1. Introduction

Industry 4.0 was theorised with the aim of making companies technologically competitive in order to ensure their future and present survival. The term Industry 4.0 was first used in Germany in 2011 to support automation in the manufacturing sector [

1]. This paradigm aims to integrate new production technologies to support working conditions, create new business models and increase the productivity and quality of industrial plants. Today, there are several technologies, such as blockchain, Internet of Things (IoT), additive manufacturing and artificial intelligence (AI), that can radically change traditional manufacturing processes and supply chain management (SCM) [

2,

3]. In this context, recent social, economic and political evolutions have highlighted the need to accelerate digital transformation to improve the sustainable development of companies [

4,

5]. Indeed, sustainability has become a fundamental prerogative in business strategy, products and processes [

6]. The goals set by the United Nations 2030 Agenda have highlighted that sustainable development is no longer an option, but rather necessary for the survival of organisations and communities [

7]. Recently, Industry 4.0 and sustainability issues have been associated, helping SCM scholars and practitioners to develop a more sustainable theorisation and approach to operations management [

8]. In particular, organisations should adopt digital technologies to strengthen their sustainability performance on operations and activities [

9,

10,

11]. In this way, the concept of Industry 5.0 has been theorised by complementing the existing Industry 4.0 approach with the transition towards a sustainable, human-centric and resilient development.

Several studies highlight the potential of digital technologies in SCM operations by analysing specific case studies or pilot projects [

12,

13,

14]. Most of the research on digital transformation in SCM has focused on the design of technology infrastructures and their integration according to Industry 4.0 principles [

15]. In this scenario, sustainability aspects have been less investigated and discussed. Specifically, the potential benefits of adopting digital technologies in SCM are reported by academics [

16,

17], however in a fragmented manner. Indeed, there are studies that focus on the adoption of a single technology in SCM in order to improve sustainability [

18,

19]. Other researchers investigate the adoption of different technologies to evaluate sustainability aspects in a single sector [

20,

21]. Most contributions focus on specific topics, such as the circular economy, lean manufacturing, life cycle assessment or new product development [

22,

23,

24,

25].

Therefore, there is a research gap in the literature of studies that comprehensively analyse sustainable emerging practices based on digital technologies within the SCM. While the potential benefits of integrating digital technologies and SCM have been widely discussed by academics and practitioners [

26], less is known about the current literature on the state of the art and benefits of implementing technologies from a 3BL perspective. Specifically, there are few frameworks in the literature concerning the adoption of technologies that enable sustainable emerging practices in SCM following the Industry 5.0 concepts.

Gaps in the existing literature led to the development of the following research questions that will guide the paper:

