A Systematic Review of Energy Management Systems for Battery/Supercapacitor Electric Vehicle Applications

Abstract

1. Introduction

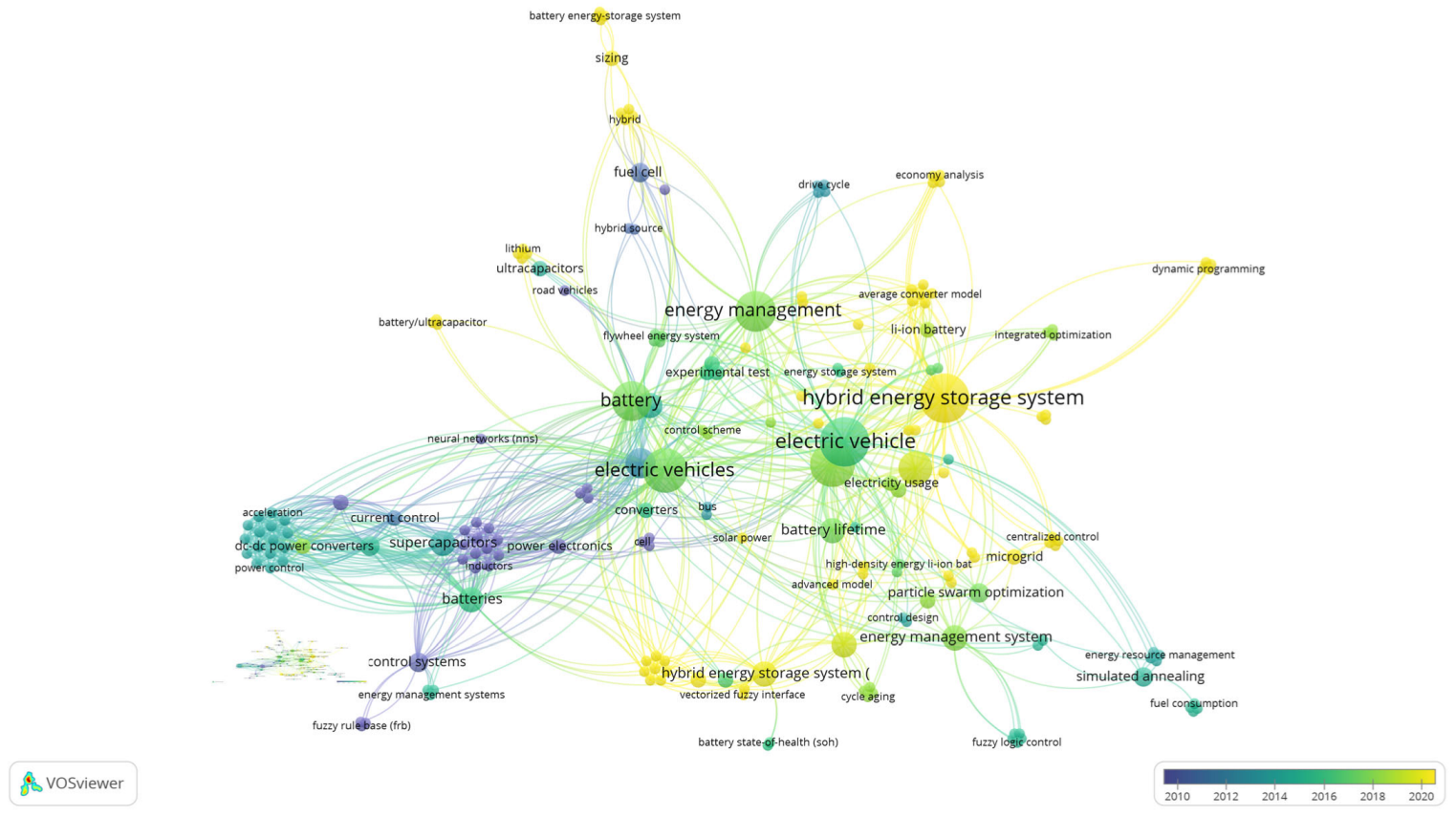

2. Research Methodology

3. Battery and Supercapacitor in Hybrid Energy Storage System

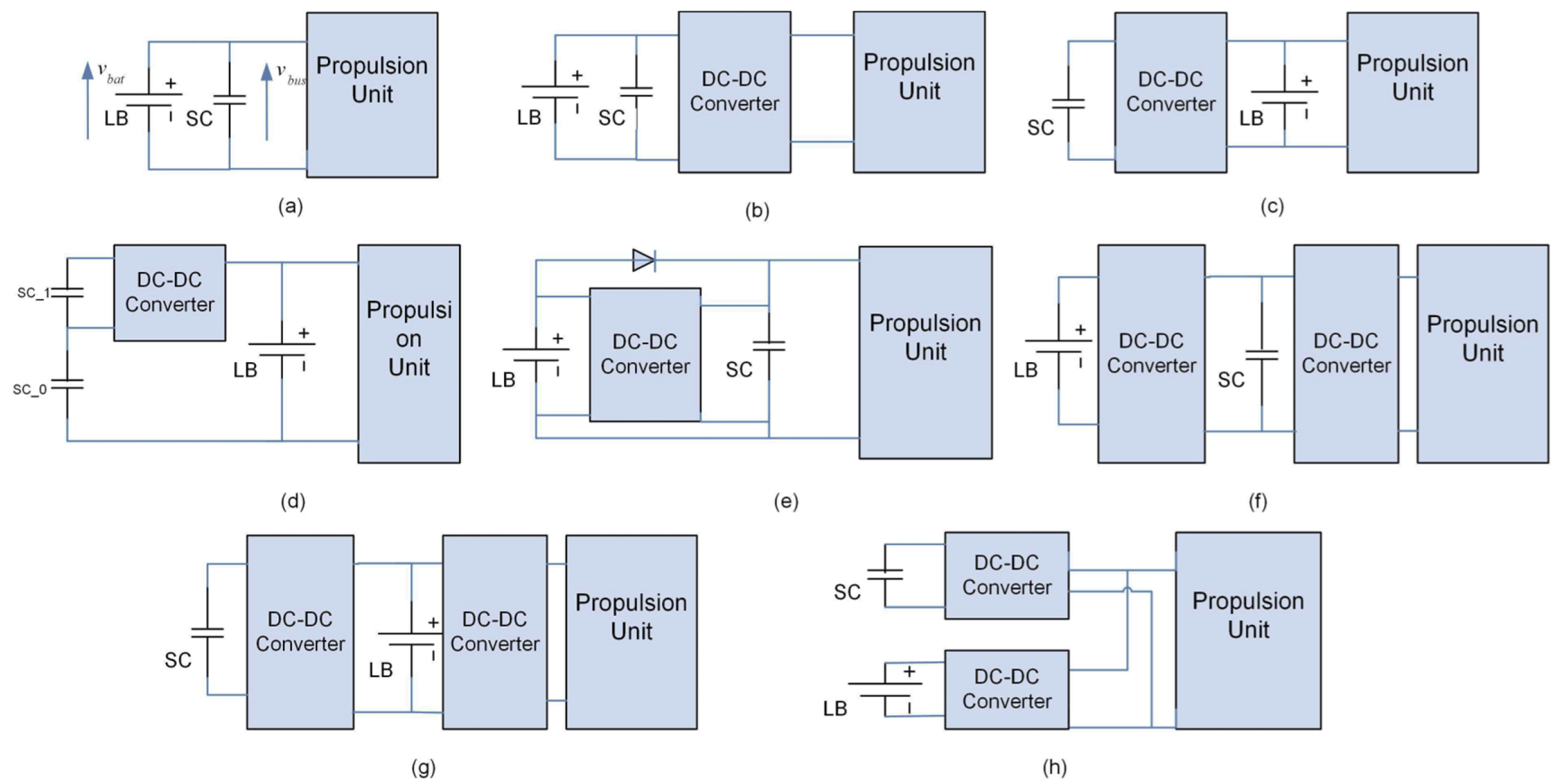

4. DC/DC Converter Topologies for Energy Source

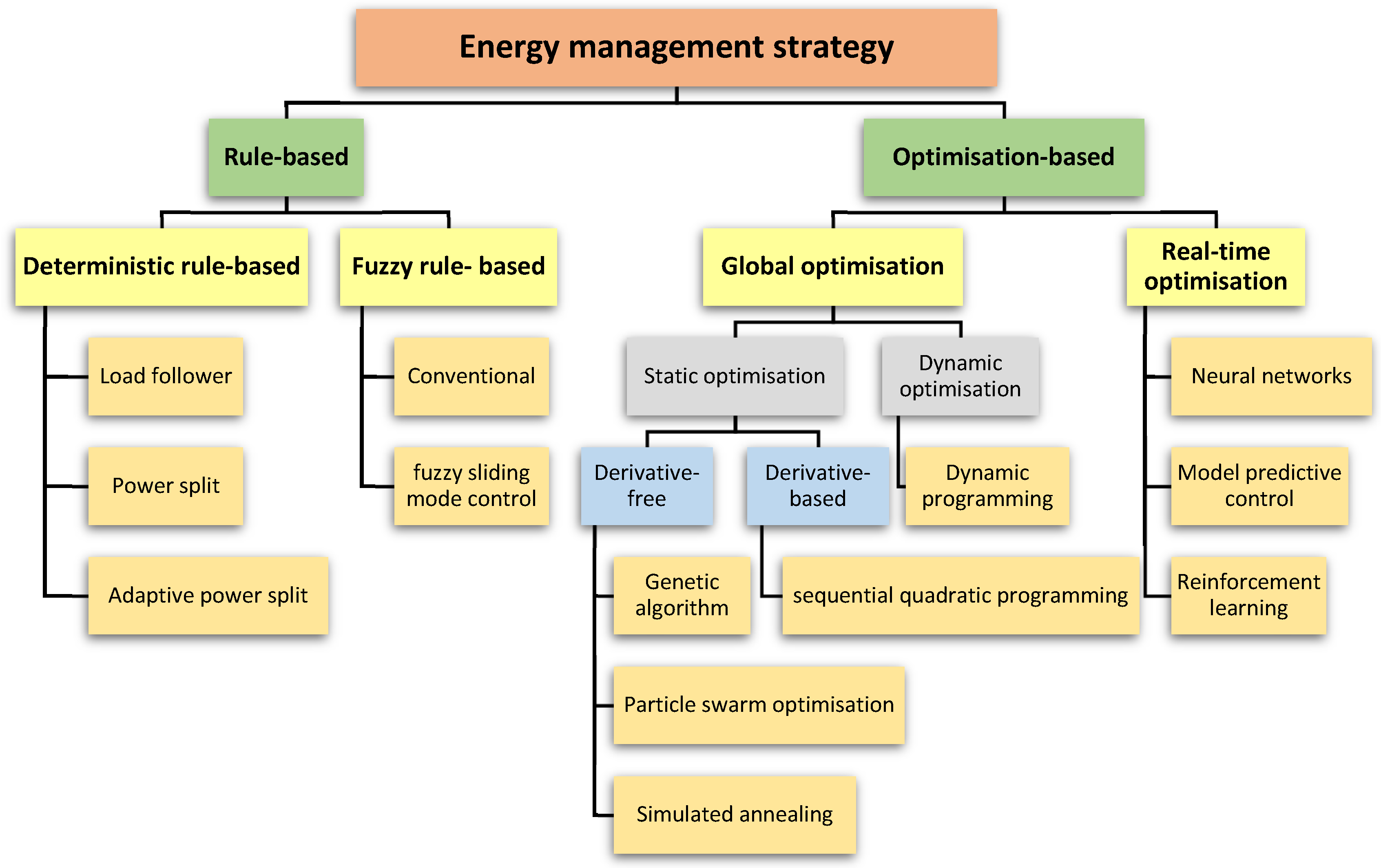

5. Energy Management Strategies for EV Applications

5.1. Rule-Based Energy Management Strategy

5.1.1. Deterministic Rule-Based Energy Management Strategy

5.1.2. Fuzzy-Rule-Based Energy Management Strategy

5.2. Optimization-Based Energy Management Strategy

5.2.1. Global Optimization Energy Management Strategy

