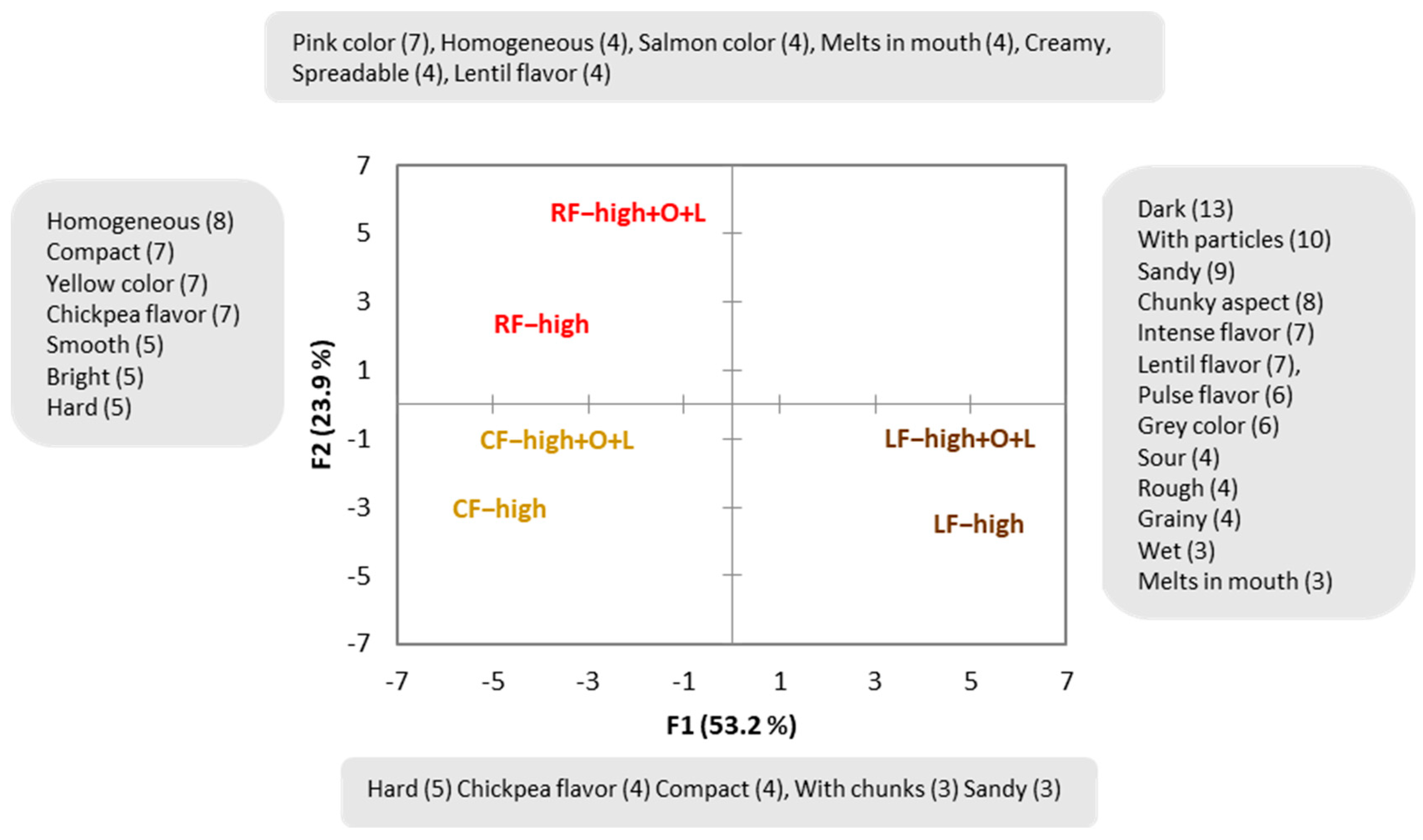

3.2. Sensory Properties of Pulse Gels

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Argel, N.S.; Ranalli, N.; Califano, A.N.; Andrés, S.C. Influence of Partial Pork Meat Replacement by Pulse Flour on Physicochemical and Sensory Characteristics of Low-Fat Burgers. J. Sci. Food Agric. 2020, 100, 3932–3941. [Google Scholar] [CrossRef] [PubMed]

- Tarrega, A.; Rizo, A.; Murciano, A.; Laguna, L.; Fiszman, S. Current Research in Food Science Are Mixed Meat and Vegetable Protein Products Good Alternatives for Reducing Meat Consumption? A Case Study with Burgers. Curr. Res. Food Sci. 2020, 3, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Gebhardt, B. Plant-Based for the Future Insights on European Consumer and Expert Opinion. 2020. Available online: https://www.eitfood.eu/media/documents/Uni_Hohenheim_Whitepaper_16zu9.pdf (accessed on 27 May 2023).

