Potential of Using Waste Materials in Flexible Pavement Structures Identified by Optimization Design Approach

Abstract

:1. Introduction

- -

- Reduction in costs associated with disposal.

- -

- Preservation of landfill capacity.

- -

- Conservation of mined natural resources.

- -

- Reduction in environmental and ecological impacts.

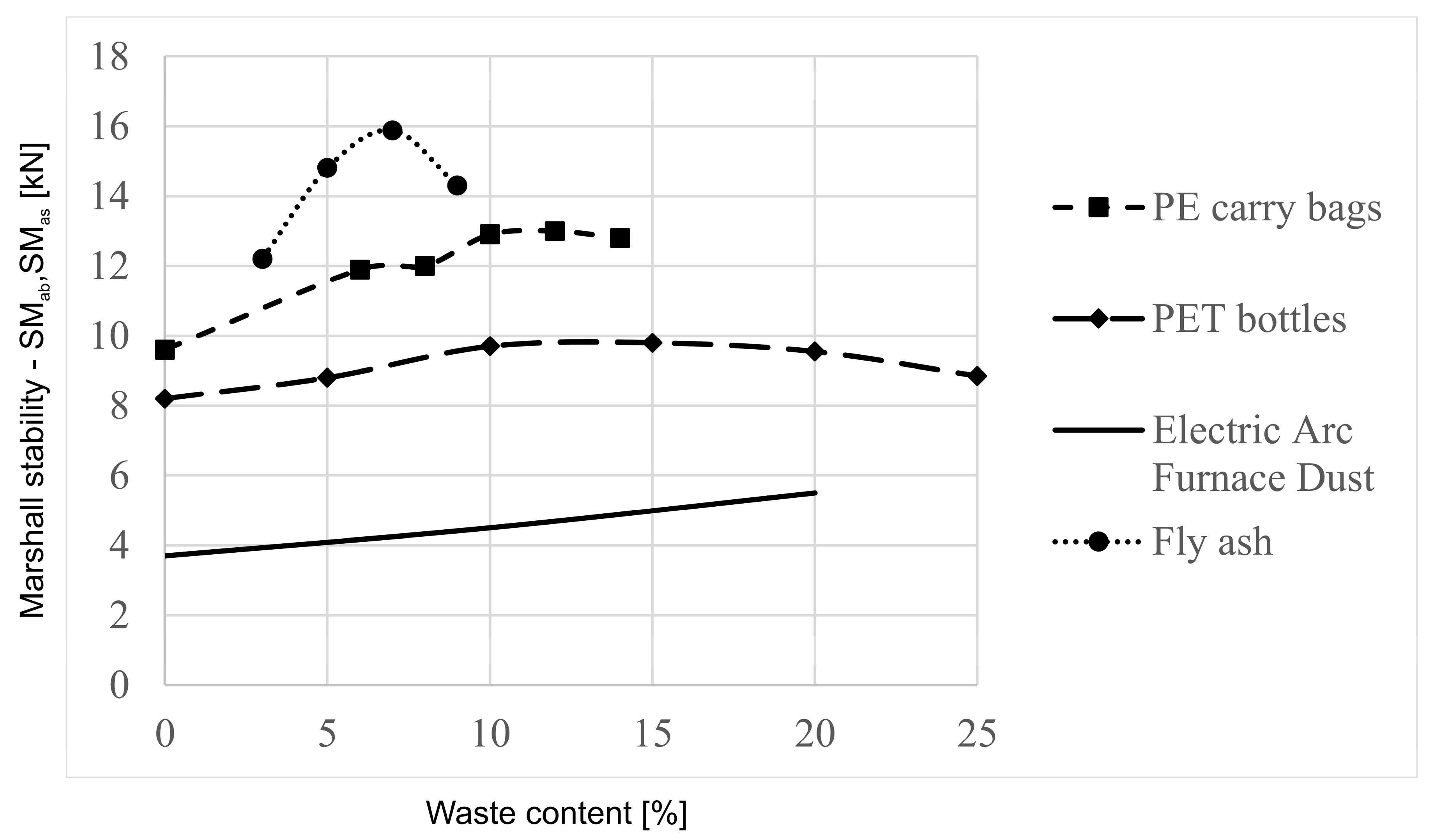

2. The Performance of Asphalt and Unbound Layers Containing Waste Materials

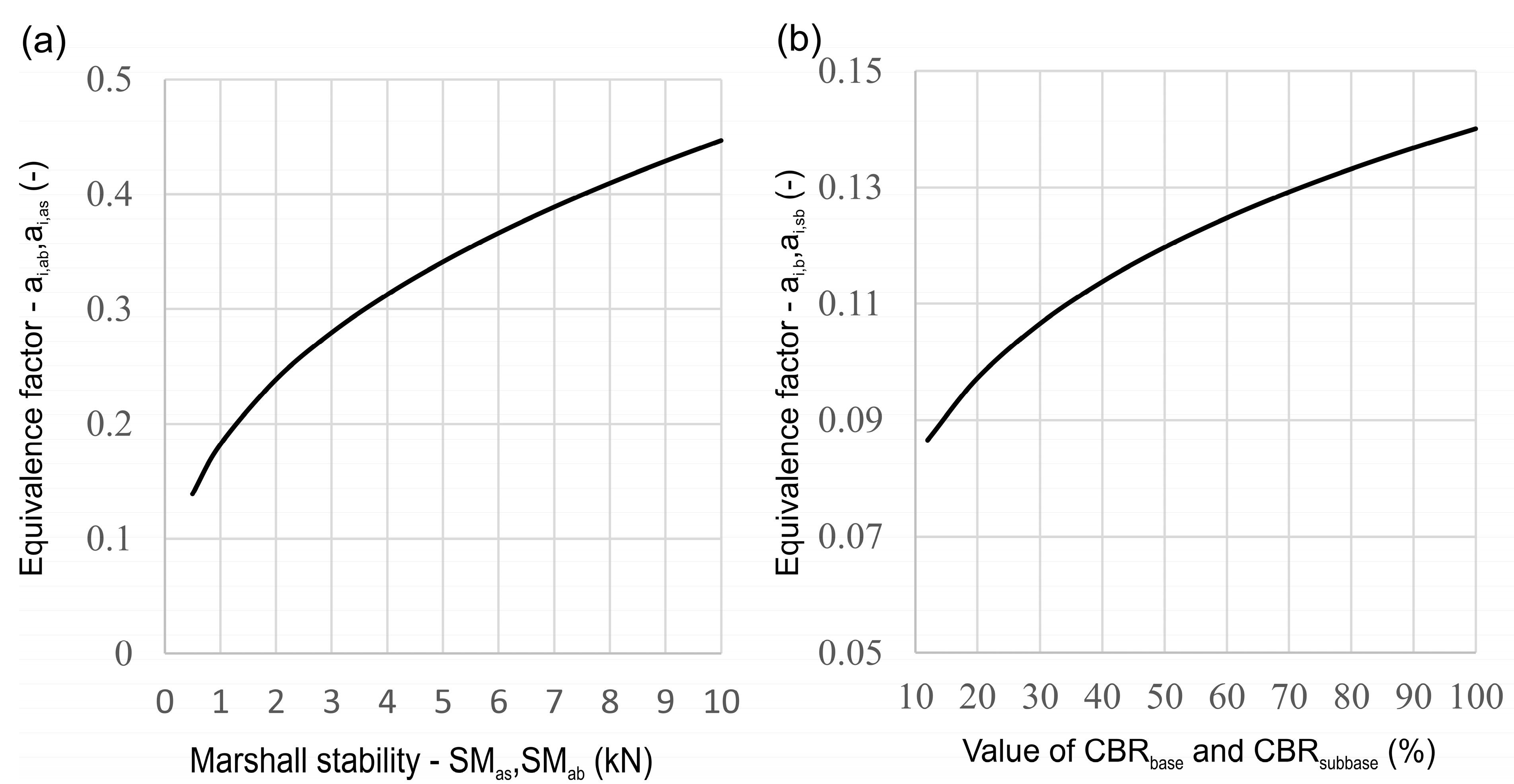