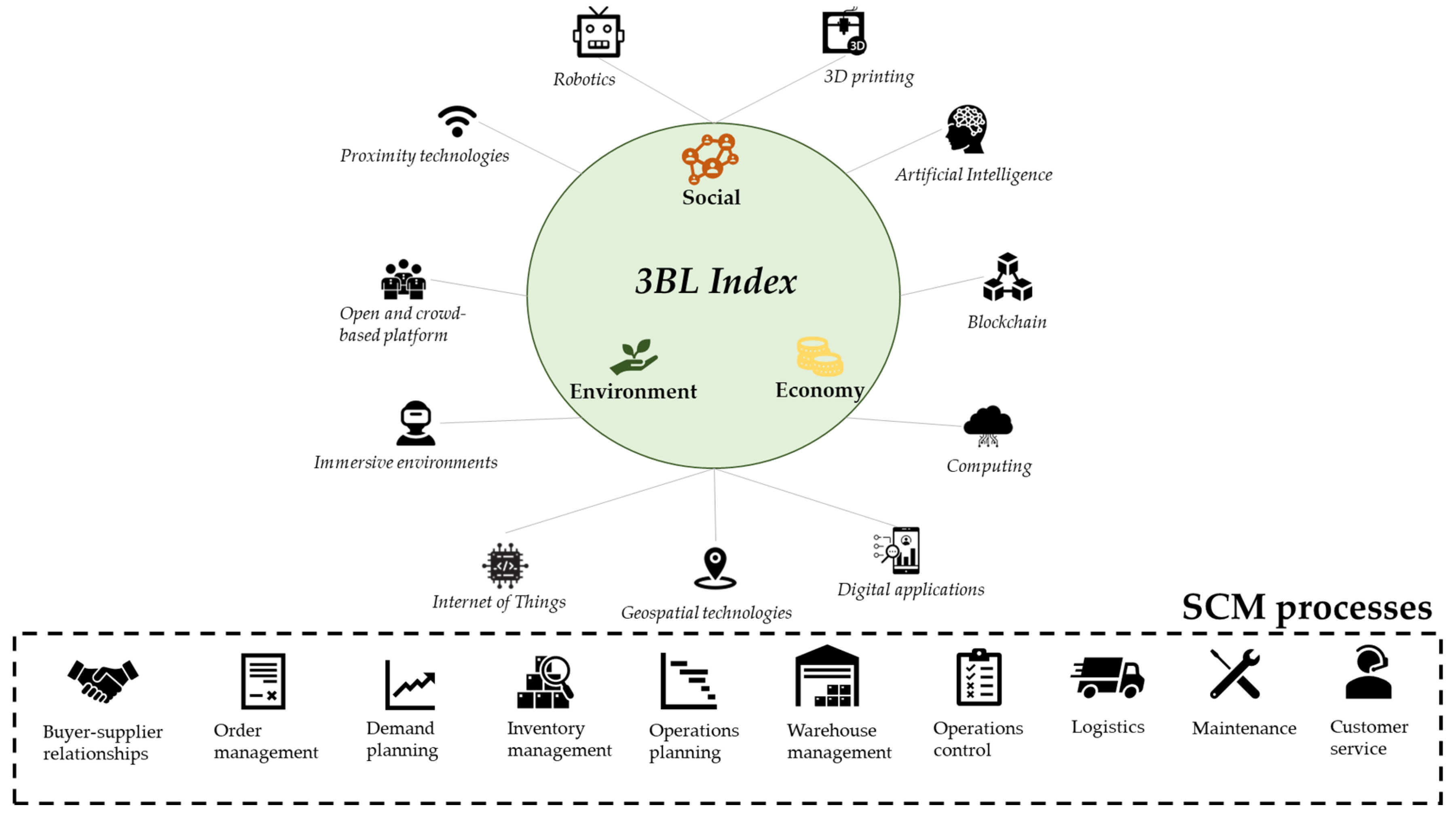

Hence, the purpose of this paper is twofold. Firstly, the work aims to provide a comprehensive understanding of the use of digital technologies to enable sustainable emerging practices in SCM. For this reason, 11 digital technologies were considered: 3D printing, artificial intelligence, blockchain, computing, digital applications, geospatial technologies, IoT, immersive environments, open and crowd-based platforms, proximity technologies and robotics. For each digital technology, sustainable practices have been identified that can be used in SCM, considering the environmental, social and economic dimensions. This outlined the opportunities for implementing digital technologies in the business world. Secondly, the article aims to identify which technologies are most oriented towards sustainable emerging practices in SCM, using a specific indicator (3BL index). This research addresses the lack of studies by analysing several digital technologies simultaneously and their evaluation into specific sustainable business practices for SCM. This study could help organisations to understand which digital technologies might be suitable for their business in order to increase their sustainability performance. To achieve the aim of the article, a systematic literature review (SLR) was conducted to investigate the relationship between Industry 4.0 technologies and sustainability after the 3BL perspective. Specifically, 5011 peer-reviewed scientific articles were analysed and a theoretical framework for sustainable emerging practices based on digital technologies in SCM was proposed.

The document is structured as follows.

Section 2 presents the framework conceptualisation.

Section 3 describes the research methodology adopted.

Section 4 analyses the results of the study. Sustainable emerging practices for each digital technology are described, classifying them according to environmental, social and economic aspects. At the end of this section, the

3BL index is shown clarifying which technologies are most promising to favour sustainable practices in SCM.

Section 5 presents the discussions by outlining theoretical and managerial implications, limitations and potential directions for future research.

Section 6 closes the paper.

2. Framework Conceptualisation

The literature widely discusses how the Industry 4.0 paradigm is mainly driven by the rapid advancement of technological development and productivity improvement [

27]. The basic principle of this theory is to make production systems hyper-connected by sharing devices and machines in order to automate production processes by reducing human intervention [

28]. Industry 4.0 has addressed these challenges through the adoption of various technologies in manufacturing systems and SCM such as AI, cloud computing, robotics, big data, blockchain, virtual reality, 3D printing, blockchain and RFID to focus on the theme of Smart Manufacturing [

29,

30]. Using these technologies, it was possible to reduce logistics and production costs and improve quality management by increasing efficiency and productivity. However, these benefits for the company negatively affect the social dimension of sustainability where there is a higher unemployment rate and a mismatch for the workers’ skills [

31]. Although some scholars believed that Industry 4.0 supported sustainable development at the micro-organisation level (e.g., energy efficiency of transportation and consumed resources), they ignored many other sustainability issues such as the digital gap, autonomy in the workplace and overconsumption of resources [

32,

33]. The European Commission has stated that the Industry 4.0 paradigm cannot be applied for a sustainable industrial transformation and to address the current social, economic and environmental issues. It lacks specific features such as promoting social welfare, improving the circular economy and preventing environmental disasters. This new perspective gave birth to the Industry 5.0 agenda that integrates the technological advantages of Industry 4.0 with the objectives of environmental protection, social and economic development and welfare [

34].

The technological components of Industry 5.0 are the emerging and enabling technologies already present in Industry 4.0. Although these technologies have been used since the third industrial revolution, they can be employed effectively to promote the digital and sustainable transformation of Industry 5.0 [

35]. Several authors have addressed the use of different digital technologies in supply chains and production systems, trying to classify the different opportunities and challenges of implementation [

17,

36,

37,

38]. Starting from previous studies, in which Industry 4.0 technologies were identified and classified [

39,

40,

41], the framework in

Figure 1 was proposed. The technological dimension of Industry 5.0 (i.e., emerging technologies) is combined with the triple bottom line approach (i.e., environmental, social and economic dimensions of sustainable development) by the use of a specific indicator (

3BL index), attempting to identify the opportunities that each technology can bring between economic growth and the preservation of socio-environmental values. In addition, the aim of the work is to investigate the use of these technologies in sustainable business practices in SCM. In the proposed framework, they were intercepted in various areas and supply chain processes to achieve sustainability values such as environmental and social responsibility, green transformation and supply chain transparency and visibility.

