The Influence of Road Pavement Materials on Surface Texture and Friction

Abstract

:1. Introduction

2. Methodology of Measurements

2.1. Measuring Devices

2.1.1. British Pendulum Tester

2.1.2. Static Road Scanner

2.2. Testing Surfaces

2.2.1. Reference Surfaces

2.2.2. Specimens of Aggregate

2.2.3. Specimens of Asphalt Mixture

3. Results and Discussion

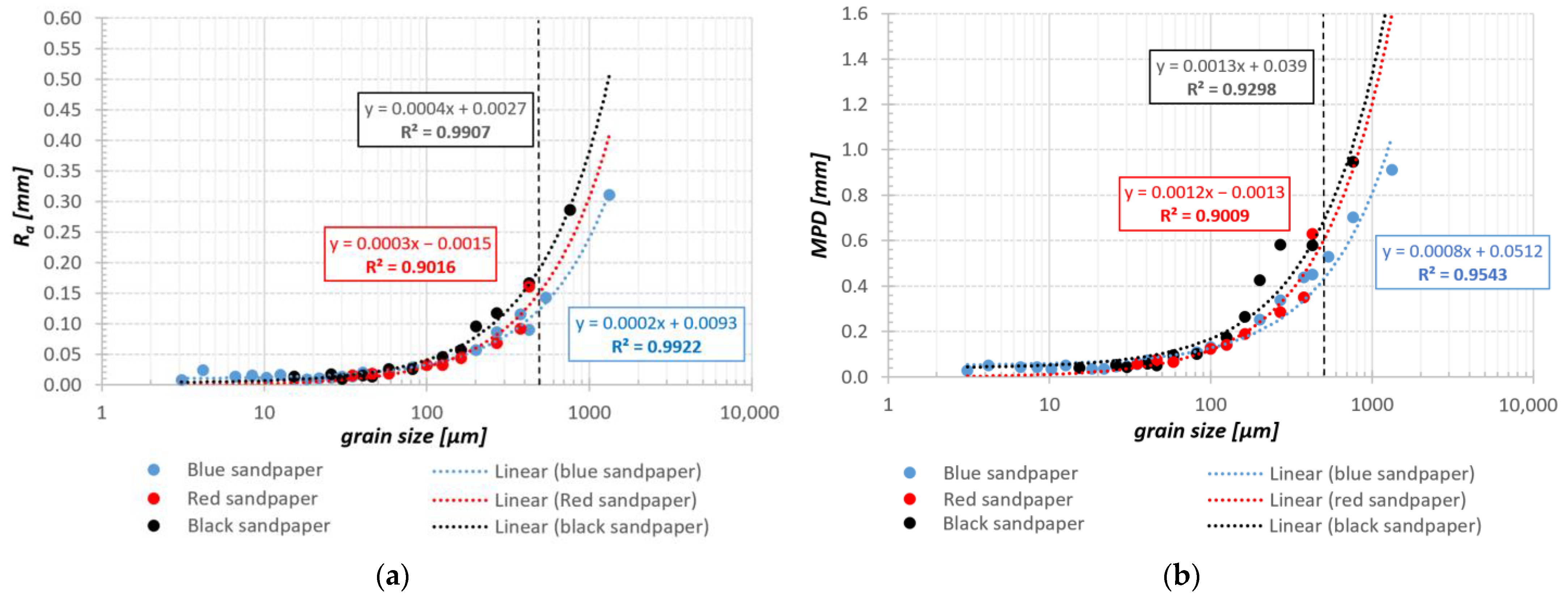

3.1. Results of Reference Surfaces

3.2. Results Obtained on Specimens of Aggregate

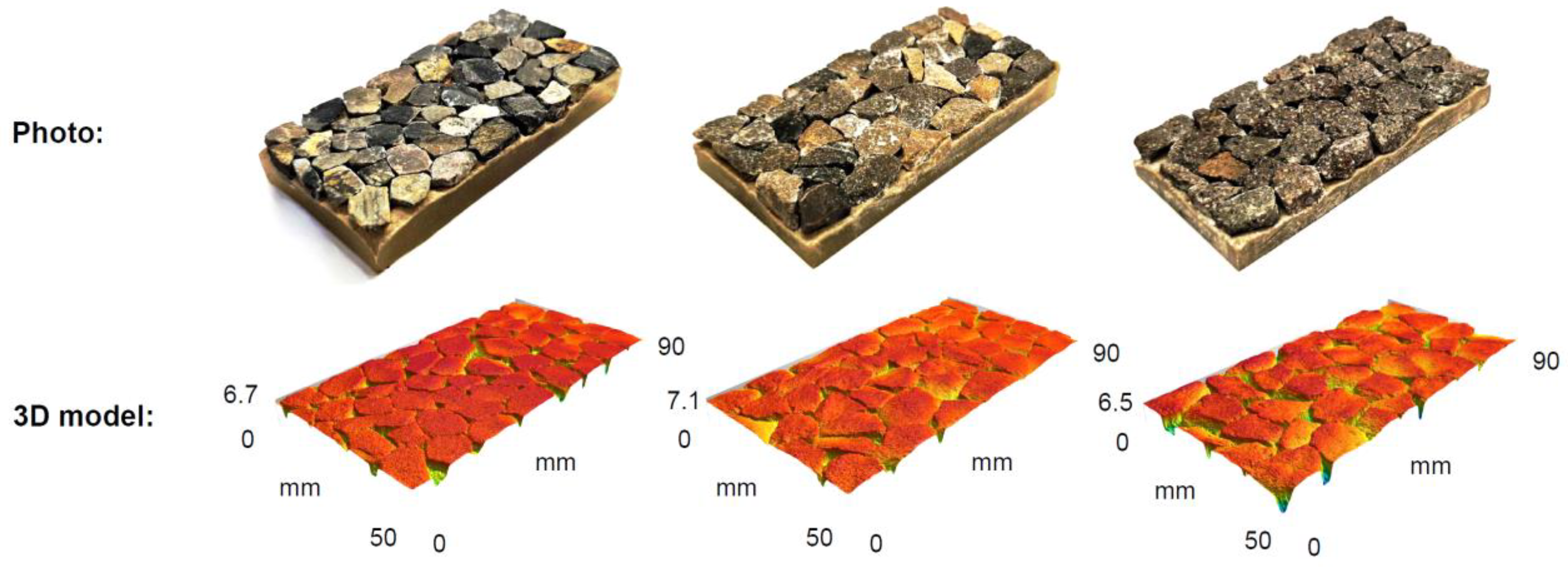

3.2.1. Results of Texture Measurement on Aggregate Specimens

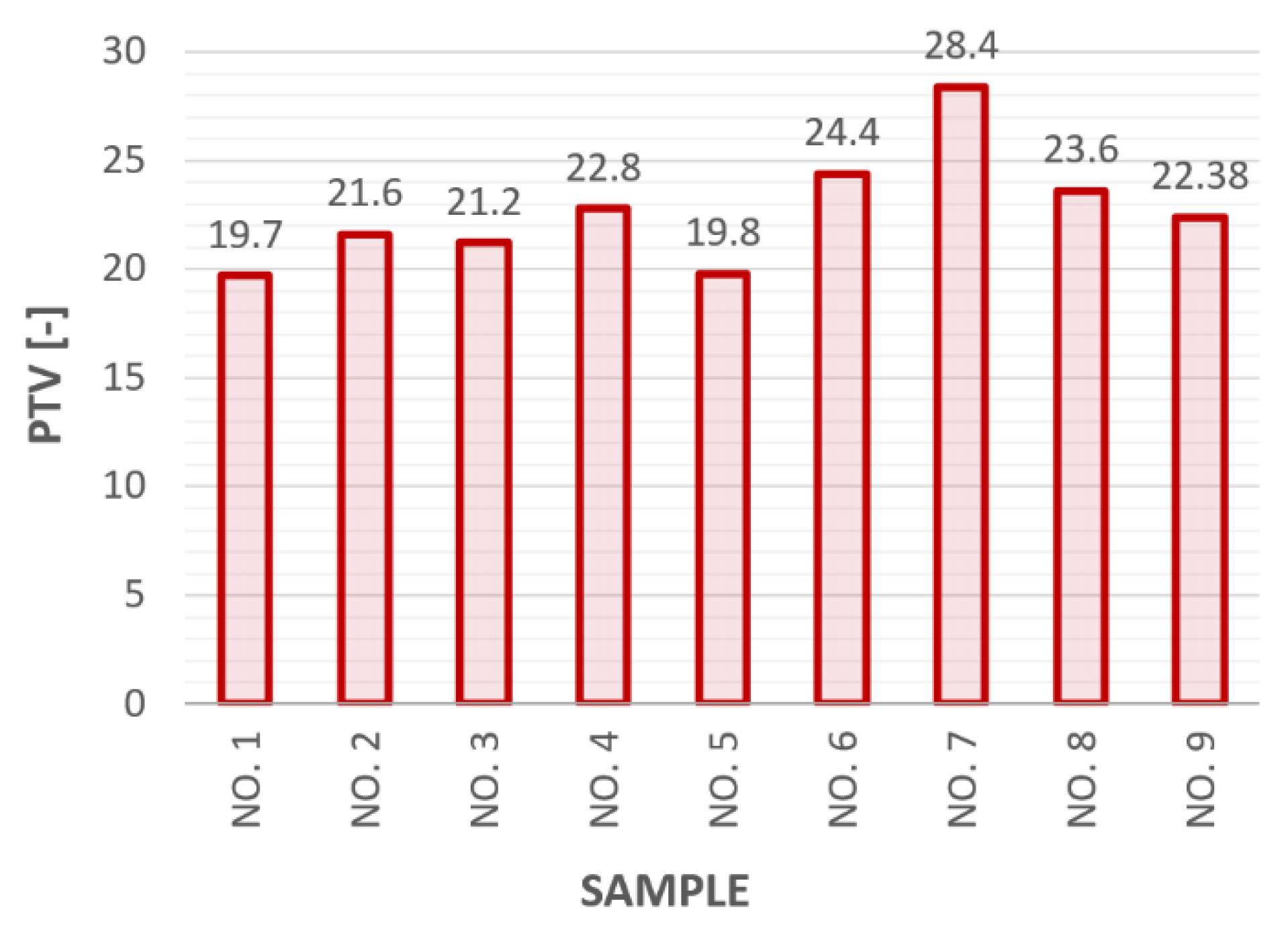

3.2.2. Skid Resistance Results on Aggregate Specimens

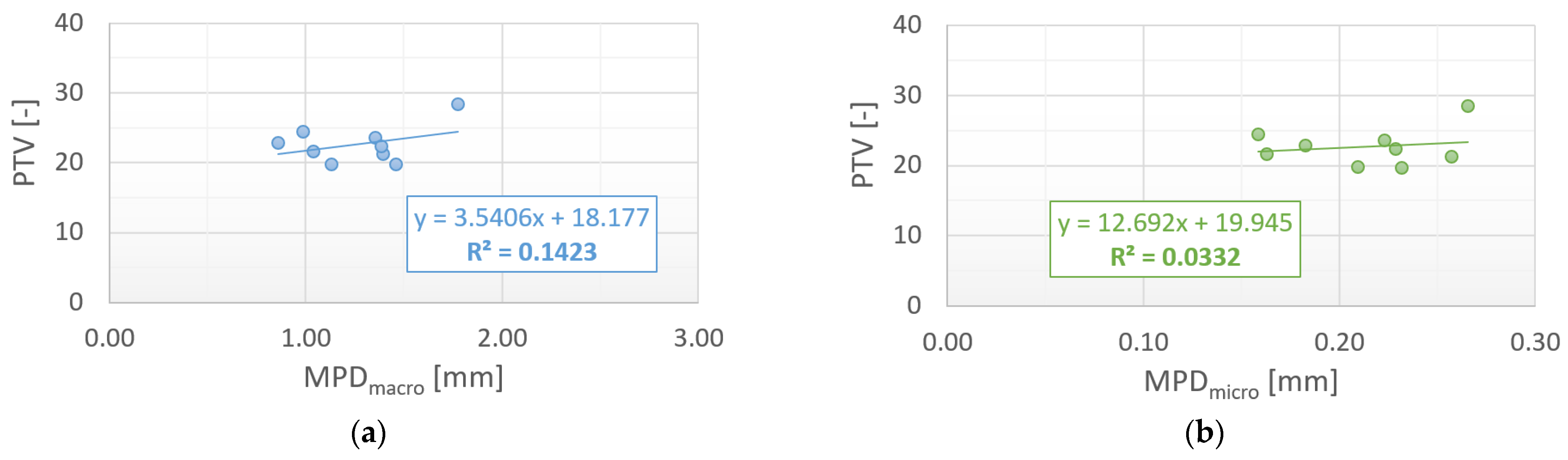

3.2.3. Relationship between Texture and Friction on Aggregate Specimens

3.3. Results Obtained on Specimens of Asphalt Mixture

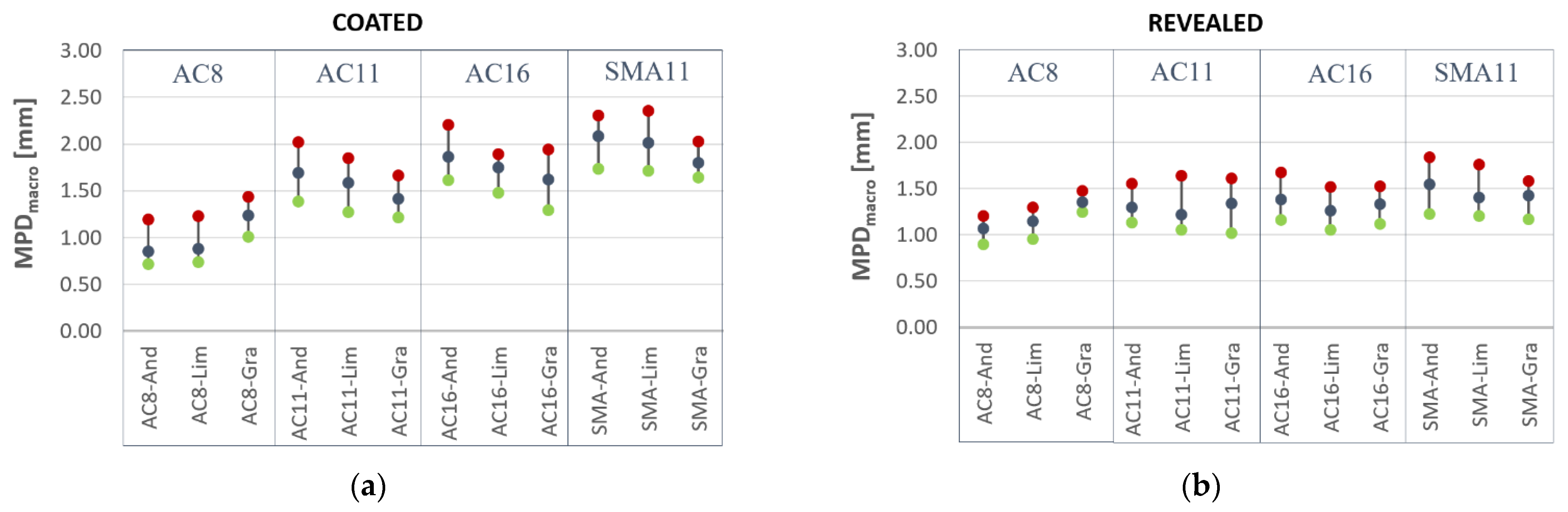

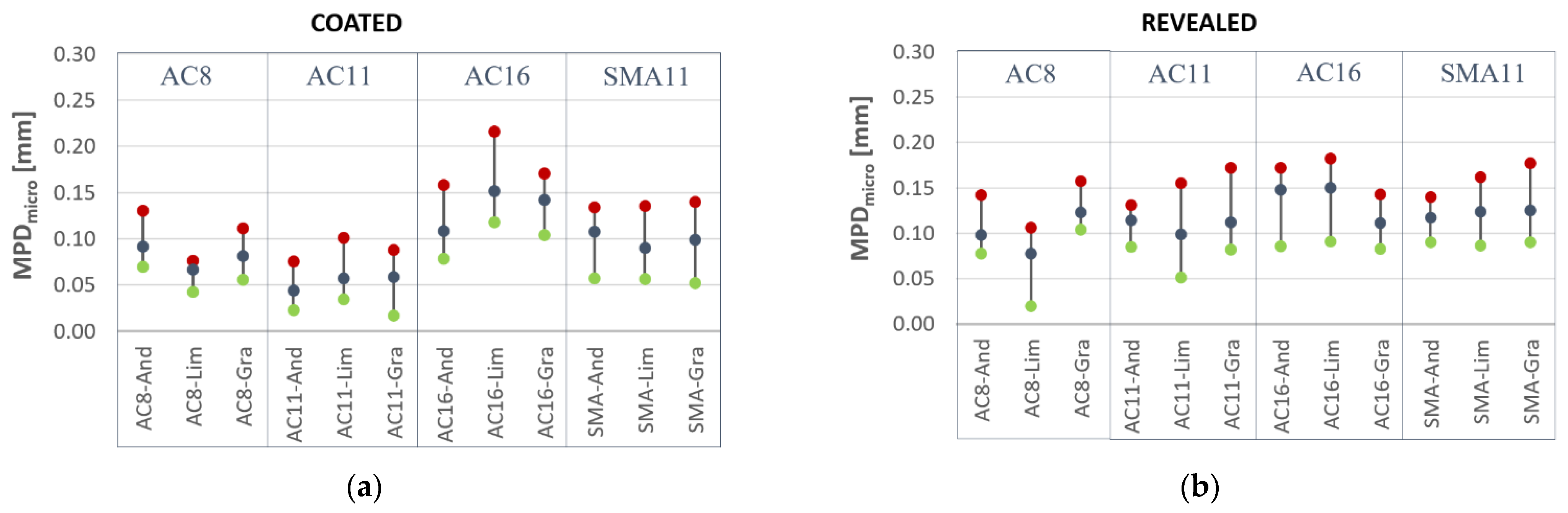

3.3.1. Texture Results on Asphalt Specimens