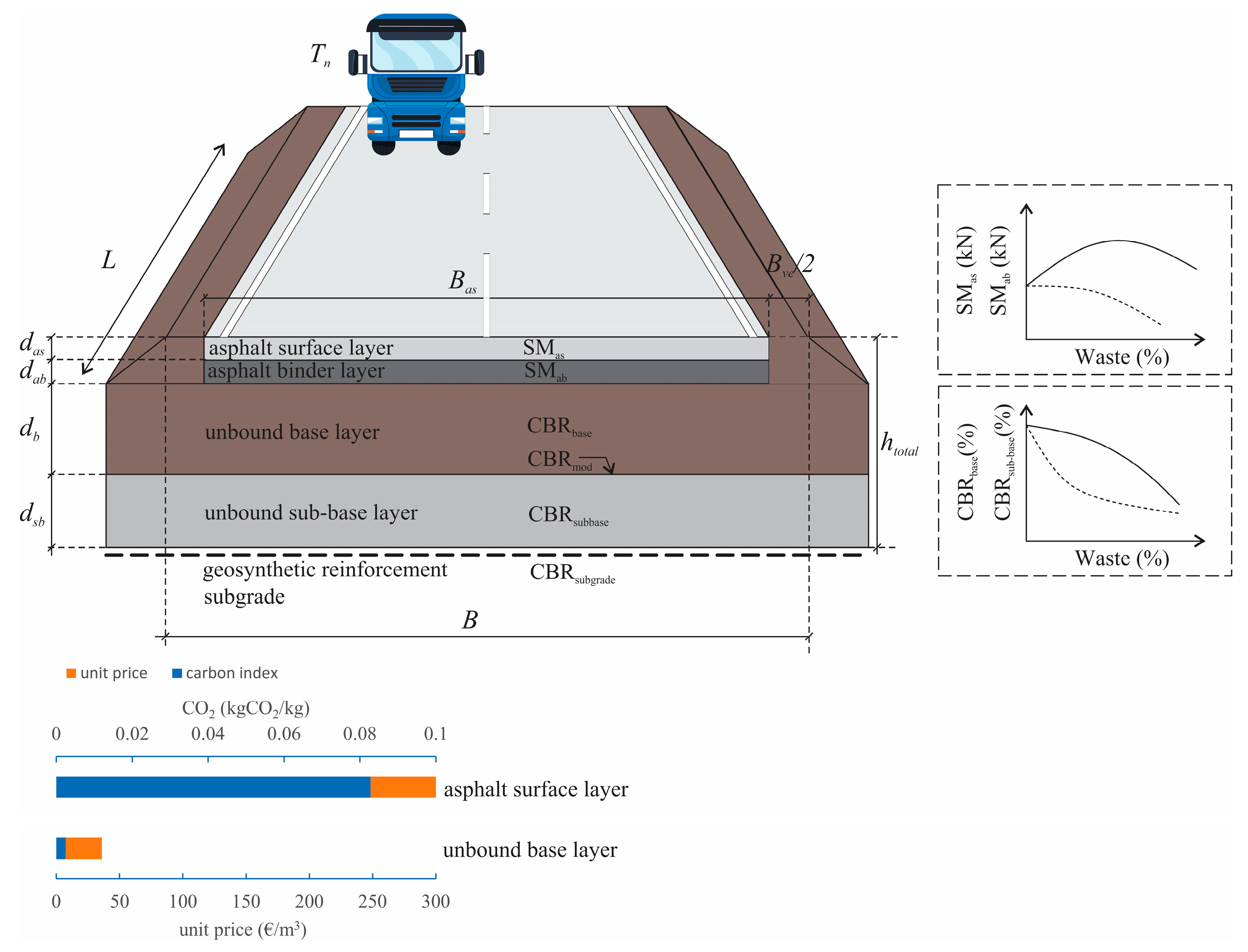

3. Optimization Model of Pavement Structure

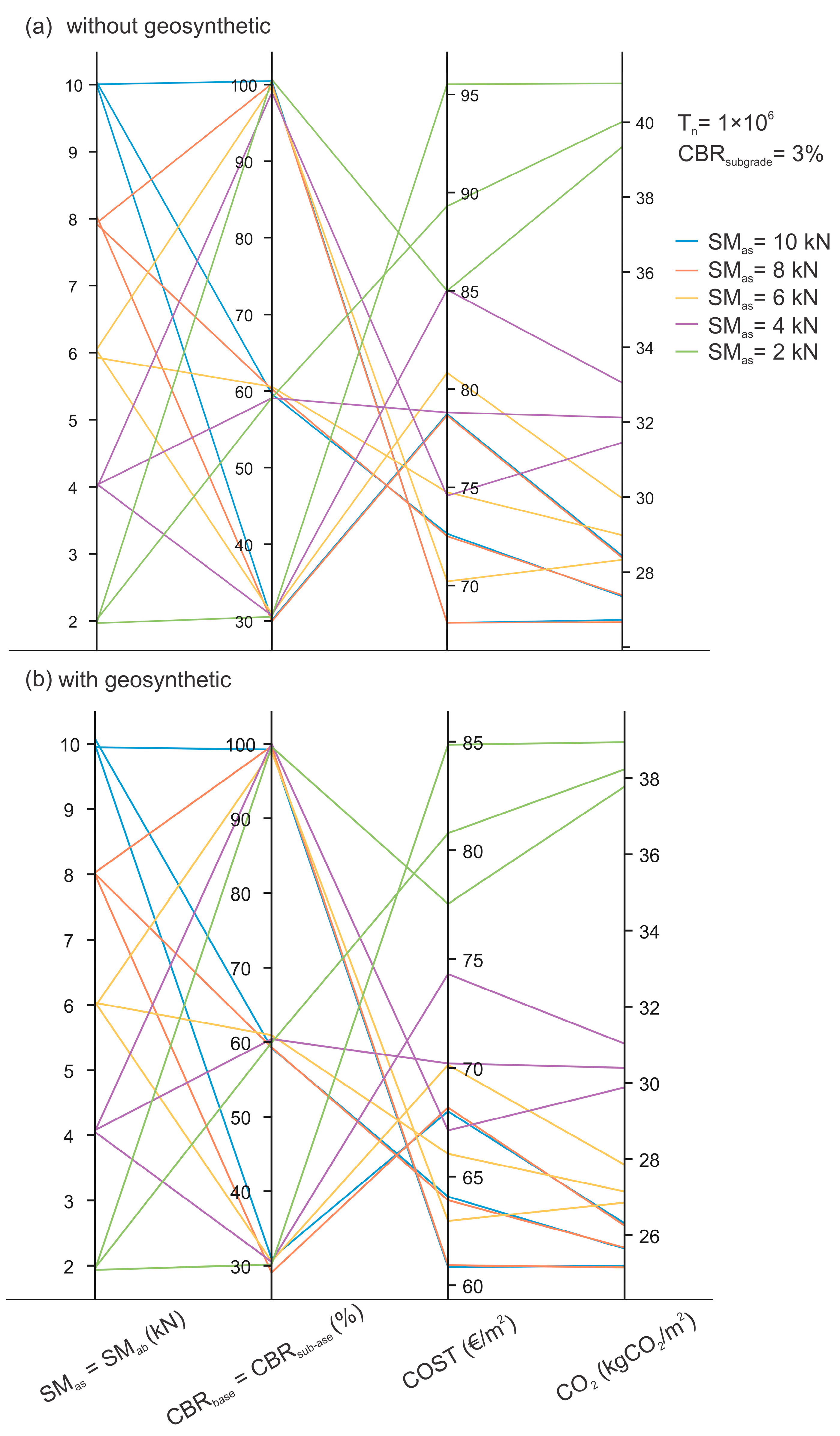

4. Multi Parametric Optimization

- -

- Total number of ESALs: Tn (1 × 104; 1 × 105; 1 × 106; 1 × 107; 1 × 107).

- -

- California Bearing Ratio of subgrade: CBR (3%; 4%; 5%; 6%; 7%).

- -

- Marshall stability of asphalt layers: SMas = SMab (2 kN; 4 kN; 6 kN; 8 kN; 10 kN).

- -

- California Bearing Ratio of unbound layers: CBRbase = CBRsubbase (100%; 60%; 30%).

5. Conclusions

- -

- For the most unfavorable design parameters examined in the parametric analysis, the thickness of the unbound layers increased from 91 cm to 120 cm (32% increase in thickness) when the CBR value of the base and sub-base layers decreased from 100% to 30%.

- -

- For the most unfavorable design parameters examined in the parametric analysis, the thickness of the asphalt layer increased from 36 cm to 58 cm (61% increase in thickness) when the Marshall stability value of the asphalt layer decreased from 10 kN to 2 kN.