4. Results

Table 1 shows the linkage between technologies and sustainability according to 3BL. The starting point of the analysis is the overall number of emerging practices in the sample (EP = 14,707). For each technology

t, the number of examples of emerging practices reporting the focal technology is calculated (EP

t), as well as the ratio of EP

t on EP (%EP

t) that underscores the weight of the focal technology on the entire dataset. A filter on the total sample, considering only sustainable emerging practices (SEP) employing these technologies, identified 2496 elements. This subset is further split into three distinct groups according to the specific dimension of sustainability after the 3BL perspective: environmental sustainability (SEP

env), economic sustainability (SEP

eco) and social sustainability (SEP

soc). Similarly, for each digital technology

t, the count of practices is performed for each sustainability dimension, i.e., environmental (SEP

t,env), economic (SEP

t,eco) and social (SEP

t,soc). Then, it is possible to define the share of each digital technology for each sustainability dimension, %SEP

t,env, %SEP

t,eco and %SEP

t,soc. For instance, %SEP

t,env is the ratio of SEP

t,env on SEP

env.

In the following sections, the opportunities for implementing these digital technologies in SCM with a view to improving sustainability aspects will be described and analysed.

4.1. 3D Printing

3D printing has revolutionised the way in which new components and products are designed and developed. It reduces transport and storage costs, improves last-mile delivery, reduces product development cycles, outsources production costs to the end consumer and decreases CO

2 emissions and energy consumption [

51]. Firstly, these processes save the material used and, secondly, the waste can be reused several times for subsequent prints, reducing the energy impact by 10–12% [

52,

53]. 3D printing reduces energy consumption because it simplifies the process with fewer steps [

54]. In addition, it supports production by using recycled plastic material to produce high-quality parts and minimising the raw material required, e.g., for the production of tyre rubber [

55,

56]. It takes less time to create product prototypes considering the readiness of CAD software. 3D printing processes are applicable to the repair of damaged parts and can extend the life of a component by saving energy and resources compared to the energy required to make new parts [

57]. The main economic advantages of using this technology include the cost reduction of both raw materials and the energy consumed and the time reduction for product development. The social benefits relate to end users being able to purchase digital product data and print the physical version of the product themselves [

51].

Table 2 summarises the sustainable aspects of implementing 3D printing in SCM.

4.2. Artificial Intelligence

Artificial intelligence can be used in different sustainable practices in SCM. Machine learning algorithms are used for the optimisation and reduction of resource consumption using the amount of data available in companies [

61]. For example, natural resources forecasting tools have gained significant value in recent decades. The whole logistical process remains very expensive due to their storage. Any difference between the volume ordered and the actual consumption leads to significant losses for companies. Therefore, machine learning techniques could support these activities through predictive models [

62]. Furthermore, these techniques can be used for predictive maintenance for the machinery used [

63]. For example, data on machine performance and maintenance can be collected and machine learning techniques can react promptly to the slightest anomaly; this increases the life cycle of machines, providing greater control over them and their systems [

64].

To improve the environmental conditions of the workplace during the logistics activities of workers, data on human behaviour can be collected using smart environmental sensors. Thus, machine learning techniques can analyse this data to investigate the effect on employee productivity, well-being, fatigue and safety [

65]. This could be helpful for managers in planning logistics activities and designing warehouse facilities to achieve higher overall performance and guarantee worker safety and well-being [

66]. AI is often used to provide logistics companies with optimal global solutions for pick-up and delivery routing, thus improving distribution synchronisation in collaboration with other partners [

67]. Specific AI models can be employed to build predictive modelling to determine variations in electric vehicle consumption with the aim of helping logistics and supply chain decision-makers interested in reducing environmental impacts [

68]. Particular meta-heuristic algorithms can limit the maximum allowed continuous driving time by introducing a predefined break time for drivers. By using these techniques, car manufacturers can offer their customers the possibility of accurately estimating the remaining battery life of their vehicles to reduce the problem of being stranded due to a discharged battery during a journey and promote their deployment [

69].

AI can support shelf replenishment for perishable goods. For example, machine learning techniques can predict demand, then formulate a planning whose solution represents the supply for the freshest available goods. In this way, sustainable supply chains can decrease the amount of waste and optimise operational performance [

70]. In addition, AI can be used for all decision-making processes in the supply chain, with the aim of monitoring all critical factors that determine product quality. For example, association rule techniques can find the optimal values of all decision-making parameters that can influence product quality at every level of the supply chain, i.e., relationship with suppliers, and the production and distribution level, with the specific objective of maximising the quality of the final product [

71]. Other AI applications identify the best supplier to achieve an optimal trade-off between minimising project completion time and minimising energy consumption. As a result, production is carried out faster and in a more sustainable and energy-efficient manner [

72].

Table 3 summarises the sustainable aspects of implementing AI in SCM.

4.3. Blockchain

The introduction of blockchain technology, due to its security features, has enabled the use of new and sustainable emerging practices in SCM. It can ensure responsible sourcing and ensures compliance with environmental standards by increasing traceability and transparency in supply chains [

82]. Technology can provide all the information about the type and origin of materials to help actors prevent resource consumption. Blockchain creates a transparent solution and provides access to data for the actors involved in an agri-food supply chain to better manage data in terms of product quality and certifications [

50]. It allows for data to be stored in a secure and immutable manner, preventing fraud through the continuous and shared monitoring between the actors in the supply chain [

83]. It can help to plan work schedules by recording product data and the processes performed [

84]. Therefore, technology can lead to coordination among suppliers to achieve compliance with sustainable standards [

85]. All members of the supply chain can easily verify whether all suppliers have obtained social sustainability certificates and whether they are conducting satisfactory labour practices and maintaining acceptable occupational health and safety conditions [

