Research on Combustion and Emission Characteristics of a N-Butanol Combined Injection SI Engine

Abstract

:1. Introduction

2. Experimental Setup and Procedure

2.1. Engine and Instrument

2.2. Injection Modes and Definitions

2.3. Experimental Method

3. Results and Discussion

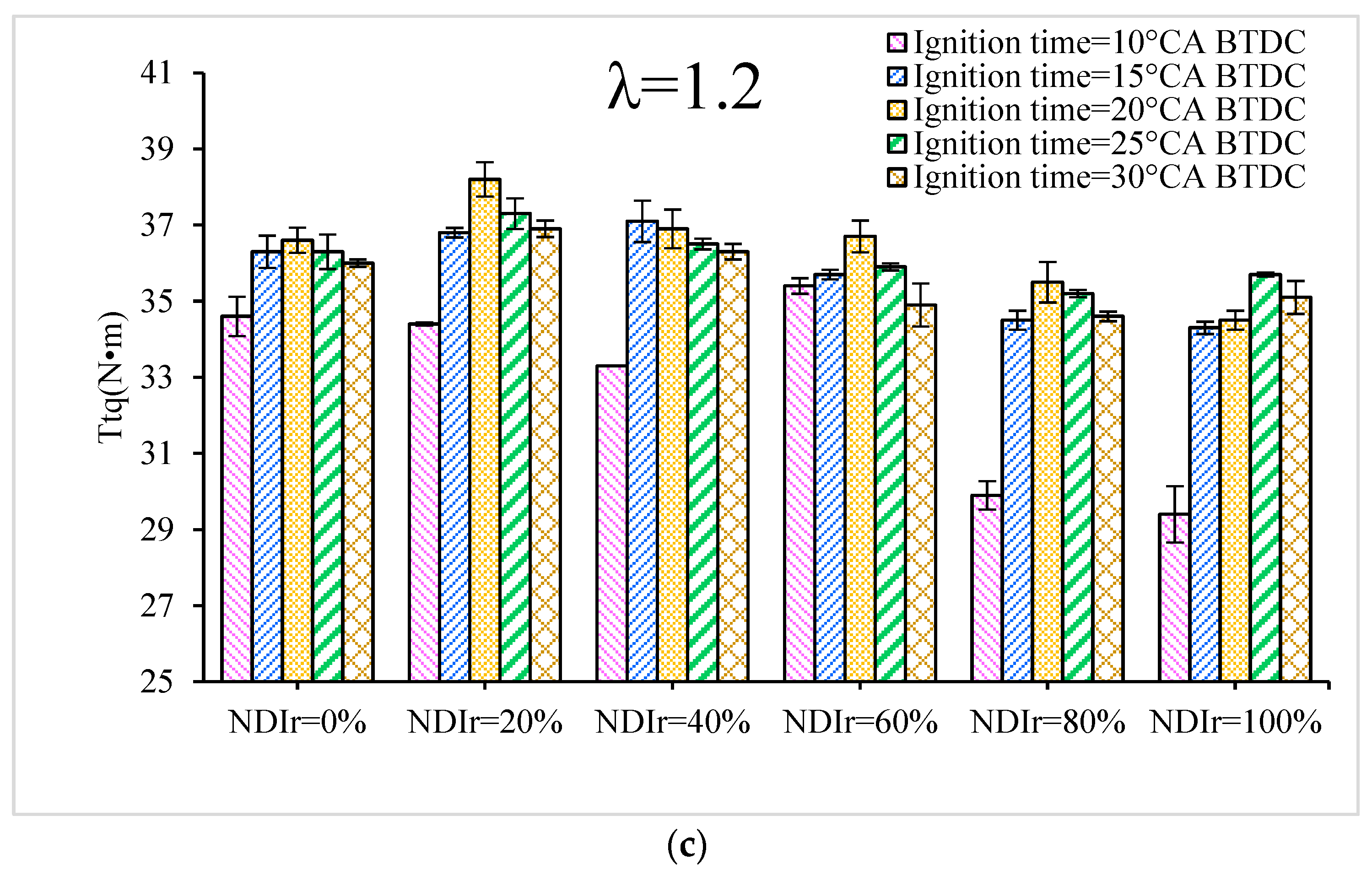

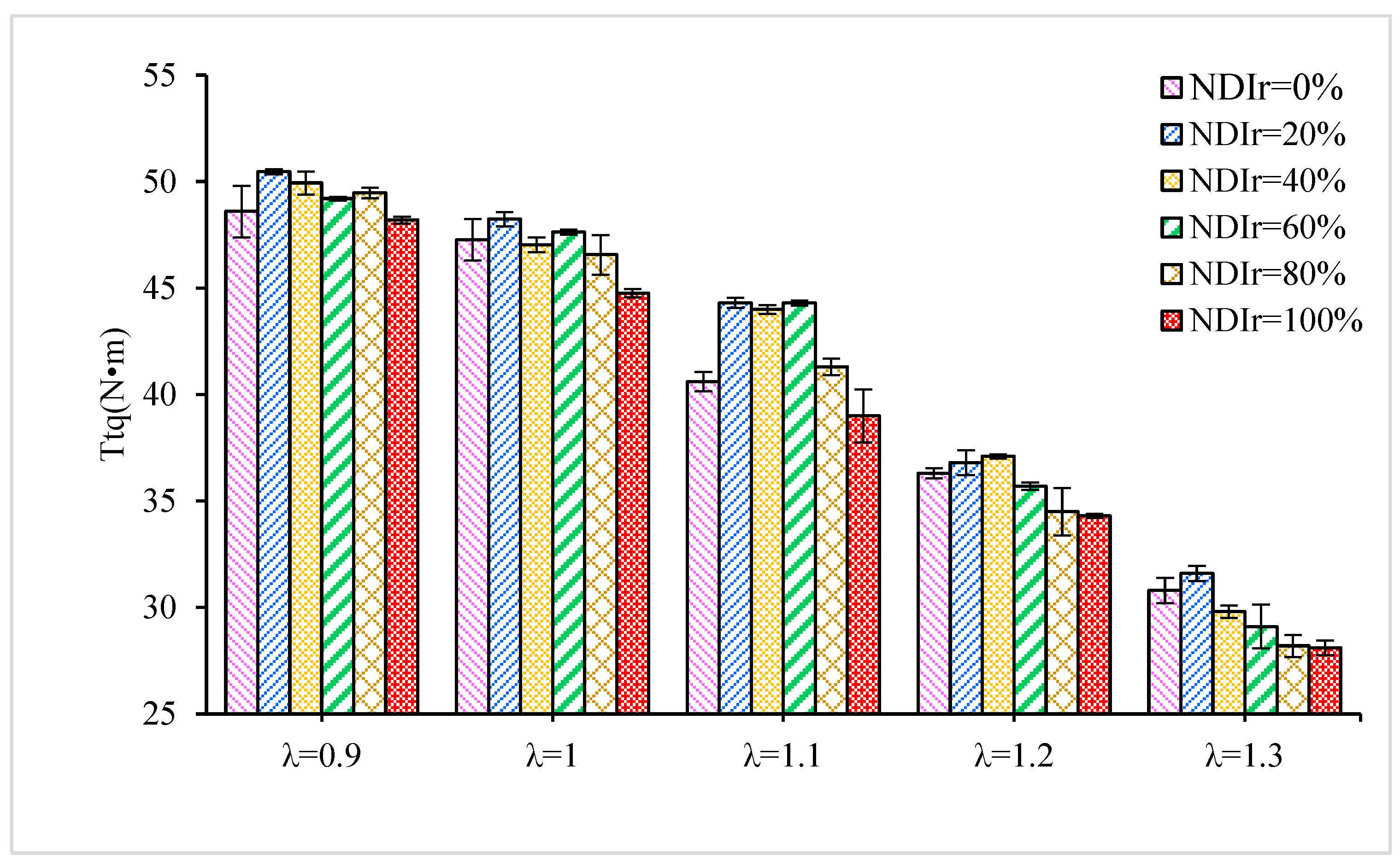

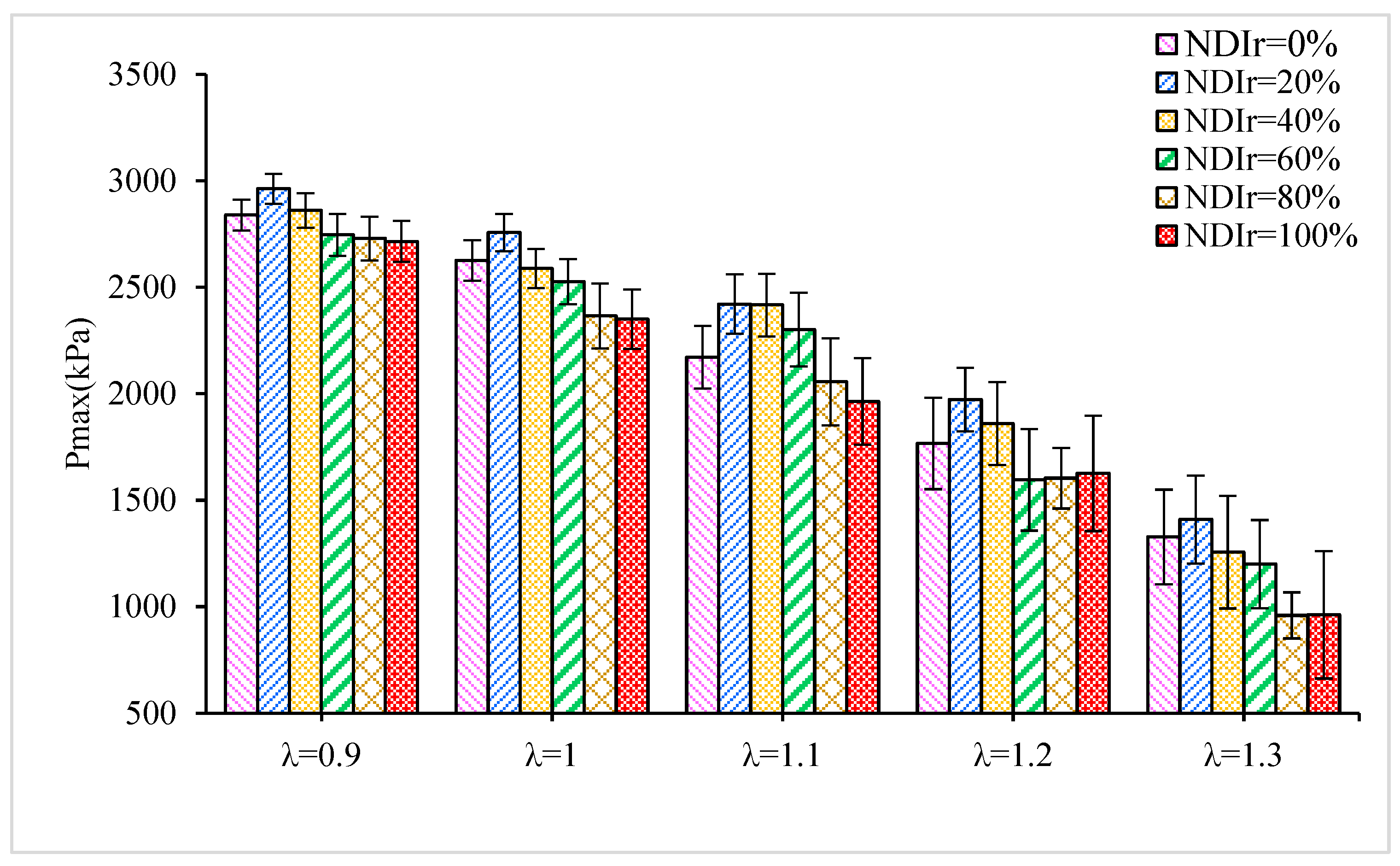

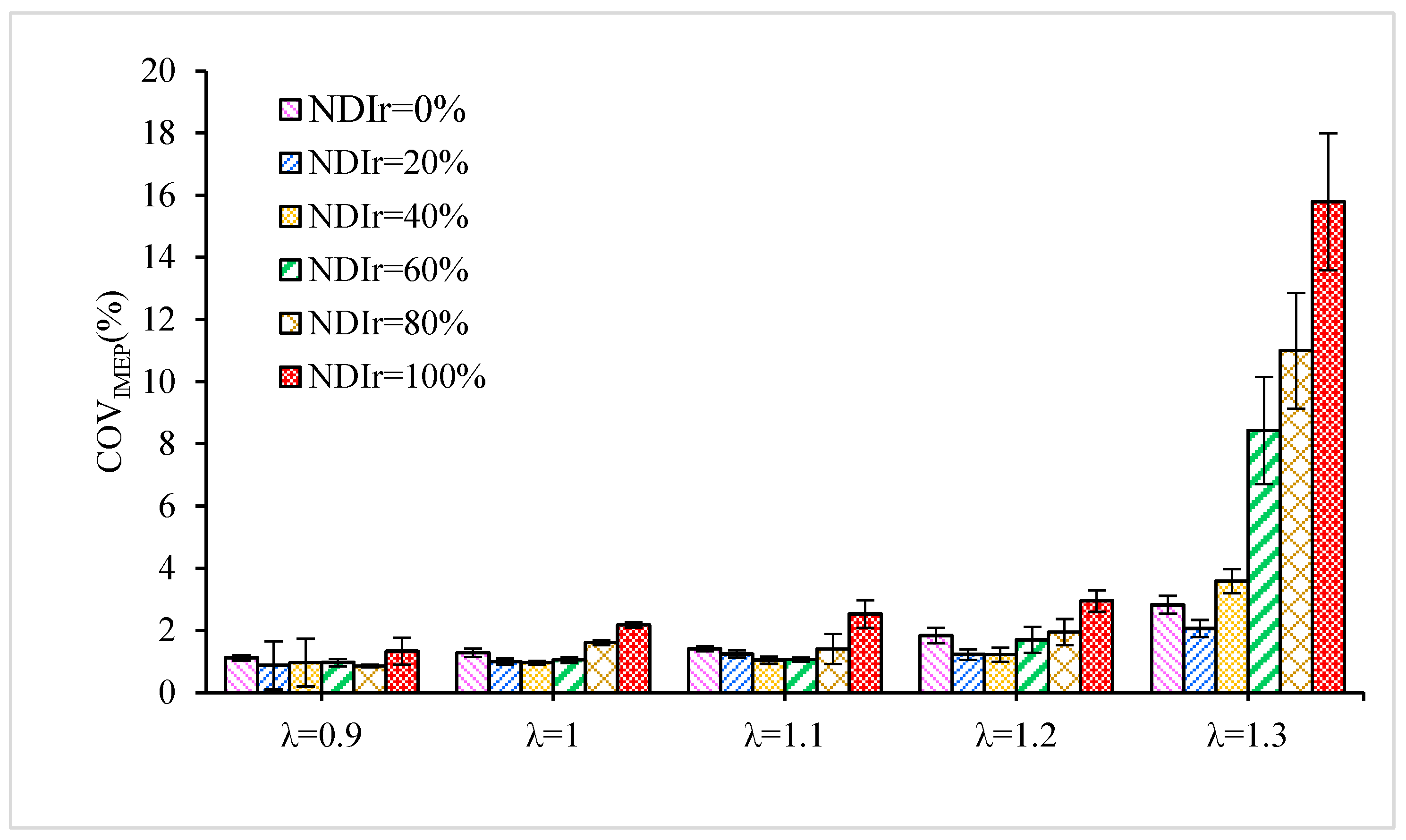

3.1. Combustion Characteristics

