Environmental Impacts in the Textile Sector: A Life Cycle Assessment Case Study of a Woolen Undershirt

Abstract

1. Introduction

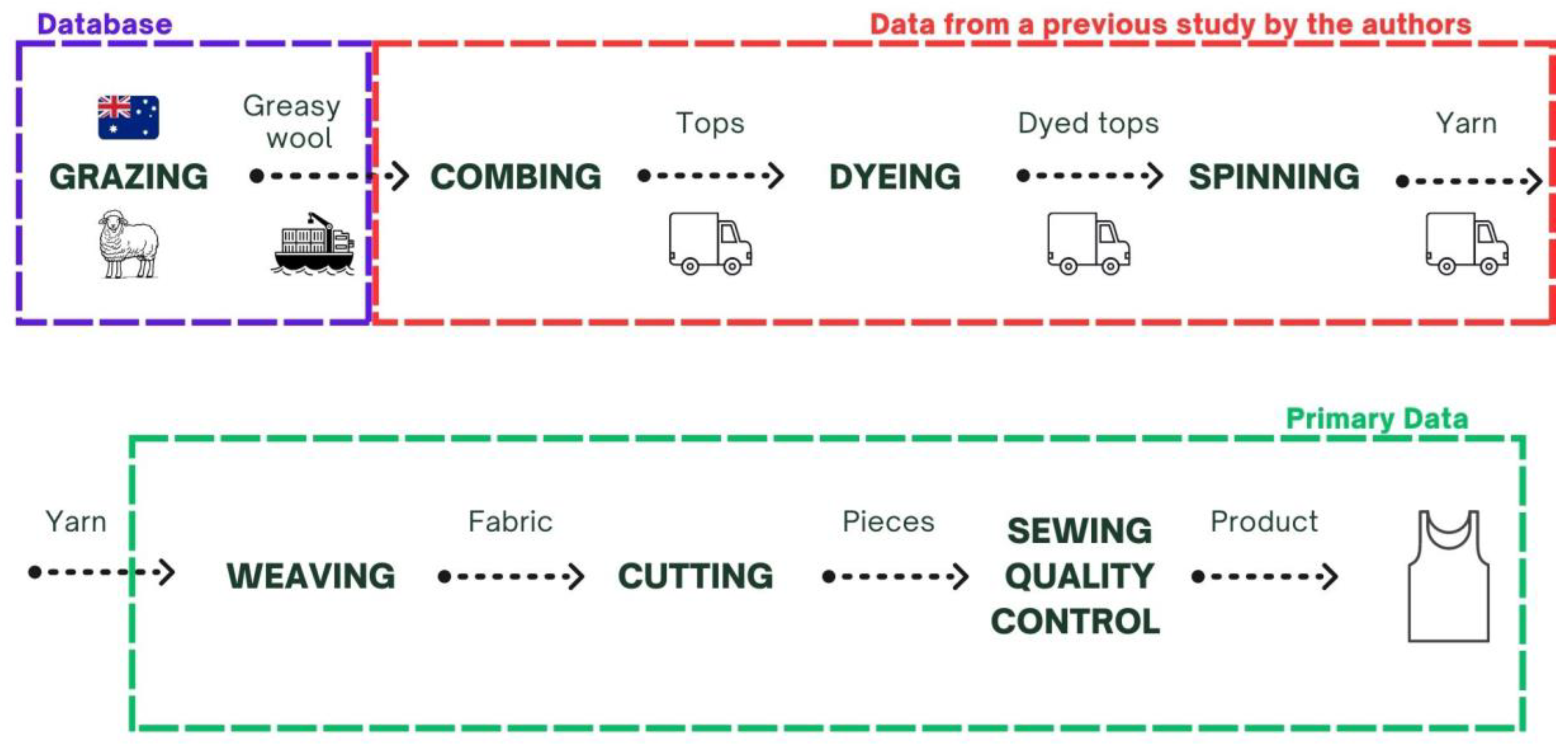

2. Materials and Methods

2.1. Goal and Scope

2.2. Inventory Data

- -

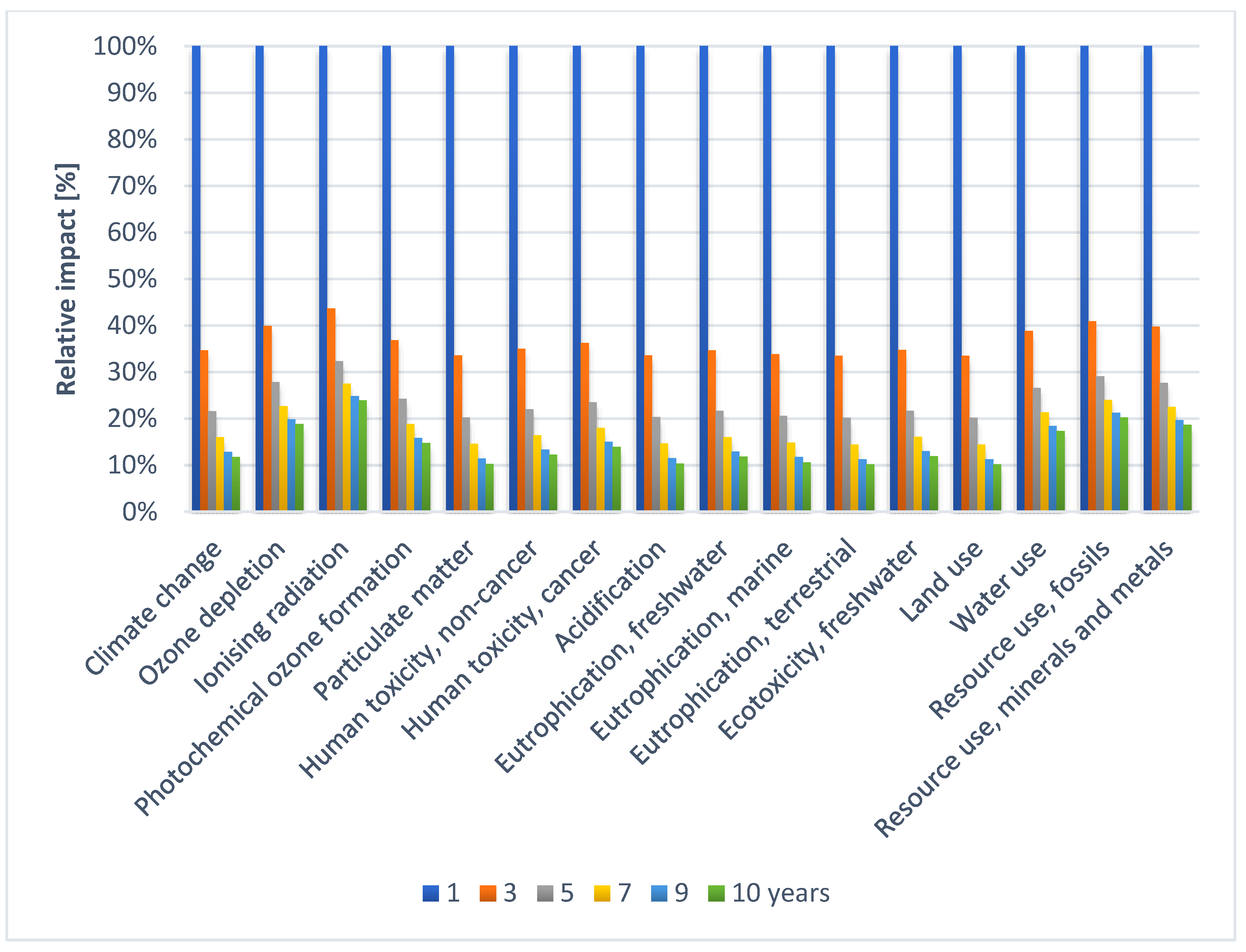

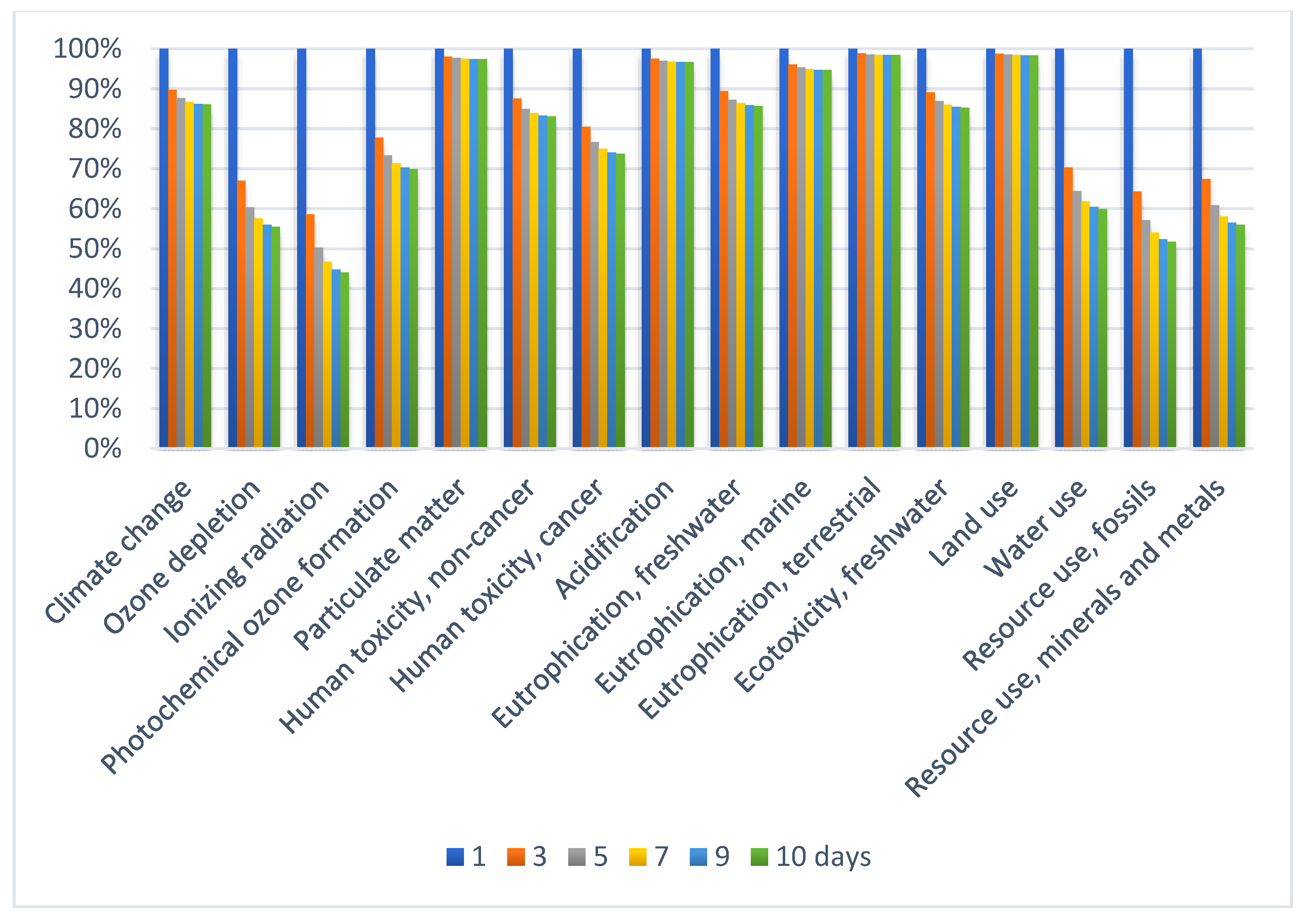

- a woolen undershirt is worn an average of 3 times before washing [36];

- -

- the wearing frequency of a single next-to-skin garment is 8.3 wearings/month [36];

- -

- a woolen undershirt is used for 6 months/year;

- -

- a woolen undershirt is used for 3 years before disposing of it [36];

- -

- the energy used to wash 1 kg of wool with a washing machine is 0.23 kWh [36], and an Italian energy mix is used in the inventory;

- -

- the water used to wash 1 kg of wool with a washing machine is 17.9 L [36];

- -

- the detergent used to wash 1 kg of wool is 6.38 g [16], and a non-ionic surfactant is used as a proxy for the inventory.

