An Experimental Study to Improve the Nutrients and the Mechanical Properties of Copper Tailings Sand in China’s Arid Zone by Biomineralization of Locally Isolated Urease-Producing Bacteria

Abstract

:1. Introduction

2. Materials and Methods

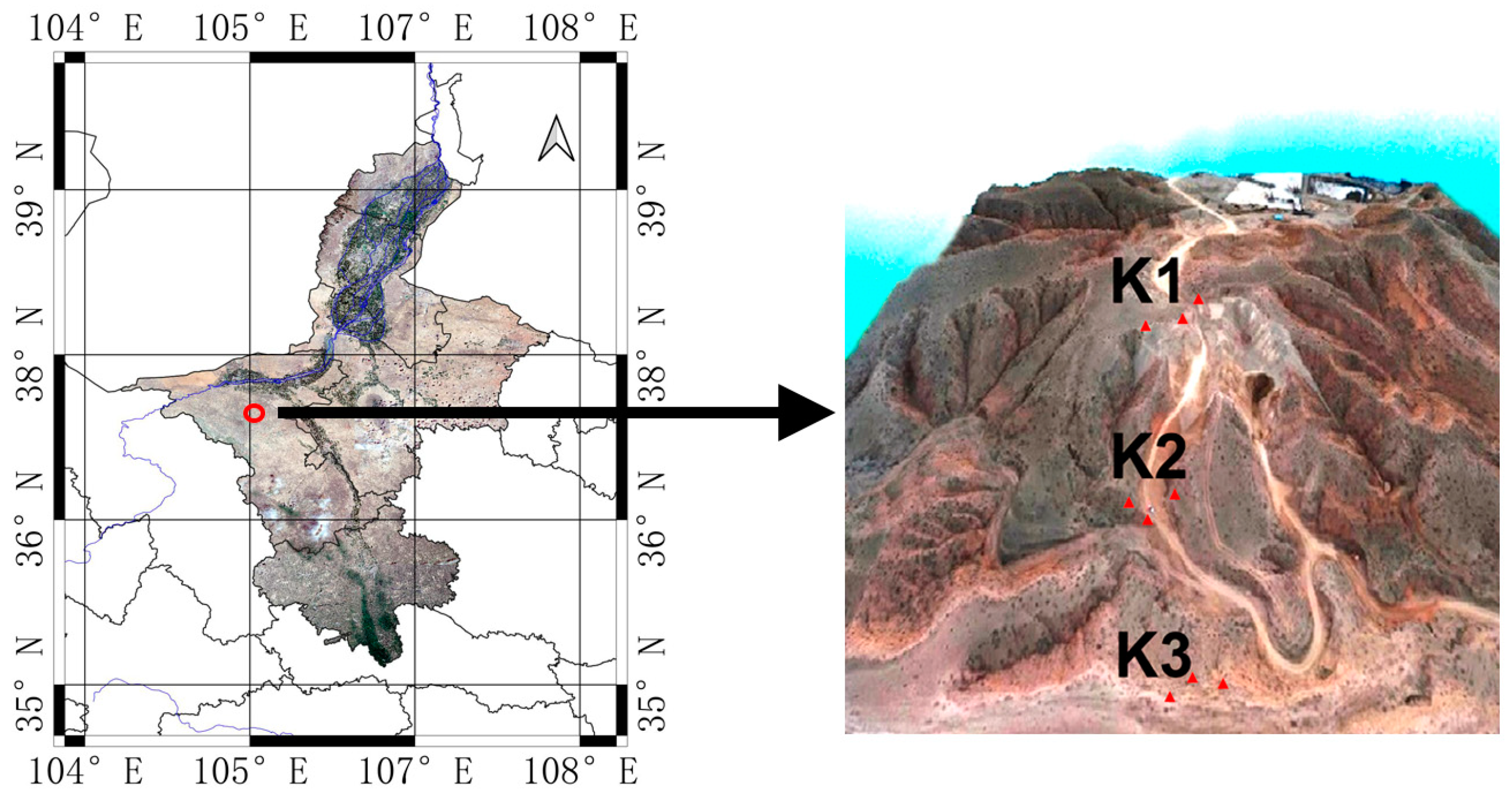

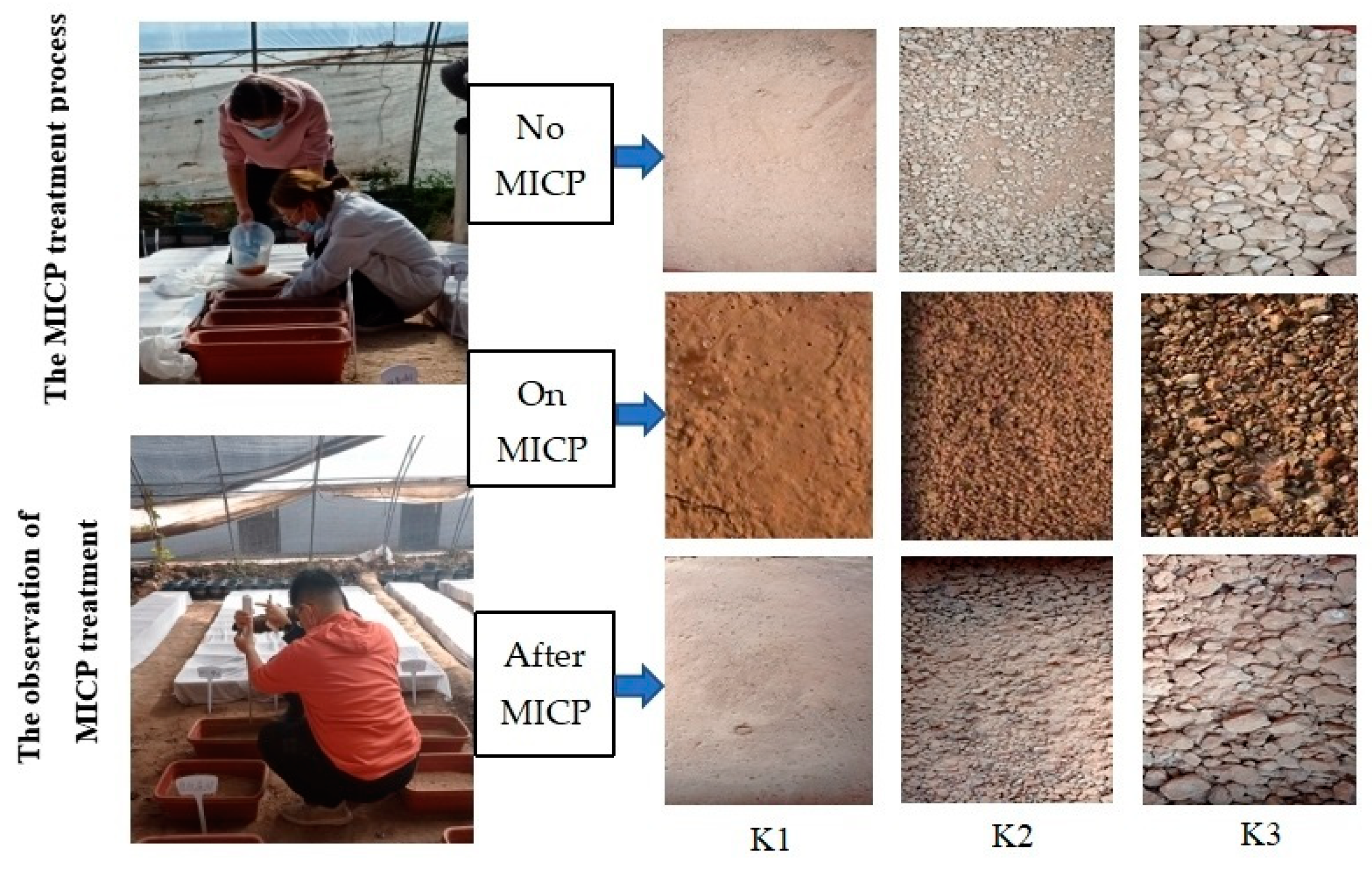

2.1. Tailing Sand Sample

2.2. Strain Screening and Identification

2.2.1. Strain Screening and Observation

2.2.2. Gene Sequencing and Phylogenetic Tree Construction

2.3. Cementation Media

2.4. Molds

2.5. Experimental Ways for the Strength Test