- -

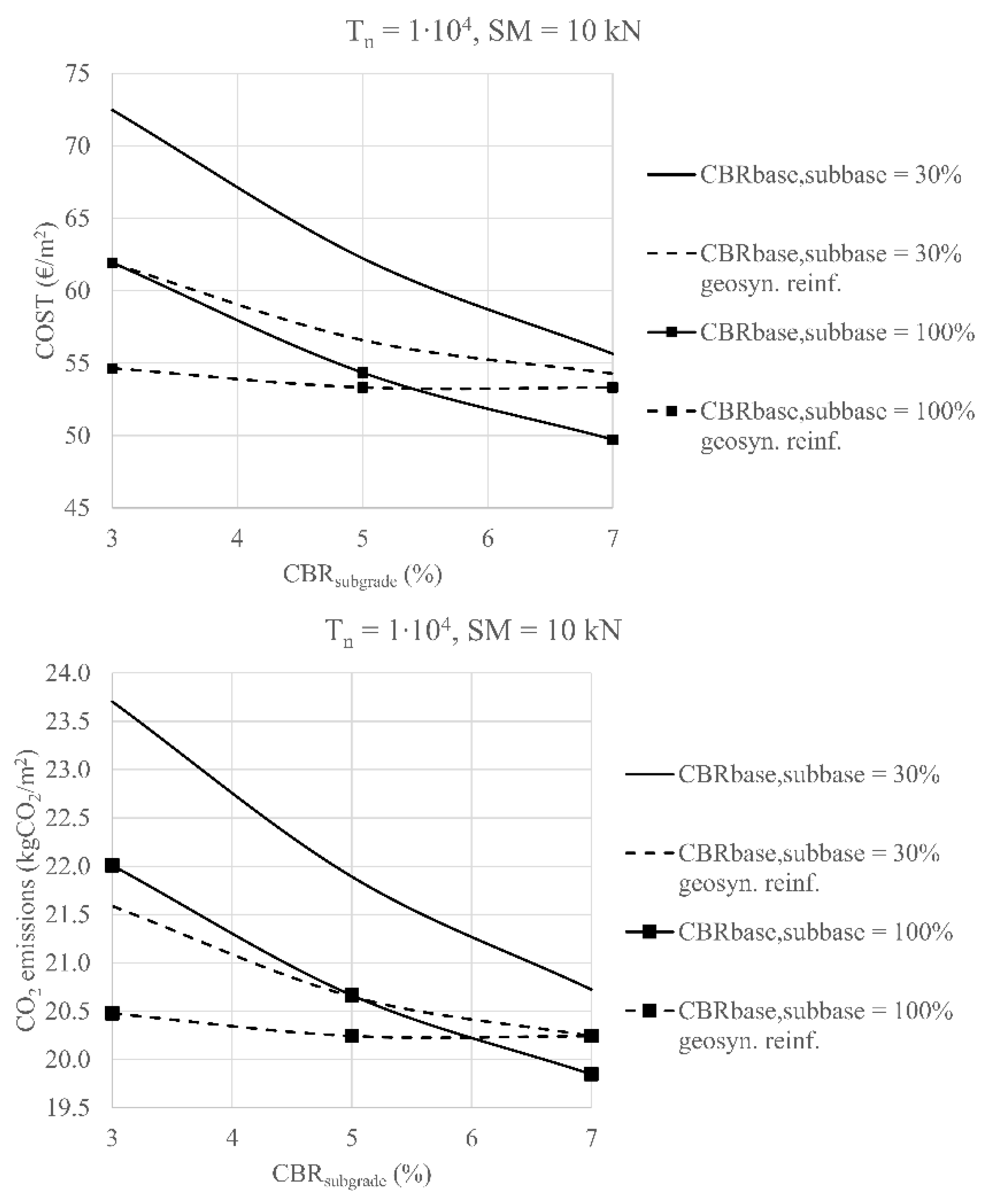

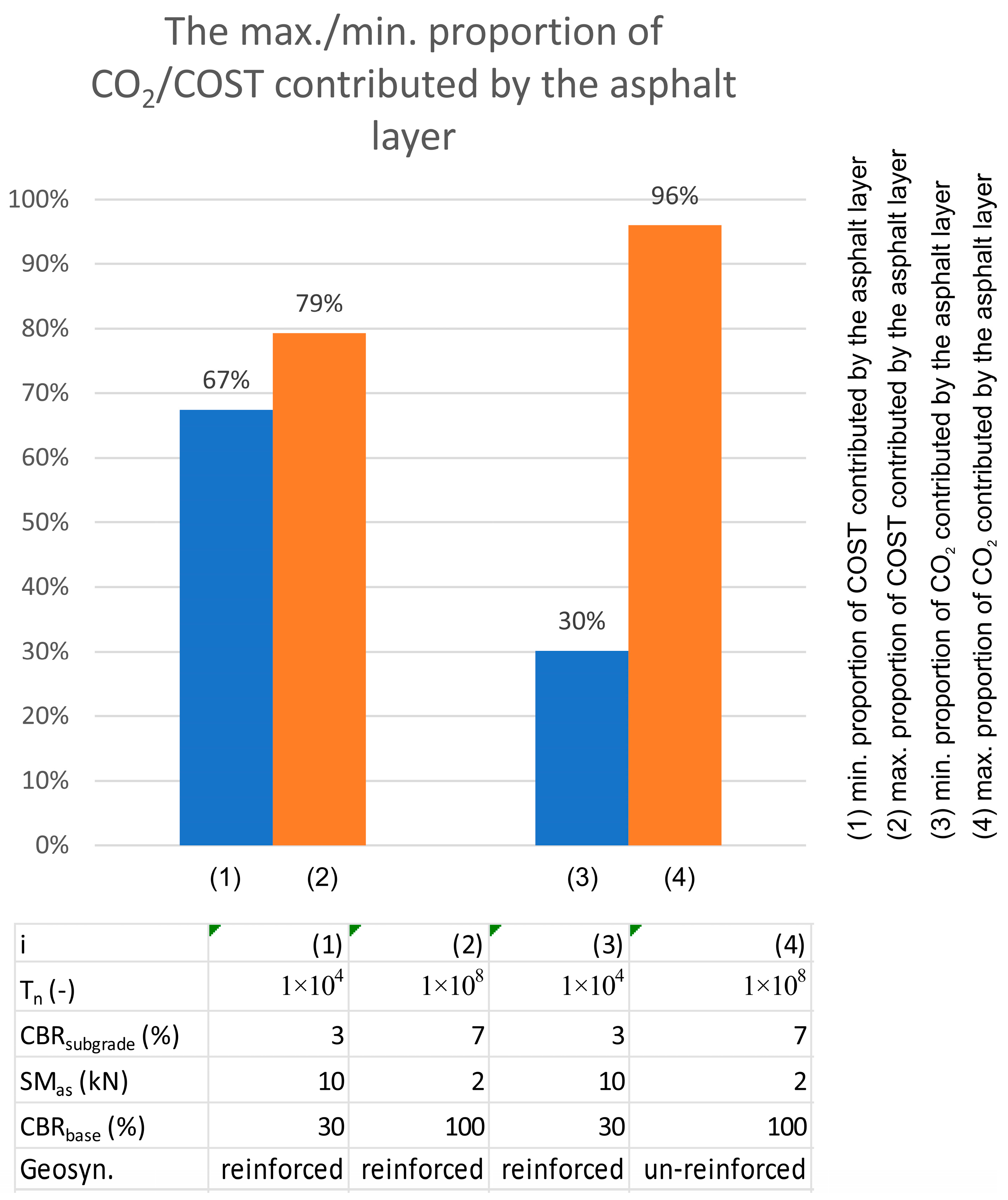

- The analysis shows that the proportion of CO2 emissions caused by asphalt layers can vary from 30% to 96% depending on the design parameters, while the proportion of costs caused by asphalt layers only ranges from 67% to 79% for the same design parameters. This is due to the fact that the ratio of CO2 emissions between the asphalt layer and the unbound layer is higher than the ratio of prices.