3. Results

4. Discussion

Contribution of This Study

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vercalsteren, A.; Nicolau, M.; Lafond, E. Textiles and the Environment in a Circular Economy; ETC/WMGE: Copenhagen, Denmark, 2019. [Google Scholar]

- Ellen McArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. Available online: https://ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 13 June 2023).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Terinte, N.; Manda, B.M.K.; Taylor, J.; Schuster, K.C.; Patel, M.K. Environmental Assessment of Coloured Fabrics and Opportunities for Value Creation: Spin-Dyeing versus Conventional Dyeing of Modal Fabrics. J. Clean. Prod. 2014, 72, 127–138. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Grammatikos, S.A. Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers 2019, 7, 101. [Google Scholar] [CrossRef]

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Evaluation of a European Textile Sorting Centre: Material Flow Analysis and Life Cycle Inventory. Resour. Conserv. Recycl. 2019, 143, 310–319. [Google Scholar] [CrossRef]

- Jhanji, Y. 18—Life Cycle Analysis of Textiles and Associated Carbon Emissions. In Sustainable Fibres for Fashion and Textile Manufacturing; Nayak, R., Ed.; The Textile Institute Book Series; Woodhead Publishing: Cambridge, UK, 2023; pp. 403–431. ISBN 978-0-12-824052-6. [Google Scholar]

- Subramanian, K.; Chopra, S.S.; Cakin, E.; Li, X.; Lin, C.S.K. Environmental Life Cycle Assessment of Textile Bio-Recycling–Valorizing Cotton-Polyester Textile Waste to Pet Fiber and Glucose Syrup. Resour. Conserv. Recycl. 2020, 161, 104989. [Google Scholar] [CrossRef]

- World Trade Organization (WTO). World Trade Statistical Review; World Trade Organization (WTO): Geneva, Switzerland, 2018. [Google Scholar]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020.

- European Commission. EU Strategy for Sustainable and Circular Textiles; COM(2022) 141 Final; European Commission: Geneva, Switzerland, 2022.

- European Commission. Commission Decision of 5 June 2014 Establishing the Ecological Criteria for the Award of the EU Ecolabel for Textile Products; Official Journal of the European Union: Luxembourg, 2014.

- ISO 14040:2006/Amd 1:2020; The International Standards Organisation Environmental Management—Life Cycle Assessment—Principles and Framework—Amendment 1. ISO: Geneva, Switzerland, 2020.

- ISO 14044:2006/Amd 2:2020; The International Standards Organisation Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2020.

- Quantis. Draft Product Environmental Footprint Category Rules; Apparel and Footwear: Zürich, Switzerland, 2021. [Google Scholar]

- Confindustria Toscana Nord. Schema Nazionale Volontario “Made Green in Italy”. Regole di Categoria di Prodotto (RCP): Tessuti in Lana Cardata o Peli Fini Cardati; Confindustria Toscana Nord: Prato, Italy, 2021; p. 40. [Google Scholar]

- Guo, S.; Li, X.; Zhao, R.; Gong, Y. Comparison of Life Cycle Assessment between Lyocell Fiber and Viscose Fiber in China. Int. J. Life Cycle Assess. 2021, 26, 1545–1555. [Google Scholar] [CrossRef]

- Gomez-Campos, A.; Vialle, C.; Rouilly, A.; Sablayrolles, C.; Hamelin, L. Flax Fiber for Technical Textile: A Life Cycle Inventory. J. Clean. Prod. 2021, 281, 125177. [Google Scholar] [CrossRef]

- Yacout, D.M.M.; Abd El-Kawi, M.A.; Hassouna, M.S. Cradle to Gate Environmental Impact Assessment of Acrylic Fiber Manufacturing. Int. J. Life Cycle Assess. 2016, 21, 326–336. [Google Scholar] [CrossRef]

- Gonzalez, V.; Lou, X.; Chi, T. Evaluating Environmental Impact of Natural and Synthetic Fibers: A Life Cycle Assessment Approach. Sustainability 2023, 15, 7670. [Google Scholar] [CrossRef]