2.6. Physical and Chemical Properties Tests

2.7. Scanning Electron Microscopy (SEM)

2.8. Statistical Analysis

3. Results

3.1. MICP Role on Different Copper Tailings Sand Sizes by Strength and CaCO3 Content Test

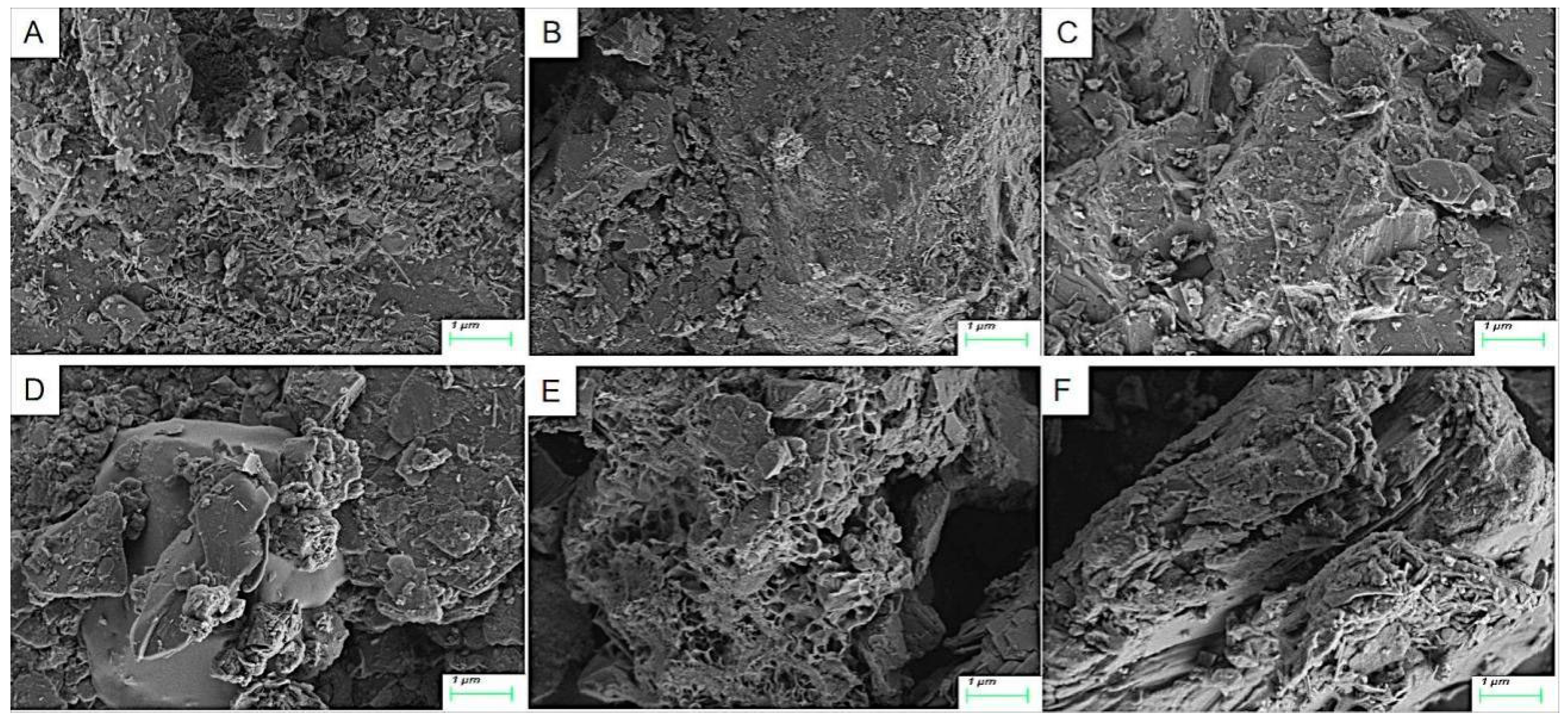

3.2. Effects of MICP Treatment on the Microstructure of Different-Sized Tailing Sands

3.3. Effects of MICP Treatment on the Salinity and pH of Different-Sized Tailing Sand

3.4. Effects of MICP Treatment on the Nutrition of Different-Sized Tailing Sands

3.5. Effects of MICP Treatment on the Nitrogen and Carbon of Different-Sized Tailing Sands

