Innovative Energy-Efficient Prefabricated Movable Buildings for Smart/Co-Working: Performance Assessment upon Varying Building Configurations

Abstract

:1. Introduction

1.1. Motivation and Background

1.2. Literature Review of Prefabricated Movable Buildings Exploiting Renewable Sources and Research Gaps

- the “Smart-POD” model proposed by Ceranic et al. [24] was designed as a response to an unexpected increase in pupil numbers in schools, as a replacement during the refurbishing of existing schools, or to support the continuous operation of unsafe/damaged schools. The model has a net floor area of 117 m2. It satisfies the electric demand through the installation of 40 m2 of photovoltaic (PV) panels on the roof; the electric surplus is sold to the electric central grid or stored in a lithium-ion battery. Heating requirements are covered by means of a thermal storage of 9 m × 6 m × 0.5 m crushed rock bed, a mechanical ventilation heat recovery system, and/or an air-to-air electrically driven vapor-compression heat pump, depending on boundary conditions. Both the thermal storage and the mechanical ventilation heat recovery system could also be used for cooling purposes. The installed LED appliances are controlled according to illuminance levels and occupancy sensors. Rainwater harvesting could be adopted for toilet and/or drinking purposes thanks to the use of filters and UV treatment;

- the “Pre-fab Eco Smart House” model was developed by a research team from the University of Cyprus [25,26]. A mobile “kit-of-parts” system was developed; it consists of seven structural components that can be juxtaposed in different configurations. Windows, walls, and shading devices were also developed with a “plug n’ play” logic since they are modular, with dimensions of 1.00 m width and 2.70 m height. The internal space has a total net floor area of 20.7 m2 and a height of 2.7 m. The total volume is 55.89 m3. The building envelope has the following thermal transmittance values: 0.280 W/m2 K for exterior walls, 0.316 W/m2 K for the floor, 0.263 W/m2 K for the roof, and 2.00 W/m2 K for the glazings. The heating/cooling demands are covered by an electric reversing heat pump. C. Vassiliades et al. [26] investigated the adoption of two hybrid building-integrated photovoltaic/thermal (BIPV/T) solar systems consisting of a single PV panel (1 m × 2.50 m) with a 0.08 m thick insulation on the back. An air gap of 0.05 m is adopted between the back of the PV panel and the insulating layer; to enhance the heat removal from PV cells, a set of four fans is placed within the air gap. The electric output of the systems is used to power an air-to-air electrically driven vapor-compression reversing heat pump; the surplus is sold to the central grid, which is also used to cover peak demands;

- the “Ecocapsule Original” model designed by the Nice Architects Studio of Bratislava in 2018 [27], for medium-term off-grid living of 1/2 people. It can become a cottage, pop-up hotel, mobile office, research station, or be used for interventions in emergency areas. It has a length of 4.67 m, a width of 2.20 m, and a height of 2.50 m, with a net floor area of 6.3 m2 and a total volume of 25.68 m3. It has two openable and two fixed triple-glazed windows. The exterior part is made of insulated fiberglass shells overlaying a steel framework. Solar and wind sources are used to cover the energy demands. The PV panels, with an area of 2.6 m2 and a peak power of 880 W, are installed on the roof, while the wind turbine, delivering up to 750 W, is positioned on a telescopic pole. Both systems can store energy in lithium-iron phosphate (LFP) batteries with a nominal total capacity of 9.7 kWh. The model features a specially customized plant providing cooling (up to 970 W) and heating (up to 1050 W) by means of a vapor-compression electric reversing heat pump; the required air change rates are satisfied by means of a mechanical ventilation heat recovery system (up to 130 m3/h). In the model, there are three tanks: (i) a harvested water tank (96 L) containing rainwater that is disinfected via a pre-filtration system and a UV LED lamp; (ii) a grey water tank (96 L) containing wastewater from the shower and sinks; and (iii) a black water tank (24 L) containing urine. The capital cost of the model is EUR 79,900;

- the “Living Box” model proposed by [28] was designed considering two cell typologies (A-type and B-type): the A-type cell has a net internal height equal to 2.70 m, while the B-type cell has a net internal height equal to 2.40 m. It has a length of 8 m, a width of 8.80 m, and a height of 3 m, with a net floor area of 45 m2 and a total volume of 211.2 m3. The model has two openable and five fixed double-glazing windows, characterized by a thermal transmittance equal to 1.5 W/m2 K. The thermal transmittance of the walls is 0.207 W/m2 K for the A-type cell and 0.308 W/m2 K for the B-type cell; the thermal transmittance of the roof is 0.138 W/m2 K. A heating, ventilation, and air-conditioning plant, including an air-to-air electrically driven vapor-compression reversing heat pump, is used to control the indoor thermal comfort. Domestic hot water (DHW) is produced by means of an air-to-water heat pump, connected to a 150 L storage tank. A PV plant of 36 modules, each having a peak power of 87.5 W, was architectonically integrated in the roof of the A-type cells; solar thermal devices are installed over the roof of the B-type to supplement the production of DHW;

- the “Biosphera Equilibrium” model was realized by Aktivhaus in 2018 [29]. It can become a real home for 2 people, a classroom for 11 people, or a mobile office for 3 people. It has a length of 15.3 m, a width of 2.97 m, and a height of 3.28 m, with a net floor area of 30.45 m2 and a total volume of 67.16 m3. It has three openable and two fixed triple-glazing windows. The external structure of the model is characterized by 5-layer X-LAM timber panels and is insulated with rockwool. It uses the solar source to cover the energy demands through two generation systems: the first consists of 19 PV panels positioned on the roof, while the second is an innovative PV system applied to the façade of the model. The total peak power of the PV system is 8 kW, with an annual electricity production capacity of 8000 kWh/year. Taking into account that the model is characterized by a nominal annual electricity consumption of 2000 kWh/year, the electricity surplus produced by the PV system is stored in the “ZHERO” battery (with a storage capacity of 20 kWh). In the model, the cooling/heating demand is covered by using radiant panels installed into the ceiling as hydraulic terminal units. As for lighting, LED lamps that allow for both a variable luminous flux and a correlated color temperature are used.

- (a)

- there are few studies focused on prefabricated movable buildings exploiting renewable sources, and, therefore, further research has to be performed;

- (b)

- the use of smart windows is not considered in the analyzed case studies, and its suitability from energy, environmental, and economic points of view has to be addressed;

- (c)

- the utilization of small wind turbines is investigated only in one of the selected examples [27]; as a consequence, the possibility of covering the building’s electric demand with the power generated by small wind turbines has to be further analyzed;

- (d)

- there are no quantitative analyses reporting the energy, environmental, and economic savings that could potentially be achieved with the use of alternative and innovative energy measures compared to the case of using traditional systems; the potential impact of such technologies should be assessed in more detail;

- (e)

- there are no cases in which the simultaneous use of smart windows, photovoltaic panels, small wind turbines, and electric energy storages is envisaged (with the exception of the “Ecocapsule Original” model [27], which considers the combined utilization of photovoltaic panels, a wind turbine, and an electric energy storage, which, however, relates to an office application for only 1–2 people); in particular, it should be verified if prefabricated movable buildings that are 100% self-sufficient from an energy point of view (thanks to the adoption of different renewable sources) can be realized in an economically feasible way.

1.3. Goals and Organization of the Study

- Configuration A, based on the adoption of smart windows operated under different logics controlling their state;

- configuration B, based on the utilization of both smart windows and photovoltaic panels combined with electric energy storages;

- configuration C, based on the utilization of both smart windows together with photovoltaic panels as well as a small wind turbine combined with electric energy storages.

- ➢

- evaluate the energy, environmental, and economic performance of an innovatively designed prefabricated movable building under various configurations differing in terms of building envelope and energy systems;

- ➢

- assess the potential benefits of smart windows and related control logics in the case of prefabricated movable buildings;

- ➢

- characterize the operation of photovoltaic panels eventually combined with electric storages when applied to a prefabricated movable building;

- ➢

- estimate the performance associated with building configurations simultaneously including photovoltaic panels, electric storages, and a wind turbine;

- ➢

- identify an energy-self-sufficient prefabricated movable building that can be used as a stand-alone system for smart/co-working.