- -

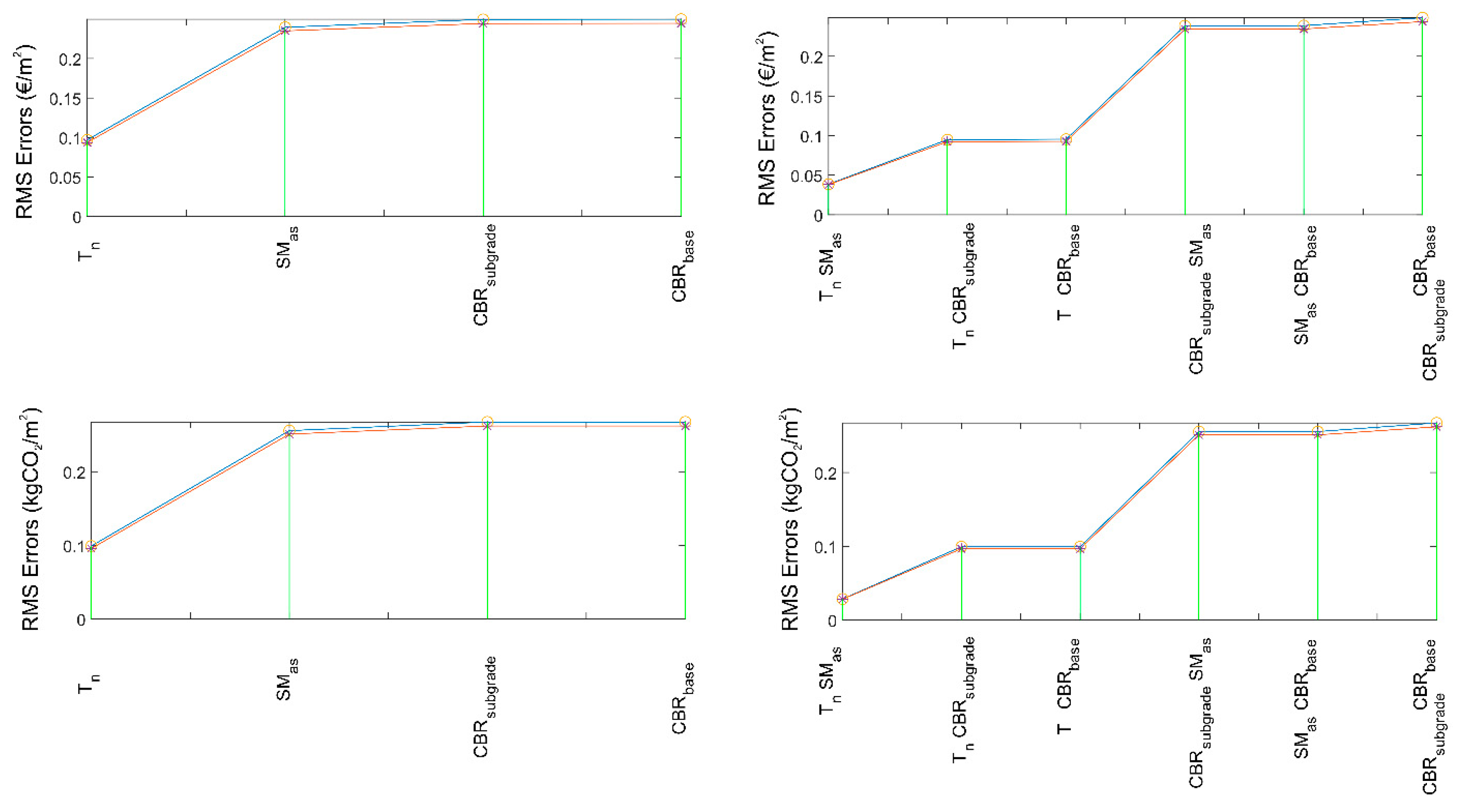

- The results of the parametric analysis show that the total number of ESALs (Tn) is the most important parameter for achieving the optimal cost of a pavement structure. This is followed by the Marshall stability (SM), the CBR value of the subgrade (CBRsubgrade), and the CBR value of the unbound layers (CBRbase = CBRsubbase) in terms of their importance.

- -

- The use of geosynthetics could result in a 15% reduction in pavement structure cost and a 9% reduction in CO2 emissions due to the reduced thickness of unbound layers. However, the use of geosynthetics could also result in an increase in road pavement structure cost and CO2 emissions under favorable site conditions (e.g., with a CBR subgrade of 7%).

- -

- The empirical design method for pavements limits the Marshall stability to approximately 10 kN, although the stability of asphalt concrete could be higher. Therefore, the mechanical-empirical design method could further improve the optimization model by considering even larger Marshall stability values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hale, S.E.; Roque, A.J.; Okkenhaug, G.; Sørmo, E.; Lenoir, T.; Carlsson, C.; Kupryianchyk, D.; Flyhammar, P.; Žlender, B. The Reuse of Excavated Soils from Construction and Demolition Projects: Limitations and Possibilities. Sustainability 2021, 13, 6083. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Bassey, D.E.; Olukanni, D.O.; Ngene, B.U.; Adegoke, D.; Odetoyan, A.O.; Kareem, M.A.; Enabulele, D.O.; Nworgu, A.T. Waste materials in highway applications: An overview on generation and utilization implications on sustainability. J. Clean. Prod. 2021, 283, 124581. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Patel, S.; Pai, R.R.; Bakare, M.D.; Shahu, J.T. Field evaluation of road pavement constructed with waste materials through nondestructive testing. Mater. Today Proc. 2020, 28, 1254–1260. [Google Scholar] [CrossRef]

- Abukhettala, M.; Fall, M. Geotechnical characterization of plastic waste materials in pavement subgrade applications. Transp. Geotech. 2021, 27, 100472. [Google Scholar] [CrossRef]

- Khan, S.; Ashish, P.K.; Kannelli, V.; Hossain, K.; Nagabhushana, M.N.; Tiwari, D. Potential application of over-burnt brick and fly ash for sustainable inverted pavement structure. Constr. Build. Mater. 2022, 345, 128298. [Google Scholar] [CrossRef]

- Zimar, Z.; Robert, D.; Zhou, A.; Giustozzi, F.; Setunge, S.; Kodikara, J. Application of coal fly ash in pavement subgrade stabilisation: A review. J. Environ. Manag. 2022, 312, 114926. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Qureshi, H.J.; Al Fuhaid, A.F.; Alanazi, F.; Javed, M.F.; Eldin, S.M. Novel ensemble modelling for prediction of fundamental properties of bitumen incorporating plastic waste. J. Mater. Res. Technol. 2023, 24, 3334–3351. [Google Scholar] [CrossRef]

