Analysis on the Substitution of Perfluoro-Octane Sulphonates in Foam-Based Extinguishing Agents in China

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

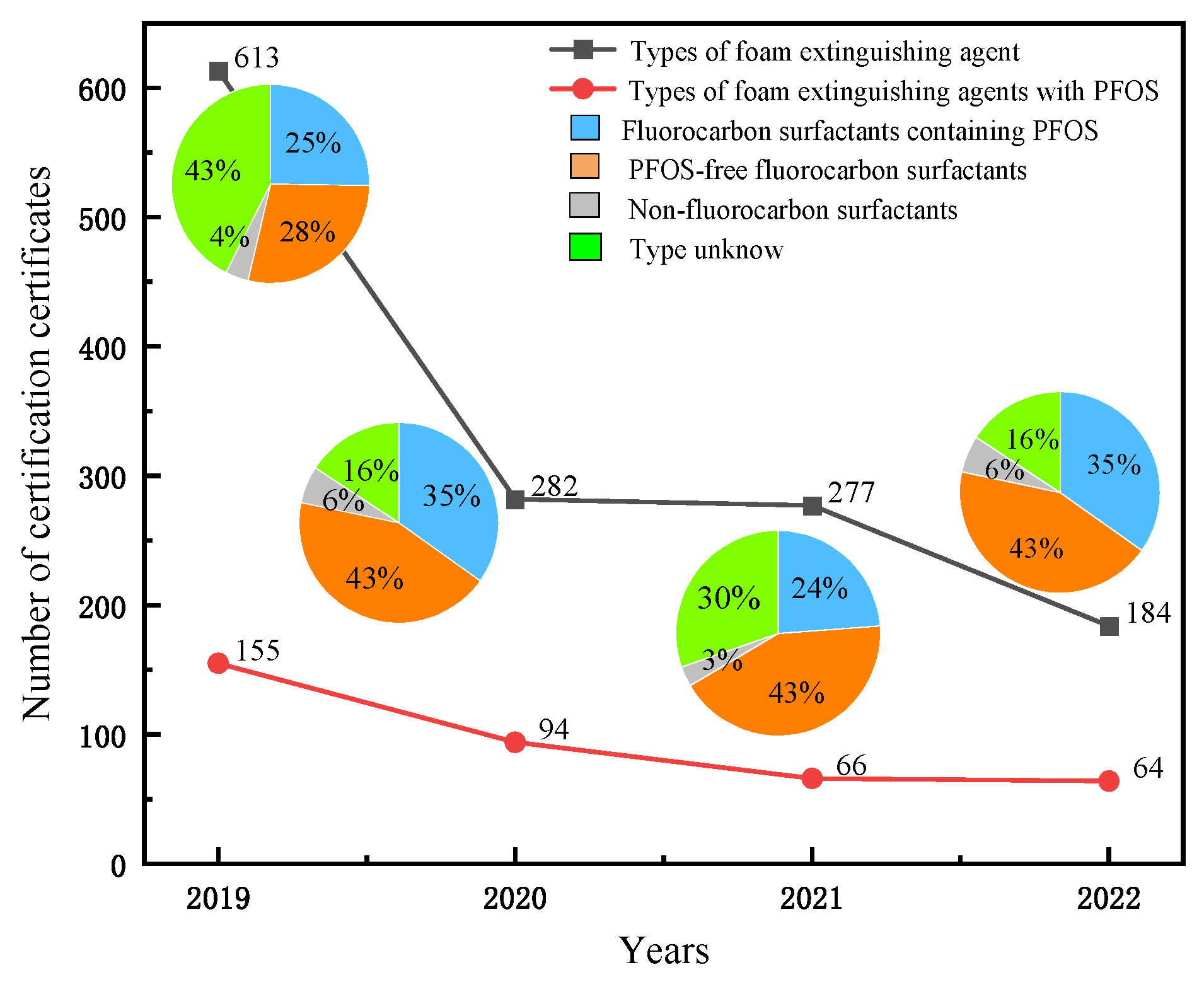

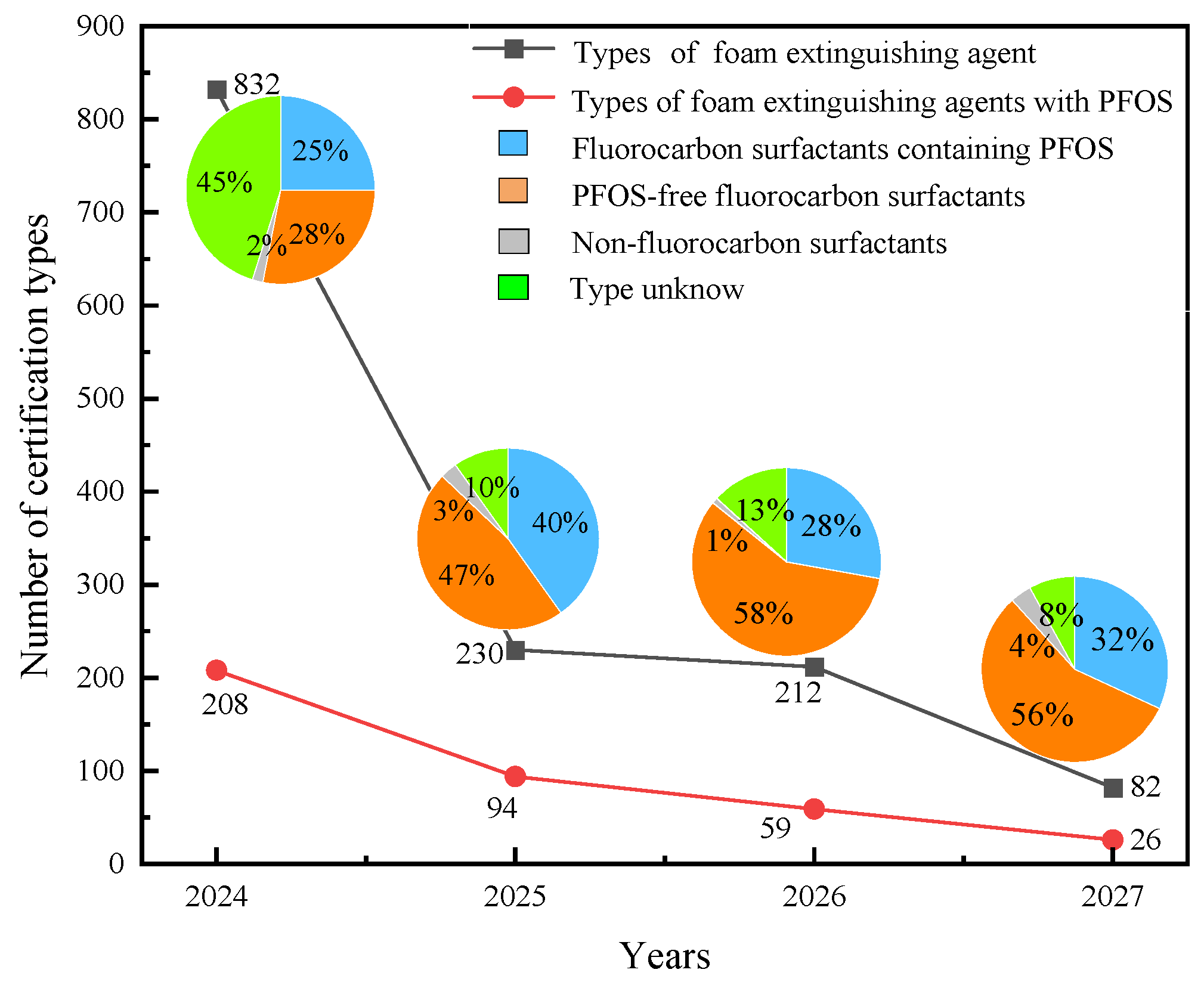

3.1. Foam-Based Extinguishing Agent Certification in the Last Four Years in China

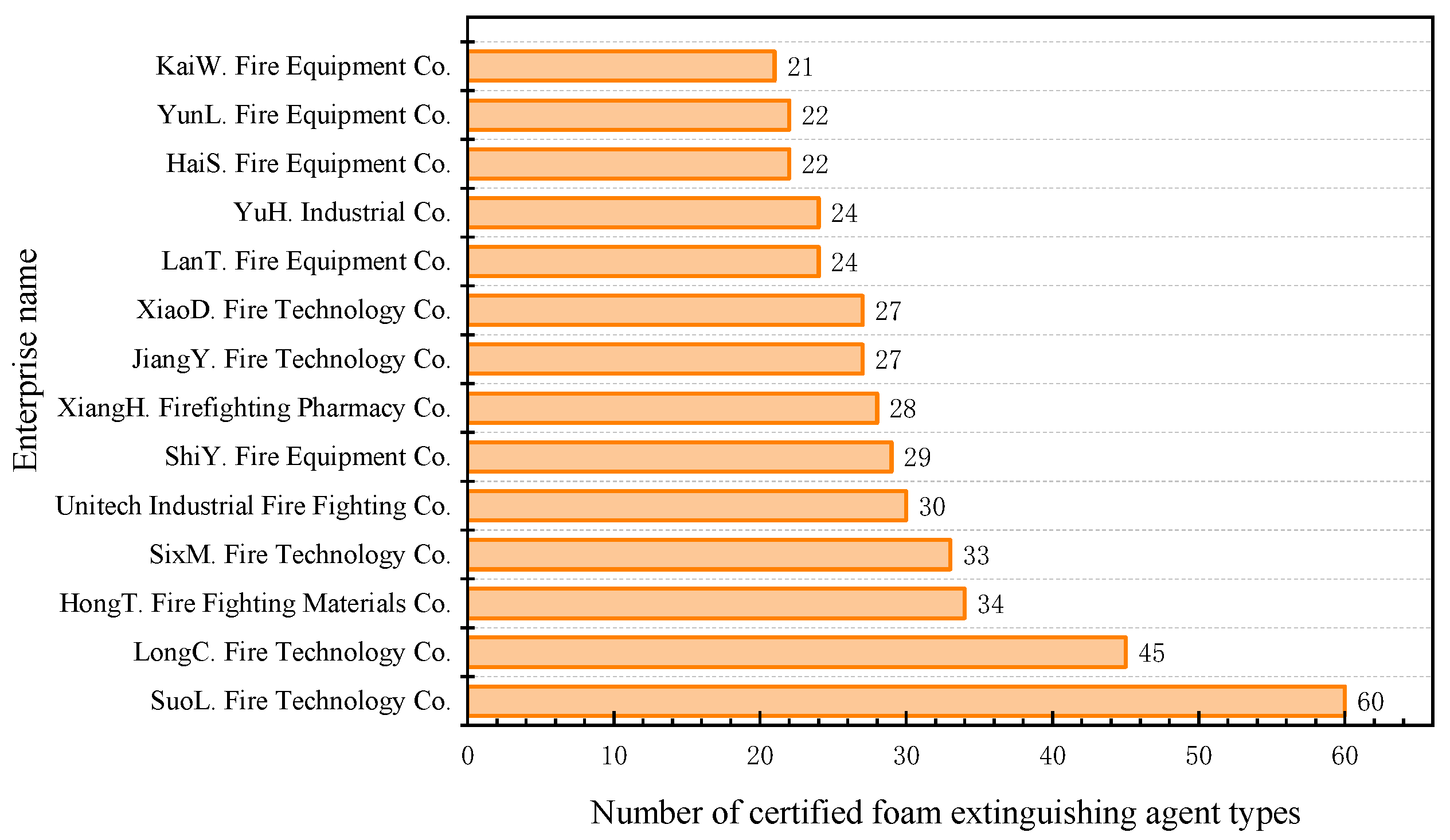

3.2. Foam-Based Extinguishing Agent Manufacturers

3.3. The Types of Surfactants Used in Foam-Based Extinguishing Agents

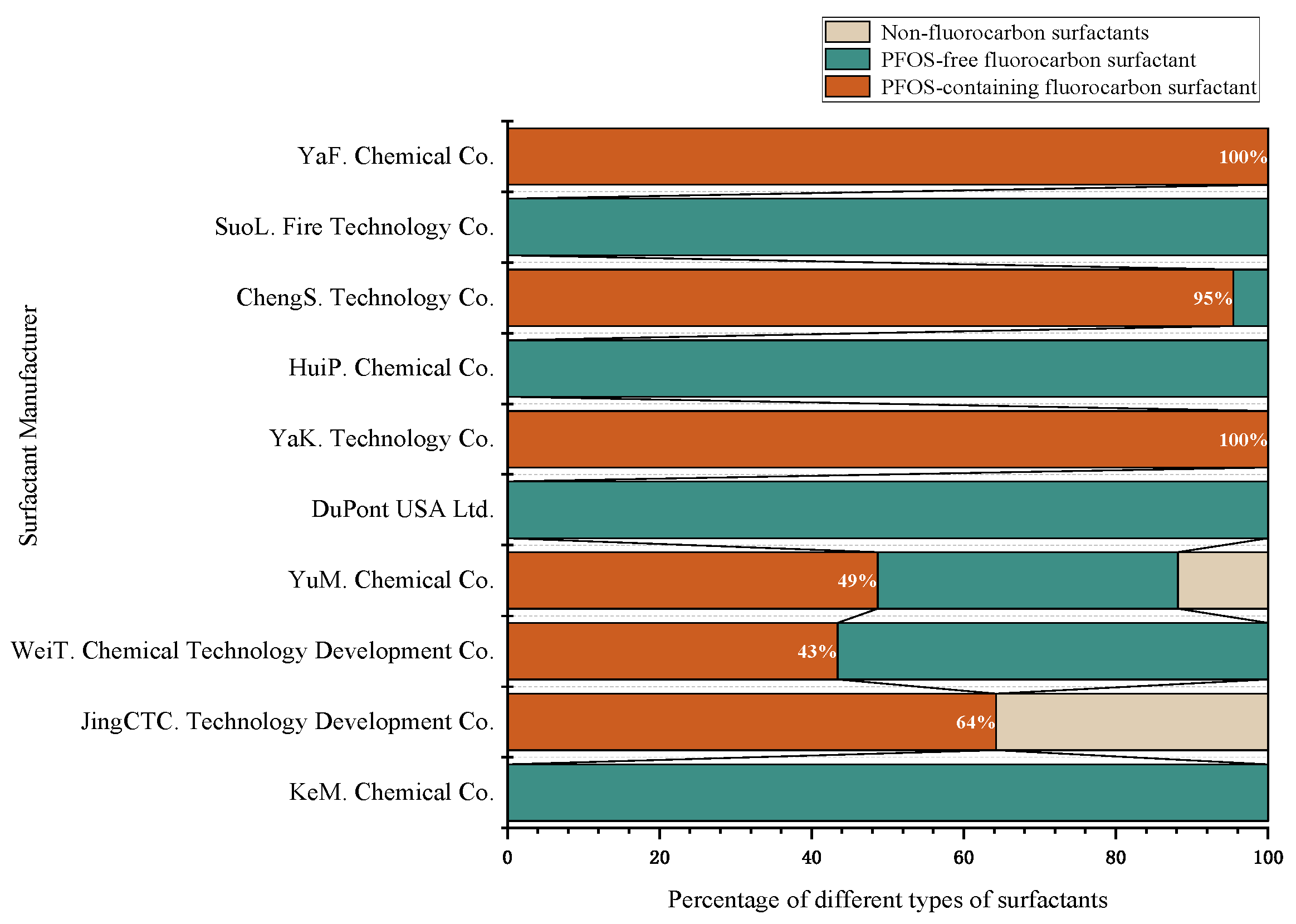

3.4. Surfactant Manufacturers

