Abstract

This study explores the underlying mechanisms of achieving sustainable digital innovation in the context of manufacturing companies. Building on the perspective of organizational unlearning, we propose that organizational unlearning could disrupt current innovation routines and positively relate to the sustainability of digital innovation, the features of which are self-referential improvement and iterative scalability. This study conducted a questionnaire survey of 274 Chinese manufacturing companies and used SmartPLS 4.0 to analyze the data. Drawing insights from data analysis results, this study discovers that organizational-level unlearning is able to make digital innovation achievable and sustainable. In addition, this study articulates the partial mediation mechanism of strategic flexibility and organizational slack. The findings unearth the utility of organizational unlearning to manufacturing companies in the digital context, contribute to the emerging literature on digital innovation by introducing organizational unlearning as a new theoretical perspective for introducing digital transformation, and offer managerial insights to help manufacturing companies leverage organizational unlearning proactively to release its long-term benefits.

1. Introduction

The emergence of new digital technologies incurs paradigm shifts in many industries and changes the competence logic among firms [1]. In order to sustain profitability in the changing environment, companies can use the development of digital transformation to remain competitive in their respective markets [2,3]. Digital transformation processes can provide access to and means of sharing the knowledge that is created and transferred [4], and embracing digital technologies becomes more relevant and is recognized as a new strategic imperative that changes the basis of firms’ sustainable advantages [5]. Although companies are well aware of the pivotal role of digital transformation, many companies remain cautious in adopting digital transformation solutions or do not know how to enact digital transformation [6] due to resource constraints, a lack of digital technology knowledge, and dependence on inherent knowledge. In addition, a crucial question emerged: how can we resolve the tension between digital and non-digital routines in one organization?

As a means of integrating resources, changing knowledge bases, and creating new knowledge, organizational learning is critical for companies to implement business strategies and obtain sustainable competitive advantages. From the perspective of organizational learning, digital transformation is a learning process geared towards using digital technologies and automated production to realize intended business goals [7,8]. Next, it becomes necessary for firms to systematically abandon the obsolete, the outdated, and the old in order to free up resources and unlearn the routines that could hamper their innovation [9,10], namely, organizational unlearning, especially when faced with new logic required to gain sustainable competitive advantages. However, there are mixed findings on the relationship between organizational unlearning and innovation [11,12], and the previous unlearning literature did not relate to the context of companies’ digital transformation. This issue shows that unlearning may be doubtful in innovation in a general sense, though whether it can play a vital role in promoting exploratory digital businesses is still ambiguous.

In addition, the focus on organizational sustainable competitiveness in the digital context is transformed into digital innovation, which results from “the new combinations of digital and physical components enabled by digital technology” [13]. Digital innovation has become an important sustainable competitiveness index [14,15]. Scholars and managers have found common ground based on the fact that manufacturing firms should adopt digital innovations in a long-lasting and organic way. Although previous studies supported the idea that sustainable digital transformation should be built on innovative companies and their business ecosystems [16], existing studies on digital innovation have not clearly distinguished its forming process and potential outcome [17,18]. Thus, the means through which manufacturing companies can iterate and match their traditional processes, structures, and norms in innovation, as well as the latent mechanism clarifying how sustainable digital innovation can be achieved, are still underexplored. Furthermore, there is obviously a research gap in explaining why some manufacturing firms are more compatible with digital innovation. Even though digital skills and competences are important resources for digital innovation, the extant literature devotes attention to critical capabilities [19,20,21]. Studies examining the process of how organizations build capabilities for sustainable digital innovation are scant, especially in the context of manufacturing companies. It is still ambiguous how and why manufacturing companies that adopt the same digital artifact, digital platform, or digital infrastructure can deliver different innovations, as well as how we can make these digital innovations sustainable instead of being a one-off transformation project. In line with this objective, the guiding research question for this study is as follows:

How could organizational unlearning lead to manufacturing firms’ sustainable digital innovation?

This paper responds to the stated research question by examining the process of sustainable digital innovation. Drawing on the organizational learning perspective, this paper argues that firms can leverage organizational unlearning for sustainable digital innovation by enhancing strategic flexibility and organizational slack. Previous studies on organizational unlearning suggest that unlearning manifests as discarding outdated routines [22] or degrading unimportant knowledge [23]. However, more often than not, firms forget the old ways of using knowledge in the digital era as firms’ knowledge bases grow with the development of cloud storage and more digital knowledge management tools. Thus, we argue that organizational unlearning is to give up the knowledge utilization pattern [24,25]. In line with this definition, firms can benefit from flexible routines and restructured knowledge due to organizational unlearning. More resources would be freed up, and the flexibility involved in coordinating resources would be enhanced. Thus, it would be easier for companies to advance their digital knowledge to achieve sustainable competitiveness. In other words, organizational slack and strategic flexibility are necessary mediating mechanisms through which organizational unlearning can turn into digital innovation.

In sum, this research advances and tests a model that proposes the mediating role of organizational slack and strategic flexibility on the relationship between organizational unlearning and digital innovation. Based on data collected from Chinese traditional manufacturing firms, we seek contributions in three ways. Firstly, as we investigated the process of sustainable digital innovation, this paper echoes the strategy–competence–competitive framework and enriches the understanding of new competitiveness for traditional manufacturing firms in the digital context. This framework aims to inform scholars of the unique utility of unlearning to non-digital firms in the attainment of competency, as well as the specific strategies involved in unlearning. Secondly, this paper sheds light on how organizational unlearning serves as a catalyst for sustainable digital innovation to bridge intra-organizational innovation management with research on digital innovation [26]. As we scrutinized the two viable mechanisms between these factors, we again demonstrated the important role of organizational internal systems in firms’ sustainable competitive advantage [17]. Nonetheless, a small but growing body of empirical evidence suggests that organizational unlearning can promote the successfulness of firms’ innovation [27,28]; this paper advances this line and promotes the integration of unlearning and innovation management in the digital context. In addition, this paper provides useful cues for digital transformation practitioners on how to develop sustainable digital innovation through organizational unlearning. The richness of description in the process of sustainable digital innovation provides valuable insights for both traditional companies in urgent need of digital transformation and entrepreneurs involved in digital ventures.

2. Theoretical Framework

2.1. Organizational Unlearning and Sustainable Digital Innovation

In the digital context, innovation is no longer a simple technological innovation behavior that mainly relies on the international resources of companies, but rather the result of the interaction and action between multiple innovation entities and the innovation ecosystem [29]. The innovation process involves not only the creation and commercialization of new technologies, but also the transformation of resource allocation routines, production routines, and institutional arrangements following the digital technology paradigm [13,17]. Thus, digital innovation is defined as the use of digital technologies, such as 3D printing, cloud computing, etc., to develop new business models or invent new products [26]. The convergence between digital technology and industrial technology helps manufacturing firms to achieve new strategic purposes [13,30], while the generativity of digital technology fosters real-time iteration and innovation according to the changes in users’ demand and feedback [26]. Sustainable digital innovation is not just about developing new digital products or developing new products digitally; it is a self-referential and scalable process of continuous iteration and improvement [15,18]. Therefore, sustainable digital innovation is not only the result of the convergence of digital technologies or digital platforms with traditional technologies, but is also influenced by the digital orientation of companies that have long been committed to digital innovation [31].

The innovation management literature highlights the essential role of unlearning in coping with technological changes and turbulence regarding firms’ activities [2,32]. In the process of creating new knowledge combinations, unlearning can blur intra-organizational boundaries and enhance cooperation efficiency among organizational units, and thus leverage both axiomatic and procedural knowledge. The former is formulated by the fundamental beliefs that appear as business strategy and organizational value, while the latter is shared knowledge existing in routines [28]. As it helps to recognize routines that cannot comfortably fit into the domain of organizational learning [10], unlearning changes the path-dependence of employees or physical objects so as to foster the cognitive importance of digital innovation among organizations [33,34]. Then, it is possible to generate new tacit knowledge on integrating with digital infrastructure, and thus build a purposeful organizational identity towards sustainable digital innovation. As such, the nature of unlearning becomes a decisive factor for redesigning and restructuring the innovation process, releasing organizational inertia due to inherent practices, and providing organizations with sustainable innovative benefits.

On one hand, unlearning leverages axiomatic knowledge by disrupting current organizational arrangement, redeploys inclusive workflow and culture, and alters the traditional ways of organizational functions [35], which creates various opportunities to form open technological architectures and new organizational forms, such as virtual groups, etc. [36]. In this way, organizational unlearning reduces the challenge posed by digital technology to current routines that frame markets and products, mitigates the confusing or protective organizational responses to digital changes, and allows participation by previously separate entities [37], which can be characterized as convergence between digital and traditional businesses.

On the other hand, unlearning adds to procedural knowledge by discarding rigid or outdated routines, which can quickly improve or iterate firms’ digital infrastructure in response to changes to meet external requirements [38]. Unlearning contributes to the abandonment of old technical experience, outdated cognitive skills, etc., at both the organizational and individual levels [39] via the continuous updating of situational cognition and knowledge exploration [40]. Thus, manufacturing companies would be equipped with modification and reconstruction of new digital-enabled products [41], which could be replicated and implemented into new scenarios and could be characterized as generativity of digital innovation [42].

Therefore, unlearning alleviates the path-dependent method of seeking innovation by following past technological paradigms but making use of axiomatic knowledge and procedural knowledge appropriately [26,43], and thus initiates the emergence and diffusion of sustainable digital innovation in a long-lasting way. Therefore, the authors propose the following hypothesis:

H1.

Unlearning has a positive effect on manufacturing firms’ sustainable digital innovation.

2.2. The Role of Strategic Flexibility in Sustainable Digital Innovation

The first and most important mechanism underlying sustainable digital innovation is capability building through organizational unlearning. Out of its non-linear feature, unlearning can help companies to enhance strategic flexibility and overcome rigidity, so that they can not only respond prospectively, but also quickly [44]. Strategic flexibility is considered as a strategic attribute of handling contingencies, especially in a rapidly changing environment, which is important in achieving business goals and is essential for firms to leave some leeway to cope with environmental change, since “every conceivable eventuality cannot be foreseen prior to implementation” [45]. Table 1 shows previous studies that discussed strategic flexibility from different angles.

Table 1.

Different views on strategic flexibility.