- Kumar, B.; Kumar, N. Assessment of Marshall Stability of asphalt concrete with plastic waste using soft computing techniques. Multiscale Multidiscip. Model. Exp. Des. 2023. [Google Scholar] [CrossRef]

- Lee, S.; Le, T.H.M. Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive. Polymers 2023, 15, 3293. [Google Scholar] [CrossRef]

- White, G.; Reid, G. Recycled waste plastic for extending and modifying asphalt binders. In Proceedings of the 8th Symposium on Pavement Surface Characteristics (SURF), Brisbane, Australia, 2–4 May 2018; p. 12. [Google Scholar]

- Vasudevan, R.; Sekar, A.R.C.; Sundarakannan, B.; Velkennedy, R. A technique to dispose waste plastics in an ecofriendly way –Application in construction of flexible pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Wen, Y.; Wang, Y.; Zhao, K.; Chong, D.; Huang, W.; Hao, G.; Mo, S. The engineering, economic, and environmental performance of terminal blend rubberized asphalt binders with wax-based warm mix additives. J. Clean. Prod. 2018, 184, 985–1001. [Google Scholar] [CrossRef]

- Wang, T.; Li, K.; Liu, D.; Yang, Y.; Wu, D. Estimating the Carbon Emission of Construction Waste Recycling Using Grey Model and Life Cycle Assessment: A Case Study of Shanghai. Int. J. Environ. Res. Public Health 2022, 19, 8507. [Google Scholar] [CrossRef]

- Bosurgi, G.; Celauro, C.; Pellegrino, O.; Ruggeri, A.; Sollazzo, G. Mechanical and environmental performance comparisons of improved asphalt pavement wearing courses with high quality aggregates, steel slags, and polymeric compound. Constr. Build. Mater. 2023, 382, 131252. [Google Scholar] [CrossRef]

- You, L.; Long, Z.; You, Z.; Ge, D.; Yang, X.; Xu, F.; Hashemi, M.; Diab, A. Review of recycling waste plastics in asphalt paving materials. J. Traffic Transp. Eng. 2022, 9, 742–764. [Google Scholar] [CrossRef]

- White, P.; Golden, J.S.; Biligiri, K.P.; Kaloush, K. Modeling climate change impacts of pavement production and construction. Resour. Conserv. Recycl. 2010, 54, 776–782. [Google Scholar] [CrossRef]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Macrebur. Available online: https://www.macrebur.com/#projects (accessed on 8 August 2023).

- VolkerWessels. Available online: https://www.volkerwessels.com/en/projects/plasticroad (accessed on 8 August 2023).

- TechniSoil Industrial. Available online: https://technisoilind.com/technisoil-roads.html (accessed on 8 August 2023).

- Jelušič, P.; Varga, R.; Žlender, B. Parametric analysis of the minimum cost design of flexible pavements. Ain Shams Eng. J. 2023, 14, 101840. [Google Scholar] [CrossRef]

- Naveed, M.; Raza, M.A.; Mehmood, R. Performance analyses of conventional hot mix asphalt with waste additives. Case Stud. Constr. Mater. 2022, 16, e00850. [Google Scholar] [CrossRef]

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Hake, S.L.; Damgir, R.M.; Awsarmal, P.R. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. Transp. Res. Procedia 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- Heydari, S.; Hajimohammadi, A.; Javadi, N.H.S.; Khalili, N. The use of plastic waste in asphalt: A critical review on asphalt mix design and Marshall properties. Constr. Build. Mater. 2021, 309, 125185. [Google Scholar] [CrossRef]

- Projektiranje Dimenzioniranje Novih Asfaltnih Vozišcnih Konstrukcij; TSC 06.520:2009; Ministrstvo za promet—Direkcija RS za ceste: Ljubljana, Slovenia, 2009.

- Bohara, N. Study of the Influence of Fly Ash and Its Content in Marshall Properties of Asphalt Concrete. J. Sustain. Constr. Mater. Technol. 2018, 3, 261–270. [Google Scholar] [CrossRef]

- Rajput, P.S.; Yadav, R.K. Use of Plastic Waste in Bituminuous Road Construction. Int. J. Sci. Technol. Eng. 2016, 2, 509–513. [Google Scholar]

- Shah, A.M.; Lodhi, R.H.; Javed, M.F.; Jasiński, M.; Jasińska, E.; Gono, M. Structural Performance of Waste Plastic Bottles Modified Asphalt: A Review. Resources 2023, 12, 10. [Google Scholar] [CrossRef]

- Loaiza, A.; Colorado, H.A. Marshall stability and flow tests for asphalt concrete containing electric arc furnace dust waste with high ZnO contents from the steel making process. Constr. Build. Mater. 2018, 166, 769–778. [Google Scholar] [CrossRef]

- Ficko, G.; Žlender, B. The analysis of permanent deformations of repeatedly loaded gravels from the Mura region. Acta Geotech. Slov. 2005, 2, 24–37. [Google Scholar]

- Jing, P.; Chazallon, C. Hydro-Mechanical Behaviour of an Unbound Granular Base Course Material Used in Low Traffic Pavements. Materials 2020, 13, 852. [Google Scholar] [CrossRef] [PubMed]

- Orduz-Duarte, E.J.; Pineda-Jaimes, J.A. Performance of a Reinforced Pavement Structure with Geocells via Numerical Simulation, Considering a Discontinuous Subgrade. In Proceedings of the 2017 Congreso Internacional de Innovacion y Tendencias en Ingenieria (CONIITI), Bogota, Colombia, 3–5 October 2018; pp. 1–6. [Google Scholar]

- Ghanizadeh, A.R.; Ghaderi, F.; Tavassoti, P. Numerical Investigation of the Performance of Geocell-Reinforced Granular Base in Inverted Pavement Systems Using Nonlinear Finite Element Modeling. Can. J. Civ. Eng. 2022, 50, 395–407. [Google Scholar] [CrossRef]

- EU Project CINDERELA—New Circular Economy Business Model for More Sustainable Urban Construction. Available online: https://www.cinderela.eu/The-project (accessed on 8 August 2023).