- Firstly, there is the optimization of the parameters of a rule-based energy management control strategy. With this method, the energy management problem turns into a parameter optimization problem, and it is called a static optimization problem. Thus, a derivative-free static optimization method can be implemented, i.e., a genetic algorithm (GA), particle swarm optimization (PSO), and simulated annealing (SA). In addition, a derivative-based static optimization method such as sequential quadratic programming (SQP) can also be applied.

- Secondly, the energy management problem of EV applications is considered as a dynamic, nonlinear, and constrained optimization problem. This is recognized as an optimal control problem. The optimization problem can be determined by dynamic optimization methods such as dynamic programming.

- Thirdly, the optimal control problem is approximately modeled as a mathematical problem. After that, the problem is solved by static optimization methods such as SQP.

Static Optimization Method

Dynamic Optimization Method

5.2.2. Real-Time Optimization Energy Management Strategy

Neural Network Control Strategy

Model Predictive Control Strategy

Reinforcement Learning Control Strategy

6. Discussion on Major Findings of Energy Management Strategies

7. Conclusions

- The findings declared the significance of the HESS for EVs in terms of performance, life cycle, and controllability via DC-DC power converters in the literature and provided scoring for a suitable configuration for applications.

- A review on the non-isolated half-bridge bi-directional DC-DC converter is proposed for smooth operation based on the limitations of low weight, low cost, and low loss with good dependability.