- Jeske, S.; Zannini, E.; Arendt, E.K. Past, Present and Future: The Strength of Plant-Based Dairy Substitutes Based on Gluten-Free Raw Materials. Food Res. Int. 2018, 110, 42–51. [Google Scholar] [CrossRef]

- Sharma, N.; Bansal, V.; Sahu, J.K. Plant-Based Gels; Elsevier Inc.: Amsterdam, The Netherlands, 2023; ISBN 9780323898423. [Google Scholar]

- Aschemann-Witzel, J.; Gantriis, R.F.; Fraga, P.; Perez-Cueto, F.J.A. Plant-Based Food and Protein Trend from a Business Perspective: Markets, Consumers, and the Challenges and Opportunities in the Future. Crit. Rev. Food Sci. Nutr. 2020, 61, 3119–3128. [Google Scholar] [CrossRef]

- Alcorta, A.; Porta, A.; Amparo, T. Foods for Plant-Based Diets: Challenges and Innovations. Foods 2021, 10, 293. [Google Scholar] [CrossRef]

- Dagevos, H. Finding Flexitarians: Current Studies on Meat Eaters and Meat Reducers. Trends Food Sci. Technol. 2021, 114, 530–539. [Google Scholar] [CrossRef]

- Amar, A.; Surono, I.S. Physico-Chemical, and Sensory Properties of Soy Based Gouda Cheese Analog Made from Different Concentration of Fat, Sodium Citrate and Various Cheese Starter Cultures. MAKARA J. Technol. Ser. 2013, 16, 149–156. [Google Scholar] [CrossRef]

- Matias, N.S.; Bedani, R.; Castro, I.A.; Saad, S.M.I. A Probiotic Soy-Based Innovative Product as an Alternative to Petit-Suisse Cheese. LWT 2014, 59, 411–417. [Google Scholar] [CrossRef]

- Grasso, N.; Roos, Y.H.; Crowley, S.V.; Arendt, E.K.; Mahony, J.A.O. Composition and Physicochemical Properties of Commercial Plant-Based Block-Style Products as Alternatives to Cheese. Future Foods 2021, 4, 100048. [Google Scholar] [CrossRef]

- Guldiken, B.; Franczyk, A.; Boyd, L.; Wang, N.; Choo, K.; Sopiwnyk, E.; House, J.; Paliwal, J.; Nickerson, M. Physicochemical, Nutritional and Functional Properties of Chickpea (Cicer Arietinum) and Navy Bean (Phaseolus Vulgaris) Flours from Different Mills. Eur. Food Res. Technol. 2022, 248, 1847–1858. [Google Scholar] [CrossRef]

- Saint-Eve, A.; Granda, P.; Legay, G.; Cuvelier, G.; Delarue, J. Consumer Acceptance and Sensory Drivers of Liking for High Plant Protein Snacks. J. Sci. Food Agric. 2019, 99, 3983–3991. [Google Scholar] [CrossRef] [PubMed]

- Proserpio, C.; Bresciani, A.; Marti, A.; Pagliarini, E. Legume Flour or Bran: Sustainable, Fiber-Rich Ingredients for Extruded Snacks? Foods 2020, 9, 1680. [Google Scholar] [CrossRef] [PubMed]

- Shevkani, K.; Singh, N.; Chen, Y.; Kaur, A. Pulse Proteins: Secondary Structure, Functionality and Applications. J. Food Sci. Technol. 2019, 56, 2787–2798. [Google Scholar] [CrossRef]

- Ferawati, F.; Hefni, M.; Witthöft, C. Flours from Swedish Pulses: Effects of Treatment on Functional Properties and Nutrient Content. Food Sci. Nutr. 2019, 7, 4116–4126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jahreis, G.; Brese, M.; Leiterer, M.; Schäfer, U.; Böhm, V. Legume Flours: Nutritionally Important Sources of Protein and Dietary Fiber. Ernahr. Umsch. 2016, 63, 36–42. [Google Scholar] [CrossRef]