- Bianco, I.; Gerboni, R.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of MWool® Recycled Wool Fibers. Resources 2022, 11, 41. [Google Scholar] [CrossRef]

- Chen, F.; Ji, X.; Chu, J.; Xu, P.; Wang, L. A Review: Life Cycle Assessment of Cotton Textiles. Ind. Textila 2021, 72, 19–29. [Google Scholar] [CrossRef]

- Şener Fidan, F.; Kızılkaya Aydoğan, E.; Uzal, N. The Impact of Organic Cotton Use and Consumer Habits in the Sustainability of Jean Production Using the LCA Approach. Environ. Sci. Pollut. Res. 2023, 30, 8853–8867. [Google Scholar] [CrossRef] [PubMed]

- Bech, N.M.; Birkved, M.; Charnley, F.; Laumann Kjaer, L.; Pigosso, D.C.A.; Hauschild, M.Z.; McAloone, T.C.; Moreno, M. Evaluating the Environmental Performance of a Product/Service-System Business Model for Merino Wool Next-to-Skin Garments: The Case of Armadillo Merino®. Sustainability 2019, 11, 5854. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Clarke, S.J.; Russell, S.J. Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater. Sustainability 2022, 14, 1081. [Google Scholar] [CrossRef]

- Dahlbo, H.; Aalto, K.; Eskelinen, H.; Salmenperä, H. Increasing Textile Circulation—Consequences and Requirements. Sustain. Prod. Consum. 2017, 9, 44–57. [Google Scholar] [CrossRef]

- Muthu, S.S.; Li, Y.; Hu, J.Y.; Ze, L. Carbon Footprint Reduction in the Textile Process Chain: Recycling of Textile Materials. Fibers Polym. 2012, 13, 1065–1070. [Google Scholar] [CrossRef]

- Zamani, B.; Svanström, M.; Peters, G.; Rydberg, T. A Carbon Footprint of Textile Recycling: A Case Study in Sweden. J. Ind. Ecol. 2015, 19, 676–687. [Google Scholar] [CrossRef]

- D’Adamo, I.; Lupi, G.; Morone, P.; Settembre Blundo, D. Towards the Circular Economy in the Fashion Industry: The Second-Hand Market as a Best Practice of Sustainable Responsibility for Businesses and Consumers. Environ. Sci. Pollut. Res. 2022, 29, 46620–46633. [Google Scholar] [CrossRef]

- Colasante, A.; D’Adamo, I. The Circular Economy and Bioeconomy in the Fashion Sector: Emergence of a “Sustainability Bias”. J. Clean. Prod. 2021, 329, 129774. [Google Scholar] [CrossRef]

- D’Adamo, I.; Colasante, A. Survey Data to Assess Consumers’ Attitudes towards Circular Economy and Bioeconomy Practices: A Focus on the Fashion Industry. Data Brief 2022, 43, 108385. [Google Scholar] [CrossRef]

- Kumar, L.; Kamil, I.; Ahmad, M.; Naqvi, S.; Deitch, M.; Amjad, A.; Basheer, S.; Arshad, M.; Sassanelli, C.; Ikram, M.; et al. In-House Resource Efficiency Improvements Supplementing the End of Pipe Treatments in Textile SMEs under a Circular Economy Fashion. Front. Environ. Sci. 2022, 10, 1002319. [Google Scholar] [CrossRef]

- Kumar, L.; Nadeem, F.; Sloan, M.; Restle-Steinert, J.; Deitch, M.J.; Ali Naqvi, S.; Kumar, A.; Sassanelli, C. Fostering Green Finance for Sustainable Development: A Focus on Textile and Leather Small Medium Enterprises in Pakistan. Sustainability 2022, 14, 11908. [Google Scholar] [CrossRef]

- European Commission. Product Environmental Footprint (PEF) Guide; European Commission: Geneva, Switzerland, 2013.