- An evaluation of the energy management strategies was provided where we found that rule-based real-time control is an acceptable solution for vehicle manufacturing. However, the performance of the real-time optimization strategy is acknowledged and has good prospects unless the economy of scale is established.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Husain, I. Electric and Hybrid Vehicles, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 9780429490927. [Google Scholar]

- Wang, Y.; Sun, Z.; Chen, Z. Energy Management Strategy for Battery/Supercapacitor/Fuel Cell Hybrid Source Vehicles Based on Finite State Machine. Appl. Energy 2019, 254, 113707. [Google Scholar] [CrossRef]

- Chemali, E.; Peindl, M.; Malysz, P.; Emadi, A. Electrochemical and Electrostatic Energy Storage and Management Systems for Electric Drive Vehicles: State-of-the-Art Review and Future Trends. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1117–1134. [Google Scholar] [CrossRef]

- Pullen, K.R.; Dhand, A. Mechanical and Electrical Flywheel Hybrid Technology to Store Energy in Vehicles. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; Woodhead Publishing: Sawston, UK, 2014; pp. 476–504. ISBN 9780857095220. [Google Scholar]

- Rimpas, D.; Kaminaris, S.D.; Aldarraji, I.; Piromalis, D.; Vokas, G.; Papageorgas, P.G.; Tsaramirsis, G. Energy Management and Storage Systems on Electric Vehicles: A Comprehensive Review. Mater. Today Proc. 2022, 61, 813–819. [Google Scholar] [CrossRef]

- ISO. Win the Energy Challenge with ISO 50001; ISO Central Secretariat: Geneva, Switzerland, 2011. [Google Scholar]

- Choi, M.; Lee, J.; Seo, S. Real-Time Optimization for Power Management Systems of a Battery/Supercapacitor Hybrid Energy Storage System in Electric Vehicles. IEEE Trans. Veh. Technol. 2014, 63, 3600–3611. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Hou, J.; Han, X.; Ouyang, M. Energy Management Strategies Comparison for Electric Vehicles with Hybrid Energy Storage System. Appl. Energy 2014, 134, 321–331. [Google Scholar] [CrossRef]

- Aharon, I.; Kuperman, A. Topological Overview of Powertrains for Battery-Powered Vehicles with Range Extenders. IEEE Trans. Power Electron. 2011, 26, 868–876. [Google Scholar] [CrossRef]

- Ahmed, O.A.; Bleijs, J.A.M. An Overview of DC–DC Converter Topologies for Fuel Cell-Ultracapacitor Hybrid Distribution System. Renew. Sustain. Energy Rev. 2015, 42, 609–626. [Google Scholar] [CrossRef]

- Pay, S.; Baghzouz, Y.; Member, S. Effectiveness of Battery-Supercapaicitor Combination in Electric Vehicles. In Proceedings of the 2003 IEEE Bologna Power Tech Conference Proceedings, Bologna, Italy, 23–26 June 2003. [Google Scholar]

- Lukic, S.M.S.M.; Cao, J.; Bansal, R.C.R.C.; Rodriguez, F.; Emadi, A.; Member, S.S.; Cao, J.; Bansal, R.C.R.C.; Member, S.S.; Rodriguez, F. Energy Storage Systems for Automotive Applications. Ind. Electron. IEEE Trans. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Iannuzzi, D.; Tricoli, P. Speed-Based State-of-Charge Tracking Control for Metro Trains with Onboard Supercapacitors. IEEE Trans. Power Electron. 2012, 27, 2129–2140. [Google Scholar] [CrossRef]

- Armenta, J.; Núñez, C.; Visairo, N.; Lázaro, I. An Advanced Energy Management System for Controlling the Ultracapacitor Discharge and Improving the Electric Vehicle Range. J. Power Sources 2015, 284, 452–458. [Google Scholar] [CrossRef]

- Dixon, J.; Nakashima, I.; Arcos, E.F.; Ortúzar, M. Electric Vehicle Using a Combination of Ultracapacitors and ZEBRA Battery. IEEE Trans. Ind. Electron. 2010, 57, 943–949. [Google Scholar] [CrossRef]

- Ortúzar, M.; Moreno, J.; Dixon, J. Ultracapacitor-Based Auxiliary Energy System for an Electric Vehicle: Implementation and Evaluation. IEEE Trans. Ind. Electron. 2007, 54, 2147–2156. [Google Scholar] [CrossRef]

- Moreno, J.; Ortuzar, M.E.; Dixon, J.W. Energy-Management System for a Hybrid Electric Vehicle, Using Ultracapacitors and Neural Networks. IEEE Trans. Ind. Electron. 2006, 53, 614–623. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N. Student Research Highlight: Acceleration-Based Design of Electric Vehicle Auxiliary Energy Source. IEEE Aerosp. Electron. Syst. Mag. 2016, 31, 32–35. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N.; Jusoh, A.; Muhamad, N.D.; Chamchuen, S. Acceleration-Based Control Strategy and Design for Hybrid Electric Vehicle Auxiliary Energy Source. ECTI Trans. Comput. Inf. Technol. 2015, 9, 83–92. [Google Scholar] [CrossRef]