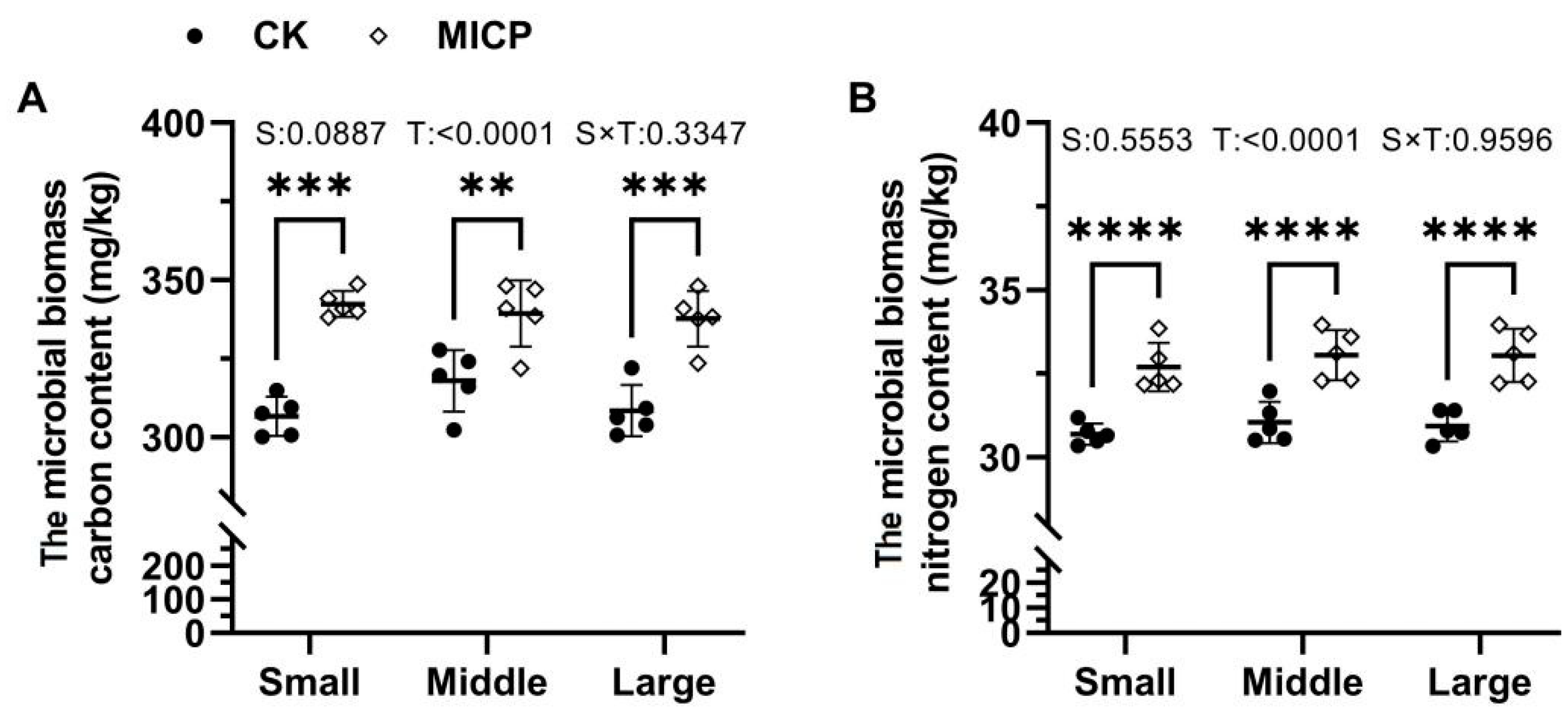

3.6. Effects of MICP Treatment on the Microbial Biomass Nitrogen and Carbon of Different-Sized Tailing Sands

3.7. Effects of MICP Treatment on the Enzyme Activity of Different-Sized Tailing Sands

3.8. The Correlation Analysis of Tailing Sand Physicochemical Properties with MICP Treatment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koptsik, S.; Koptsik, G.; Korotkov, V.; Spiers, G.; Beckett, P. Successes in application of biotechnologies to mine land remediation in the Russian Sub-Arctic. In Bio-Geotechnologies for Mine Site Rehabilitation; Elsevier: Amsterdam, The Netherlands, 2018; pp. 547–570. [Google Scholar]

- Kiventerä, J.; Perumal, P.; Yliniemi, J.; Illikainen, M. Mine tailings as a raw material in alkali activation: A review. Int. J. Miner. Metall. Mater. 2020, 27, 1009–1020. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection; Ministry of Land and Resources. National Soil Pollution Investigation Bulletin. Available online: http://www.gov.cn/foot/site1/20140417/782bcb88840814ba158d01.pdf (accessed on 17 April 2014).

