Green Supply Chains and Digital Supply Chains: Identifying Overlapping Areas

Abstract

1. Introduction

2. Background

2.1. Green Supply Chains

2.2. Digital Technologies and Industry 4.0

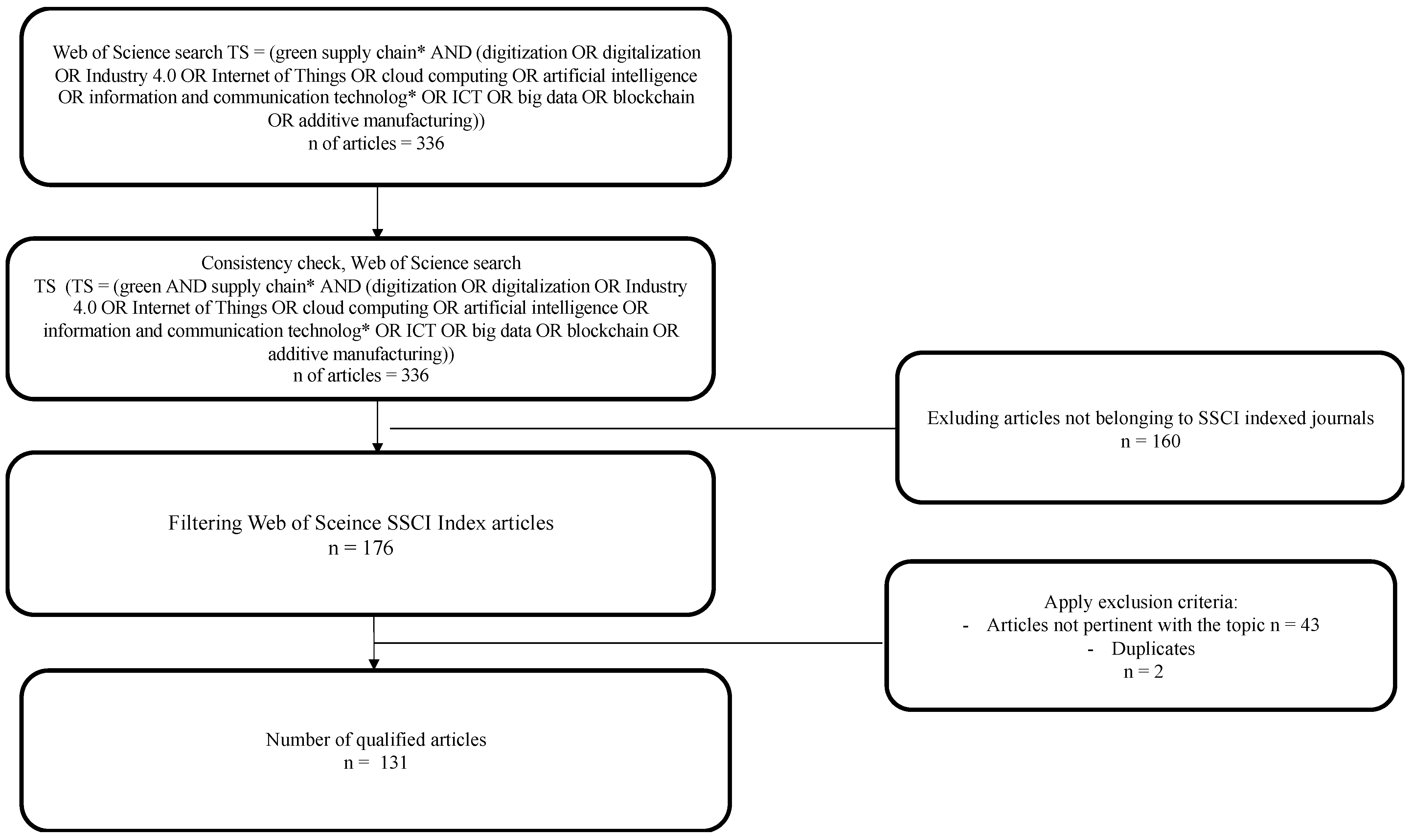

3. Methodology

4. Results

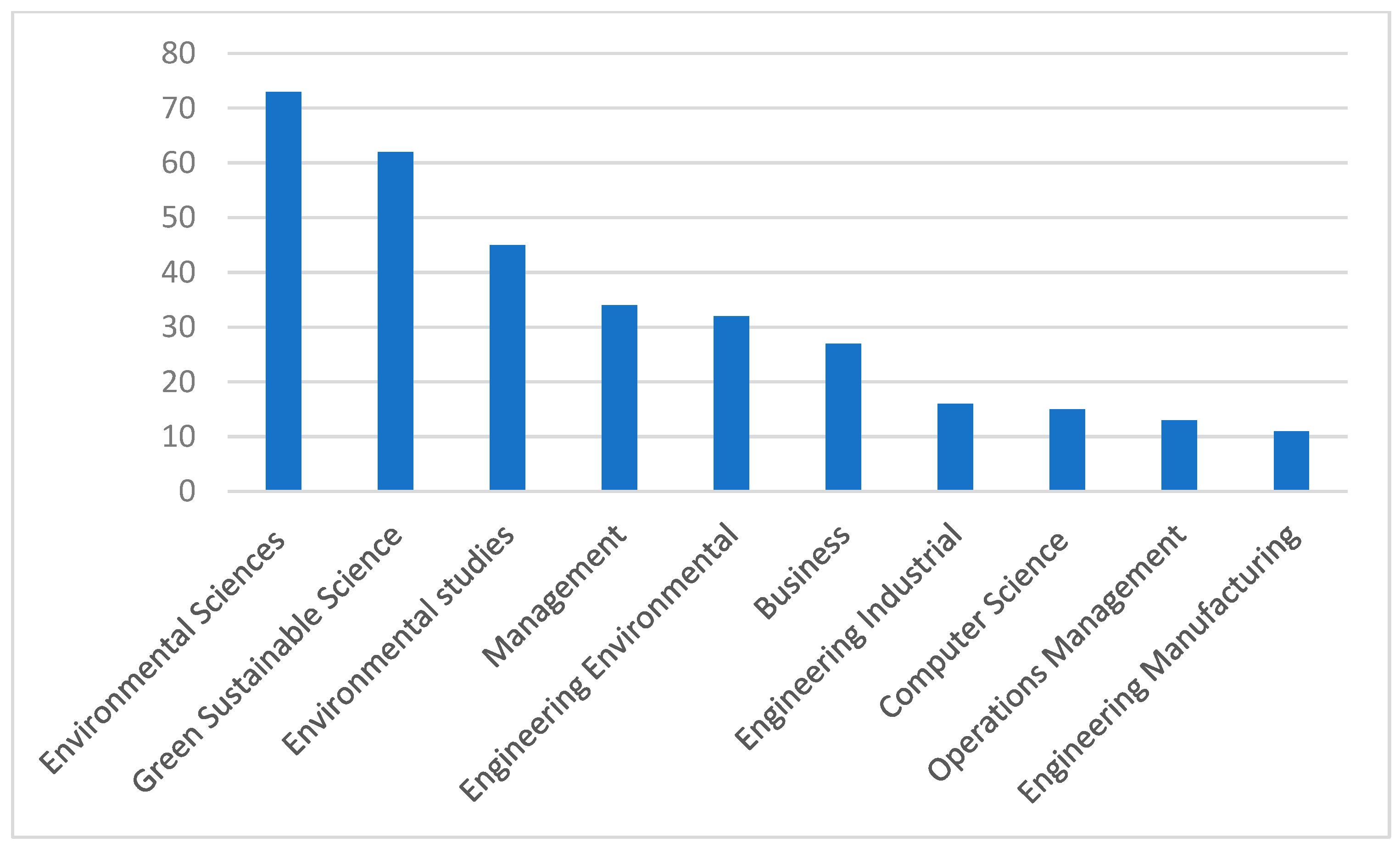

