6.1. Discussion and Policy Recommendations

In this paper, in addition to the impact of the MI on PM

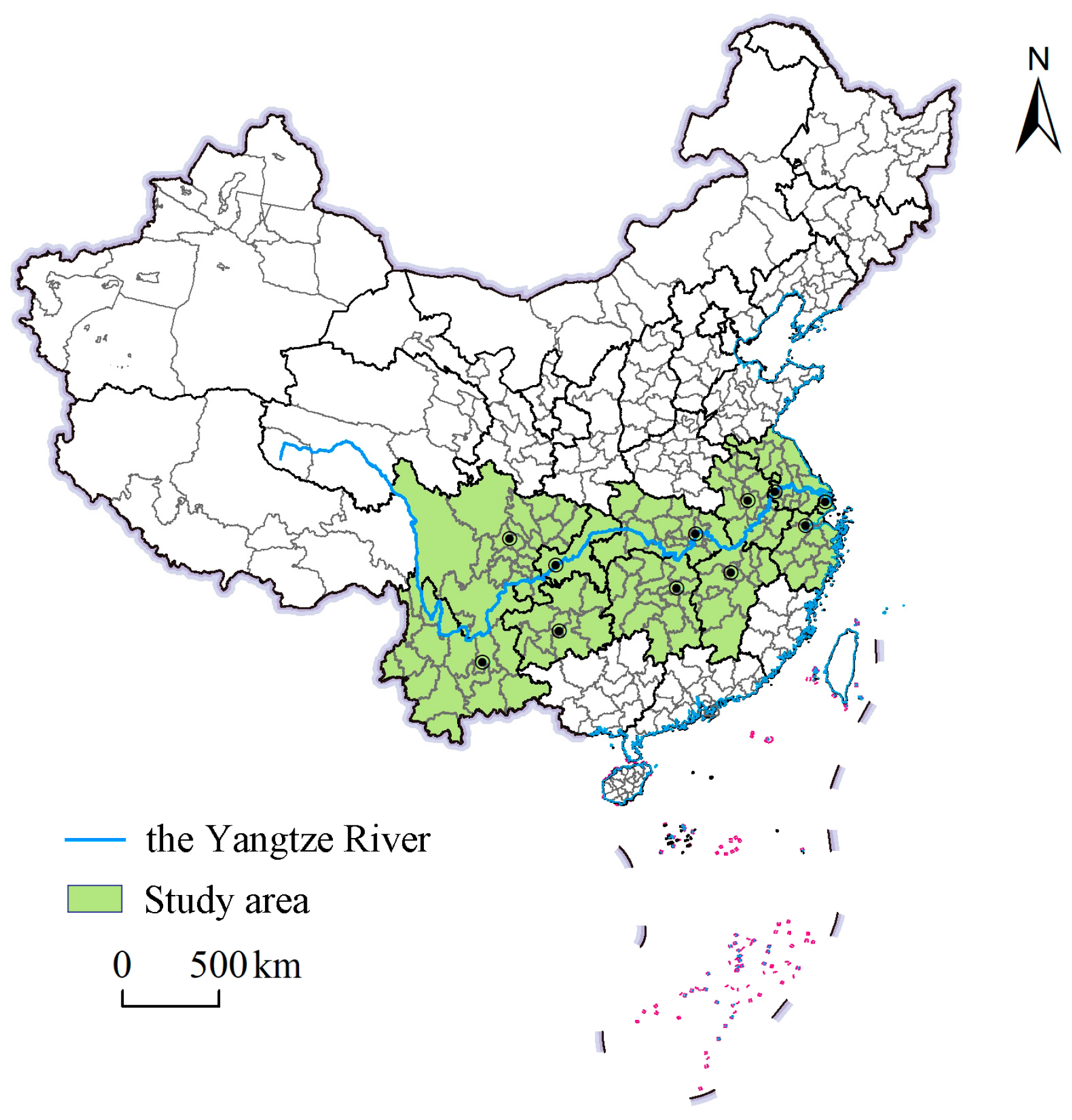

2.5 based on perspective space overflow, the spatial pattern characteristics in the MI in the YERB are probed from multiple perspectives. This not only serves as a useful supplement to the study on the environmental effect of industrial agglomeration but also an empirical test to explore the development pattern in the MI in the YREB and its environmental effect with certain theoretical and empirical value. According to our research conclusions, during the development of the MI in the YREB, an industrial pattern of “the lower reaches are higher than the middle and upper reaches, and the central cities are higher than the surrounding areas” was formed with significant agglomeration characteristics presented in the spatial distribution. The research results in this paper are consistent with the research conclusions of related scholars on Greece [