- Bianco, I.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of Worsted and Woollen Processing in Wool Production: ReviWool® Noils and Other Wool Co-Products. J. Clean. Prod. 2023, 415, 137877. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Henry, B. Use Phase of Wool Apparel: A Literature Review for Improving LCA. PLATE Prod. Lifetimes Environ. 2017, 202–207. [Google Scholar]

- Henry, B. Understanding the Environmental Impacts of Wool: A Review of Life Cycle Assessment Studies; International Wool Textile Organisation: Brussels, Belgium, 2012. [Google Scholar]

- Gowane, G.R.; Gadekar, Y.P.; Prakash, V.; Kadam, V.; Chopra, A.; Prince, L.L.L. Climate Change Impact on Sheep Production: Growth, Milk, Wool, and Meat. In Sheep Production Adapting to Climate Change; Springer: Singapore, 2017; pp. 31–69. [Google Scholar]

- Henry, B.K.; Russell, S.J.; Ledgard, S.F.; Gollnow, S.; Wiedemann, S.G.; Nebel, B.; Maslen, D.; Swan, P. LCA of Wool Textiles and Clothing. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 217–254. [Google Scholar]

- Tourangeau, W.; Sherren, K. Leverage Points for Sustainable Wool Production in the Falkland Islands. J. Rural. Stud. 2020, 74, 22–33. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Yan, M.-J.; Henry, B.K.; Murphy, C.M. Resource Use and Greenhouse Gas Emissions from Three Wool Production Regions in Australia. J. Clean. Prod. 2016, 122, 121–132. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.G.; Swan, P.G.; Watson, K. Environmental Impacts Associated with the Production, Use, and End-of-Life of a Woollen Garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

| Weaving | |||

| Input Flows | Measuring Unit | Quantity | Ecoinvent Dataset |

| Woolen yarn | g | 106 | Fine yarn, dyed, from worsted processing (from [35]) |

| Electricity (Italian grid mix) | MJ | 2.5 × 10−3 | Electricity, medium voltage {IT}|market for|Cut-off, S |

| Electricity (from PV panels) | MJ | 6.8 × 10−3 | Electricity, low voltage {IT}|electricity production, photovoltaic, 3 kWp slanted-roof installation, multi-Si, panel, mounted|Cut-off, S |

| Heat | MJ | 0.46 | Heat, from steam, in chemical industry {RER}|market for heat, from steam, in chemical industry|Cut-off, S |

| Water | kg | 0.52 | Tap water {Europe without Switzerland}|market for|Cut-off, S |

| Transport with 16–32 t lorry | kgkm | 21.2 | Transport, freight, lorry 16–32 metric ton, euro6 {RER}|market for transport, freight, lorry 16–32 metric ton, EURO6|Cut-off, S |

| Transport with small lorry | kgkm | 10.6 | Transport, freight, lorry 3.5–7.5 metric ton, euro6 {RER}|market for transport, freight, lorry 3.5–7.5 metric ton, EURO6|Cut-off, S |

| Output flow | Measuring unit | Quantity | |

| Raw fabric, after weaving | g | 106 | |

| Cutting | |||

| Input flows | Measuring unit | Quantity | Ecoinvent dataset |

| Raw fabric, after weaving | g | 111 | |

| Transport with small lorry | kgkm | 1.2 × 10−2 | Transport, freight, lorry 3.5–7.5 metric ton, euro6 {RER}|market for transport, freight, lorry 3.5–7.5 metric ton, EURO6|Cut-off, S |

| Electricity (Italian grid mix) | MJ | 1.2 × 10−4 | Electricity, medium voltage {IT}|market for|Cut-off, S |

| Electricity (from PV panels) | MJ | 3.0 × 10−4 | Electricity, low voltage {IT}|electricity production, photovoltaic, 3 kWp slanted-roof installation, multi-Si, panel, mounted|Cut-off, S |

| Output flows | Measuring unit | Quantity | Ecoinvent dataset |

| Undershirt, after cutting | g | 106 | |

| Finishing | |||

| Input flows | Measuring unit | Quantity | Ecoinvent dataset |

| Undershirt, after cutting | g | 106 | |

| Woolen yarn | g | 8.5 | Fine yarn, dyed, from worsted processing (from [35]) |

| Electricity (Italian grid mix) | MJ | 7.9 × 10−3 | Electricity, medium voltage {IT}|market for|Cut-off, S |

