Correlation of Two Biodegradability Indices of PLA-Based Polymers under Thermophilic Aerobic Laboratory Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bioplastic Samples and Compost

2.2. Sample Preparation and Experimental Procedure

2.3. Moisture Content and Volatile Solids Determination

2.4. CO2 Determination via Titration

3. Results and Discussion

3.1. Moisture Content and Total Solids of Biomaterials

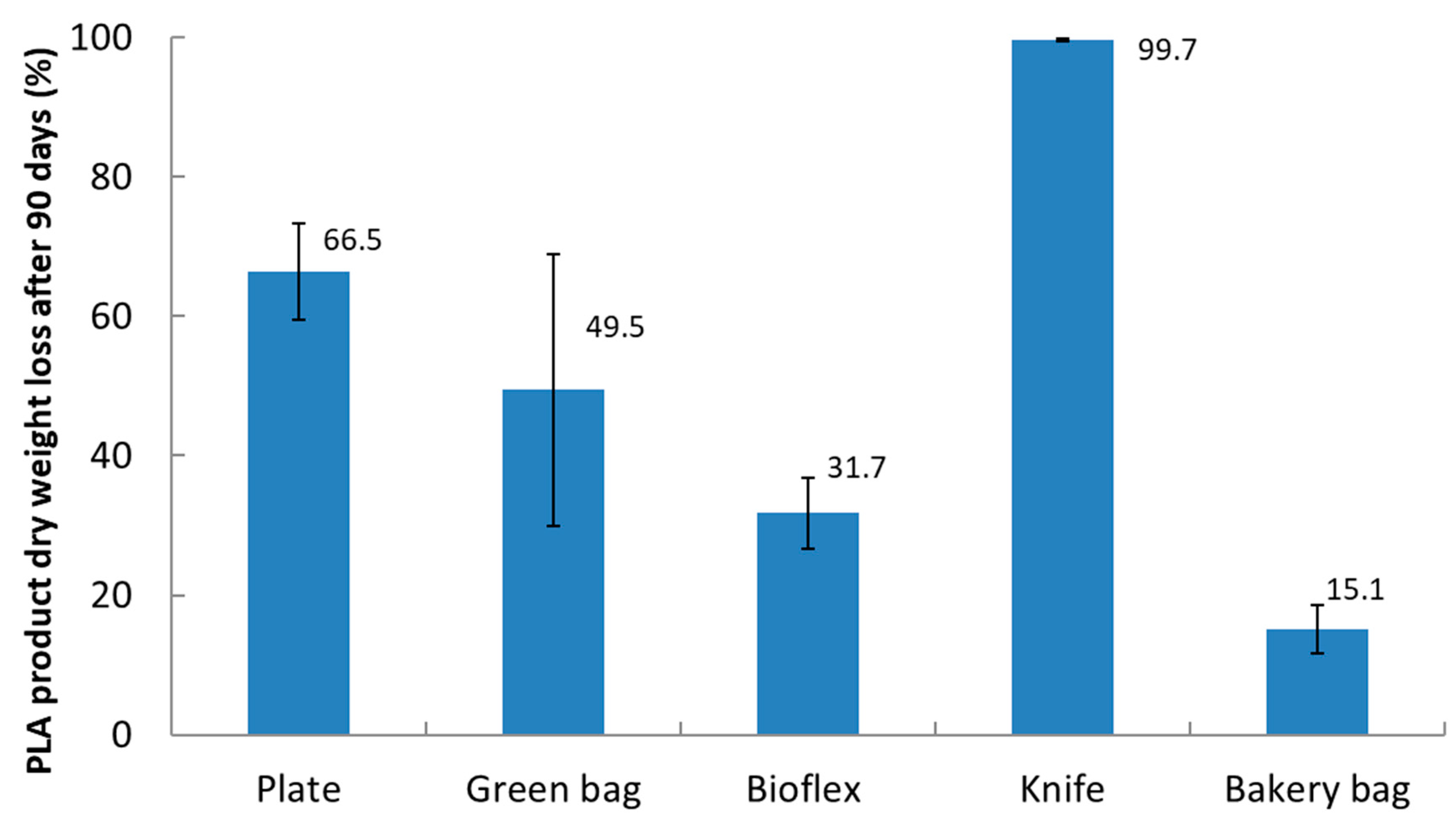

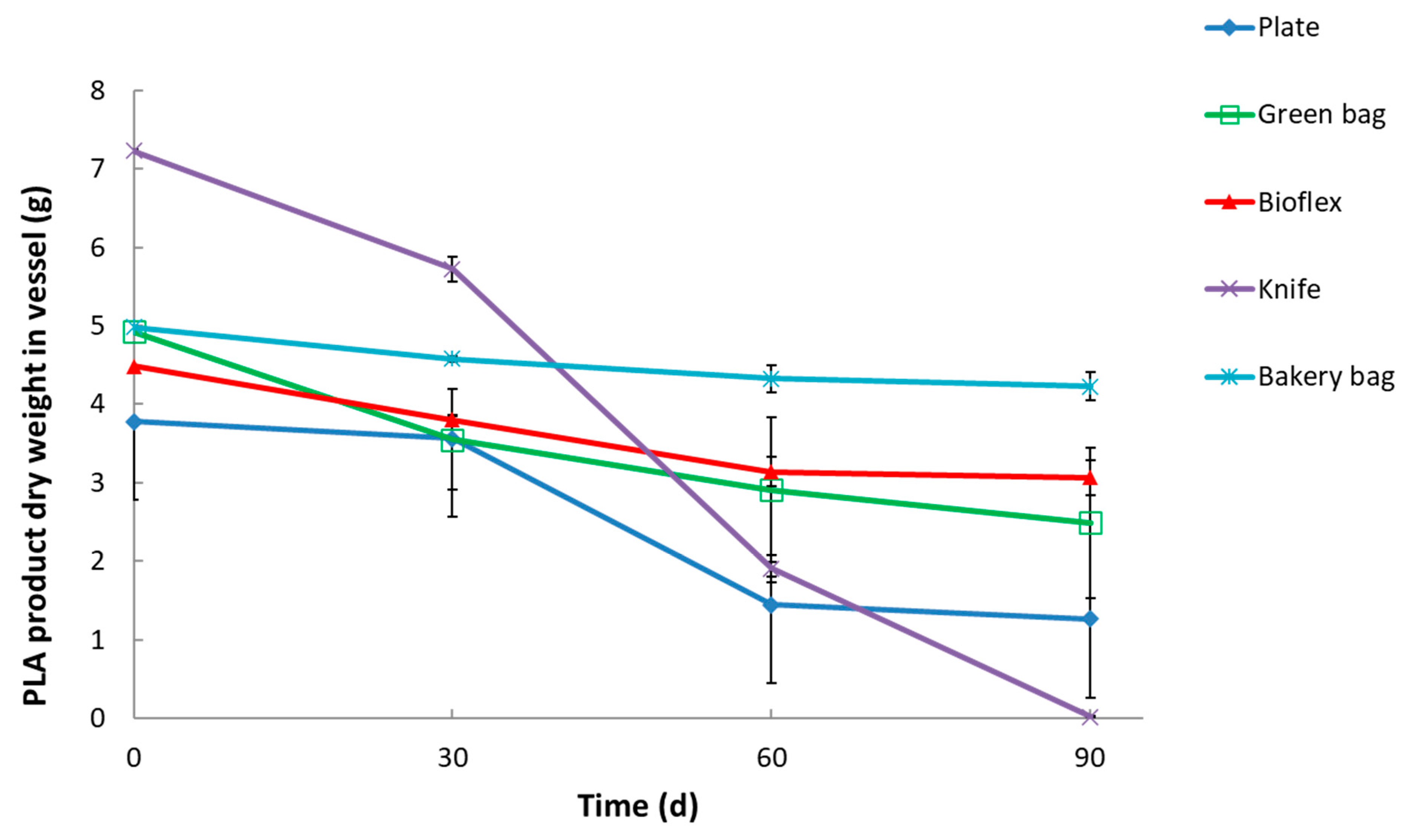

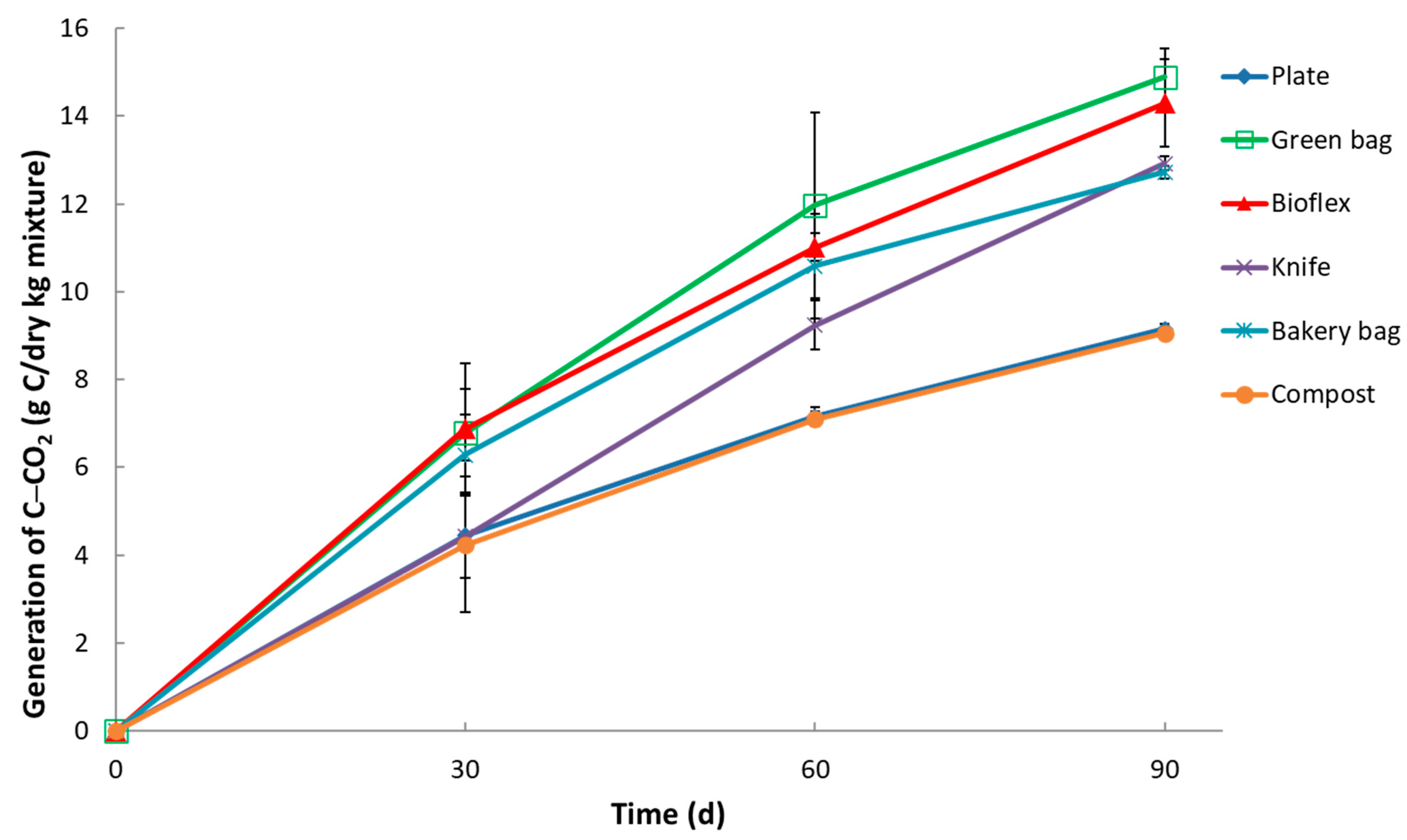