86]. Staff training and learning data on occupational health and safety can be recorded in the blockchain network as a basic requirement. In this way, governments can effectively monitor all the companies involved in a supply chain and prevent inappropriate behaviour. In addition, a distributed ledger can be adopted in a perishable supply chain to match supply and demand, leading to less product loss. This increases consumer trust and leads to more sustainable food withdrawal and higher quality products. By adopting blockchain, it is possible to create a collaborative peer-to-peer marketplace, which allows trading while avoiding fraud or opportunistic behaviour, and enables the selection of green suppliers [

87]. This technology can be used for reverse logistics such as plastic recycling. People in the community collect plastic and take it to a company’s recycling points. The ‘collectors’ are paid through ‘tokenizer rewards’. In this way, the distributed ledger certifies all stages of the plastic’s journey, confirming that the producer uses only recycled plastic [

88]. With the help of smart contracts, it is possible to reduce the time of order management by automating various procedures and making them visible to all the actors in the network [

82]. They can reduce delays in carrying out business operations and facilitate, verify or enforce contractual obligations according to contract clauses [

89]. In addition, they can be used to increase cash flow, have a better chance of obtaining a loan and reduce the risk of bankruptcy [

90].

Table 4 summarises the sustainable aspects of implementing blockchain in SCM.

4.4. Computing

Cloud technology is becoming increasingly promising for sustainable emerging practices. From an economic and social perspective, there are business models that use mobile applications based on cloud and edge computing technology to make the supply chain more efficient by increasing the connection between the parties involved in transactions. The recording of transactions in a shared manner allows for the monitoring of product health and quality for the various actors involved in the supply chain network. This guarantees awareness of resource consumption and enables responsive production management [

93,

94]. There are other applications of cloud technology that store inventory, lifecycle and carbon footprint assessment data to increase collaboration with other actors in the supply chain [

95]. Cloud platforms can be used to manage connected machines. They consist of connecting machines to computers by collecting performance and maintenance data. The system reacts promptly to the slightest anomaly by storing utilisation data; this increases efficiency levels and lengthens the machine’s life cycle, giving maintenance personnel greater control over the machines [

64]. From an environmental point of view, cloud technology supports the data storage of a product from its production to its disposal. This allows utilisation, reuse, repair and recycling programmes for equipment [

96]. Cloud platforms that carry out effective planning for waste management are on the rise. Specifically, this technology monitors the fill level of company-owned bins and analyses trends in bin filling so that a higher emptying priority can be established [

97].

Table 5 summarises the sustainable aspects of implementing computing in SCM.

4.5. Digital Applications

Digital applications such as mobile and web applications and social media can be used to ensure various sustainable emerging practices. Regarding social sustainability, the use of social media platforms can connect buyers and suppliers so that they can more easily share information on how safety risks and child labour in the supply chain should be addressed and resolved [

99]. To better manage food transparency and traceability systems, companies can collect data, such as the location and equipment used, in a mobile app, which are then recorded on a web application and shared with the final consumer [

100]. From an environmental point of view, web platforms can encourage interaction between food waste producers and potential buyers, reducing and facilitating the recovery of food waste [

101]. Moreover, there are mobile applications that can be used by organisations to motivate employees to adopt pro-environmental behaviour to reduce energy consumption. The system allows employees to monitor their own energy consumption and receive practical information on energy savings through subsystems such as energy consumption tracking, energy feedback and energy-saving recommendations [

102].

Considering the economic impacts, mobile applications are used to increase customer satisfaction for delivery. For example, mobile apps support setting the date and time slot to receive the ordered goods. Upon delivery, the recipient receives a message via the app to pick up the item in the locker [

103]. Specific web applications can help consumers to choose a more sustainable delivery option (i.e., slower delivery instead of standard next-day delivery) on the payment page of the online shop using non-financial incentives. In spite of financial incentives involving additional costs for both consumers (e.g., fast delivery with a surcharge) and retailers (e.g., slow delivery with a discount), these suggestions have negligible costs. In addition, longer delivery times allow logistics service providers to load and route vehicles more efficiently [

104]. By analysing product opinions on social networks, it can help manufacturers to develop appropriate strategies and to optimise the product development. Data can be collected using the social media API and then analysed on the basis of expert opinions [

105]. Studying social media content can identify trends and retrieve ideas for product, packaging and technology development activities focused on sustainability efforts [

106].

Table 6 summarises the sustainable aspects of implementing digital applications in SCM.

4.6. Geospatial Technologies

Geospatial technologies can be employed for several aspects of environmental, social and economic sustainability. For example, satellite remote sensing combined with georeferenced data can estimate yields in smallholder production systems to understand how soil quality and fertiliser use affect productivity. This can allow for a more effective agricultural policy [

108]. Satellite imagery, together with remote sensing surveys, allow for data collection to better understand soil erosion risks, considering various practices such as agriculture [

109]. The technology supports farmland monitoring with better strategies for irrigation systems, and thus makes agriculture more efficient and competitive [

110]. From a social perspective, the use of remote sensing is useful to identify the deforestation risks caused by the primary sector [

111].

For economic sustainability, GPS can be used to track transport vehicles in transit from the producer to the distribution point and to consumers to constantly monitor route changes and potential routing optimisations [

89]. Geographic Information Systems (GIS) can support transport planning as they can determine the quickest routes for the delivery of food products to prevent perishability and reduce transport costs. This technology reduces the carbon footprint, minimises fuel use and CO

2 emissions and aims to achieve a green supply chain and an efficient logistics model [

112]. The high volumes of spatial data analysed by GIS could be used to show the cartographic information of natural resources, logistical networks and potential industrial sites. In order to generate optimal logistics costs, GIS can identify the shortest road distances of raw material supplies to meet the needs of industrial sites [

113].