- Guidi, G.; Undeland, T.M.; Hori, Y. Optimized Power Electronics Interface for Auxiliary Power Buffer Based on Supercapacitors. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, VPPC 2008, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Guidi, G.; Undeland, T.M.; Hori, Y. An Optimized Converter for Battery-Supercapacitor Interface. In Proceedings of the PESC Record-IEEE Annual Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 2976–2981. [Google Scholar]

- Guidi, G.; Undeland, T.M.; Hori, Y. An Interface Converter with Reduced VA Ratings for Battery-Supercapacitor Mixed Systems. In Proceedings of the Fourth Power Conversion Conference-NAGOYA, PCC-NAGOYA 2007-Conference Proceedings, Nagoya, Japan, 2–5 April 2007; pp. 936–941. [Google Scholar]

- Cao, J.; Emadi, J. A New Battery/UltraCapacitor Hybrid Energy Storage System for Electric, Hybrid, and Plug-In Hybrid Electric Vehicles. IEEE Trans. Power Electron. 2012, 27, 122–132. [Google Scholar] [CrossRef]

- Kuperman, A.; Aharon, I. Battery–Ultracapacitor Hybrids for Pulsed Current Loads: A Review. Renew. Sustain. Energy Rev. 2011, 15, 981–992. [Google Scholar] [CrossRef]

- Laldin, O.; Moshirvaziri, M.; Trescases, O. Predictive Algorithm for Optimizing Power Flow in Hybrid Ultracapacitor/Battery Storage Systems for Light Electric Vehicles. IEEE Trans. Power Electron. 2013, 28, 3882–3895. [Google Scholar] [CrossRef]

- Florescu, A.; Bacha, S.; Munteanu, I.; Iuliana, A.; Rumeau, A.; Bratcu, A.I.; Rumeau, A. Adaptive Frequency-Separation-Based Energy Management System for Electric Vehicles. J. Power Sources 2015, 280, 410–421. [Google Scholar] [CrossRef]

- Source, B.P.; Hredzak, B.; Agelidis, V.G.; Member, S.; Jang, M. A Model Predictive Control System for a Hybrid. IEEE Trans. Power Electron. 2014, 29, 1469–1479. [Google Scholar]

- Zhou, S.Q.; Guo, G.F.; Xiang, Y.Y. Multi-Objective Optimal Sizing Hybrid Power System in a Solar Electric Vehicle Using Particle Swarm Optimization Algorithm. Adv. Mater. Res. 2013, 694–697, 2699–2703. [Google Scholar] [CrossRef]

- Wong, J.H.; Sutikno, T.; Idris, N.R.N.; Anwari, M. A Parallel Energy-Sharing Control Strategy for Fuel Cell Hybrid Vehicle. Telkomnika 2011, 9, 357–364. [Google Scholar] [CrossRef]

- Schupbach, R.M.; Balda, J.C. Comparing DC-DC Converters for Power Management in Hybrid Electric Vehicles. In IEEE International Electric Machines and Drives Conference, 2003. IEMDC’03; IEEE: Piscataway, NJ, USA, 2003; pp. 1369–1374. [Google Scholar] [CrossRef]

- Amjadi, Z.; Williamson, S.S. Prototype Design and Controller Implementation for a Battery-Ultracapacitor Hybrid Electric Vehicle Energy Storage System. IEEE Trans. Smart Grid 2012, 3, 332–340. [Google Scholar] [CrossRef]

- Fernão Pires, V.; Romero-Cadaval, E.; Vinnikov, D.; Roasto, I.; Martins, J.F. Power Converter Interfaces for Electrochemical Energy Storage Systems—A Review. Energy Convers. Manag. 2014, 86, 453–475. [Google Scholar] [CrossRef]

- Jain, M.; Desai, C.; Williamson, S.S. Genetic Algorithm Based Optimal Powertrain Component Sizing and Control Strategy Design for a Fuel Cell Hybrid Electric Bus. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 980–985. [Google Scholar]

- Borhan, H.A.; Vahidi, A. Model Predictive Control of a Power-Split Hybrid Electric Vehicle with Combined Battery and Ultracapacitor Energy Storage. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 5031–5036. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Alsofyani, I.M. Energy and Power Control Strategy for Battery Electric Vehicle with Supercapacitors. In Proceedings of the 2014 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 13–14 October 2014; pp. 13–18. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Yao, L.W. The Energy Management Control Strategy for Electric Vehicle Applications. In Proceedings of the 2014 International Conference and Utility Exhibition on Green Energy for Sustainable Development (ICUE), Pattaya, Thailand, 19–21 March 2014; pp. 1–5. [Google Scholar]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Alsofyani, I.M. Acceleration-Based Design Auxiliary Power Source for Electric Vehicle Applications. In Proceedings of the 2014 11th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Nakhon Ratchasima, Thailand, 14–14 May 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, F.; Du, C. A Comprehensive Analysis of Energy Management Strategies for Hybrid Electric Vehicles Based on Bibliometrics. Renew. Sustain. Energy Rev. 2015, 48, 88–104. [Google Scholar] [CrossRef]

