Properties and Microcosmic Mechanism of Coral Powder Modified Asphalt in Offshore Islands and Reefs Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

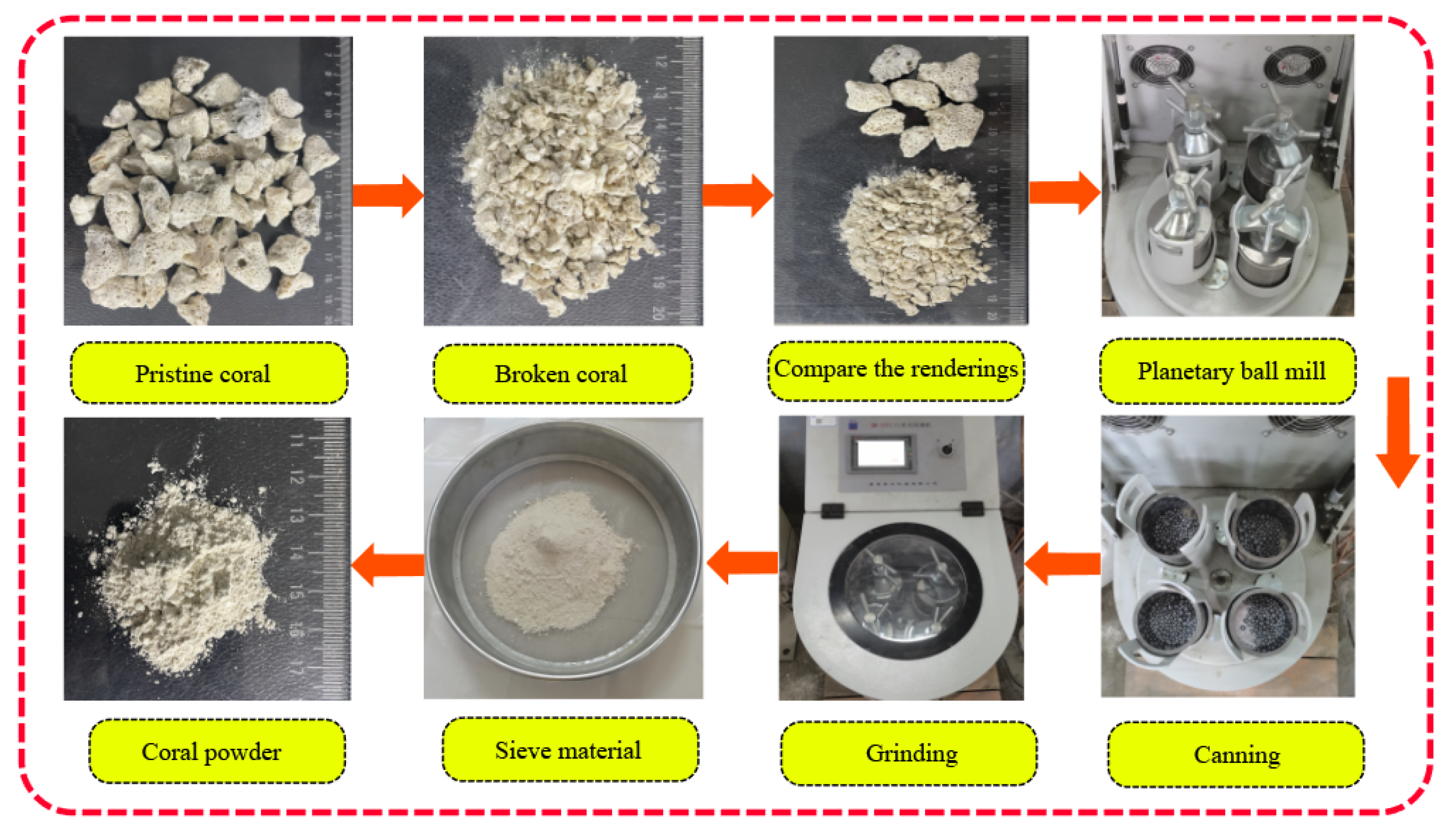

2.2. Preparation and Characteristic of Coral Powder

2.2.1. Preparation of Coral Powder

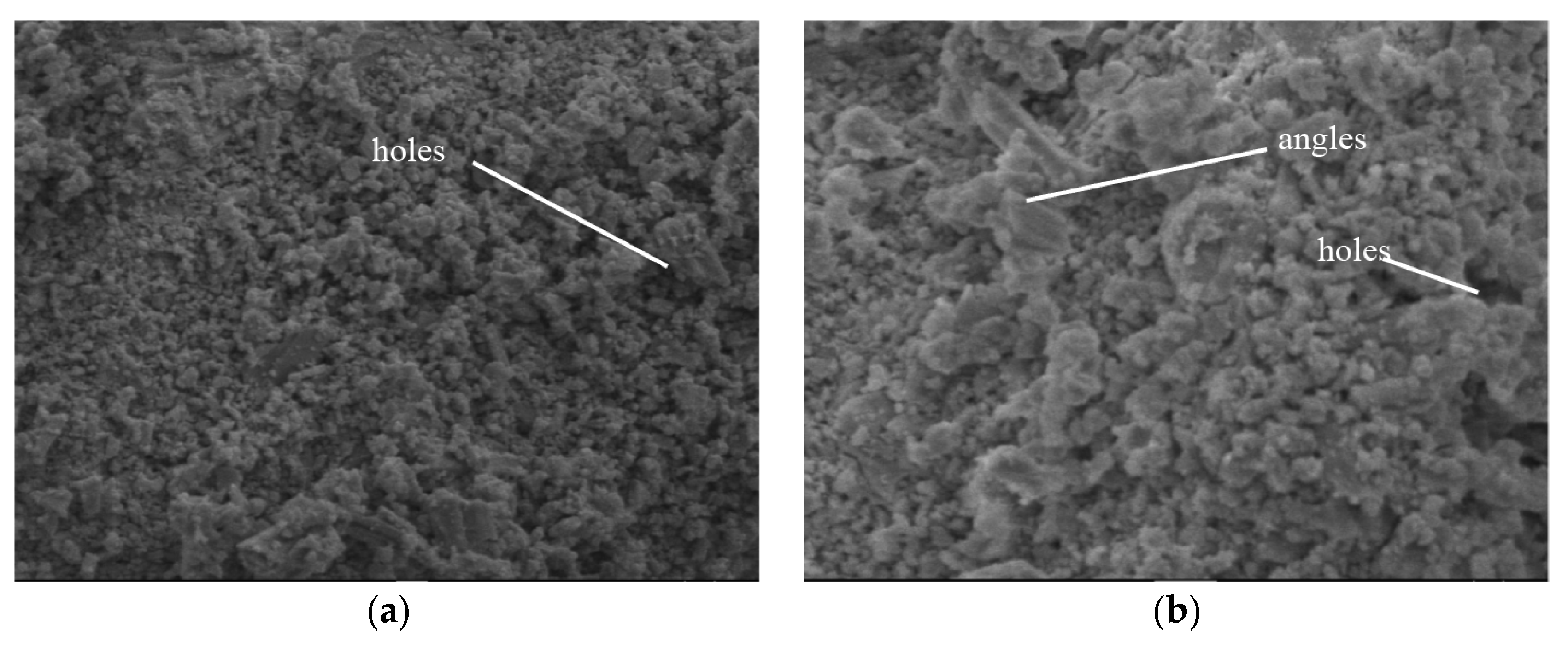