3.2. Weight Loss of PLA-Based Products during Biodegradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- STATISTICA. Projected Plastic Waste Generation Worldwide from 2019 to 2060. Available online: https://www.statista.com/statistics/1338839/global-plastic-waste-generation-outlook/ (accessed on 26 February 2023).

- STATISTICA. Distribution of Plastic Waste Generation Worldwide in 2018, by Sector. Available online: https://www.statista.com/statistics/1166582/global-plastic-waste-generation-by-sector/ (accessed on 26 February 2023).

- UNEP. Our Planet is Choking on Plastic. Available online: https://www.unep.org/interactives/beat-plastic-pollution/ (accessed on 26 February 2023).

- OECD. Plastic Pollution Is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD. Available online: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm#:~:text=Globally%2C%20only%209%25%20of%20plastic,recycled%20while%2022%25%20is%20mismanaged (accessed on 26 February 2023).

- OECD. Plastic Leakage and Greenhouse Gas Emissions Are Increasing. Available online: https://www.oecd.org/environment/plastics/increased-plastic-leakage-and-greenhouse-gas-emissions.htm (accessed on 26 February 2023).

- EuropeanBioplastics. What Are Bioplastics? Available online: https://www.european-bioplastics.org/bioplastics/ (accessed on 26 February 2023).