- EU Project URGE—Circular Building Cities. Available online: https://urbact.eu/networks/urge (accessed on 8 August 2023).

- Øiseth, E.; Aabøe, R.; Hoff, I. Field Test Comparing Frost Insulation Materials in Road Construction. In Current Practices in Cold Regions Engineering; American Society of Civil Engineers: Reston, VA, USA; pp. 1–11.

| Objective function | |

| CO2 emissions | |

| Condition 1 | |

| Condition 2 | |

| Condition 3 | |

| Condition 4 | |

| Condition 5 | |

| Condition 6 | |

| Condition 7 | |

| Condition 8 | |

| Condition 9 | |

| Condition 10 | |

| Condition 11 |

| Symbol | Value | Description |

|---|---|---|

| cexe (€/m3) | 9 | unit price of the ground excavation |

| cgc (€/m2) | 2.5 | unit price of the ground compaction |

| cfill,sb (€/m3) | 24 | unit price of the unbound sub-base fill |

| cfill,b (€/m3) | 36 | unit price for unbound base fill |

| cas,subs (€/m2) | 1.5 | unit price of the asphalt substrate |

| cas (€/m3) | 300 | unit price of the asphalt surface layer |

| cab (€/m3) | 200 | unit price of the asphalt binder layer |

| cgeo (€/m2) | 3.2 | unit price of the geosynthetics |

| Bve (m) | 1 | width of the verge |

| Bas (m) | 8 | width of the asphalt surface |

| L (m) | 1000 | length of pavement sections |

| ciexe (kgCO2/m3) | 1.38 | carbon index for the ground excavation |

| cifill,b (kgCO2/kg) | 0.00248 | carbon index for unbound sub-base fill |

| cias,subs (kgCO2/m2) | 0.35 | carbon index for unbound base fill |

| cifill,sb (kgCO2/kg) | 0.00248 | carbon index for asphalt substrate |

| cias (kgCO2/kg) | 0.08278 | carbon index for asphalt surface layer |

| ciab (kgCO2/kg) | 0.08278 | carbon index for asphalt binder layer |

| cigeo(kgCO2/m2) | 0.396 | carbon index for geosynthetics |

| ρbase (kg/m3) | 1800 | density of the unbound base fill |

| ρsub-base (kg/m3) | 1800 | density of the unbound sub-base fill |

| ρas (kg/m3) | 2400 | density of the asphalt surface layer |

| ρab (kg/m3) | 2400 | density of the asphalt binder layer |

| t1= t3 (-) | 0.182104767 | parameter for ai,as and ai,ab determination |

| t2= t4 (-) | 0.389702035 | parameter for ai,as and ai,ab determination |

| t5= t7 (-) | 0.049219606 | parameter for ai,b and ai,sb determination |

| t6= t8 (-) | 0.227144669 | parameter for ai,b and ai,sb determination |

| a1 (-) | 0.6567 | parameter for required thickness of the asphalt |

| a2 (-) | 0.2175 | parameter for required thickness of the asphalt |

| b1 (-) | 8.382 | parameter for required thickness of sub-base |

| b2 (-) | −0.791 | parameter for required thickness of sub-base |

| b3 (-) | 1.975 | parameter for required thickness of sub-base |

| b4 (-) | 1.912 | parameter for required thickness of sub-base |

| c1 (-) | 6.239 | parameter for required thickness of base layer |

| c2 (-) | 0.376 | parameter for required thickness of base layer |

| c3 (-) | 26.64 | parameter for required thickness of base layer |

| c4 (-) | 0.141 | parameter for required thickness of base layer |

| c5 (-) | 4.882 | parameter for required thickness of base layer |

| CBRmod (%) | 15.0 | modified CBR value at the top of the sub-base layer |

| γgeo,sb(-) | 2.0 | reduction factor for the consideration of the geosynthetic |

| hm (cm) | 80 | depth of frost penetration |

| ffr (-) | 0.8 | Factor for the conditions of the material at the site |

| das,min (m) | 0.04 | minimum thickness of the asphalt surface layer |

| dab,min (m) | 0.06 | minimum thickness of the asphalt binder layer |

| db,min (m) | 0.25 | minimum thickness of the unbound base layer |

| dsb,min (m) | 0.20 | minimum thickness of the unbound sub-base layer |

| Resistance of the Material under the Pavement Structure against the Effects of Freezing and Thawing | Hydrological Conditions | Minimum Thickness of Pavement Structure hreq = (ffr)∙hm hm Is Depth of Frost Penetration | |

|---|---|---|---|

| to an Altitude of 600 m | from an Altitude of 600 m | ||

| resistant | favorable | (0.6)∙hm | (0.7)∙hm |

| unfavorable | (0.7)∙hm | (0.8)∙hm | |

| not resistant | favorable | (0.7)∙hm | (0.8)∙hm |

| unfavorable | (0.8)∙hm | (0.9)∙hm | |

| CBRbase = CBRsubbase = 100% | CBRbase = CBRsubbase = 30% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tn (ESAL) | SM | das + dab | db | dsb | COST | CO2 | das + dab | db | dsb | COST | CO2 |

| (-) | (kN) | (cm) | (cm) | (cm) | (€/m2) | (kgCO2/m2) | (cm) | (cm) | (cm) | (€/m2) | (kgCO2/m2) |

| 1.0 × 104 | 10 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 105 | 10 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 106 | 10 | 13 | 25 | 66 | 68.2 | 26.7 | 13 | 33 | 87 | 78.7 | 28.4 |

| 1.0 × 107 | 10 | 22 | 25 | 66 | 87.0 | 40.9 | 22 | 33 | 87 | 97.5 | 42.6 |

| 1.0 × 108 | 10 | 36 | 25 | 66 | 116.3 | 62.9 | 36 | 33 | 87 | 126.8 | 64.6 |

| 1.0 × 104 | 8 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 105 | 8 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 106 | 8 | 13 | 25 | 66 | 68.2 | 26.7 | 13 | 33 | 87 | 78.7 | 28.4 |

