Characterization of Cross-Linking in Guar Gum Hydrogels via the Analysis of Thermal Decomposition Behavior and Water Uptake Kinetics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. GEH Preparation

2.3. Characterization

2.4. Mechanical Strength

2.5. Swelling Rate

2.6. Water Uptake

2.7. Degree of Mass Cross-Linking

2.8. Statistical Analysis

3. Results and Discussion

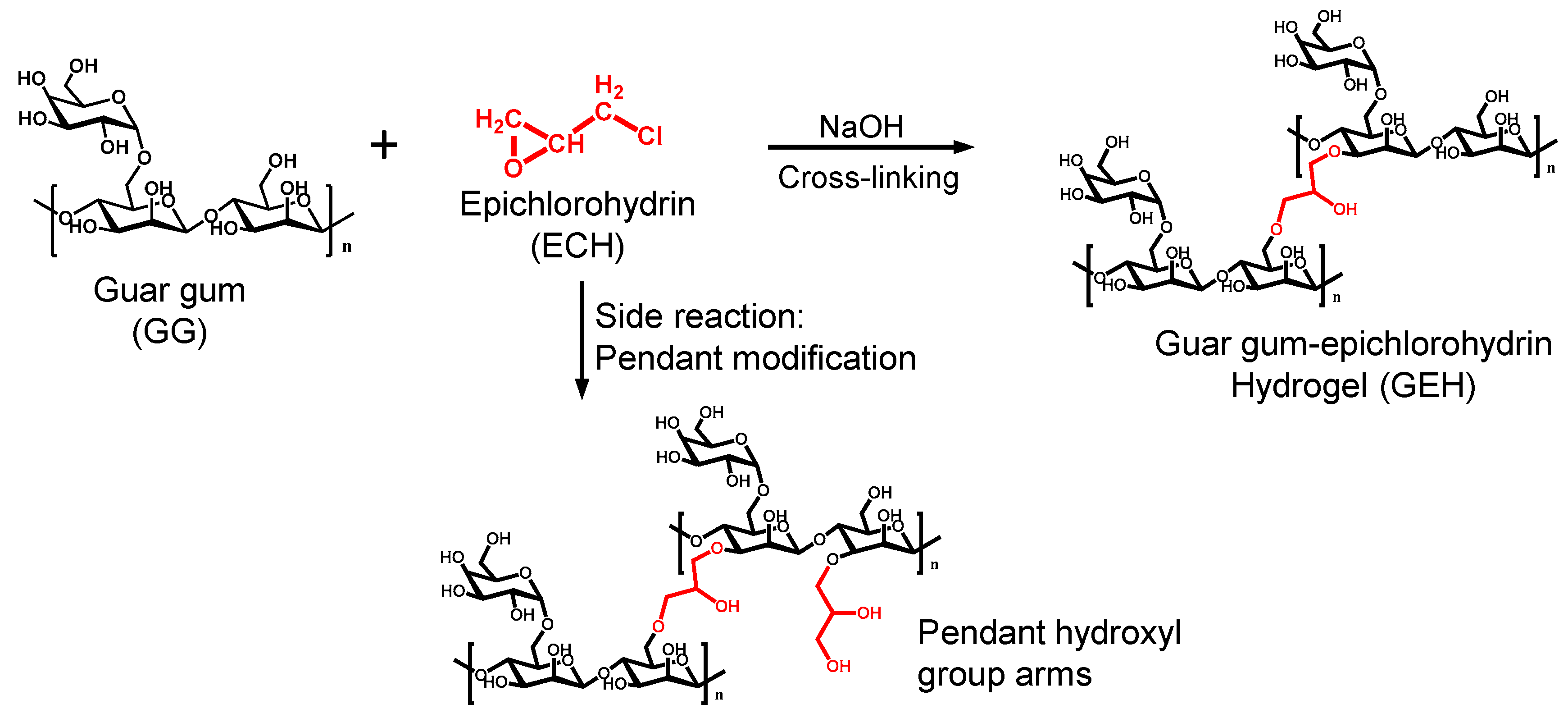

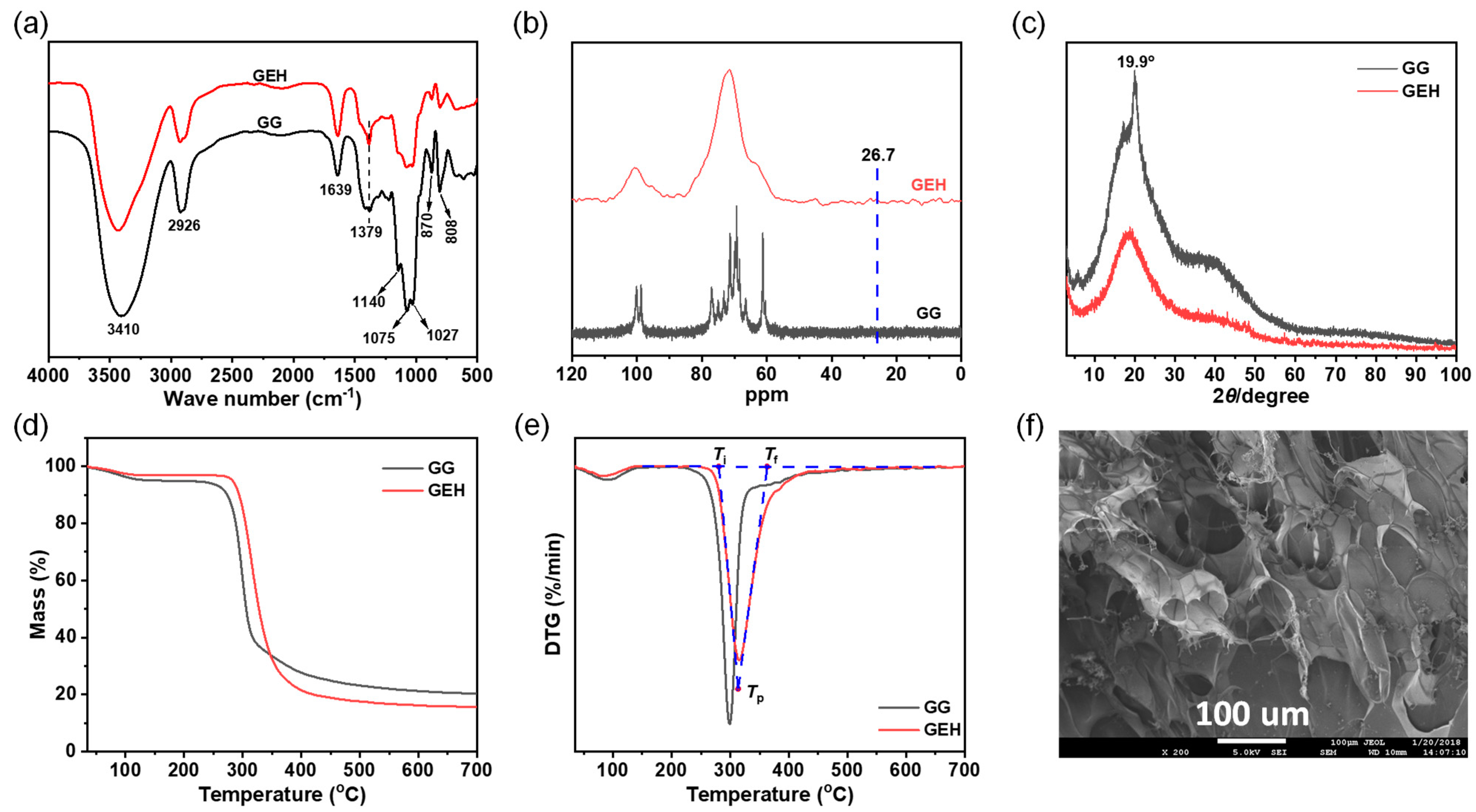

3.1. Characterization of Physical and Chemical Properties

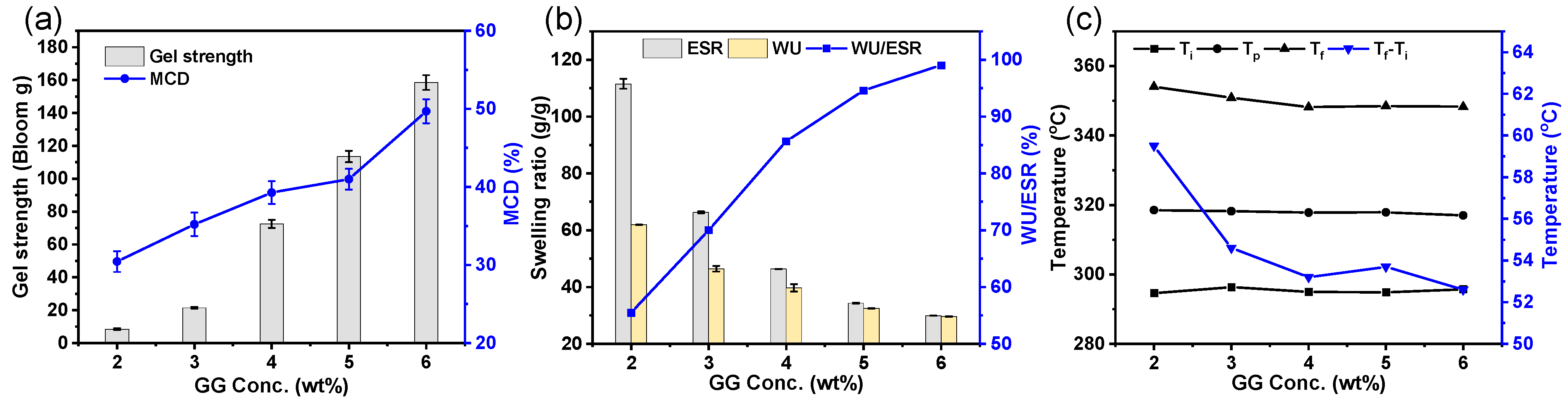

3.2. Influence of GG Concentration on the Cross-Linking Characteristics of the GEHs

3.3. Influence of Cross-Linking Agent Concentration on the Cross-Linking Characteristics of the GEHs

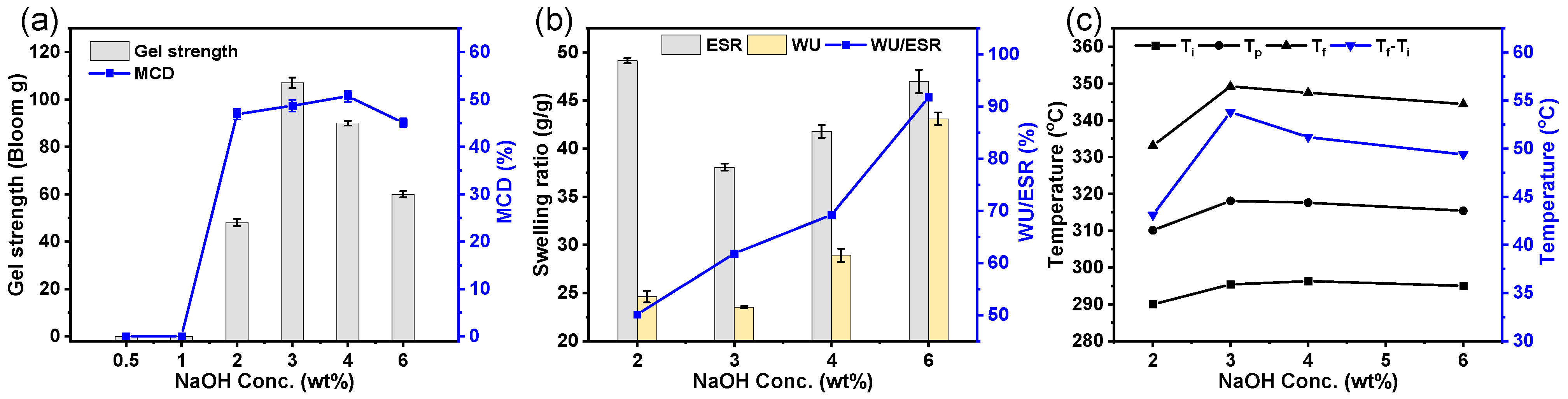

3.4. Influence of Catalyst Concentration on the Cross-Linking Characteristics of the GEHs