2. Baseline Building

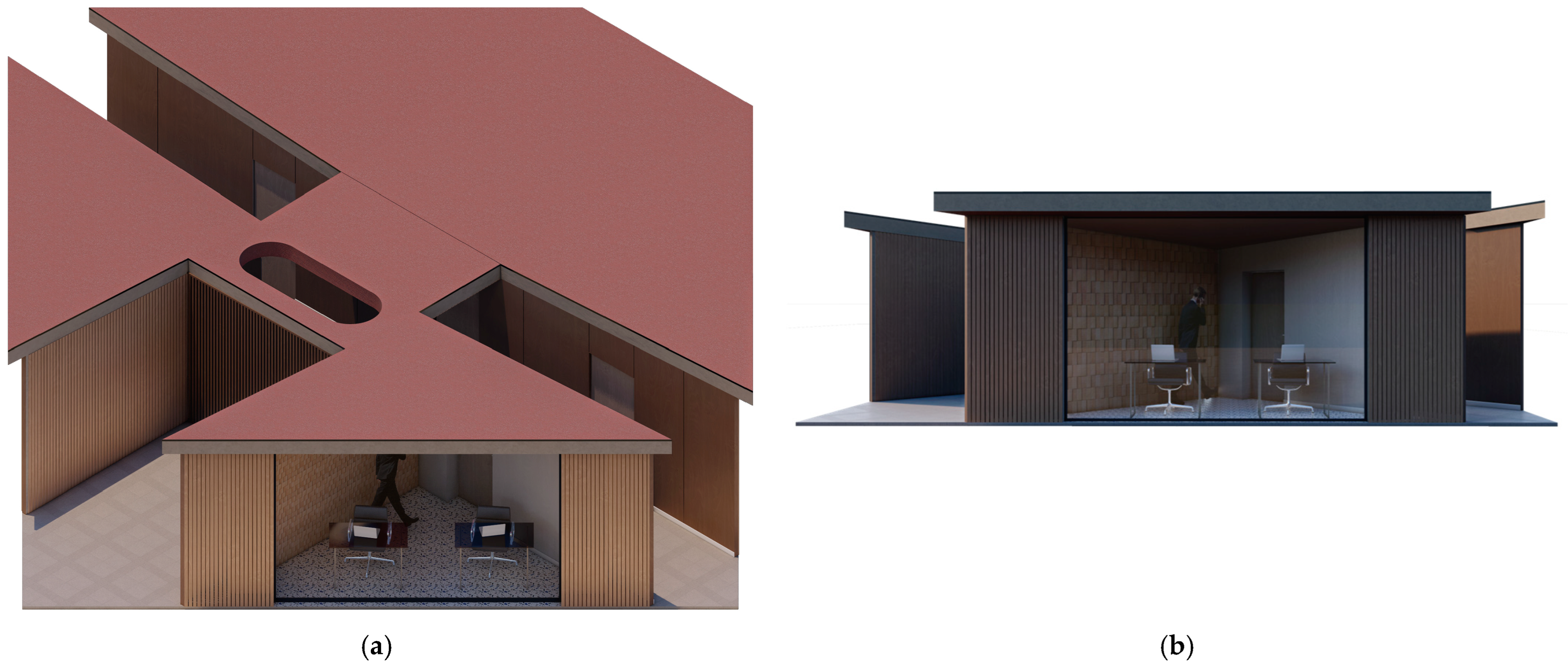

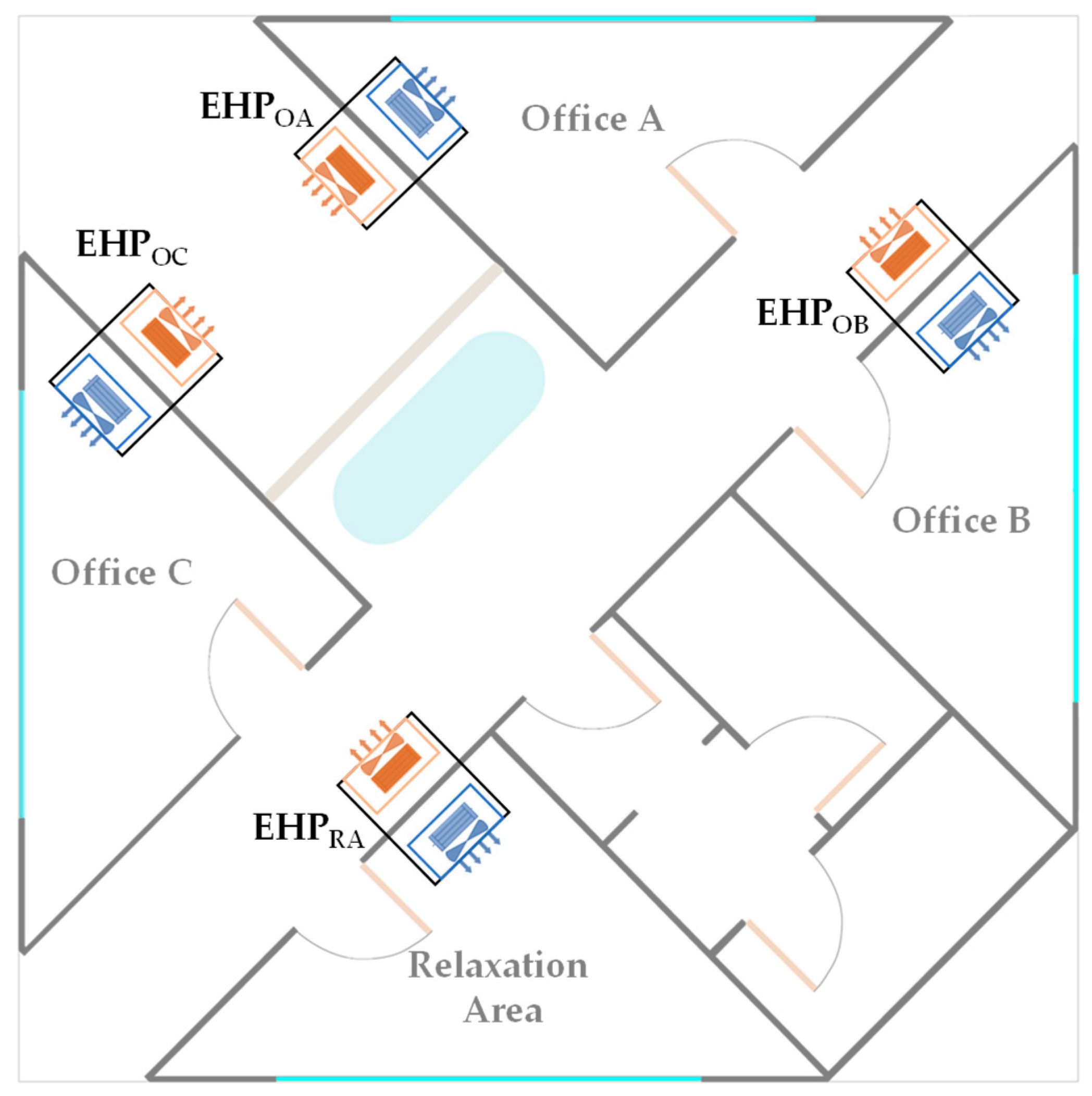

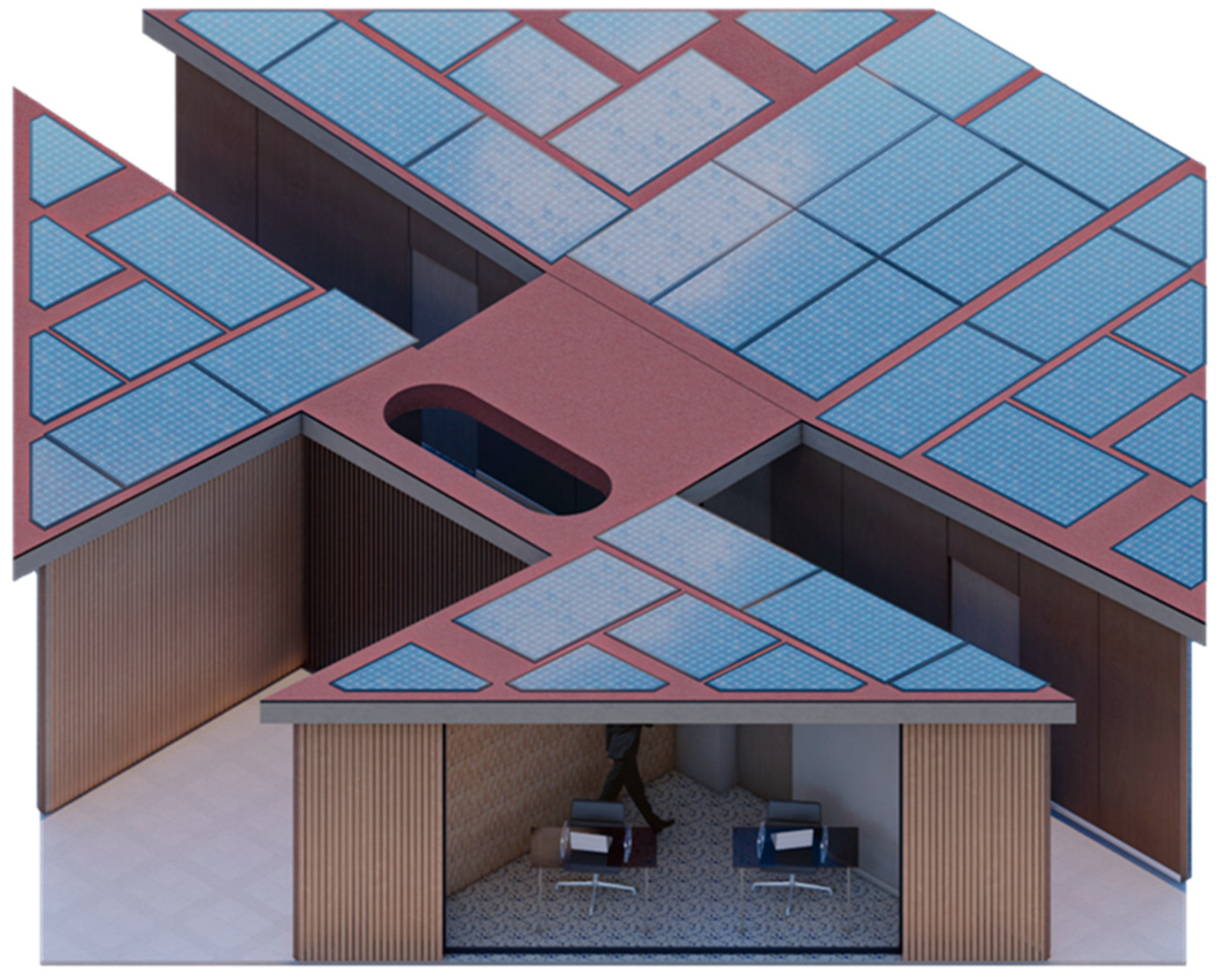

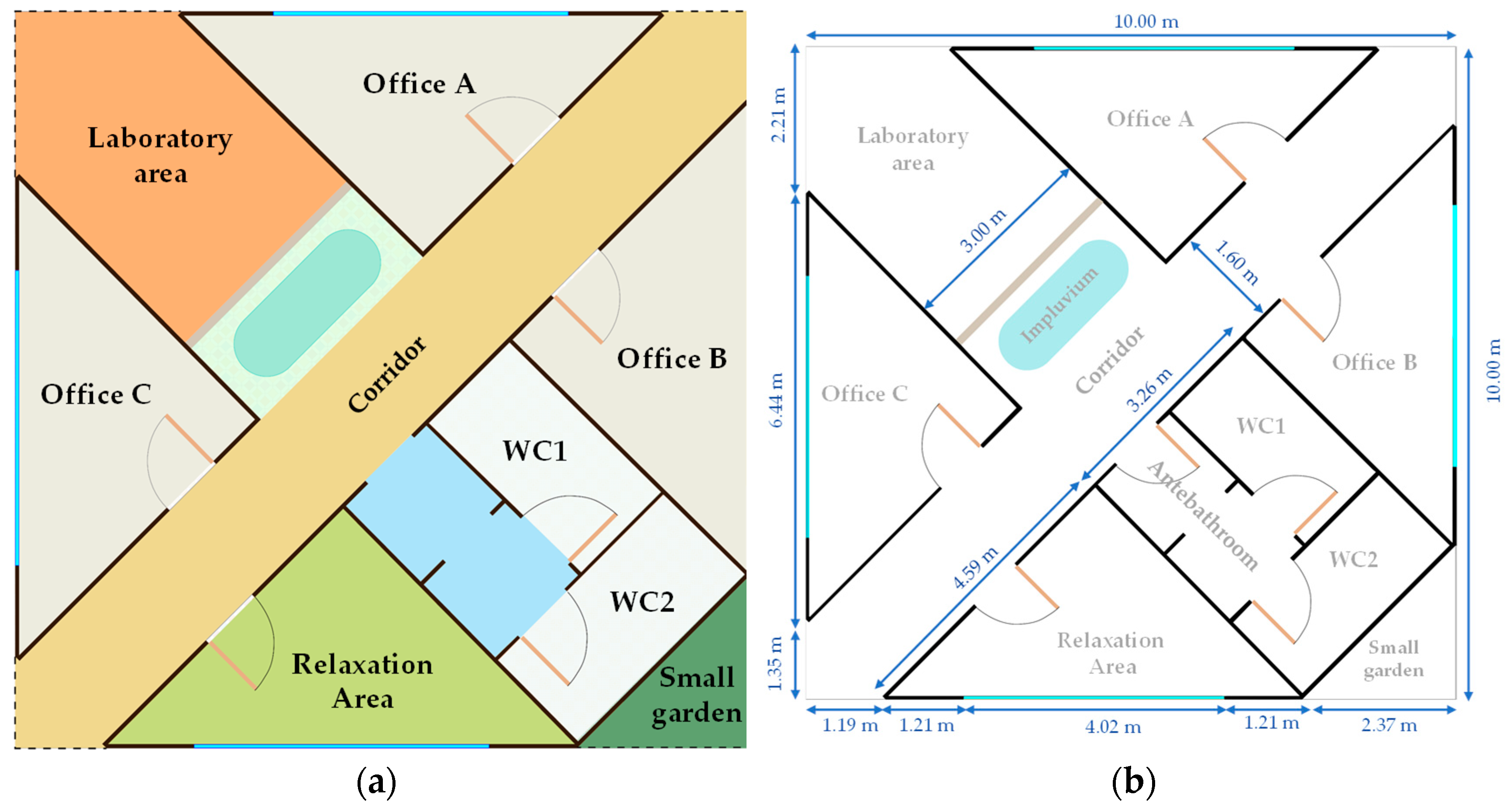

2.1. Baseline Building Geometry and Design

2.2. Baseline Building Envelope

| Layer Material (from Outside to Inside) | Thickness (m) | Thermal Conductivity (W/mK) | Specific Heat Capacity (kJ/kgK) | Density (kg/m3) | |

|---|---|---|---|---|---|

| Ceiling of the offices, relaxation area, and toilets | Galvanized corrugated sheet | 0.0050 | 52 [40] | 0.460 [40] | 7800 [40] |

| Rock wool | 0.0400 | 0.042 [41] | 0.835 [40] | 70 [41] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Polyurethane resins (PUR) | 0.0720 | 0.02 [42] | 1.255 [40] | 39 [42] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Fir timber panel | 0.0100 | 0.12 [43] | 2.72 [40] | 450 [43] | |

| Floor of the offices, relaxation area, and toilets | Galvanized and pre-painted steel profile | 0.0015 | 52 [40] | 0.460 [40] | 7800 [40] |

| Galvanized sheet | 0.0060 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Polyurethane resins (PUR) | 0.0720 | 0.02 [42] | 1.255 [40] | 39 [42] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Timber panel | 0.0180 | 0.12 [5] | 2.090 [40] | 600 [5] | |

| Porcelain stoneware | 0.0100 | 2.3 [40] | 0.835 [40] | 2300 [40] | |

| External vertical walls of the offices, relaxation area, and toilets | Fir timber panel | 0.0100 | 0.12 [43] | 2.72 [40] | 450 [43] |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Polyurethane resins (PUR) | 0.0720 | 0.02 [42] | 1.255 [40] | 39 [42] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Fir timber panel | 0.0100 | 0.12 [43] | 2.72 [40] | 450 [43] | |

| Internal vertical walls of the offices, relaxation area, and toilets | Fir timber panel | 0.0100 | 0.12 [43] | 2.72 [40] | 450 [43] |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Polyurethane resins (PUR) | 0.0320 | 0.02 [42] | 1.255 [40] | 39 [42] | |