In this study, strategic flexibility is defined as the capabilities that firms have to flexibly deploy knowledge and reconfigure learning processes to handle conflicting, turbulent environments [52], and it guides firms’ innovation towards sustainable digital innovation. We take resource flexibility and coordination flexibility as crucial dimensions of strategic flexibility [53]. Resource flexibility is static, which mainly emphasizes the inherent properties of enterprise knowledge, and refers to the difficulty, speed, and cost of converting existing knowledge into potential new knowledge. Coordination flexibility is dynamic and emphasizes the acquisition and use of new knowledge through re-integrating and reconfiguring its learning process or adjusting its operation system.

2.2.1. Organizational Unlearning and Strategic Flexibility

Organizational routines are a major source of stability [54]. With technicians sharing and discussing their views and decisions, the same types of knowledge are collected or used in the same mode of learning, thus leading to inertia within the enterprise and inflexibility in responding to environmental changes [55,56]. This prevents the enterprise from noticing the generation of new knowledge. In particular, when the existing knowledge brings successful experience, this will lead to the limitation of the enterprise in the change in the technology paradigm.

Yet, organizational unlearning disrupts the coordinated resource allocation system and common language system between new and old knowledge, makes managers aware of negative signals early on, and improves the sensitivity of enterprises to changes in the external environment, playing a key role in shaping strategic flexibility. First, the disruption of learning routines opens up the limits of the scope of the incumbent knowledge base and disrupts its structure. At the same time, the cost and time of knowledge conversion from old to new are greatly reduced, leading to resource flexibility. Second, organizational unlearning brings short-term non-performance to the forefront, prevents the interpretation of existing learning routines, and allows mental space for strategic shifts. The ability of firms to make use of lessons and learn from failure could be leveraged through organizational unlearning, which leads to coordination flexibility for future preparation. Enterprises can realize effective allocation and re-integration of homogeneous or heterogeneous knowledge in a timely manner by means of organizational unlearning to improve the coordination flexibility of knowledge. Thus, organizational unlearning reminds managers to adjust the current learning routines for corporate knowledge, which accordingly provides the opportunity for improving both the resource and coordination flexibility of knowledge utilization. Based on this, we propose the following hypothesis:

H2a.

Organizational unlearning is positively associated with manufacturing firms’ strategic flexibility.

2.2.2. Strategic Flexibility and Sustainable Digital Innovation

Although strategic flexibility generates consequential pressure, high cost, and lack of strategic focus, which lead to negative results for enterprises, especially in slow-pace industries [57,58], strategic flexibility certainly has more positive impacts on innovation activities in terms of innovation performance [59], new product performance [50], and the growth performance of SMEs [60], especially in a fast-paced digital context. It enables a preemptive maneuver for firms to start technological transformation and gain sustainable competitive advantages for the long term.

Previous studies have concluded that the relationships between strategic flexibility and innovation performance could escalate firms’ technological innovation and managerial innovation during the development and production of products [53]. This is a necessary capability in the transformation of technological paradigms and firms’ matching strategies. Beyond exploring new opportunities, strategic flexibility provides firms with the capability to discover product and technological innovations [49], and influences the implementation of new business models on an open innovation basis [61]. In the digital context, strategic flexibility first allows proactive manufacturing firms to adapt to a changing environment with new competing logic and preemptively utilize new digital technologies; thus, manufacturing companies can survive and continue to evolve with the digital paradigm. Moreover, companies would be able to absorb knowledge, assimilate prior knowledge flexibly, and create derivative digital products or digital new services or deploy digital-enabled business models. For manufacturing firms, strategic flexibility means a higher processing capacity to integrate digital technology and new product development, trigger managerial innovations, and implement digital business models. Thus, strategic flexibility pushes manufacturing firms to be more effective and flexible through utilizing new digital technologies in aspects of developing, producing, and marketing products. Therefore, the author hypothesizes that:

H2b.

Strategic flexibility is positively associated with manufacturing firms’ sustainable digital innovation.

2.2.3. The Mediation Effect of Strategic Flexibility

Unlearning rigid routines in traditional manufacturing processes is a fundamental step in learning with the aim of sustainable digital innovation. The search for sustainable digital innovation can be achieved by linking incumbent business with digital technologies [62], or by speeding up digital innovation [63]. For one thing, organizational unlearning provides firms with resource flexibility and coordination flexibility, and incurs better performance in digital innovation, which magnifies firms’ competitive advantage in traditional manufacturing, and makes them sustainable in the digital era. Organizational unlearning dissolves the current learning routine and breaks down the current “department wall” [64], decouples the axiomatic knowledge and procedural knowledge, and adds to companies’ new procedural knowledge regarding digitalization. Thus, the communication method and the knowledge flow within the company become more flexible. With changing information sharing mechanisms and workflows, it is easier for traditional manufacturing firms to take up digital technologies and link with digital platforms, achieving convergence [40]. Boundary-spinning interactions can help to actively transfer ideas and knowledge between different units, and create a balanced and flexible structure in favor of collaboratively committing to digital innovation [65].

In addition, the strategic flexibility brought about by organizational unlearning helps traditional manufacturing firms to prepare in advance, which shifts firms’ competitive advantage to a digital trajectory [19] and is associated with the potential for embracing digitalization cognitively and behaviorally. The organizational-level unlearning of current routines is an essential step in turning to a digital orientation and shifting firms’ focus on learning [27]. Strategic flexibility enhances the reshuffle of organizational knowledge, making it possible for firms to recognize, subside and even commercialize their core knowledge base using digital methods. This process encourages manufacturing firms to leverage digital technologies with their axiomatic knowledge as the fulcrum, leveraging new applications in new situations—for example, seeking digital solutions and serving their peer companies instead of providing tangible products to end-users, so as to continuously apply and share their own advantageous axiomatic knowledge to achieve digital innovation. Therefore, we hypothesize that:

H2c.

Strategic flexibility mediates the positive relationship between organizational unlearning and manufacturing firms’ sustainable digital innovation.

2.3. The Role of Organizational Slack in Sustainable Digital Innovation

Organizational slack is a real or potential resource buffer of an enterprise, which enables the enterprise to make successful adjustments in order to adapt to internal adjustments or external changes, and to make strategic changes in order to adapt to the external environment. Organizational slack has been broadly referred to as resource slack in many aspects, such as slack of capacity, human resources, financial resources, customer relationships, social networks, underdeveloped opportunities, etc. [28,66]. From the perspective of behavior theory, organizational slack is manifested in extra resources that are beyond the regular operational process, which could potentially help firms to cope with uncertain environmental factors and act as a buffer in the case of business recession, enabling the organization to make strategic responses at the proper time [67,68]. Thus, resource slack plays an important role in firms’ competition and survival. Based on a resource-based view, scholars believe that organizational slack assists firms in innovative activities to gain competitive advantages [69], and can be seen as the accumulated resources that are excessive to what is required in production, including extra financial capital and personnel [70]. It is noted that maintaining adequate resource slack has the potential to explain firms’ positive performance [71].

Previous studies have divided organizational slack into absorbed slack and unabsorbed slack [72]. Absorbed slack represents the extra resources generated from what firms have already assimilated and applied to real practices, e.g., extra personnel and administrative budgets, which are hard to discover and re-deploy. Meanwhile, unabsorbed slack represents the available resources waiting for redeployment and utilization by organizations, such as mobile human resources and cash. However, the viable ways of discovering organizational slack in the digital era should be further specified.

2.3.1. Organizational Unlearning and Organizational Slack

In the digital context, digital technology can be used as the amplifier of organizational resources, and the dimensions and application range of resources can be greatly increased [73]. Thus, it is possible for organizations to realize digital dividends by linking slack resources to market demands.

From the perspective of organizational learning, organizational unlearning works as an important antecedent for organizational slack [28]. First, unlearning subverts the inherent learning routine [74], disconnects the knowledge and resources from certain talents [75], and turns them into organizational-level resources, which can help make absorbed organizational slack visible. Firms can thus identify and reserve this slack, especially intangible slack resources such as knowledge and relationship resources embedded in human resources [76]. In the digital context, digital technologies make it possible for firms to unlearn non-digital, traditional routines and workflows, which can release committed human capital proactively and boost absorbed organizational slack [77].

Second, organizational unlearning overcomes the structural problems in the current knowledge utilization [24]; it helps firms to escape from the original characteristics or existing utilization habits of knowledge, and creates new values and combinations [2]. Therefore, unlearning does not mean forgetting knowledge in incumbent business, but rather forgetting the combination of knowledge so as to initiate heterogeneity and overcome the immobility of knowledge [2,24,78]. This leads to the development of new dimensions of resources and helps enterprises to create unabsorbed organizational slack. In addition, in the digital context, unlearning incumbent and traditional knowledge can reduce administrative and payroll expenses on last-generation technology [74,79,80], providing opportunities for new linkages between resources and digital technology, so as to boost unabsorbed slack. Hence, we hypothesize that:

H3a.

Organizational unlearning is positively associated with manufacturing firms’ organizational slack.

2.3.2. Organizational Slack and Sustainable Digital Innovation

It has been generally acknowledged that organizational slack has a positive impact on the innovation activities of firms, as it can help them to handle uncertain environmental changes by providing excessive resources, and it ensures that their technological competence and performance will not be affected by business recession [81]. In firms’ transformation towards digitalization, the challenge is not only establishing how to create digital innovation, but also how to make digital innovation sustainable. Organizational slack is helpful in enhancing the innovation ability of firms and alleviates various conflicts between traditional innovation and digital innovation caused by resource scarcity [82]. This study argues that organizational slack can lead to sustainable digital innovation due to the following reasons.

First, organizational slack provides more discretion for managers to engage in digital innovation. Although in the initial stage of digital innovation, the idle rate and depreciation rate of absorbed organizational slack will delay the positive emergence of digital innovation, the amount of organizational slack will have a significant influence on the investment that guarantees digital innovation, addressing the risks of high capital investment and a long payback period. Thus, organizational slack is the prerequisite for achieving long-term digital goals and leads to sustainable subsequent development of digital innovation by ensuring generativity.