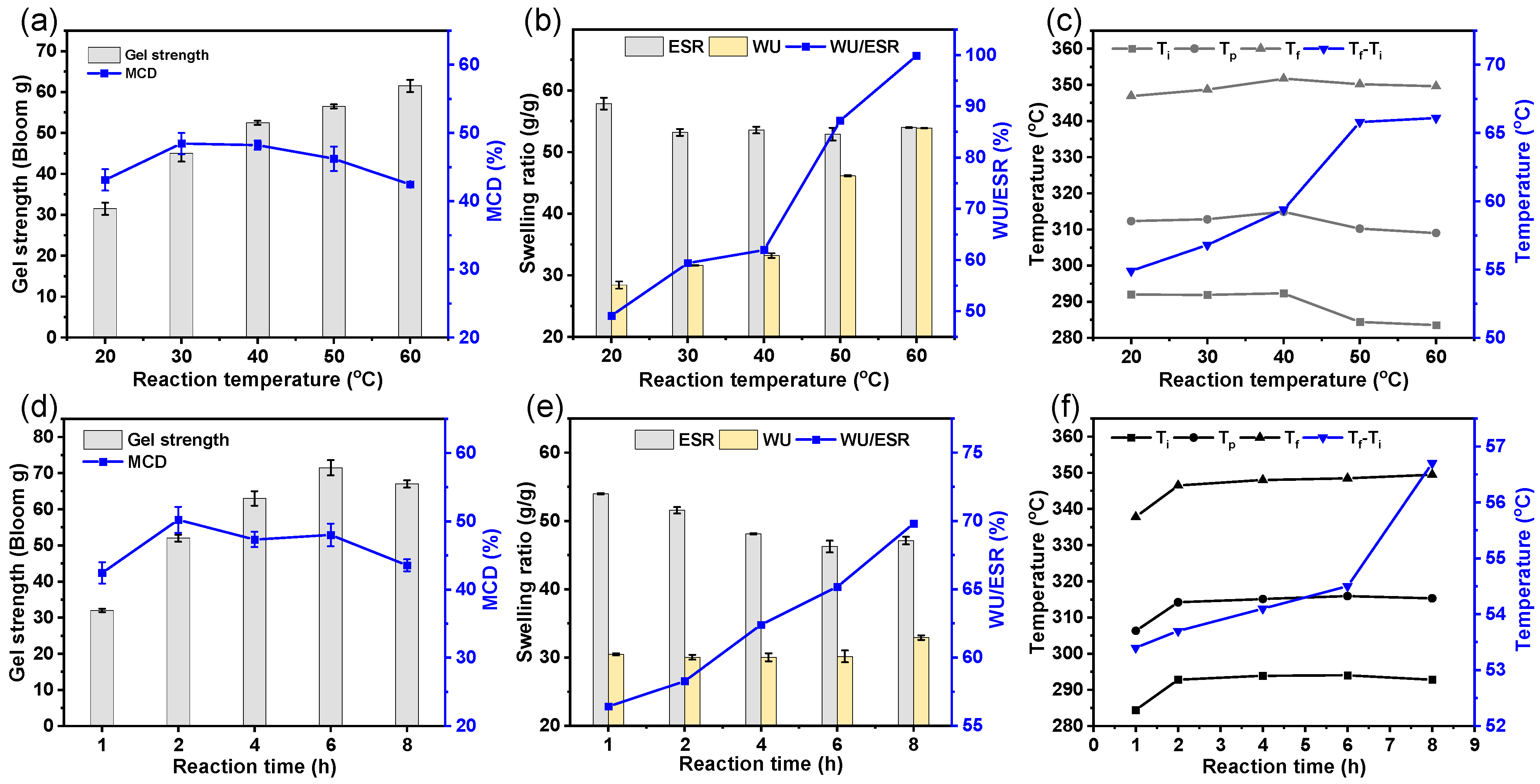

3.5. Influence of Cross-Linking Temperature and Time on the Cross-Linking Characteristics of the GEHs

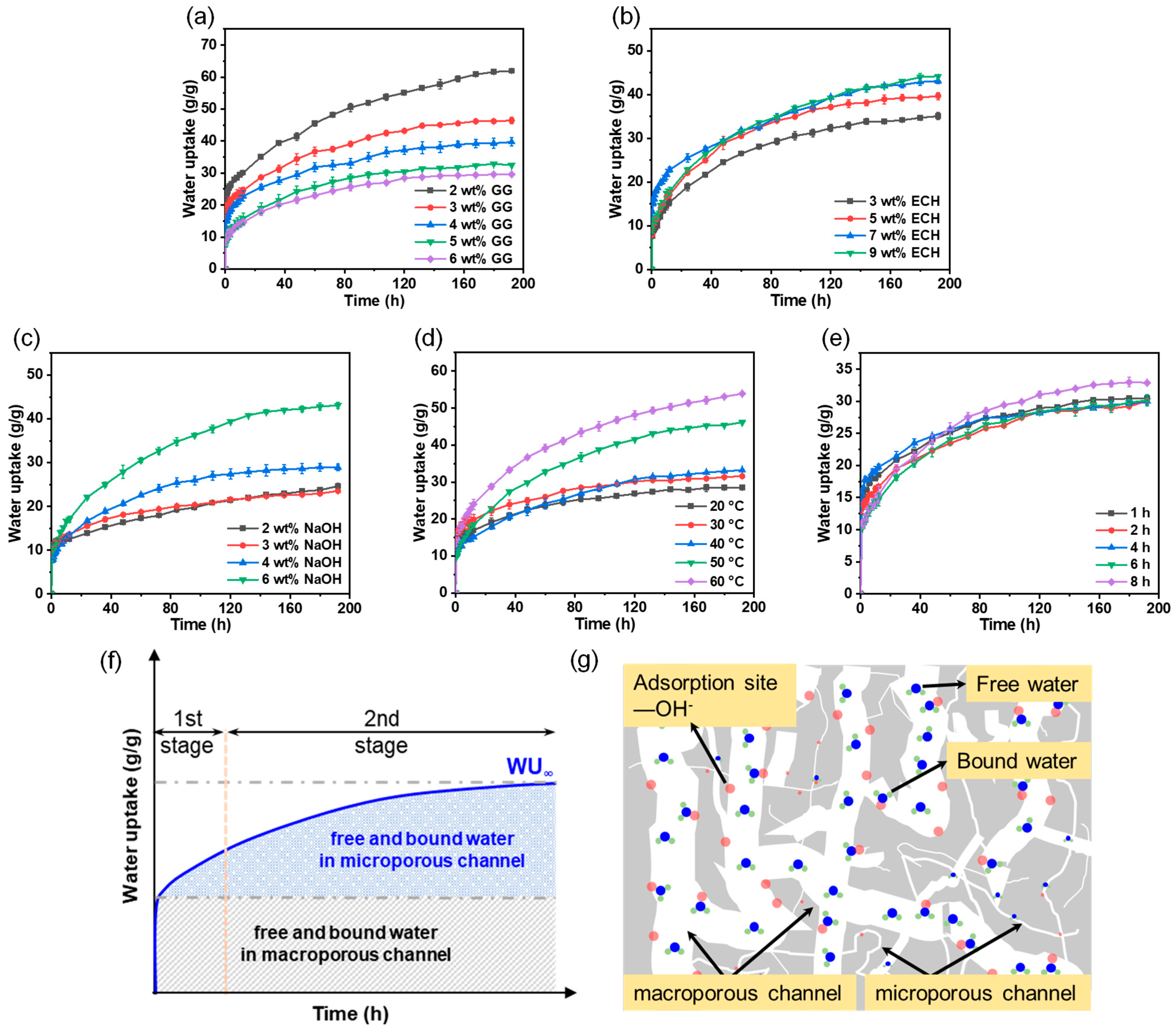

3.6. Relationship between the Water Uptake Kinetics and Cross-Linking Characteristics of the Freeze-Dried Hydrogels

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yadav, H.; Maiti, S. Research Progress in Galactomannan-Based Nanomaterials: Synthesis and Application. Int. J. Biol. Macromol. 2020, 163, 2113–2126. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Jian, H.; Cristhian, C.; Zhang, W.; Sun, R. Structural and Thermal Characterization of Galactomannans from Genus Gleditsia Seeds as Potential Food Gum Substitutes. J. Sci. Food Agric. 2011, 91, 732–737. [Google Scholar] [CrossRef] [PubMed]