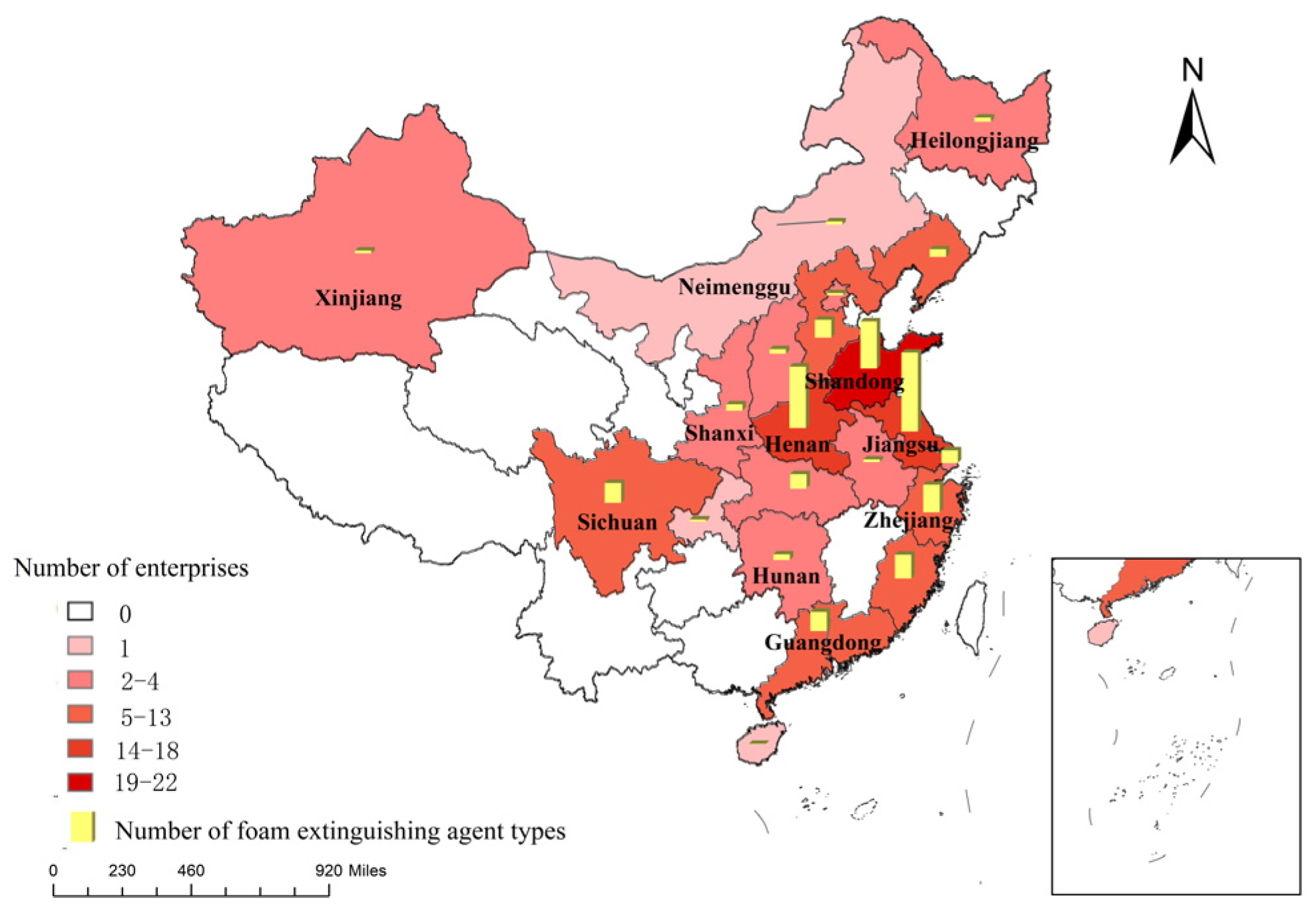

3.5. Distribution of Foam-Based Extinguishing Agent Manufacturers

3.6. Relationship between Foam-Based Extinguishing Agent Manufacturers and Certified Product Types

3.7. Correlation Analysis of the Characteristics of Foam-Based extinguishing Agent Types

3.8. Analysis of Foam-Based Extinguishing Agent Types in the Future

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mumtaz, M.; Bao, Y.X.; Liu, L.Q.; Huang, J.; Cagnetta, G.; Yu, G. Per- and Polyfluoroalkyl Substances in Representative Fluorocarbon Surfactants Used in Chinese