Second, organizational slack relieves internal resource constraints and balances inputs [83,84]. Unabsorbed slack includes unrestricted resources in the process of knowledge utilization, operation, or service [85], not limited to specific technical fields. Due to the unlimited scope and wide range of unabsorbed slack [86], it has natural advantages when manufacturing enterprises turn to unconventional digital innovation [87]. When resources are scarce in digital fields, managers can quickly apply unabsorbed slack to different digital transformation scenarios. In addition, when unabsorbed slack is high, the advantages of highly elastic resources tend to bring confidence to the management team [88], so they will orchestrate suitable resources towards digital innovation boldly. In the long run, the application fields of digital innovation are gradually enriched, and sufficient unabsorbed resources improve enterprises’ efficiency in resource allocation and alleviate the risks in digital innovation [84,85], thus leading to sustainable digital innovation. Therefore, we hypothesize that:

H3b.

Organizational slack is positively associated with manufacturing firms’ sustainable digital innovation.

2.3.3. The Mediation Effect of Organizational Slack

Since unlearning is basically a disruption process instead of a value creation process [74], it is difficult for organizational unlearning to directly facilitate sustainable digital innovation. Thus, we argue that by unlearning, firms can eliminate the inefficient non-digital routines or workflows [89], suspend unfavorable learning routines [74,90], and free up specialized talents and their capabilities from centralization [91], thus generating absorbed and unabsorbed slack resources which would eventually lead to sustainable digital innovation.

From a learning perspective, unlearning obsolete routines in the digital context could reduce the path dependence and core rigidity of firms [92], balance the resource competition between manufacturing business and digital business [78], free up or re-structure internal resources and knowledge in the traditional technology paradigm [93], and form organizational slack. Having excessively available slack is regarded as one of the foundations for learning new technologies [94], and it can first stimulate the attention of enterprises in neglected and promising areas [95], thereby leveraging new focus and additional support to facilitate knowledge acquisition and transfer between digital technology and manufacturing areas, which sustains the convergence characteristic of sustainable digital innovation.

In addition, unlearning outdated production and administration routines in manufacturing could reduce costs [96], and thus provide extra budget to support risk-taking experiments, R&D, or other innovation activities [97]. The organizational slack created works as a technical buffer in digital innovation processes [98], while it can help to solve the conflicts in knowledge application and hedge the risks in digital innovation. Managers can quickly apply organizational slack to different scenarios in digital innovation, so as to guarantee the generativity of digital innovation, and help to capture the share of future innovations spawned by existing businesses. Therefore, the authors hypothesize that:

H3c.

Organizational slack mediates the positive relationship between organizational unlearning and manufacturing firms’ sustainable digital innovation.

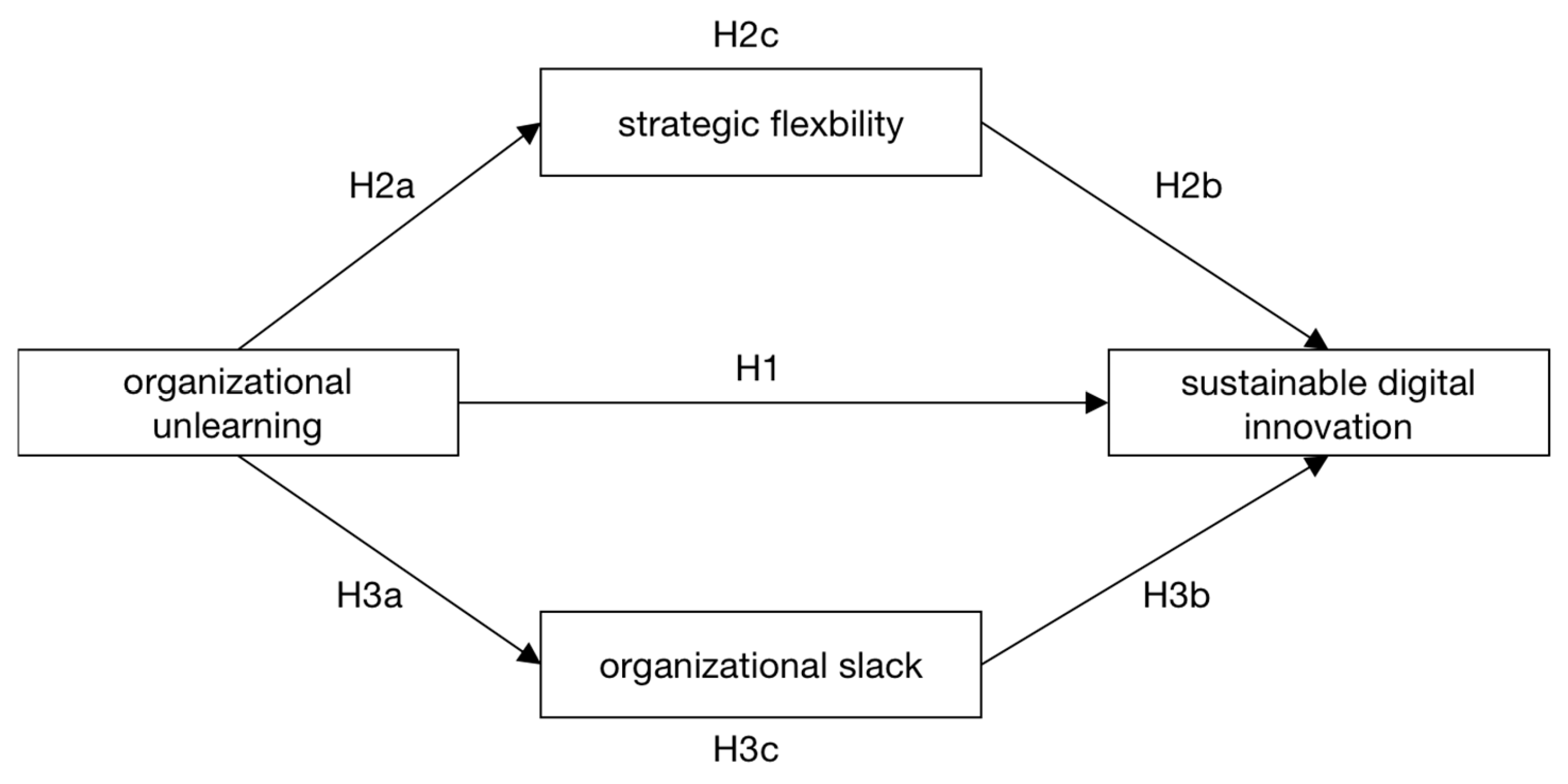

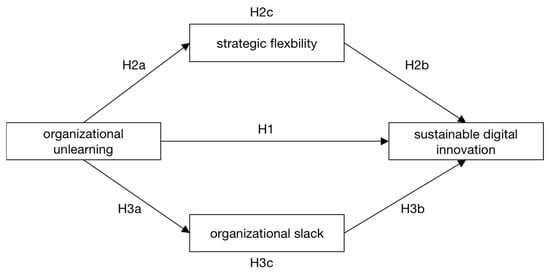

The research model is shown in Figure 1.

Figure 1.

Research Model.

3. Method

This study aims to elaborate the underlying mechanism of how organizational unlearning can lead to sustainable digital innovation through improving strategic flexibility or enhancing organizational slack. To test the above hypotheses, we examine traditional manufacturing firms operating in sectors such as the machinery and electronics industry, textile and clothing industry, chemical products manufacturing, etc., in China. China provides a suitable setting to test our model as the large scale and volume of China’s digital enterprises have created new driving forces and opportunities for the development and transformation of manufacturing firms. Since this study performs organizational-level research, a questionnaire survey was adopted to collect data.

3.1. Questionnaire Design

We first developed an English questionnaire based on previous studies. Then, two authors translated it into Chinese and back-translated it into English twice to ensure conceptual equivalence [99]. Then, we used the Chinese questionnaire in our study. We conducted four in-depth interviews with experts and senior managers to ensure the content and face validity of the measures.

The questionnaire items were measured using a seven-point Likert scale; thus, the responses were objective [100]. To prevent participants giving irrational and biased responses [101], the authors clarified that this survey was not for business purposes, and it would only be used for academic studies. In order to secure their identities, all of the participants were anonymous, and their company names were not required to be filled in. Furthermore, in order to avoid memory construction while answering the survey [102], all of the questions are addressed based on their organizational situations at the current time, so they could answer the questionnaire without recalling memories.

3.2. Variables and Measures

3.2.1. Organizational Unlearning

The independent variable in this study was organizational unlearning (UN). We adopted measures from previous works and specified the organizational unlearning in innovation processes. The specific measurements are shown in Table 2.

Table 2.

Measurements of unlearning.

3.2.2. Strategic Flexibility

The first mediator in this study was strategic flexibility (SF), which reflects the level of organizational capability regarding resource allocation flexibility and strategic responses to changing environments. Following the study of Wang et al., (2013) [55], we modified the measures of strategic flexibility by adding in the digital context. As shown in Table 3, SF is measured in terms of allocation processes, market responses, and strategic adjustment.

Table 3.

Measurements of strategic flexibility.

3.2.3. Organizational Slack

Another mediator in this study was organizational slack (OS), which reflects the level of resources in an organization exceeding the minimum required. In underlying empirical studies, organizational slack is usually measured in terms of absorbed and unabsorbed slack. As shown in Table 4, built on the previous work of Danneels (2008) [103] and Yang et al., (2014) [28], this study added digital context in classic measurements in terms of available internal resources, external resources, and human capital. The first item, OS1, was set as a reversed item suggesting that there are no excess resources within the firm, in order to verify whether participants were consistent in answering their situations of organizational slack. By cross-checking the responses of OS1 and other items, it allowed us to filter out the invalid questionnaires.

Table 4.

Measurements of organizational slack.

3.2.4. Sustainable Digital Innovation

The dependent variable in this study was sustainable digital innovation (SDI), which reflects the sustainability of firms’ digital innovation. We measured sustainable digital innovation based on Khin and Ho, 2019 [104], as shown in Table 5. On one hand, we considered the newness and efficiency of digital innovation (SDI 1 and SDI 2); on the other, we also evaluated whether digital innovation can be sustained in competition by measuring the convergence (SDI 3) and generativity (SDI4) of digital innovation.

Table 5.

Measurement items of sustainable digital innovation.