Table 7 summarises the sustainable aspects of implementing geospatial technologies in SCM.

4.7. Immersive Environments

Immersive environments are a relatively new technology that is beginning to be used in sustainable supply chains. For example, the creation of a digital twin can simulate and anticipate the replacement of batteries in electric vehicles [

91]. It can be used to monitor the engine of a machine in order to control its performance and avoid higher fuel consumption, hence higher costs, and a consequent increase in greenhouse gas emissions. Specifically, it can simulate and detect performance by checking whether there is a difference between expected and real behaviour and, in the case of a high variation, suggest a potential failure [

114]. Digital twin platforms can analyse traffic conditions, logistics information and weather data. In this way, they can predict traffic demand, enabling operations personnel to accurately predict traffic congestion, further reducing fuel consumption and emissions [

115].

In the industrial field, to achieve sustainable production in machining processes, it is necessary to develop strategies to effectively change the way components are manufactured. By using a digital twin, the waste of highly polluting materials can be avoided [

116]. Another useful technology for sustainable supply chains is gamification. It can be used to induce sustainable behaviour in offices to reduce energy consumption. Through a gamified mobile app, office users can monitor their energy consumption and behaviour through football games, prizes and teamwork [

117].

For social sustainability, digital twins have the potential to predict the remaining days of life based on the response of the physical, biochemical and physiological states of perishable products. In this way, each shipment or pallet of perishable products can be labelled with an expiry date. This can help consumers to better plan the purchase of products in order to reduce waste [

118]. By using augmented reality inside shops, consumers’ attention can be attracted to sustainable products [

119].

Table 8 summarises the sustainable aspects of implementing immersive environments in SCM.

4.8. Internet of Things

IoT is a technology often adopted within supply chains for several sustainable aspects. The use of an IoT-based architecture, in which a large amount of data is collected, can improve the working conditions, safety, health and welfare of people. It enables supply chain actors, including retailers, to find out information about the sustainability of supply chains, such as satisfactory working practices and occupational health, and avoid issues such as machinery breakdowns or defective raw materials for operations and logistics, respectively [

122]. For instance, smartwatches can collect data on human behaviour to continuously monitor the conditions of the working environment during the logistics activities of warehouse workers. A better understanding of human and environmental characteristics can support managers in planning logistics activities and designing warehouse facilities to achieve a higher overall performance and guarantee worker safety and well-being [

65].

From an economic point of view, smart sensors can automate the replenishment of products; they can discover stocking units on the wholesalers’ shelves and can automate reordering to reduce delivery times [

89]. Smart sensors can track and monitor an object in real time such as its location, departure, arrival time and any event that might affect the quality of the product. This ensures product traceability, safety and transparency [

92]. For food quality control, smart sensors can be used to monitor the food health; they can classify them as healthy or unhealthy, or ripe or sour by assessing their qualities at regular stages [

89]. For the environment, the IoT can be used for the management of the recovery of electric vehicle batteries in the end-of-life phase to ensure more sustainable waste management, cost reduction and material recovery and reuse [

123]. In addition, the technology can acquire data on waste generation in the various business processes and share it in real time with the actors in the food supply chain in order to achieve better resource efficiency and reduce disposal costs [

124].

Table 9 summarises the sustainable aspects of implementing IoT in SCM.

4.9. Open and Crowd-Based Platforms

Recently, there are several applications based on open, collaborative and crowd-based platforms that promote sustainable practices in SCM [

125,

126]. For example, open-source technologies enable specific solutions for agriculture to provide goods and services to small farms for free [

127]. These systems can support farmers sustainably manage natural resources at any level [

128]. Moreover, companies can obtain funding using sustainability-oriented reward-based crowdfunding. For instance, there are crowdfunding policies where companies have launched a new product reward programme to attract potential customers to a more sustainable product based on renewable systems [

129]. Crowdfunding is important because it can raise money from customers by spreading financial risk. The crowdfunding model brings about numerous benefits (increased revenue), including for social welfare (reduced emissions and prices), particularly if the competition is sufficiently intense or the fixed costs are high [

130]. Crowd-shipping can be used as a new pickup/delivery system. Customers can make delivery requests and casual carriers can accept them, considering their availability in terms of time and distance. The use of this innovative system can result in a reduction in shipping time and an increase in the quality of life for both the applicants and occasional couriers [

131].

For the environment, open-source technology can enable industries to track the movement of plastic pollution so that they can offer increasingly environmentally friendly products to the market. This technology can identify the location of storing large amounts of plastic pollution in real time [

132].

Table 10 summarises the sustainable aspects of implementing open and crowd-based platforms in SCM.

4.10. Proximity Technologies

Proximity technologies are widely used in SCM to favour sustainable practices. From both economic and social perspectives, information about product features can be collected by RFID sensors. They can be used by consumers by scanning the QR code on the product label to see data on origin, manufacture and processes [

136]. RFID is used to solve conflicts that can occur between suppliers and retailers, such as inaccurate inventory information or errors that could result in lost items and consequently wasted inventory [

137]. Pallets with RFID enable real-time information collection to ensure product traceability, security and transparency [

92].