Film-forming Foams: Levels, Profile Shift, and Environmental Implications. Environ. Sci. Technol. Lett. 2019, 6, 259–264. [Google Scholar] [CrossRef]

- Garg, S.; Wang, J.S.; Kumar, P.; Mishra, V.; Arafat, H.; Sharma, R.S.; Dumée, L.F. Remediation of water from per-/poly-fluoroalkyl substances (PFAS)—Challenges and perspectives. J. Environ. Chem. Eng. 2021, 9, 105784. [Google Scholar] [CrossRef]

- Magrabi, S.A.; Dlugogorski, B.Z.; Jameson, G.J. Free drainage in aqueous foams: Model and experimental study. Aiche J. 2001, 47, 314–327. [Google Scholar] [CrossRef]

- Sheng, Y.J.; Jiang, N.; Lu, S.X.; Li, C. Fluorinated and fluorine-free firefighting foams spread on heptane surface. Colloids Surf. A-Physicochem. Eng. Asp. 2018, 552, 1–8. [Google Scholar] [CrossRef]

- Magrabi, S.A.; Dlugogorski, B.Z.; Jameson, G.J. A comparative study of drainage characteristics in AFFF and FFFP compressed-air fire-fighting foams. Fire Saf. J. 2002, 37, 21–52. [Google Scholar] [CrossRef]

- Bao, Z.; Chen, T.; Fu, X.; Zhang, X.Z.; Wang, R.J. Effectiveness of compressed air protein foam for suppression of liquid fire. Fire Saf. Sci. 2012, 21, 203–208. [Google Scholar]