3.3. Data Collection

The questionnaire survey was distributed to senior managers, technical directors, or digitalization managers, who use big data and play an important role in facilitating sustainable digital innovation, so as to ensure that the respondents were highly matched and familiar with the questionnaire items. In order to ensure that both sides had the same understanding of sustainable digital innovation and that the companies to which the respondents belonged had experience in using specific digital resources such as data or digital tools, this study specifically defined relevant definitions in the questionnaire instructions and set up questions to measure whether companies used relevant data resources or technologies. Three rounds of questionnaire distribution were conducted in this survey. The first round was on-site distribution. We recruited trained research assistants to conduct onsite surveys to generate high-quality data [105]. Before the respondents answered the questionnaire, our research assistants asked them to confirm the most prominent digital innovation achievements within the past three years. By doing so, we ensured that the questions were relevant to digital innovation and tested the respondents’ knowledge level pertaining to survey questions. The second and third rounds were online questionnaires. In the questionnaire, we also asked respondents to indicate their familiarity with their companies’ digital strategy and digital innovation operation. The means were 5.91 and 5.17 (1 = little knowledge, 7 = a great deal of knowledge), indicating that informants were qualified respondents. Therefore, 350 questionnaires were issued in total and 298 were recovered. After eliminating invalid questionnaires, 274 valid questionnaires were finally obtained, with an effective recovery rate of 78.3%.

In order to reduce the common method deviation, this study guaranteed the quality of the results through prior procedure control and post-statistical control. In terms of prior procedure control, it was made clear at the beginning of the questionnaire that an anonymous method was adopted, the results of the questionnaire were only to be used for academic research analysis, and all data and contents would be kept strictly confidential to increase the psychological acceptance of the interviewees, so as to obtain more authentic data. For post hoc statistical control, the Harman single factor test was used, and the results showed that the percentage of variance explained for the first extracted principal component factor was 33.70%, which was less than 40%, inferring that the common method deviation problem was not serious.

4. Results

4.1. Demographic and Descriptive Statistics

This study used 274 manufacturing companies as a sample. The demographic features included firm age, firm size, annual sales, and industry type, as seen in Table 6. Firm age was calculated by how long firms have been established, from their first year to 2023. Firm size in this study was represented by the number of employees, and the respondents needed to choose the intervals of “less than 50”, “50 to 100”, “101 to 500”, “501 to 1000” and “more than 1000”. The majority (50.72%) of the respondents were middle-size companies, with the number of employees between 100 to 500. Firm annual sales represented the financial situation of sample firms. The respondents needed to respond regarding firms’ approximate gross profit for the previous year, and we offered five intervals “less than 1 million CNY”, “1 million to 10 million CNY”, “10 million to 50 million CNY”, “50 million to 100 million CNY” and “more than 100 million CNY” for them to choose from. Overall, 56% of sample companies had an annual size between 10 million and 100 million CNY. In addition, Industry type was distinguished as the technology complexity varying across different manufacturing sub-industries. The respondents were asked whether their company was a high-tech company. The vast majority (78.9%) of the respondents were traditional manufacturing companies with low technological complexity.

Table 6.

Demographics of respondents.

All variables in this study were measured using a seven-point Likert scale ranging from 1 = strongly disagree to 7 = strongly agree. The descriptive statistical values of all items are shown in Table 7. In addition, the VIF values for all the items were found to be less than 2, indicating no multicollinearity concerns. The skewness and kurtosis values of the data distribution were between −2 and 2, showing that the data were normally distributed.

Table 7.

Descriptive analysis (p-value < 0.001 ***, p-value < 0.01 **).

4.2. Statistical Analysis and Hypothesis Testing

The partial least squares (PLS) method was adopted to analyze the research model. The PLS approach is preferable to avoid covariance-based methods. It imposes fewer requirements on sample size, does not require data to conform to normal distribution, and can handle complex structural models with multiple facets [105,106]. In addition, PLS is an effective tool for examining causality [107]. We adopted SmartPLS 4.0 (SmartPLS GmbH, Oststeinbeck, Germany) to conduct the PLS analysis.

We first tested the measurement model by assessing the reliability and validity of the theoretical constructs [102], as well as the confirmatory factor analysis. Then, the structural model tests and the path analysis were estimated to verify the causal relationship and the hypotheses in this research model [108].

4.2.1. Measurement Model

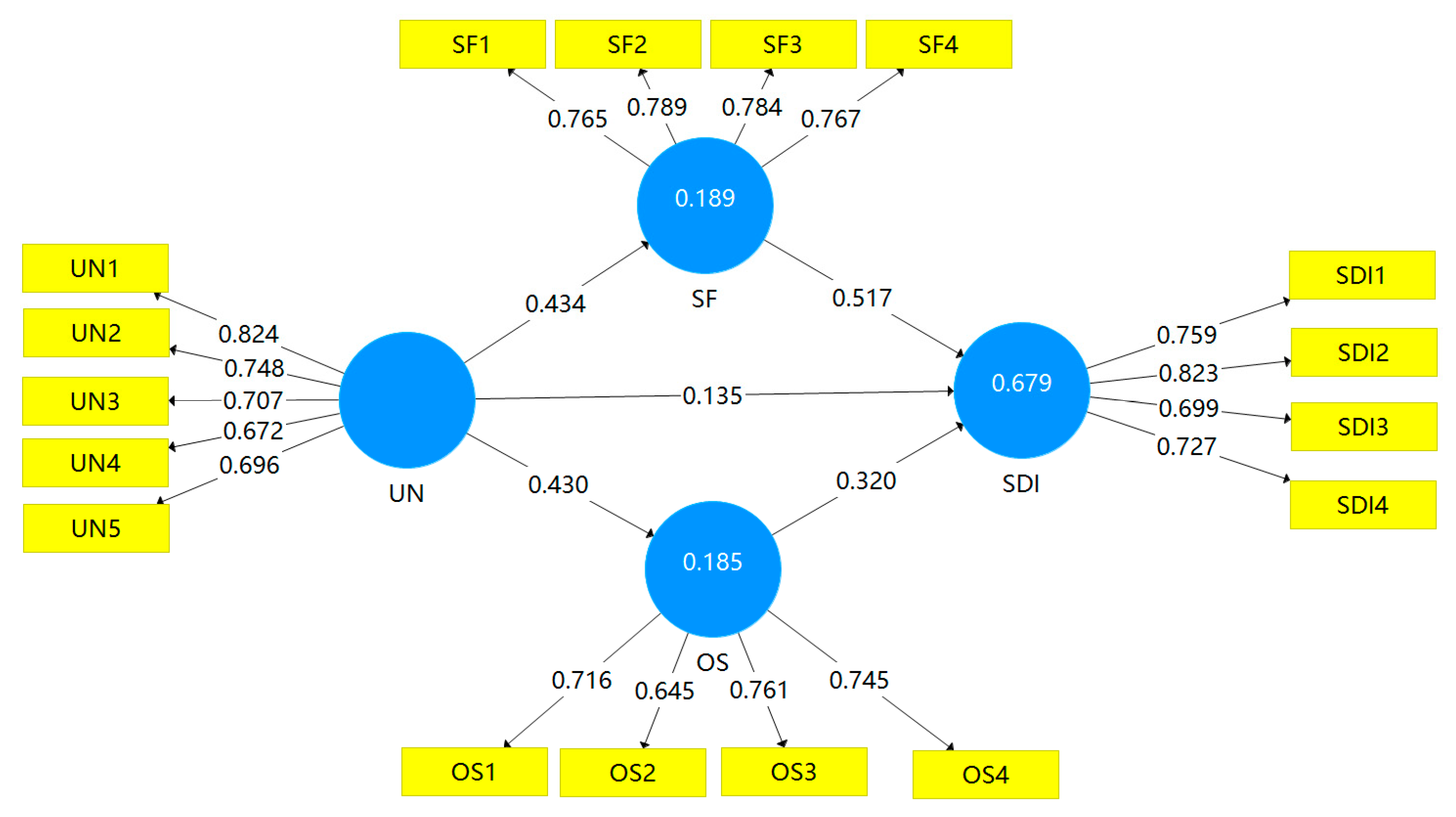

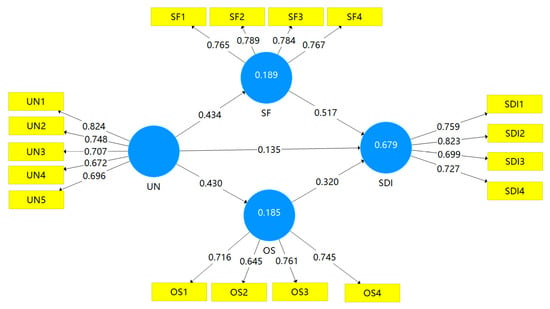

The evaluation results of the measurement model are shown in Table 8 and Figure 2. Internal consistency reliability reflects the reliability relationship among the questions within the survey, and examines whether each question measures the same content or quality. Table 8 shows that the Cronbach’s α value and Combination Reliability of all observed variables are greater than 0.7, indicating that the measurement items have good internal consistency and high reliability [109]. In addition, the factor loading value of the outer model shows that each measurement item is between 0.65 and 0.84 [106,107], and the average variation extraction (AVE) value of each variable is greater than 0.5, indicating that the measurements have good convergent validity.

Table 8.

Measurement model.

Figure 2.

Measurement model evaluation.

HTMT (heterotrait–monotrait ratio of correlations) and the “Fornell–Larcker 1981” matrix were adopted to test the discriminant validity [110]. Table 8 shows that the HTMT value of all variables is less than 0.85 [111], indicating that discriminant validity has been ascertained. The Fornell–Larcker criterion is an analysis to compare the value of the AVE square root with the construct correlation value. Table 8 also shows the correlation coefficient of each variable. It can be seen that the correlation coefficient between any two variables is less than the square root of AVE value of each variable, indicating that the measurement model has good discriminant validity. In addition, the four variables, organizational unlearning, strategic flexibility, organizational slack, and sustainable digital innovation, are significantly positively correlated, which meets the precondition of the mediating effect test.