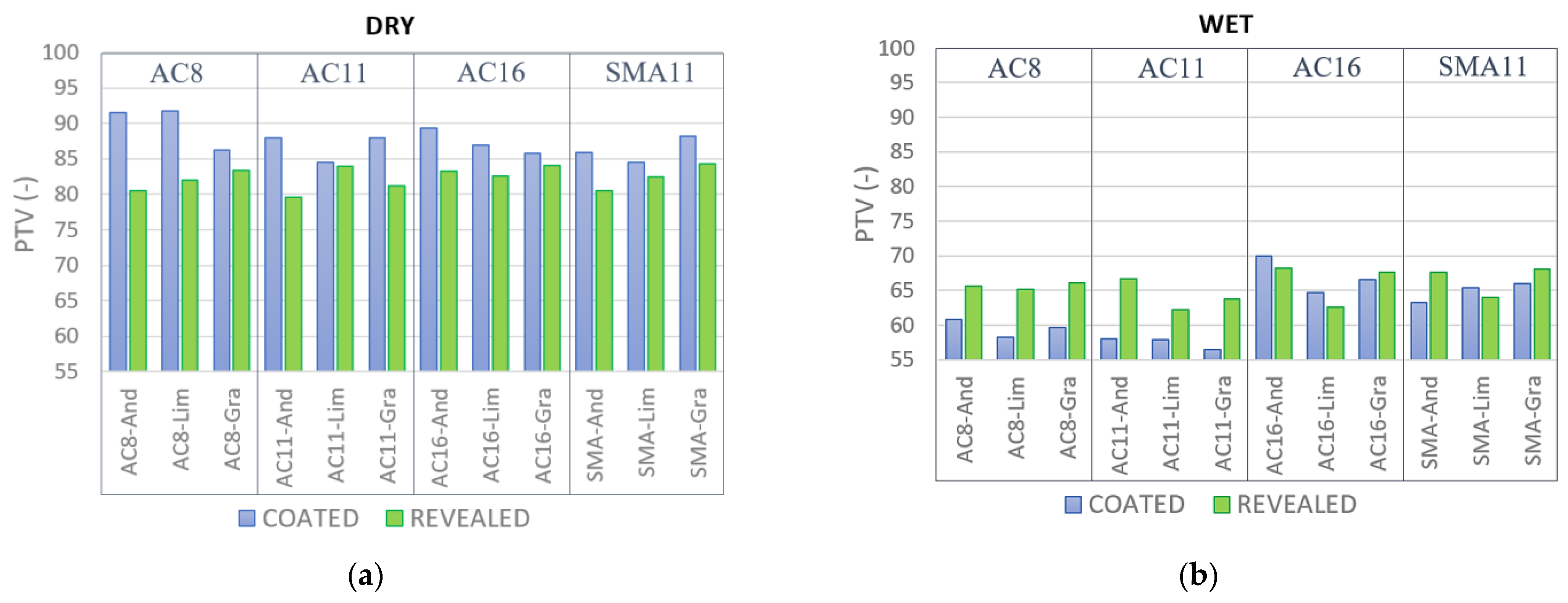

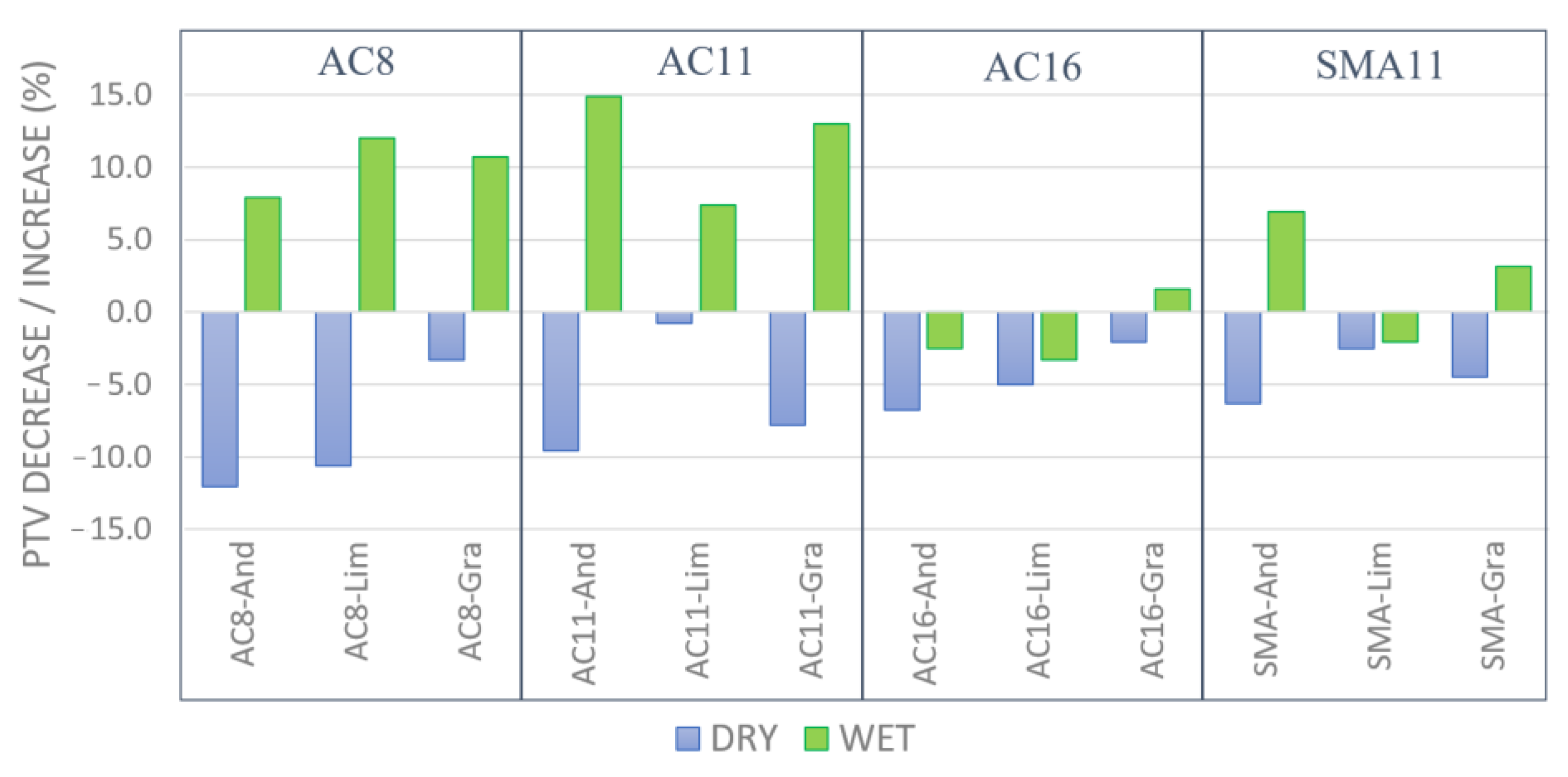

3.3.2. Results of Skid Resistance on Asphalt Specimens

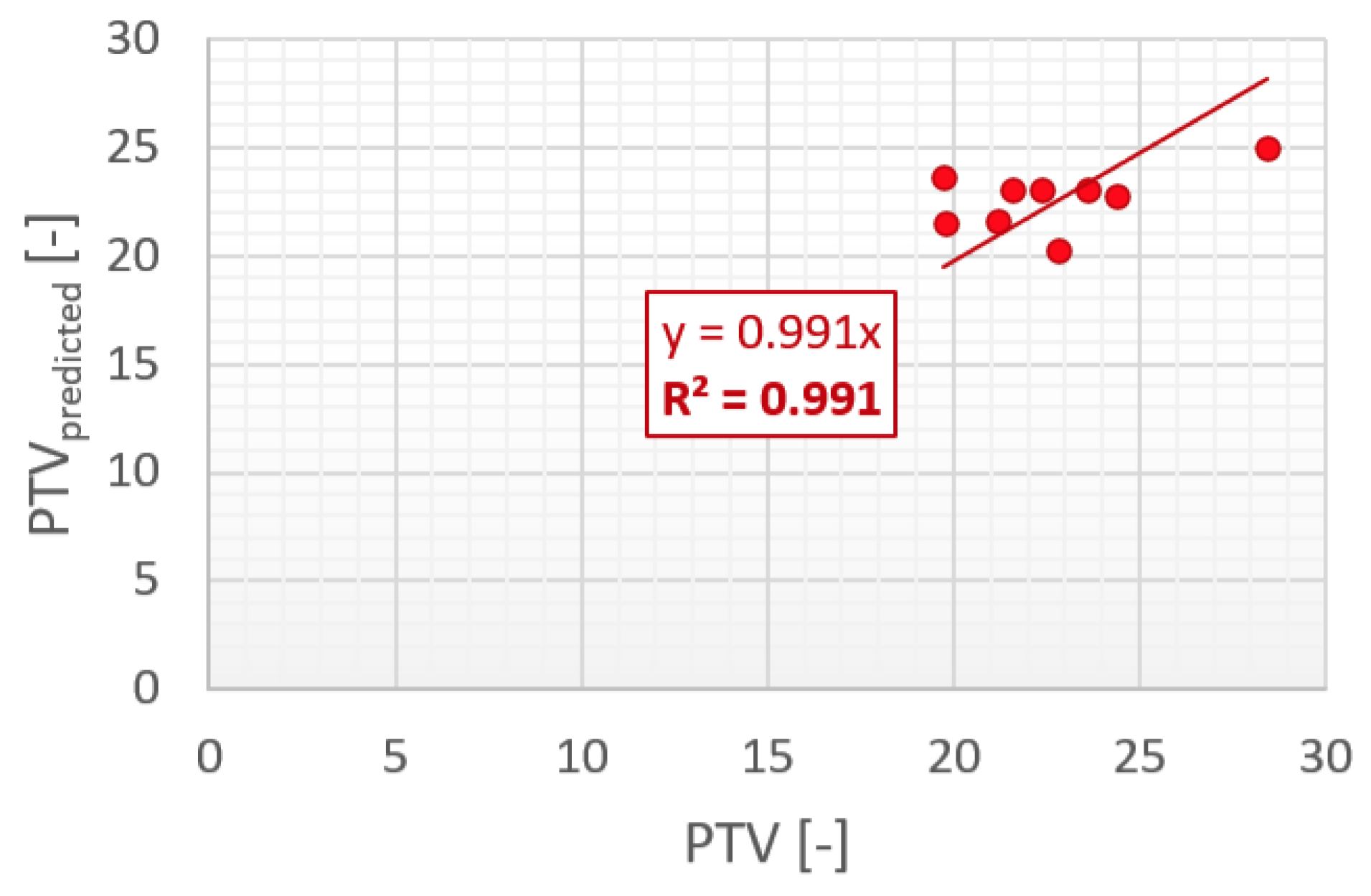

3.3.3. Relationship between Texture and Friction on Asphalt Specimens

4. Conclusions

- The SRS device designed at the University of Žilina is reliable and suitable for pavement texture evaluation. The measurements demonstrated this on reference surfaces with a known surface roughness;

- The measurements on the reference surfaces showed that increasing microtexture values do not only indicate increasing skid resistance values. The highest pendulum test values were achieved on surfaces with grain sizes ranging from 80 to 125 µm. After the grain size exceeded 150 µm, a decreasing trend of skid resistance was recorded. In the part of the microtexture level up to 125 µm, it was possible to find a relatively strong correlation between the microtexture and friction;