- Jian, H.; Cristhian, C.; Zhang, W.; Jiang, J. Influence of Dehulling Pretreatment on Physicochemical Properties of Gleditsia Sinensis Lam. Gum. Food Hydrocoll. 2011, 25, 1337–1343. [Google Scholar] [CrossRef]

- Chen, Y.; Xiong, X.; Gao, Q. Digestibility and Physicochemical Properties of Starch-Galactomannan Complexes by Heat-Moisture Treatment. Food Hydrocoll. 2018, 77, 853–862. [Google Scholar] [CrossRef]

- Rashid, F.; Hussain, S.; Ahmed, Z. Extraction Purification and Characterization of Galactomannan from Fenugreek for Industrial Utilization. Carbohydr. Polym. 2018, 180, 88–95. [Google Scholar] [CrossRef]

- Depoorter, J.; Mourlevat, A.; Sudre, G.; Morfin, I.; Prasad, K.; Serghei, A.; Bernard, J.; Fleury, E.; Charlot, A. Fully Biosourced Materials from Combination of Choline Chloride-Based Deep Eutectic Solvents and Guar Gum. ACS Sustain. Chem. Eng. 2019, 7, 16747–16756. [Google Scholar] [CrossRef]

- Seeli, D.S.; Prabaharan, M. Guar Gum Oleate-Graft-Poly(Methacrylic Acid) Hydrogel as a Colon-Specific Controlled Drug Delivery Carrier. Carbohydr. Polym. 2017, 158, 51–57. [Google Scholar] [CrossRef]

- Pal, P.; Rangra, N.; Samanta, S.; Aryan, A.; Pandey, J.P.; Sen, G. Graft Copolymer of PVP—A Sutureless, Haemostatic Bioadhesive for Wound Healing Application. Polym. Bull. 2020, 77, 5191–5212. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, M.; Manzoor, K.; Purwar, R.; Ikram, S. A Review on Latest Innovations in Natural Gums Based Hydrogels: Preparations & Applications. Int. J. Biol. Macromol. 2019, 136, 870–890. [Google Scholar]

- Sharma, G.; Kumar, A.; Devi, K.; Sharma, S.; Naushad, M.; Ghfar, A.A.; Ahamad, T.; Stadler, F.J. Guar Gum-Crosslinked-Soya Lecithin Nanohydrogel Sheets as Effective Adsorbent for the Removal of Thiophanate Methyl Fungicide. Int. J. Biol. Macromol. 2018, 114, 295–305. [Google Scholar] [CrossRef]

- Liu, C.; Lei, F.; Li, P.; Jiang, J.; Wang, K. Borax Crosslinked Fenugreek Galactomannan Hydrogel as Potential Water-Retaining Agent in Agriculture. Carbohydr. Polym. 2020, 236, 116100. [Google Scholar] [CrossRef]

- Chen, W.; Bu, Y.; Li, D.; Liu, Y.; Chen, G.; Wan, X.; Li, N. Development of High-Strength, Tough, and Self-Healing Carboxymethyl Guar Gum-Based Hydrogels for Human Motion Detection. J. Mater. Chem. C 2020, 8, 900–908. [Google Scholar] [CrossRef]

- Thombare, N.; Mishra, S.; Siddiqui, M.Z.; Jha, U.; Singh, D.; Mahajan, G.R. Design and Development of Guar Gum Based Novel, Superabsorbent and Moisture Retaining Hydrogels for Agricultural Applications. Carbohydr. Polym. 2018, 185, 169–178. [Google Scholar] [CrossRef]