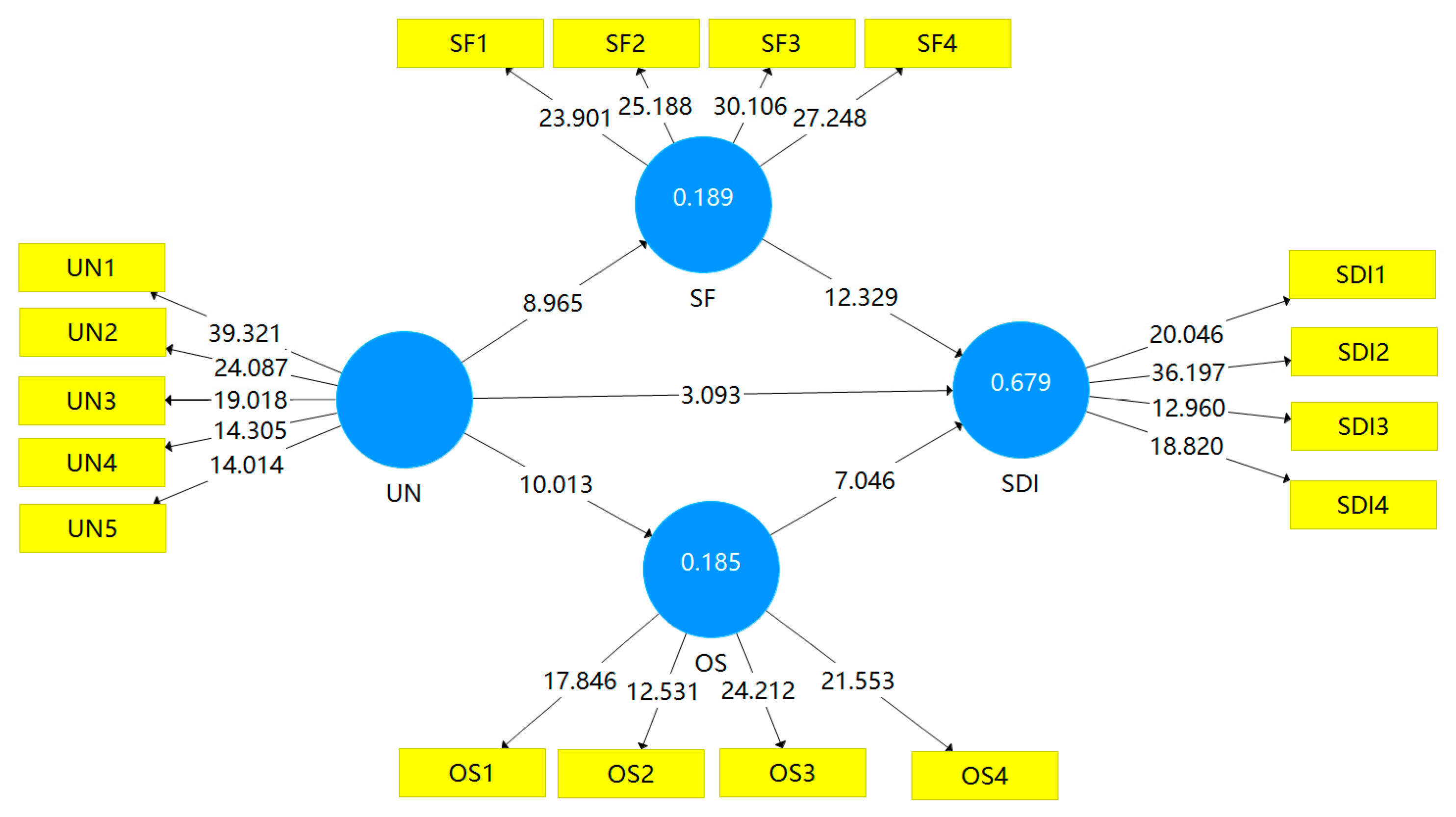

4.2.2. Structural Model

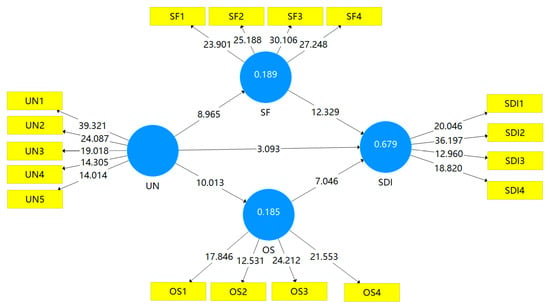

In the second step, the structural model tests and the path analysis are estimated to verify the hypotheses. Table 9 shows the path coefficient, t-value, and p-value for each path. The path coefficient describes the strength of the relationship between latent variables. Bootstrapping techniques were adopted to assess the significance of each path coefficient. f2 illustrates the effect size indicating that the exogenous latent variables have a large influence degree on endogenous variables. f2 = 0.15 indicates moderate influence, and f2 = 0.35 indicates a strong effect size [112].

Table 9.

Path coefficient and effect size.

H1 assesses the positive impact of organizational unlearning on sustainable digital innovation. The path coefficients under 0.30 are considered as causing moderate effects, those between 0.30 to 0.60 are considered as causing strong effects, and those above 0.60 are considered as causing very strong effects [113]. As such, organizational unlearning establishes a strong, positive, significant effect on sustainable digital innovation (path coefficient = 0.135; t-value > 3.093; p-value < 0.005). When the company can unlearn its current knowledge base and the routine through which it processes knowledge, it will possibly develop a higher level of sustainable digital innovation. However, f2 indicates to what degree organizational unlearning contributes to the explanation of sustainable digital innovation. The f2 value is 0.043, which is lower than 0.15, indicating that the direct effect size is not ideal.

Then, H2a and H3a assess the positive impact of organizational unlearning on strategic flexibility (path coefficient = 0.434; t-value > 8.965; p-value < 0.001) and organizational slack (path coefficient = 0.430; t-value > 10.013; p-value < 0.001)—the effect sizes are 0.233 and 0.226, respectively, between 0.15 and 0.35. These results indicate that organizational unlearning has a positive, strong, and significant effect on strategic flexibility and organizational slack, which means that organizational unlearning provides opportunities for improving strategic flexibility and accumulating organizational slack. Therefore, H2a and H3a confirm empirical support from the data.

The other results show the significant positive impact of strategic flexibility and organizational slack on sustainable digital innovation (SF: path coefficient = 0.517; t-value > 12.329; p-value < 0.001; OS: path coefficient = 0.320; t-value > 7.046; p-value < 0.001)—the effect sizes are 0.511 and 0.196, respectively, which are larger than 0.15. These results demonstrate that with a higher level of strategic flexibility and organizational slack, manufacturing companies are strongly likely to achieve sustainability in digital innovation. Therefore, H2b and H3b are supported. The structural model evaluation is shown in Figure 3.

Figure 3.

Structural model evaluation.

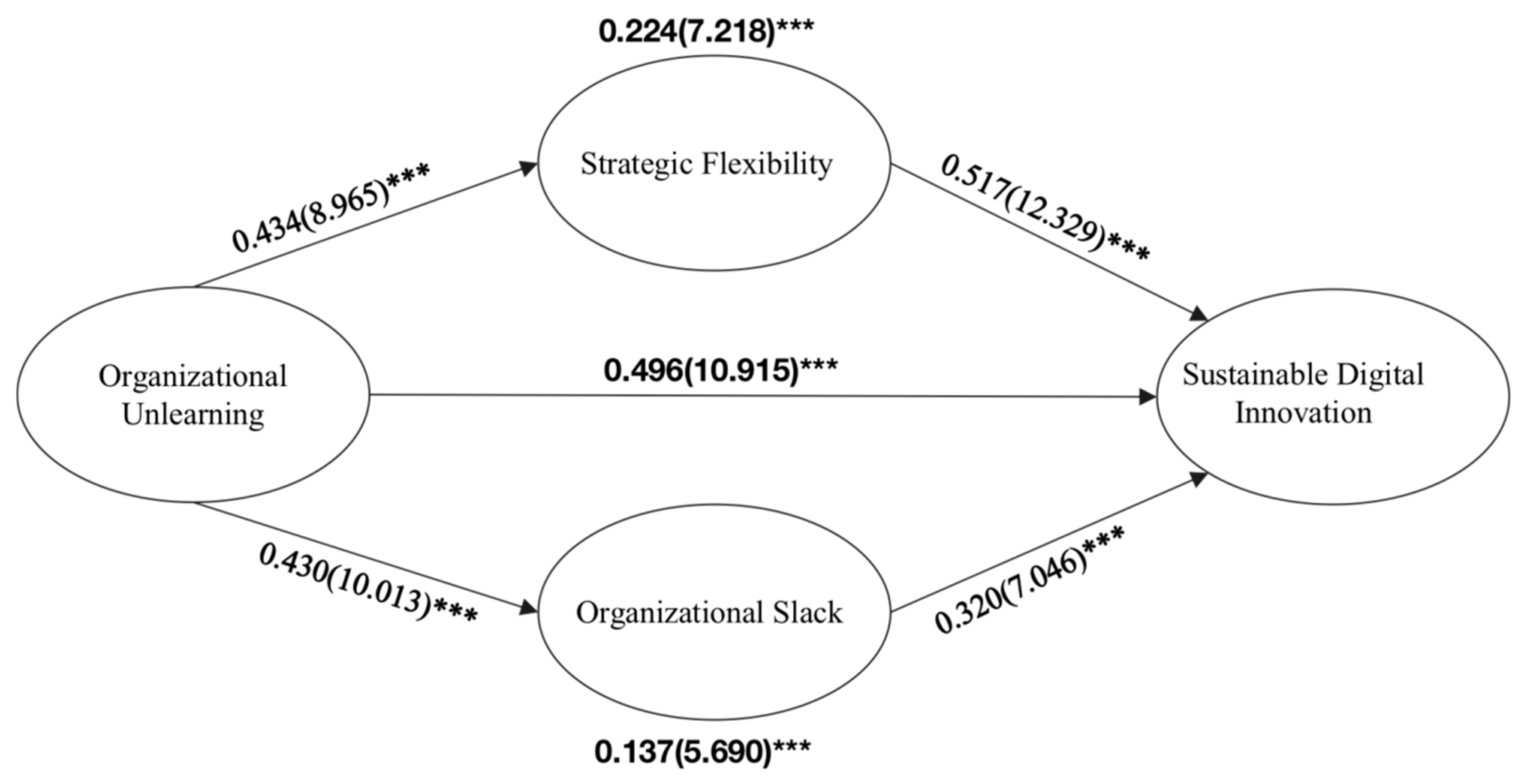

4.2.3. Mediation Effect

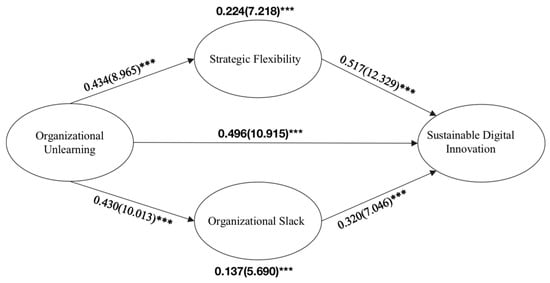

This study further tested the chain mediation effect by conducting repeated sampling 5000 times using Bootstrap techniques provided by SmartPLS. The specific mediation path analysis is shown in Table 10.

