Abstract

This paper aims to define and measure the environmental impacts associated with three distinct industry techniques used in the production of fresh tomatoes, from planting to harvesting. A comparative Life Cycle Assessment (LCA) is conducted to evaluate the environmental performance of producing one kilogram of fresh processing tomatoes. The study includes three Italian companies representing different Business Models: standard production, integrated production, and precision farming. The impact evaluation method used is ReCiPe, at both midpoint and endpoint levels. The results reveal that the adoption of advanced technology, such as precision farming, in managing the agricultural production of fresh tomatoes leads to a significant reduction in environmental impacts across all categories analyzed. Interestingly, the largest contribution to climate-changing gases comes from the use of fertilizers. Precision farming demonstrates a remarkable reduction of CO2 emissions by 52% compared to integrated production and 67% compared to standard production. This analysis provides valuable insights for managers and policymakers in developing strategies for large-scale, sustainable production using innovative techniques. The main contribution of this study lies in comparing the performance of three different Business Models employed in Italian fresh tomato production.

1. Introduction

In recent years, the agri-food industry has taken on particular importance concerning European policies for sustainable production and consumption [1,2]. The goal is to develop new Business Models (for consumption and production) that are more efficient from an environmental, social, and economic point of view. The last is fundamental for companies in the sector that want to implement their Business Model to remain competitive over time [3,4]. At the same time, the compliance obligations imposed by the European Commission define the future horizons for agriculture: a 50% reduction in waste, conservation of biodiversity, reduction of soil and groundwater exploitation, and independence from non-renewable energy sources [5]. The Common Agricultural Policy (CAP) deals with the promotion of intervention plans ensuring the compatibility of European productions with environmental and social needs [6]. Agri-food raw materials contribute significantly to the exploitation of natural resources; one of the EIPRO (Environmental Impact of Products) studies showed that food is responsible for 30% of the environmental impacts of total consumption and more than 50% of marine eutrophication [7]. One of the key aspects in assessing the impact on each raw material is precisely that of assessing the entire life cycle [8]. The key tool for impact analysis is LCA (Life Cycle Assessment), which allows for accurate estimation of the environmental performance of that food [9]. The use of LCA makes it possible to determine critical points on which to intervene to reduce this or that impact category. In recent years, impact analysis has been applied to various products and services, especially those in the agri-food industry [10].

In this sector, several issues have been highlighted to be investigated, for example, the definition of the functional unit, system boundaries, the origin of databases, and the rapid evolution of technologies and models for the dispersion of fertilizers and pesticides. Some common methodologies and recommendations for evaluating impact categories are contained within the European Commission’s ILCD manual and the ENVIFOOD protocol [11,12].

Further, the ESG disclosure and other non-financial communication efforts are crucial means to evaluate the environmental performance of firms, from institutions and consumers. In particular, some findings show that communication practices exert a positive effect on consumers’ WTB (want to buy) and WOM (word of mouth), and how much effect is magnified both by consumers’ environmentalism and status consumption orientation, in the attempt to show others a green status and their green consumption tendency [13]. Other forms of communication are brands and labels, which represent a good form to improve non-financial disclosure towards all stakeholders [14]. The brand encompasses the overall perception, image, reputation, and emotional connection that consumers have with a particular company or its offerings. A brand includes various components, such as the company name, logo, slogan, design elements, product quality, customer service, and the associated values. It represents the unique identity and positioning of a company in the market, defining the level of its accountability [15]. Labels typically include details such as the product name, ingredients, nutritional information, manufacturing date, expiry date, usage instructions, warnings, certifications, and any other relevant information, such as environmental impact statements required by regulations or helpful for consumers. Labels serve as a communication tool to inform and guide consumers about the product’s attributes, usage, disposal methods, and compliance with standards [16].

In recent years, corporate governance has sought to improve the level of image and accountability of its company by resorting to a series of certifications, brands, labels, and production specifications (i.e., IGP, DOP, STG, protocol as ENVIFOOD, and environmental declaration). This has led to difficulties in comparing competitors, especially when companies utilize different certifications to measure their qualities, particularly when these certifications originate from different countries. The commitment expected from companies in the present era extends beyond mere legal compliance and encompasses responsibility toward all stakeholders [17,18,19]. To attract investment from major funds, companies must meet specific environmental criteria, often referred to as “green” requirements. These criteria include energy independence, carbon neutrality, waste valorization, and social engagement [19,20]. Consequently, access to financial resources becomes crucial for companies to acquire modern technologies that optimize production volume, while minimizing environmental and social impacts. Precision farming serves as an exemplar, as it embodies these goals. Consequently, a self-perpetuating cycle emerges, wherein companies lacking access to the necessary resources for acquiring such technologies find themselves forced out of the market [21].

The aim of this study is to estimate the environmental impacts related to the cultivation of industrial tomatoes using three different Business Models, such as standard production (LAA1), integrated production (LAA2), and precision farming (LAA3), through the application of LCA as the cases in Colombia [22], Norway [23], and Sweden [24]. This paper aims to identify and quantify those practices aimed at mitigating the impacts of industrial tomato production on air, soil, and water. In addition, the structure of the Business Model is highlighted in correspondence with the sample of companies that use a different production.

2. Business Model Innovation

More global trends are affecting agriculture: population growth, increasing urbanization, climate change, and technological change. Modern farms are trying to survive in this rapidly changing world. Modern food systems face the growing challenges of climate variability, population growth, and changing consumer preferences. New agricultural equipment uses sensors and information technology, such as robots, temperature and humidity sensors, aerial images, and GPS technology. Since the second decade of the 2000s, a new agricultural revolution has emerged that has enabled farms to increase their profitability, efficiency, safety, and environmental sustainability as the emergence of a new Business Model [25].

With the diffusion of stakeholder theory and corporate shared value (CSV) within corporate governance summits, companies in the agricultural sector in particular are being required to reduce environmental damage and make today’s production ecologically sustainable [26,27,28]. To meet these demands, a new Business Model based on precision farming is emerging [29,30,31].

A new technological paradigm for the reasons mentioned above (trade-off between limited food raw materials and population boom) forces agrarian firms to change their previous Business Model. Investments, information systems, human capital, and new technologies are some of the many examples of driving forces behind the innovation of Business Models. Of course, the aim is to increase the degree of resilience in the face of change and, in the same way, increase corporate competitiveness [32,33,34]

According to some scholars [35,36,37], innovating a Business Model does not simply mean innovation in services/products or technology, but it has to change the value proposition model and the operating model. The value proposition model comprises the following components: target segment, product/service offering, and revenue model. The operating model includes a value chain, cost model, and organization. Amit & Zott [38] discuss that the innovation of a Business Model usually occurs in three ways: setting up a new activity, linking activities in new ways, and changing the parts that perform an activity. In precision farming, the literature has highlighted various elements of complexity (farm characteristics, socio-economic, and psychological), which may limit the broader use of precision agricultural technologies inside farms and the knowledge transfer process [39].

Table S1 presents the main factors of the Business Model in the case of conventional and precision farming technology. Thanks to extensive data on filling and yield, precision farmers have been able to provide better monitoring and traceability for their buyers. There is no change in the shape of the products, but the quality and quantity of them are superior. Due to the optimization of zone-specific inputs, production risks are lower than in conventional farming, and yield (quality and quantity) is stable. The application of site-specific inputs has contributed to the development of new, less environmentally harmful production, which is becoming increasingly important for consumers and sustainable finance. The cost of inputs may have decreased and the cost of machinery may have increased contemporarily due to precision farming.

Recently, the rapid development of technology has enabled humans to establish interconnected systems between physical–human, physical–physical, and human–human interactions, facilitated by the Internet. This interconnection has significantly improved communication systems in various industries [40,41]. The emergence of the fourth industrial revolution (Industry 4.0) has witnessed the extensive utilization of the Internet of Things (IoT) in diverse operations [42]. These operations encompass communication, data accumulation, data storage, big data analysis, real-time data retrieval, activation, control of smart devices, supply chain management, accountability, and financial management [43].

The primary goal of IoT is to bridge the gap between the physical and digital worlds. In the context of Industry 4.0, IoT is commonly referred to as Industrial IoT or IIoT. IIoT plays a crucial role in advancing traditional manufacturing and operating systems towards Internet-based cyber–physical systems (CPS) (CITAs). CPS facilitates both machine-to-machine (M2M) and human-to-machine (H2M) communication systems (CITAs). Moreover, the implementation of IIoT enables the development of self-maintenance systems for production and operations. In the past, optimizing and analyzing parameters, such as production chambers, tank levels, temperatures, material quantities, and real-time statuses, were predominantly performed manually [44]. However, with the integration of IIoT, humans can now monitor their statuses in real-time, empowering workers to make informed decisions [45,46].

Expensive, IT-based machinery is being used, so the efficient use of equipment is crucial (such as the use of biosensors allows the farmer to intervene when the software detects anomalies in the various check gates); otherwise, the delta between the costs of the old technology and the new technology may not be covered by the new revenues and cause budget deficits. Often, the benefits of innovation occur in the long run, thus leading to the exit of many companies from the sector that cannot afford the high short-term costs (both in terms of monetary and intellectual capital) [38,47].