- The measurements on asphalt mixture specimens with various values of micro- and macrotexture confirmed some expected results. These included, for example, the level of the macrotexture being influenced by the size of the maximum aggregate grain used, a decrease in the skid resistance value on wet surfaces, and an increase on wet surfaces without a bitumen film. Despite these expected results, some did not turn out as expected. One of them was that the evaluation of the microtexture did not confirm the expected friction levels for different types of aggregates. Although an effort was made to create surfaces with a wide range of micro- and macrotexture values, this range proved insufficient. This could also have caused the relationships between the texture and skid resistance on the asphalt specimens to be shallow for the investigated samples. For this reason, it is recommended to expand this range in further research to ensure sufficiently different levels of texture;

- It was shown that high texture values do not necessarily mean high skid resistance. These results indicate that it will not be possible to predict the skid resistance of the surface of individual materials based only on simple texture parameters. Therefore, the following research must focus on evaluating the 3D area and volume characteristics in a broader range of surfaces with different micro- and macrotextures. In terms of asphalt mixture design, the optimum ratio of the size combination of micro- and macrotexture., i.e., the type and size of used aggregates, is necessary for optimal road pavement surface skid resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pranjić, I.; Deluka-Tibljaš, A. Pavement Texture–Friction Relationship Establishment via Image Analysis Methods. Materials 2022, 15, 846. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Xiong, C.; Li, W.; He, J.; Zhang, X. Assessing Surface Texture Features of Asphalt Pavement Based on Three-Dimensional Laser Scanning Technology. Buildings 2021, 11, 623. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Z.; Han, Y.; Li, W.; Pei, L. Evaluate Pavement Skid Resistance Performance Based on Bayesian-LightGBM Using 3D Surface Macrotexture Data. Materials 2022, 15, 5275. [Google Scholar] [CrossRef] [PubMed]

- Davies, R.; Cenek, P.; Henderson, R. The Effect of Skid Resistance and Texture on Crash Risk. In Proceedings of the Surface Friction Roads and Runways, Christchurch, New Zealand, 1–4 May 2005. [Google Scholar]

- Fwa, T.F. Skid Resistance Determination for Pavement Management and Wet-Weather Road Safety. Int. J. Transp. Sci. Technol. 2017, 6, 217–227. [Google Scholar] [CrossRef]

- Sandberg, U. Influence of Road Surface Texture on Traffic Characteristics Related to Environment, Economy and Safety: A State-of-the-Art Study Regarding Measures and Measuring Methods; Swedish National Road and Transport Research Institute (VTI): Linköping, Sweden, 1998. [Google Scholar]

- Mikolaj, J.; Remek, L. Material Structural and Economical Aspects of Life Cycle Extension of Asphalt Concrete Surfacing. In Pavement and Asset Management; CRC Press: Boca Raton, FL, USA, 2019; pp. 685–692. [Google Scholar]

- Georgiou, P.; Loizos, A. A Laboratory Compaction Approach to Characterize Asphalt Pavement Surface Friction Performance. Wear 2014, 311, 114–122. [Google Scholar] [CrossRef]

- Jandacka, D.; Durcanska, D.; Cibula, R. Concentration and Inorganic Elemental Analysis of Particulate Matter in a Road Tunnel Environment (Žilina, Slovakia): Contribution of Non-Exhaust Sources. Front. Environ. Sci. 2022, 10, 952577. [Google Scholar] [CrossRef]

- Kocianova, A.; Drliciak, M.; Pitlova, E. Influence of Roundabout Capacity Enhancement on Emission Production. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012035. [Google Scholar] [CrossRef]

- Jandacka, D.; Kovalova, D.; Durcanska, D.; Decky, M. Chemical Composition, Morphology, and Distribution of Particulate Matter Produced by Road Pavement Abrasion Using Different Types of Aggregates and Asphalt Binder. Cogent Eng. 2021, 8, 1884325. [Google Scholar] [CrossRef]