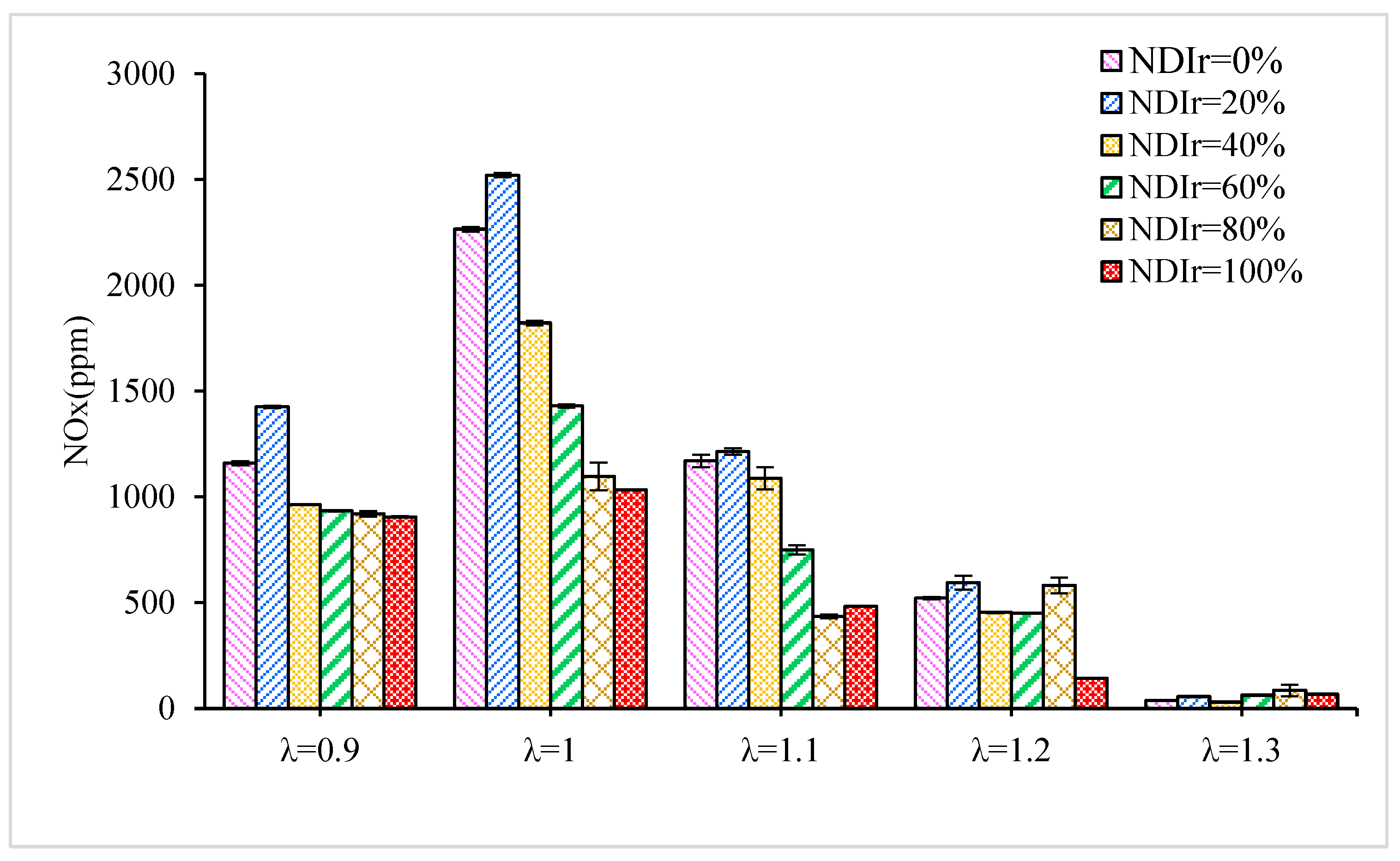

3.2. Gaseous Emissions Characteristics

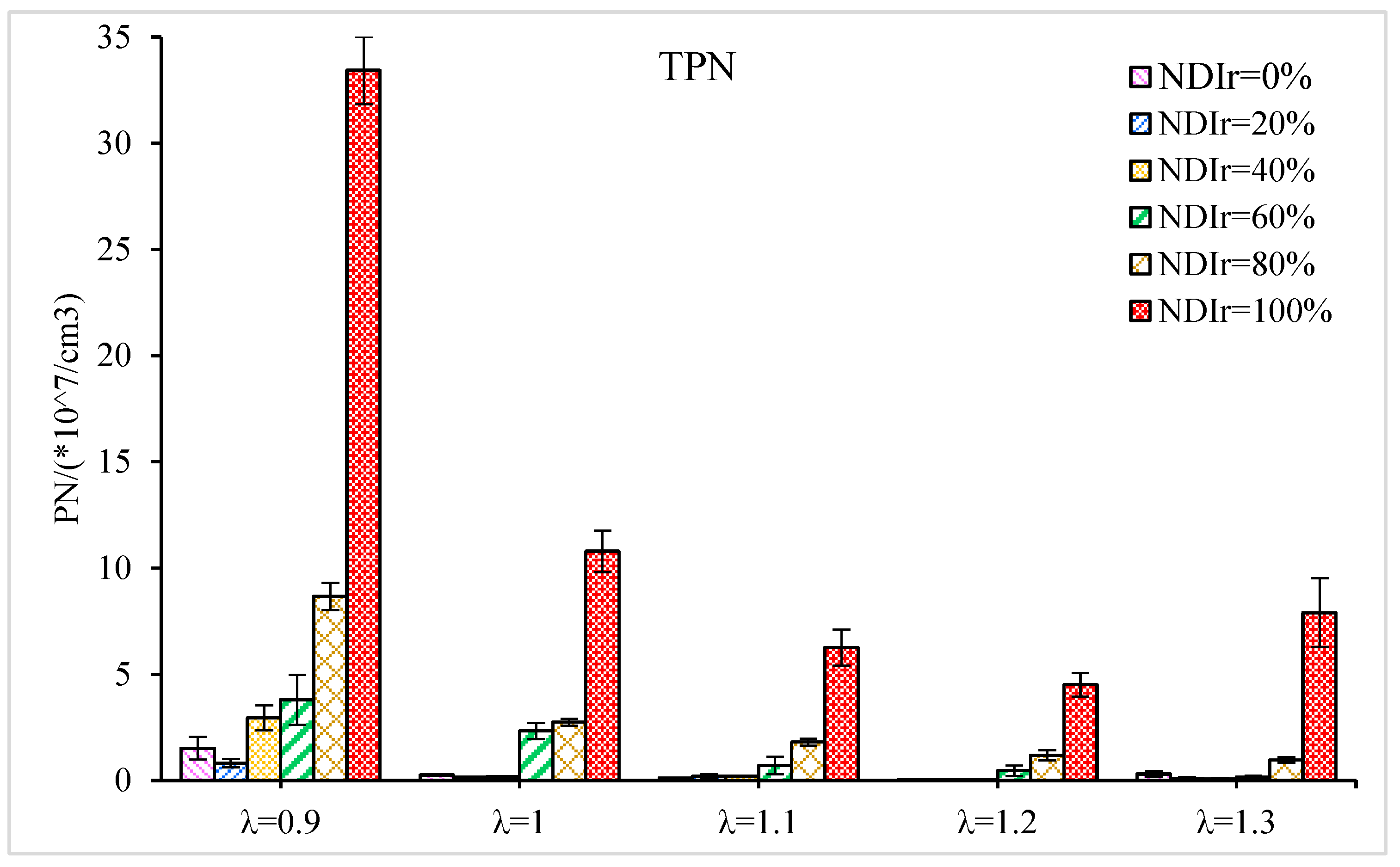

3.3. Particle Emissions Number

4. Conclusions

- Compared with the single injection mode, The dual injection of butanol engines with a smaller NDIr can form a local fuel-rich region near the spark, which is conducive to ignition and creates a more stable flame core, thus improving the comprehensive performance of butanol engines.

- From the combustion performance index, Ttq, Pmax, Tmax, and dQmax all rise first and then drop, reaching the maximum value at NDIr = 20% and minimum value at NDIr = 100%. The AdQmax, θ0-90, and COV decrease first and then increase as NDIr increases. Thus, N20DI is considered to have an optimal combustion performance, followed by N40DI.

- The dual injection mode has little affected on CO emission except for λ = 0.9, but can significantly reduce HC emissions than those relative to NPI and NDI. When λ is more than 0.9, the NDIr of 40–60% reduces HC emission most significantly, while the NDIr of 20% at λ = 0.9. NOx emissions increase in the dual injection mode, especially at N20DI, but not by much at NDIr of 40–80%.

- NPN, APN, and TPN increase continuously as NDIr increases, the dual injection mode. The dual injection mode can effectively reduce particulate emissions relative to the in-cylinder direct injection mode, especially when λ = 0.9.

- To summarize, the dual injection mode with NDIr of 20% to 40% significantly reduces HC and particulate emissions and maintains good combustion characteristics. In addition, the dual injection mode with a proper excess air ratio can effectively inhibit the increase in NOx emission caused by dual injection. Therefore, the dual injection mode with the proper NDIr can effectively optimize butanol engines’ combustion and emission performance.