3. Types of Production

According to the Food and Agriculture Organization of the United Nations (FAO), Italy is the second-largest producer of fresh tomatoes for canning, following China, which maintains its leadership in the sector with an annual production of 59.9 million tonnes, accounting for approximately 30% of the global production. Italy’s tomato production amounts to around 5.5 million tonnes per year, equivalent to approximately 7% of the worldwide production. The industrial turnover amounts to EUR 3.5 billion, of which 1.8 billion comes from exports [48]. The challenge of meeting increasing food demands under resource restrictions, while also reducing environmental impacts from agriculture, has led to the use of life cycle assessment (LCA) to evaluate food products and agricultural systems [49].

Historically, LCAs assessing greenhouse operations for fresh tomatoes, not processing tomatoes, have been completed for a number of countries, including Spain [50,51], Australia [52], Canada [53], and California [54]. In Italy, LCA analyses have been conducted on tomato cultivation [9,55]; however, these studies have focused on the analysis of impact categories identifying primary hotspots for the improvement of environmental performance, such as the use of non-renewable energy raw materials (fossil fuels), natural resources (water and soil), and fertilizers and pesticides. For the cultivation of processing tomatoes, studies have found that the use of fertilizers and electricity for irrigation represents two hot spots on which to act for future production. Based on this, three different production types are compared on the basis of the hot spots highlighted in the literature. The aim is to understand whether and how the type of Business Model and technology adopted can minimize the environmental impacts of irrigation and fertilization in particular.

3.1. Standard Production

In order to facilitate an effective comparison among the three production methods, an equal number of farms were selected from the CRPV (Centro Ricerche Produzioni Vegetali) database, all of which are located in the Emilia-Romagna region of Italy. There are several reasons why we might choose the Emilia-Romagna region as a sample for LCA. Agricultural Importance: Emilia-Romagna is known for its significant agricultural sector. It is one of the most productive regions in Italy in terms of agri-food production. The region has diverse agricultural activities, including crop cultivation, livestock farming, and food processing. Choosing this region allows you to study a region with a rich and varied agri-food system. Regional Specificities: Emilia-Romagna may possess specific aspects, such as traditional farming practices, local varieties of crops, or particular environmental concerns, which make it interesting to study from an LCA perspective. Analyzing the region can provide insights into the specific sustainability issues and potential improvement strategies related to agri-food production in that area. Policy Relevance: Emilia-Romagna may have implemented specific policies or initiatives related to sustainable agriculture or environmental protection, such as the National Quality System for Integrated Production and precision farming. By choosing this region, you can assess the effectiveness of such policies and identify areas for further improvement. The findings from the LCA analysis can contribute to evidence-based decision-making and policy development at the regional or national level.

The first production method is based on the cross-compliance rules introduced by the CAP, according to the EC regulation No. 1306/2013 introducing the principle that farmers—to have access to the EU payment system—must comply with certain rules concerning the correct agronomic management of the land, environmental protection, public health, animal health, and animal welfare (Agea Agenzia per le Erogazioni in Agricoltura). Non-compliance and non-compliance with the standards entail a mechanism to reduce the total amount of both direct payments (Single Payment) and Rural Development payments, to which each farmer would be entitled. The level of attention towards the environment involved is of a minimum level: compliance obligations (LAA) (Table S3).

3.2. Integrated Production

This production envisages the adhesion of the companies to the SQNPI (National Quality System for Integrated Production) certification system in compliance with UNI EN ISO 22005:2008 standards [56]. SQNPI envisages the definition of national guidelines that represent a guideline tool aimed at an increasing harmonization of regional ‘Technical Norms’, respecting the climatic/environmental, cultivation, and phytosanitary peculiarities that distinguish the different agricultural areas of the Italian territory. They indicate the intervention criteria, agronomic solutions, and strategies to be adopted for crop defense and weed control, with a view to a lower impact on man and the environment, allowing economically sustainable production.

The adoption of regional integrated production specifications and the implementation of a rigorous traceability system are aimed at proving that certified products come from farms that apply these specifications. Integrated agricultural production maximizes the use of natural resources, as long as they can adequately substitute for the technical means adopted in conventional agriculture, and only the use of the latter when they are deemed necessary to optimize the compromise between environmental and health requirements and economic needs. About available techniques, all things being equal, the choice falls primarily on those with less impact and, in any case, excludes those with a high impact. The level of attention towards the environment is medium: certifications and quality labels (LAA2) (Table S3).

3.3. Advanced Agronomic Techniques: Precision Farming

Precision agriculture is a farming management strategy whereby data are collected, processed, analyzed, and combined with other information to guide decisions according to spatial and temporal variability to improve the resource efficiency, productivity, quality, profitability, and sustainability of agricultural production [50]. It is also known as precision agriculture, using information and digital technologies, to rationally manage temporal variability and variability within plots, and to modulate cultivation interventions to maximize their efficiency. In other words, it is a set of technologies aimed at collecting data that, once analyzed, can be used to make decisions regarding production activities in the field, doing the right thing, at the right time and the right point. The goal is to increase production, both qualitatively and quantitatively, while minimizing input costs and the impact of agricultural activities on the environment. The level of attention towards the environment is high: Advanced Agronomic Techniques (LAA3) (Table S3).

4. Methodology

4.1. Goal and Scope

The goal is to calculate the environmental impacts related to the cultivation of processing tomatoes, at 3 different levels of environmental awareness (LAA), by applying LCA analysis. The system studied relates to the production of processing tomatoes, analyzing only the agricultural phase monitored at a specific sample of 3 farms codified as follows: LAA1 Cross Compliance Standards (Cross Compliance), LAA2 Integrated Production, LAA3 Advanced Agronomic Techniques (Precision Farming). The functional unit to which the study refers is represented by 1 kg of tomato.

4.2. System Boundaries

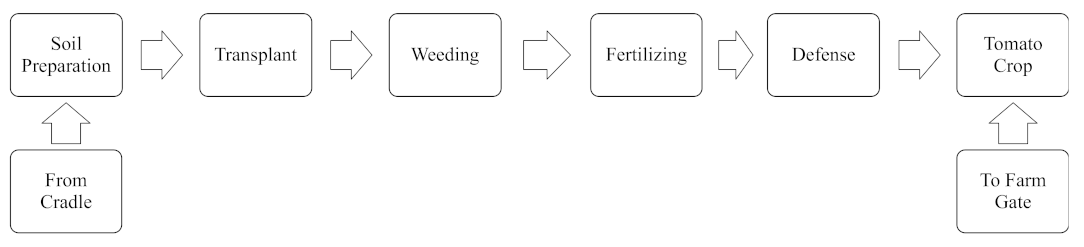

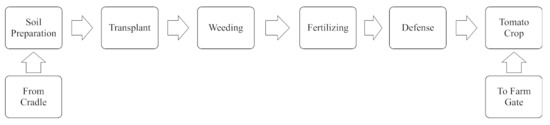

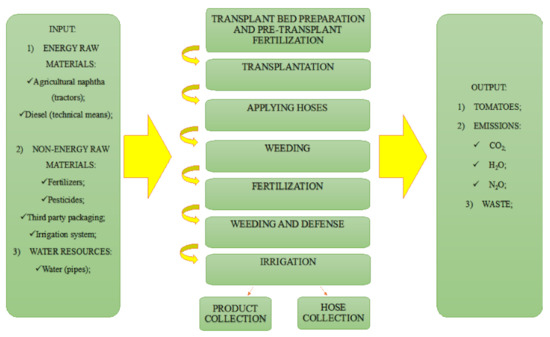

Given the objectives of the study, the system covers all material, energy, and transport flows related to tomato production limited to the primary phase on the monitored farms (see Figure 1) (from cradle to farm gate).

Figure 1.

System boundaries for the LCA corresponding to the industries tomato value chain.

4.3. Inventory and Impact Assessment

The data were collected from the CRPV database (CRPV LIFE+ Project). To minimize exogenous variables that may influence the following analyses, two years are considered: 2018 and 2019. We chose to use two years for the analysis to mitigate some exogenous variables that could have influenced impact assessment, such as seasonal variability, complete production cycle, reduce data variability, and consideration of long-term impacts. The calculation model for the LCIA is ReCiPe, and the software used was OpenLCA (1.11 version), a very flexible software that allows the quantification of impacts derived from inputs and outputs. The ReCiPe method analyzes impacts at two levels of investigation: midpoint and endpoint [57,58]. The endpoint approach involved three targets, such as Human Health, Ecosystems, and Resources. For the calculation of the GWP-Global Warming Potential indicator, the IPCC 2007 characterization factors (vers.1.02) were used in the LCIA (Life Cycle Impact Assessment) phase. In consideration of the guidelines given in PCR 2011:20 (vers. 1.01) (Product Category Rules, following ISO 14025:2006) [59], we refer to the product category “Vegetables”. It was decided to base the study on the assumptions reported in Table S2.

