Investigation of Load-Bearing Capacity for Reinforced Concrete Foundation Retrofitted Using Steel Strut–Tie Retrofit System

Abstract

:1. Introduction

1.1. Background

1.2. Research Purpose

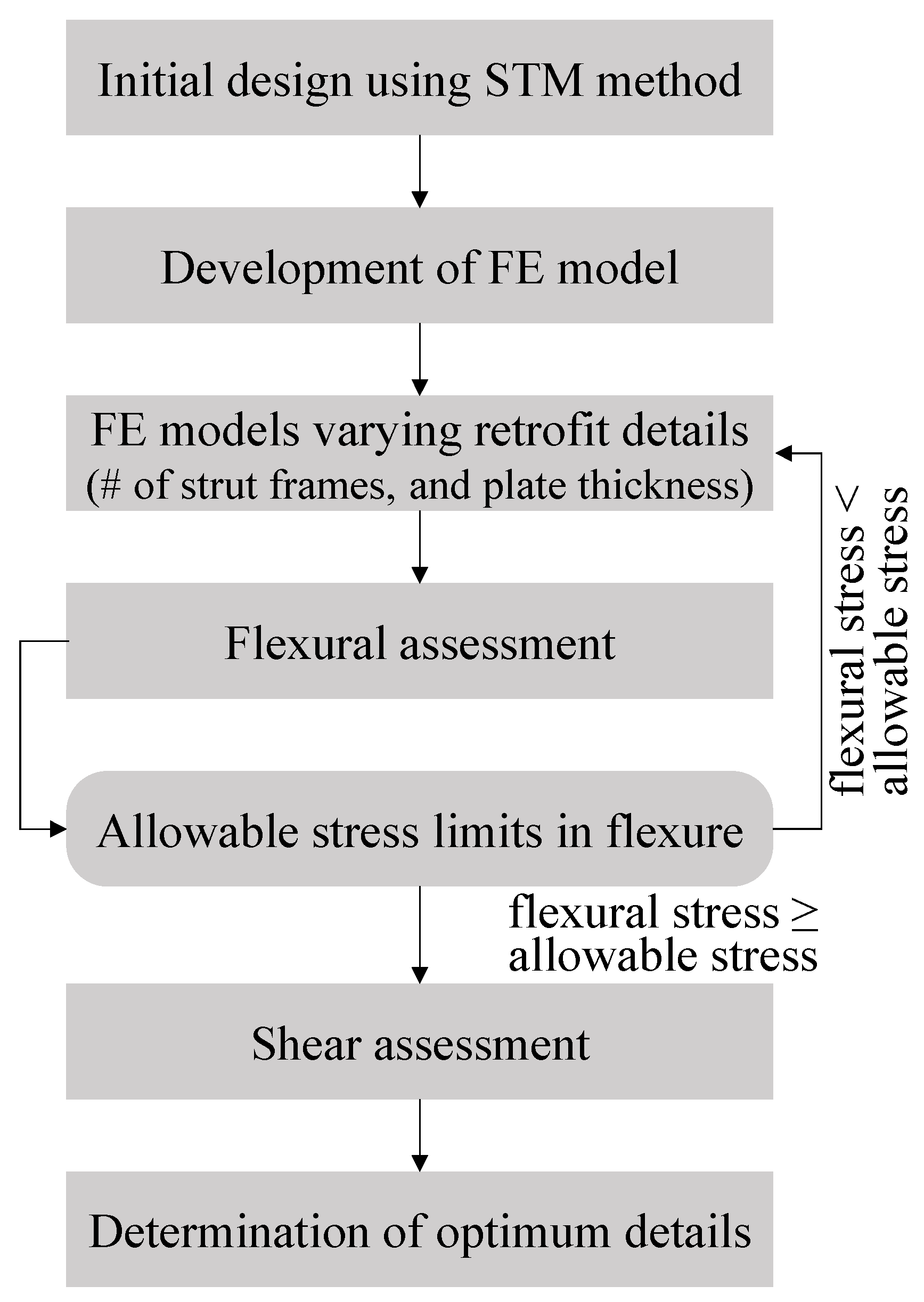

2. Design of Steel Strut Using Strut and Tie Model

2.1. Strut and Tie Model Approach

- (1)

- Develop an FE model to analyze the stress distribution for the given load combinations without the strut retrofit system.