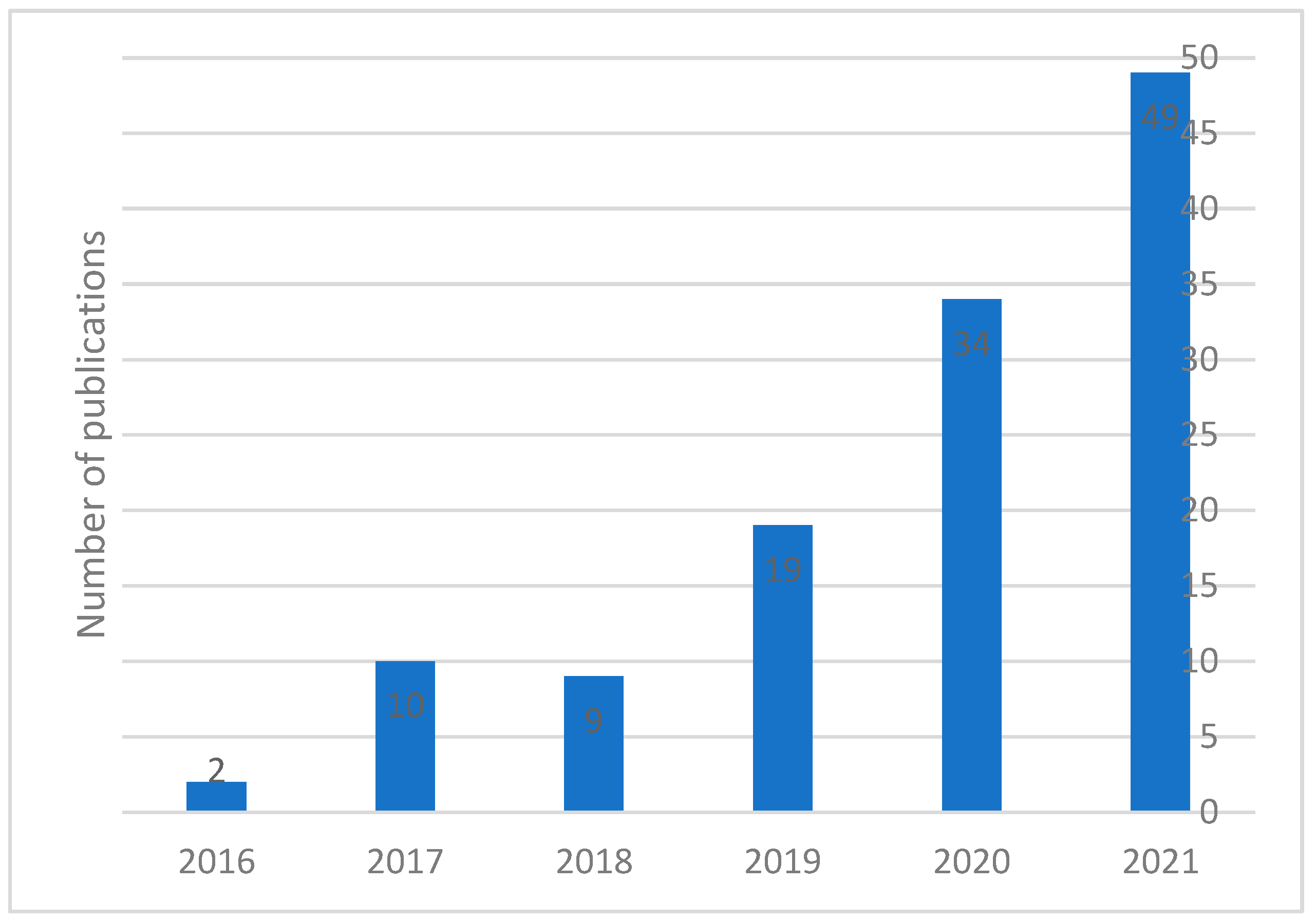

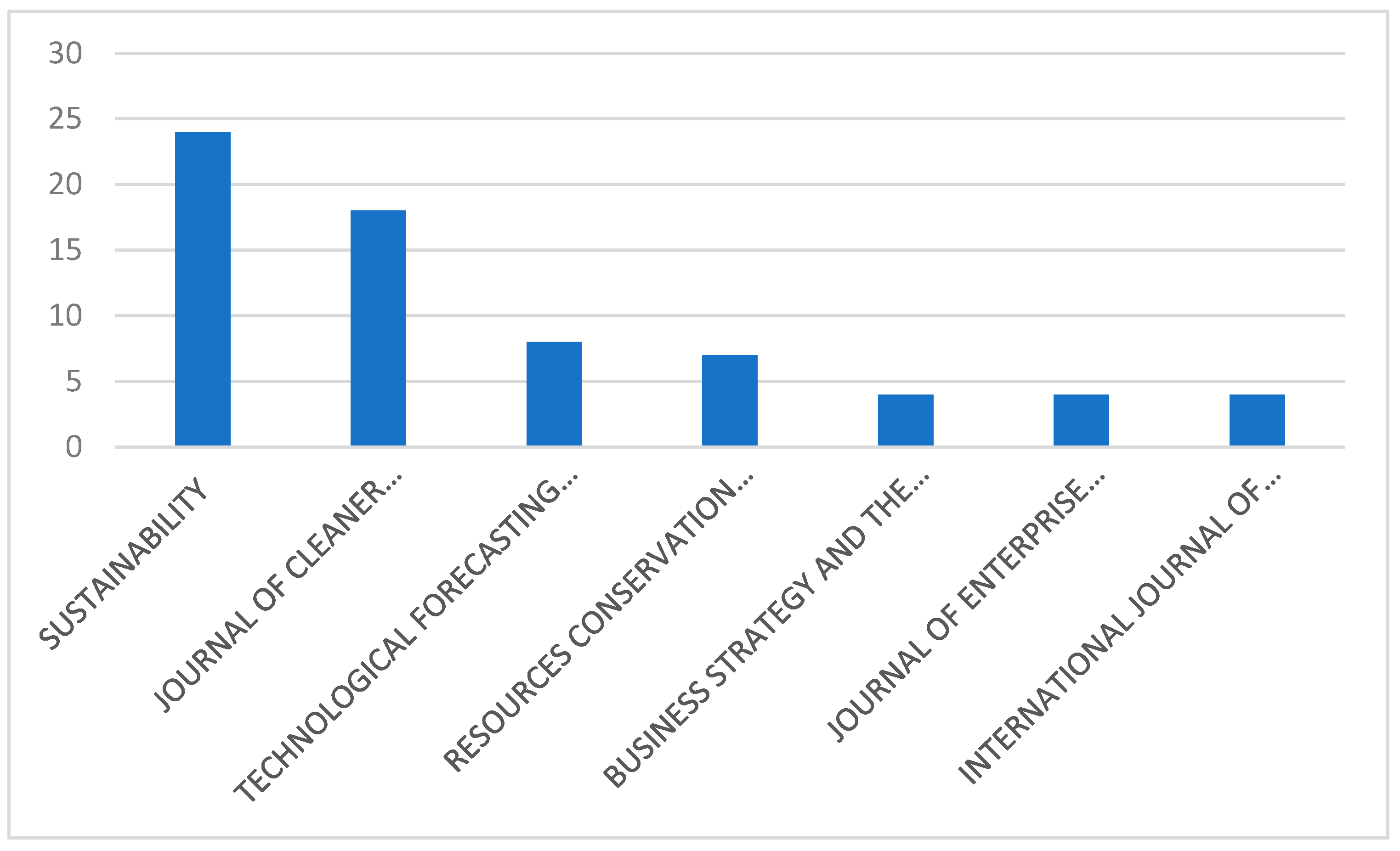

4.1. Descriptive Statistics

4.2. Bibliographic Coupling Map

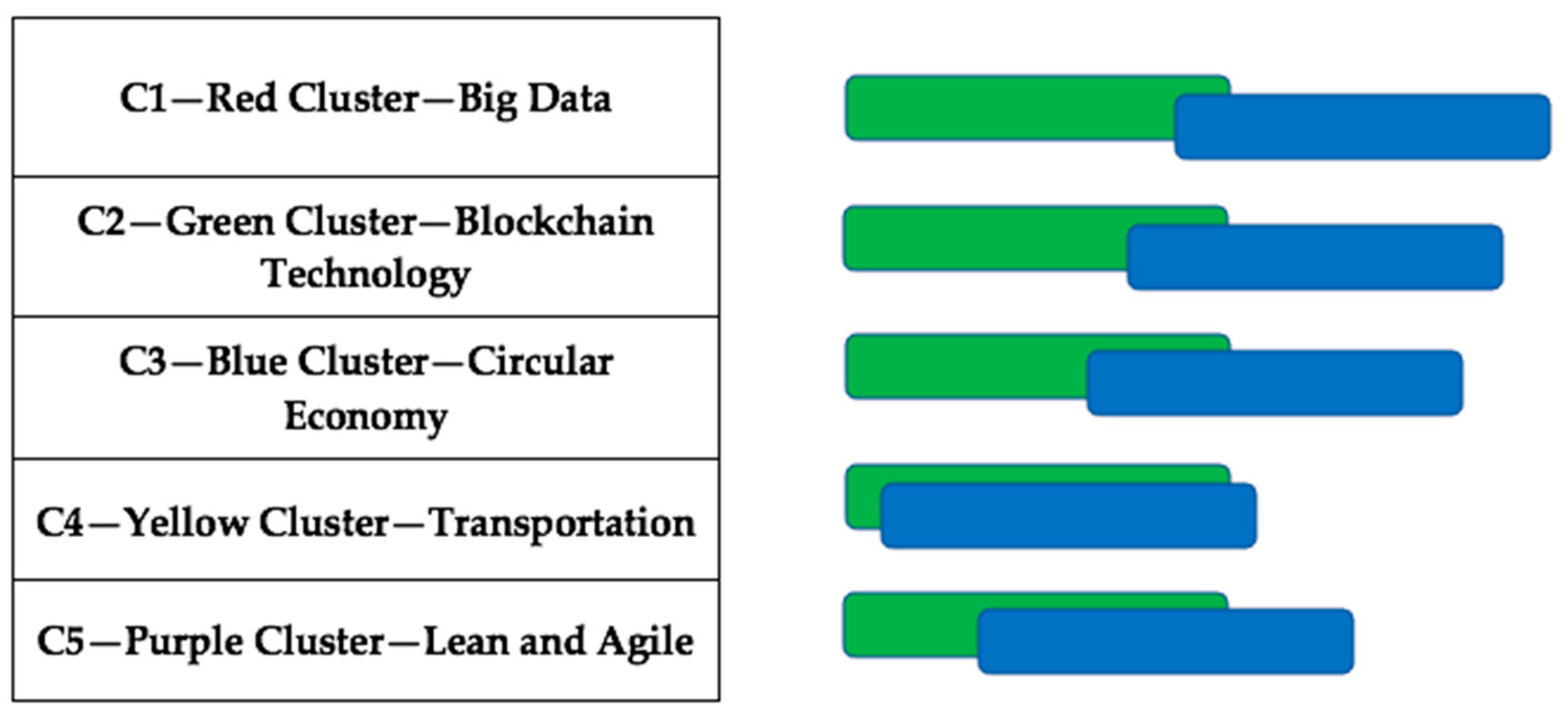

4.2.1. Cluster 1—Red Cluster—Big Data

4.2.2. Cluster 2—Green Cluster—Blockchain Technology

4.2.3. Cluster 3—Blue Cluster—Circular Economy

4.2.4. Cluster 4—Yellow Cluster—Transportation

4.2.5. Cluster 5—Purple Cluster—Lean and Agile Approaches

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azevedo, S.G.; Pimentel, C.M.O.; Alves, A.C.; Matias, J.C.O. Support of Advanced Technologies in Supply Chain Processes and Sustainability Impact. Appl. Sci. 2021, 11, 3026. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Foray, D.; Mowery, D.C.; Nelson, R.R. Public R & D and social challenges: What lessons from mission R & D programs? Res. Policy 2012, 41, 1697–1792. [Google Scholar] [CrossRef]