For the environment, it is possible to incorporate RFID tags into electronic devices at the production stages for end-of-life product recovery. In this way, RFID can track them from depots and household waste and generate a new return channel by increasing the recycling and return rate [

138]. RFID technology can be used to manage perishable products by collecting time and temperature history so that a dynamic expiration date can be set resulting in better final product quality and a lower percentage of lost product and reducing costs [

139]. Information such as waste disposal time, type, volume, and location can be recorded in RFID tags. QR codes can be physically attached to waste containers to track geolocation, weight and temperature in real time and then share this information. This supports supply chain actors to plan the receipt, treatment and shipment of hazardous waste [

140].

Table 11 summarises the sustainable aspects of implementing proximity technologies in SCM.

4.11. Robotics

Robotics is increasingly being used in manufacturing processes to improve the efficiency of operations, but also to favour sustainable emerging practices. For example, the use of autonomous freight trucks can support delivery reliability, transparency in transportation and increase customer satisfaction [

141]. For last-mile delivery, drones can be managed by a script that allows the user to monitor and plan the route. This results in quick deliveries and reduced labour costs [

142]. In addition, they could refuel trucks along the route, avoiding additional routes for refuelling [

143].

For the environment, the use of autonomous and virtually connected platoons of trucks for transportation can reduce the air resistance they face, which allows for lower fuel consumption. Lower fuel consumption means lower transportation costs and emissions [

144]. The combined use of drones and autonomous delivery robots instead of traditional vehicles allows for energy, time and CO

2 emissions optimisation [

145]. The use of drones can influence consumer behaviour with respect to decision-making. In particular, environmental behaviour has a great influence on consumers’ willingness to purchase products from green transportation [

146].

Table 12 summarises the sustainable aspects of implementing robotics in SCM.

4.12. 3BL Index

This section will present the calculation of the

3BL index. From the percentages of

Table 1 (%EPt, SEPt,env, %SEPt,env, SEPt,soc, %SEPt,soc, %SEPt,eco, %SEPt,eco) it is possible to calculate different sustainability indicators for each technology. For instance, the environmental sustainability index (

Env) is the ratio between the percentages of the environmentally sustainable practices (%SEP

t,env) on the overall percentage of the emerging practices for each technology (%EP

t). If the ratio is higher than 1, it implies that the weight of the environmentally sustainable emerging practices employing the specific technology on the overall sample of environmentally sustainable emerging practices is higher than the weight of all the emerging practices employing the specific technology on the overall sample of emerging practices. In the same way, the indicators of social (

Soc) and economic (

Eco) sustainability were calculated. Finally, the

3BL Index is calculated with the following formula, which considers the economic, environmental and social sustainability indices (1):

This index summarises the global contribution of the focal technology on sustainability, thus providing an overview of the contribution of emerging technologies towards sustainability.

Table 13 shows the value of the

Env,

Soc,

Eco and

3BL indices.

Figure 4 shows the bar chart sorted in descending order according to the

3BL index. Technologies such as blockchain, geospatial tech and IoT favour sustainable emerging practices. For instance, the

3BL index for blockchain is 2.71, indicating that the general contribution of blockchain on sustainability issues is higher than those of other technologies. Even if the result may seem counterintuitive, the technology supports various sustainable practices by transparently, visibly and securely recording data on the distributed ledger to avoid issues related to illegality, fraud and counterfeiting. In addition, the technology favours the effective and efficient management of energy consumption, and supports the cost and time reduction of activities. The result highlights the fact that many scholars are focusing on this technology to sustainably improve traditional business practices in SCM. It is clear that its use has a heterogeneous influence on different aspects of sustainability. Specifically, its role as a secure database ensures support for economic and environmental practices—by facilitating the immutable accounting of recycling activities and the correct tracking of energy and economic resources—but also social ones, such as the tracking of fair practices in developing countries and the rapid identification of fraud and illegal activities. The results also show that digital technologies, such as robotics, are not particularly studied by scholars considering their application in sustainable business practices. The literature has completely ignored the role of this technology in the social dimension. Robotics and cyber-physical systems have increased the unemployment rate and the digital skills gap for workers in supply chains. On the one hand, the automation of tasks by robots enables better productivity and time performance, but on the other hand, the costs for implementing these systems can be high and unsustainable for supply chains. Finally, assessing the environmental dimension, while the implementation of this technology can help reduce carbon emissions for transport, the design and development of robots with innovative materials and semiconductors can cause a high consumption of valuable energy resources.

Figure 5 shows a spider diagram in which the indices of economic, social and environmental sustainability have been graphically projected in relation to the technologies considered. This representation allows us to immediately visualise the technologies that are the most promising for the achievement of sustainable emerging practices. Geospatial technology, 3D printing and blockchain are more promising for environmental sustainability; blockchain, geospatial technologies and the IoT matter more for social sustainability; and blockchain, proximity tech and IoT are those that favour economically sustainable practices.

5. Discussion

The article provides a comprehensive overview of the use of digital technologies to favour sustainable emerging practices in SCM considering environmental, economic and social dimensions. The article evaluates and classifies scientific publications with the aim of identifying how digital technologies can be appropriately employed in SCM from an Industry 5.0 perspective. Through the 3BL index, the study assesses which technologies have been most researched and addressed by scholars from a sustainability perspective for SCM, and investigates which sustainable practices are promoted by traditional and emerging technologies. The research confirms the power and role of digital technologies in unlocking new sustainable practices following the Industry 5.0 theories explained by the European Commission. This is one of the first studies to try to quantify the attention on sustainability issues in SCM when innovative digital technologies are adopted.