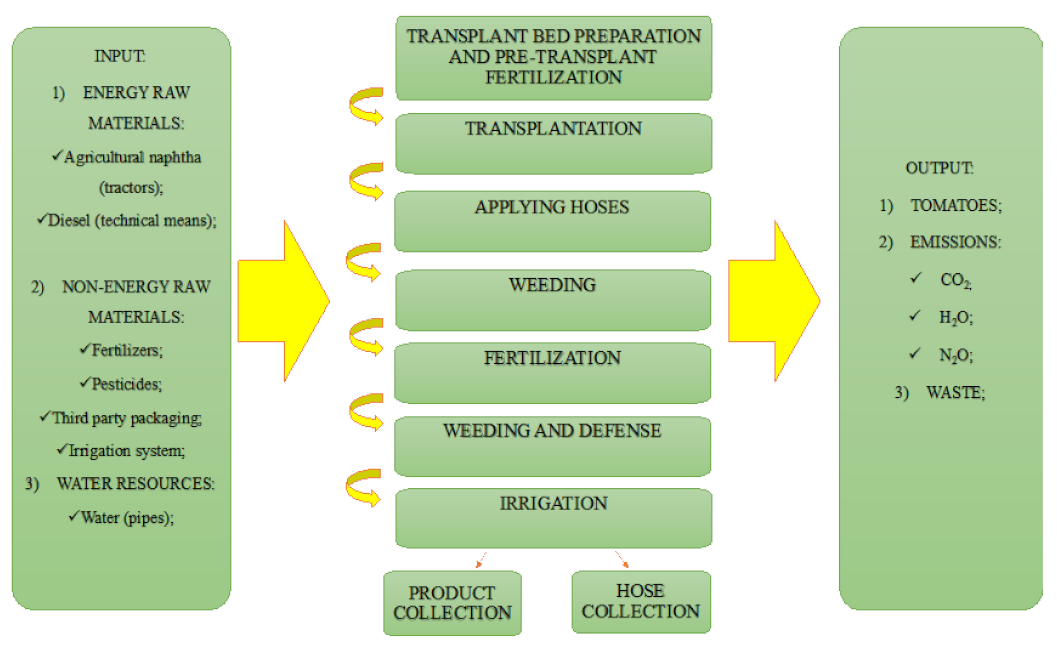

The analysis of the life cycle begins with the preparatory tillage of the soil for planting. The production process involves the preparatory tillage of the soil with any pre-seeding fertilization, transplanting with any simultaneous laying of hoses for drip irrigation, chemical weed control treatments, nitrogenous cover fertilization, weeding, irrigation, and defense treatments for diseases and insects. Harvesting is conducted with special self-propelled harvesters that load the tomatoes directly into trailers for transport. Table S3 summarizes the main characteristics of the monitored farms and the level of the main inputs. The categorization of the results (GWP) by relevant emission stages in tomatoes is described in Table 1. The reference database is Ecoinvent, which constitutes a complete, consistent, and transparent source of data.

Table 1.

Description of the impact categories considered in LCA.

Figure 2 shows the flowchart representing the input and output flows studied in the analysis described above.

Figure 2.

Tomato production Flow Chart (CRPV LIFE+ Project).

5. Results

5.1. Life Cycle Impact Assessment

In this section, the estimation of impacts resulting from the Business Models adopted in fresh tomato production—LAA1, LAA2, and LAA3—is presented. The data collected in the LCI phase are processed by the OpenLCA software to compare and evaluate the strengths and weaknesses of the productions under consideration. The ReCiPe method was applied at the endpoint level, and Carbon Footprint results were represented for greater comprehensiveness of the analyses.