- Jandačka, D.; Ďurčanská, D. Particulate Matter Assessment in the Air Based on the Heavy Metals Presence. Civ. Environ. Eng. 2014, 10, 26–39. [Google Scholar] [CrossRef] [Green Version]

- Margorínová, M.; Trojanová, M.; Decký, M.; Remišová, E. Noise Costs from Road Transport. Civ. Environ. Eng. 2018, 14, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Trojanová, M.; Hodásová, K.; Kleštincová, M. Contextual Design of Road Traffic Noise Reducing Devices. Civ. Environ. Eng. 2022, 18, 515–522. [Google Scholar] [CrossRef]

- Remisova, E. The influence of the asphalt mixture composition on the pavement surface texture and noise emissions production. Air Pollut. Clim. Change 2014, 2, 583–590. [Google Scholar] [CrossRef]

- Pavement Management Guide, 2nd ed.; AASHTO—American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Saliminejad, S.; Gharaibeh, N.G. Impact of Error in Pavement Condition Data on the Output of Network-Level Pavement Management Systems. Transp. Res. Rec. J. Transp. Res. Board 2013, 2366, 110–119. [Google Scholar] [CrossRef]

- Mikolaj, J.; Remek, Ľ.; Kozel, M. Optimization of Bituminous Road Surfacing Rehabilitations Based on Optimization of Road Asset Value. Appl. Sci. 2022, 12, 10466. [Google Scholar] [CrossRef]

- Juraszek, J.; Gwozdz-Lason, M.; Gago, F.; Bulko, R. FBG Monitoring of a Communication Paths and Roadways with a Geosynthetic Systems on Mining Heaps. Civ. Environ. Eng. 2023, 19, 414–425. [Google Scholar] [CrossRef]

- Petru, J.; Krivda, V. The Process of Setting the Parameters for Ensuring Passage of Oversized Cargos. Balt. J. Road Bridge Eng. 2019, 14, 425–442. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Pei, J.; Huang, G.; Hu, Z.; Niu, Z.; Cannone Falchetto, A. Evolution of Tire-Pavement Friction with the Regular Surface Macro-Texture Characteristics and Environmental Factors Using Three-Dimensional (3D) Printing Technology. J. Clean. Prod. 2023, 382, 135293. [Google Scholar] [CrossRef]

- Rasol, M.; Schmidt, F.; Ientile, S. FriC-PM: Machine Learning-Based Road Surface Friction Coefficient Predictive Model Using Intelligent Sensor Data. Constr. Build. Mater. 2023, 370, 130567. [Google Scholar] [CrossRef]

- Henry, J.J. Evaluation of Pavement Friction Characteristics; National Academy Press: Washington, DC, USA, 2000. [Google Scholar]

- Ergun, M.; Iyinam, S.; Iyinam, A.F. Prediction of Road Surface Friction Coefficient Using Only Macro- and Microtexture Measurements. J. Transp. Eng. 2005, 131, 311–319. [Google Scholar] [CrossRef]

- Hall, J.W.; Smith, K.L.; Titus-Glover, L.; Wambold, J.C.; Yager, T.J.; Rado, Z. Guide for Pavement Friction; The National Academies Press: Washington, DC, USA, 2009. [Google Scholar]

- Noyce, D.A.; Yambó, J.M.; Kim, G.-H. Incorporating Road Safety into Pavement Management: Maximizing Asphalt Pavement Surface Friction for Road Safety Improvements; Draft Literature Review and State Surveys, Midwest Regional University Transportation Center (UMTRI): Madison, WI, USA, 2005. [Google Scholar]

- Deng, Q.; Zhan, Y.; Liu, C.; Qiu, Y.; Zhang, A. Multiscale Power Spectrum Analysis of 3D Surface Texture for Prediction of Asphalt Pavement Friction. Constr. Build. Mater. 2021, 293, 123506. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Alsheyab, M.A. Effect of Nominal Maximum Aggregate Size and Aggregate Gradation on the Surface Frictional Properties of Hot Mix Asphalt Mixtures. Constr. Build. Mater. 2020, 244, 118355. [Google Scholar] [CrossRef]

- Dahir, S.H. A Review of Aggregate Selection Criteria for Improved Wear Resistance and Skid Resistance of Bituminous Surfaces. ASTM J. Test. Eval. 1979, 7. [Google Scholar] [CrossRef]

- Fwa, T.F.; Ong, G.P. Wet-Pavement Hydroplaning Risk and Skid Resistance: Analysis. J. Transp. Eng. 2008, 134, 182–190. [Google Scholar] [CrossRef]

- Villani, M.M.; Artamendi, I.; Kane, M.; Scarpas, A. Contribution of Hysteresis Component of Tire Rubber Friction on Stone Surfaces. Transp. Res. Rec. J. Transp. Res. Board 2011, 2227, 153–162. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; Zheng, B.; Zhao, R.; Liu, X.; Cao, Q.; Zhu, S. Real-Time Identification System of Asphalt Pavement Texture Based on the Close-Range Photogrammetry. Constr. Build. Mater. 2019, 226, 910–919. [Google Scholar] [CrossRef]

- Cui, X.; Zhou, X.; Lou, J.; Zhang, J.; Ran, M. Measurement Method of Asphalt Pavement Mean Texture Depth Based on Multi-Line Laser and Binocular Vision. Int. J. Pavement Eng. 2017, 18, 459–471. [Google Scholar] [CrossRef]

- Du, Y.; Weng, Z.; Li, F.; Ablat, G.; Wu, D.; Liu, C. A Novel Approach for Pavement Texture Characterisation Using 2D-Wavelet Decomposition. Int. J. Pavement Eng. 2022, 23, 1851–1866. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Masad, E.A.; Woodward, D.; Millar, P. Relating Surface Texture Parameters from Close Range Photogrammetry to Grip-Tester Pavement Friction Measurements. Constr. Build. Mater. 2018, 166, 227–240. [Google Scholar] [CrossRef]