- Hu XD, C.; Andrews, D.Q.; Lindstrom, A.B.; Bruton, T.A.; Schaider, L.A.; Grandjean, P.; Lohmann, R.; Carignan, C.C.; Blum, A.; Balan, S.A.; et al. Detection of Poly- and Perfluoroalkyl Substances (PFASs) in US Drinking Water Linked to Industrial Sites, Military Fire Training Areas, and Wastewater Treatment Plants. Environ. Sci. Technol. Lett. 2016, 3, 344–350. [Google Scholar]

- Fang, Y.D.; Ellis, A.; Choi, Y.J.; Boyer, T.H.; Higgins, C.P.; Schaefer, C.E.; Strathmann, T.J. Removal of Per- and Polyfluoroalkyl Substances (PFASs) in Aqueous Film-Forming Foam (AFFF) Using Ion-Exchange and Nonionic Resins. Environ. Sci. Technol. 2021, 55, 5001–5011. [Google Scholar] [CrossRef]

- Eberle, D.; Ball, R.; Boving, T.B. Impact of ISCO Treatment on PFAA Co-Contaminants at a Former Fire Training Area. Environ. Sci Technol 2017, 51, 5127–5136. [Google Scholar] [CrossRef]

- Meng, P.; Deng, S.; Maimaiti, A.; Wang, B.; Huang, J.; Wang, Y.; Cousins, I.T.; Yu, G. Efficient removal of perfluorooctane sulfonate from aqueous film-forming foam solution by aeration-foam collection. Chemosphere 2018, 203, 263–270. [Google Scholar] [CrossRef]