5.2. Endpoint Results

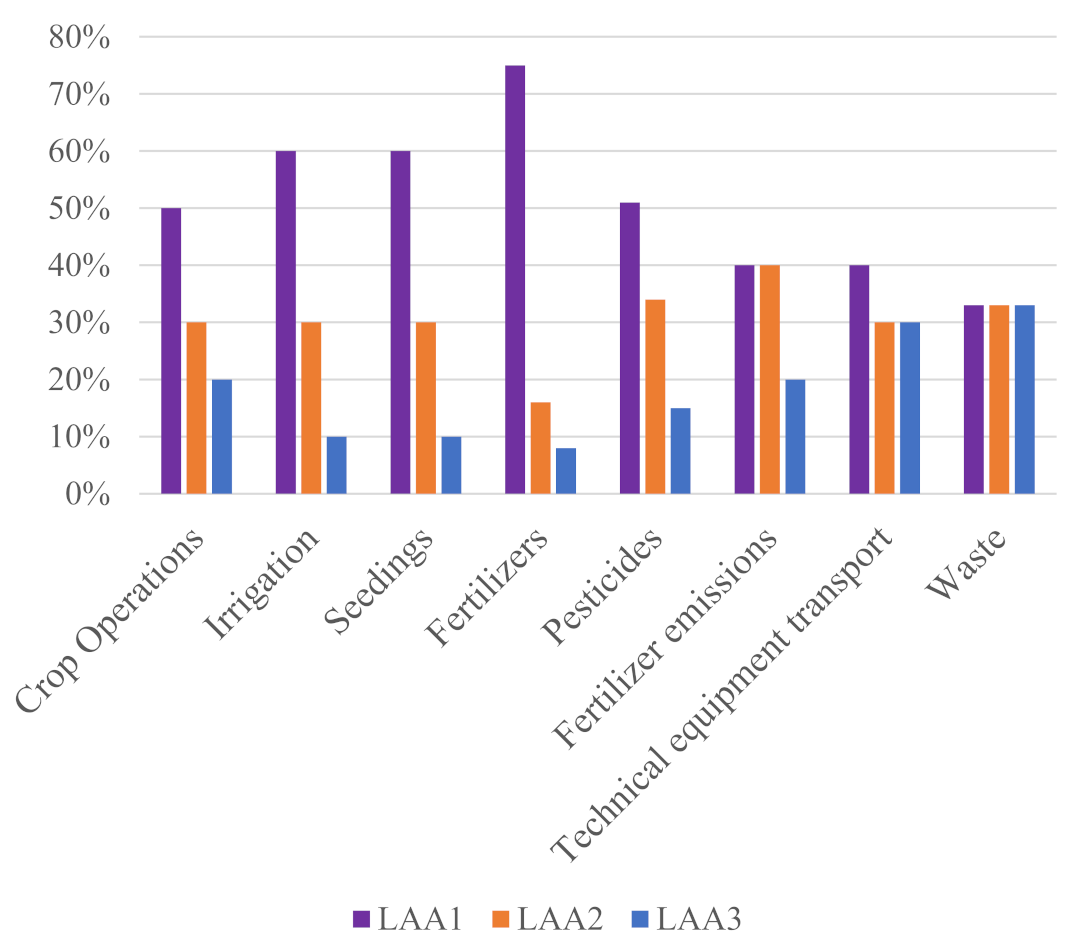

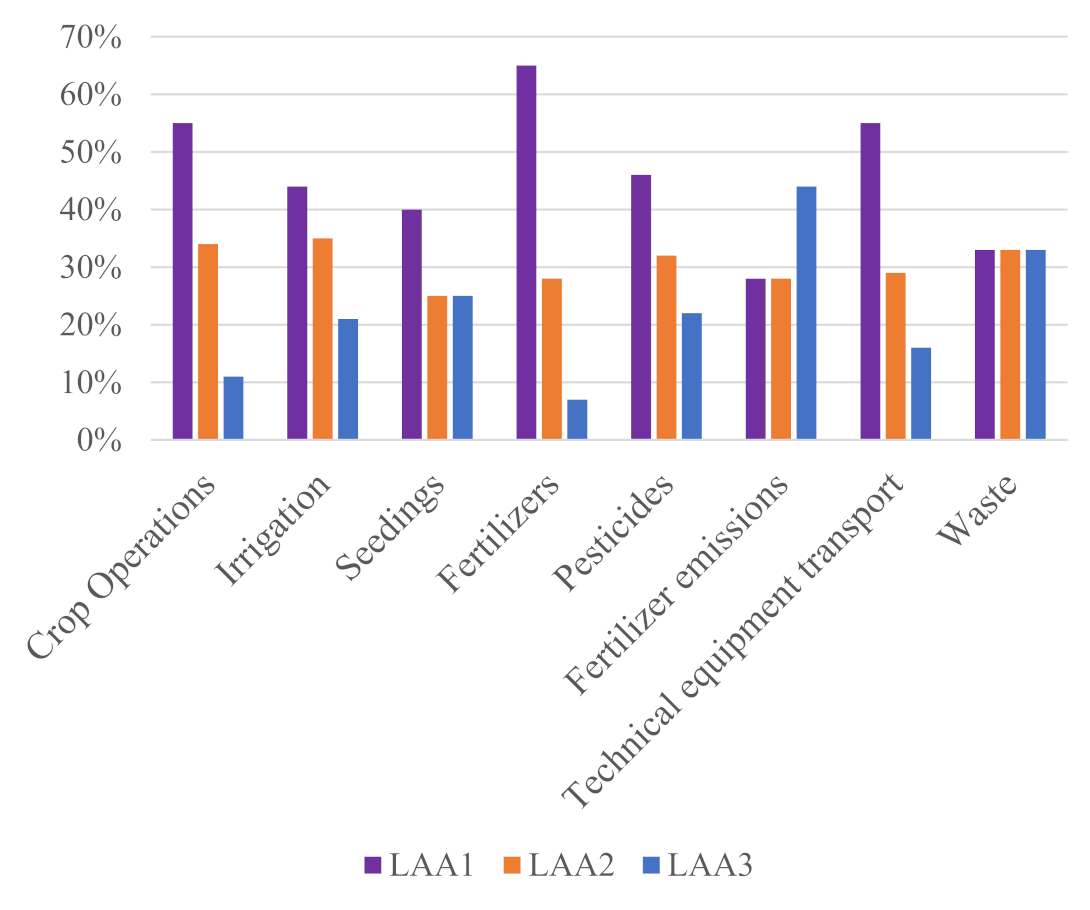

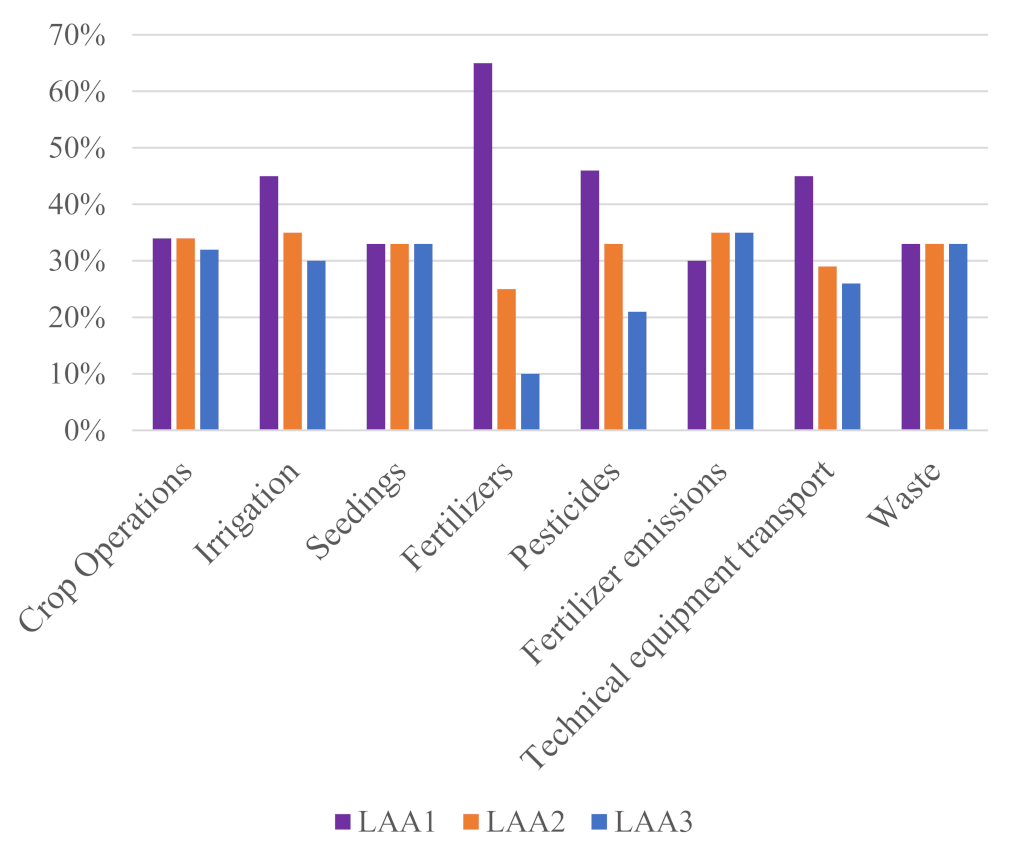

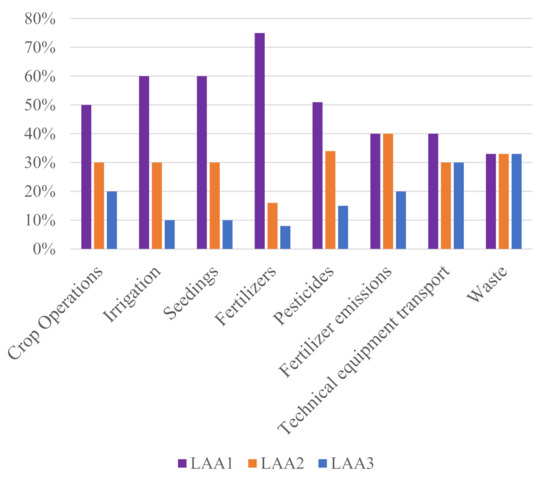

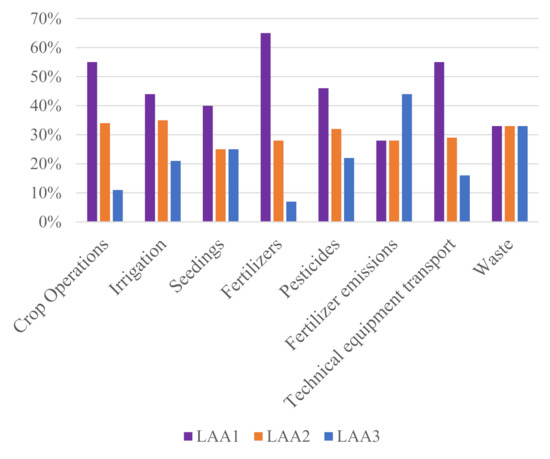

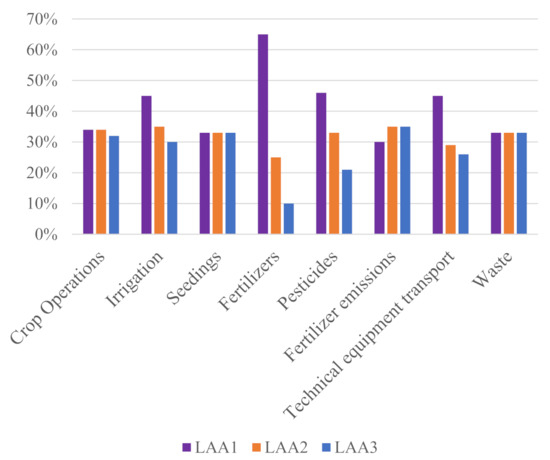

Through the analysis of impacts at the endpoint level, a general overview of the environmental damage caused by the production stages of the three techniques under consideration was obtained. Figure 3, Figure 4 and Figure 5 show the endpoint results for the macro-areas, respectively, Human Health, Ecosystems, and Resources. To make the comparison, the data were standardized, and the results were represented through the following histograms. Results are presented in base 100, where 100% represents the total impacts caused for each stage of production.

Figure 3.

ReCiPe method results on endpoint. Impact category: Human Health (source: OpenLCA 1.11).

Figure 4.

ReCiPe method results on endpoint. Impact category: Ecosystems (source: OpenLCA 1.11).

Figure 5.

ReCiPe method results on endpoint. Impact category: Resources (source: OpenLCA 1.11).

In Figure 3, we have depicted the endpoint results for the Human Health impact category. We observed that the precision farming Business Model has record performance in terms of environmental impact. For example, it manages to reduce impacts in the irrigation phase by 90% compared to standard production. Precision farming manages to reduce impacts from fertilizer use by 92%. LAA2 has improvements over standard production, such as 20% less during crop operation, 30% less irrigation, 30% less seeding, and 56% less fertilizer. For pesticides, we observe an opposite trend to the predecessor, with LAA3 impacting 10% more than LAA1 and LAA2.

In Figure 4, we have depicted the endpoint results for the Ecosystems impact category. LAA3 reduces impacts by 44% in crop operations, 23% in irrigation, 15% in sowing, 58% in fertilizers, and 39% in technical equipment transport compared to standard production. As in Human Health, LAA3 has a greater impact on Ecosystems than LAA1 and LAA2. Integrated production is in line with standard production, differing with reduced impacts compared to LAA1 for crop operation (21%) and fertilizers (37%).

Looking at the results in Figure 5, the trend in favor of LAA3 is confirmed for the Fertilizers, Crop Operations, and Irrigation phases. However, the emission from fertilizer use reverses the previous trend in favor of LAA1 and LAA2. The fertilization phase represents the best result of precision farming compared to integrated production and standard production. In conclusion, we can state that LAA3 for each macro-area analyzed, such as Human Health (Figure 3), Ecosystems (Figure 4), and Resources (Figure 5), succeeds in impacting less significantly. Integrated production performs in line with standard production with a few exceptions, such as crop operations and fertilizers.