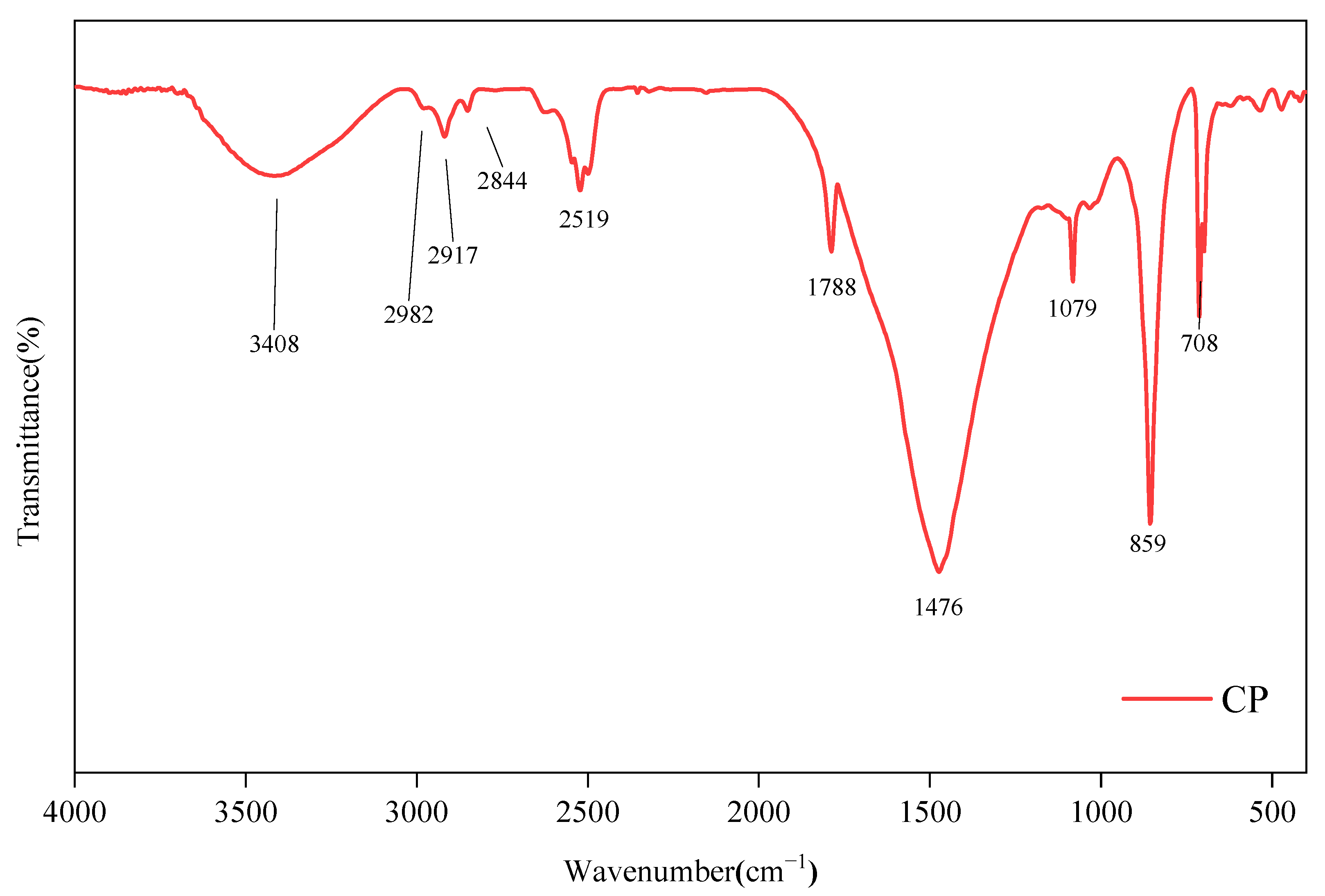

2.2.2. Characteristic of Coral Powder

2.3. Preparation of Modified Asphalts

2.4. Test Method

2.4.1. Base Properties Testing

2.4.2. Storage Stability

2.4.3. Rotational Viscometer (RV)

2.4.4. Temperature Sweep of DSR

2.4.5. Multiple Stress Creep and Recovery Test (MSCR)