- Salmasi, F.R. Control Strategies for Hybrid Electric Vehicles: Evolution, Classification, Comparison, and Future Trends. IEEE Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Trovão, J.P.; Antunes, C.H. A Comparative Analysis of Meta-Heuristic Methods for Power Management of a Dual Energy Storage System for Electric Vehicles. Energy Convers. Manag. 2015, 95, 281–296. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A Review of Power and Energy Management Strategies in Electric Vehicles. In Proceedings of the 2012 4th International Conference on Intelligent and Advanced Systems (ICIAS2012), Kuala Lumpur, Malaysia, 12–14 June 2012; pp. 412–417. [Google Scholar]

- Tie, S.F.; Tan, C.W. A Review of Energy Sources and Energy Management System in Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Dixon, J.W.; Ortúzar, M.E. Ultracapacitors + DC-DC Converters in Regenerative Braking System. IEEE Aerosp. Electron. Syst. Mag. 2002, 17, 16–21. [Google Scholar] [CrossRef]

- Thounthong, P.; Sethakul, P.; Raël, S.; Davat, B. Performance Evaluation of Fuel Cell/Battery/Supercapacitor Hybrid Power Source for Vehicle Applications. In Proceedings of the 2009 IEEE Industry Applications Society Annual Meeting, Houston, TX, USA, 4–8 October 2009; pp. 1–8. [Google Scholar]

- Thounthong, P.; Raël, S.; Davat, B. Energy Management of Fuel Cell/Battery/Supercapacitor Hybrid Power Source for Vehicle Applications. J. Power Sources 2009, 193, 376–385. [Google Scholar] [CrossRef]

- Faggioli, E.; Rena, P.; Danel, V.; Andrieu, X.; Mallant, R.; Kahlen, H. Supercapacitors for the Energy Management of Electric Vehicles. J. Power Sources 1999, 84, 261–269. [Google Scholar] [CrossRef]

- Ortuzar, M.; Dixon, J.; Moreno, J. Design, Construction and Performance of a Buck-Boost Converter for an Ultracapacitor-Based Auxiliary Energy System for Electric Vehicles. In Proceedings of the IECON’03, 29th Annual Conference of the IEEE Industrial Electronics Society (IEEE Cat. No.03CH37468), Roanoke, VA, USA, 2–6 November 2003; Volume 3, pp. 2889–2894. [Google Scholar] [CrossRef]

- Dixon, J.W.; Ortúzar, M.; Wiechmann, E. Regenerative Braking for an Electric Vehicle Using Ultracapacitores and a Buck-Boost Converter. In Proceedings of the 17th Electric Vehicle Symposium (EVS17), Montreal, QC, Canada, 15–18 October 2000. [Google Scholar]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D. Power Converter Design for Electric Vehicle Applications. J. Teknol. Sci. Eng. 2014, 67, 25–31. [Google Scholar] [CrossRef]

- Karunarathne, E.; Wijesekera, A.; Samaranayake, L.; Binduhewa, P.; Ekanayake, J. On the Implementation of Hybrid Energy Storage for Range and Battery Life Extension of an Electrified Tuk-Tuk. J. Energy Storage 2022, 46, 103897. [Google Scholar] [CrossRef]

- Wang, G.; Yang, P.; Zhang, J. Fuzzy Optimal Control and Simulation of Battery-Ultracapacitor Dual-Energy Source Storage System for Pure Electric Vehicle. In Proceedings of the 2010 International Conference on Intelligent Control and Information Processing, Dalian, China, 13–15 August 2010; pp. 555–560. [Google Scholar] [CrossRef]

- Huang, X.; Curti, J.M.A.; Yoichi, H. Energy Management Strategy with Optimized Power Interface for the Battery Supercapacitor Hybrid System of Electric Vehicles. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 4635–4640. [Google Scholar] [CrossRef]

- Zandi, M.; Payman, A.; Martin, J.; Pierfederici, S.; Davat, B.; Meibody-Tabar, F. Energy Management of a Fuel Cell/Supercapacitor/Battery Power Source for Electric Vehicular Applications. IEEE Trans. Veh. Technol. 2011, 60, 433–443. [Google Scholar] [CrossRef]