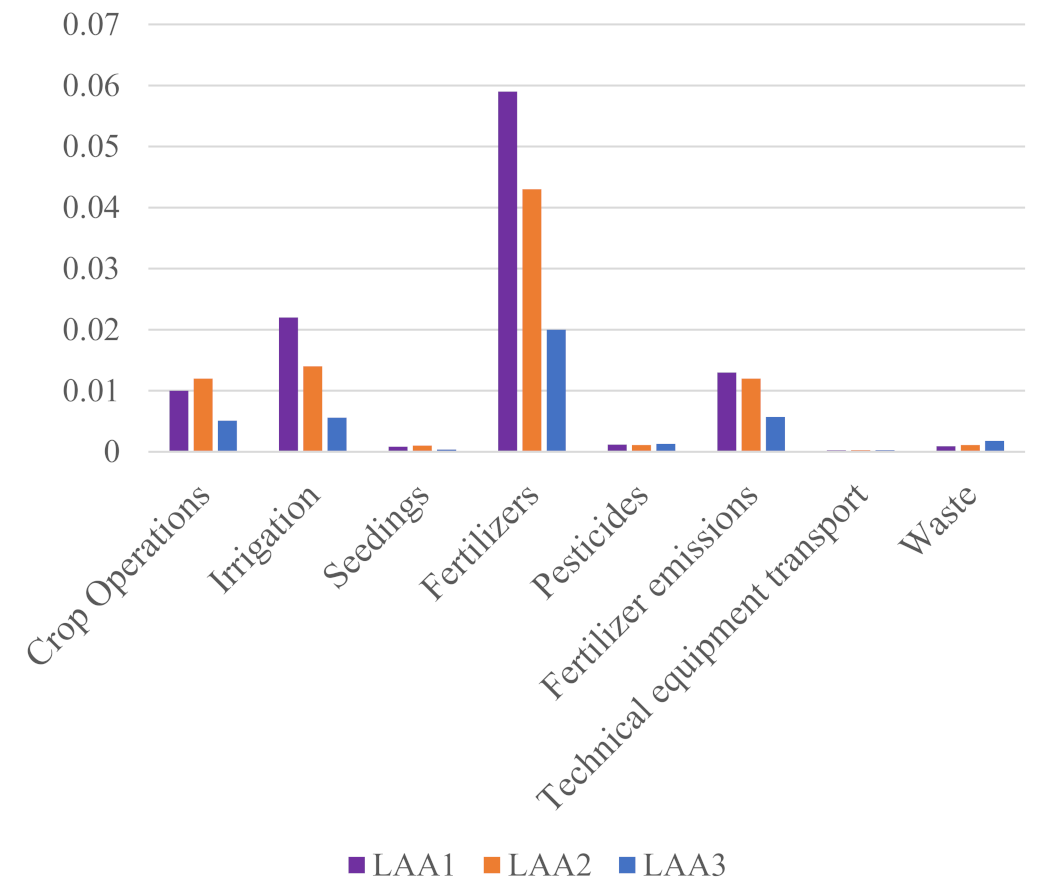

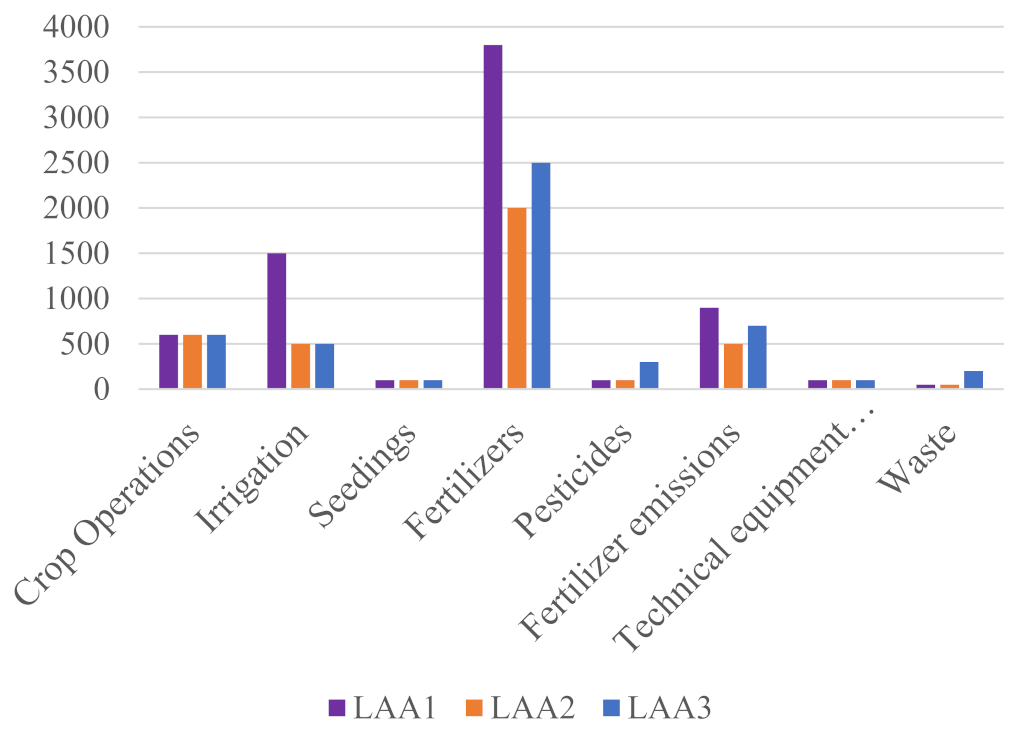

5.3. Carbon Footprint

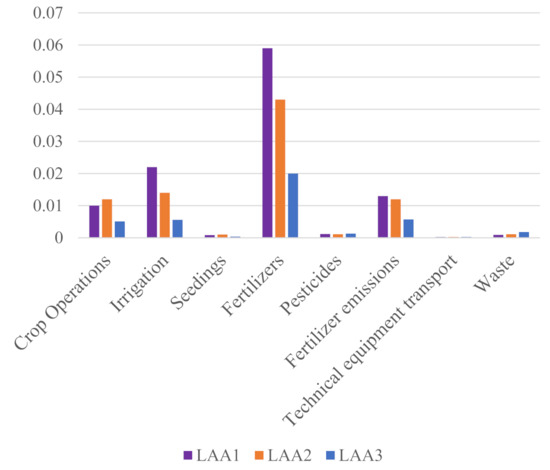

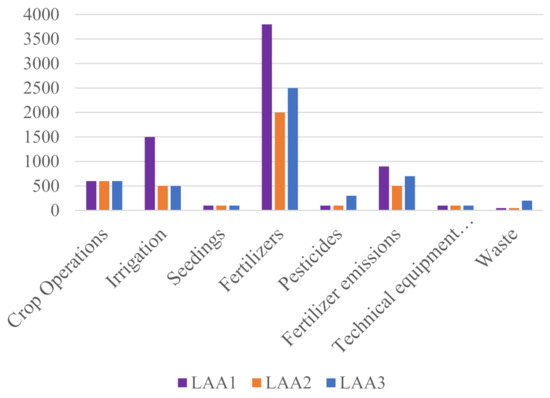

Figure 6 and Figure 7 show the results of the amount of carbon dioxide emitted by the LAA1, LAA2, and LAA3 productions for each functional unit (1 kg of fresh processing tomatoes), concerning the individual production steps.

Figure 6.

Comparison of IPCC GWP emissions kg CO2eq/kg produced by LAA1, LAA2, and LAA3 production techniques (source: OpenLCA 1.11).

Figure 7.

Comparison of IPCC GWP emissions kg CO2eq/ha produced by LAA1, LAA2, and LAA3 production techniques (source: OpenLCA 1.11).

The greatest climate-altering potential is attributed to fertilizer production, with values ranging from 0.59 in LAA1 to 0.44 in LAA3. It should be pointed out that between Levels 2 and 3, the difference in terms of nitrogenous U.F. is not great (105 and 97 kg); however, the lower percentage importance of the fertilizer item in Level 3 is evident, which is mainly attributable to the use of pelleted manure, rather than synthetic products alone.

As in Figure 6 and Figure 7, the substantial difference of LAA3 is evident, not only in comparison with LAA1, but also with LAA2, production, compared to which it has 52% lower emissions; this is mainly attributable to the more efficient use of inputs. It is confirmed that the greatest climate-altering potential comes from fertilizer production, with percentages ranging from 55% of total emissions in LAA1 to 50% in LAA3. This is followed by emissions from irrigation due to increased use resulting from increasingly dry summers in Italy in recent years, the use of nitrogen fertilizers, and crop operations [60,61].

The irrigation item, which is the main discriminating factor between the different LAAs, assumes decreasing importance going from LAA1 (20.4%) to LAA2 (16.1%) and finally to LAA3 (13.9%). The waste item of Level 3, which includes hose disposal (considered to be of annual duration), is higher than Level 2 in absolute terms and accounts for 4.4% of the total emissions compared to about 1% in the other cases (Table S5). Environmental Level 2 allowed a saving of 0.023 kg CO2eq/kg compared to LAA1 and, thus, considering the 54 t/ha of production, an overall saving of 1242 kg CO2eq. LAA3, on the other hand, allowed a decrease in emissions, compared to LA2, of 0.044 kg CO2eq/kg, with an overall saving, given the 136 t/ha of production, of 5984 kg CO2eq (Table S4).