- Tang, H.; Liu, Y.; Li, Y.; Li, Q.; Liu, X. Hydroxypropylation of Cross-Linked Sesbania Gum, Characterization and Properties. Int. J. Biol. Macromol. 2020, 152, 1010–1019. [Google Scholar] [CrossRef]

- Zhao, N.; Chai, Y.; Wang, T.; Wang, K.; Jiang, J.; Yang, H. Preparation and Physical/Chemical Modification of Galactomannan Film for Food Packaging. Int. J. Biol. Macromol. 2019, 137, 1060–1067. [Google Scholar] [CrossRef] [PubMed]

- Orsu, P.; Matta, S. Fabrication and Characterization of Carboxymethyl Guar Gum Nanocomposite for Application of Wound Healing. Int. J. Biol. Macromol. 2020, 164, 2267–2276. [Google Scholar] [CrossRef] [PubMed]

- Butt, A.; Jabeen, S.; Nisar, N.; Islam, A.; Gull, N.; Iqbal, S.S.; Khan, S.M.; Yameen, B. Controlled Release of Cephradine by Biopolymers Based Target Specific Crosslinked Hydrogels. Int. J. Biol. Macromol. 2019, 121, 104–112. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Gu, J.; Liu, W.; Wang, K.; Huang, C.; Lai, C.; Yong, Q. Actuating, Shape Reconstruction, and Reinforcement of Galactomannan-Based Hydrogels by Coordination Bonds Induced Metal Ions Capture. Int. J. Biol. Macromol. 2020, 165, 2721–2730. [Google Scholar] [CrossRef]

- Li, J.; Mooney, D.J. Designing Hydrogels for Controlled Drug Delivery. Nat. Rev. Mater. 2016, 1, 16071. [Google Scholar] [CrossRef]

- Tokuyama, H.; Nakahata, Y.; Ban, T. Diffusion Coefficient of Solute in Heterogeneous and Macroporous Hydrogels and Its Correlation with the Effective Crosslinking Density. J. Membr. Sci. 2020, 595, 117533. [Google Scholar] [CrossRef]

- Eelkema, R.; Pich, A. Pros and Cons: Supramolecular or Macromolecular: What Is Best for Functional Hydrogels with Advanced Properties? Adv. Mater. 2020, 32, 1906012. [Google Scholar] [CrossRef]

- Kopač, T.; Ručigaj, A.; Krajnc, M. The Mutual Effect of the Crosslinker and Biopolymer Concentration on the Desired Hydrogel Properties. Int. J. Biol. Macromol. 2020, 159, 557–569. [Google Scholar] [CrossRef]

- Wende, F.J.; Xue, Y.; Nestor, G.; Öhrlund, Å.; Sandström, C. Relaxation and Diffusion of Water Protons in BDDE Cross-Linked Hyaluronic Acid Hydrogels Investigated by NMR Spectroscopy—Comparison with Physicochemical Properties. Carbohydr. Polym. 2020, 248, 116768. [Google Scholar] [CrossRef]

- Xu, W.; Liu, Y.; Zhang, F.; Lei, F.; Wang, K.; Jiang, J. Physicochemical Characterization of Gleditsia Triacanthos Galactomannan during Deposition and Maturation. Int. J. Biol. Macromol. 2020, 144, 821–828. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, T.; He, J.; Jiang, J.; Lei, F. Synthesis, Characterization, and Selective Dye Adsorption by PH- and Ion-Sensitive Polyelectrolyte Galactomannan-Based Hydrogels. Carbohydr. Polym. 2021, 264, 118009. [Google Scholar] [CrossRef]

- Uhl, F.M.; Levchik, G.F.; Levchik, S.V.; Dick, C.; Liggat, J.J.; Snape, C.E.; Wilkie, C.A. The Thermal Stability of Cross-Linked Polymers: Methyl Methacrylate with Divinylbenzene and Styrene with Dimethacrylates. Polym. Degrad. Stab. 2001, 71, 317–325. [Google Scholar] [CrossRef]

- Li, D.; Yang, N.; Zhang, Y.; Guo, L.; Sang, S.; Jin, Z.; Xu, X. Structural and Physicochemical Changes in Guar Gum by Alcohol–Acid Treatment. Carbohydr. Polym. 2018, 179, 2–9. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. X-ray Diffraction, IR Spectroscopy and Thermal Characterization of Partially Hydrolyzed Guar Gum. Int. J. Biol. Macromol. 2012, 50, 1035–1039. [Google Scholar] [CrossRef] [PubMed]

- Motta, M.V.L.; de Castro, E.V.R.; Muri, E.J.B.; Loureiro, B.V.; Costalonga, M.L.; Filgueiras, P.R. Thermal and Spectroscopic Analyses of Guar Gum Degradation Submitted to Turbulent Flow. Int. J. Biol. Macromol. 2019, 131, 43–49. [Google Scholar] [CrossRef]