Table 10.

Path coefficient of the mediation effect.

The mediating effect value of unlearning-driven strategic flexibility is 0.224 (t-value > 7.218, p-value < 0.001), indicating that strategic flexibility plays a positive mediating effect between the organizational unlearning of manufacturing companies and sustainable digital innovation. Similarly, the mediating effect value of unlearning-driven organizational slack is 0.137 (t-value > 5.690, p-value < 0.001), which shows that the accumulation of organizational slack also has a positive mediating effect between the organizational unlearning of manufacturing companies and sustainable digital innovation.

Because PLS does not require data to be normally distributed, the variance ratio (VAF) was calculated to determine the strength of the indirect effect on the total effect, and then was interpreted for judging the significance of the mediation effect. If VAF < 20%, then the indirect effect can be neglected; 20% < VAF < 80% indicates partial mediation; and VAF > 80% suggests full mediation. It can be seen from the bottom two rows in Table 10 that the value for the indirect effect was 0.362, and that for the total effect was 0.496. Thus, the indirect effect explains 72.98% of variance of the total effect, indicating that partial mediation effects are significant. Therefore, the influence of manufacturing companies’ organizational unlearning on sustainable digital innovation is partially mediated by the chain of strategic flexibility and organizational slack. H2c and H3c were thus supported.

4.2.4. Assessment of the Structural Inner Model

In the end, this study examines the model’s ability to explain and predict the variation in the endogenous variables caused by the exogenous variable. First, the results of the R2 value show the ability to predict the model. An R2 value of at least 0.1 is required to ensure a satisfactory model fit [107], and an R2 value above 0.50 shows a strong aptitude in explaining the exogenous variable [105]. Accordingly, the mediating variables “strategic flexibility” and “organizational slack” have R2 values of 0.189 and 0.185, respectively, and the endogenous variable “sustainable digital innovation” has an R2 value of 0.679. All R2 values exceeded the recommended threshold score, indicating that the model is sufficiently able to predict 67.9% of the variation of sustainable digital innovation.

Likewise, the Stone–Geisser Q2 is a method used to test predictive relevance. If the Q2 value is more than zero, then the structural model has a satisfactory predictive power to the construct. Cross-validation redundancy is a metric used to evaluate the quality of each structural equation. Cross-validated communality estimates the common factor variance of cross validation, and provides the Q2 of each measurement block. Using blindfolding techniques, Table 11 shows that all Q2 values are higher than zero, which indicates a satisfactory predictive power of the structural model [114].

Table 11.

Coefficient of determination and Q2 and model fit.

Finally, the goodness of fit is reported by calculating the square root of the product of CV communality and R2. The value of the goodness of fit is 0.315, and the SRMR value is 0.077, which is less than 0.08, indicating that the overall model displays goodness of fit. Hence, the data analysis results demonstrate a positive partial strong indirect mediating relationship between organizational unlearning and sustainable digital innovation. Thus, Figure 3 shows the results of the structural model analysis and the path coefficients along with their significance levels. Additionally, all hypotheses were supported. The results of the structural model and hypotheses are shown in Figure 4 and Table 12.

Figure 4.

Results of the structural model (p-value < 0.001 ***).

Table 12.

Testing results of hypotheses.

5. Discussion and Implication

5.1. Conclusions

Research on digital innovation reveals its convergence and generativity features, and hence sustainable digital innovation represents a self-referential and scalable process of iteration between digital technology and industrial knowledge [13,30]. This research aims to unpack the specific way for manufacturing companies to achieve sustainable digital innovation. Drawing on organizational learning theory and the characteristics of sustainable digital innovation, this research examines the process for manufacturing firms to achieve sustainable digital innovation via organizational unlearning. Based on a survey of 274 traditional manufacturing firms, we find that organizational unlearning has a positive effect on sustainable digital innovation. In addition, we further elucidate the organizational factors resulting from organizational unlearning and producing sustainable digital innovation. Strategic flexibility and organizational slack define ways to establish a clear direction for manufacturing firms to resolve path dependency in incumbent business, leverage digital innovation, and continue to expand the scenarios of digital innovation, so as to achieve sustainable digital innovation. As such, strategic flexibility and organizational slack work as dual mediation bridges between organizational unlearning and sustainable digital innovation. Therefore, rather than obstructing organizational functioning [93] or leading to the leakage of incumbent knowledge [115], this study enriches the consequences of organizational unlearning and deepens the knowledge of how organizational unlearning facilitates sustainable digital innovation by focusing on strategic flexibility and organizational slack as crucial links in the competitive digital context. This study thereby provides several theoretical contributions and managerial implications.

5.2. Theoretical Contributions

First, this paper deepens the understanding of organizational unlearning in the digital era. Although organizational unlearning has been linked to organizational change [10,22], there is still a scant understanding of what role organizational unlearning plays in the digital context. We conclude that organizational unlearning is able to disconnect and open the scope of incumbent knowledge, pause the interpretation of existing learning routines, and help to identify the work processes that cannot comfortably fit into the digital era. In this way, organizational unlearning motivates companies to jump out of current utilization habits of knowledge, and thus leads to strategic flexibility and organizational slack. Consequently, this paper extends the conceptual boundary of organizational unlearning to the digital context.

Secondly, this paper clarifies the conceptual links on how organizational unlearning can promote the success of firms’ digital innovation [26,27,28]. As we discovered viable mechanisms of strategic flexibility and organizational slack, we demonstrated how to reasonably allocate internal resources and capabilities in operations with the aim of building sustainable competitive advantages for the digital paradigm [17]. It is noted that the nature of unlearning is not to forget the knowledge on manufacturing business, but to release time and energy and to promote continuous learning and secure the dynamism in innovation, which is in accordance with the generativity and iteration features of digital technologies. In addition, unlearning is able to bring improvisational efforts that are coordinated to deal with the balance of structure and flexibility, resource overlaps and slack; thus, it helps companies to relax prior deeply held assumptions, establish new digital roles, and reap the benefits of digital innovation. Therefore, the framework aims to inform scholars of the unique role of unlearning for non-digital firms in the attainment of competency, and the specific strategies involved in unlearning.

Thirdly, this paper joins the emerging literature on digital innovation [13,26] and sheds light on understanding how traditional manufacturing firms can generate new competitiveness in the digital context. Although digital innovation is considered key to building sustainable competitiveness in the digital era [65], few studies directly examine the process of improving core competitiveness. This study contributes to filling this research gap by examining the dual mediating effect of strategic flexibility and organizational slack between organizational unlearning and sustainable digital innovation. On the one hand, the convergence feature of sustainable digital innovation implies that the knowledge scope and boundary for digital innovation are no longer clear [106], and unlearning has the potential to redefine the connection. Secondly, the generativity of digital innovation means that sustainable digital innovation requires continuous improvement and change [37]. Therefore, we find that organizational unlearning is conducive to making appropriate choices and formulating strategies for re-structuring and re-optimizing knowledge and resources, together with the sustained and digital benefits for innovation.

5.3. Implications

Our findings also provide some important managerial implications. First, with the growth of the digital economy, firms should look at digital innovation dialectically. Because of the different development stages and production demands, manufacturing firms must focus on the major learning direction of digital innovation. One of the empirical conclusions of this paper is that the learning management required by digital innovation is significantly different from that of traditional business. Companies can further improve the initiative of unlearning and carry out real-time iterative innovation according to user feedback and various scenarios in the operation process. Therefore, companies need to strengthen the digitalization of the core business production process by unlearning in the short term. In the long-term plan, it is also necessary to gradually transfer the strategic focus by unlearning, and fully release the dividends of digital transformation.

Secondly, in view of the mediating role of strategic flexibility and redundant resources between unearning and digital innovation, enterprises need to deliberately incur organizational unlearning and tolerate the apparent knowledge disruption during the initial stage. As organizational unlearning releases its long-term advantages, companies should pay attention to the accumulation of digital-related flexible capabilities and redundant resources, and give full play to the advantages of both in improving the sustainability of digital innovation.

Finally, it is suggested that the government should consolidate and improve the infrastructure and governance system for the development of digital innovation. For example, the government should introduce targeted fiscal and tax policies to help enterprises actively unlearn and transition to a digital trajectory, so as to embrace the transformation of digital business; strengthen the flow of regional digital resources, including digital talents, data, and financial resources; improve the strategic flexibility and organizational slack for traditional manufacturing firms in the face of changes; and thus improve the long-term sustainability of digital innovation.

5.4. Limitations and Further Studies

Our findings should be interpreted with some caution. First, our analysis of organizational unlearning is limited to the specific context in which traditional manufacturing companies are making efforts to fit into the digital economy. Further research should also examine the role of organizational unlearning in domains other than digital innovation. Second, as our research focuses on the underlying mechanism of organizational unlearning, it is worth investigating the effectiveness boundary of this underlying mechanism. The moderating impact of the company and industry effect, business strategy effect, and firm types (e.g., leading firms and latecomer firms) on the relationship between organizational unlearning and digital innovation is worthy of investigation.