| Steel sheet | 0.0040 | 52 [40] | 0.460 [40] | 7800 [40] | |

| Fir timber panel | 0.0100 | 0.12 [43] | 2.72 [40] | 450 [43] |

| Window Type | Geometry (mm) | Spacing Gas | Af (m2) | Ag (m2) | Uf (W/m2 K) | Ug (W/m2 K) | SHGC (-) | τvis (-) |

|---|---|---|---|---|---|---|---|---|

| Double glazing | 9.1/12/4 | Krypton | 1.6 | 9.4 | 1.00 | 1.10 | 0.40 | 0.60 |

2.3. TRNSYS Simulation Model of the Baseline Building

| Type of Appliance | Numbers of Appliances | Pel,ON/ Pel,Stand-by (W) | Pth,ON/ Pth,Stand-by (W) | ||||

|---|---|---|---|---|---|---|---|

| Office A | Office B | Office C | Relaxation Area | WC1 + WC2 | |||

| Laptop [51] | 2 | 2 | 2 | 0 | 0 | 59/0 | 53/0 |

| Mobile phone [51] | 2 | 2 | 2 | 0 | 0 | 5/0 | 5/0 |

| Printer [52] | 1 | 1 | 1 | 0 | 0 | 351/4 | 101/1.2 |

| Wi-Fi router [53] | 0 | 0 | 0 | 1 | 0 | 7/0 | 7/0 |

| Coffee machine [51] | 0 | 0 | 0 | 1 | 0 | 1400/0 | 385/0 |

| Mini fridge [51] | 0 | 0 | 0 | 1 | 0 | 130/0 | 125/0 |

| Microwave oven [51] | 0 | 0 | 0 | 1 | 0 | 1000/0 | 713/0 |

| Electric hand dryer [54] | 0 | 0 | 0 | 1 | 0 | 900/0 | 900/0 |

| Lighting appliances [48] | 16 | 16 | 16 | 16 | 4 | 9.6/0 | 7.2/0 |

2.4. Performance of the Baseline Building

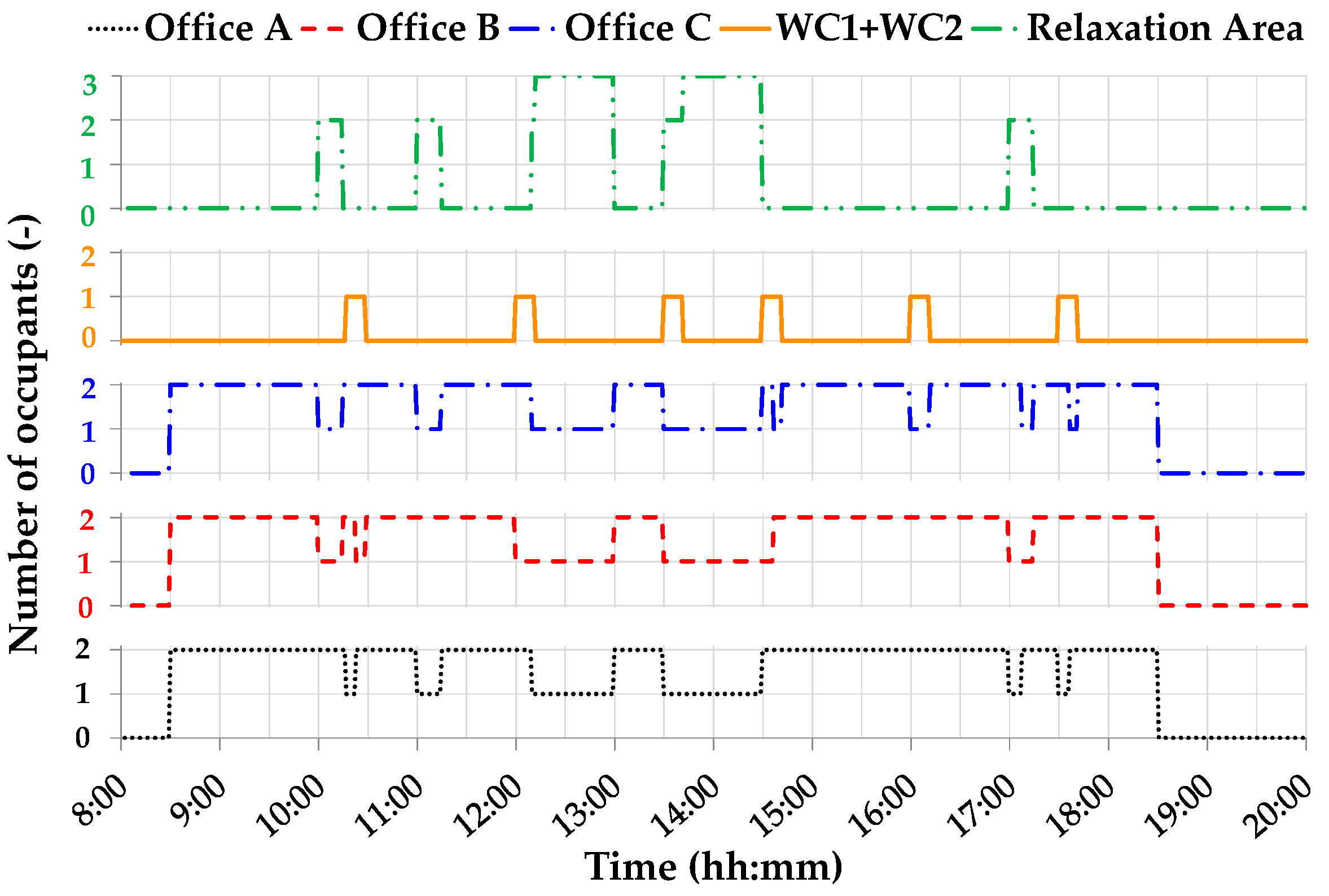

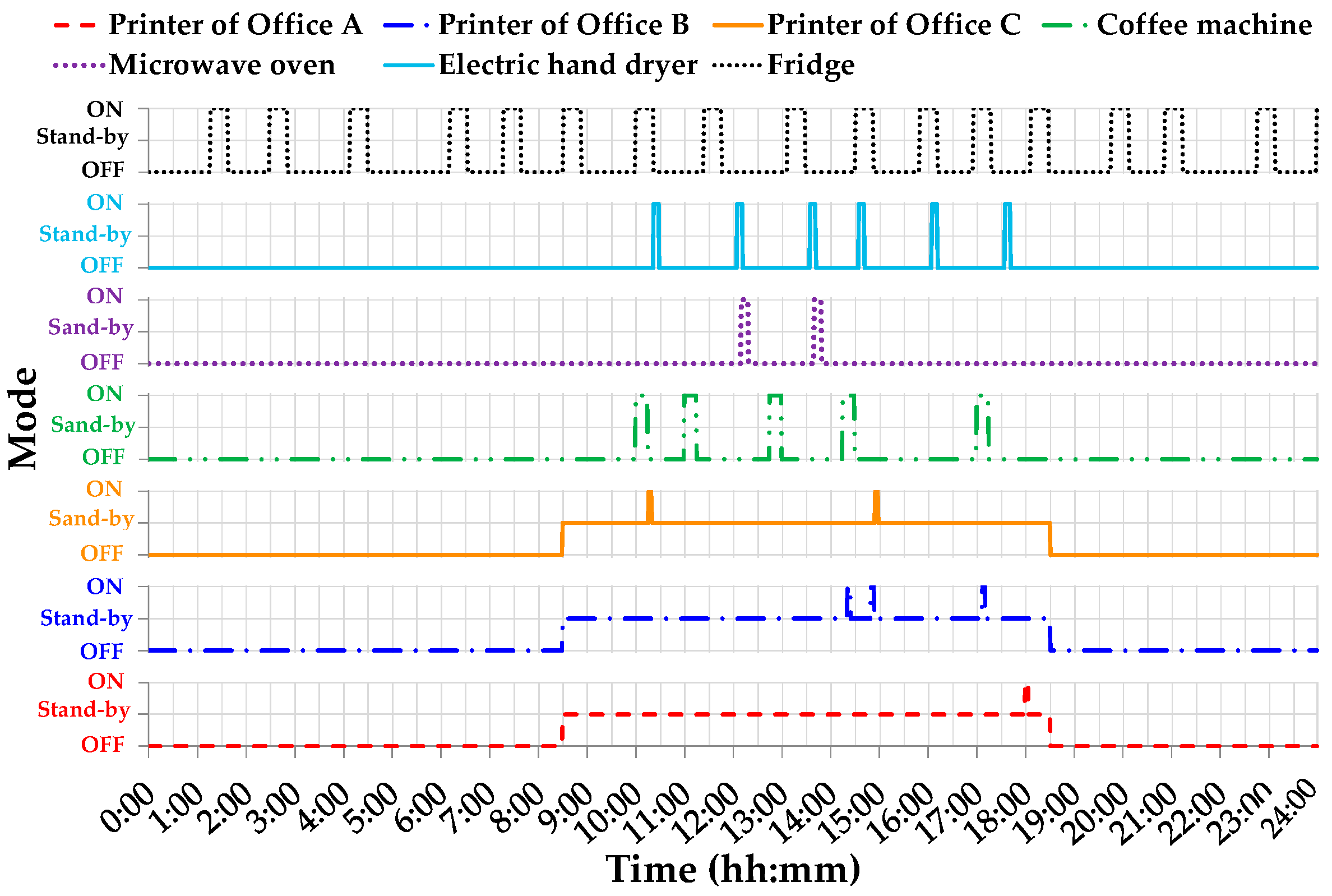

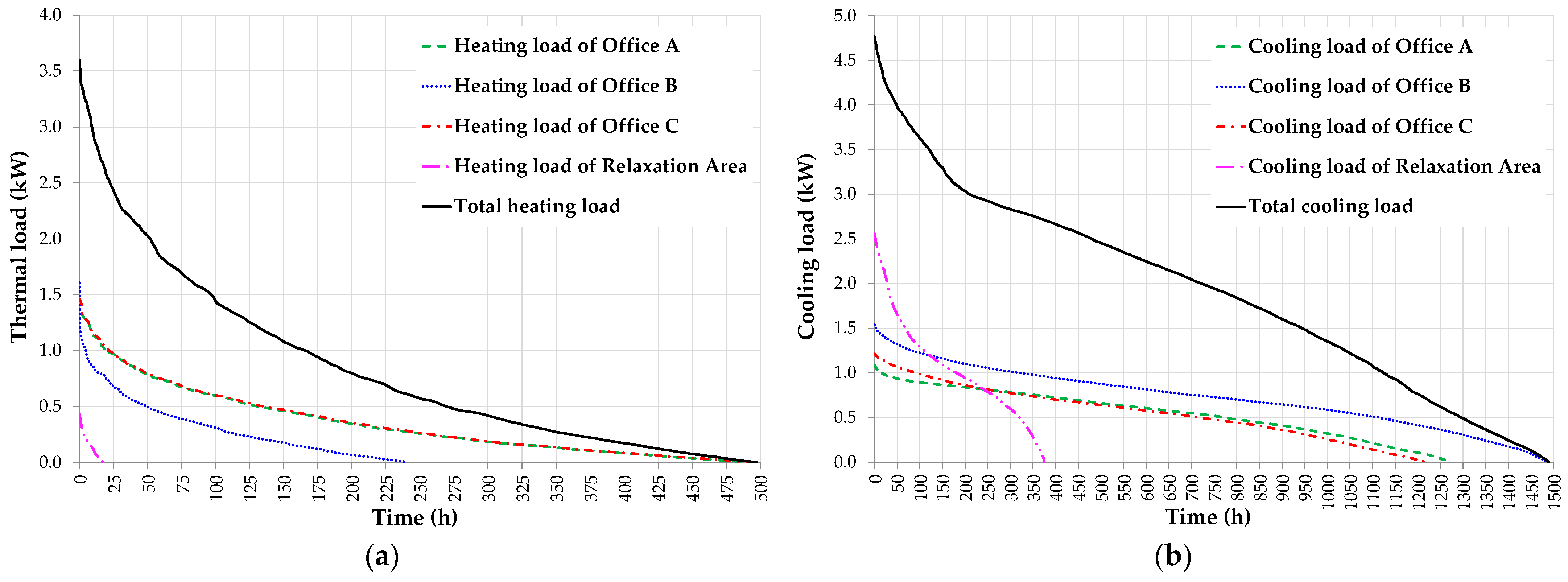

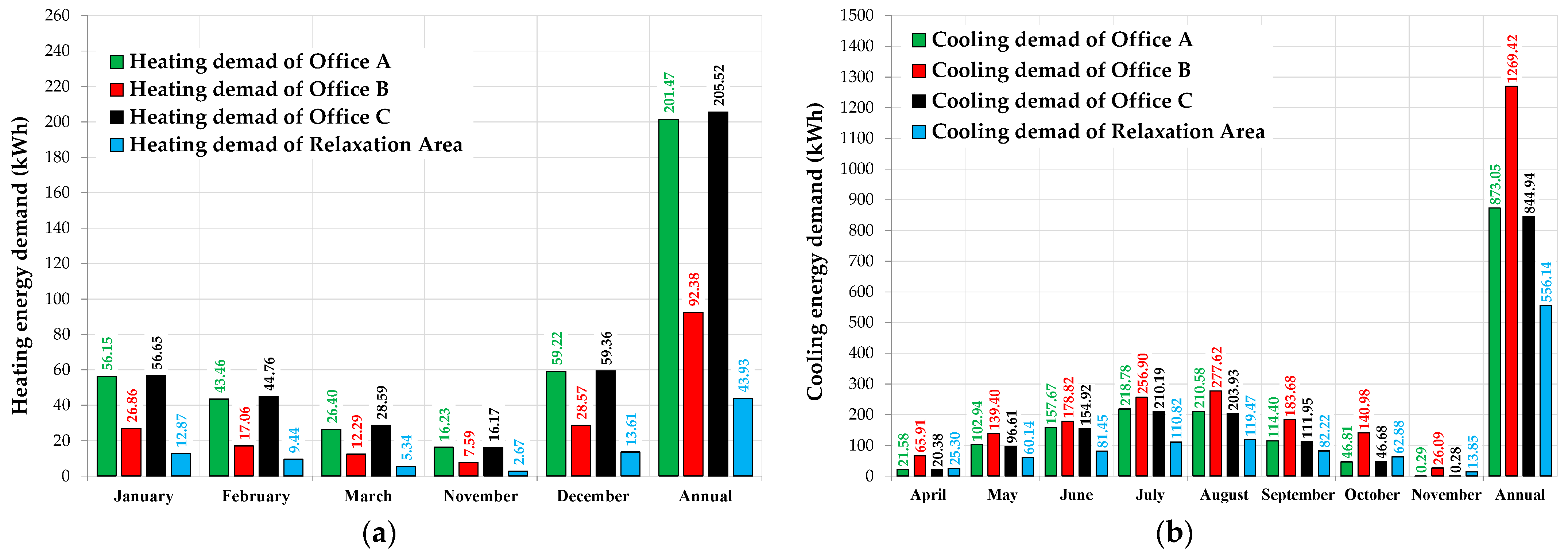

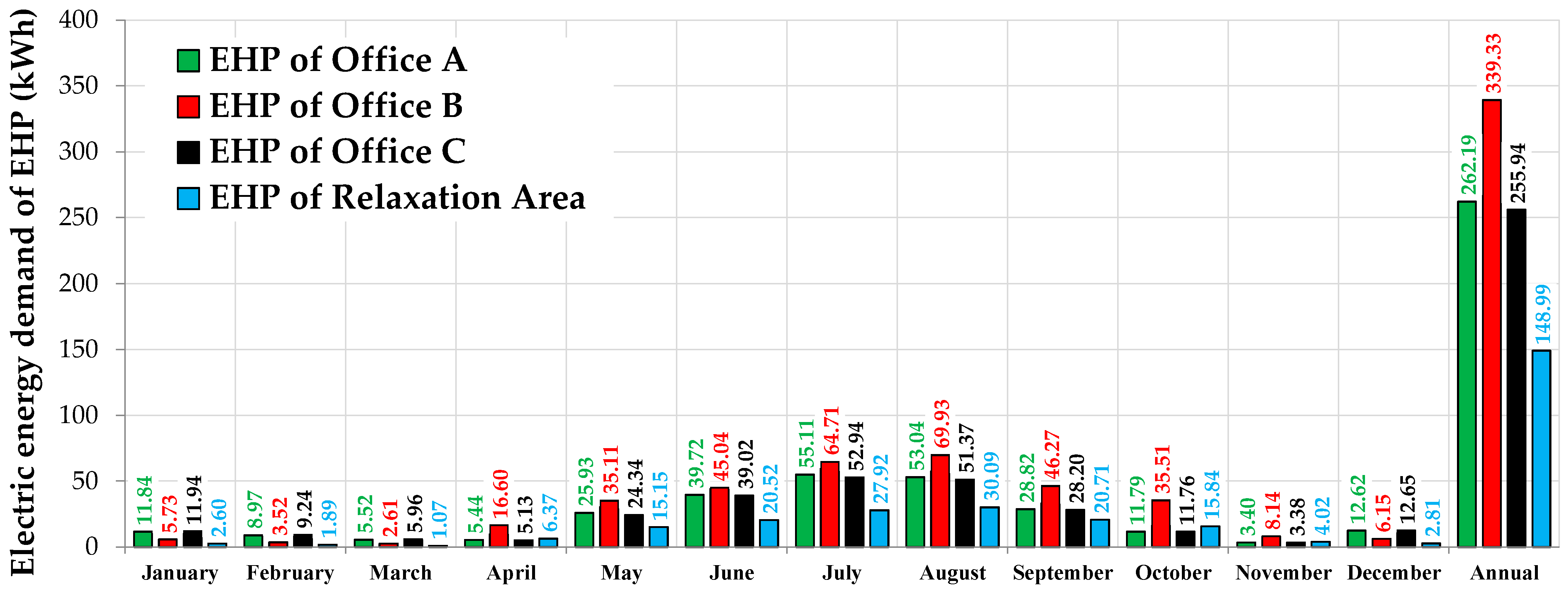

- the heating demand of office A (north-east oriented) has a duration of about 495.0 h, with a maximum value of about 1.5 kW (Figure 6a);

- the heating demand of office B (south-east oriented) has a duration of about 245.0 h, with a maximum value of about 1.6 kW (Figure 6a);

- the heating demand of office C (north-west oriented) has a duration of about 496.0 h, with a maximum value of about 1.5 kW (Figure 6a);

- the heating demand of the relaxation area (south-west oriented) has a duration of about 18.0 h, with a maximum value of about 0.5 kW (Figure 6a);

- the total heating demand of the baseline building has a duration of about 503.0 h, with a maximum value of about 3.6 kW (Figure 6a);

- the cooling demand of office A (north-east oriented) has a duration of about 1282.0 h, with a maximum value of about 1.1 kW (Figure 6b);

- the cooling demand of office B (south-east oriented) has a duration of about 1498.0 h, with a maximum value of about 1.6 kW (Figure 6b);

- the cooling demand of office C (north-west oriented) has a duration of about 1228.0 h, with a maximum value of about 1.2 kW (Figure 6b);

- the cooling demand of the relaxation area (south-west oriented) has a duration of about 378.0 h, with a maximum value of about 2.6 kW (Figure 6b);

- the total cooling demand of the baseline building has a duration of about 1504.0 h, with a maximum value of about 4.8 kW (Figure 6b).

3. Proposed Alternative Building Configurations

3.1. Building Configuration A with Smart Windows (SWs)

- Case 1:

- the state of all the smart windows is always dark;

- Case 2:

- the state of each smart window is controlled based on the vertical solar radiation incident on the corresponding smart window, φs,i;

- Case 3:

- the state of each smart window is controlled based on the indoor air temperature achieved in the corresponding thermal zone, Ti.

3.2. Building Configuration B with PhotoVoltaic Panels (PVs) and Electric Storages

- Case 4:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels without electric storage;

- Case 5:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels + a single 13.5 kWh electric storage;

- Case 6:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels + two electric storages (13.5 kWh per each).

3.3. Building Configuration C with Photovoltaic Panels (PVs), wind Turbine and Electric Storages

- Case 7:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels (as in cases 4–6) + a single wind turbine (DS300) with a nominal electric output of 300 W + 2 electric storages (same model used in cases 5–6) with a nominal electric capacity of 13.5 kWh per each.