2.4.6. Scanning Electron Microscope (SEM)

2.4.7. Fourier Transform Infrared (FTIR) Spectroscopy

3. Results and Discussion

3.1. Base Properties Analysis

3.1.1. Penetration

3.1.2. Softening Point

3.1.3. Ductility

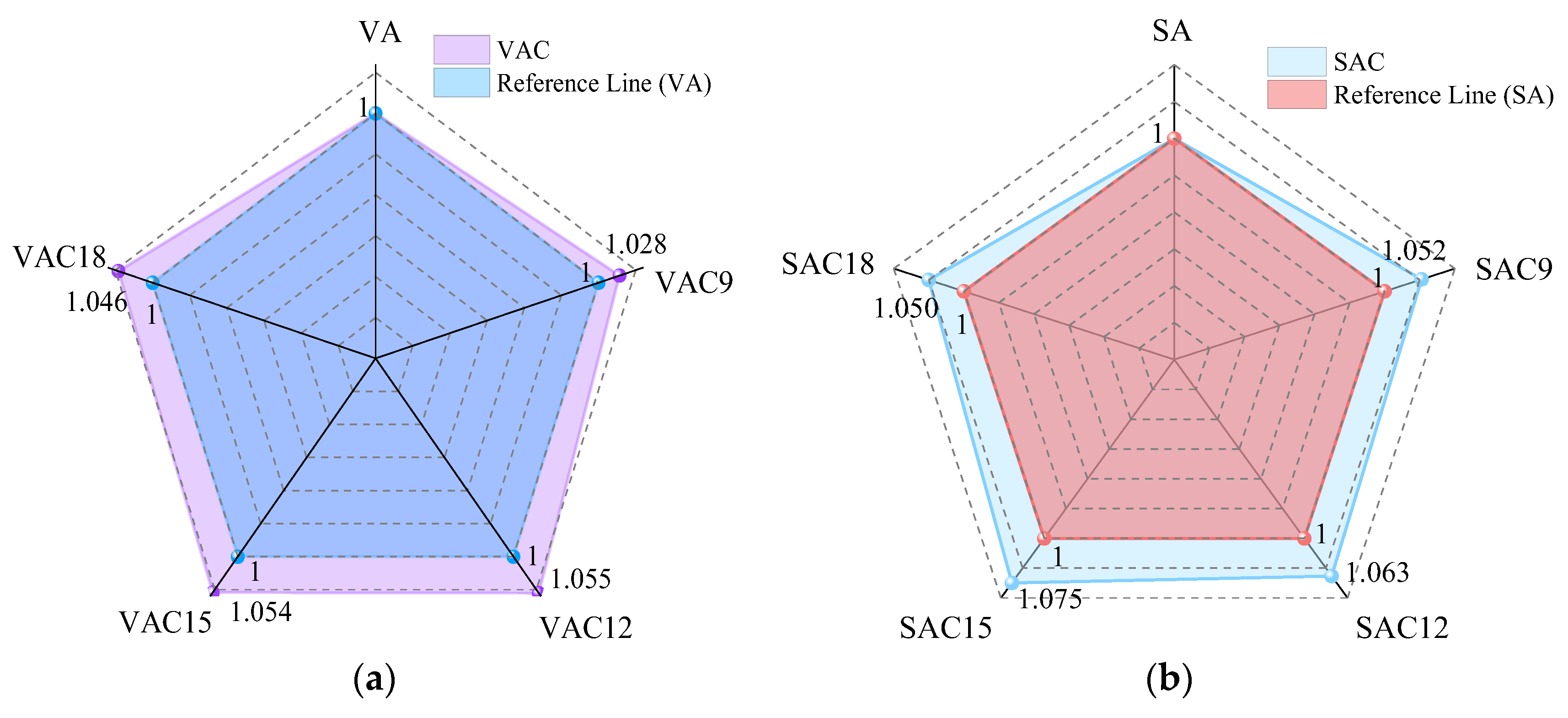

3.2. Storage Stability Analysis