- Badia-Olmos, C.; Laguna, L.; Haros, C.M.; Tárrega, A. Techno-Functional and Rheological Properties of Alternative Plant-Based Flours. Foods 2023, 12, 1411. [Google Scholar] [CrossRef]

- Díaz, O.; Ferreiro, T.; Rodríguez-Otero, J.L.; Cobos, Á. Characterization of Chickpea (Cicer Arietinum L.) Flour Films: Effects of PH and Plasticizer Concentration. Int. J. Mol. Sci. 2019, 20, 1246. [Google Scholar] [CrossRef] [Green Version]

- Kaur, M.; Singh, N. Studies on Functional, Thermal and Pasting Properties of Flours from Different Chickpea (Cicer Arietinum L.) Cultivars. Food Chem. 2005, 91, 403–411. [Google Scholar] [CrossRef]

- Tas, O.; Ertugrul, U.; Grunin, L.; Oztop, M.H. An Investigation of Functional Quality Characteristics and Water Interactions of Navy Bean, Chickpea, Pea, and Lentil Flours. Legum. Sci. 2022, 4, e136. [Google Scholar] [CrossRef]

- Ladjal Ettoumi, Y.; Chibane, M. Some Physicochemical and Functional Properties of Pea, Chickpea and Lentil Whole Flours. Int. Food Res. J. 2015, 22, 987–996. [Google Scholar]

- Aguilera, Y.; Esteban, R.M.; Benítez, V.; Mollá, E.; Martín-Cabrejas, M.A. Starch, Functional Properties, and Microstructural Characteristics in Chickpea and Lentil as Affected by Thermal Processing. J. Agric. Food Chem. 2009, 57, 10682–10688. [Google Scholar] [CrossRef]

- Ladjal-Ettoumi, Y.; Boudries, H.; Chibane, M.; Romero, A. Pea, Chickpea and Lentil Protein Isolates: Physicochemical Characterization and Emulsifying Properties. Food Biophys. 2016, 11, 43–51. [Google Scholar] [CrossRef]

- Moussaoui, D.; Chaya, C.; Badia-Olmos, C.; Rizo, A.; Tarrega, A. Effect of pH and Calcium on the Technofunctional Properties of Different Pulse Flours, Pastes, and Gels. Under Rev. 2023; Unpublish. [Google Scholar]

- Shevkani, K.; Kaur, M. Singh|Narpinder Composition, Pasting, Functional, and Microstructural Properties of Flours from Different Split Dehulled Pulses (Dhals). J. Food Process Preserv. 2021, 45, 15485. [Google Scholar] [CrossRef]

- Renkema, J.M.S.; Gruppen, H.; van Vliet, T. Influence of PH and Ionic Strength on Heat-Induced Formation and Rheological Properties of Soy Protein Gels in Relation to Denaturation and Their Protein Compositions. Agric. Food Chem. 2002, 50, 6064–6071. [Google Scholar] [CrossRef] [PubMed]

- Patrascu, L.; Vasilean, I.; Banu, I.; Aprodu, I. Functional Properties of Pulse Flours and Their Opportunities in Spreadable Food Products. Qual. Assur. Saf. Crop. Foods 2017, 9, 67–78. [Google Scholar] [CrossRef]

- Boukid, F. The Realm of Plant Proteins with Focus on Their Application in Developing New Bakery Products, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2022; Volume 99, ISBN 9780323855570. [Google Scholar]

- Dairou, V.; Sieffermann, J.M. A Comparison of 14 Jams Characterized by Conventional Profile and a Quick Original Method, the Flash Profile. J. Food Sci. 2002, 67, 826–834. [Google Scholar] [CrossRef]

- Lassoued, N.; Delarue, J.; Launay, B.; Michon, C. Baked Product Texture: Correlations between Instrumental and Sensory Characterization Using Flash Profile. J. Cereal Sci. 2008, 48, 133–143. [Google Scholar] [CrossRef]

- Tarrega, A.; Rizo, A.; Fiszman, S. Sensory space of battered surimi rings: Key features determined by Flash Profiling. J. Sens. Stud. 2017, 32, e12274. [Google Scholar] [CrossRef]

- Gacula, M.C. Design and Analysis of Sensory Optimization; Food & Nutrition Press: Trumbull, CT, USA, 1993. [Google Scholar]

- Bayarri, S.; Costell, E.; Dura, L. Influence of Low Sucrose Concentrations on the Compression Resistance of Gellan Gum Gels Q. Food Hydrocoll. 2002, 16, 593–597. [Google Scholar] [CrossRef]