- Case 8:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels (as in cases 4–6) + a single wind turbine (DS300) with a nominal electric output of 300 W + 3 electric storages (same model used in cases 5–6) with a nominal electric capacity of 13.5 kWh per each.

- Case 9:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels (as in cases 4–6) + a single wind turbine (DS700) with a nominal electric output of 700 W + 2 electric storages (the same model used in cases 5–6) with a nominal electric capacity of 13.5 kWh per each.

- Case 10:

- Smart windows (controlled based on the indoor air temperature) + 10.34 kWp PV panels (as in cases 4–6) + a single wind turbine (DS700) with a nominal electric output of 700 W + 3 electric storages (the same model used in cases 5–6) with a nominal electric capacity of 13.5 kWh per each.

4. Comparison between Baseline Building and Alternative Building Configurations: Methods of Analysis

5. Results and Discussion

5.1. Comparison between the Proposed Alternative Building Configuration A and the Baseline Building

- (a)

- the values of (EBB–EPB) are negative with reference to the annual heating demand for all the case studies; this means that the baseline building is characterized by a lower annual heating demand due to the fact that the smart windows reduce the solar gains with respect to the baseline case characterized by traditional windows that are always clear;

- (b)

- the values of (EBB–EPB) are positive with reference to both the annual cooling demand and the annual EHP electric demand, whatever the case study is. These results indicate that smart windows allow for reducing the cooling (up to 50%) and electric (up to 46%) demands of the building with respect to the conventional windows (always characterized by a clear state) thanks to the fact that the smart windows reduce the solar loads during summer; the difference is more significant in terms of annual cooling demand with respect to electric consumption;

- (c)

- case study 1 is characterized by the largest reduction in terms of both cooling energy demand and EHP electric demand with respect to the baseline building, but it results in the worst configuration with reference to the annual heating demand. This is due to the fact that in case 1, the state of the smart windows is always dark (this helps in reducing the solar gains during the summer, but it is negative during the heating period), while in cases 2 and 3, the state of the smart windows is dark only when the incident solar radiation is larger than 400 W/m2 (case 2) or the indoor air temperature is greater than 25.5 °C (case 3);

- (d)

- the values of PES, ΔCO2, and ΔOC are always positive, whatever the simulation case is; this means that all the proposed case studies of building configuration A allow for reducing the primary energy consumption, the equivalent CO2 emissions, as well as the operating costs in comparison to the baseline building; these results are obtained thanks to the fact that the adoption of smart windows allows reducing the cooling energy demand;

- (e)

- the values of PES, ΔCO2, and ΔOC are almost constant, whatever the case study is; in particular, the values of PES and ΔCO2 are characterized by a value a bit larger than 10%, while the value of ΔOC has a value of about 8.5%. This is mostly related to the fact that the thermal/cooling energy demands are almost the same, whatever the building configuration under consideration is. Case 1 is characterized by values slightly better in comparison to cases 2 and 3, thanks to the fact that the electric demand of the EHP corresponding to case 1 is a bit lower in contrast with the other two cases.

- in case 1, the windows’ state is always dark, so that the visual interaction with the outside world is completely prevented (even if it is characterized by the largest values of PES, ΔCO2, and ΔOC);

- the difference in terms of PES, ΔCO2, and ΔOC between case 2 and case 3 is negligible, but, with respect to case 2, case 3 is characterized by a lower heating demand during the winter (thanks to more significant solar gains).