- (2)

- Propose a truss model (STM) for the longitudinal and transverse directions in a bridge structure based on the stress distribution of the FE model (STM shape determination).

- (3)

- Calculate the axial forces of the compression and tension members of the truss model for each load combination.

- (4)

- Design the strut based on the compressive axial forces (determine the required cross-sectional width and calculate the required number of struts).

- (5)

- Design the tie based on the tensile force of the tension member (design the steel wire and reinforcement).

2.2. Design Process of Steel Struts and Ties

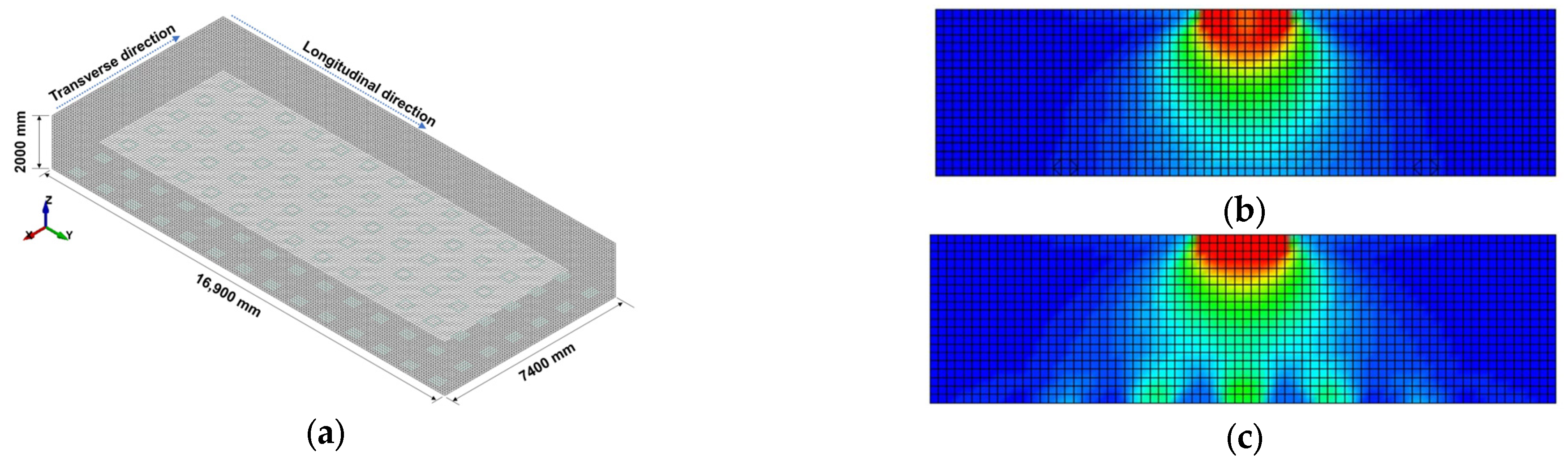

3. Finite Element Model

4. Load-Bearing Capacity Assessment

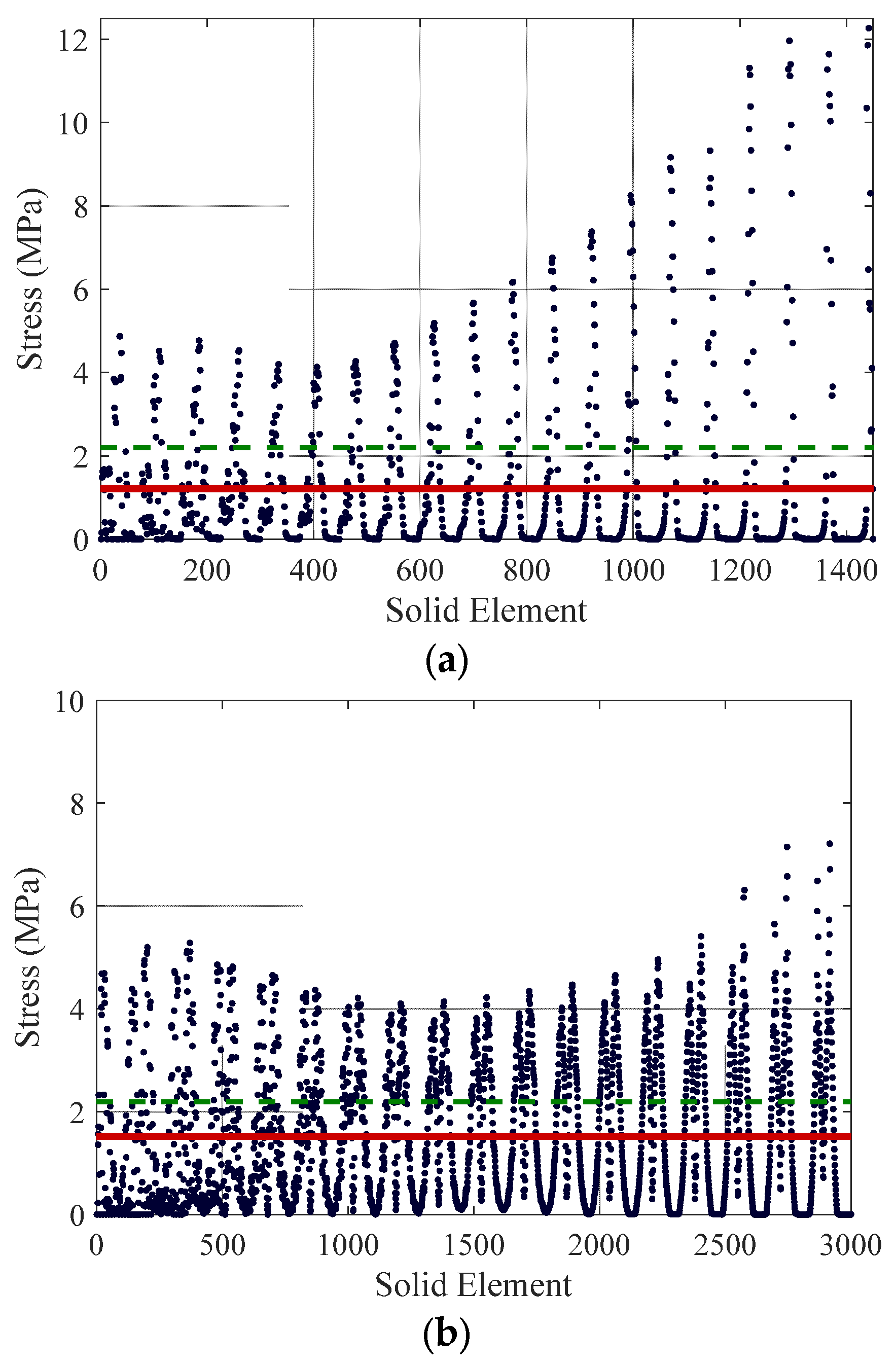