- Song, W. Correlation between Morphology Parameters and Skid Resistance of Asphalt Pavement. Transp. Saf. Environ. 2022, 4, tdac002. [Google Scholar] [CrossRef]

- Kane, M.; Artamendi, I.; Scarpas, T. Long-Term Skid Resistance of Asphalt Surfacings: Correlation between Wehner–Schulze Friction Values and the Mineralogical Composition of the Aggregates. Wear 2013, 303, 235–243. [Google Scholar] [CrossRef]

- Do, M.-T.; Tang, Z.; Kane, M.; de Larrard, F. Evolution of Road-Surface Skid-Resistance and Texture Due to Polishing. Wear 2009, 266, 574–577. [Google Scholar] [CrossRef]

- Ahammed, M.A.; Tighe, S.L. Pavement Surface Mixture, Texture, and Skid Resistance: A Factorial Analysis. In Airfield and Highway Pavements: Efficient Pavements Supporting Transportation’s Future, Proceedings of the 2008 Airfield and Highway Pavements Conference, Bellevue, WA, USA, 15–18 October 2008; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 370–384. [Google Scholar]

- STN EN 13036-4; Road and Airfield Surface Characteristics.Test Methods. Part 4: Method for Measurement of Slip/Skid Re-sistance of a Surface: The Pendulum Test. ISO: Geneva, Switzerland, 2011.

- STN EN ISO 4287; Geometrical Product Specifications (GPS). Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 1999.

- STN EN ISO 13473-1; Characterization of Pavement Texture by Use of Surface Profiles—Part 1: Determination of Mean Profile Depth. ISO: Geneva, Switzerland, 2021.

- ISO 16610-61:2015; Geometrical Product Specification (GPS)—Filtration—Part 61: Linear Areal Filters—Gaussian Filters. ISO: Geneva, Switzerland, 2015.

| No. | Specimen | MPDmacro | MPDmicro | PTVWET |

|---|---|---|---|---|

| (mm) | (mm) | (-) | ||

| 1. | Dolomitic limestone | 1.458 | 0.232 | 19.70 |

| 2. | Dolomitic limestone | 1.038 | 0.163 | 21.60 |

| 3. | Dolomitic limestone | 1.395 | 0.257 | 21.20 |

| 4. | Siliceous limestone | 0.859 | 0.183 | 22.80 |

| 5. | Dolomites | 1.130 | 0.210 | 19.80 |

| 6. | Andesite | 0.985 | 0.159 | 24.40 |

| 7. | Andesite | 1.774 | 0.265 | 28.40 |

| 8. | Andesite | 1.355 | 0.223 | 23.60 |

| 9. | Granodiorite | 1.384 | 0.229 | 22.38 |

| Mixture | COATED | REVEALED | ||||||

|---|---|---|---|---|---|---|---|---|

| MPDmacro | MPDmicro | PTVDRY | PTVWET | MPDmacro | MPDmicro | PTVDRY | PTVWET | |

| (mm) | (mm) | (-) | (-) | (mm) | (mm) | (-) | (-) | |

| AC8-And | 0.85 | 0.092 | 92 | 61 | 1.70 | 0.098 | 81 | 66 |

| AC8-Lim | 0.88 | 0.066 | 92 | 58 | 1.15 | 0.077 | 82 | 65 |

| AC8-Gra | 1.23 | 0.075 | 86 | 60 | 1.35 | 0.123 | 83 | 66 |

| AC11-And | 1.69 | 0.044 | 88 | 58 | 1.29 | 0.114 | 80 | 67 |

| AC11-Lim | 1.58 | 0.059 | 85 | 58 | 1.22 | 0.099 | 84 | 62 |

| AC11-Gra | 1.41 | 0.055 | 88 | 56 | 1.34 | 0.112 | 81 | 64 |

| AC16-And | 1.86 | 0.109 | 89 | 70 | 1.38 | 0.148 | 83 | 68 |

| AC16-Lim | 1.75 | 0.155 | 87 | 65 | 1.26 | 0.150 | 83 | 63 |

| AC16-Gra | 1.62 | 0.142 | 86 | 67 | 1.33 | 0.111 | 84 | 68 |

| SMA11-And | 2.80 | 0.107 | 86 | 63 | 1.55 | 0.117 | 81 | 68 |

| SMA11-Lim | 2.10 | 0.090 | 85 | 65 | 1.41 | 0.123 | 82 | 64 |

| SMA11-Gra | 1.80 | 0.099 | 88 | 66 | 1.42 | 0.125 | 84 | 68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kováč, M.; Brna, M.; Pisca, P.; Jandačka, D.; Decký, M. The Influence of Road Pavement Materials on Surface Texture and Friction. Sustainability 2023, 15, 12195. https://doi.org/10.3390/su151612195

Kováč M, Brna M, Pisca P, Jandačka D, Decký M. The Influence of Road Pavement Materials on Surface Texture and Friction. Sustainability. 2023; 15(16):12195. https://doi.org/10.3390/su151612195

Chicago/Turabian StyleKováč, Matúš, Matej Brna, Peter Pisca, Dušan Jandačka, and Martin Decký. 2023. "The Influence of Road Pavement Materials on Surface Texture and Friction" Sustainability 15, no. 16: 12195. https://doi.org/10.3390/su151612195

APA StyleKováč, M., Brna, M., Pisca, P., Jandačka, D., & Decký, M. (2023). The Influence of Road Pavement Materials on Surface Texture and Friction. Sustainability, 15(16), 12195. https://doi.org/10.3390/su151612195