- Briffa, J.; Sinagra, E.; Blundell, R. Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 2020, 6, e04691. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Song, C.; Ye, S.; Cheng, C.; Gao, P. The spatiotemporal variation in heavy metals in China’s farmland soil over the past 20 years: A meta-analysis. Sci. Total Environ. 2022, 806, 150322. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Chang, Q.; Liu, J.; Clevers, J.; Kooistra, L. Identification of soil heavy metal sources and improvement in spatial mapping based on soil spectral information: A case study in northwest China. Sci. Total Environ. 2016, 565, 155–164. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, S.; Xue, G. Temperature field and crack control technology of large-volume concrete in arid area. J. Ningbo Univ. Technol. 2018, 30, 39–45. [Google Scholar]

- Song, G.; Huang, J.-T.; Ning, B.-H.; Wang, J.-W.; Zeng, L. Effects of groundwater level on vegetation in the arid area of western China. China Geol. 2021, 4, 527–535. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, Z.; Guo, H.; Guan, L. Effects of sesame cake fertilizer on soil biological activity in the rhizosphere of flue-cured tobacco. Tob. Sci. Technol. 2003, 6, 31–34. [Google Scholar]

- Song, C.; Zhao, Y.; Cheng, W.; Hu, X.; Zhu, S.; Wu, M.; Fan, Y.; Liu, W.; Zhang, M. Preparation of microbial dust suppressant and its application in coal dust suppression. Adv. Powder Technol. 2021, 32, 4509–4521. [Google Scholar] [CrossRef]

- Omoregie, A.I.; Khoshdelnezamiha, G.; Senian, N.; Ong, D.E.L.; Nissom, P.M. Experimental optimisation of various cultural conditions on urease activity for isolated Sporosarcina pasteurii strains and evaluation of their biocement potentials. Ecol. Eng. 2017, 109, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Sharma, M.; Satyam, N.; Reddy, K.R. Comparison of improved shear strength of biotreated sand using different ureolytic strains and sterile conditions. Soil Use Manag. 2022, 38, 771–789. [Google Scholar] [CrossRef]

- Hammad, I.A.; Talkhan, F.N.; Zoheir, A.E. Urease activity and induction of calcium carbonate precipitation by Sporosarcina pasteurii NCIMB 8841. J. Appl. Sci. Res. 2013, 9, 1525–1533. [Google Scholar]

- Peng, J.; Liu, Z. Influence of temperature on microbially induced calcium carbonate precipitation for soil treatment. PLoS ONE 2019, 14, e0218396. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.; Yu, J.; Liu, S.; Liu, J.; Wang, R.; Dong, B. Experimental study to improve the mechanical properties of iron tailings sand by using MICP at low pH. Constr. Build. Mater. 2021, 273, 121729. [Google Scholar] [CrossRef]

- Pan, L.; Li, Q.; Zhou, Y.; Song, N.; Yu, L.; Wang, X.; Xiong, K.; Yap, L.; Huo, J. Effects of different calcium sources on the mineralization and sand curing of CaCO3 by carbonic anhydrase-producing bacteria. RSC Adv. 2019, 9, 40827–40834. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malicki, M.A.; Walczak, R.T. Evaluating soil salinity status from bulk electrical conductivity and permittivity. Eur. J. Soil Sci. 1999, 50, 505–514. [Google Scholar] [CrossRef]

- Wright, A.F.; Bailey, J.S. Organic carbon, total carbon, and total nitrogen determinations in soils of variable calcium carbonate contents using a Leco CN-2000 dry combustion analyzer. Commun. Soil Sci. Plant Anal. 2001, 32, 3243–3258. [Google Scholar] [CrossRef]

- Bao, S.D. Agrochemical Analysis of Soil; China Agriculture Press: Beijing, China, 2000. [Google Scholar]

- Jiang, H.L.; Li, Z.; Liu, S.D.; Xu, A.D.; Yang, C.; Zhang, Y.; Liu, G.S.; Ye, X.F. Effects of consecutive turnover of green manure and N fertilizer on soil microbial biomass and enzyme activity in tobacco-planted field. Ind. J. Agric. Res. 2013, 47, 185–191. [Google Scholar]

- Liu, W.; Zhao, Y.; Hu, X.; Li, X.; Geng, Z.; Wang, Q.; Liu, J.; Wang, H.; You, G. High performance of coal dust suppression with waste activated sludge using microbially induced calcite precipitation technology. Powder Technol. 2022, 404, 117464. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Li, M.; Zhou, N.; Song, W.; Wang, Z.; Qi, S. A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: Material preparation and macro-micro analyses. Sci. Total Environ. 2021, 770, 145241. [Google Scholar] [CrossRef]

- Griffiths, S.R. Activity of Insectivorous Bats at Gold Mining Water Bodies: Risks Associated with Consumption of Cyanide-bearing Waste Solutions. Ph.D. Thesis, University of Melbourne, Parkville, Australia, 2013. [Google Scholar]