In Figure 7, CO2eq comparisons are expressed per unit area (hectare). In this case, decoupling the result from production per hectare, and hence from input efficiency, reverses the order of magnitude of emissions between Tiers 2 and 3, with LAA3, which sees greater use of fertilizers and pesticides, standing at 5542 kg CO2eq/ha compared to 4547 in LAA2; however, there is still a differential, with LAA1 ranging from 1600 kg CO2eq/ha in LAA3 to 2595 in LAA2.

6. Discussion and Implications

6.1. Theoretical Discussions and Implications

From a theoretical standpoint, our objective is to contribute to the adoption of stakeholder theory and corporate shared value (CSV) within corporate governance summits, specifically focusing on the agricultural sector. We emphasize the significance of the environment as a crucial stakeholder for firms, necessitating the implementation of Business Model Innovation to mitigate environmental damage and achieve ecological sustainability in production practices. To address these demands, a new Business Model based on precision farming is emerging.

Through our analysis of relevant cases, our aim is to demonstrate and argue that a new technological paradigm, driven by the trade-off between limited food resources and population growth, compels agrarian firms to modify their existing Business Models. Investments, information systems, human capital, and new technologies are among the various factors driving the innovation of Business Models. This transformation is crucial for enhancing resilience in the face of change and improving corporate competitiveness.

Furthermore, Business Model Innovation is not only embedded in changes to value propositions, strategies, and operating models, but also in the establishment of new activities, the reconfiguration of activity linkages, and the modification of activity components, as suggested by Amit & Zott. In the context of precision farming, although existing literature has highlighted various complexities, such as farm characteristics, socio-economic factors, and psychological aspects that may hinder the widespread adoption of precision agricultural technologies and the transfer of knowledge, we argue for a comprehensive analysis to comprehend how precision farming combines these three different modes of innovation, as depicted in Table S1.

6.2. Managerial Discussion and Implications

Today’s large globalized market provides new goals and horizons to be reached in terms of sustainability. There is a trade-off between quantity (such as the number of units produced) and quality (the new ESG approach). The aim is to create a new product that fully meets the needs of current and future generations. To do this, companies must innovate and pick up those aspects that have made them resilient to change in the past. A new technological paradigm is on the horizon: precision farming in the present study seems to respond well to the climatic changes of recent years [57,62] and to set new records for tomato production in Emilia-Romagna compared to the other two types of Business Models examined. The strengths of this model are the possibility of constantly monitoring air, soil, and crop humidity and adapting techniques and quantities of raw materials to the production process accordingly.

AI makes it possible, with the help of biosensors, to establish check gates, beyond which self-cleaning measures are foreseen, where the system can report a control situation or where the presence of the operator is required. Unlike LAA1 and LAA2, human intervention is targeted and measured concerning the critical control points detected by the system. In this way, even in the face of particularly variable seasons or differently fertile soils, the output is maximized without the maximum use of fertilizers and pesticides to safeguard the entire annual production.

This paper indicates the impacts related to the production of processing tomatoes concerning three levels of focus: LAA1, LAA2, and LAA3. The type of Business Model adopted in the three productions differs substantially in the level of technological specialization applied. Precision farming uses less human capital in favor of an AI-controlled automated system capable of self-managing hydroponic harvesting. Integrated production uses a more traditional approach based on SQNPI quality certification systems. Finally, the first level, based mainly on the activity and experience of the farmer, is limited to European regulations and standards for tomato harvesting. The large gap between the different productions imposes the emergence of different Business Models, depending on the level of technology required.

From the endpoint results shown in Figure 3, Figure 4 and Figure 5, it can be observed that LAA3 has a significantly lower impact than LAA1 and LAA2, except in the case of pesticides. In this particular case, precision farming shows slightly higher impact levels compared to the other techniques. It might appear that the use of high technology fails to minimize pesticide usage. However, by referring to Table S3, we can observe that the yield of fresh tomatoes per hectare is much higher for LAA3 (100) than for LAA2 (62) and LAA1 (77). Hence, we can conclude that precision farming achieves a 30% higher yield than standard production and a 61% higher yield than integrated production.

Despite the use of advanced systems, such as LAA3, the use of fertilizers remains otherwise high, although precision farming manages to minimize damage to resources and impacts from fertilizers compared to other techniques in the ReCiPe endpoint in Figure 3, Figure 4 and Figure 5. Similarly, in Figure 6 and Figure 7, in the IPCC GWP comparison, kg CO2eq/kg/ha fertilizers are the input with the highest atmospheric CO2 emissions. Again, the most important differential is represented by LAA3, which deviates strongly from the performance of LAA1 and LAA3. In Figure 7, it is interesting to note that “crop operations” have the same levels of greenhouse gas emissions, because tomato harvesting is one of those stages of “technical equipment transport” that has not been affected by innovation.

The particularly low cost of harvesting operations both in Italy and abroad does not incentivize company Business Models to change, as they are currently based on an almost optimal price–quality ratio for the company. Tomato harvesting is still conducted by hand, with a very low labor cost and a high level of quality compared to possible automation, as also shown in other studies [58,63,64]. In conclusion, we can define LAA3 as one of the best Business Models adopted in Emilia-Romagna by companies in the agri-food sector in terms of environmental performance measured through LCA analysis.

7. Conclusions and Implications

Despite empirical evidence demonstrating that precision farming can improve sustainability outcomes for businesses, the limitations and barriers to the adoption of innovative Business Models in this sector have been extensively investigated in the literature. From contextual factors (both external and internal) to farm characteristics, to behavioral factors, the literature has highlighted many obstacles to the introduction of innovations, particularly those derived from a structured process of knowledge acquisition and formalization (the AKAP approach). The aforementioned barriers may result in a reduced rate of innovation and an unequal distribution of knowledge access among potential beneficiaries, leading to the emergence of phenomena such as elite capture. This is confirmed by the EU communication on the Future of Food and Farming, which highlights the uneven access to technology and knowledge across the Union. This may limit the effectiveness of Common Agricultural Policy (CAP) instruments, thereby reducing the future competitiveness and sustainability of the farming sector and rural areas. This scenario indirectly challenges the role of institutional arrangements in facilitating knowledge transfer and innovation adoption. Institutional factors play a crucial role in the adoption of innovation, as some institutional environments are more conducive to innovation than others. Sauer and Vrolijk emphasize the significance of the institutional context, in which a farm operates for its innovation behavior, including factors such as access to finance, institutional support, cultural values, and cooperation with research entities and knowledge-producing institutions. Inadequate local policy interventions, insufficient institutional support, lack of coordination between public and private sectors, and distance from markets or suppliers can also hinder the adoption process [25,65,66].

Environmental impacts, such as climate change, water consumption, land use, and pollution, can be mitigated through the implementation of pollution reduction strategies across food production and consumption systems. For example, hydrothermal carbonization (HTC) is a technology that enables the valorization of various types of agricultural waste, including wood, straw, and rice husks, for the production of carbon-negative materials. HTC involves a process where lignocellulosic biomass undergoes thermal treatment in a water-based medium, resulting in the production of valuable carbon-based products [67].

Additionally, the adoption of innovative approaches to sustainability, such as increasing access to local food outlets, promoting local food production, implementing closed-loop resource recovery systems, and other novel strategies, can further enhance the sustainability of these systems.

In literature studies, LCA has some limitations, such as the difficulty of having frequently updated databases with data for each country or region. This could lead to quite a few alterations concerning the calculation of impact categories because the degree of supply of raw materials varies depending on the natural resources a country has [68]. In agricultural production, land morphology, as well as climate and temperature, influences production. Various studies show that the productions that have the least impact are not always the most economically and socially efficient [10,12]. The use of state-of-the-art technologies very often hides notional costs, such as the knowledge costs necessary for the proper functioning of technology systems [69]. Therefore, it would be useful to compare the three productions under consideration by applying S-LCA and LCC [70,71,72].

Life Cycle Assessment (LCA) provides a fundamental framework for producers to comprehensively evaluate the human health and environmental impacts associated with food production and consumption. However, current LCA models and databases are limited in their ability to accurately assess the short- and long-term risks and benefits of food, feed, and biofuel production systems. To address emerging issues in agricultural production, such as pesticide exposure, soil degradation, biodiversity loss, and the spread of genetically modified crops, LCA practitioners and researchers must continue to refine and develop LCA tools. In order to achieve significant advances in the use of Life Cycle Assessment (LCA) concepts and life cycle-based tools, it is imperative that we push the boundaries of our current methodology. This includes developing new and improved methods and models, as well as building comprehensive databases to support these efforts. This is particularly important in addressing the numerous and wide-ranging health and nutritional challenges that society currently faces.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su151310365/s1, Table S1. Presented the main factors of business model in case of conventional and precision farming technology (Lencsés, et al., 2020) [29]. Table S2. LCI: Inventory of following inputs/outputs and observe the following operating methodologies (Database CRPV Soc. Coop.). Table S3. The main characteristics of industrial tomato industry (Database CRPV Soc. Coop.). Table S4. IPCC GWP LAA1, LAA2 and LAA3 productions (KgCO2 eq/kg tomato) (Database CRPV Soc. Coop.). Table S5. IPCC GWP LAA1, LAA2 and LAA3 productions (% KgCO2 eq/kg tomato) (Database CRPV Soc. Coop.).