4.1. Flexure Assessment

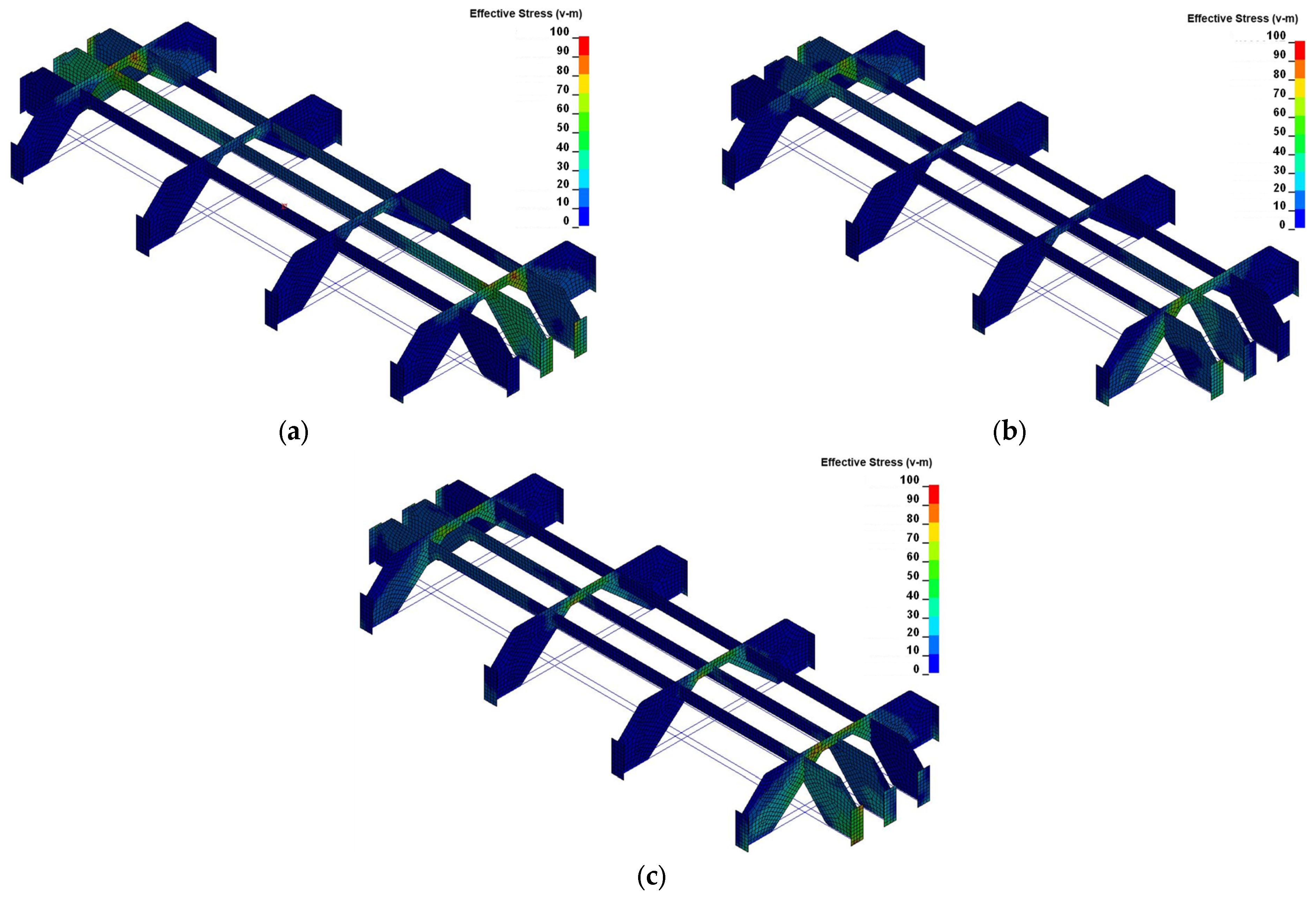

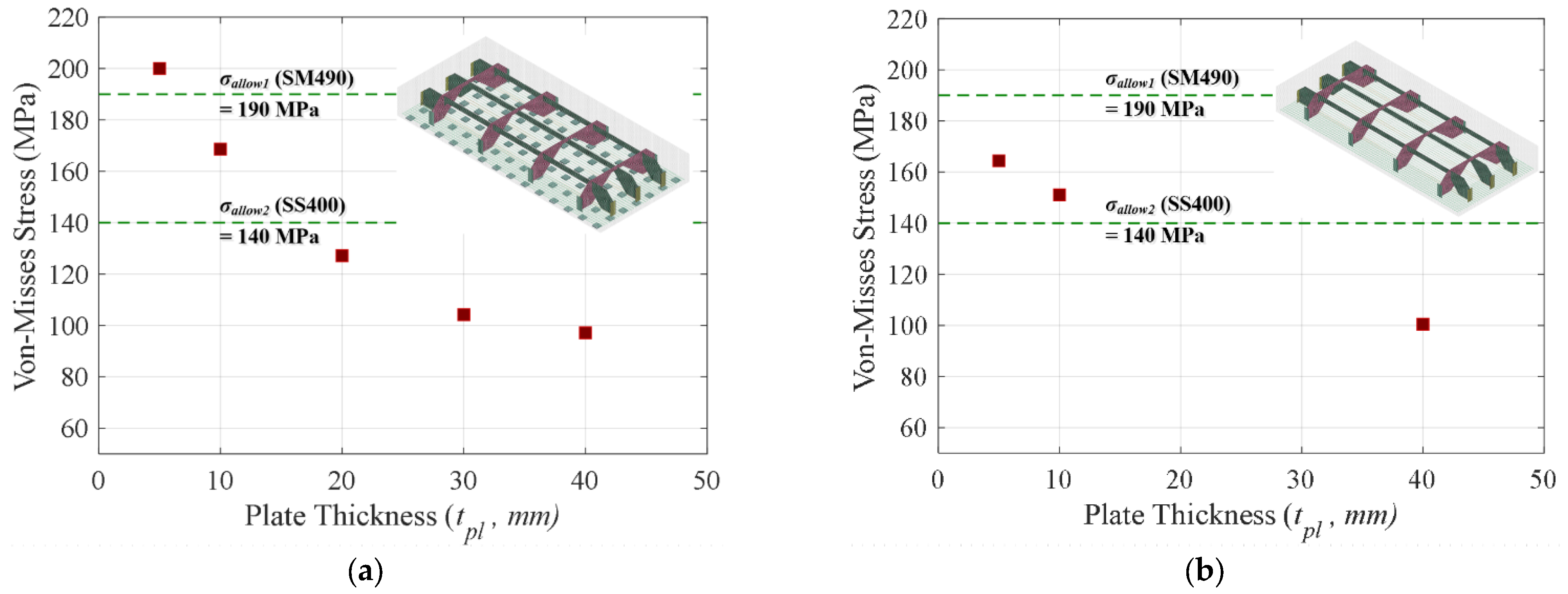

4.2. FE-Simulation-Based Optimum Details

4.3. Shear Assessment

5. Conclusions

- (1)

- The foundation with a strut–tie retrofit system developed using the STM-based design method specified in the current code reduced the thickness of the typical RC foundation by 20%. The numbers of strut–tie retrofit systems in the transverse and longitudinal directions when the strut frame thickness was 40 mm were four and three, respectively. In the FE simulations, the effective stress values obtained from the strut–tie retrofit system did not exceed the permissible stress limit for the LC-1 load combination where the stress values were maximized in all directions (approximately 70% of the permissible stress of LC-1 for SS400 structural steel).

- (2)

- Based on the flexural assessment, a decrease in the plate thickness of the strut–tie retrofit system increased the effective stress in the retrofit system. A decrease in the number of strut frames led to an increase in the flexural stress. This was attributed to the stress concentration caused by the decrease in the retrofit details. The flexural assessment of the foundation models with reduced material consumption in the strut–tie retrofit system continued until the strut frames exceeded the permissible stress limits specified in the current code.

- (3)

- To optimize the design details of the strut–tie retrofit system (strut plate thickness and structural steel type), the FE simulation results (the maximum effective stress values) for the loading combinations were compared with the permissible stress specified in the current code. The FE simulation results with the loading combinations reveal that SS400 structural steel can be used. Furthermore, the strut plate thickness for the transverse direction (wherein the stress rate is higher than that in the longitudinal direction) is 18 mm. Although the number of strut–tie retrofit systems was reduced from three to two in the longitudinal direction, which had a lower load distribution rate than the transverse direction, the maximum effective stress of the retrofit system did not exceed the permissible stress of the structural steel type until the plate thickness was reduced to 8 mm.