3.3. Rotational Viscometer Analysis

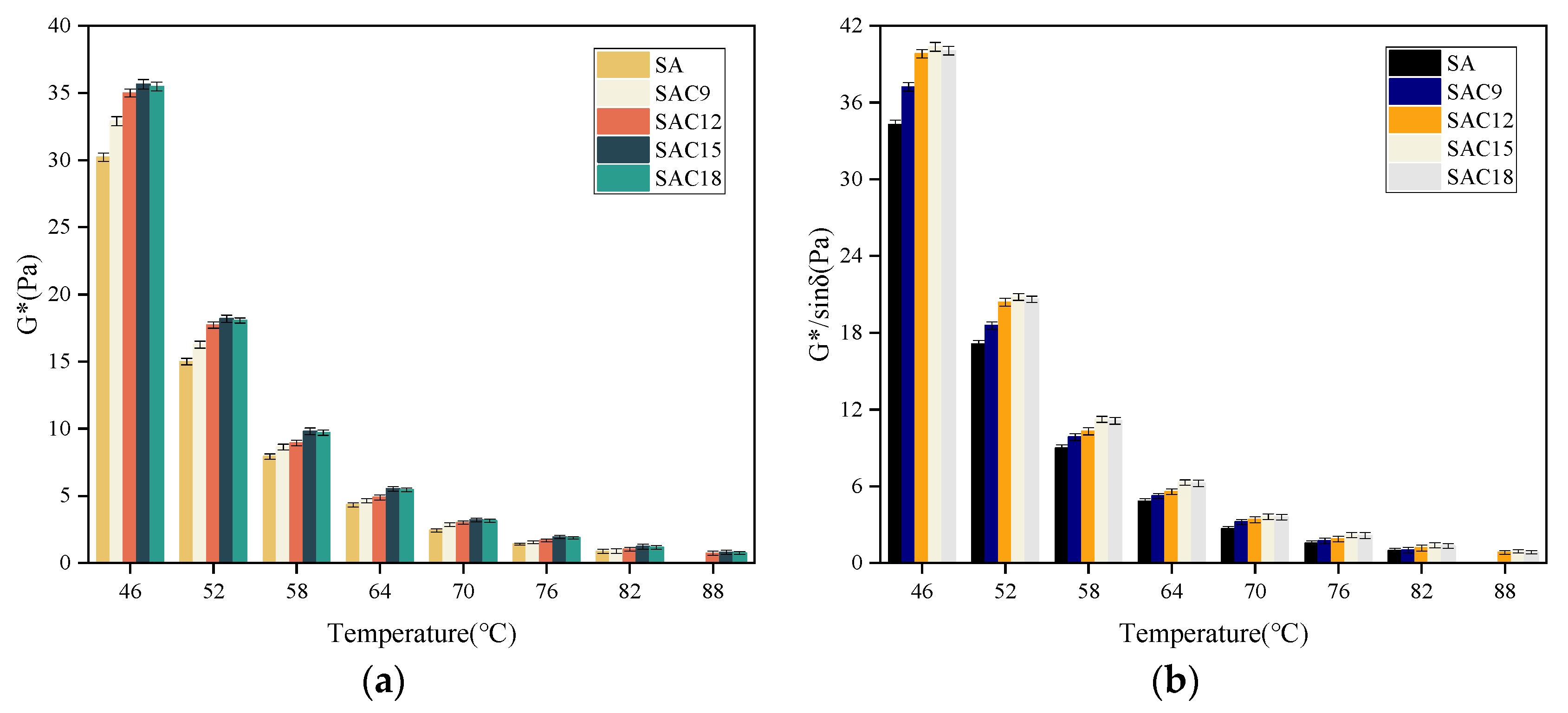

3.4. Temperature Sweep

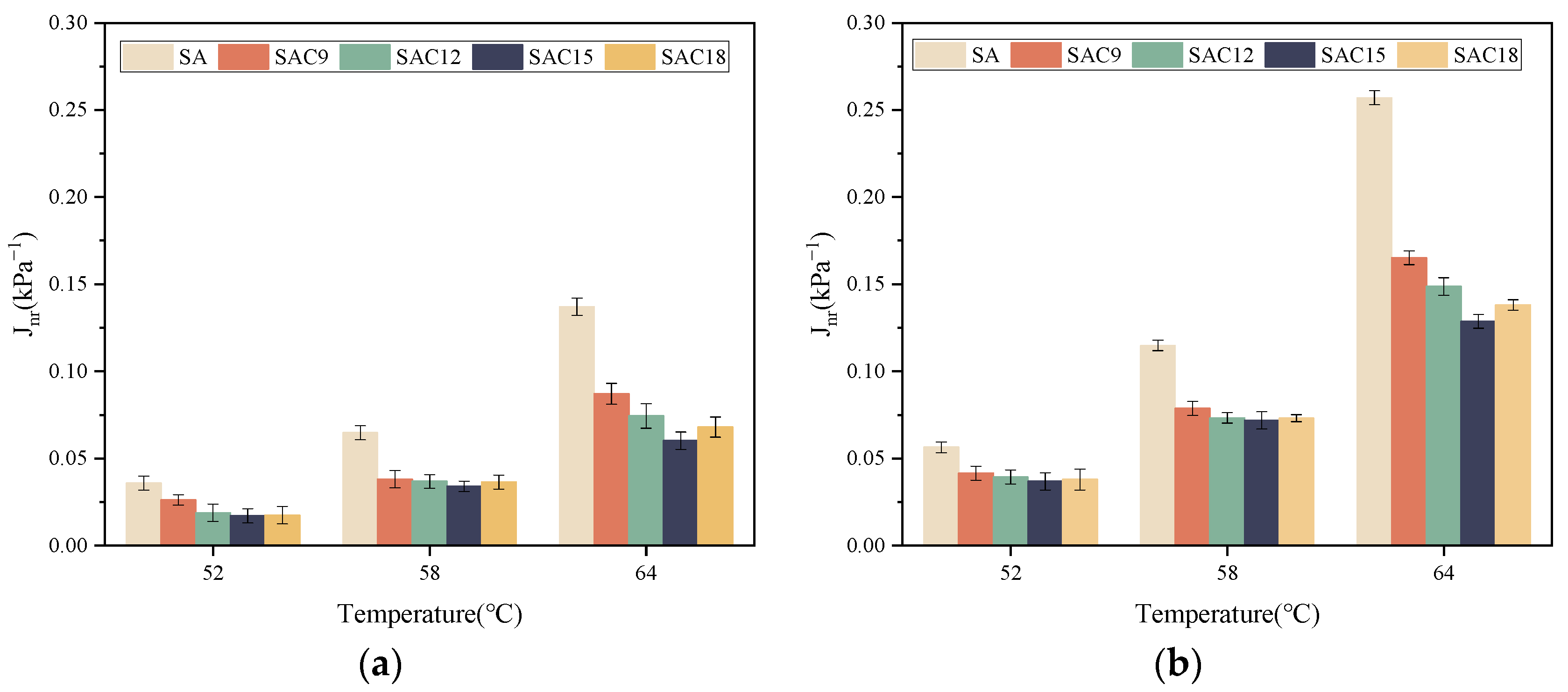

3.5. MSCR

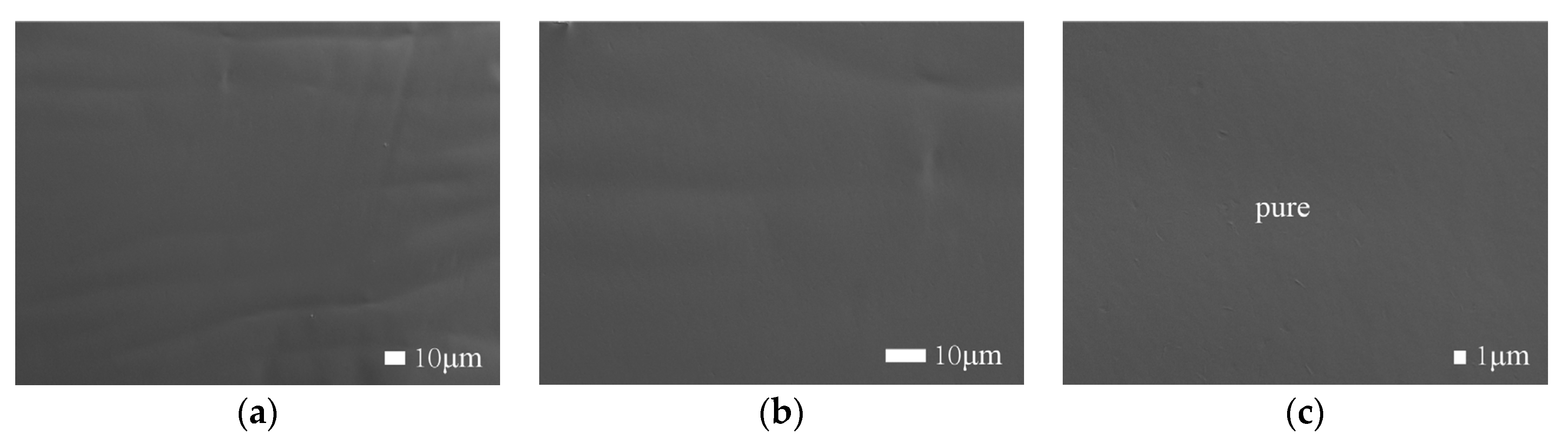

3.6. SEM

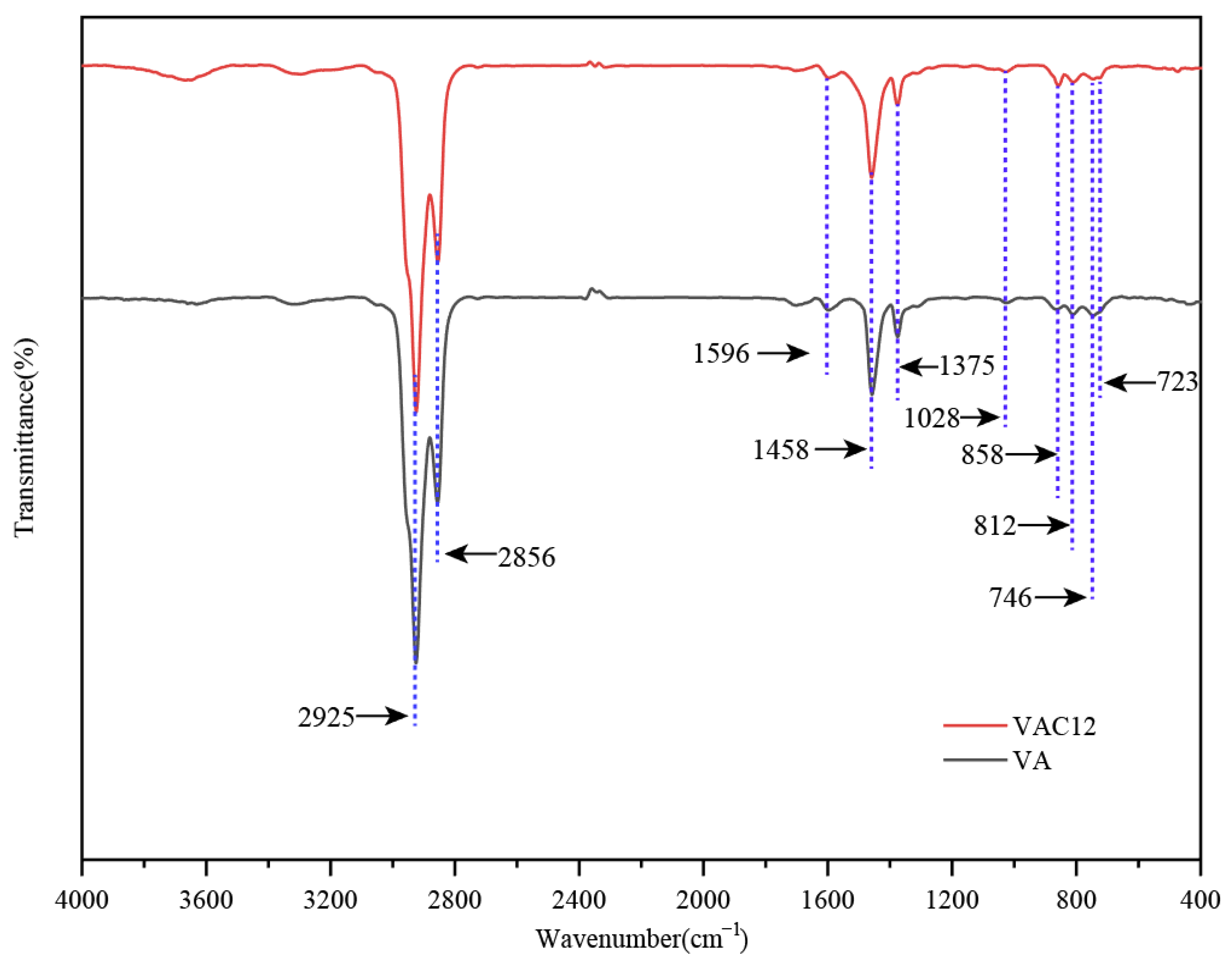

3.7. FTIR

4. Conclusions

- (1)

- Based on the analysis of base properties, it was found that the incorporation of CP reduced the ductility of asphalt but effectively improved the high-temperature properties and rheological properties of the binder. CP was used as a modifier to improve the viscosity of asphalt binder, increase its internal cohesion, and enhance its resistance to flow.

- (2)