- Cao, J.; Cao, B.; Bai, Z.; Chen, W. Energy-Regenerative Fuzzy Sliding Mode Controller Design for Ultracapacitor-Battery Hybrid Power of Electric Vehicle. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–9 August 2007; pp. 1570–1575. [Google Scholar]

- Li, Q.; Chen, W.; Liu, Z.; Li, M.; Ma, L. Development of Energy Management System Based on a Power Sharing Strategy for a Fuel Cell-Battery-Supercapacitor Hybrid Tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Sampathnarayanan, B.; Onori, S.; Yurkovich, S. An Optimal Regulation Strategy for Energy Management of Hybrid Electric Vehicles. In Proceedings of the 2012 IEEE 51st IEEE Conference on Decision and Control (CDC), Maui, HI, USA, 10–13 December 2012; Volume 50, pp. 7063–7068. [Google Scholar]

- Dellnitz, M.; Eckstein, J.; Flaßkamp, K.; Friedel, P.; Horenkamp, C.; Köhler, U.; Ober-Blöbaum, S.; Peitz, S.; Tiemeyer, S. Development of an Intelligent Cruise Control Using Optimal Control Methods. Procedia Technol. 2014, 15, 285–294. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Yang, C.; Jiao, X. Hybrid Genetic Algorithm-Based Optimization of Powertrain and Control Parameters of Plug-in Hybrid Electric Bus. J. Franklin Inst. 2015, 352, 776–801. [Google Scholar] [CrossRef]

- Ren, Y.; Zhong, Z. A Combined Particle Swarm Optimization-Wavelet Transform Based Strategy for Power Management of PEM Fuel Cell Powered Hybrid System. Adv. Mater. Res. 2014, 973, 954–957. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Xia, B.; You, C. Energy Management of Power-Split Plug-in Hybrid Electric Vehicles Based on Simulated Annealing and Pontryagin’s Minimum Principle. J. Power Sources 2014, 272, 160–168. [Google Scholar] [CrossRef]

- Sousa, T.; Vale, Z.; Carvalho, J.P.; Pinto, T.; Morais, H. A Hybrid Simulated Annealing Approach to Handle Energy Resource Management Considering an Intensive Use of Electric Vehicles. Energy 2014, 67, 81–96. [Google Scholar] [CrossRef]

- Chen, Z.; Xia, B.; You, C.; Mi, C.C. A Novel Energy Management Method for Series Plug-in Hybrid Electric Vehicles. Appl. Energy 2015, 145, 172–179. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R. Adaptive Energy Management of a Plug-in Hybrid Electric Vehicle Based on Driving Pattern Recognition and Dynamic Programming. Appl. Energy 2015, 155, 68–78. [Google Scholar] [CrossRef]

- Samanta, C.K.; Hota, M.K.; Nayak, S.R.; Panigrahi, S.P.; Panigrahi, B.K. Energy Management in Hybrid Electric Vehicles Using Optimized Radial Basis Function Neural Network. Int. J. Sustain. Eng. 2014, 7, 352–359. [Google Scholar] [CrossRef]

- Anubi, O.M.; Clemen, L. Energy-Regenerative Model Predictive Control. J. Franklin Inst. 2015, 352, 2152–2170. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Zhao, W. Deep Reinforcement Learning Based Energy Management Strategy for Fuel Cell/Battery/Supercapacitor Powered Electric Vehicle. Green Energy Intell. Transp. 2022, 1, 100028. [Google Scholar] [CrossRef]

- Thounthong, P.; Davat, B. Control Strategy of Fuel Cell/Supercapacitors Hybrid Power Sources for Electric Vehicle. J. Power Sources 2006, 158, 806–814. [Google Scholar] [CrossRef]

- Thounthong, P.; Chunkag, V.; Sethakul, P.; Davat, B.; Hinaje, M. Comparative Study of Fuel-Cell Vehicle Hybridization with Battery or Supercapacitor Storage Device. IEEE Trans. Veh. Technol. 2009, 58, 3892–3904. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N.; Jusoh, A.; Muhamad, N.D.; Chaitusaney, S. Design and Development of Auxiliary Energy Storage for Battery Hybrid Electric Vehicle. J. Energy Storage 2022, 51, 104533. [Google Scholar] [CrossRef]

- Shen, J.; Khaligh, A. Design and Real-Time Controller Implementation for a Battery-Ultracapacitor Hybrid Energy Storage System. IEEE Trans. Ind. Inform. 2016, 12, 1910–1918. [Google Scholar] [CrossRef]