- Bioplastics Europe. What Are “Bio-Plastics”? Available online: https://bioplasticseurope.eu/about (accessed on 26 February 2023).

- Gerassimidou, S.; Martin, O.V.; Chapman, S.P.; Hahladakis, J.N.; Iacovidou, E. Development of an integrated sustainability matrix to depict challenges and trade-offs of introducing bio-based plastics in the food packaging value chain. J. Clean. Prod. 2021, 286, 125378. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Market Data. Available online: https://www.european-bioplastics.org/market/ (accessed on 26 February 2023).

- Vaverková, M.D.; Adamcová, D. Biodegrability of bioplastic materials in a controlled composting environment. J. Ecol. Eng. 2015, 16, 155–160. [Google Scholar] [CrossRef]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Souza, V.G.L.; Fuciños, P.; Pastrana, L.; Fernando, A.L. Methodologies to assess the biodegradability of bio-based polymers—Current knowledge and existing gaps. Polymers 2022, 14, 1359. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- RameshKumar, S.; Shaiju, P.; O’Connor, K.E. Bio-based and biodegradable polymers-State-of-the-art, challenges and emerging trends. Curr. Opin. Green Sustain. Chem. 2020, 21, 75–81. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly (lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Jiménez, L.; Mena, M.; Prendiz, J.; Salas, L.; Vega-Baudrit, J. Polylactic acid (PLA) as a bioplastic and its possible applications in the food industry. J. Food Sci. Nutr. 2019, 5, 2–6. [Google Scholar]

- Kalita, N.K.; Damare, N.A.; Hazarika, D.; Bhagabati, P.; Kalamdhad, A.; Katiyar, V. Biodegradation and characterization study of compostable PLA bioplastic containing algae biomass as potential degradation accelerator. Environ. Chall. 2021, 3, 100067. [Google Scholar] [CrossRef]

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly(lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crop. Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Kalita, N.K.; Sarmah, A.; Bhasney, S.M.; Kalamdhad, A.; Katiyar, V. Demonstrating an ideal compostable plastic using biodegradability kinetics of poly (lactic acid)(PLA) based green biocomposite films under aerobic composting conditions. Environ. Chall. 2021, 3, 100030. [Google Scholar] [CrossRef]

- Kalita, N.K.; Nagar, M.K.; Mudenur, C.; Kalamdhad, A.; Katiyar, V. Biodegradation of modified Poly (lactic acid) based biocomposite films under thermophilic composting conditions. Polym. Test. 2019, 76, 522–536. [Google Scholar] [CrossRef]

- Cucina, M.; Carlet, L.; De Nisi, P.; Somensi, C.A.; Giordano, A.; Adani, F. Degradation of biodegradable bioplastics under thermophilic anaerobic digestion: A full-scale approach. J. Clean. Prod. 2022, 368, 133232. [Google Scholar] [CrossRef]

- USDA; USCC. Test Methods for the Examination of Composting and Compost; Thomson, W., Ed.; The Composting Council Research and Education Foundation: Holbrook, NY, USA, 2002.

- Komilis, D.P.; Ham, R.K. A laboratory method to investigate gaseous emissions and solids decomposition during composting of municipal solid wastes. Compost. Sci. Util. 2000, 8, 254–265. [Google Scholar] [CrossRef]

- Zaborowska, M.; Bernat, K.; Pszczółkowski, B.; Cydzik-Kwiatkowska, A.; Kulikowska, D.; Wojnowska-Baryła, I. Multi-faceted analysis of thermophilic anaerobic biodegradation of poly(lactic acid)-based material. Waste Manag. 2023, 155, 40–52. [Google Scholar] [CrossRef]

- Sarasa, J.; Gracia, J.M.; Javierre, C. Study of the biodisintegration of a bioplastic material waste. Bioresour. Technol. 2009, 100, 3764–3768. [Google Scholar] [CrossRef] [PubMed]

- Mulbry, W.; Ahn, H. Greenhouse gas emissions during composting of dairy manure: Influence of the timing of pile mixing on total emissions. Biosyst. Eng. 2014, 126, 117–122. [Google Scholar] [CrossRef]

- Sangamithirai, K.; Jayapriya, J.; Hema, J.; Manoj, R. Evaluation of in-vessel co-composting of yard waste and development of kinetic models for co-composting. Int. J. Recycl. Org. Waste Agric. 2015, 4, 157–165. [Google Scholar] [CrossRef] [Green Version]