5.1. Comprehensive Overview of Digital Technologies That Favour Sustainable Emerging Practices in SCM following the 3BL Approach

The digital technologies of Industry 4.0 considered in this study have enormous potential when implemented within supply chains to automate and manage operations and reduce human labour. Although they have been widely studied to assess their impacts in supply chains [

17,

38,

41], little research has explored the single technology in improving the sustainability dimensions. This section discusses the results achieved in answering the first research question and attempts to provide further insights. Specific opportunities for sustainable improvement have been identified for each technology.

From the results, two categories of technologies can be identified. Technologies such as blockchain, computing, digital applications, IoT, geospatial technologies and proximity technologies are widely used to support aspects of traceability, transparency and the visibility of products and services. These digital technologies can be used to collect data for analysis and, subsequently, to plan sustainable decisions. Specifically, they can be classified and evaluated as useful for data monitoring and control activities. In this sense, they could be defined as ‘monitoring technologies’. Proper data management favours and promotes virtuous aspects for all dimensions of sustainability.

Secondly, 3D printing, artificial intelligence, immersive environments, open and crowd-based platforms and robotics enhance aspects of the circular economy, carbon reduction, waste reduction and the optimisation of production and logistics processes. In particular, they are useful to support concrete actions in business practices. In this perspective, they could be defined as ‘action technologies’. While ‘monitoring technologies’ help decision-makers to make choices on the operations management, ‘action technologies’ enable activities to be carried out with high levels of automation, optimisation and efficiency. From this perspective, they can have a direct impact on business practices in SCM by providing immediate sustainability benefits. Although these technologies previously aimed to optimise processes and increase productivity, with the advent of the Industry 5.0 paradigm, they could complement the former concepts by aiming for more sustainable actions. The first part of the results provided a comprehensive overview of the use of digital technologies in SCM, classified according to the 3BL approach. This study laid the foundation for analysing and investigating how digital technologies could be employed in sustainable practices in SCM in the various environmental, economic and social dimensions.

5.2. Identifying the Digital Technologies Most Oriented towards Sustainable Practices in SCM

Although previous research has investigated and analysed digital technologies in various dimensions of sustainability, most studies are either qualitative or focus on a specific sustainability indicator, such as reducing carbon emissions and reducing energy and resource consumption [

18,

20,

21,

23]. The main global sustainability model used—the triple-bottom-line model—has been criticised for its complexity of being quantified through specific indicators [

147]. It is important to consider that until a few years ago, linking concepts such as cost minimisation and environmental and social issues was inconceivable [

148]. Therefore, quantitative indicators on social and environmental metrics are scarcely used in the literature. To date, there is no standardised definition of ‘sustainable’ measurement in each of the three dimensions, which can make it difficult to understand which technologies could be ready to promote sustainable business practices.

To answer the second research question through quantitative parameters, the study identified four sustainability indicators, namely the

Env,

Soc,

Eco and

3BL indices. Considering the

Env index related to environmental sustainability, geospatial technologies enhance the environmental sustainability aspects in SCM. One of the purposes of these technologies is the monitoring and control of climatic, environmental, chemical and geophysical conditions through the use of specific sensors such as GIS, GPS and remote sensing. Then, the collected data is analysed using web mapping and spatial modelling tools. Another technology aimed at improving environmental sustainability is 3D printing. It can be used for various activities such as waste reduction and material reuse.

Table 13 shows how this technology is more oriented towards improving sustainable environmental practices than social and economic ones in SCM. In fact, there might be several economic and social challenges for the adoption of this technology in sustainable SCM practices starting from the high cost of materials, machinery and energy consumption. Moreover, it may have a negative impact on the workforce, as the production of customised products could reduce the demand for skilled workers.

Considering the Soc and Eco indicators, among the most used digital technologies in sustainable emerging practices are proximity technologies and IoT. These technologies can automate various processes in SCM by collecting data in real time with specific sensors, such as RFID and QR codes, and sending them via the Internet for monitoring and control. This provides the automation and control of various SCM processes, from order management to logistics and warehousing. In this way, it is easier to trace raw materials, products, equipment, machinery status and materials. This technological infrastructure reduces costs and time by making decisions more efficient and effective. From a social point of view, the traceability of products along the supply chain guarantees the expectations of end consumers. However, one of the digital technologies for which scholars have focused their attention to favour sustainable emerging practices is blockchain. It enables the permanent and secure recording of transactions and promotes information sharing. Thus, the shared and secure recording of environmental, economic and social data can support business planning, strategies and collaboration between partners, and increase awareness of the energy consumed among supply chain actors and transparency for the status of workers.

It is evident from

Table 13 that blockchain, proportionally, favours more sustainable emerging practices than the total number of emerging practices identified in this analysis. Furthermore, the higher value of the

3BL index is a measure of how much scholars and academics are focusing on investigating the potential of this technology on the sustainability aspects of SCM. This analysis is particularly relevant because it highlights the effort that scholars are putting into sustainability issues when blockchain is adopted in supply chains. However, the analysis shows that technologies such as artificial intelligence and robotics, where there are many emerging practices, are at the bottom in terms of sustainable emerging practices. Therefore, there is a lack of research on the contribution that specific technologies can make to sustainable practices in SCM. In particular,

Table 1 shows that among the 1010 emerging practices identified for blockchain, 526 concerned applications in sustainable practices. While for robotics, 1476 practices were collected, of which only 241 were related to sustainable business practices. Interestingly, certain technologies are very broad, such as AI and digital applications, while blockchain is a group with limited scope (see

Appendix A). This highlights the relevance that specific digital technologies have on sustainable SCM processes.