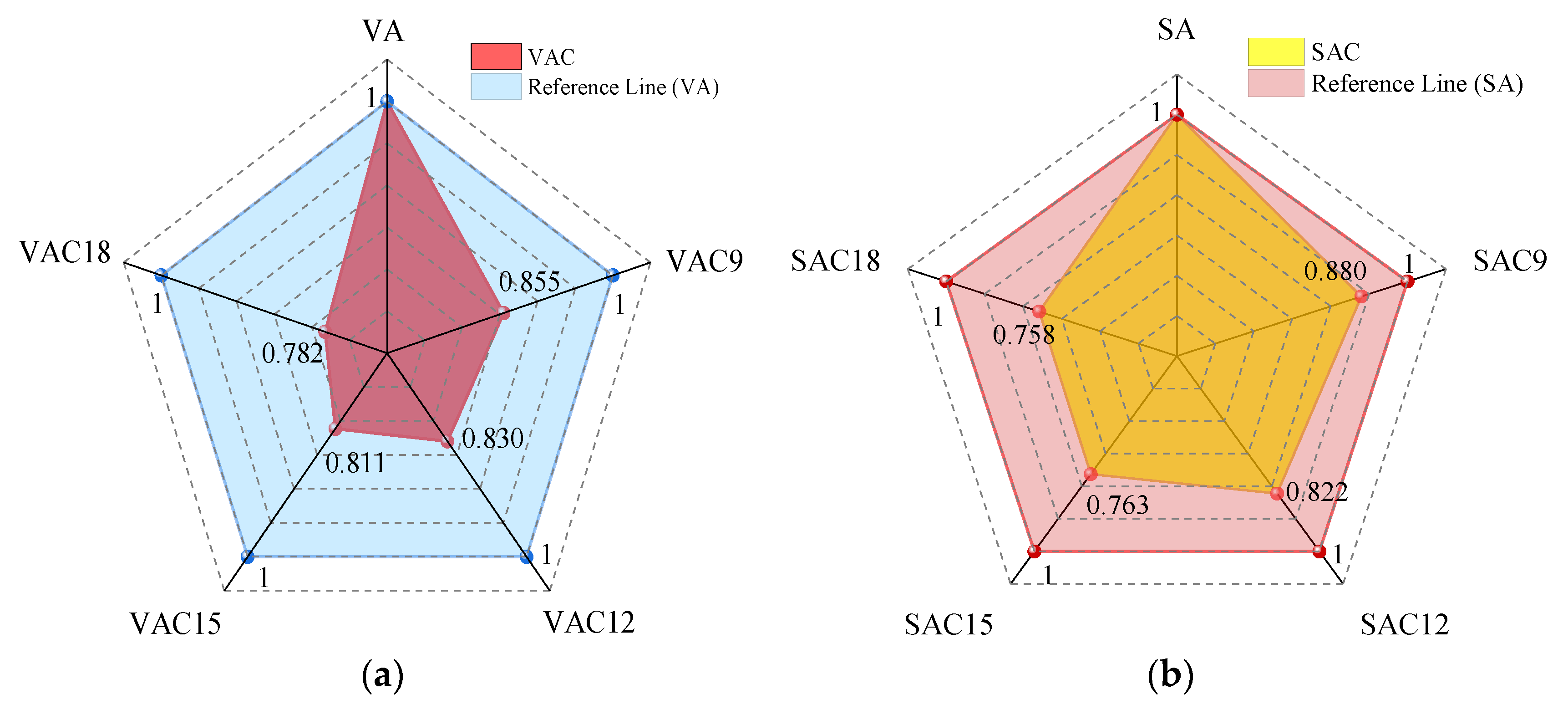

- The results obtained from temperature sweep tests and MSCR testing indicate that CP can enhance the high-temperature rheological properties, elastic recovery capacity, and resistance to permanent deformation of the asphalt binder. However, excessive CP content can have adverse effects on its performance.

- (3)

- After observing the microstructure of the samples through SEM tests, the results showed that the asphalt and CP were well compatible at the optimal CP content. Furthermore, FTIR results showed that the modification of asphalt with CP was mainly achieved through physical modification. Therefore, based on the fact that coral powder and asphalt are linked by physical interaction, the article can enhance the performance of coral-powder-modified asphalt by coupling agent in the future.

- (4)

- Considering the base properties, high-temperature rheological properties and micro-morphological characteristics of asphalt binder, the recommended dosage of CP-modified VA and SA was determined to be 12% and 15%, respectively.

5. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.L.; Bao, J.W.; Zhang, P.; Sun, Y.Q.; Cui, Y.F. A state-of-the-art review on the durability of seawater coral aggregate concrete exposed to marine environment. J. Build. Eng. 2022, 60, 105199. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Lin, H.W. Constitutive relations of coral aggregate concrete under uniaxial and triaxial compression. Constr. Build. Mater. 2020, 251, 118957. [Google Scholar] [CrossRef]

- Liu, G.P.; Zhang, Y.; Liu, B.; Sun, J.; Li, W.Y.; Cui, L. Bone regeneration in a canine cranial model using allogeneic adipose derived stem cells and coral scaffold. Biomaterials 2013, 34, 2655–2664. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, K.; Thanakkasaranee, S.; Lim, I.J.; Seo, J. Calcined marine coral powders as a novel ecofriendly antimicrobial agent. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 107, 110193. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.G.; Lyu, B.C.; Zhang, Z.H.; Liu, K.W.; Xu, H.Y.; Sun, D.S. The development of coral concretes and their upgrading technologies: A critical review. Constr. Build. Mater. 2018, 187, 1004–1019. [Google Scholar] [CrossRef]

- Wu, W.J.; Wang, R.; Zhu, C.Q.; Meng, Q.S. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Dong, Z.Q.; Wang, Q. Enhancement of Bond Performance of FRP Bars with Seawater Coral Aggregate Concrete by Utilizing Ecoefficient Slag-Based Alkali-Activated Materials. J. Compos. Constr. 2022, 26, 04021059. [Google Scholar] [CrossRef]

- Zhang, B.; Cheng, Y.Z.; Zhu, H. Bond performance between BFRP bars and alkali-activated seawater coral aggregate concrete. Eng. Struct. 2023, 279, 115596. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wan, P.; Guo, S.; Ma, W. Characteristics of calcareous sand filler and its influence on physical and rheological properties of asphalt mastic. Constr. Build. Mater. 2021, 301, 124112. [Google Scholar] [CrossRef]

- Zhou, L.L.; Guo, S.C.; Zhang, Z.H.; Shi, C.J.; Jin, Z.Q.; Zhu, D.J. Mechanical behavior and durability of coral aggregate concrete and bonding performance with fi ber-reinforced polymer (FRP) bars: A critical review. J. Clean. Prod. 2021, 289, 125652. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H. Compressive stress-strain behavior of slag-based alkali-activated seawater coral aggregate concrete after exposure to seawater environments. Constr. Build. Mater. 2023, 367, 130294. [Google Scholar] [CrossRef]

- Li, F.Z.; Zhang, B.; Zhu, H.; Wang, Q.; Ji, J.H. Axial compressive behavior of GFRP-confined seawater coral aggregate concrete incorporating slag-based alkali-activated materials. Constr. Build. Mater. 2022, 347, 128437. [Google Scholar] [CrossRef]

- Da, B.; Chen, Y.; Yu, H.F.; Ma, H.Y.; Chen, D.; Wu, Z.Y.; Liu, J.W.; Li, Y.P. Preparation technology, mechanical properties and durability of coral aggregate seawater concrete in the island-reef environment. J. Clean. Prod. 2022, 339, 130572. [Google Scholar] [CrossRef]

- Cai, Y.; Ren, H.Q.; Long, Z.L.; Guo, R.Q.; Du, K.M.; Chen, S.S.; Zheng, Z.H. Comparison study on the impact compression mechanical properties of coral aggregate concrete and ordinary Portland concrete. Structures 2022, 44, 1403–1415. [Google Scholar] [CrossRef]

- Ma, H.Y.; Yue, C.J.; Yu, H.F.; Mei, Q.Q.; Chen, L.; Zhang, J.H.; Zhang, Y.D.; Jiang, X.Q. Experimental study and numerical simulation of impact compression mechanical properties of high strength coral aggregate seawater concrete. Int. J. Impact. Eng. 2020, 137, 103466. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Han, Y.; Hao, R.; Ding, X. Test and Simulation of Impact Compressive Properties of Hybrid Fiber Reinforced Coral Aggregate Concrete. J. Chin. Ceram. Soc. 2022, 50, 2897–2908. [Google Scholar]