- The combination of combined injection technology and butanol can reflect the excellent characteristics of butanol fuel to a greater extent, but the change of combustion state under different working conditions needs the real-time adjustment of combined injection strategy to meet the effect of dynamic optimization under full operating conditions. Therefore, it is necessary to explore the combustion and emission characteristics of the combined injection butanol engine under more engine speed and load conditions and establish the global optimization control strategy in the next research stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| SI | spark ignition | Pmax | peak in-cylinder pressure |

| NDIr | n-butanol direct injection ratio | Ttq | the engine torque |

| PFI | the port fuel injection | dQmax | the maximum rate of heat release |

| NDI | n-butanol direct injection | AdQmax | position of dQmax |

| NPI | port n-butanol injection | Tmax | peak in-cylinder temperature |

| MBT | maximum brake torque | θ0-90 | total combustion duration |

| TDC | top dead center | COV | coefficient of variance |

| BTDC | before top dead center | TPN | total particle number |

| λ | excess air ratio | APN | accumulation mode particle number |

| IMEP | indicated mean effective pressure | TPN | nucleation mode particle number |

| HC | Hydrocarbon | CO | carbon monoxide |

| NOx | nitrogen monoxide or nitric oxide |

References

- Bao, J.; Qu, P.; Wang, H.; Zhou, C.; Zhang, L.; Shi, C. Implementation of various bowl designs in an HPDI natural gas engine focused on performance and pollutant emissions. Chemosphere 2022, 303, 135275. [Google Scholar] [CrossRef] [PubMed]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Sidik, N.C.; Yusaf, T.; Kadirgama, K.; Kettner, M. Alcohol and ether as alternative fuels in spark ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 2586–2605. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Comparative assessment of spray behavior, combustion and engine performance of ABE-biodiesel/diesel as fuel in DI diesel engine. Energies 2020, 13, 6521. [Google Scholar] [CrossRef]

- Iliev, S.; Stanchev, H.; Mitev, E. An Experimental Investigation of a Common-rail Diesel Engine with Butanol Additives. In Proceedings of the 2020 7th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Ruse, Bulgaria, 12–14 November 2020; pp. 1–4. [Google Scholar]

- Kumar, B.R.; Saravanan, S. Use of higher alcohol biofuels in diesel engines: A review. Renew. Sustain. Energy Rev. 2016, 60, 84–115. [Google Scholar] [CrossRef]

- Shi, C.; Chai, S.; Wang, H.; Ji, C.; Ge, Y.; Di, L. An insight into direct water injection applied on the hydrogen-enriched rotary engine. Fuel 2023, 339, 127352. [Google Scholar] [CrossRef]

- Bao, J.; Wang, H.; Wang, R.; Wang, Q.; Di, L.; Shi, C. Comparative experimental study on macroscopic spray characteristics of various oxygenated diesel fuels. Energy Sci. Eng. 2023, 11, 1579–1588. [Google Scholar] [CrossRef]

- Shang, W.; Yu, X.; Shi, W.; Xing, X.; Guo, Z.; Du, Y.; Liu, H.; Wang, S. Effect of exhaust gas recirculation and hydrogen direct injection on combustion and emission characteristics of a n-butanol SI engine. Int. J. Hydrogen Energy 2020, 45, 17961–17974. [Google Scholar] [CrossRef]

- Thangavel, V.; Momula, S.Y.; Gosala, D.B.; Asvathanarayanan, R. Experimental studies on simultaneous injection of ethanol–gasoline and n-butanol–gasoline in the intake port of a four stroke SI engine. Renew. Energy 2016, 91, 347–360. [Google Scholar] [CrossRef]

- Papagiannakis, R.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Theoretical Study of the Effects of Spark Timing on the Performance and Emissions of a Light-Duty Spark Ignited Engine Running under Either Gasoline or Ethanol or Butanol Fuel Operating Modes. Energies 2017, 10, 1198. [Google Scholar] [CrossRef] [Green Version]

- Atmanli, A.; Yilmaz, N. A comparative analysis of n-butanol/diesel and 1-pentanol/diesel blends in a compression ignition engine. Fuel 2018, 234, 161–169. [Google Scholar] [CrossRef]

- Hergueta, C.; Bogarra, M.; Tsolakis, A.; Essa, K.; Herreros, J.M. Butanol-gasoline blend and exhaust gas recirculation, impact on GDI engine emissions. Fuel 2017, 208, 662–672. [Google Scholar] [CrossRef] [Green Version]

- Csemány, D.; DarAli, O.; Rizvi SA, H.; Józsa, V. Comparison of volatility characteristics and temperature-dependent density, surface tension, and kinematic viscosity of n-butanol-diesel and ABE-diesel fuel blends. Fuel 2022, 312, 122909. [Google Scholar] [CrossRef]

- Jeon, J.M.; Song, H.S.; Lee, D.G.; Hong, J.W.; Hong, Y.G.; Moon, Y.M.; Bhatia, S.K.; Yoon, J.J.; Kim, W.; Yang, Y.H. Butyrate-based n-butanol production from an engineered Shewanella oneidensis MR-1. Bioprocess Biosyst. Eng. 2018, 41, 1195–1204. [Google Scholar] [CrossRef]