- Zhai, C.; Luo, F.; Liu, Y. A Novel Predictive Energy Management Strategy for Electric Vehicles Based on Velocity Prediction. IEEE Trans. Veh. Technol. 2020, 69, 12559–12569. [Google Scholar] [CrossRef]

| Configuration | Converter Size (Score 0–3) | DC Bus Voltage (Score 0–2) | Reliability (Score 0–1) | Total Score |

|---|---|---|---|---|

| (a) | None (0) | Follow battery (1) | High (1) | 2 |

| (b) | 1 full size (1) | Constant (2) | Low (0) | 3 |

| (c) | 1 medium size (2) | Follow battery (1) | High (1) | 4 |

| (d) | 1 small size (3) | Follow battery (1) | High (1) | 5 |

| (e) | 1 medium size (2) | Follow SC (0) | High (1) | 3 |

| (f)–(h) | 1 full 1 medium size (1) | Constant (2) | Low (0) | 3 |

| Paper | EMS | Control Structure | Main Contributions | Validation | Limitations | Year |

|---|---|---|---|---|---|---|

| [15,16,17,47,48] | Rule based; load follower | SC converter for current control within bandwidth |

| Real-world application |

| 2000–2010 |

| [44,67,68] | SC converter for current control based on energy and power |

| Experimental validation |

| 2006–2009 | |

| [29] | SC converter for voltage and current control |

| Experimental validation |

| 2011 | |

| [14] | SC converter for power control based on vehicle dynamic |

| Simulation |

| 2015 | |

| [69] | SC converter for current control based on vehicle dynamic |

| Simulation and lab-scale experiment |

| 2022 | |

| [8] | Rule based; power split | SC converter for power control based on vehicle kinetic energy |

| Simulation |

| 2014 |

| [26] | Rule based; adaptive power split | SC converter for current and voltage control |

| Real-time simulation |

| 2015 |

| [50] | Rule based; power split using Kalman filter | Battery and SC converter for SOC control |

| Real-vehicle experiment |

| 2022 |

| [51] | Rule based; conventional fuzzy logic | Battery and SC converter for power control |

| Simulation in ADVISOR 2002 |

| 2010 |

| [53] | Battery and SC converter for energy and power control |

| Simulation and experiment |

| 2011 | |

| [54] | Rule based; fuzzy sliding mode | Battery and SC converter for SOC control |

| Micro EV experiment |

| 2007 |

| [55] | Rule based Harr-wavelet fuzzy logic | Battery and SC converter for power control |

| Tramway experiment |

| 2015 |

| [57] | Offline optimization; sequential quadratic programming | Minimized battery’s SOC and velocity variation |

| Simulation |

| 2014 |

| [33] | Offline optimization; non-dominated sorting genetic algorithm | Minimized fuel economy and cost |

| Simulation |

| 2009 |

| [59] | Offline optimization; PSO-wavelet-transform | Estimation of battery and SC SOC and optimization of PID parameters |

| Simulation |

| 2014 |

| [62] | Offline optimization; simulated annealing | Optimal battery power |

| Simulation in Autonomie |

| 2015 |

| [63] | Offline optimization; dynamic programming | Optimal power distribution |

| Simulation |

| 2015 |

| [15,70] | Real-time optimization; neural network | SC converter for current control |

| Real-vehicle experiment, real-time experiment |

| 2010, 2016 |

| [34,71] | Real-time optimization; model predictive | Battery and SC converter for SOC control |

| Simulation |

| 2010,2020 |

| [66] | Real-time optimization; deep-reinforcement learning | Fuel cell/battery/SC converter |

| Simulation |

| 2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wangsupphaphol, A.; Phichaisawat, S.; Nik Idris, N.R.; Jusoh, A.; Muhamad, N.D.; Lengkayan, R. A Systematic Review of Energy Management Systems for Battery/Supercapacitor Electric Vehicle Applications. Sustainability 2023, 15, 11200. https://doi.org/10.3390/su151411200

Wangsupphaphol A, Phichaisawat S, Nik Idris NR, Jusoh A, Muhamad ND, Lengkayan R. A Systematic Review of Energy Management Systems for Battery/Supercapacitor Electric Vehicle Applications. Sustainability. 2023; 15(14):11200. https://doi.org/10.3390/su151411200

Chicago/Turabian StyleWangsupphaphol, Aree, Sotdhipong Phichaisawat, Nik Rumzi Nik Idris, Awang Jusoh, Nik Din Muhamad, and Raweewan Lengkayan. 2023. "A Systematic Review of Energy Management Systems for Battery/Supercapacitor Electric Vehicle Applications" Sustainability 15, no. 14: 11200. https://doi.org/10.3390/su151411200

APA StyleWangsupphaphol, A., Phichaisawat, S., Nik Idris, N. R., Jusoh, A., Muhamad, N. D., & Lengkayan, R. (2023). A Systematic Review of Energy Management Systems for Battery/Supercapacitor Electric Vehicle Applications. Sustainability, 15(14), 11200. https://doi.org/10.3390/su151411200