Author Contributions

Methodology, S.S.; Software, A.B.; Writing—original draft, A.B.; Writing—review & editing, D.C.; Supervision, S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study due to not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The Role of Life Cycle Assessment in Supporting Sustainable Agri-Food Systems: A Review of the Challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Calero, M.; Clemente, G.; Fartdinov, D.; Bañón, S.; Muñoz, I.; Sanjuán, N. Upscaling via a Prospective LCA: A Case Study on Tomato Homogenate Using a Near-to-Market Pasteurisation Technology. Sustainability 2022, 14, 1716. [Google Scholar] [CrossRef]

- Lazonick, W. The New Economy Business Model and Sustainable Prosperity. SSRN Electron. J. 2008, 1–35. [Google Scholar] [CrossRef]

- Massa, L.; Tucci, C.L.; Afuah, A. A Critical Assessment of Business Model Research. Acad. Manag. Ann. 2017, 11, 73–104. [Google Scholar] [CrossRef]

- Montanarella, L.; Panagos, P. The Relevance of Sustainable Soil Management within the European Green Deal. Land Use Policy 2021, 100, 104950. [Google Scholar] [CrossRef]

- Pe’er, G.; Finn, J.A.; Díaz, M.; Birkenstock, M.; Lakner, S.; Röder, N.; Kazakova, Y.; Šumrada, T.; Bezák, P.; Concepción, E.D.; et al. How Can the European Common Agricultural Policy Help Halt Biodiversity Loss? Recommendations by over 300 Experts. Conserv. Lett. 2022, 15, e12901. [Google Scholar] [CrossRef]

- Zaborowska, M.; Bernat, K.; Pszczółkowski, B.; Wojnowska-Baryła, I.; Kulikowska, D. Anaerobic Degradability of Commercially Available Bio-Based and Oxo-Degradable Packaging Materials in the Context of Their End of Life in the Waste Management Strategy. Sustainability 2021, 13, 6818. [Google Scholar] [CrossRef]

- Pushkar, S. Life-Cycle Assessment of LEED-CI v4 Projects in Shanghai, China: A Case Study. Sustainability 2023, 15, 5722. [Google Scholar] [CrossRef]

- Del Borghi, A.; Gallo, M.; Strazza, C.; Del Borghi, M. An Evaluation of Environmental Sustainability in the Food Industry through Life Cycle Assessment: The Case Study of Tomato Products Supply Chain. J. Clean. Prod. 2014, 78, 121–130. [Google Scholar] [CrossRef]

- Sica, D.; Esposito, B.; Malandrino, O.; Supino, S. The Role of Digital Technologies for the LCA Empowerment towards Circular Economy Goals: A Scenario Analysis for the Agri-Food System. Int. J. Life Cycle Assess. 2022, 1–24. [Google Scholar] [CrossRef]

- Borghesi, G.; Stefanini, R.; Vignali, G. Life Cycle Assessment of Packaged Organic Dairy Product: A Comparison of Different Methods for the Environmental Assessment of Alternative Scenarios. J. Food Eng. 2022, 318, 110902. [Google Scholar] [CrossRef]

- Colucci, V.; Manfrida, G.; Mendecka, B.; Talluri, L.; Zuffi, C. LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability 2021, 13, 1935. [Google Scholar] [CrossRef]

- Sestino, A.; Rossi, M.V.; Giraldi, L.; Faggioni, F. Innovative Food and Sustainable Consumption Behaviour: The Role of Communication Focus and Consumer-Related Characteristics in Lab-Grown Meat (LGM) Consumption. Br. Food J. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Jestratijevic, I.; Uanhoro, J.O.; Creighton, R. To Disclose or Not to Disclose? Fashion Brands’ Strategies for Transparency in Sustainability Reporting. J. Fash. Mark. Manag. Int. J. 2022, 26, 36–50. [Google Scholar] [CrossRef]

- Bozkurt, S.; Gligor, D.; Gligor, N. Investigating the Impact of Psychological Customer Engagement on Customer Engagement Behaviors: The Moderating Role of Customer Commitment. J. Mark. Anal. 2022, 10, 408–424. [Google Scholar] [CrossRef]

- Rietveld, R.; Van Dolen, W.; Mazloom, M.; Worring, M. What You Feel, Is What You like Influence of Message Appeals on Customer Engagement on Instagram. J. Interact. Mark. 2020, 49, 20–53. [Google Scholar] [CrossRef]

- Sun, Y.; Bao, Q.; Taghizadeh-Hesary, F. Green Finance, Renewable Energy Development, and Climate Change: Evidence from Regions of China. Hum. Soc. Sci. Commun. 2023, 10, 107. [Google Scholar] [CrossRef] [PubMed]

- Lemoine, G.J.; Eva, N.; Meuser, J.D.; Falotico, P. Organizational Performance with a Broader Focus: The Case for a Stakeholder Approach to Leadership. Bus. Horiz. 2021, 64, 401–413. [Google Scholar] [CrossRef]

- Sigel, A. CSR statements: Incentives and enforcement in the wake of the business roundtable’s statement on corporate purpose. Boston Univ. Law Rev. 2021, 101, 803–833. [Google Scholar]

- López Nevárez, V.; Zavala Féliz, B.D. La Responsabilidad Social En Las Dimensiones de La Ciudadanía Corporativa. Un Estudio de Caso En La Manufactura Agrícola. CIRIEC-España Rev. Econ. Pública Soc. Coop. 2019, 97, 179–211. [Google Scholar] [CrossRef]

- Degieter, M.; Gellynck, X.; Goyal, S.; Ott, D.; De Steur, H. Life Cycle Cost Analysis of Agri-Food Products: A Systematic Review. Sci. Total Environ. 2022, 850, 158012. [Google Scholar] [CrossRef] [PubMed]

- Bojacá, C.R.; Wyckhuys, K.A.G.; Schrevens, E. Life Cycle Assessment of Colombian Greenhouse Tomato Production Based on Farmer-Level Survey Data. J. Clean. Prod. 2014, 69, 26–33. [Google Scholar] [CrossRef]

- Naseer, M.; Persson, T.; Hjelkrem, A.-G.R.; Ruoff, P.; Verheul, M.J. Life Cycle Assessment of Tomato Production for Different Production Strategies in Norway. J. Clean. Prod. 2022, 372, 133659. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Life Cycle Analysis of Organic Tomato Production and Supply in Sweden. J. Clean. Prod. 2018, 196, 635–643. [Google Scholar] [CrossRef]

- Tell, J.; Hoveskog, M.; Ulvenblad, P.; Ulvenblad, P.-O.; Barth, H.; Ståhl, J. Business Model Innovation in the Agri-Food Sector: A Literature Review. Br. Food J. 2016, 118, 1462–1476. [Google Scholar] [CrossRef]

- Knierim, A.; Boenning, K.; Caggiano, M.; Cristóvão, A.; Dirimanova, V.; Koehnen, T.; Labarthe, P.; Prager, K. The AKIS Concept and Its Relevance in Selected EU Member States. Outlook Agric. 2015, 44, 29–36. [Google Scholar] [CrossRef]

- Knierim, A.; Kernecker, M.; Erdle, K.; Kraus, T.; Borges, F.; Wurbs, A. Smart Farming Technology Innovations—Insights and Reflections from the German Smart-AKIS Hub. NJAS Wagening. J. Life Sci. 2019, 90–91, 100314. [Google Scholar] [CrossRef]

- Seo, J.; Lee, J.; Jung, S.; Park, S. The Role of Creating Shared Value and Entrepreneurial Orientation in Generating Social and Economic Benefits: Evidence from Korean SMEs. Sustainability 2023, 15, 6168. [Google Scholar] [CrossRef]

- Lencsés, E.; Mészáros, K. Business Model Innovation with Precision Farming Technology from the Farmers Point of View. Hung. Agric. Eng. 2020, 8, 79–81. [Google Scholar] [CrossRef]

- Rose, D.C.; Chilvers, J. Agriculture 4.0: Broadening Responsible Innovation in an Era of Smart Farming. Front. Sustain. Food Syst. 2018, 2, 87. [Google Scholar] [CrossRef]

- Kovács, I.; Husti, I. The Role of Digitalization in the Agricultural 4.0—How to Connect the Industry 4.0 to Agriculture? Hung. Agric. Eng. 2018, 33, 38–42. [Google Scholar] [CrossRef]

- Lazonick, W. Innovative Business Models and Varieties of Capitalism: Financialization of the U.S. Corporation. Bus. Hist. Rev. 2010, 84, 675–702. [Google Scholar] [CrossRef]

- Sutherland, L.-A.; Adamsone-Fiskovica, A.; Elzen, B.; Koutsouris, A.; Laurent, C.; Stræte, E.P.; Labarthe, P. Advancing AKIS with Assemblage Thinking. J. Rural Stud. 2023, 97, 57–69. [Google Scholar] [CrossRef]