The spider diagram further clarifies the distribution of the three pillars of sustainability by providing further insights. For example, immersive environments have been less studied from a 3BL perspective. The main reason is that these technologies are relatively new and under development and therefore there is still much research to be done on social and environmental impacts. Nevertheless, they can potentially have negative environmental effects by being powered by electricity. In addition, the use of devices can lead to the generation of e-waste and the need to recycle it sustainably. From a social point of view, there are concerns about social isolation and addiction that could have a negative impact on mental health and social relationships. From an economic perspective, there are still uncertainties about the demand for immersive devices and their potential uses, which makes it difficult to predict their long-term impact on economic growth. The results of this study show that for both robotics and AI, where many emerging practices are collected, their use for social and economic sustainability is little investigated. There are still uncertainties regarding their safety, regulation and ethics that need to be resolved. The adoption of these technologies could have a negative social impact by causing an increase in poverty and economic inequality. Moreover, they could entail high costs, both in terms of initial investment and ongoing maintenance, and thus limit their accessibility to developing countries.

5.3. Theoretical and Managerial Implications

From a theoretical point of view, this SLR has generated two contributions: the state of the art of digital technologies in SCM for sustainability objectives and the identification of the digital technologies that are most focused on favouring sustainable practices. The research findings reveal how blockchain technology, geospatial technology and IoT are being used more to favour sustainable practices. Most of the research has presented the combination of digital technologies and sustainability in SCM, considering a few technologies at a time, or analysing specific business case studies or simulation models. Instead, the findings of this paper present a comprehensive overview of how digital technologies can support emerging new and innovative sustainable practices. This study presents 11 digital technologies in which they are grouped and classified into 88 single technologies. The article identifies which technologies are more focused on specific aspects of sustainability in SCM. For example, organisations looking to achieve a reduction in energy consumption could adopt 3D printing, AI, blockchain, digital applications, immersive environments or open and crowd-based platforms. Other organisations that want to improve social sustainability aspects such as worker safety and illegal activity detection can implement technologies such as AI, blockchain, digital applications, geospatial technologies or IoT. The analysis of the results shows that specific digital technologies are still under-researched and have not attracted the attention of academics. Certain digital technologies do not seem to be oriented towards sustainable development in SCM. This is due to limited implementation in SCM due to lack of knowledge about the potential of the technology or their complex implementation in specific contexts.

For managerial implications, the results of this research are useful for managers, policymakers, researchers and academics. First, managers can gain insights into which digital technologies could be useful to reshape the structure of their traditional supply chain from a sustainability perspective. This study provides a comprehensive overview of 11 digital technologies that will potentially soon be deployed in the business world to ensure levels of quality, efficiency, effectiveness and sustainability suitable for institutions. This document provides clear, valuable information and guidelines on what opportunities digital technologies can offer for sustainable supply chains. The article aims to strongly assist managers in improving the adoption rate of digital technologies in SCM to carry out operations and activities from a sustainable perspective. It can be used as a guideline for sustainable digitisation in SCM and can align organisational activities with the 2030 Agenda.

5.4. Limitations and Guidelines for Future Research

The SLR has some limitations. First, the study selected only scientific articles for the literature review. Thus, it is impossible to state that all business cases and applications have been considered; researchers may not have yet studied some opportunities to achieve environmental, economic and social sustainability goals in SCM. Furthermore, scientific journal contributions were collected solely by Scopus. There may be articles outside this database that may be relevant to the purpose of the study. A further limitation is the lack of inclusion of grey literature covering material from professional and corporate reports. To support the continuous updating of this database and avoid that the results are fixed for a precise time horizon, a high effort of reading, analysing and updating sustainable practices by the group of industrial engineers is required. Therefore, this is a highly time-consuming activity. In this study, business case studies, pilot projects and simulation models that positively improve sustainability aspects were considered. However, the negative factors affecting the implementation of these digital technologies have not been considered. This produces a bias, e.g., the use of public blockchain might be unsustainable in SCM due to high energy consumption.

This study is the starting point for further insights related to the topics of Industry 5.0, technology and sustainability. It evaluated one digital technology at a time, but future developments may focus on analysing the conjoint use of digital technologies to improve business practices in SCM. By adopting an integrated approach, the entire value chain can be assessed, and a holistic view of sustainability can be promoted with greater relevance. The combination of technologies can offer new horizons for future research through the creation of synergies that enable benefits unthinkable with observation based on single technologies. Future studies aim to broaden the data source using interviews with experts in digital technologies, SCM and sustainability. Further ideas could derive from the context of application of digital technologies, from sectors, nations and different cultural aspects. It is necessary to conduct studies to understand the disadvantages and challenges of integrating these technologies into the SCM considering unsustainable aspects. Future research could examine the adoption maturity of digital technologies in sustainable supply chains of different sectors and industrial configurations. The analysis of the results shows that some available technologies have been less investigated to be implemented in the SCM from a sustainable point of view. Research could explore new sustainable practices that could employ digital technologies to increase supply chain performance. Further research opportunities could also arise from the use of new technologies that will be brought onto the market. Future developments could evaluate the adoption of these technologies within specific business processes and verify their sustainability impact. Finally, some of these sustainable emerging practices might become the best sustainable practices in the future.