Author Contributions

Conceptualization, Z.Z. and Y.Y.; methodology, Z.Z. and Y.Y.; writing—original draft preparation, Z.Z.; writing—review and editing, Z.Z. and Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Science Technology Department of Zhejiang Province (No.: 2022C35065) and Department of Education of Zhejiang Province (No.:2021QH006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are available from authors upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tushman, M.L.; Anderson, P. Technological discontinuities and organizational environments. Adm. Sci. Q. 1986, 31, 439–465. [Google Scholar] [CrossRef]

- Akgün, A.E.; Byrne, J.C.; Lynn, G.S.; Keskin, H. New product development in turbulent environments: Impact of improvisation and unlearning on new product performance. J. Eng. Technol. Manag. 2007, 24, 203–230. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Urbinati, A.; Ünal, E.; Chiaroni, D. Framing the managerial practices for circular economy business models: A case study analysis. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing digital technology: A new strategic imperative. MIT Sloan Manag. Rev. 2014, 55, 1. [Google Scholar]

- Schröder, C. The Challenges of Industry 4.0 for Small and Medium-Sized Enterprises; Friedrich-Ebert-Stiftung: Bonn, Germany, 2016. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Gupta, G.; Bose, I. Digital transformation in entrepreneurial firms through information exchange with operating environment. Inf. Manag. 2022, 59, 103243. [Google Scholar] [CrossRef]

- Mattila, M.; Yrjölä, M.; Hautamäki, P. Digital transformation of business-to-business sales: What needs to be unlearned? J. Pers. Sell. Sales Manag. 2021, 41, 113–129. [Google Scholar] [CrossRef]

- Burt, G.; Nair, A.K. Rigidities of imagination in scenario planning: Strategic foresight through ‘Unlearning’. Technol. Forecast. Soc. Change 2020, 153, 119927. [Google Scholar] [CrossRef]

- Tsang, E.W.; Zahra, S.A. Organizational unlearning. Hum. Relat. 2008, 61, 1435–1462. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, Y.; Wang, X. Organizational unlearning and organizational relearning: A dynamic process of knowledge management. J. Knowl. Manag. 2013, 17, 902–912. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Mei, L.; Shen, R. Digital innovation and performance of manufacturing firms: An affordance perspective. Technovation 2023, 119, 102458. [Google Scholar] [CrossRef]

- Fichman, R.G.; Dos Santos, B.L.; Zheng, Z. Digital innovation as a fundamental and powerful concept in the information systems curriculum. MIS Q. 2014, 38, 329–354. [Google Scholar] [CrossRef]

- Yousaf, Z.; Radulescu, M.; Sinisi, C.I.; Serbanescu, L.; Păunescu, L.M. Towards sustainable digital innovation of SMEs from the developing countries in the context of the digital economy and frugal environment. Sustainability 2021, 13, 5715. [Google Scholar] [CrossRef]

- Rupeika-Apoga, R.; Petrovska, K. Barriers to Sustainable Digital Transformation in Micro-, Small-, and Medium-Sized Enterprises. Sustainability 2022, 14, 13558. [Google Scholar] [CrossRef]

- Mendling, J.; Pentland, B.T.; Recker, J. Building a complementary agenda for business process management and digital innovation. Eur. J. Inf. Syst. 2020, 29, 208–219. [Google Scholar] [CrossRef]

- Bican, P.M.; Brem, A. Digital business model, digital transformation, digital entrepreneurship: Is there a sustainable “digital”? Sustainability 2020, 12, 5239. [Google Scholar] [CrossRef]

- Teece, D.J. Towards a capability theory of (innovating) firms: Implications for management and policy. Camb. J. Econ. 2017, 41, 693–720. [Google Scholar] [CrossRef]

- Warner, K.S.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Tortora, D.; Chierici, R.; Briamonte, M.F.; Tiscini, R. ‘I digitize so I exist’. Searching for critical capabilities affecting firms’ digital innovation. J. Bus. Res. 2021, 129, 193–204. [Google Scholar] [CrossRef]

- Mehrizi, M.H.R.; Lashkarbolouki, M. Unlearning troubled business models: From realization to marginalization. Long Range Plan. 2016, 49, 298–323. [Google Scholar] [CrossRef]

- Wang, X.; Qi, Y.; Zhao, Y. Individual unlearning, organizational unlearning and strategic flexibility: The down-up change perspective. Balt. J. Manag. 2019, 14, 2–18. [Google Scholar] [CrossRef]

- Wensley, A.K.; Navarro, J.G.C. Overcoming knowledge loss through the utilization of an unlearning context. J. Bus. Res. 2015, 68, 1563–1569. [Google Scholar] [CrossRef]

- Zhang, F.; Lyu, C.; Zhu, L. Organizational unlearning, knowledge generation strategies and radical innovation performance: Evidence from a transitional economy. Eur. J. Mark. 2022, 56, 133–158. [Google Scholar] [CrossRef]

- Nambisan, S.; Lyytinen, K.; Majchrzak, A.; Song, M. Digital innovation management. MIS Q. 2017, 41, 223–238. [Google Scholar] [CrossRef]

- Lyu, C.; Yang, J.; Zhang, F.; Teo, T.S.; Guo, W. Antecedents and consequence of organizational unlearning: Evidence from China. Ind. Mark. Manag. 2020, 84, 261–270. [Google Scholar] [CrossRef]

- Yang, K.P.; Chou, C.; Chiu, Y.J. How unlearning affects radical innovation: The dynamics of social capital and slack resources. Technol. Forecast. Soc. Change 2014, 87, 152–163. [Google Scholar] [CrossRef]

- Liang, X.; Luo, Y.; Shao, X.; Shi, X. Managing complementors in innovation ecosystems: A typology for generic strategies. Ind. Manag. Data Syst. 2022, 122, 2072–2090. [Google Scholar] [CrossRef]

- Yoo, Y.; Henfridsson, O.; Lyytinen, K. Research commentary—The new organizing logic of digital innovation: An agenda for information systems research. Inf. Syst. Res. 2010, 21, 724–735. [Google Scholar] [CrossRef]

- Nylén, D.; Holmström, J. Digital innovation strategy: A framework for diagnosing and improving digital product and service innovation. Bus. Horiz. 2015, 58, 57–67. [Google Scholar] [CrossRef]

- Lyu, C.; Yang, J.; Zhang, F.; Teo, T.S.; Mu, T. How do knowledge characteristics affect firm’s knowledge sharing intention in interfirm cooperation? An Empirical Study. J. Bus. Res. 2020, 115, 48–60. [Google Scholar] [CrossRef]

- Grégoire, D.A.; Barr, P.S.; Shepherd, D.A. Cognitive processes of opportunity recognition: The role of structural alignment. Organ. Sci. 2010, 21, 413–431. [Google Scholar] [CrossRef]

- Garud, R.; Giuliani, A.P. A narrative perspective on entrepreneurial opportunities. Acad. Manag. Rev. 2013, 38, 157–160. [Google Scholar] [CrossRef]

- Enkel, E.; Gassmann, O.; Chesbrough, H. Open R&D and open innovation: Exploring the phenomenon. RD Manag. 2009, 39, 311–316. [Google Scholar]

- Zammuto, R.F.; Griffith, T.L.; Majchrzak, A.; Dougherty, D.J.; Faraj, S. Information technology and the changing fabric of organization. Organ. Sci. 2007, 18, 749–762. [Google Scholar] [CrossRef]

- Yoo, Y.; Boland, R.J., Jr.; Lyytinen, K.; Majchrzak, A. Organizing for innovation in the digitized world. Organ. Sci. 2012, 23, 1398–1408. [Google Scholar] [CrossRef]

- Henfridsson, O.; Bygstad, B. The generative mechanisms of digital infrastructure evolution. MIS Q. 2013, 37, 907–931. [Google Scholar] [CrossRef]

- Rebernik, M.; Širec, K. Fostering innovation by unlearning tacit knowledge. Kybernetes Int. J. Syst. Cybern. 2007, 36, 406–419. [Google Scholar] [CrossRef]

- Choi, T.M.; Kumar, S.; Yue, X.; Chan, H.L. Disruptive technologies and operations management in the Industry 4.0 era and beyond. Prod. Oper. Manag. 2022, 31, 9–31. [Google Scholar] [CrossRef]

- Srivardhana, T.; Pawlowski, S.D. ERP systems as an enabler of sustained business process innovation: A knowledge-based view. J. Strateg. Inf. Syst. 2007, 16, 51–69. [Google Scholar] [CrossRef]

- Kohli, R.; Melville, N.P. Digital innovation: A review and synthesis. Inf. Syst. J. 2019, 29, 200–223. [Google Scholar] [CrossRef]

- Di Vaio, A.; Palladino, R.; Pezzi, A.; Kalisz, D.E. The role of digital innovation in knowledge management systems: A systematic literature review. J. Bus. Res. 2021, 123, 220–231. [Google Scholar] [CrossRef]

- Akgün, A.E.; Lynn, G.S.; Byrne, J.C. Antecedents and consequences of unlearning in new product development teams. J. Prod. Innov. Manag. 2006, 23, 73–88. [Google Scholar] [CrossRef]

- March, J.G. Footnotes to organizational change. Adm. Sci. Q. 1981, 26, 563–577. [Google Scholar] [CrossRef]

- Evans, J.S. Strategic flexibility for high technology manoeuvres: A conceptual framework. J. Manag. Stud. 1991, 28, 69–89. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Nevo, S.; Benitez, J.; Kou, G. Improving strategic flexibility with information technologies: Insights for firm performance in an emerging economy. J. Inf. Technol. 2017, 32, 10–25. [Google Scholar] [CrossRef]

- Sanchez, R. Preparing for an uncertain future: Managing organizations for strategic flexibility. Int. Stud. Manag. Organ. 1997, 27, 71–94. [Google Scholar] [CrossRef]

- Wei, Z.; Yi, Y.; Guo, H. Organizational learning ambidexterity, strategic flexibility, and new product development. J. Prod. Innov. Manag. 2014, 31, 832–847. [Google Scholar] [CrossRef]

- Grewal, R.; Tansuhaj, P. Building organizational capabilities for managing economic crisis: The role of market orientation and strategic flexibility. J. Mark. 2001, 65, 67–80. [Google Scholar] [CrossRef]

- Singh, D.; Singh Oberoi, J.; Singh Ahuja, I. An empirical investigation of dynamic capabilities in managing strategic flexibility in manufacturing organizations. Manag. Decis. 2013, 51, 1442–1461. [Google Scholar] [CrossRef]

- Zhou, K.Z.; Wu, F. Technological capability, strategic flexibility, and product innovation. Strateg. Manag. J. 2010, 31, 547–561. [Google Scholar] [CrossRef]

- Sanchez, R. Strategic flexibility in product competition. Strateg. Manag. J. 1995, 16, 135–159. [Google Scholar] [CrossRef]