- Dodi, G.; Pala, A.; Barbu, E.; Peptanariu, D.; Hritcu, D.; Popa, M.I.; Tamba, B.I. Carboxymethyl Guar Gum Nanoparticles for Drug Delivery Applications: Preparation and Preliminary in-Vitro Investigations. Mater. Sci. Eng. C 2016, 63, 628–636. [Google Scholar] [CrossRef]

- Das, A.; Das, A.; Basu, A.; Datta, P.; Gupta, M.; Mukherjee, A. Newer Guar Gum Ester/Chicken Feather Keratin Interact Films for Tissue Engineering. Int. J. Biol. Macromol. 2021, 180, S0141813021005523. [Google Scholar] [CrossRef]

- Mahto, A.; Mishra, S. Design, Development and Validation of Guar Gum Based PH Sensitive Drug Delivery Carrier via Graft Copolymerization Reaction Using Microwave Irradiations. Int. J. Biol. Macromol. 2019, 138, 278–291. [Google Scholar] [CrossRef]

- Su, T.; Wu, L.; Pan, X.; Zhang, C.; Shi, M.; Gao, R.; Qi, X.; Dong, W. Pullulan-Derived Nanocomposite Hydrogels for Wastewater Remediation: Synthesis and Characterization. J. Colloid Interface Sci. 2019, 542, 253–262. [Google Scholar] [CrossRef]

- Uddin, K.M.A.; Ago, M.; Rojas, O.J. Hybrid Films of Chitosan, Cellulose Nanofibrils and Boric Acid: Flame Retardancy, Optical and Thermo-Mechanical Properties. Carbohydr. Polym. 2017, 177, 13–21. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Bian, C.; Zhong, Y.; Jing, X. Effect of Chemical Structure and Cross-Link Density on the Heat Resistance of Phenolic Resin. Polym. Degrad. Stab. 2015, 111, 239–246. [Google Scholar] [CrossRef]

- Kim, J.; Zhang, G.; Shi, M.; Suo, Z. Fracture, Fatigue, and Friction of Polymers in Which Entanglements Greatly Outnumber Cross-Links. Science 2021, 374, 212–216. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Li, Q.; Liu, Y.; Li, J. Ultralight and Highly Flexible Aerogels with Long Cellulose I Nanofibers. Soft Matter 2011, 7, 10360–10368. [Google Scholar] [CrossRef]

- Díez-García, I.; de Costa Lemma, M.R.; Barud, H.S.; Eceiza, A.; Tercjak, A. Hydrogels Based on Waterborne Poly(Urethane-Urea)s by Physically Cross-Linking with Sodium Alginate and Calcium Chloride. Carbohydr. Polym. 2020, 250, 116940. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Souza, B.W.S.; Simões, J.; Teixeira, J.A.; Domingues, M.R.M.; Coimbra, M.A.; Vicente, A.A. Structural and Thermal Characterization of Galactomannans from Non-Conventional Sources. Carbohydr. Polym. 2011, 83, 179–185. [Google Scholar] [CrossRef]

- Fukata, Y.; Kimura, S.; Iwata, T. Synthesis of α-1,3-Glucan Branched Ester Derivatives with Excellent Thermal Stability and Thermoplasticity. Polym. Degrad. Stab. 2020, 177, 109130. [Google Scholar] [CrossRef]

- Yang, B.; Guo, X.; Zang, H.; Liu, J. Determination of Modification Degree in BDDE-Modified Hyaluronic Acid Hydrogel by SEC/MS. Carbohydr. Polym. 2015, 131, 233–239. [Google Scholar] [CrossRef]

- Ruhr, D.; John, M.; Reiche, A. Determination of the Effective Degree of Cross-Linking of Porous Cellulose Membranes Cross-Linked with Bifunctional Epoxides. Carbohydr. Polym. 2021, 251, 117043. [Google Scholar] [CrossRef]

- Chang, C.; Zhang, L.; Zhou, J.; Zhang, L.; Kennedy, J.F. Structure and Properties of Hydrogels Prepared from Cellulose in NaOH/Urea Aqueous Solutions. Carbohydr. Polym. 2010, 82, 122–127. [Google Scholar] [CrossRef]

- Salimi-Kenari, H.; Mollaie, F.; Dashtimoghadam, E.; Imani, M.; Nyström, B. Effects of Chain Length of the Cross-Linking Agent on Rheological and Swelling Characteristics of Dextran Hydrogels. Carbohydr. Polym. 2018, 181, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Roberts, S.A.; Cameron, R.E. The Effects of Concentration and Sodium Hydroxide on the Rheological Properties of Potato Starch Gelatinisation. Carbohydr. Polym. 2002, 50, 133–143. [Google Scholar] [CrossRef]