5.2. Comparison between the Proposed Alternative Building Configuration B and the Baseline Building

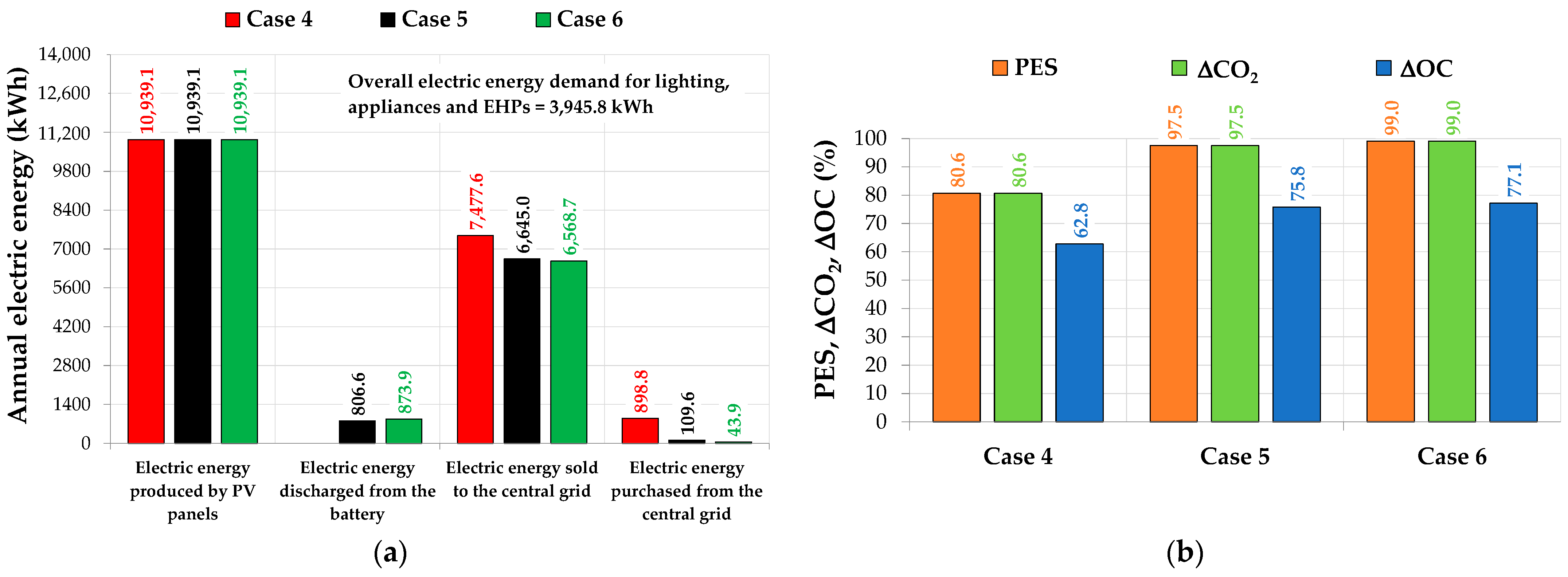

- (a)

- the values of the electric energy produced by the PV panels are constant upon varying the case study and equal to about 11,000 kWh; this result was expected, taking into account that all the case studies are characterized by the same number, type, and orientation of the PV panels;

- (b)

- the electric energy sold to the central grid is maximum for case 4 (thanks to the fact that this building configuration is not equipped with electric storages); it is minimum for case 6 due to the adoption of two electric storages;

- (c)

- the electric energy purchased from the central grid is maximum for case 4 (as a consequence of the fact that this building configuration is without electric storages), while it is minimum for case 6 thanks to the operation of the two electric storages;

- (d)

- the value of electric energy discharged from the battery and used to satisfy the energy demands of the building is maximum for case 6 (thanks to the fact that this configuration is equipped with two electric storages);

- (e)

- the values of PES, ΔCO2, and ΔOC are always positive, whatever the simulation case is; this means that all the proposed configurations allow to always reduce the primary energy consumption, the equivalent CO2 emissions, as well as the operating costs in comparison to the baseline building; this is thanks to the fact that using the PV panels with or without electric storage allows reducing the electric energy imported from the central grid;

- (f)

- the values of PES, ΔCO2, and ΔOC are maximum for case 6 (with the values of PES and ΔCO2 equal to 99.0% and the value of ΔOC equal to about 77%) thanks to a greater number of electric batteries allowing for better exploitation of electric energy generated by the PV panels. Taking into account that a value of PES close to the maximum has been achieved, a further case study with four batteries has not been investigated;

- (g)

- a further case study with three batteries was not considered because of the fact that the PES value is already 100% with reference to the cooling period in case 6, whereas in the heating period, the two batteries in case 6 already fail to charge due to the reduced availability of solar radiation;

- (h)

- the values of PES, ΔCO2, and ΔOC associated with configuration B are much higher than those obtained in the case of configuration A (whatever the case is), thanks to the electric energy generated by the PV panels (which allows reducing the amount of electricity imported from the central grid).

- a lower value of the electric energy purchased from the national electric grid in comparison to both cases 4 and 5;

- a greater value of the electric energy discharged from the battery and used to satisfy the electric demands with respect to cases 4 and 5;

- bigger values of PES (99.0%), ΔCO2 (99.0%), and ΔOC (77.1%) than cases 4 and 5.

5.3. Comparison between the Proposed Alternative Building Configuration C and the Baseline Building

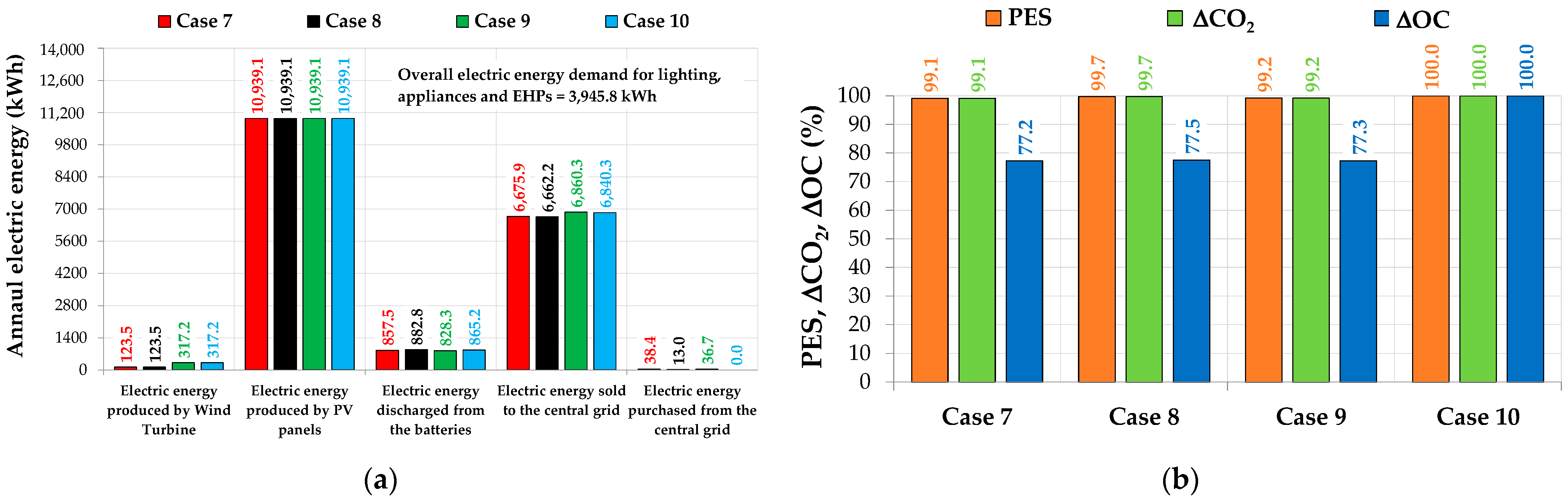

- (a)

- the electric energy produced by the wind turbine is up to about 3% of the electricity generated by the PV panels;

- (b)

- the electric energy sold to the central grid is maximum in case 9 (configuration with the 700 W wind turbine coupled with two batteries) thanks to the facts that (i) in cases 7 and 8 a wind turbine with lower capacity (300 W instead of 700 W) is adopted, (ii) while in case 10 the capacity of the electric batteries is larger (three electric storages instead of two), thus allowing for a more significant amount of stored electricity;

- (c)

- the electric energy purchased from the central grid is generally very low and maximum for case 7 (due to the fact that this building configuration is equipped with the wind turbine of lower capacity (300 W) and two electric storages only), while it is minimum (equal to 0) for case 10 thanks to the adoption of the wind turbine with higher electric capacity (700 W) and three electric storages;

- (d)

- the electric energy discharged from the battery and used to satisfy the energy demand in case 8 is maximum and larger than that associated with case 10 (thanks to the same capacity of the electric storages combined with a wind turbine with a lower nominal electric output);

- (e)

- the values of PES, ΔCO2, and ΔOC are always positive, whatever the simulation case is; this means that all the proposed configurations allow to always reduce the primary energy consumption, the equivalent CO2 emissions, as well as the operating costs in comparison to the baseline building thanks to the operation of renewable-based electric generation systems;

- (f)

- the values of PES, ΔCO2, and ΔOC associated with configuration C are slightly larger than those obtained in the case of configuration B (whatever the case is) thanks to the addition of the small wind turbine for electricity generation; however, the differences are very small and, therefore, the addition of the small wind turbine is not strictly mandatory;

- (g)

- PES, ΔCO2, and ΔOC are maximum for case 10, achieving a value of 100.0%; this means that in case 10, the entire electric demand is covered by renewable energy sources (solar and wind);

- (h)

- the difference among cases 7, 8, and 9 is negligible from all points of view.

- the electric energy purchased from the national electric grid is zero;

- the values of PES, ΔCO2, and ΔOC are equal to 100%, meaning that the corresponding building configuration is energetically self-sufficient (thanks to the electric energy produced by both the wind turbine and the photovoltaic panels coupled with three electrical storages) and can be used for stand-alone applications.

5.4. Comparison between the Baseline Building and the Proposed Alternative Building Configurations A, B and C in Terms of Investment Costs

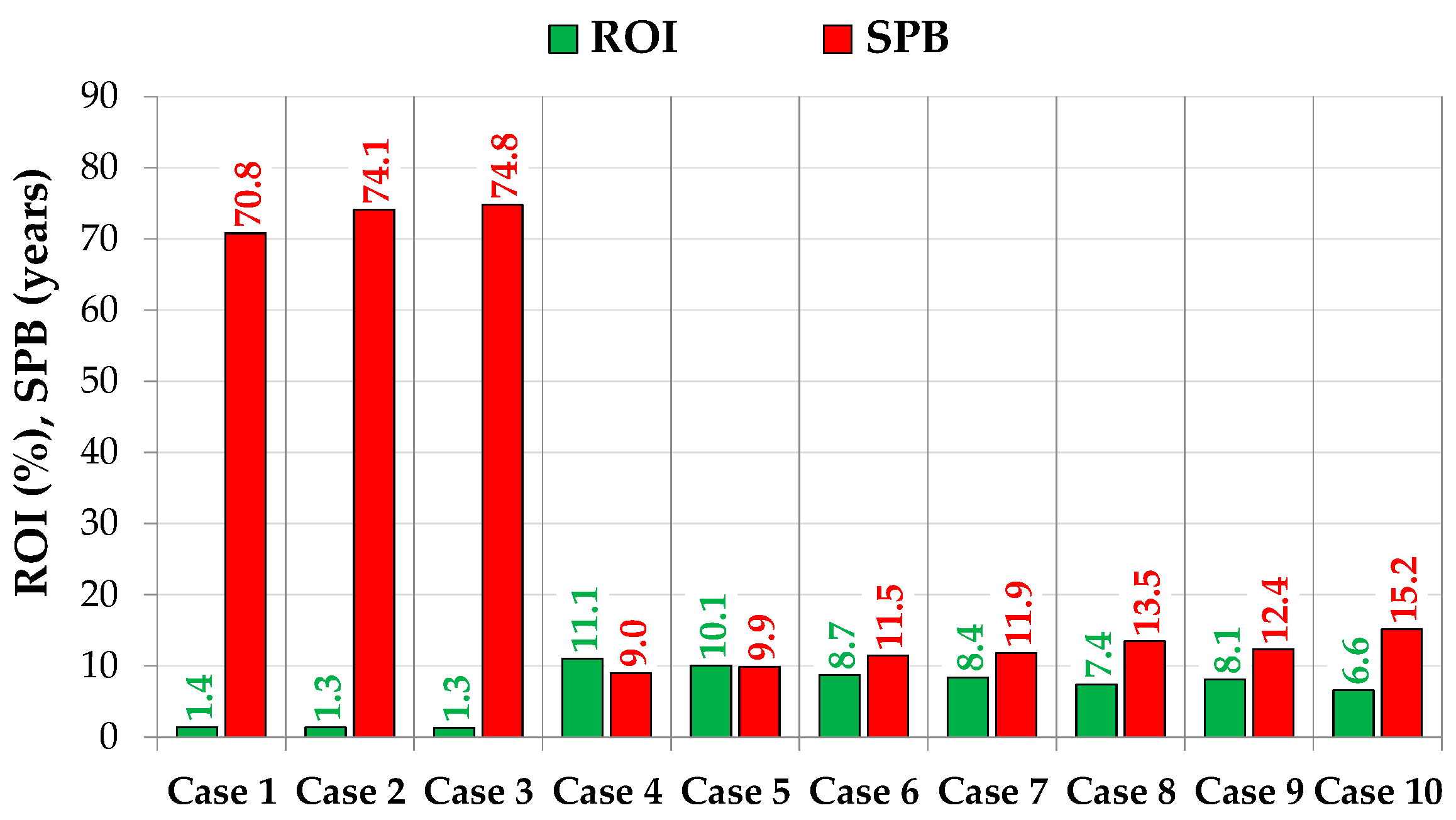

- with reference to all the investigated case studies, the ROI ranges from a minimum of 1.3% (corresponding to cases 2 and 3) up to a maximum of 11.1% (corresponding to case 4);