- He, S.S.; Jiao, C.J.; Li, S. Investigation of mechanical strength and permeability characteristics of pervious concrete mixed with coral aggregate and seawater. Constr. Build. Mater. 2023, 363, 129508. [Google Scholar] [CrossRef]

- Lu, C.; Wu, H.; Shi, M. Laboratory tests of cement stabilized & solidified coral reef and sand for use of highway pavement. J. Eng. Geol. 2019, 27, 1440–1447. [Google Scholar]

- Zeng, Z.J.; Miao, C.W.; Shi, M.L.; Zhang, R.K.; Xu, Y.F. Study on the dense structure and properties of cement-stabilized coral aggregates. Constr. Build. Mater. 2022, 359, 129465. [Google Scholar] [CrossRef]

- Geng, J.G.; Chen, M.Y.; Shang, T.; Xue, C.; Chen, H.X.; Zhang, C. The Influence of an Expansive Agent on the Performance of Cement-Stabilized Coral Sand. Adv. Civ. Eng. 2021, 10, 8830070. [Google Scholar] [CrossRef]

- Sun, X.L.; Qin, X.; Liu, Z.S.; Yin, Y.M.; He, S.H. New evaluating method and case study of thermal stability for asphalt pavement functional paving materials. Constr. Build. Mater. 2019, 228, 117067. [Google Scholar] [CrossRef]

- Zhang, C.; Tan, Y.Q.; Gao, Y.M.; Fu, Y.K.; Li, J.L.; Li, S.; Zhou, X.Y. Resilience assessment of asphalt pavement rutting under climate change. Transport. Res. Pt. D Transport. Environ. 2022, 109, 103395. [Google Scholar] [CrossRef]

- Gong, F.; Cheng, X.; Fang, B.; Cheng, C.; Liu, Y.; You, Z. Prospect of 3D printing technologies in maintenance of asphalt pavement cracks and potholes. J. Clean. Prod. 2023, 387, 136551. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H.N.; Chen, X.; Yang, X.; You, Z.P.; Dong, S.; Gao, J.F. Shear property, high-temperature rheological performance and low-temperature flexibility of asphalt mastics modified with bio-oil. Constr. Build. Mater. 2018, 174, 30–37. [Google Scholar] [CrossRef]

- Wang, H.; Jing, Y.F.; Zhang, J.P.; Cao, Y.B.; Lyu, L. Preparation and performance evaluation of swine manure bio-oil modified rubber asphalt binder. Constr. Build. Mater. 2021, 294, 123584. [Google Scholar] [CrossRef]

- Zhou, T.; Dong, Z.; Wang, P.; Yang, C.; Luan, H. Incorporating chemical acids to react with bio-oil: Hydrophobicity improvement and effect on the moisture susceptibility of bio-binder. Constr. Build. Mater. 2020, 255, 119402. [Google Scholar] [CrossRef]

- Gao, J.F.; Wang, H.N.; Liu, C.C.; Ge, D.D.; You, Z.P.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Lv, S.T.; Xia, C.D.; Yang, Q.; Guo, S.C.; You, L.Y.; Guo, Y.P.; Zheng, J.L. Improvements on high-temperature stability, rheology, and stiffness of asphalt binder modified with waste crayfish shell powder. J. Clean. Prod. 2020, 264, 121745. [Google Scholar] [CrossRef]

- Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt. Appl. Sci. 2018, 8, 415. [Google Scholar] [CrossRef] [Green Version]

- Ashan, M.H.; Siddique, M.S.; Farooq, S.H.; Usman, M.; Ul Aleem, M.A.; Hussain, M.; Hanif, A. Mechanical behavior of high-strength concrete incorporating seashell powder at elevated temperatures. J. Build. Eng. 2022, 50, 104226. [Google Scholar] [CrossRef]

- Peceno, B.; Arenas, C.; Alonso-Farinas, B.; Leiva, C. Substitution of Coarse Aggregates with Mollusk-Shell Waste in Acoustic-Absorbing Concrete. J. Mater. Civ. Eng. 2019, 31, 04019077. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Wu, S.; Jiang, Q.; Xu, H.; Zhao, Z.; Lv, Y. Effects of waterborne polyurethane on storage stability, rheological properties, and VOCs emission of crumb rubber modified asphalt. J. Clean. Prod. 2022, 340, 130682. [Google Scholar] [CrossRef]

- Zhou, L.L.; Guo, S.C.; Ma, W.B.; Xu, F.; Shi, C.J.; Yi, Y.; Zhu, D.J. Internal curing effect of saturated coral coarse aggregate in high-strength seawater sea sand concrete. Constr. Build. Mater. 2022, 331, 127280. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Salih, N.R. Application of eggshell wastes for boron remediation from water. J. Mol. Liq. 2018, 256, 599–610. [Google Scholar] [CrossRef]

- Ahmed, N.S.; Kamil, F.H.; Hasso, A.A.; Abduljawaad, A.N.; Saleh, T.F.; Mahmood, S.K. Calcium carbonate nanoparticles of quail’s egg shells: Synthesis and characterizations. J. Mech. Behav. Mater. 2022, 31, 1–7. [Google Scholar] [CrossRef]

- Fan, L.; Yang, M. Charecteristics of FTIR spectra of biogenic calcites in precious red coral. J. Mineral. Petrol. 2010, 30, 21–24. [Google Scholar]

- Kaczorowska, B.; Hacura, A.; Kupka, T.; Wrzalik, R.; Talik, E.; Pasterny, G.; Matuszewska, A. Spectroscopic characterization of natural corals. Anal. Bioanal. Chem. 2003, 377, 1032–1037. [Google Scholar] [CrossRef] [PubMed]

- Gangopadhyay, A.; Sarkar, A.; Sarkar, A. A study on natural coral stone-a fractal solid. Appl. Phys. A Mater. 2012, 109, 979–983. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, X.; Ji, G.; Zhang, Y.; Su, H.; Luo, Y. Effect of Recycled Shell Waste as a Modifier on the High- and Low-Temperature Rheological Properties of Asphalt. Sustainability 2021, 13, 10271. [Google Scholar] [CrossRef]

- Fan, G.; Liu, H.; Liu, C.; Xue, Y.; Ju, Z.; Ding, S.; Zhang, Y.; Li, Y. Analysis of the Influence of Waste Seashell as Modified Materials on Asphalt Pavement Performance. Materials 2022, 15, 6788. [Google Scholar] [CrossRef]

- AASHTO T49; Standard Method of Test for Penetration of Bituminous Materials. AASHTO Standards: Washington, DC, USA, 2015.