- Berglund, J.; Azhar, S.; Lawoko, M.; Lindström, M.; Vilaplana, F.; Wohlert, J.; Henriksson, G. The Structure of Galactoglucomannan Impacts the Degradation under Alkaline Conditions. Cellulose 2019, 26, 2155–2175. [Google Scholar] [CrossRef]

- Haseeb, M.T.; Hussain, M.A.; Yuk, S.H.; Bashir, S.; Nauman, M. Polysaccharides Based Superabsorbent Hydrogel from Linseed: Dynamic Swelling, Stimuli Responsive on–off Switching and Drug Release. Carbohydr. Polym. 2016, 136, 750–756. [Google Scholar] [CrossRef]

- Patra, P.; Patra, N.; Pal, S. Opposite Swelling Characteristics through Changing the Connectivity in a Biopolymeric Hydrogel Based on Glycogen and Glycine. Polym. Chem. 2020, 11, 2630–2634. [Google Scholar] [CrossRef]

- El-Naggar, M.E.; Othman, S.I.; Allam, A.A.; Morsy, O.M. Synthesis, Drying Process and Medical Application of Polysaccharide-Based Aerogels. Int. J. Biol. Macromol. 2020, 145, 1115–1128. [Google Scholar] [CrossRef]

- Ciftci, D.; Ubeyitogullari, A.; Huerta, R.R.; Ciftci, O.N.; Flores, R.A.; Saldaña, M.D.A. Lupin Hull Cellulose Nanofiber Aerogel Preparation by Supercritical CO2 and Freeze Drying. J. Supercrit. Fluids 2017, 127, 137–145. [Google Scholar] [CrossRef]

- Gharekhani, H.; Olad, A.; Mirmohseni, A.; Bybordi, A. Superabsorbent Hydrogel Made of NaAlg-g-Poly(AA-Co-AAm) and Rice Husk Ash: Synthesis, Characterization, and Swelling Kinetic Studies. Carbohydr. Polym. 2017, 168, 1–13. [Google Scholar] [CrossRef]

- Li, H.-X.; Wang, Q.; Zhang, L.; Tian, X.; Cao, Q.; Jin, L. Influence of the Degrees of Polymerization of Cellulose on the Water Absorption Performance of Hydrogel and Adsorption Kinetics. Polym. Degrad. Stab. 2019, 168, 108958. [Google Scholar] [CrossRef]

- Tan, T.; Zhou, J.; Gao, X.; Tang, X.; Zhang, H. Synthesis, Characterization and Water-Absorption Behavior of Tartaric Acid-Modified Cellulose Gel Fromcorn Stalk Pith. Ind. Crops Prod. 2021, 169, 113641. [Google Scholar] [CrossRef]

- Cheng, S.; Liu, X.; Zhen, J.; Lei, Z. Preparation of Superabsorbent Resin with Fast Water Absorption Rate Based on Hydroxymethyl Cellulose Sodium and Its Application. Carbohydr. Polym. 2019, 225, 115214. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Pandey, S.; Arotiba, O.A. Development of a Sodium Alginate-Based Organic/Inorganic Superabsorbent Composite Hydrogel for Adsorption of Methylene Blue. Carbohydr. Polym. 2016, 153, 34–46. [Google Scholar] [CrossRef] [PubMed]

- da Silva Fernandes, R.; Tanaka, F.N.; de Moura, M.R.; Aouada, F.A. Development of Alginate/Starch-Based Hydrogels Crosslinked with Different Ions: Hydrophilic, Kinetic and Spectroscopic Properties. Mater. Today Commun. 2019, 21, 100636. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, Y.; Xie, Z.; Wang, T.; Lu, J.; Li, P.; Jiang, J. Characterization of Cross-Linking in Guar Gum Hydrogels via the Analysis of Thermal Decomposition Behavior and Water Uptake Kinetics. Sustainability 2023, 15, 9778. https://doi.org/10.3390/su15129778

Lan Y, Xie Z, Wang T, Lu J, Li P, Jiang J. Characterization of Cross-Linking in Guar Gum Hydrogels via the Analysis of Thermal Decomposition Behavior and Water Uptake Kinetics. Sustainability. 2023; 15(12):9778. https://doi.org/10.3390/su15129778

Chicago/Turabian StyleLan, Yanjiao, Zhoujian Xie, Ting Wang, Jianfang Lu, Pengfei Li, and Jianxin Jiang. 2023. "Characterization of Cross-Linking in Guar Gum Hydrogels via the Analysis of Thermal Decomposition Behavior and Water Uptake Kinetics" Sustainability 15, no. 12: 9778. https://doi.org/10.3390/su15129778

APA StyleLan, Y., Xie, Z., Wang, T., Lu, J., Li, P., & Jiang, J. (2023). Characterization of Cross-Linking in Guar Gum Hydrogels via the Analysis of Thermal Decomposition Behavior and Water Uptake Kinetics. Sustainability, 15(12), 9778. https://doi.org/10.3390/su15129778