- Thomson, L. Leveraging the Value from Digitalization: A Business Model Exploration of New Technology-Based Firms in Vertical Farming. J. Manuf. Technol. Manag. 2022, 33, 88–107. [Google Scholar] [CrossRef]

- Massa, L.; Tucci, C.L. Business Model Innovation; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Mitchell, D.W.; Bruckner Coles, C. Business Model Innovation Breakthrough Moves. J. Bus. Strategy 2004, 25, 16–26. [Google Scholar] [CrossRef]

- Lindgardt, Z.; Reeves, M.; Stalk, G., Jr.; Deimler, M. Business Model Innovation: When the Game Gets Tough, Change the Game. In Own the Future; Wiley: Hoboken, NJ, USA, 2012; pp. 291–298. [Google Scholar]

- Amit, R.; Zott, C. Creating Value Through Business Model Innovation. MIT Sloan Manag. Rev. 2012, 53, 41–49. [Google Scholar]

- Schnebelin, É. Linking the Diversity of Ecologisation Models to Farmers’ Digital Use Profiles. Ecol. Econ. 2022, 196, 107422. [Google Scholar] [CrossRef]

- Lampropoulos, G.; Siakas, K.; Anastasiadis, T. Internet of Things in the Context of Industry 4.0: An Overview. Int. J. Entrep. Knowl. 2019, 7, 4–19. [Google Scholar] [CrossRef]

- Pallavi, B.; Othman, B.; Trivedi, G.; Manan, N.; Pawar, R.S.; Singh, D.P. The Application of the Internet of Things (IoT) to Establish a Technologically Advanced Industry 4.0 for Long-Term Growth and Development. In Proceedings of the 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 28–29 April 2022; pp. 1927–1932. [Google Scholar]

- Silverio-Fernández, M.; Renukappa, S.; Suresh, S. What Is a Smart Device?—A Conceptualisation within the Paradigm of the Internet of Things. Vis. Eng. 2018, 6, 3. [Google Scholar] [CrossRef]

- Sestino, A.; Prete, M.I.; Piper, L.; Guido, G. Internet of Things and Big Data as Enablers for Business Digitalization Strategies. Technovation 2020, 98, 102173. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Killeen, P.; Ding, B.; Kiringa, I.; Yeap, T. IoT-Based Predictive Maintenance for Fleet Management. Procedia Comput. Sci. 2019, 151, 607–613. [Google Scholar] [CrossRef]

- Boye, J.I.; Arcand, Y. Current Trends in Green Technologies in Food Production and Processing. Food Eng. Rev. 2013, 5, 1–17. [Google Scholar] [CrossRef]

- Mazzucato, M.; Shipman, A. Accounting for Productive Investment and Value Creation. Ind. Corp. Chang. 2014, 23, 1059–1085. [Google Scholar] [CrossRef]

- Cellura, M.; Ardente, F.; Longo, S. From the LCA of Food Products to the Environmental Assessment of Protected Crops Districts: A Case-Study in the South of Italy. J. Environ. Manag. 2012, 93, 194–208. [Google Scholar] [CrossRef] [PubMed]

- Heller, M.C.; Keoleian, G.A.; Willett, W.C. Toward a Life Cycle-Based, Diet-Level Framework for Food Environmental Impact and Nutritional Quality Assessment: A Critical Review. Environ. Sci. Technol. 2013, 47, 12632–12647. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Muñoz, P.; Antón, A.; Rieradevall, J. Assessment of Tomato Mediterranean Production in Open-Field and Standard Multi-Tunnel Greenhouse, with Compost or Mineral Fertilizers, from an Agricultural and Environmental Standpoint. J. Clean. Prod. 2011, 19, 985–997. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a Tomato Crop in a Multi-Tunnel Greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Page, G.; Ridoutt, B.; Bellotti, B. Carbon and Water Footprint Tradeoffs in Fresh Tomato Production. J. Clean. Prod. 2012, 32, 219–226. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Khosla, S.; Van Acker, R.; Young, S.B.; Whitney, S.; Hendricks, P. Life Cycle Perspectives on the Sustainability of Ontario Greenhouse Tomato Production: Benchmarking and Improvement Opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Winans, K.; Brodt, S.; Kendall, A. Life Cycle Assessment of California Processing Tomato: An Evaluation of the Effects of Evolving Practices and Technologies over a 10-Year (2005–2015) Timeframe. Int. J. Life Cycle Assess. 2020, 25, 538–547. [Google Scholar] [CrossRef]

- De Marco, I.; Riemma, S.; Iannone, R. Uncertainty of Input Parameters and Sensitivity Analysis in Life Cycle Assessment: An Italian Processed Tomato Product. J. Clean. Prod. 2018, 177, 315–325. [Google Scholar] [CrossRef]

- Guidi, E.; Albonetti, S. A New Food Chain Approach: Uni EN ISO 22005:2008 Voluntary Certification. Ital. J. Food Saf. 2011, 1, 291. [Google Scholar] [CrossRef]

- Zaragüeta, A.; Enrique, A.; Portell, X.; Antón, R.; Virto, I.; Orcaray, L. A Fertilisation Strategy Combining Mineral Fertiliser and Biosolid Improves Long-Term Yield and Carbon Storage in a Calcareous Soil. Agriculture 2023, 13, 860. [Google Scholar] [CrossRef]

- Finger, R.; Swinton, S.M.; El Benni, N.; Walter, A. Precision Farming at the Nexus of Agricultural Production and the Environment. Annu. Rev. Resour. Econ. 2019, 11, 313–335. [Google Scholar] [CrossRef]

- Ingwersen, W.W.; Stevenson, M.J. Can We Compare the Environmental Performance of This Product to That One? An Update on the Development of Product Category Rules and Future Challenges toward Alignment. J. Clean. Prod. 2012, 24, 102–108. [Google Scholar] [CrossRef]

- Fernandes de Oliveira, A.; Mameli, M.G.; De Pau, L.; Satta, D. Almond Tree Adaptation to Water Stress: Differences in Physiological Performance and Yield Responses among Four Cultivar Grown in Mediterranean Environment. Plants 2023, 12, 1131. [Google Scholar] [CrossRef]

- Tolettini, L.; Di Maria, E. Structuring and Measuring Environmental Sustainability in the Steel Sector: A Single Case Study. Sustainability 2023, 15, 6272. [Google Scholar] [CrossRef]

- Colovic, M.; Yu, K.; Todorovic, M.; Cantore, V.; Hamze, M.; Albrizio, R.; Stellacci, A.M. Hyperspectral Vegetation Indices to Assess Water and Nitrogen Status of Sweet Maize Crop. Agronomy 2022, 12, 2181. [Google Scholar] [CrossRef]

- Vecchio, Y.; Agnusdei, G.P.; Miglietta, P.P.; Capitanio, F. Adoption of Precision Farming Tools: The Case of Italian Farmers. Int. J. Environ. Res. Public Health 2020, 17, 869. [Google Scholar] [CrossRef]

- Vecchio, Y.; De Rosa, M.; Adinolfi, F.; Bartoli, L.; Masi, M. Adoption of Precision Farming Tools: A Context-Related Analysis. Land Use Policy 2020, 94, 104481. [Google Scholar] [CrossRef]

- Barth, H.; Ulvenblad, P.-O.; Ulvenblad, P. Towards a Conceptual Framework of Sustainable Business Model Innovation in the Agri-Food Sector: A Systematic Literature Review. Sustainability 2017, 9, 1620. [Google Scholar] [CrossRef]

- Sauer, J.; Vrolijk, H. Innovation and Performance—Evidence at Micro Level. Appl. Econ. 2019, 51, 4673–4699. [Google Scholar] [CrossRef]

- Yu, S.; Yang, X.; Li, Q.; Zhang, Y.; Zhou, H. Breaking the Temperature Limit of Hydrothermal Carbonization of Lignocellulosic Biomass by Decoupling Temperature and Pressure. Green Energy Environ. 2023; in press. [Google Scholar] [CrossRef]

- Mirabella, N.; Allacker, K.; Sala, S. Current Trends and Limitations of Life Cycle Assessment Applied to the Urban Scale: Critical Analysis and Review of Selected Literature. Int. J. Life Cycle Assess. 2019, 24, 1174–1193. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Skitmore, M. Ameliorating Time and Cost Control with Project Learning and Communication Management. Int. J. Manag. Proj. Bus. 2020, 13, 767–792. [Google Scholar] [CrossRef]

- Arcese, G.; Lucchetti, M.C.; Massa, I.; Valente, C. State of the Art in S-LCA: Integrating Literature Review and Automatic Text Analysis. Int. J. Life Cycle Assess. 2018, 23, 394–405. [Google Scholar] [CrossRef]

- Heijungs, R.; Settanni, E.; Guinée, J. Toward a Computational Structure for Life Cycle Sustainability Analysis: Unifying LCA and LCC. Int. J. Life Cycle Assess. 2013, 18, 1722–1733. [Google Scholar] [CrossRef]

- Notarnicola, B.; Hayashi, K.; Curran, M.A.; Huisingh, D. Progress in Working towards a More Sustainable Agri-Food Industry. J. Clean. Prod. 2012, 28, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).