- Post, G.B.; Gleason, J.A.; Cooper, K.R. Key scientific issues in developing drinking water guidelines for perfluoroalkyl acids: Contaminants of emerging concern. PLoS Biol. 2017, 15, e2002855. [Google Scholar] [CrossRef]

- Sunderland, E.M.; Hu, X.C.; Dassuncao, C.; Tokranov, A.K.; Wagner, C.C.; Allen, J.G. A review of the pathways of human exposure to poly- and perfluoroalkyl substances (PFASs) and present understanding of health effects. J. Expo. Sci. Environ. Epidemiol. 2019, 29, 131–147. [Google Scholar] [CrossRef] [PubMed]

- Houtz, E.F.; Higgins, C.P.; Field, J.A.; Sedlak, D.L. Persistence of Perfluoroalkyl Acid Precursors in AFFF-Impacted Groundwater and Soil. Environ. Sci. Technol. 2013, 47, 8187–8195. [Google Scholar] [CrossRef] [PubMed]

- Grandjean, P. Serum Vaccine Antibody Concentrations in Children Exposed to Perfluorinated Compounds. J. Am. Med. Assoc. 2012, 307, 391–397. [Google Scholar] [CrossRef]

- Cordner, A.; De La Rosa, V.Y.; Schaider, L.A.; Rudel, R.A.; Richter, L.; Brown, P. Guideline levels for PFOA and PFOS in drinking water: The role of scientific uncertainty, risk assessment decisions, and social factors. J. Expo. Sci. Environ. Epidemiol. 2020, 30, 585–586. [Google Scholar] [CrossRef]

- Liu, J.; Mejia Avendano, S. Microbial degradation of polyfluoroalkyl chemicals in the environment: A review. Environ. Int 2013, 61, 98–114. [Google Scholar] [CrossRef]

- Martin, J.W.; Whittle, D.M.; Muir, D.C.; Mabury, S.A. Perfluoroalkyl Contaminants in a Food Web from Lake Ontario. Environ. Sci Technol 2004, 38, 5379–5385. [Google Scholar] [CrossRef]

- Fuhar Dixit, B.B.; Mostafavi, S.G.; Mohseni, M. PFOA and PFOS removal by ion exchange for water reuse and drinking applications: Role of organic matter characteristics. Environ. Sci. Water Res. Technol. 2019, 5, 1782–1795. [Google Scholar] [CrossRef]

- Lalonde, B.; Garron, C. Perfluoroalkyl Substances (PFASs) in the Canadian Freshwater Environment. Arch. Environ. Contam. Toxicol. 2022, 82, 581–591. [Google Scholar] [CrossRef] [PubMed]

- Xing, H.; Jia, X.; Xiao, J. Fluorinated surfactants and fluoropolymers (IV) Strategy for PFOS problems. China Surfactant Deterg. Cosmet. 2016, 46, 189–194, 203. [Google Scholar]

- Xie, S.; Lu, Y.; Wang, T.; Liu, S.; Jones, K.; Sweetman, A. Estimation of PFOS emission from domestic sources in the eastern coastal region of China. Environ. Int. 2013, 59, 336–343. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.P.; Zhu, L.Y.; Liu, Z.T. Occurrence and partition of perfluorinated compounds in water and sediment from Liao River and Taihu Lake, China. Chemosphere 2011, 83, 806–814. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.W.; Wang, T.Y.; Liu, S.J.; Jones, K.C.; Sweetman, A.J.; Lu, Y. Industrial source identification and emission estimation of perfluorooctane sulfonate n hina. Environ. Int. 2013, 52, 1–8. [Google Scholar] [CrossRef]

- Place, B.J.; Field, J.A. Identification of Novel Fluorochemicals in Aqueous Film-Forming Foams Used by the US Military. Environ. Sci. Technol. 2012, 46, 7120–7127. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Zhao, J.; Liu, R.; Chen, A. Progress of new fluorinated surfactants alternatives for PFOA/PFOS. Chem. Ind. Eng. Prog. 2015, 34, 1412–1421, 1439. [Google Scholar]