- with reference to cases 1, 2, and 3 corresponding to building configuration A, the variation of the ROI is almost negligible;

- with reference to cases 4, 5, and 6 corresponding to building configuration B, the ROI is between 10.1% (case 5) and 11.1% (case 4); case 4 is characterized by larger values of the ROI in comparison to cases 4 and 5 thanks to the fact that the corresponding net profit is larger as well as its related extra cost of investment being reduced;

- with reference to cases 7, 8, 9, and 10 corresponding to building configuration C, the ROI is in the range of 6.6% (case 10)/8.4% (case 7); case 10 is characterized by lower values of the ROI with respect to cases 7–9 due to the fact that there are no revenues from the electric energy sold to the central grid;

- configuration B (cases 4, 5, and 6) is characterized by larger values of the ROI with respect to configuration C (cases 7, 8, 9, and 10), which, in turn, allows to obtain better values of the ROI in contrast with configuration A (cases 1, 2 and 3);

- with reference to all the investigated case studies, the SPB period ranges from a minimum of 9.0 years (corresponding to case 4) up to a maximum of 74.8 years (corresponding to case 3);

- with reference to cases 1, 2, and 3 corresponding to building configuration A, the SPB period varies between 70.8 years (case 1) and 74.8 years (case 3); case 1 is characterized by better values of the SPB thanks to the fact that the corresponding control logic allows to obtain a more significant reduction in the operating costs (see Figure 10);

- with reference to cases 4, 5, and 6 corresponding to building configuration B, the SPB period is in the range between 9.0 years (case 4) and 11.5 years (case 6); case 4 is characterized by lower values of the SPB period in comparison to cases 4 and 5 thanks to the fact that its extra cost of investment is reduced;

- with reference to cases 7, 8, 9, and 10 corresponding to building configuration C, the SPB period ranges from 11.9 years (case 7) to 15.2 years (case 10); case 10 is characterized by larger values of the SPB period with respect to cases 7–9 due to the fact that electric energy is not sold to the central grid in this case;

- configuration B (cases 4, 5, and 6) is characterized by lower values of the SPB period with respect to configuration C (cases 7, 8, 9, and 10), which, in turn, allows to obtain better values of the SPB period in contrast with configuration A (cases 1, 2, and 3);

- taking into account that the useful lifetime of all the proposed measures/components is greater than 15.2 years, it can be clearly stated that the buildings corresponding to cases 4, 5, 6, 7, 8, 9, and 10 (configurations B and C) are economically feasible, while the buildings corresponding to cases 1, 2, and 3 (configuration A) are not acceptable from an economic point of view;

- case 4 is characterized by the largest value of the ROI as well as the lowest SPB period, thus representing the best building configuration in terms of investment profitability;

- the lowest value of the ROI and the largest SPB period are associated with case 3, thus corresponding to the worst building configuration from the investment point of view.

6. Conclusions

- all the proposed alternative configurations allow for savings in primary energy, equivalent CO2 emissions, and operating costs with respect to the baseline building;

- the primary energy savings range from a minimum of 10.3% (case studies 2 and 3) up to a maximum of 100% (case study 10);

- the reduction in terms of equivalent CO2 emissions varies from a minimum of 10.3% (case studies 2 and 3) up to a maximum of 100% (case study 10);

- the operating cost reduction is between 8.5% (case studies 2 and 3) and 100% (case study 10);

- the contribution of small wind turbines is almost negligible in covering the electric building demand when solar radiation is reduced;

- the building configurations including smart windows alone are not economically feasible in terms of the simple pay-back (SPB) period, while the building configurations equipped with photovoltaic panels and/or electric storages and/or wind turbines represent a suitable investment thanks to an SPB lower than 15.2 years;

- a stand-alone building configuration for smart/co-working with energy demands totally covered by means of renewable sources is possible (PES = ΔCO2 = ΔOC = 100%) by combining smart windows, photovoltaic panels, electric storages, and wind turbines; in addition, it has been demonstrated that it is economically feasible thanks to an SPB period equal to 15.2 years and, therefore, lower than its expected lifetime.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin letters | |

| A | Area (m2) |

| AC | Alternating current |

| AR | Annual revenues |

| BB | Baseline building |

| BIPV/T | Photovoltaic/thermal solar systems |

| C | Cost (EUR) |

| CC | Capital cost (EUR) |

| CDF | Cumulative distribution function |

| CO2 | Equivalent emissions of carbon dioxide |

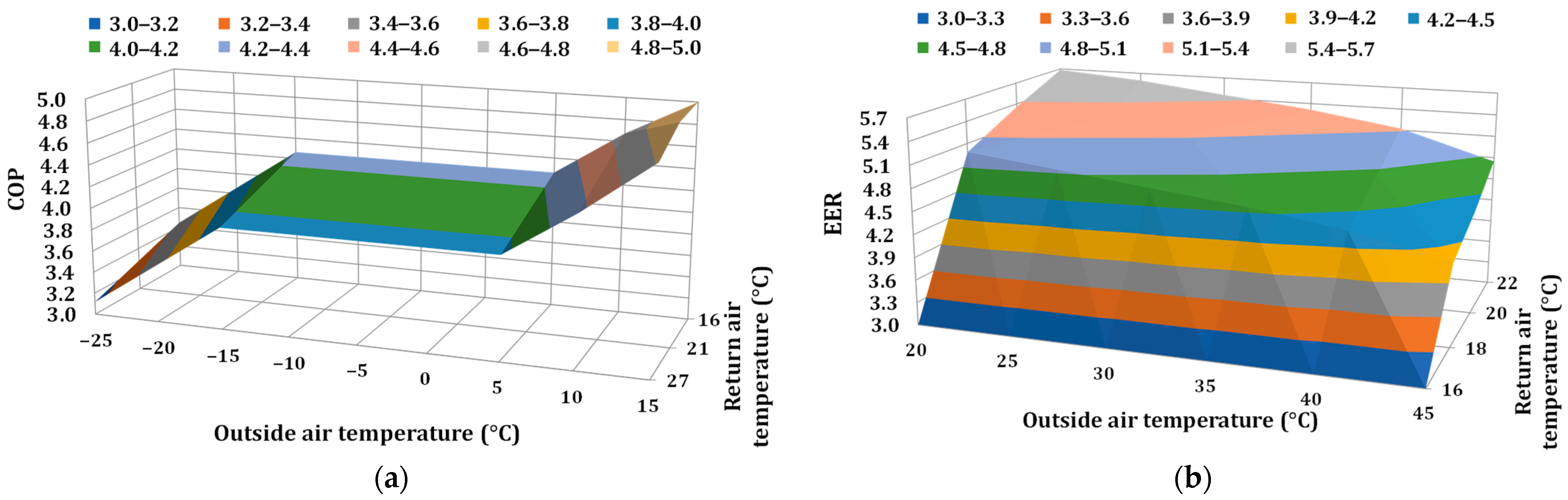

| COP | Coefficient of performance |

| DC | Direct current |

| DHW | Domestic hot water |

| E | Energy (kWh) |

| ECI | Extra cost of investment |

| EER | Energy efficiency ratio (-) |

| EHP | Electric reversing heat pump (-) |

| EI | Economic incentive |

| ES | Electric storage |

| F1 | Average cost of electricity for the F1 band |

| F2 | Average cost of electricity for the F2 band |

| F3 | Average cost of electricity for the F3 band |

| FS | Finkelstein–Schafer |

| I | Current I |

| LED | Light-emitting diode |

| LFP | Lithium-iron phosphate |

| m | Mass (kg) |

| N | Number |

| NES | Number of electric storages |

| OC | Operation cost (EUR) |

| OFF | Turned off |

| ON | In operation |

| P | Power (kW) |

| PB | Proposed alternative building configurations |

| PES | Primary energy saving (%) |

| PUN | National single price (EUR/kWh) |

| PV | Photovoltaic |

| PZ | Zonal price (EUR/kWh) |

| R | Resistance |

| ROI | Return on investment (%) |

| SCW | Smart/co-working |

| SHGC | Solar heat gain coefficient |

| SPB | Simple pay-back (years) |

| SW | Smart window |

| T | Temperature (°C) |

| U | Thermal transmittance (W/m2 K) |

| UC | Unit cost (EUR/kWh) |

| UCC | Unit capital cost |

| UV | Ultraviolet |

| v | Wind speed (m/s) |

| V | Voltage (V) |

| VWT | Vertical wind turbine |

| WT | Wind turbine |

| Greeks | |

| α | CO2 equivalent emission factor for electricity production (kgCO2/kWhel) |

| τ | Transmission coefficient |

| ∆ | Difference |

| η | Efficiency |

| φ | Incident solar radiation (W/m2) |

| Superscripts/Subscripts | |

| appliances | Electric appliances |

| CO2 | Carbon dioxide |

| el | Electric |

| ES | Electric storage |

| f | Frame |

| g | Glazing |

| i | Indoor |

| import | Imported from the central grid |

| lighting | Lighting systems |

| max | Maximum |

| NS | Electricity network services |

| OA | Office A |

| OB | Office B |

| OC | Office C |

| ON | In operation |

| p | Peak |

| POD | Withdrawal point |

| PP | Power plant |

| RA | Relaxation area |

| th | Thermal gain/load |

| Stand-by | Stand-by operation |

| vis | Visible |

| wind | Wind |

| WT | Wind turbine |

Appendix A

References

- Long, J.; Reuschke, D. Daily Mobility Patterns of Small Business Owners and Homeworkers in Post-Industrial Cities. Comput. Environ. Urban Syst. 2021, 85, 101564. [Google Scholar] [CrossRef]

- Howell, T. Coworking Spaces: An Overview and Research Agenda. Res. Policy 2022, 51, 104447. [Google Scholar] [CrossRef]

- ONES Smart Office, Building the Future. Available online: https://ones.software/blog/2022/11/29/coworking-statistics-trends/ (accessed on 6 April 2023).

- Wang, R.; Ye, Z.; Lu, M.; Hsu, S.C. Understanding Post-Pandemic Work-from-Home Behaviours and Community Level Energy Reduction via Agent-Based Modelling. Appl. Energy 2022, 322, 119433. [Google Scholar] [CrossRef]

- Global Status Report for Buildings and Construction. Available online: https://globalabc.org/resources/publications/2021-global-status-report-buildings-and-construction (accessed on 6 April 2023).

- Xiang, X.; Ma, M.; Ma, X.; Chen, L.; Cai, W.; Feng, W.; Ma, Z. Historical Decarbonization of Global Commercial Building Operations in the 21st Century. Appl. Energy 2022, 322, 119401. [Google Scholar] [CrossRef]

- European Union in Focus: Energy Efficiency in Buildings. Available online: https://commission.europa.eu/news/focus-energy-efficiency-buildings-2020-02-17_en (accessed on 6 April 2023).

- Ma, M.; Feng, W.; Huo, J.; Xiang, X. Operational Carbon Transition in the Megalopolises’ Commercial Buildings. Build. Environ. 2022, 226, 109705. [Google Scholar] [CrossRef]

- Awada, M.; Becerik-Gerber, B.; Hoque, S.; O’Neill, Z.; Pedrielli, G.; Wen, J.; Wu, T. Ten Questions Concerning Occupant Health in Buildings during Normal Operations and Extreme Events including the COVID-19 Pandemic. Build. Environ. 2021, 188, 107480. [Google Scholar] [CrossRef]

- Oakman, J.; Kinsman, N.; Stuckey, R.; Graham, M.; Weale, V. A Rapid Review of Mental and Physical Health Effects of Working at Home: How Do We Optimise Health? BMC Public Health 2020, 20, 1825. [Google Scholar] [CrossRef] [PubMed]

- Berman, M.G.; Jonides, J.; Kaplan, S. The Cognitive Benefits of Interacting with Nature. Psychol. Sci. 2008, 19, 1207–1212. [Google Scholar] [CrossRef] [PubMed]

- European Union EPBD Recast 2021. Available online: https://ec.europa.eu/energy/sites/default/files/proposal-recast-energy-performance-buildings-directive.pdf (accessed on 6 April 2023).