- Acciarini, C.; Borelli, F.; Capo, F.; Cappa, F.; Sarrocco, C. Can digitalization favour the emergence of innovative and sustainable business models? A qualitative exploration in the automotive sector. J. Strat. Manag. 2022, 15, 335–352. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital supply chain: Challenges and future directions. Supply Chain Forum Int. J. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Cammarano, A.; Varriale, V.; Michelino, F.; Caputo, M. The importance of possessing knowledge on black-box components: The case of smartphone OEMs. J. Eng. Technol. Manag. 2023, 67, 101727. [Google Scholar] [CrossRef]

- Cammarano, A.; Varriale, V.; Michelino, F.; Caputo, M. A Patent-Based Tool to Support Component Suppliers Assessment in the Smartphone Supply Chain. IEEE Trans. Eng. Manag. 2021, 1–18. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing supply chain digitalization and unphysicalization to enhance supply chain performance: A conceptual framework. Int. J. Phys. Distrib. Logist. Manag. 2023. ahead of print. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2018, 57, 829–846. [Google Scholar] [CrossRef]

- Cammarano, A.; Varriale, V.; Michelino, F.; Caputo, M. A Framework for Investigating the Adoption of Key Technologies: Presentation of the Methodology and Explorative Analysis of Emerging Practices. IEEE Trans. Eng. Manag. 2023, 1–24. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Lawson, B.; Pil, F.K.; Wagner, S.M. The digitalization of operations and supply chain management: Theoretical and methodological implications. J. Oper. Manag. 2019, 65, 728–734. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Information and digital technologies of Industry 4.0 and Lean supply chain management: A systematic literature review. Int. J. Prod. Res. 2020, 58, 5034–5061. [Google Scholar] [CrossRef]

- Zeng, F.; Lee, S.H.N.; Lo, C.K.Y. The Role of Information Systems in the Sustainable Development of Enterprises: A Systematic Literature Network Analysis. Sustainability 2020, 12, 3337. [Google Scholar] [CrossRef]

- Aryal, A.; Liao, Y.; Nattuthurai, P.; Li, B. The emerging big data analytics and IoT in supply chain management: A systematic review. Supply Chain Manag. Int. J. 2020, 25, 141–156. [Google Scholar] [CrossRef]

- Cammarano, A.; Varriale, V.; Michelino, F.; Caputo, M. Blockchain as enabling factor for implementing RFID and IoT technologies in VMI: A simulation on the Parmigiano Reggiano supply chain. Oper. Manag. Res. 2022, 1–29. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable Supply Chains with Blockchain, IoT and RFID: A Simulation on Order Management. Sustainability 2021, 13, 6372. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Telles, R.; Bonilla, S.H. Blockchain and supply chain management integration: A systematic review of the literature. Supply Chain Manag. Int. J. 2020, 25, 241–254. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. New organizational changes with blockchain: A focus on the supply chain. J. Organ. Chang. Manag. 2021, 34, 420–438. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. The Unknown Potential of Blockchain for Sustainable Supply Chains. Sustainability 2020, 12, 9400. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transp. Res. Part D Transp. Environ. 2017, 53, 454–470. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro Da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2019, 58, 1462–1484. [Google Scholar] [CrossRef]

- Sun, X.; Yu, H.; Solvang, W.D.; Wang, Y.; Wang, K. The application of Industry 4.0 technologies in sustainable logistics: A systematic literature review (2012–2020) to explore future research opportunities. Environ. Sci. Pollut. Res. Springer Sci. Bus. Media Dtschl. 2022, 29, 9560–9591. [Google Scholar] [CrossRef] [PubMed]

- Touriki, F.E.; Benkhati, I.; Kamble, S.S.; Belhadi, A.; El Fezazi, S. An integrated smart, green, resilient, and lean manufacturing framework: A literature review and future research directions. J. Clean. Prod. 2021, 319, 128691. [Google Scholar] [CrossRef]

- Galvagno, M. Bibliometric literature review: An opportunity for marketing scholars. Mercat. Compet. 2017, 4, 7–15. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- De Giovanni, P.; Vinzi, V.E. The benefits of a monitoring strategy for firms subject to the Emissions Trading System. Transp. Res. Part D Transp. Environ. 2014, 33, 220–233. [Google Scholar] [CrossRef]

- Gorane, S.; Kant, R. Supply chain practices and organizational performance: An empirical investigation of Indian manufacturing organizations. Int. J. Logist. Manag. 2017, 28, 75–101. [Google Scholar] [CrossRef]

- Green, K.W.; Toms, L.C.; Clark, J.H. Impact of market orientation on environmental sustainability strategy. Manag. Res. Rev. 2015, 38, 217–238. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Gangwani, K.K. Green supply chain management: Scientometric review and analysis of empirical research. J. Clean. Prod. 2021, 284, 124722. [Google Scholar] [CrossRef]

- Cammarano, A.; Perano, M.; Michelino, F.; Del Regno, C.; Caputo, M. SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution. Sustainability 2022, 14, 1325. [Google Scholar] [CrossRef]

- de Oliveira, U.R.; Espindola, L.S.; da Silva, I.R.; da Silva, I.N.; Rocha, H.M. A systematic literature review on green supply chain management: Research implications and future perspectives. J. Clean. Prod. 2018, 187, 537–561. [Google Scholar] [CrossRef]