- (4)

- The FE-based design approach can reduce the material consumption of the retrofit details (number of strut frames in the longitudinal direction and the plate thickness) by 55.0% and 86.7% in the transverse and longitudinal directions as compared to the initial details determined from the STM model. The shear and flexural forces of the foundation members with optimum retrofit details under the given loading combinations were estimated to be within the code-defined permissible limits.

- (5)

- Based on the load-bearing capacity assessment, the FE-based design method was more effective in minimizing the material quantities for the strut–tie retrofit system than the conventional design method. The conventional STM-based design method assumes that the arch-shaped strut frames resist the shear produced by the load combinations. However, the FE-based design method implemented for optimizing the retrofit details predicted the actual structural behavior relatively more accurately because it assumed that the concrete and arch-shaped strut frames resisted shear. In a previous study [6], the durability of reinforced concrete members associated with laboratory-based parameters, service life, and raw material demand was reduced due to decreases in the concrete material consumption (20% reduction in the foundation member’s thickness). To propose eco-efficient retrofit details, in a future study, a durability-based life-cycle assessment will be conducted for a foundation member installed using a steel strut–tie retrofit system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yoon, S.M.; Park, H.M.; Park, J.W.; Lee, J.Y. Evaluation of the Structural Behavior of RC Foundations reinforced with Steel Struts. J. Archit. Inst. Korea-Struct. Constr. 2009, 25, 13–22. (In Korean) [Google Scholar]

- Kim, B.H.; Yun, Y.M. An indeterminate strut-tie model and load distribution ratio for RC deep beams-(I) Model & Load Distribution Ratio. Adv. Struct. Eng. 2011, 14, 1031–1041. [Google Scholar]

- Di, H.; Guo, H.; Zhou, S.; Chen, J.; Wen, L. Investigation of the axial force compensation and deformation control effect of servo steel struts in a deep foundation pit excavation in soft clay. Adv. Civ. Eng. 2019, 2019, 5476354. [Google Scholar] [CrossRef] [Green Version]

- Feng, H.H.; Wang, X. Causes and control measures of mass concrete crack of high-rise building basement foundation slab. Adv. Mater. Res. 2011, 163, 1609–1613. [Google Scholar] [CrossRef]

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact, performance and lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Ren, Q.; Zheng, Q.; Jiang, Z. Durability of concrete coupled with life cycle assessment: Review and perspective. Cem. Concr. Compos. 2023, 21, 105041. [Google Scholar] [CrossRef]

- Panjehpour, M.; Chai, H.K.; Voo, Y.L. Refinement of strut-and-tie model for reinforced concrete deep beams. PLoS ONE 2015, 10, e0130734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdul-Razzaq, K.S.; Jebur, S.F. Experimental verification of strut and tie method for reinforced concrete deep beams under various types of loadings. J. Eng. Sustain. Dev. 2017, 21, 39–55. [Google Scholar]

- Farhangi, V.; Karakouzian, M.; Geertsema, M. Effect of micropiles on clean sand liquefaction risk based on CPT and SPT. Appl. Sci. 2020, 10, 3111. [Google Scholar] [CrossRef]

- Stone, R.C.; Farhangi, V.; Fatahi, B.; Karakouzian, M. A novel short pile foundation system bonded to highly cemented layers for settlement control. Can. Geotech. J. 2023. [Google Scholar] [CrossRef]

- Kannaujiya, P.; Jaiswal, S.; Chauhan, V.B. Studies on the piled raft foundation for a high-rise building using finite element modeling. In Advances in Geo-Science and Geo-Structures: Select Proceedings of GSGS 2020; Springer: Singapore, 2022; pp. 245–252. [Google Scholar]

- Schlaich, J.; Schafer, K. Design and detailing of structural concrete using strut-and-tie models. Struct. Eng. 1991, 69, 113–125. [Google Scholar]