- Sheik, M.S.; Kakati, P.; Dandotiya, D.; M, U.R.; S, R.C. A Comprehensive Review on Various Cooling Techniques to Decrease an Operating Temperature of Solar Photovoltaic Panels. Energy Nexus 2022, 8, 100161. [Google Scholar] [CrossRef]

- Yang, A.S.; Su, Y.M.; Wen, C.Y.; Juan, Y.H.; Wang, W.S.; Cheng, C.H. Estimation of Wind Power Generation in Dense Urban Area. Appl. Energy 2016, 171, 213–230. [Google Scholar] [CrossRef]

- Ertek, G.; Kailas, L. Analyzing a Decade of Wind Turbine Accident News with Topic Modeling. Sustainability 2021, 13, 12757. [Google Scholar] [CrossRef]

- O’Shaughnessy, E.; Cutler, D.; Ardani, K.; Margolis, R. Solar plus: Optimization of Distributed Solar PV through Battery Storage and Dispatchable Load in Residential Buildings. Appl. Energy 2018, 213, 11–21. [Google Scholar] [CrossRef]

- Casini, M. Active Dynamic Windows for Buildings: A Review. Renew Energy 2018, 119, 923–934. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Long, E.; Deng, S. An Experimental Study on the Indoor Thermal Environment in Prefabricated Houses in the Subtropics. Energy Build. 2016, 127, 529–539. [Google Scholar] [CrossRef]

- Ye, R.; Wang, J.; Jiang, H.; Xie, N. Numerical Study on Thermal Comfort and Energy-Saving Potential of a Prefabricated Temporary House Integrated with Composite Phase Change Materials. Energy Build. 2022, 268, 112169. [Google Scholar] [CrossRef]

- Košir, M.; Iglič, N.; Kunič, R. Optimisation of Heating, Cooling and Lighting Energy Performance of Modular Buildings in Respect to Location’s Climatic Specifics. Renew Energy 2018, 129, 527–539. [Google Scholar] [CrossRef]

- Greenreport Italian Depopulation. Available online: https://greenreport.it/news/scienze-e-ricerca/in-italia-avanza-la-desertificazione-non-solo-del-suolo-ma-anche-della-popolazione/ (accessed on 6 April 2023).

- ISTAT Demographic Statistics. Available online: https://www.istat.it/ (accessed on 6 April 2023).

- Maffei, L.; Ciervo, A.; Diodato, D.; Rosato, A. Prefabricated Movable Modular Building Solutions Exploiting Renewable Sources: Energy Systems Review. In Proceedings of the Proceedings Book of Extended Abstracts “Beyond All Limits—International Conference on Sustainability in Architecture, Planning, and Design”, Officina Vanvitelli-Real Belvedere di San Leucio, Caserta, Italy, 11–12 May 2022; pp. 301–306. [Google Scholar]

- Ceranic, B.; Beardmore, J.; Cox, A. Rapid Deployment Modular Building Solutions and Climatic Adaptability: Case Based Study of a Novel Approach to “Thermal Capacity on Demand”. Energy Build. 2018, 167, 124–135. [Google Scholar] [CrossRef]

- Michael, A.; Savvides, A.; Vassiliades, C.; Triantafyllidou, E. Design and Creation of an Energy Efficient Prefabricated Housing Unit Based on Specific Taxonomy and Optimization Techniques. Procedia Manuf. 2020, 44, 261–268. [Google Scholar] [CrossRef]

- Vassiliades, C.; Barone, G.; Buonomano, A.; Forzano, C.; Giuzio, G.F.; Palombo, A. Assessment of an Innovative Plug and Play PV/T System Integrated in a Prefabricated House Unit: Active and Passive Behaviour and Life Cycle Cost Analysis. Renew Energy 2022, 186, 845–863. [Google Scholar] [CrossRef]

- Ecocapsule. Available online: https://www.ecocapsule.sk/sites/default/files/ec_ecocapsule_katalog-2022_0.pdf (accessed on 31 May 2023).

- Leoncini, L.; Garzaniti, S.; Bertagni, S. Living Box—Sistema Abitativo Modulare Prefabbricato in Legno Living Box—Prefabricated Modular Wood-House System. KEP Energy 2017, 1–30. Available online: http://www.kep-energy.com/blog/ (accessed on 31 May 2023).

- Biosphera Project. Available online: https://equilibrium.biospheraproject.com/biosphera-equilibrium/concept-design/ (accessed on 31 May 2023).

- Universal Nature Energy Zhero. Available online: https://www.unesrl.com/en/products/ (accessed on 31 May 2023).

- Chen, D.; Wang, G.; Chen, G. Lego Architecture: Research on a Temporary Building Design Method for Post-Disaster Emergency. Front. Archit. Res. 2021, 10, 758–770. [Google Scholar] [CrossRef]

- Wang, C.; Deng, S.; Niu, J.; Long, E. A Numerical Study on Optimizing the Designs of Applying PCMs to a Disaster-Relief Prefabricated Temporary-House (PTH) to Improve Its Summer Daytime Indoor Thermal Environment. Energy 2019, 181, 239–249. [Google Scholar] [CrossRef]

- Papagiannidis, S.; Marikyan, D. Smart Offices: A Productivity and Well-Being Perspective. Int. J. Inf. Manag. 2020, 51, 102027. [Google Scholar] [CrossRef]

- TRNSYS The Transient Energy System Simulation Tool. Available online: http://www.trnsys.com (accessed on 6 April 2023).

- Rashad, M.; Żabnieńska-Góra, A.; Norman, L.; Jouhara, H. Analysis of Energy Demand in a Residential Building Using TRNSYS. Energy 2022, 254, 124357. [Google Scholar] [CrossRef]

- M’Saouri El Bat, A.; Romani, Z.; Bozonnet, E.; Draoui, A. Thermal Impact of Street Canyon Microclimate on Building Energy Needs Using TRNSYS: A Case Study of the City of Tangier in Morocco. Case Stud. Therm. Eng. 2021, 24, 100834. [Google Scholar] [CrossRef]

- Edilmetas Portable Modular Containers and Cabins. Available online: https://www.edilmetas.it/en/portable-modular-containers-and-cabins/ (accessed on 31 May 2023).

- SageGlass Electronically Tintable Glazing -Climaplus Classic. Available online: https://www.sageglass.com/sites/default/files/sageglass_datasheet_climaplus_42.1ec-12-4_classic_en.pdf (accessed on 6 April 2023).

- Satler PVC Profile. Available online: https://www.finestre-satler.it/Prodotti/Finestre/FINESTREINPVC/THERMIC/THERMIC.aspx (accessed on 6 April 2023).

- Stiferite On-Line Heat Transfer Calculation. Available online: http://trasmittanza.stiferite.com/resistenza_termica.html (accessed on 6 April 2023).

- Rockwool Roll Cod. 129. Available online: https://www.rockwool.com/uk/ (accessed on 6 April 2023).

- Isolpack Wall Star. Available online: http://www.isolpack.com/EN/product-details/26/star (accessed on 6 April 2023).

- UNI UNI 10351. Available online: https://store.uni.com/en/uni-10351-2021 (accessed on 6 April 2023).

- Rosato, A.; Sibilio, S.; Ciampi, G.; Entchev, E.; Ribberink, H. Energy, Environmental and Economic Effects of Electric Vehicle Charging on the Performance of a Residential Building-Integrated Micro-Trigeneration System. Energy Procedia 2017, 111, 699–709. [Google Scholar] [CrossRef]

- Trimble SketchUp Pro. Available online: https://www.sketchup.com/products/sketchup-pro (accessed on 6 April 2023).

- Rosato, A.; Ciervo, A.; Ciampi, G.; Scorpio, M.; Guarino, F.; Sibilio, S. Impact of Solar Field Design and Back-up Technology on Dynamic Performance of a Solar Hybrid Heating Network Integrated with a Seasonal Borehole Thermal Energy Storage Serving a Small-Scale Residential District Including Plug-in Electric Vehicles. Renew Energy 2020, 154, 684–703. [Google Scholar] [CrossRef]

- ASHRAE Load Calculation Applications Manual. Available online: https://www.ashrae.org/ (accessed on 6 April 2023).

- Lightnet Liquid Line-A3. Available online: https://www.lightnet-group.com/en/product/liquid-line-a3-i-system-60mm-surface-531/ (accessed on 6 April 2023).

- DIAL DIALux. Available online: https://www.dialux.com/en-GB/ (accessed on 6 April 2023).

- UNI UNI EN 12464-1. Available online: https://store.uni.com/en/uni-en-12464-1-2021 (accessed on 6 April 2023).

- Sarfraz, O.; Bach, C.K. Experimental Methodology and Results for Heat Gains from Various Office Equipment (ASHRAE RP-1742). Sci. Technol. Built. Environ. 2018, 24, 435–447. [Google Scholar] [CrossRef]

- Richardson, I.; Thomson, M. Domestic Electricity Demand Model—Simulation Example. Available online: https://dspace.lboro.ac.uk/dspace-jspui/handle/2134/5786%0A (accessed on 6 April 2023).

- Ruellan, M.; Park, H.; Bennacer, R. Residential Building Energy Demand and Thermal Comfort: Thermal Dynamics of Electrical Appliances and Their Impact. Energy Build. 2016, 130, 46–54. [Google Scholar] [CrossRef]

- Dyson Electric Hand Dryer Airblade. Available online: https://www.dyson.it/commerciale/asciugamani/airblade-9kj (accessed on 6 April 2023).

- EnergyPlus Weather Data. Available online: https://energyplus.net/weather-region/europe_wmo_region_6 (accessed on 6 April 2023).

- Climate Analytics EnergyPlus Weather File (EPW) Format. Available online: https://designbuilder.co.uk/cahelp/Content/EnergyPlusWeatherFileFormat.htm (accessed on 31 May 2023).

- Ebrahimpour, A. New Software for Generation of Typical Meteorological Year. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; Volume 57, pp. 2049–2055. [Google Scholar] [CrossRef] [Green Version]

- DAIKIN Bluevolution Catalogue. Available online: https://www.daikin.it/it_it/cataloghi-e-app/cataloghi-climatizzazione.html (accessed on 6 April 2023).

- Isaia, F.; Fiorentini, M.; Serra, V.; Capozzoli, A. Enhancing Energy Efficiency and Comfort in Buildings through Model Predictive Control for Dynamic Façades with Electrochromic Glazing. J. Build. Eng. 2021, 43, 102535. [Google Scholar] [CrossRef]

- Tavares, P.; Bernardo, H.; Gaspar, A.; Martins, A. Control Criteria of Electrochromic Glasses for Energy Savings in Mediterranean Buildings Refurbishment. Solar Energy 2016, 134, 236–250. [Google Scholar] [CrossRef] [Green Version]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of Electrochromic Windows Impact in the Energy Performance of Buildings in Mediterranean Climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef] [Green Version]

- Scorpio, M.; Ciampi, G.; Rosato, A.; Maffei, L.; Masullo, M.; Almeida, M.; Sibilio, S. Electric-Driven Windows for Historical Buildings Retrofit: Energy and Visual Sensitivity Analysis for Different Control Logics. J. Build. Eng. 2020, 31, 101398. [Google Scholar] [CrossRef]

- Ritter, V.; Matschi, C.; Schwarz, D. Assessment of Five Control Strategies of an Adjustable Glazing at Three Different Climate Zones. J. Facade Des. Eng. 2015, 3, 129–141. [Google Scholar] [CrossRef]

- Trienergia PV Modules. Available online: https://www.trienergia.com/en/ (accessed on 6 April 2023).

- TESLA Powerwall Battery. Available online: https://www.tesla.com/powerwall?redirect=no (accessed on 6 April 2023).

- De Soto, W.; Klein, S.A.; Beckman, W.A. Improvement and Validation of a Model for Photovoltaic Array Performance. Solar Energy 2006, 80, 78–88. [Google Scholar] [CrossRef]

- ETNEO DS300 Wind Turbine. Available online: https://etneo.com/wind-turbine-ds300/?lang=en (accessed on 6 April 2023).

- ETNEO DS700 Wind Turbine. Available online: https://etneo.com/wind-turbine-ds700/?lang=en (accessed on 6 April 2023).

- Ceglia, F.; Marrasso, E.; Roselli, C.; Sasso, M. Time-Evolution and Forecasting of Environmental and Energy Performance of Electricity Production System at National and at Bidding Zone Level. Energy Convers. Manag. 2022, 265, 115772. [Google Scholar] [CrossRef]

- Chicco, G.; Mancarella, P. Assessment of the Greenhouse Gas Emissions from Cogeneration and Trigeneration Systems. Part I: Models and Indicators. Energy 2008, 33, 410–417. [Google Scholar] [CrossRef]

- GME Gestore Mercati Energetici. Available online: https://www.mercatoelettrico.org/it/Statistiche/ME/PrezzoMedioFasce.aspx (accessed on 6 April 2023).