- De Giovanni, P.; Cariola, A. Process innovation through industry 4.0 technologies, lean practices and green supply chains. Res. Transp. Econ. 2021, 90, 100869. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Sarkis, J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2019, 57, 1990–2008. [Google Scholar] [CrossRef]

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- BCG. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; BCG: Boston, MA, USA, 2015. [Google Scholar]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Acciarini, C.; Cappa, F.; Boccardelli, P.; Oriani, R. How can organizations leverage big data to innovate their business models? A systematic literature review. Technovation 2023, 123, 102713. [Google Scholar] [CrossRef]

- Cappa, F.; Oriani, R.; Peruffo, E.; McCarthy, I. Big Data for Creating and Capturing Value in the Digitalized Environment: Unpacking the Effects of Volume, Variety, and Veracity on Firm Performance. J. Prod. Innov. Manag. 2020, 38, 49–67. [Google Scholar] [CrossRef]

- Chalmeta, R.; Santos-Deleón, N.J. Sustainable Supply Chain in the Era of Industry 4.0 and Big Data: A Systematic Analysis of Literature and Research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Cappa, F.; Pinelli, M. Collecting money through blockchain technologies: First insights on the determinants of the return on Initial Coin Offerings. Inf. Technol. Dev. 2020, 27, 561–578. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Sun, E.W.; Chang, M.-F.; Lin, Y.-B. Pragmatic real-time logistics management with traffic IoT infrastructure: Big data predictive analytics of freight travel time for Logistics 4.0. Int. J. Prod. Econ. 2021, 238, 108157. [Google Scholar] [CrossRef]

- De Giovanni, P.; Belvedere, V.; Grando, A. The Selection of Industry 4.0 Technologies Through Bayesian Networks: An Operational Perspective. IEEE Trans. Eng. Manag. 2022, 1–16. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Cámara, S.B.; Fuentes, J.M.; Marín, J.M.M. Cloud computing, Web 2.0, and operational performance: The mediating role of supply chain integration. Int. J. Logist. Manag. 2015, 26, 426–458. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australas. J. Inf. Syst. 2018, 22, 1734. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Vergara, A.M.C.; Garza-Reyes, J.A.; Sawhney, R. Organizational learning paths based upon industry 4.0 adoption: An empirical study with Brazilian manufacturers. Int. J. Prod. Econ. 2020, 219, 284–294. [Google Scholar] [CrossRef]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Waltman, L.; van Eck, N.J.; Noyons, E.C.M. A unified approach to mapping and clustering of bibliometric networks. J. Informetr. 2010, 4, 629–635. [Google Scholar] [CrossRef]

- van Oorschot, J.A.; Hofman, E.; Halman, J.I. A bibliometric review of the innovation adoption literature. Technol. Forecast. Soc. Chang. 2018, 134, 1–21. [Google Scholar] [CrossRef]

- D’Angelo, V.; Magnusson, M. A Bibliometric Map of Intellectual Communities in Frugal Innovation Literature. IEEE Trans. Eng. Manag. 2021, 68, 653–666. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 2017, 111, 1053–1070. [Google Scholar] [CrossRef]

- Budler, M.; Župič, I.; Trkman, P. The development of business model research: A bibliometric review. J. Bus. Res. 2021, 135, 480–495. [Google Scholar] [CrossRef]

- Van der Have, R.P.; Rubalcaba, L. Social innovation research: An emerging area of innovation studies? Res. Policy 2016, 45, 1923–1935. [Google Scholar] [CrossRef]

- Kessler, M.M. Bibliographic coupling between scientific papers. Am. Doc. 1963, 14, 10–25. [Google Scholar] [CrossRef]

- Appio, F.P.; Cesaroni, F.; Di Minin, A. Visualizing the structure and bridges of the intellectual property management and strategy literature: A document co-citation analysis. Scientometrics 2014, 101, 623–661. [Google Scholar] [CrossRef]

- Ardito, L.; Scuotto, V.; Del Giudice, M.; Petruzzelli, A.M. A bibliometric analysis of research on Big Data analytics for business and management. Manag. Decis. 2018, 57, 1993–2009. [Google Scholar] [CrossRef]

- David, R.J.; Han, S.-K. A systematic assessment of the empirical support for transaction cost economics. Strateg. Manag. J. 2004, 25, 39–58. [Google Scholar] [CrossRef]

- Di Stefano, G.; Peteraf, M.; Verona, G. Dynamic capabilities deconstructed: A bibliographic investigation into the origins, development, and future directions of the research domain. Ind. Corp. Chang. 2010, 19, 1187–1204. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, N.; Huang, T. An optimization model for green supply chain management by using a big data analytic approach. J. Clean. Prod. 2017, 142, 1085–1097. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking big data analytics and operational sustainability practices for sustainable business management. J. Clean. Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Lim, M.K.; Hu, J.; Tan, K. Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. J. Clean. Prod. 2017, 142, 663–676. [Google Scholar] [CrossRef]