- Ruggero, F.; Onderwater, R.C.; Carretti, E.; Roosa, S.; Benali, S.; Raquez, J.-M.; Gori, R.; Lubello, C.; Wattiez, R. Degradation of film and rigid bioplastics during the thermophilic phase and the maturation phase of simulated composting. J. Polym. Environ. 2021, 29, 3015–3028. [Google Scholar] [CrossRef]

- Boonmee, C.; Kositanont, C.; Leejarkpai, T. Degradation of poly (lactic acid) under simulated landfill conditions. Environ. Nat. Resour. J. 2016, 14, 1–9. [Google Scholar]

- Stloukal, P.; Kalendova, A.; Mattausch, H.; Laske, S.; Holzer, C.; Koutny, M. The influence of a hydrolysis-inhibiting additive on the degradation and biodegradation of PLA and its nanocomposites. Polym. Test. 2015, 41, 124–132. [Google Scholar] [CrossRef]

- Brdlík, P.; Novák, J.; Borůvka, M.; Běhálek, L.; Lenfeld, P. The Influence of Plasticizers and Accelerated Ageing on Biodegradation of PLA under Controlled Composting Conditions. Polymers 2023, 15, 140. [Google Scholar] [CrossRef] [PubMed]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Salomez, M.; George, M.; Fabre, P.; Touchaleaume, F.; Cesar, G.; Lajarrige, A.; Gastaldi, E. A comparative study of degradation mechanisms of PHBV and PBSA under laboratory-scale composting conditions. Polym. Degrad. Stab. 2019, 167, 102–113. [Google Scholar] [CrossRef]

- EN 13432:2000; Packaging. Requirements for packaging recoverable through composting and biodegradation. Test scheme and evaluation criteria for the final acceptance of packaging. European Norm: Brussels, Belgium.

- EN 14995:2006; Plastics—Evaluation of compostability - Test scheme and specifications. European Norm: Brussels, Belgium.

- Zumstein, M.T.; Narayan, R.; Kohler, H.-P.E.; McNeill, K.; Sander, M. Dos and do nots when assessing the biodegradation of plastics. Environ. Sci. Technol. 2019, 53, 9967–9969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [Green Version]

- Bhagwat, G.; Gray, K.; Wilson, S.P.; Muniyasamy, S.; Vincent, S.G.T.; Bush, R.; Palanisami, T. Benchmarking bioplastics: A natural step towards a sustainable future. J. Polym. Environ. 2020, 28, 3055–3075. [Google Scholar] [CrossRef]

- Rossi, V.; Cleeve-Edwards, N.; Lundquist, L.; Schenker, U.; Dubois, C.; Humbert, S.; Jolliet, O. Life cycle assessment of end-of-life options for two biodegradable packaging materials: Sound application of the European waste hierarchy. J. Clean. Prod. 2015, 86, 132–145. [Google Scholar] [CrossRef]

| Substrates | Moisture Content (% w.w. 1) | Volatile Solids (% d.w. 2) |

|---|---|---|

| Plate | 5.6 (±1.8) | 99.5 (±0.1) |

| Green bag | 1.5 (±0.9) | 98.3 (±0.1) |

| Bioflex | 0.4 (±0.1) | 94.8 (±0.1) |

| Knife | 0.4 (±0.1) | 90.5 (±1.1) |

| Bakery bag | 0.4 (±0.1) | 79.3 (±0.1) |

| Compost | 7.1 (±0.2) | 48.2 (±0.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melitou, D.; Gerassimidou, S.; Averopoulou, A.; Komilis, D. Correlation of Two Biodegradability Indices of PLA-Based Polymers under Thermophilic Aerobic Laboratory Conditions. Sustainability 2023, 15, 11411. https://doi.org/10.3390/su151411411

Melitou D, Gerassimidou S, Averopoulou A, Komilis D. Correlation of Two Biodegradability Indices of PLA-Based Polymers under Thermophilic Aerobic Laboratory Conditions. Sustainability. 2023; 15(14):11411. https://doi.org/10.3390/su151411411

Chicago/Turabian StyleMelitou, Dimitra, Spyridoula Gerassimidou, Athanassia Averopoulou, and Dimitrios Komilis. 2023. "Correlation of Two Biodegradability Indices of PLA-Based Polymers under Thermophilic Aerobic Laboratory Conditions" Sustainability 15, no. 14: 11411. https://doi.org/10.3390/su151411411