- Muntean, A.; Teodor, R. The nitrogen regime in arable soils under the influence of tailings from mining landfills in the urban perimetre of Baia Mare. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Agric. 2011, 68, 104–107. [Google Scholar] [CrossRef]

- Zhang, Q.; Wan, G.; Zhou, C.; Luo, J.; Lin, J.; Zhao, X. Rehabilitation effect of the combined application of bamboo biochar and coal ash on ion-adsorption-type rare earth tailings. J. Soils Sediments 2020, 20, 3351–3357. [Google Scholar] [CrossRef]

- Yan, M.; Li, X.; Liu, Y.; Li, Y.; He, L.; Zhang, J. Biochar enhanced soil aggregation and C-related enzyme activity in post-mining land on the Loess Plateau, China. Land Degrad. Dev. 2022, 33, 1054–1061. [Google Scholar] [CrossRef]

- Minnikova, T.; Kolesnikov, S.; Evstegneeva, N.; Timoshenko, A.; Tsepina, N. Estimation of the Enzymatic Activity of Haplic Chernozem under Contamination with Oxides and Nitrates of Ag, Bi, Te and Tl. Agronomy 2022, 12, 2183. [Google Scholar] [CrossRef]

- Yang, Y.; Chu, J.; Cao, B.; Liu, H.; Cheng, L. Biocementation of soil using non-sterile enriched urease-producing bacteria from activated sludge. J. Clean. Prod. 2020, 262, 121315. [Google Scholar] [CrossRef]

- Fan, Y.; Hu, X.; Zhao, Y.; Wu, M.; Wang, S.; Wang, P.; Xue, Y.; Zhu, S. Urease producing microorganisms for coal dust suppression isolated from coal: Characterization and comparative study. Adv. Powder Technol. 2020, 31, 4095–4106. [Google Scholar] [CrossRef]

- Lam, E.J.; Montofré, Í.L.; Ramírez, Y. Mine tailings phytoremediation in arid and semiarid environments. In Phytorestoration of Abandoned Mining and Oil Drilling Sites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 115–166. [Google Scholar]

| pH | Water Content (%) | Carbonate Ion (mg/kg) | Water-Soluble Salt (mg/kg) | Available Phosphorus (mg/kg) | Alkali-Hydrolyzed Nitrogen (mg/kg) | Available Potassium (mg/kg) |

|---|---|---|---|---|---|---|

| 9.23 | 2.24 | 0 | 26,101 | 12.35 | 11.97 | 25.47 |

| Sample | Number | Mass (kg) | Thick (cm) | Cementation Fluid ① (mL) | Cementation Fluid ② (mL) | Cementation Fluid ③ (mL) | Treat Period (d) |

|---|---|---|---|---|---|---|---|

| K1 | 5 | 6.5 | 3.5 | 0 | 0 | 0 | 15 |

| K2 | 5 | 6.5 | 3.5 | 0 | 0 | 0 | 15 |

| K3 | 5 | 6.5 | 3.5 | 0 | 0 | 0 | 15 |

| K1 + M | 5 | 6.5 | 3.5 | 850 | 300 | 200 | 15 |

| K2 + M | 5 | 6.5 | 3.5 | 600 | 500 | 200 | 15 |

| K3 + M | 5 | 6.5 | 3.5 | 300 | 600 | 200 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, J.; Song, N.; Meng, C.; Xie, L.; Chang, D. An Experimental Study to Improve the Nutrients and the Mechanical Properties of Copper Tailings Sand in China’s Arid Zone by Biomineralization of Locally Isolated Urease-Producing Bacteria. Sustainability 2023, 15, 10077. https://doi.org/10.3390/su151310077

Yue J, Song N, Meng C, Xie L, Chang D. An Experimental Study to Improve the Nutrients and the Mechanical Properties of Copper Tailings Sand in China’s Arid Zone by Biomineralization of Locally Isolated Urease-Producing Bacteria. Sustainability. 2023; 15(13):10077. https://doi.org/10.3390/su151310077

Chicago/Turabian StyleYue, Jianmin, Naiping Song, Chen Meng, Li Xie, and Daoqin Chang. 2023. "An Experimental Study to Improve the Nutrients and the Mechanical Properties of Copper Tailings Sand in China’s Arid Zone by Biomineralization of Locally Isolated Urease-Producing Bacteria" Sustainability 15, no. 13: 10077. https://doi.org/10.3390/su151310077