- Xiang, Z.; Xu, M. Dynamic game strategies of a two-stage remanufacturing closed-loop supply chain considering Big Data marketing, technological innovation and overconfidence. Comput. Ind. Eng. 2020, 145, 106538. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Hales, D.N. Cloud computing and its impact on economic and environmental performance: A transaction cost economics perspective. Decis. Support Syst. 2016, 86, 73–82. [Google Scholar] [CrossRef]

- Singh, S.K.; El-Kassar, A.-N. Role of big data analytics in developing sustainable capabilities. J. Clean. Prod. 2019, 213, 1264–1273. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green sourcing in the era of industry 4.0: Towards green and digitalized competitive advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Liu, S.; Hu, Y.; Zhang, Y. Supply Chain Partner Selection under Cloud Computing Environment: An Improved Approach Based on BWM and VIKOR. Math. Probl. Eng. 2018, 2018, 7012827. [Google Scholar] [CrossRef]

- Allaoui, H.; Guo, Y.; Sarkis, J. Decision support for collaboration planning in sustainable supply chains. J. Clean. Prod. 2019, 229, 761–774. [Google Scholar] [CrossRef]

- Adjei-Bamfo, P.; Maloreh-Nyamekye, T.; Ahenkan, A. The role of e-government in sustainable public procurement in developing countries: A systematic literature review. Resour. Conserv. Recycl. 2019, 142, 189–203. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Ionescu, L.; Uță, C.; Hurloiu, I.; Andronie, M.; Dijmărescu, I. Environmentally Responsible Behavior and Sustainability Policy Adoption in Green Public Procurement. Sustainability 2020, 12, 2110. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Khan, M.; Ajmal, M.M. The role of big data analytics capabilities in greening e-procurement: A higher order PLS-SEM analysis. Technol. Forecast. Soc. Chang. 2021, 169, 120808. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S.; Sivarajah, U. Role of technological dimensions of green supply chain management practices on firm performance. J. Enterp. Inf. Manag. 2020, 34, 1–27. [Google Scholar] [CrossRef]

- Shafique, M.N.; Khurshid, M.M.; Rahman, H.; Khanna, A.; Gupta, D.; Rodrigues, J.J.P.C. The Role of Wearable Technologies in Supply Chain Collaboration: A Case of Pharmaceutical Industry. IEEE Access 2019, 7, 49014–49026. [Google Scholar] [CrossRef]

- Shafique, M.N.; Rashid, A.; Bajwa, I.S.; Kazmi, R.; Khurshid, M.M.; Tahir, W.A. Effect of IoT Capabilities and Energy Consumption behavior on Green Supply Chain Integration. Appl. Sci. 2018, 8, 2481. [Google Scholar] [CrossRef]

- Forza, C. Survey research in operations management: A process-based perspective. Int. J. Oper. Prod. Manag. 2002, 22, 152–194. [Google Scholar] [CrossRef]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411–423. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Sarkis, J. Blockchain Practices, Potentials, and Perspectives in Greening Supply Chains. Sustainability 2018, 10, 3652. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Tan, B.Q.; Wang, F.; Liu, J.; Kang, K.; Costa, F. A Blockchain-Based Framework for Green Logistics in Supply Chains. Sustainability 2020, 12, 4656. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Sarwat, S.; Godil, D.I.; Amin, S.; Shujaat, S. The role of block chain technology in circular economy practices to improve organisational performance. Int. J. Logist. Res. Appl. 2021, 25, 605–622. [Google Scholar] [CrossRef]

- Ahmadi, S.; Shokouhyar, S.; Shahidzadeh, M.H.; Papageorgiou, I.E. The bright side of consumers’ opinions of improving reverse logistics decisions: A social media analytic framework. Int. J. Logist. Res. Appl. 2020, 25, 977–1010. [Google Scholar] [CrossRef]

- Bányai, T.; Tamás, P.; Illés, B.; Stankevičiūtė, Ž.; Bányai, Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. Int. J. Environ. Res. Public Health 2019, 16, 634. [Google Scholar] [CrossRef] [PubMed]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Wood, L.C.; Dhamija, P.; Joshi, S. Industry 4.0 and the circular economy: Resource melioration in logistics. Resour. Policy 2020, 68, 101776. [Google Scholar] [CrossRef]

- Govindan, K.; Gholizadeh, H. Robust network design for sustainable-resilient reverse logistics network using big data: A case study of end-of-life vehicles. Transp. Res. Part E Logist. Transp. Rev. 2021, 149, 102279. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy, Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Wight, UK, 2012. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Bag, S.; Dhamija, P.; Bryde, D.J.; Singh, R.K. Effect of eco-innovation on green supply chain management, circular economy capability, and performance of small and medium enterprises. J. Bus. Res. 2022, 141, 60–72. [Google Scholar] [CrossRef]

- Ersoy, P.; Börühan, G.; Mangla, S.K.; Hormazabal, J.H.; Kazancoglu, Y.; Lafcı, Ç. Impact of information technology and knowledge sharing on circular food supply chains for green business growth. Bus. Strat. Environ. 2022, 31, 1875–1904. [Google Scholar] [CrossRef]

- Wang, Y.; Coe, N.M. Platform ecosystems and digital innovation in food retailing: Exploring the rise of Hema in China. Geoforum 2021, 126, 310–321. [Google Scholar] [CrossRef]