- Ramirez, J.A. Strut-Tie Shear Design of Pretensioned Concrete. Struct. J. 1994, 91, 572–578. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete and Commentary; ACI 318-05; American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Liang, Q.Q.; Uy, B.; Steven, G.P. Performance-based optimization for strut-tie modeling of structural concrete. J. Struct. Eng. 2002, 128, 815–823. [Google Scholar] [CrossRef] [Green Version]

- Yun, Y.M.; Ramirez, J.A. Strength of concrete struts in three-dimensional strut-tie models. J. Struct. Eng. 2016, 142, 04016117. [Google Scholar] [CrossRef]

- Xia, Y.; Langelaar, M.; Hendriks, M.A. Optimization-based three-dimensional strut-and-tie model generation for reinforced concrete. Comput.-Aided Civ. Infrastruct. Eng. 2021, 36, 526–543. [Google Scholar] [CrossRef]

- KCI. KDS 14 20 00; Korean Concrete Standard Specification. KCI: Seoul, Republic of Korea, 2021.

- Livermore Software Technology Corporation. LS-DYNA Keyword User’s Manual, Version 971/R7.0; Livermore Software Technology Corporation: Livermore, CA, USA, 2013.

- Crawford, J.; Wu, Y.; Choi, H.; Magallanes, J.; Lan, S. Use and Validation of the Release III K&C Concrete Material Model in LSDYNA; TR-11-36.6 Technical Report; Karagozian & Case: Glendale, CA, USA, 2012. [Google Scholar]

- Wu, Y.; Crawford, J.E. Numerical modeling of concrete using a partially associative plasticity model. J. Eng. Mech. 2015, 141, 04015051. [Google Scholar] [CrossRef]

- Weatherby, J.H. Investigation of Bond Slip between Concrete and Steel Reinforcement under Dynamic Loading Conditions. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2003. [Google Scholar]

- Tabiei, A.; Wu, J. Roadmap for crashworthiness finite element simulation of roadside safety structures. Finite Elem. Anal. Des. 2000, 34, 145–157. [Google Scholar] [CrossRef] [Green Version]

- Shin, J.; Stewart, L.K.; Yang, C.S.; Scott, D.W. Implementation of Bond-Slip Performance Models in the Analyses of Non-Ductile Reinforced Concrete Frames Under Dynamic Loads. J. Earthq. Eng. 2020, 24, 129–154. [Google Scholar] [CrossRef]

- MOLIT. Railway Design Standard of the Ministry of Land, Infrastructure, and Transport; MOLIT: Seoul, Republic of Korea, 2015.

- Ghosn, M.; Moses, F. NCHRP Report 489: Design of Highway Bridge for Extreme Events; Transportation Research Board of the National Academies; Transportation Research Board: Washington, DC, USA, 2003. [Google Scholar]

- Korea Bridge Design Code. Limit-State-Based Bridge Design Specifications; Korea Road and Transportation Association: Seoul, Republic of Korea, 2012. [Google Scholar]

| Classification | Loading Combination | Shear (kN) | Axial Load (kN) | Moment (kN-m) | |

|---|---|---|---|---|---|

| Transvers direction | Maximum axial load | LC-1 | 1265 | 54,229 | 21,027 |

| Maximum moment | LC-2 | 1265 | 51,656 | 21,027 | |

| Earthquake | LC-3 | 2968 | 54,519 | 52,527 | |

| Longitudinal direction | Maximum axial load | LC-1 | 2431 | 54,229 | 180 |

| Maximum moment | LC-2 | 119 | 50,508 | 1945 | |

| Earthquake | LC-3 | 5133 | 54,519 | 51,140 | |

| Concrete Strength (fck, MPa) | Steel Reinforcing Bar | Steel Type | Tie (Steel Wire) | Foundation Thickness (mm) | ||

|---|---|---|---|---|---|---|

| Yielding Strength (fsy, MPa) | Diameter (mm) | Tensile Strength (fpu, MPa) | Diameter (mm) | |||