- Ferreira, S.; Pereira, R.; Wahl, S.A.; Rocha, I. Metabolic engineering strategies for butanol production in Escherichia coli. Biotechnol. Bioeng. 2020, 117, 2571–2587. [Google Scholar] [CrossRef]

- Bao, T.; Feng, J.; Jiang, W.; Fu, H.; Wang, J.; Yang, S.T. Recent advances in n-butanol and butyrate production using engineered Clostridium tyrobutyricum. World J. Microbiol. Biotechnol. 2020, 36, 138. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Lai, M.C.; Harrington, D.L. Automotive spark-ignited direct-injection gasoline engines. Prog. Energy Combust. Sci. 1999, 25, 437–562. [Google Scholar] [CrossRef]

- Shang, Z.; Yu, X.; Shi, W.; Huang, S.; Li, G.; Guo, Z.; He, F. Numerical research on effect of hydrogen blending fractions on idling performance of an n-butanol ignition engine with hydrogen direct injection. Fuel 2019, 258, 116082. [Google Scholar] [CrossRef]

- Guo, Z.; Yu, X.; Sang, T.; Chen, Z.; Cui, S.; Xu, M.; Yu, L. Experimental study on combustion and emissions of an SI engine with gasoline port injection and acetone-butanol-ethanol (ABE) direct injection. Fuel 2021, 284, 119037. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Zhang, D.; Dong, F.; Liu, X.; Yang, Y.; Huang, H.; Wang, Y.; Wang, Q.; Zheng, Z. Investigation on blending effects of gasoline fuel with n-butanol, DMF, and ethanol on the fuel consumption and harmful emissions in a GDI vehicle. Energies 2019, 12, 1845. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Hong, W.; Xie, F.; Su, Y.; Han, L.; Wu, B. Experimental Investigation of Impacts of Injection Timing and Pressure on Combustion and Particulate Matter Emission in a Spray-Guided GDI Engine. Int. J. Automot. Technol. 2018, 19, 393–404. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, X.; Ding, Y.; Du, Y.; Chen, Z.; Zuo, X. Experimental comparative study on combustion and particle emission of n-butanol and gasoline adopting different injection approaches in a spark engine equipped with dual-injection system. Fuel 2018, 211, 837–849. [Google Scholar] [CrossRef]

- Yang, J.; Ji, C. A comparative study on performance of the rotary engine fueled hydrogen/gasoline and hydrogen/n-butanol. Int. J. Hydrogen Energy 2018, 43, 22669–22675. [Google Scholar] [CrossRef]

- Ravikumar, R.; Antony, A.J. An experimental investigation to study the performance and emission characteristics of n-butanol-gasoline blends in a twin spark ignition engine. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 401–414. [Google Scholar]

- Agbro, E.; Zhang, W.; Tomlin, A.S.; Burluka, A. Experimental Study on the Influence of n-Butanol Blending on the Combustion, Autoignition, and Knock Properties of Gasoline and Its Surrogate in a Spark-Ignition Engine. Energy Fuels 2018, 32, 10052–10064. [Google Scholar] [CrossRef] [Green Version]

- Saraswat, M.; Chauhan, N.R. Comparative assessment of butanol and algae oil as alternate fuel for SI engines. Eng. Sci. Technol. Int. J. 2020, 23, 92–100. [Google Scholar] [CrossRef]

- Meng, F.; Yu, X.; He, L.; Liu, Y.; Wang, Y. Study on combustion and emission characteristics of a n-butanol engine with hydrogen direct injection under lean burn conditions. Int. J. Hydrogen Energy 2018, 43, 7550–7561. [Google Scholar] [CrossRef]

- Su, T.; Ji, C.; Wang, S.; Cong, X.; Shi, L.; Yang, J. Investigation on combustion and emissions characteristics of a hydrogen-blended n-butanol rotary engine. Int. J. Hydrogen Energy 2017, 42, 26142–26151. [Google Scholar] [CrossRef]

- Merola, S.S.; Irimescu, A.; Marchitto, L.; Tornatore, C.; Valentino, G. Effect of injection timing on combustion and soot formation in a direct injection spark ignition engine fueled with butanol. Int. J. Engine Res. 2017, 18, 490–504. [Google Scholar] [CrossRef]

- Sandhu, N.S.; Yu, X.; Leblanc, S.; Zheng, M.; Ting, D.; Li, T. Combustion Characterization of Neat n-Butanol in an SI Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Kalwar, A.; Singh, A.P.; Agarwal, A.K. Utilization of primary alcohols in dual-fuel injection mode in a gasoline direct injection engine. Fuel 2020, 276, 118068. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M.; Kyritsis, D.C. Effects of butanol–diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Heywood, J.B.; Vilchis, F.R. Comparison of flame development in a spark-ignition engine fueled with propane and hydrogen. Combust. Sci. Technol. 1984, 38, 313–324. [Google Scholar] [CrossRef]