- Bird, R.; Hall, A.D.; Momentè, F.; Reggiani, F. What Corporate Social Responsibility Activities are Valued by the Market? J. Bus. Ethic. 2007, 76, 189–206. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Zacharia, Z.G.; Swami, S. Supply chain resilience for managing the ripple effect in Industry 4.0 for green product diffusion. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 897–930. [Google Scholar] [CrossRef]

- Nimawat, D.; Gidwani, B.D. Prioritization of barriers for Industry 4.0 adoption in the context of Indian manufacturing industries using AHP and ANP analysis. Int. J. Comput. Integr. Manuf. 2021, 34, 1139–1161. [Google Scholar] [CrossRef]

- Saraji, M.K.; Streimikiene, D.; Kyriakopoulos, G.L. Fermatean Fuzzy CRITIC-COPRAS Method for Evaluating the Challenges to Industry 4.0 Adoption for a Sustainable Digital Transformation. Sustainability 2021, 13, 9577. [Google Scholar] [CrossRef]

- Gale, F.; Ascui, F.; Lovell, H. Sensing Reality? New Monitoring Technologies for Global Sustainability Standards. Glob. Environ. Politics 2017, 17, 65–83. [Google Scholar] [CrossRef]

- Mckinnon, A.; Cullinane, S.; Browne, M.; Whiteing, A. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page Publishers: London, UK, 2015. [Google Scholar]

- Miklautsch, P.; Woschank, M. A framework of measures to mitigate greenhouse gas emissions in freight transport: Systematic literature review from a Manufacturer’s perspective. J. Clean. Prod. 2022, 366, 132883. [Google Scholar] [CrossRef]

- Pan, S.; Trentesaux, D.; Ballot, E.; Huang, G.Q. Horizontal collaborative transport: Survey of solutions and practical implementation issues. Int. J. Prod. Res. 2019, 57, 5340–5361. [Google Scholar] [CrossRef]

- Chung, S.-H. Applications of smart technologies in logistics and transport: A review. Transp. Res. Part E Logist. Transp. Rev. 2021, 153, 102455. [Google Scholar] [CrossRef]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2021, 34, 139–158. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2019, 58, 1644–1661. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Hajmohammad, S.; Vachon, S.; Klassen, R.D.; Gavronski, I. Lean management and supply management: Their role in green practices and performance. J. Clean. Prod. 2013, 39, 312–320. [Google Scholar] [CrossRef]

- Hallam, C.; Contreras, C. Integrating lean and green management. Manag. Decis. 2016, 54, 2157–2187. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Garza-Reyes, J.A.; Cherrafi, A.; Lameijer, B. Integrated green lean approach and sustainability for SMEs: From literature review to a conceptual framework. J. Clean. Prod. 2019, 240, 118205. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Govindan, K.; Garza-Reyes, J.A.; Lameijer, B.; Samadhiya, A. A framework for the systematic implementation of Green-Lean and sustainability in SMEs. Prod. Plan. Control 2022, 1–19. [Google Scholar] [CrossRef]

- Fu, H.-P.; Chang, T.-S.; Yeh, H.-P.; Chen, Y.-X. Analysis of Factors Influencing Hospitals’ Implementation of a Green E-Procurement System Using a Cloud Model. Int. J. Environ. Res. Public Health 2019, 16, 5137. [Google Scholar] [CrossRef]

- Su, Y.; Yu, Y.; Zhang, N. Carbon emissions and environmental management based on Big Data and Streaming Data: A bibliometric analysis. Sci. Total. Environ. 2020, 733, 138984. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Y.; Zhang, N. Sustainable supply chain management under big data: A bibliometric analysis. J. Enterp. Inf. Manag. 2020, 34, 427–445. [Google Scholar] [CrossRef]

| Cluster | No. of Articles | Methodology |

|---|---|---|

| C1—Red Cluster—Big Data | 54 | survey |

| C2—Green Cluster—Blockchain Technology | 41 | mathematical modeling |

| C3—Blue Cluster—Circular Economy | 29 | mathematical modeling |

| C4—Yellow Cluster—Transportation | 4 | mathematical modeling |

| C5—Purple Cluster—Lean and Agile | 3 | case studies |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Angelo, V.; Belvedere, V. Green Supply Chains and Digital Supply Chains: Identifying Overlapping Areas. Sustainability 2023, 15, 9828. https://doi.org/10.3390/su15129828

D’Angelo V, Belvedere V. Green Supply Chains and Digital Supply Chains: Identifying Overlapping Areas. Sustainability. 2023; 15(12):9828. https://doi.org/10.3390/su15129828

Chicago/Turabian StyleD’Angelo, Viviana, and Valeria Belvedere. 2023. "Green Supply Chains and Digital Supply Chains: Identifying Overlapping Areas" Sustainability 15, no. 12: 9828. https://doi.org/10.3390/su15129828

APA StyleD’Angelo, V., & Belvedere, V. (2023). Green Supply Chains and Digital Supply Chains: Identifying Overlapping Areas. Sustainability, 15(12), 9828. https://doi.org/10.3390/su15129828