- Feldman, M.S.; Pentland, B.T. Reconceptualizing organizational routines as a source of flexibility and change. Adm. Sci. Q. 2003, 48, 94–118. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Y.; Zhao, Y.; Gong, S.; Li, B. Organisational unlearning, organisational flexibility and innovation capability: An empirical study of SMEs in China. Int. J. Technol. Manag. 2013, 61, 132–155. [Google Scholar] [CrossRef]

- Shimizu, K.; Hitt, M.A. Strategic flexibility: Organizational preparedness to reverse ineffective strategic decisions. Acad. Manag. Perspect. 2004, 18, 44–59. [Google Scholar] [CrossRef]

- Das, T.K.; Elango, B. Managing strategic flexibility: Key to effective performance. J. Gen. Manag. 1995, 20, 60–75. [Google Scholar] [CrossRef]

- Nadkarni, S.; Narayanan, V.K. Strategic schemas, strategic flexibility, and firm performance: The moderating role of industry clockspeed. Strateg. Manag. J. 2007, 28, 243–270. [Google Scholar] [CrossRef]

- Kamasak, R.; Yavuz, M.; Altuntas, G. Is the relationship between innovation performance and knowledge management contingent on environmental dynamism and learning capability? Evidence from a turbulent market. Bus. Res. 2016, 9, 229–253. [Google Scholar] [CrossRef]

- Fachrunnisa, O.; Adhiatma, A.; Lukman, N.; Ab Majid, M.N. Towards SMEs’ digital transformation: The role of agile leadership and strategic flexibility. J. Small Bus. Strategy 2020, 30, 65–85. [Google Scholar]

- Rajala, R.; Westerlund, M.; Möller, K. Strategic flexibility in open innovation—Designing business models for open source software. Eur. J. Mark. 2012, 46, 1368–1388. [Google Scholar] [CrossRef]

- Robertsone, G.; Lapiņa, I. Digital transformation as a catalyst for sustainability and open innovation. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100017. [Google Scholar] [CrossRef]

- Park, Y.W.; Hong, P. A research framework for sustainable digital innovation: Case studies of japanese firms. Sustainability 2022, 14, 9218. [Google Scholar] [CrossRef]

- Hevner, A.; Gregor, S. Envisioning entrepreneurship and digital innovation through a design science research lens: A matrix approach. Inf. Manag. 2022, 59, 103350. [Google Scholar] [CrossRef]

- Svahn, F.; Mathiassen, L.; Lindgren, R. Embracing Digital Innovation in Incumbent Firms. MIS Q. 2017, 41, 239–254. [Google Scholar] [CrossRef]

- Mishina, Y.; Pollock, T.G.; Porac, J.F. Are more resources always better for growth? Resource stickiness in market and product expansion. Strateg. Manag. J. 2004, 25, 1179–1197. [Google Scholar] [CrossRef]

- Cyert, R.M.; March, J.G. A Behavioral Theory of the Firm; Prentice Hall: Endlewood Cliffs, NJ, USA, 1963; pp. 169–187. [Google Scholar]

- Bourgeois, L.J., III. On the measurement of organizational slack. Acad. Manag. Rev. 1981, 6, 29–39. [Google Scholar] [CrossRef]

- Huang, Y.F.; Chen, C.J. The impact of technological diversity and organizational slack on innovation. Technovation 2010, 30, 420–428. [Google Scholar] [CrossRef]

- Zona, F. Corporate investing as a response to economic downturn: Prospect theory, the behavioural agency model and the role of financial slack. Br. J. Manag. 2012, 23, 42–57. [Google Scholar] [CrossRef]

- Tyler, B.B.; Caner, T. New product introductions below aspirations, slack and R&D alliances: A behavioral perspective. Strateg. Manag. J. 2016, 37, 896–910. [Google Scholar]

- Singh, J.V. Performance, slack, and risk taking in organizational decision making. Acad. Manag. J. 1986, 29, 562–585. [Google Scholar] [CrossRef]

- Lanzolla, G.; Lorenz, A.; Miron-Spektor, E.; Schilling, M.; Solinas, G.; Tucci, C.L. Digital transformation: What is new if anything? Emerging patterns and management research. Acad. Manag. Discov. 2020, 6, 341–350. [Google Scholar]

- Akgün, A.E.; Byrne, J.C.; Lynn, G.S.; Keskin, H. Organizational unlearning as changes in beliefs and routines in organizations. J. Organ. Change Manag. 2007, 20, 794–812. [Google Scholar] [CrossRef]

- Park, S.; Kim, E.J. Exploring linkages between unlearning and human resource development: Revisiting unlearning cases. Hum. Resour. Dev. Q. 2020, 31, E6–E16. [Google Scholar] [CrossRef]

- Sinkula, J.M. Market-based success, organizational routines, and unlearning. J. Bus. Ind. Mark. 2002, 17, 253–269. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Eldridge, S.; Roldán, J.L.; Leal-Millán, A.G.; Ortega-Gutiérrez, J. Organizational unlearning, innovation outcomes, and performance: The moderating effect of firm size. J. Bus. Res. 2015, 68, 803–809. [Google Scholar] [CrossRef]

- Gabriel Cegarra-Navarro, J.; Sánchez-Vidal, M.E.; Cegarra-Leiva, D. Balancing exploration and exploitation of knowledge through an unlearning context: An empirical investigation in SMEs. Manag. Decis. 2011, 49, 1099–1119. [Google Scholar] [CrossRef]

- Chirico, F.; Nordqvist, M. Dynamic capabilities and trans-generational value creation in family firms: The role of organizational culture. Int. Small Bus. J. 2010, 28, 487–504. [Google Scholar] [CrossRef]

- Martignoni, D.; Keil, T. It did not work? Unlearn and try again—Unlearning success and failure beliefs in changing environments. Strateg. Manag. J. 2021, 42, 1057–1082. [Google Scholar] [CrossRef]

- Cheng, J.L.; Kesner, I.F. Organizational slack and response to environmental shifts: The impact of resource allocation patterns. J. Manag. 1997, 23, 1–18. [Google Scholar] [CrossRef]

- Palmer, T.B.; Wiseman, R.M. Decoupling risk taking from income stream uncertainty: A holistic model of risk. Strateg. Manag. J. 1999, 20, 1037–1062. [Google Scholar] [CrossRef]

- Dolmans, S.A.; van Burg, E.; Reymen, I.M.; Romme, A.G.L. Dynamics of resource slack and constraints: Resource positions in action. Organ. Stud. 2014, 35, 511–549. [Google Scholar] [CrossRef]

- Troilo, G.; De Luca, L.M.; Atuahene-Gima, K. More innovation with less? A strategic contingency view of slack resources, information search, and radical innovation. J. Prod. Innov. Manag. 2014, 31, 259–277. [Google Scholar] [CrossRef]

- Tabesh, P.; Vera, D.; Keller, R.T. Unabsorbed slack resource deployment and exploratory and exploitative innovation: How much does CEO expertise matter? J. Bus. Res. 2019, 94, 65–80. [Google Scholar] [CrossRef]

- Lee, C.L.; Wu, H.C. How do slack resources affect the relationship between R&D expenditures and firm performance? R D Manag. 2016, 46, 958–978. [Google Scholar]

- Chan, C.M.; Teoh, S.Y.; Yeow, A.; Pan, G. Agility in responding to disruptive digital innovation: Case study of an SME. Inf. Syst. J. 2019, 29, 436–455. [Google Scholar] [CrossRef]

- Lau, C.M. Team and organizational resources, strategic orientations, and firm performance in a transitional economy. J. Bus. Res. 2011, 64, 1344–1351. [Google Scholar] [CrossRef]

- Miller, K.D.; Pentland, B.T.; Choi, S. Dynamics of performing and remembering organizational routines. J. Manag. Stud. 2012, 49, 1536–1558. [Google Scholar] [CrossRef]

- Peschl, M.F. Unlearning towards an uncertain future: On the back end of future-driven unlearning. Learn. Organ. 2019, 26, 454–469. [Google Scholar] [CrossRef]

- Sharma, S.; Lenka, U. On the shoulders of giants: Uncovering key themes of organizational unlearning research in mainstream management journals. Rev. Manag. Sci. 2022, 16, 1599–1695. [Google Scholar] [CrossRef]

- Xi, Y.; Wang, X.; Zhu, Y. Organizational unlearning and knowledge transfer in cross-border M&As: The mediating role of knowledge integration from a routine-based view. J. Knowl. Manag. 2020, 24, 841–860. [Google Scholar]

- Zahra, S.A.; Abdelgawad, S.G.; Tsang, E.W. Emerging multinationals venturing into developed economies: Implications for learning, unlearning, and entrepreneurial capability. J. Manag. Inq. 2011, 20, 323–330. [Google Scholar] [CrossRef]

- Ju, M.; Zhao, H. Behind organizational slack and firm performance in China: The moderating roles of ownership and competitive intensity. Asia Pac. J. Manag. 2009, 26, 701–717. [Google Scholar] [CrossRef]

- Klammer, A.; Gueldenberg, S. Unlearning and forgetting in organizations: A systematic review of literature. J. Knowl. Manag. 2019, 23, 860–888. [Google Scholar] [CrossRef]

- Lei, D.; Slocum, J.W.; Pitts, R.A. Designing organizations for competitive advantage: The power of unlearning and learning. Organ. Dyn. 1999, 27, 24–38. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, B.; Yin, Y. Open innovation search in manufacturing firms: The role of organizational slack and absorptive capacity. J. Knowl. Manag. 2017, 21, 656–674. [Google Scholar] [CrossRef]

- Lin, W.T.; Cheng, K.Y.; Liu, Y. Organizational slack and firm’s internationalization: A longitudinal study of high-technology firms. J. World Bus. 2009, 44, 397–406. [Google Scholar] [CrossRef]

- Hoskisson, R.E.; Eden, L.; Lau, C.M.; Wright, M. Strategy in emerging economies. Acad. Manag. J. 2000, 43, 249–267. [Google Scholar] [CrossRef]

- Allen, I.E.; Seaman, C.A. Likert scales and data analyses. Qual. Prog. 2007, 40, 64–65. [Google Scholar]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Alwin, D.F. How good is survey measurement? Assessing the reliability and validity of survey measures. Handb. Surv. Res. 2010, 2, 405–434. [Google Scholar]

- Danneels, E. Organizational antecedents of second-order competences. Strateg. Manag. J. 2008, 29, 519–543. [Google Scholar] [CrossRef]