| Electricity (from PV panels) | MJ | 2.9 × 10−3 | Electricity, low voltage {IT}|electricity production, photovoltaic, 3 kWp slanted-roof installation, multi-Si, panel, mounted|Cut-off, S |

| Heat | MJ | 0.10 | Heat, from steam, in chemical industry {RER}|market for heat, from steam, in chemical industry|Cut-off, S |

| Output flows | Measuring unit | Quantity | Ecoinvent dataset |

| Finished undershirt | Item | 1 | |

| Impact Category | Unit | Potential Impact |

|---|---|---|

| Climate change | kg CO2 eq | 1.17 × 101 |

| Ozone depletion | kg CFC11 eq | 2.49 × 10−7 |

| Ionizing radiation | kBq U-235 eq | 1.53 × 10−1 |

| Photochemical ozone formation | kg NMVOC eq | 1.14 × 10−2 |

| Particulate matter | disease inc. | 1.76 × 10−6 |

| Human toxicity, non-cancer | CTUh | 8.45 × 10−8 |

| Human toxicity, cancer | CTUh | 3.62 × 10−9 |

| Acidification | mol H+ eq | 2.50 × 10−1 |

| Eutrophication, freshwater | kg P eq | 2.81 × 10−3 |

| Eutrophication, marine | kg N eq | 4.30 × 10−2 |

| Eutrophication, terrestrial | mol N eq | 1.10 |

| Ecotoxicity, freshwater | CTUe | 1.81 × 102 |

| Land use | Pt | 1.14 × 103 |

| Water use | m3 depriv. | 2.15 |

| Resource use, fossils | MJ | 2.78 × 101 |

| Resource use, minerals and metals | kg Sb eq | 2.13 × 10−5 |

| Impact Category | Unit | Potential Impact |

|---|---|---|

| Climate change | kg CO2 eq | 8.34 × 10−2 |

| Ozone depletion | kg CFC11 eq | 2.21 × 10−9 |

| Ionizing radiation | kBq U-235 eq | 1.58 × 10−3 |

| Photochemical ozone formation | kg NMVOC eq | 8.93 × 10−5 |

| Particulate matter | disease inc. | 1.19 × 10−8 |

| Human toxicity, non-cancer | CTUh | 6.09 × 10−10 |

| Human toxicity, cancer | CTUh | 2.75 × 10−11 |

| Acidification | mol H+ eq | 1.69 × 10−3 |

| Eutrophication, freshwater | kg P eq | 2.00 × 10−5 |

| Eutrophication, marine | kg N eq | 2.94 × 10−4 |

| Eutrophication, terrestrial | mol N eq | 7.38 × 10−3 |

| Ecotoxicity, freshwater | CTUe | 1.29 |

| Land use | Pt | 7.69 |

| Water use | m3 depriv. | 1.82 × 10−2 |

| Resource use, fossils | MJ | 2.58 × 10−1 |

| Resource use, minerals and metals | kg Sb eq | 1.88 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianco, I.; De Bona, A.; Zanetti, M.; Panepinto, D. Environmental Impacts in the Textile Sector: A Life Cycle Assessment Case Study of a Woolen Undershirt. Sustainability 2023, 15, 11666. https://doi.org/10.3390/su151511666

Bianco I, De Bona A, Zanetti M, Panepinto D. Environmental Impacts in the Textile Sector: A Life Cycle Assessment Case Study of a Woolen Undershirt. Sustainability. 2023; 15(15):11666. https://doi.org/10.3390/su151511666

Chicago/Turabian StyleBianco, Isabella, Alice De Bona, Mariachiara Zanetti, and Deborah Panepinto. 2023. "Environmental Impacts in the Textile Sector: A Life Cycle Assessment Case Study of a Woolen Undershirt" Sustainability 15, no. 15: 11666. https://doi.org/10.3390/su151511666

APA StyleBianco, I., De Bona, A., Zanetti, M., & Panepinto, D. (2023). Environmental Impacts in the Textile Sector: A Life Cycle Assessment Case Study of a Woolen Undershirt. Sustainability, 15(15), 11666. https://doi.org/10.3390/su151511666