- Laguna, L.; Sanz, T.; Sahi, S.; Fiszman, S.M. Role of Fibre Morphology in Some Quality Features of Fibre-Enriched Biscuits. Int. J. Food Prop. 2014, 17, 2912. [Google Scholar] [CrossRef]

- Pang, Z.; Cao, J.; Li, H.; Chen, C.; Liu, X. Rheology and Tribology Properties of Cereal and Legume Flour Paste from Different Botanical Origins. J. Food Sci. 2020, 85, 4130–4140. [Google Scholar] [CrossRef] [PubMed]

- Bresciani, A.; Emide, D.; Saitta, F.; Barbiroli, A.; Marti, A.; Fessas, D.; Iametti, S. Impact of Thermal Treatment on the Starch-Protein Interplay in Red Lentils: Connecting Molecular Features and Rheological Properties. Molecules 2022, 27, 1266. [Google Scholar] [CrossRef] [PubMed]

- Johansson, M.; Johansson, D.; Ström, A.; Rydén, J.; Nilsson, K.; Karlsson, J.; Moriana, R.; Langton, M. Effect of Starch and Fibre on Faba Bean Protein Gel Characteristics. Food Hydrocoll. 2022, 131, 107741. [Google Scholar] [CrossRef]

- Portman, D.; Maharjan, P.; McDonald, L.; Laskovska, S.; Walker, C.; Irvin, H.; Blanchard, C.; Naiker, M.; Panozzo, J.F. Nutritional and functional properties of cookies made using down-graded lentil—A candidate for novel food production and crop utilization. Cereal Chem. 2019, 97, 95–103. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Vasquez Mejía, S.M.; Murch, S.J.; Bohrer, B.M. Cooking Loss, Texture Properties, and Color of Comminuted Beef Prepared with Breadfruit (Artocarpus Altilis) Flour. Meat Muscle Biol. 2019, 3, 231–243. [Google Scholar] [CrossRef]

- Torres, M.D.; Raymundo, A.; Sousa, I. Influence of Na+, K+ and Ca2+ on Mechanical and Structural Properties of Gels from Chestnut and Rice Flours. Carbohydr. Polym. 2014, 102, 30–37. [Google Scholar] [CrossRef]

- Langton, M.; Ehsanzamir, S.; Karkehabadi, S.; Feng, X.; Johansson, M.; Johansson, D.P. Gelation of Faba Bean Proteins—Effect of Extraction Method, PH and NaCl. Food Hydrocoll. 2020, 103, 105622. [Google Scholar] [CrossRef]

- Wang, Y.; Kim, W.; Naik, R.R.; Selomulya, C. Functionality of Plant-Based Proteins; Elsevier Inc.: Amsterdam, The Netherlands, 2023; ISBN 9780323898423. [Google Scholar]

- Johansson, M.; Karkehabadi, S.; Johansson, D.P.; Langton, M. Gelation Behaviour and Gel Properties of the 7S and 11S Globulin Protein Fractions from Faba Bean (Vicia Faba Var. Minor) at Different NaCl Concentrations. Food Hydrocoll. 2023, 142, 143747. [Google Scholar] [CrossRef]

- Hirashima, M.; Takahashi, R.; Nishinari, K. The Gelatinization and Retrogradation of Cornstarch Gels in the Presence of Citric Acid. Food Hydrocoll. 2012, 27, 390–393. [Google Scholar] [CrossRef]

- Jiménez, M.J.; Tárrega, A.; Fuentes, R.; Canet, W.; Álvarez, M.D. Consumer Perceptions, Descriptive Profile, and Mechanical Properties of a Novel Product with Chickpea Flour: Effect of Ingredients. Food Sci. Technol. Int. 2016, 22, 547–562. [Google Scholar] [CrossRef]