49], Spain, and China’s Pearl River Delta [

50,

51]. This paper comes to certain scientific and universal conclusions. On the one hand, the reasons for this result may be related to the regional characteristics of the Yangtze River Economic Belt. There are significant differences in the economic and social development of the Yangtze River Economic Belt. The development foundation of the central cities in the lower reaches and the middle and upper reaches of the Yangtze River Economic Belt is significantly higher than that in other regions, and they are more attractive to the manufacturing industry. On the other hand, the results may be related to the industrial characteristics of the manufacturing industry, which develops with the development of the industrial division of labor, while the central cities or core areas of the Yangtze River Economic Belt can communicate easier with the surrounding cities and form scale effects with the division of labor and cooperation with the surrounding cities, thus forming the spatial agglomeration and distribution pattern of the MI. The exchanges among various R&D institutions and different researchers will also be facilitated by the spatial proximity and agglomeration of the MI, forming a learning effect. The spatial agglomeration distribution is also characteristic of other industries such as the digital industry [

52], logistics industry [

53], aviation industry, etc., in addition to the MI, whose geographical pattern has a certain economic and social orientation [

54]. Renewable energy and other industries also show agglomeration distribution characteristics but in close relation to spatial distribution patterns with the natural environment, resource endowment, and other factors, varying from the MI [

55].

Based on empirical analysis, we determined that the environmental effects of air pollution exerted by the manufacturing agglomeration verify the research conclusion of Jones [

56] and were basically consistent with the research results of Cheng et al. (2016) [

57], indicating that the research conclusion of this study is scientific to some extent while reflecting the complexity and urgency of transforming industries into ecological, green, and high-end industries in the YREB. On the one hand, the spatial agglomeration of the MI is usually accompanied by the spatial agglomeration of population and economic production, increasing regional energy consumption and pollutant emission as well as environmental pressure. On the other hand, the MI is the main sector for consumption of production factors such as resources and energy. which covers many energy-intensive and pollution-intensive industries. Along with the development of the MI, the expanding industrial scale will reduce the cost of pollution control by leveraging the strengths of infrastructure utilization and developing a circular economy [

58]. Moreover, the empirical analysis results of this paper are different from the conclusions of previous studies on the nonlinear relationship between the agglomeration of the MI and air pollution, that is, the agglomeration of MI can indirectly reduce regional air pollution with technological innovation and other paths [

37]. On the one hand, the reasons for this phenomenon may be related to the regional characteristics of the YREB. Compared with other regions, the Yangtze River Economic Belt enjoys a more concentrated population and industries, although the region is facing a typical problem, namely, the environmental pollution caused by industrial development. On the other hand, although the YREB, especially the Yangtze River Delta region, is a relatively active area of technological innovation in China, it is still haunted by problems such as imperfect environmental supervision and insufficient transformation mechanisms underlying innovation achievements. Improving the technological innovation level may also expand the production scale, produce rebound effect, and increase the emission of regional pollutants.

The results of this paper are also significant in the aspect of policy. Based on the empirical analysis, the policy proposals are as follows:

(1) Construct a green manufacturing cluster and improve the quality of industrial agglomeration. On the one hand, with reasonable planning and active guidance, similar industries and pollution-intensive manufacturing industries associated with the previous and the following items are promoted for gathering in the same industrial park. The production costs, transaction costs, and energy consumption of pollution-intensive manufacturing industries are reduced by the external effects of industrial agglomeration, such as economies of scale, factor resource sharing, knowledge spillover, and infrastructure sharing. On the other hand, different taxes, such as carbon tax, energy tax, and environmental tax, are set for different types of MI to optimize the interest balance mechanism between different industries, enterprises, and interest subjects, and incorporate market-oriented operation mechanisms, economic incentive mechanisms, and public supervision mechanisms into the pollution industry management system, thus promote the ecological level of the industry. In addition, for the key ecological functional areas of the YREB, a negative list system must be established for industrial access, prohibiting the entry of industries with high pollution, high energy consumption, and high emissions, and guiding the green development of industries. For the central cities in the lower reaches of the YREB and the middle and upper reaches of the YREB, we suggest building influential high-tech industrial parks and cultivating green and low-carbon, high-tech industrial clusters on the basis of industrial development, giving full play to the advantages of science and education resources. For the middle and upper reaches of the YREB, we recommend speeding up the transformation of traditional industries such as steel, nonferrous metals, and textiles, eliminating backward production capacity, and promoting the development of clean industries.