- ARERA Italian Regulatory Authority for Energy, Networks and Environment. Available online: https://www.arera.it/it/docs/21/623-21.htm (accessed on 31 May 2023).

- Formica, T.; Pecht, M. Return on Investment Analysis and Simulation of a 9.12 KW (KW) Solar Photovoltaic System. Solar Energy 2017, 144, 629–634. [Google Scholar] [CrossRef]

- INVITALIA Italian Development Agency. Available online: https://www.invitalia.it/eng (accessed on 31 May 2023).

- Paiano, A.; Lagioia, G.; Ingrao, C. A Combined Assessment of the Energy, Economic and Environmental Performance of a Photovoltaic System in the Italian Context. Sci. Total Environ. 2023, 866, 161329. [Google Scholar] [CrossRef]

- Lantonio, N.A.; Krarti, M. Simultaneous Design and Control Optimization of Smart Glazed Windows. Appl. Energy 2022, 328, 120239. [Google Scholar] [CrossRef]

- McKenna, R.; Fehrenbach, D.; Merkel, E. The Role of Seasonal Thermal Energy Storage in Increasing Renewable Heating Shares: A Techno-Economic Analysis for a Typical Residential District. Energy Build. 2019, 187, 38–49. [Google Scholar] [CrossRef]

- Ettimpianti srl TESLA Powerwall 2. Available online: https://www.ettimpiantisrl.com/prodotto/tesla-powerwall-2-ac-135kwh-con-staffa-a-muro/ (accessed on 31 May 2023).

- ETNEO DS300 Wind Turbine Cost. Available online: https://etneo.com/prodotto/eolico-verticale-ibrido-300w/ (accessed on 31 May 2023).

- ETNEO DS700 Wind Turbine Cost. Available online: https://etneo.com/prodotto/eolico-verticale-ibrido-700w/ (accessed on 31 May 2023).

- Invitalia Cultura Crea 2.0. Available online: https://www.invitalia.it/cosa-facciamo/creiamo-nuove-aziende/cultura-crea-2-0 (accessed on 31 May 2023).

- Rosato, A.; Ciervo, A.; Guarino, F.; Ciampi, G.; Scorpio, M.; Sibilio, S. Dynamic Simulation of a Solar Heating and Cooling System Including a Seasonal Storage Serving a Small Italian Residential District. Therm. Sci. 2020, 24, 3555–3568. [Google Scholar] [CrossRef]

- Tsuchiya, Y.; Swai, T.A.; Goto, F. Energy Payback Time Analysis and Return on Investment of Off-Grid Photovoltaic Systems in Rural Areas of Tanzania. Sustain. Energy Technol. Assess. 2020, 42, 100887. [Google Scholar] [CrossRef]

- Muhammad-Sukki, F.; Ramirez-Iniguez, R.; Abu-Bakar, S.H.; McMeekin, S.G.; Stewart, B.G. An Evaluation of the Installation of Solar Photovoltaic in Residential Houses in Malaysia: Past, Present, and Future. Energy Policy 2011, 39, 7975–7987. [Google Scholar] [CrossRef]

- Yang, D.; Latchman, H.; Tingling, D.; Amarsingh, A.A. Design and Return on Investment Analysis of Residential Solar Photovoltaic Systems. IEEE Potentials 2015, 34, 11–17. [Google Scholar] [CrossRef]

| Smart-POD [24] | Pre-fab Eco Smart House [25,26] | Ecocapsule Original [27] | Living Box [28] | Biosphera Equilibrium [29] | |

|---|---|---|---|---|---|

| Volume | 462.2 m3 | 55.9 m3 | 25.7 m3 | 211.2 m3 | 67.2 m3 |

| Net floor area | 117.0 m2 | 20.7 m2 | 6.3 m2 | 45.0 m2 | 30.45 m2 |

| U-value of opaque envelope | 0.10/0.12 W/m2 K | 0.280 W/m2 K (Walls) 0.316 W/m2 K (Floor) 0.263 W/m2 K (Roof) | Not specified | 0.207 W/m2 K (A-type cell) 0.308 W/m2 K (B-type cell) 0.138 W/m2 K (Roof) | Not specified |

| U-value of windows | 0.70/0.75 W/m2 K | 2.00 W/m2 K | Not specified | 1.50 W/m2 K | Not specified |

| Lighting technology | LED lamps | Not specified | LED lamps | Not specified | LED lamps |

| Specific annual electric energy demand | 25.77 kWh/m2 year(location not specified) | 103.82 kWh/m2 year (Larnaca, Cyprus); 133.38 kWh/m2 year (Bolzano, Italy) | Not specified | 61.80 kWh/m2 year (Bolzano, Italy); 57.24 kWh/m2 year (Florence, Italy); 54.60 kWh/m2 year (Reggio Calabria, Italy) | 65.68 kW/m2 year (location not specified) |

| Ventilation technology | Natural and mechanical | Natural and mechanical | Natural and mechanical | Natural and mechanical | Natural |

| Electricity generation technology | 40.0 m2 PV panels (5093.0 kWh/year) | 5.0 m2 BIPV/T | 2.6 m2 PV panels (peak power of 880.0 W) and a wind turbine (peak power of 750.0 W) | 41.0 m2 BIPV/T (Peak power of 3150.0 W) | 107.0 m2 PV panels (8000.0 kWh/year) |

| Electric storage technology | Lithium-ion battery | Not specified | Lithium-iron phosphate batteries | Not specified | Salt battery (capacity of 20.0 kWh) [30] |

| Cooling technology | Mechanical ventilation with heat recovery and/or thermal storage | Air-to-air electrically driven vapor-compression refrigerating unit | Air-to-air electrically driven vapor-compression refrigerating unit (cooling power up to 970.0 W) | Air-to-air electrically driven reversing heat pump | Radiant ceiling |

| Heating technology | Air-to-air electrically driven vapor-compression heat pump or mechanical ventilation heat recovery and/or thermal storage | Air-to-air electrically driven vapor-compression refrigerating unit | Air-to-air electrically driven vapor-compression heat pump (heating power up to 1050.0 W) | Air-to-air electrically driven reversing heat pump | Radiant ceiling |

| Indoor Space | Outdoor Space | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Office A | Office B | Office C | Relaxation Area | Antebathroom/WC1/WC2 | Laboratory Area | Small Garden | Impluvium | Corridor | |

| Floor area (m2) | 11.5 | 11.5 | 11.5 | 11.5 | 4.0/5.2/5.2 | 12.4 | 2.8 | 5.2 | 19.7 |

| Orientation | North-east | South-east | North-west | South-west | South | North | South | North | - |

| Building Configuration | Differences with Respect to the Baseline Configuration | Case Studies |

|---|---|---|

| Configuration A | All the conventional windows replaced with smart windows | 3 case studies (1–3) characterized by 3 different logics controlling the smart windows’ state:

|

| Configuration B | All the conventional windows replaced with smart windows controlled via a logic based on the indoor air temperature (as in case 3) + addition of photovoltaic panels + eventual addition of electric storages | 3 case studies (4–6) with 10.34 kWp photovoltaic panels eventually combined with electric storages of different capacity:

|

| Configuration C | All the conventional windows replaced with smart windows controlled via a logic based on the indoor air temperature (as in case 3) + addition of photovoltaic panels + addition of a wind turbine + addition of electric storages | 4 case studies (7–10) differing in terms of electric output of the wind turbine and capacity of the electric storages:

|

| State | Window Type | Geometry (mm) | Spacing Gas | Af (m2) | Ag (m2) | Uf (W/m2 K) | Ug (W/m2 K) | SHGC

(-) | τvis (-) |

|---|---|---|---|---|---|---|---|---|---|

| Clear | Double glazing | 9.1/12/4 | Krypton | 1.6 | 9.4 | 1.00 | 1.10 | 0.40 | 0.60 |

| Intermediate 1 | 0.12 | 0.17 | |||||||

| Intermediate 2 | 0.07 | 0.05 | |||||||

| Dark | 0.05 | 0.01 |

| Cases | Driving Variable | Threshold Values | Smart Window State |

|---|---|---|---|

| Case 1 | - | - | Always dark |

| Case 2 | Incident solar radiation φs,i | φs,i ≤ 100 W/m2 | Clear |

| 100 W/m2 < φs,i ≤ 150 W/m2 | Intermediate 1 | ||

| 150 W/m2 < φs,i ≤ 400 W/m2 | Intermediate 2 | ||

| φs,i > 400 W/m2 | Dark | ||

| Case 3 | Indoor air temperature Ti | Ti ≤ 24.5 °C | Clear |

| 24.5 °C < Ti ≤ 25 °C | Intermediate 1 | ||

| 25 °C < Ti ≤ 25.5 °C | Intermediate 2 | ||

| Ti > 25.5 °C | Dark |

| PV Panels [64] | |||

| Model | TRI120TM-BB | TRI240TM-BB | TRI380HP-BB |

| Panel typology | Monocrystalline | ||

| Area of a single panel (m2) | 0.68 | 1.21 | 1.87 |

| Number of panels | 16 | 5 | 19 |

| Orientation | horizontal | ||

| Module voltage max power point and reference conditions (V) | 11.23 | 23.23 | 35.70 |

| Module open-circuit voltage at reference conditions (V) | 13.58 | 28.04 | 43.00 |

| Module current at max power point and reference conditions (A) | 10.63 | 10.33 | 10.65 |

| Module short-circuit current at reference conditions (A) | 10.24 | 10.65 | 11.18 |

| Temperature coefficient of open circuit current (V/K) | −0.039256 | −0.078512 | −0.120400 |

| Temperature coefficient of short circuit current (A/K) | 0.00639 | 0.00639 | 0.006708 |

| Number of individual cells wired in series within a module (-) | 21 | 42 | 63 |

| Electric storage [65] | |||

| Model | Tesla Powerwall | ||

| Usable capacity of a single battery (kWh) | 13.5 | ||

| Depth of discharge (%)/Efficiency round-trip (%) | 100/90 | ||

| Power of a single battery (kW) | 7 (peak)/5 (continuous) | ||

| Wind Turbines | ||

|---|---|---|

| DS300 [67] | DS700 [68] | |

| Rotor height (m) | 1.06 | 1.66 |

| Tower height (m) | 4 | 6 |

| Nominal electric output (W) | 300 | 700 |

| Maximum electric output (W) | 500 | 1000 |

| Cut-in wind speed (m/s) | 2.2 | 2.2 |

| Nominal wind speed (m/s) | 12.5 | 12.0 |

| Cut-out wind speed (m/s) | 15.5 | 15.5 |

| Monthly Average Values of UCel (2020–2022) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec | |

| F1 (EUR/MWh) | 128.55 | 111.70 | 139.15 | 118.47 | 111.49 | 139.46 | 216.26 | 238.10 | 227.78 | 174.70 | 199.20 | 252.23 |

| F2 (EUR/MWh) | 119.27 | 110.60 | 145.32 | 124.43 | 119.23 | 138.79 | 207.68 | 256.99 | 231.12 | 175.45 | 175.30 | 221.68 |

| F3 (EUR/MWh) | 96.20 | 90.89 | 122.23 | 104.18 | 98.02 | 114.11 | 170.37 | 214.30 | 189.52 | 135.26 | 138.04 | 176.50 |

| Annual electric energy demand by lighting systems and appliances (kWh/year) | 3391.1 |

| Annual primary energy consumption (kWh/year) | 8884.02 |

| Annual CO2 equivalent emissions (kgCO2,eq/year) | 1379.96 |

| Operating costs (EUR/year) | 1134.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maffei, L.; Ciervo, A.; Perrotta, A.; Masullo, M.; Rosato, A. Innovative Energy-Efficient Prefabricated Movable Buildings for Smart/Co-Working: Performance Assessment upon Varying Building Configurations. Sustainability 2023, 15, 9581. https://doi.org/10.3390/su15129581

Maffei L, Ciervo A, Perrotta A, Masullo M, Rosato A. Innovative Energy-Efficient Prefabricated Movable Buildings for Smart/Co-Working: Performance Assessment upon Varying Building Configurations. Sustainability. 2023; 15(12):9581. https://doi.org/10.3390/su15129581

Chicago/Turabian StyleMaffei, Luigi, Antonio Ciervo, Achille Perrotta, Massimiliano Masullo, and Antonio Rosato. 2023. "Innovative Energy-Efficient Prefabricated Movable Buildings for Smart/Co-Working: Performance Assessment upon Varying Building Configurations" Sustainability 15, no. 12: 9581. https://doi.org/10.3390/su15129581