- Zhao, L.; Folsom, P.W.; Wolstenholme, B.W.; Sun, H.; Wang, N.; Buck, R.C. 6:2 fluorotelomer alcohol biotransformation in an aerobic river sediment system. Chemosphere 2013, 90, 203–209. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Y.J.; Xue, M.H.; Ma, L.; Zhao, Y.; Wang, Q.; Liu, X. Environmentally Friendly Firefighting Foams Used to Fight Flammable Liquid Fire. Fire Technol. 2021, 57, 2079–2096. [Google Scholar] [CrossRef]

| Main Types of Fluorinated Foam-Based Extinguishing Agent | Surfactant Brand | Foam-Based Extinguishing Agent Manufacturer | Manufacturer Location |

|---|---|---|---|

| Aqueous film-forming foam (AFFF) | SF-852 | SuoL. Fire Technology Co. | Jiangsu, China |

| YF-138, F1212, F1440 | LangC. Fire Technology Co. | Henan, China | |

| VF-570, VF-9129 | HongT. Fire Materials Co. | Guangdong, China | |

| 1157 | AnG. Fire Technology Co. | Fujian, China | |

| F1470 | HaiS. Fire Equipment Co. | Hebei, China | |

| Alcohol-resistant aqueous film-forming foam (AR-AFFF) | SF-852 | SuoL. Fire Technology Co. | Jiangsu, China |

| YF-138, F1212 | LangC. Fire Technology Co. | Henan, China | |

| SF-852, SF-182 | HongT. Fire Materials Co. | Guangdong, China | |

| JF1127 | XiangH. Fire Agent Co. | Henan, China | |

| Film-forming fluoroprotein foam (FFFP) | F1440 | ShiY. Fire Equipment Co. | Hubei, China |

| Alcohol-resistant film-forming fluoroprotein foam (AR-FFFP) | - | SuoL. Fire Technology Co. | Jiangsu, China |

| Fluoroprotein foam (FP) | YM-316 | YunL. Fire Equipment Co. | Guangdong, China |

| KF402A, C810 | XiaoD. Fire Technology Co. | Jiangsu, China | |

| F1440 | TingA. Fire-fighting Materials Co. | Jiangsu, China | |

| Alcohol-resistant fluoroprotein foam (AR-FP) | YF-138 | LangC. Fire Technology Co. | Henan, China |

| VF-6116, VF-9129 | XinX. Fire Safety Equipment Co. | Henan, China | |

| 1157 | SuoL. Fire Technology Co. | Jiangsu, China |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, F.; Ren, Z.; Hussain, J.; Tian, Z.; Jia, T.; Liu, W. Analysis on the Substitution of Perfluoro-Octane Sulphonates in Foam-Based Extinguishing Agents in China. Sustainability 2023, 15, 11437. https://doi.org/10.3390/su151411437

Yin F, Ren Z, Hussain J, Tian Z, Jia T, Liu W. Analysis on the Substitution of Perfluoro-Octane Sulphonates in Foam-Based Extinguishing Agents in China. Sustainability. 2023; 15(14):11437. https://doi.org/10.3390/su151411437

Chicago/Turabian StyleYin, Fei, Zhiyuan Ren, Javid Hussain, Zhenrong Tian, Tianqi Jia, and Wenbin Liu. 2023. "Analysis on the Substitution of Perfluoro-Octane Sulphonates in Foam-Based Extinguishing Agents in China" Sustainability 15, no. 14: 11437. https://doi.org/10.3390/su151411437

APA StyleYin, F., Ren, Z., Hussain, J., Tian, Z., Jia, T., & Liu, W. (2023). Analysis on the Substitution of Perfluoro-Octane Sulphonates in Foam-Based Extinguishing Agents in China. Sustainability, 15(14), 11437. https://doi.org/10.3390/su151411437