- Tian, Z.; Zhen, X.; Wang, Y.; Liu, D.; Li, X. Combustion and emission characteristics of n-butanol-gasoline blends in SI direct injection gasoline engine. Renew. Energy Int. J. 2020, 146, 267–279. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Q.; Luo, J.; Zhang, Y. Particle Size Distributions of Butanol-Diesel and Acetone–Butanol–Ethanol (ABE)-Diesel Blend Fuels in Wick-Fed Diffusion Flames. Energy Fuels 2020, 34, 16212–16219. [Google Scholar] [CrossRef]

- Liu, B.; Cheng, X.; Liu, J.; Pu, H. Investigation into particle emission characteristics of partially premixed combustion fueled with high n-butanol-diesel ratio blends. Fuel 2018, 223, 1–11. [Google Scholar] [CrossRef]

- Yu, X.; Guo, Z.; He, L.; Dong, W.; Sun, P.; Shi, W.; Du, Y.; He, F. Effect of gasoline/n-butanol blends on gaseous and particle emissions from an SI direct injection engine. Fuel 2018, 229, 1–10. [Google Scholar] [CrossRef]

| Fuel Properties | Methanol | Ethanol | N-butanol |

|---|---|---|---|

| Molecular formula | CH3OH | C2H5OH | C4H9OH |

| Viscosity (Pa·s) at 20 °C | 0.61 | 0.789 | 0.808 |

| Research octane number | 109–136 | 108–129 | 96–98 |

| Laminar flame speed (cm/s) | 52 | 48 | 48 |

| Latent heat of evaporation (kJ/kg) | 1103 | 840 | 582 |

| Lower caloric value (MJ/kg) | 19.7 | 26.8 | 33.1 |

| Flammability limits (% vol.) | 6.0–36.5 | 4.3–19 | 1.4–11.2 |

| Stoichiometric air–fuel ratio | 6.49 | 9.02 | 11.21 |

| Engine Parameter | Parameter Values |

|---|---|

| Engine Type | four cylinders; combined injection; naturally aspirated; water cooled; spark-ignition |

| Compression ratio | 9.6 |

| Bore/mm | 82.5 |

| Stroke/mm | 92.8 |

| Displaced volume/mL | 1984 |

| Maximum power/kW | 132 (5000–6000 rpm) |

| Maximum torque/N·m | 320 (1800–5000 rpm) |

| Parameter | Manufacturer | Range | Precision | Production Type |

|---|---|---|---|---|

| Speed | Luoyang Nanfeng Electromechanic Equipment Manufacturing Co., Ltd. (Luoyang, China) | 0–6000 rpm | ≤±1 rpm | CW160 |

| Crank angle | Kistler Instrument China Ltd. (China) | 0–720° | ≤±0.5° | Kistler-2614B4 |

| Excess air ratio | ETAS Engineering TOOLS (Germany) | 0.700–32.767 | ≤±1.5% | LAMBDA LA4 |

| Torque | Luoyang Nanfeng Electromechanic Equipment Manufacturing Co., Ltd. (Luoyang, China) | 0–600 N m | ≤±0.28 N·m | CW160 |

| Cylinder pressure | DEWETRON GmbH. (Austria) | 0–20 MPa | ≤± 0.3% | AVL-GU13Z-24 |

| n-butanol mass flow rate | Ono Sokki DF-2420 (Japan) | 0.2~82 kg/h | ≤± g/s | DF-2420 |

| Carbon monoxide (CO) | AVL List GmbH (Austria) | 0–10% vol | ≤±0.01% vol | AVL DICOM 4000 |

| Hydrocarbon (HC) | AVL List GmbH (Austria) | 0–20,000 ppm vol | ≤±1 ppm | AVL DICOM 4000 |

| Nitrogen oxides (NOx) | AVL List GmbH (Austria) | 0–5000 ppm vol | ≤±1 ppm | AVL DICOM 4000 |

| Particle number concentration | British combustion (England) | 0–1011 dN/dlogDp/cm3 | ≤±1.4 × 104 dN/dlogDp/cm3 | DMS500 |

| The Naming of Different Injection Modes | NPI | N20DI | N40DI | N60DI | N80DI | NDI |

|---|---|---|---|---|---|---|

| N-butanol direct injection ratio (NDIr) | 0% | 20% | 40% | 60% | 80% | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, W.; Yu, X.; Miao, K.; Guo, Z.; Liu, H.; Xing, X. Research on Combustion and Emission Characteristics of a N-Butanol Combined Injection SI Engine. Sustainability 2023, 15, 9696. https://doi.org/10.3390/su15129696

Shang W, Yu X, Miao K, Guo Z, Liu H, Xing X. Research on Combustion and Emission Characteristics of a N-Butanol Combined Injection SI Engine. Sustainability. 2023; 15(12):9696. https://doi.org/10.3390/su15129696

Chicago/Turabian StyleShang, Weiwei, Xiumin Yu, Kehao Miao, Zezhou Guo, Huiying Liu, and Xiaoxue Xing. 2023. "Research on Combustion and Emission Characteristics of a N-Butanol Combined Injection SI Engine" Sustainability 15, no. 12: 9696. https://doi.org/10.3390/su15129696