| Formulation | Flour % | Oil % | Lemon % | Salt % |

|---|---|---|---|---|

| 1 | 15.4 | 0.4 | 0.4 | 1.2 |

| 2 | 15.4 | 2.4 | 0.4 | 0.2 |

| 3 | 15.4 | 0.4 | 2.4 | 0.2 |

| 4 | 15.4 | 2.4 | 2.4 | 1.2 |

| 5 | 17.1 | 0.4 | 0.4 | 1.2 |

| 6 | 17.1 | 2.4 | 0.4 | 0.2 |

| 7 | 17.1 | 0.4 | 2.4 | 0.2 |

| 8 | 17.1 | 2.4 | 2.4 | 1.2 |

| 9 | 16.25 | 1.4 | 1.4 | 0.7 |

| 10 | 16.25 | 1.4 | 1.4 | 0 |

| 11 | 16.25 | 1.4 | 1.4 | 1.4 |

| 12 | 16.25 | 0 | 1.4 | 0.7 |

| 13 | 16.25 | 2.8 | 1.4 | 0.7 |

| 14 | 16.25 | 1.4 | 0 | 0.7 |

| 15 | 16.25 | 1.4 | 2.8 | 0.7 |

| 16 | 15 | 1.4 | 1.4 | 0.7 |

| 17 | 17.5 | 1.4 | 1.4 | 0.7 |

| Sample Code | Composition | ||||

|---|---|---|---|---|---|

| Lentil Flour (Session 1) | Chickpea Flour (Session 2) | Red Lentil Flour (Session 3) | Flour (%) | Oil (%) | Lemon (%) |

| LF-Low | CF-Low | RF-Low | 15.1 | 0 | 0 |

| LF-Low + O | CF-Low + O | RF-Low + O | 15.1 | 2.8 | 0 |

| LF-low + O + L | CF-Low + O + L | RF-Low + O + L | 15.1 | 2.8 | 2.8 |

| LF-High * | CF-High * | RF-High * | 17.4 | 0 | 0 |

| LF-High + O | CF-High + O | RF-High + O | 17.4 | 2.8 | 0 |

| LF-High + O + L * | CF-High + O + L * | RF-High + O + L * | 17.4 | 2.8 | 2.8 |

| Parameter | Flour Type | R2 | Model |

|---|---|---|---|

| Hardness | Lentil | 0.864 | −0.711 − 0.503Salt + 0.0087Flour2 |

| Red lentil | 0.939 | −0.85 + 0.419Salt2 − 0.095Oil2 + 0.010Flour2 − 0.0649Salt × Flour + 0.0271Oil × Flour | |

| Chickpea | 0.929 | −0.465 − 0.017Lemon2 + 0.006Flour2 − 0.015Salt × Flour | |

| Gumminess | Lentil | 0.857 | −0.690 − 0.473Salt + 0.00816Flour2 |

| Red lentil | 0.927 | −3.331 + 0.424Salt2 − 0.096Oil2 + 0.315Flour − 0.0631Salt × Flour + 0.0272Oil × Flour | |

| Chickpea | 0.918 | −0.469 − 0.018Lemon2 + 0.006Flour2 − 0.014Salt × Flour | |

| Young modulus | Lentil | 0.673 | −0.00737 − 0.0036Salt2 + 0.00015Flour2 |

| Red lentil | 0.765 | −0.0148 − 0.019Salt + 0.0037Flour + 0.0105Salt2 + 0.0002Oil × Flour | |

| Chickpea | 0.885 | −0.010 + 0.000178Flour2 − 0.0017Salt × Lemon | |

| Penetration area | Lentil | 0.934 | −4.939 − 2.552Salt + 0.059Flour2 |

| Red lentil | 0.759 | −16.77 + 1.715Flour − 0.1130Salt × Flour + 0.0522Oil × Flour | |

| Chickpea | 0.735 | −5.572 − 0.769Salt2 + 0.049Flour2 | |

| Cutting force | Lentil | 0.946 | −0.258 + 0.0054Flour2 − 0.015Salt × Flour |

| Red lentil | 0.827 | −0.562 − 0.606Salt + 0.106Flour + 0.238Salt2 + 0.0791Salt × Oil | |

| Chickpea | 0.872 | −0.339 + 0.005Flour2 − 0.052Salt × Oil |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moussaoui, D.; González, M.; Rizo, A.; Chaya, C.; Tarrega, A. Mechanical and Sensory Properties of Pulse Gels in the Development of New Plant Based Food. Sustainability 2023, 15, 9407. https://doi.org/10.3390/su15129407

Moussaoui D, González M, Rizo A, Chaya C, Tarrega A. Mechanical and Sensory Properties of Pulse Gels in the Development of New Plant Based Food. Sustainability. 2023; 15(12):9407. https://doi.org/10.3390/su15129407

Chicago/Turabian StyleMoussaoui, Djemaa, Mónica González, Arantxa Rizo, Carolina Chaya, and Amparo Tarrega. 2023. "Mechanical and Sensory Properties of Pulse Gels in the Development of New Plant Based Food" Sustainability 15, no. 12: 9407. https://doi.org/10.3390/su15129407