- AASHTO T53; Standard Method of Test for Softening Point of Bitumen (Ring-and-Ball Apparatus). AASHTO Standards: Washington, DC, USA, 2011.

- AASHTO T 300; Standard Method of Test for Force Ductility Test of Asphalt Materials. AASHTO Standards: Washington, DC, USA, 2011.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixture for Highway Engineering. Ministry of Communications of People’s Republic of China: Beijing, China, 2011.

- AASHTO T 316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. AASHTO Standards: Washington, DC, USA, 2019.

- AASHTO T 315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO Standards: Washington, DC, USA, 2010.

- AASHTO T 350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO Standards: Washington, DC, USA, 2019.

- Meng, F.; Ma, S.Y.; Muhammad, Y.; Li, J.; Sahibzada, M.; Chi, F.X. Analysis of Virgin Asphalt Brands via the Integrated Application of FTIR and Gel Permeation Chromatography. Arab. J. Sci. Eng. 2020, 45, 7999–8009. [Google Scholar] [CrossRef]

- Liu, L.; Cheng, H.; Sun, L.; Xu, L. Quantifying physical and rheological properties of trichloroethylene-asphalt system to improve performance evaluation of recycled asphalt. J. Clean. Prod. 2022, 367, 133018. [Google Scholar] [CrossRef]

- Lv, S.T.; Hu, L.; Xia, C.D.; Cabrera, M.B.; Guo, Y.P.; Liu, C.C.; You, L.Y. Recycling fish scale powder in improving the performance of asphalt: A sustainable utilization of fish scale waste in asphalt. J. Clean. Prod. 2021, 288, 125682. [Google Scholar] [CrossRef]

- Duan, S.C.; Muhammad, Y.; Li, J.; Maria, S.; Meng, F.; Wei, Y.H.; Su, Z.B.; Yang, H.Q. Enhancing effect of microalgae biodiesel incorporation on the performance of crumb Rubber/SBS modified asphalt. J. Clean. Prod. 2019, 237, 117725. [Google Scholar] [CrossRef]

- Yan, K.Z.; Chen, J.H.; You, L.Y.; Tian, S. Characteristics of compound asphalt modified by waste tire rubber (WTR) and ethylene vinyl acetate (EVA): Conventional, rheological, and microstructural properties. J. Clean. Prod. 2020, 258, 120732. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Ren, R.B.; Han, K.C.; Zhao, P.H.; Shi, J.T.; Zhao, L.; Gao, D.X.; Zhang, Z.Y.; Yang, Z.Q. Identification of asphalt fingerprints based on ATR-FTIR spectroscopy and principal component-linear discriminant analysis. Constr. Build. Mater. 2019, 198, 662–668. [Google Scholar] [CrossRef]

- Hou, X.D.; Lv, S.T.; Chen, Z.; Xiao, F.P. Applications of Fourier transform infrared spectroscopy technologies on asphalt materials. Measurement 2018, 121, 304–316. [Google Scholar] [CrossRef]

- Xu, S.; Fan, Y.; Feng, Z.G.; Ke, Y.B.; Zhang, C.L.; Huang, H.Y. Comparison of quantitative determination for SBS content in SBS modified asphalt. Constr. Build. Mater. 2021, 282, 122733. [Google Scholar] [CrossRef]

- Zhang, D.M.; Zhang, H.L.; Shi, C.J. Investigation of aging performance of SBS modified asphalt with various aging methods. Constr. Build. Mater. 2017, 145, 445–451. [Google Scholar] [CrossRef]

- Lin, P.; Huang, W.D.; Li, Y.; Tang, N.P.; Xiao, F.P. Investigation of influence factors on low temperature properties of SBS modified asphalt. Constr. Build. Mater. 2017, 154, 609–622. [Google Scholar] [CrossRef]

- Liao, M.C.; Chen, J.S.; Airey, G.D.; Wang, S.J. Rheological behavior of bitumen mixed with Trinidad Lake asphalt. Constr. Build. Mater. 2014, 66, 361–367. [Google Scholar] [CrossRef]

- Zhou, X.X.; Adhikari, S. Flow-induced crystallization of biochar in bio-asphalt under various aging conditions. Sci. Total. Environ. 2019, 695, 133943. [Google Scholar] [CrossRef]

| Test Items | Penetration 25 °C/0.1 mm | Softening Point/°C | Ductility (5 cm/min, 10 °C)/cm |

|---|---|---|---|

| Technical indicators (Grade A) | 60~80 | ≥45 | ≥15 |

| VA | 75.8 | 47.9 | 36.1 |

| Test Items | Penetration 25 °C/0.1 mm | Softening Point/°C | Ductility 5 cm/min, 5 °C/cm |

|---|---|---|---|

| Technical indicators (Class I) | ≥40 | ≥60 | ≥20 |

| SA | 64.10 | 77.7 | 58.6 |

| CP Content (%) | 0 | 9 | 12 | 15 | 18 |

|---|---|---|---|---|---|

| virgin asphalt | VA | VAC9 | VAC12 | VAC15 | VAC18 |

| SBS-modified asphalt | SA | SAC9 | SAC12 | SAC15 | SAC18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Fang, B.; Hu, H.; Gong, F.; Cheng, X.; Liu, Y. Properties and Microcosmic Mechanism of Coral Powder Modified Asphalt in Offshore Islands and Reefs Construction. Sustainability 2023, 15, 12393. https://doi.org/10.3390/su151612393

Chen Y, Fang B, Hu H, Gong F, Cheng X, Liu Y. Properties and Microcosmic Mechanism of Coral Powder Modified Asphalt in Offshore Islands and Reefs Construction. Sustainability. 2023; 15(16):12393. https://doi.org/10.3390/su151612393

Chicago/Turabian StyleChen, Yi, Bingjie Fang, Haixiao Hu, Fangyuan Gong, Xuejiao Cheng, and Yu Liu. 2023. "Properties and Microcosmic Mechanism of Coral Powder Modified Asphalt in Offshore Islands and Reefs Construction" Sustainability 15, no. 16: 12393. https://doi.org/10.3390/su151612393