(2) Construct an industrial “service-manufacturing” integrated development platform and strengthen the degree of industrial synergy. On the one hand, for downstream areas with relatively complete industrial development systems, we recommend improving market-supporting facilities, improving the development level of producer services such as commercial leasing services, information and communication industries, and modern logistics industries, improving service quality, and promoting the further integration of producer services and manufacturing industries. For the middle and upper reaches of the YREB, we recommend developing advanced manufacturing industries, such as new energy and new materials, and developing supporting services based on local industrial advantages. On the other hand, taking the large gap in the development of the MI within the studied area into account, it is necessary to actively plan and guide regions to coordinated development and the linkage mechanism. The “service-manufacturing” integrated development platform for local industries is supposed to comprehensively develop the integrated development platform of the industry with several neighboring regions as the main body. Meanwhile, promoting the free flow of production factors in different regions along with the changes in market demand, breaking the regional barriers between different industries, and driving the industrial upgrading process in neighboring areas through the development of MI in central cities are also on the proposal list.

(3) Actively foster open industries based on regional advantages and scientific and technological potential. On the one hand, attention should be paid to investing in talent, capital, and technology, attracting experts and scholars in the field of ecological civilization construction, carrying out regular personnel exchange activities, cultivating professional environmental talents, further propelling the cooperation between industries and optimizing the functions of the industry, and driving the intelligent transformation of industrial parks. On the other hand, for the coastal areas in the lower reaches of the YREB, we suggest actively developing the export-oriented economy, strengthening internal and external cooperation, actively investing in the scientific research costs in the development process for the export-oriented economy, achieving self-breakthrough, promoting the application of low-carbon and circular technologies using the sharing mechanism of industrial agglomeration and technology spillover effect, and optimizing the process flow. For the middle and upper reaches of the YREB, we recommend actively learning from the development experience of the downstream coastal areas, vigorously developing modern information technologies such as the digital economy and artificial intelligence, building innovation platforms, adjusting backward production capacity with core energy-saving technologies, and improving industrial production efficiency.

However, some shortcomings also exist in this research. Firstly, the mediation effect model is not used to discuss the influence path of the MI on PM2.5. Secondly, producer services play an important role in the geographic pattern of industrial development, providing intermediate products and services for the manufacturing industry and promoting efficient production. The collaborative agglomeration of two industries is more conducive to identifying the scale effect of industrial agglomeration. Therefore, in future studies, the focus will be on the spatial pattern of collaborative agglomeration, as well as its economic and environmental effects.

6.2. Main Conclusions

To explore the environmental effects of the manufacturing industry on PM2.5, an econometric model was established based on describing the characteristics of the spatial agglomeration pattern, spatial agglomeration level, and spatial agglomeration difference in the MI for the data on micro-enterprises, with research conclusions drawn as follows:

(1) The kernel density in the MI increases gradually, showing a geographically centralized distribution in space. The kernel density in the downstream region is higher than that in the middle and upper reaches, and that in the central city is higher than that in the surrounding cities. In the periphery of the central city, the kernel density values show a trend of distance attenuation based on the distance from the central city.

(2) The MI presents a significant spatial agglomeration feature, and its subdivision industry has a significant spatial agglomeration that is gradually increasing. Different industries vary in concentration levels, and the concentration level of technology-intensive MIs is higher than that of capital-intensive and labor-intensive MIs. The Gini coefficient for the whole basin area and its sub-regions is declining, and the regional differences gradually decrease, which indicates that the coordinated development in the basin has been in certain progress in recent years. In addition, there are still large differences between the upper, middle, and lower reaches in the MI, and coordinated development needs to be further promoted.

(3) There is a significant positive correlation between the MI and PM2.5 pollution. An increase in the number of manufacturing enterprises may lead to the geographic concentration of polluting industries, resulting in the congestion effect and further aggravating regional air pollution. In addition, the influence of lnMI on PM2.5 is not limited to local areas, and PM2.5 pollution in a local city may be influenced by neighboring cities. From the perspective of the heterogeneity analysis, the influence of MI on PM2.5 in the downstream region is not significant, reflecting gradual improvement in the development level and resource allocation efficiency of the MI in the region in recent years, as well as the continuous enhancement in intensive pollution emission control ability. The conclusions of this study in the upper and middle reaches are consistent with the overall study area.