| 35 | 400 | 29 | SM490 | 1100 | 32 | 2000 (80% of typical foundation thickness) |

| Direction | fck (MPa) | Size (mm) | Thickness (mm) | Strut Frame | Tie | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel Type | Yielding Strength (MPa) | Plate Thickness (tpl, mm) | Required Number | Tensile Strength (MPa) | Wire Diameter (mm) | Required Number | ||||

| Transverse direction | 35 | 7400 | 2000 | SM490 | 315 | 40 | 8 | 1100 | 32 | 16 |

| Longitudinal direction | 16,900 | 3 | 1100 | 32 | 6 | |||||

| Poisson’s Ratio | Density (g/mm3) | Compressive Strength (MPa) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Max. Aggregate Size (mm) | Dilation Factor |

|---|---|---|---|---|---|---|

| 0.16 | 0.0023 | 35 | 2.69 | 29937.9 | 6.35 | 0.8 |

| Type | Poisson’s Ratio | Density (g/mm3) | Elastic Modulus (MPa) | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|---|---|---|

| D29 rebar | 0.3 | 0.0078 | 206,000 | 400 | 512 |

| SM490 strut | 0.3 | 0.0078 | 206,000 | 315 | 490 |

| φ47 steel wire | 0.3 | 0.0078 | 206,000 | 400 | 512 |

| Stress Type | Plate Thickness | SS400 SM400 SMA400 | SM490 | SM490Y SM520 SMA490 | SM580 SMA570 |

|---|---|---|---|---|---|

| Axial stress | ≤40 mm | 140 MPa | 190 MPa | 215 MPa | 270 MPa |

| Flexural stress | ≤40 mm | 140 MPa | 190 MPa | 215 MPa | 270 MPa |

| Direction | Strut Frame | Tie | |||||

|---|---|---|---|---|---|---|---|

| Steel Type | Yielding Stress (MPa) | Plate Thickness (mm) | Req. Number | Yielding Stress (MPa) | Steel Wire Diameter (mm) | Req. Number (Actual) | |

| Transverse | SS400 | 235 | 18 | 4 | 400 | 50 | 7(8) |

| Longitudinal | 8 | 2 | 400 | 50 | 6(6) | ||

| Direction | Initial Strut–Tie Retrofit System with STM-Based Design Method | Optimum Strut–Tie Retrofit System with FE-Based Design Method | Volume Reduction Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Unit Area of Strut Frame (mm2) | tpl (mm) | Req. Number | Total Volume (mm3) | Unit Area of Strut Frame (mm2) | tpl (mm) | Req. Number | Total Volume (mm3) | ||

| Transverse | 6.62 × 106 | 40 | 4 | 1.06 × 109 | 6.62 × 106 | 18 | 4 | 4.77 × 108 | 55.0% |

| Longitudinal | 9.96 × 106 | 40 | 3 | 1.15 × 106 | 9.96 × 106 | 8 | 2 | 1.53 × 108 | 86.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.; Lee, K. Investigation of Load-Bearing Capacity for Reinforced Concrete Foundation Retrofitted Using Steel Strut–Tie Retrofit System. Sustainability 2023, 15, 10372. https://doi.org/10.3390/su151310372

Shin J, Lee K. Investigation of Load-Bearing Capacity for Reinforced Concrete Foundation Retrofitted Using Steel Strut–Tie Retrofit System. Sustainability. 2023; 15(13):10372. https://doi.org/10.3390/su151310372

Chicago/Turabian StyleShin, Jiuk, and Kihak Lee. 2023. "Investigation of Load-Bearing Capacity for Reinforced Concrete Foundation Retrofitted Using Steel Strut–Tie Retrofit System" Sustainability 15, no. 13: 10372. https://doi.org/10.3390/su151310372

APA StyleShin, J., & Lee, K. (2023). Investigation of Load-Bearing Capacity for Reinforced Concrete Foundation Retrofitted Using Steel Strut–Tie Retrofit System. Sustainability, 15(13), 10372. https://doi.org/10.3390/su151310372