| 1.0 × 107 | 8 | 22 | 25 | 66 | 87.0 | 40.9 | 22 | 33 | 87 | 97.5 | 42.6 |

| 1.0 × 108 | 8 | 36 | 25 | 66 | 116.3 | 62.9 | 36 | 33 | 87 | 126.8 | 64.6 |

| 1.0 × 104 | 6 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 105 | 6 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 106 | 6 | 14 | 25 | 66 | 70.3 | 28.3 | 14 | 33 | 87 | 80.8 | 30.0 |

| 1.0 × 107 | 6 | 23 | 25 | 66 | 89.1 | 42.4 | 23 | 33 | 87 | 99.6 | 44.1 |

| 1.0 × 108 | 6 | 38 | 25 | 66 | 120.5 | 66.0 | 38 | 33 | 87 | 131.0 | 67.7 |

| 1.0 × 104 | 4 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 105 | 4 | 10 | 25 | 66 | 61.9 | 22.0 | 10 | 33 | 87 | 72.5 | 23.7 |

| 1.0 × 106 | 4 | 16 | 25 | 66 | 74.5 | 31.4 | 16 | 33 | 87 | 85.0 | 33.1 |

| 1.0 × 107 | 4 | 27 | 25 | 66 | 97.5 | 48.7 | 27 | 33 | 87 | 108.0 | 50.4 |

| 1.0 × 108 | 4 | 44 | 25 | 66 | 133.0 | 75.4 | 44 | 33 | 87 | 143.5 | 77.1 |

| 1.0 × 104 | 2 | 13 | 25 | 66 | 68.2 | 26.7 | 13 | 33 | 87 | 78.7 | 28.4 |

| 1.0 × 105 | 2 | 13 | 25 | 66 | 68.2 | 26.7 | 13 | 33 | 87 | 78.7 | 28.4 |

| 1.0 × 106 | 2 | 21 | 25 | 66 | 84.9 | 39.3 | 21 | 33 | 87 | 95.5 | 41.0 |

| 1.0 × 107 | 2 | 36 | 25 | 66 | 116.3 | 62.9 | 36 | 33 | 87 | 126.8 | 64.6 |

| 1.0 × 108 | 2 | 58 | 25 | 66 | 162.3 | 97.4 | 58 | 33 | 87 | 172.8 | 99.1 |

| CBRbase = CBRsubbase = 100% | CBRbase = CBRsubbase = 30% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tn (ESAL) | SM | das + dab | db | dsb | COST | CO2 | das + dab | db | dsb | COST | CO2 |

| (-) | (kN) | (cm) | (cm) | (cm) | (€/m2) | (kgCO2/m2) | (cm) | (cm) | (cm) | (€/m2) | (kgCO2/m2) |

| 1.0 × 104 | 10 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 105 | 10 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 106 | 10 | 13 | 25 | 33 | 60.9 | 25.2 | 13 | 33 | 44 | 68.1 | 26.3 |

| 1.0 × 107 | 10 | 22 | 25 | 33 | 79.7 | 39.3 | 22 | 33 | 44 | 87.0 | 40.4 |

| 1.0 × 108 | 10 | 36 | 25 | 33 | 109.0 | 61.3 | 36 | 33 | 44 | 116.2 | 62.4 |

| 1.0 × 104 | 8 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 105 | 8 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 106 | 8 | 13 | 25 | 33 | 60.9 | 25.2 | 13 | 33 | 44 | 68.1 | 26.3 |

| 1.0 × 107 | 8 | 22 | 25 | 33 | 79.7 | 39.3 | 22 | 33 | 44 | 87.0 | 40.4 |

| 1.0 × 108 | 8 | 36 | 25 | 33 | 109.0 | 61.3 | 36 | 33 | 44 | 116.2 | 62.4 |

| 1.0 × 104 | 6 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 105 | 6 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 106 | 6 | 14 | 25 | 33 | 63.0 | 26.8 | 14 | 33 | 44 | 70.2 | 27.9 |

| 1.0 × 107 | 6 | 23 | 25 | 33 | 81.8 | 40.9 | 23 | 33 | 44 | 89.0 | 42.0 |

| 1.0 × 108 | 6 | 38 | 25 | 33 | 113.2 | 64.5 | 38 | 33 | 44 | 120.4 | 65.6 |

| 1.0 × 104 | 4 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 105 | 4 | 10 | 25 | 33 | 54.6 | 20.5 | 10 | 33 | 44 | 61.9 | 21.6 |

| 1.0 × 106 | 4 | 16 | 25 | 33 | 67.2 | 29.9 | 16 | 33 | 44 | 74.4 | 31.0 |

| 1.0 × 107 | 4 | 27 | 25 | 33 | 90.2 | 47.2 | 27 | 33 | 44 | 97.4 | 48.3 |

| 1.0 × 108 | 4 | 44 | 25 | 33 | 125.7 | 73.9 | 44 | 33 | 44 | 132.9 | 75.0 |

| 1.0 × 104 | 2 | 13 | 25 | 33 | 60.9 | 25.2 | 13 | 33 | 44 | 68.1 | 26.3 |

| 1.0 × 105 | 2 | 13 | 25 | 33 | 60.9 | 25.2 | 13 | 33 | 44 | 68.1 | 26.3 |

| 1.0 × 106 | 2 | 21 | 25 | 33 | 77.6 | 37.8 | 21 | 33 | 44 | 84.9 | 38.9 |

| 1.0 × 107 | 2 | 36 | 25 | 33 | 109.0 | 61.3 | 36 | 33 | 44 | 116.2 | 62.4 |

| 1.0 × 108 | 2 | 58 | 25 | 33 | 155.0 | 95.9 | 58 | 33 | 44 | 162.2 | 97.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jelušič, P.; Gücek, S.; Žlender, B.; Gürer, C.; Varga, R.; Bračko, T.; Taciroğlu, M.V.; Korkmaz, B.E.; Yarcı, Ş.; Macuh, B. Potential of Using Waste Materials in Flexible Pavement Structures Identified by Optimization Design Approach. Sustainability 2023, 15, 13141. https://doi.org/10.3390/su151713141

Jelušič P, Gücek S, Žlender B, Gürer C, Varga R, Bračko T, Taciroğlu MV, Korkmaz BE, Yarcı Ş, Macuh B. Potential of Using Waste Materials in Flexible Pavement Structures Identified by Optimization Design Approach. Sustainability. 2023; 15(17):13141. https://doi.org/10.3390/su151713141

Chicago/Turabian StyleJelušič, Primož, Süleyman Gücek, Bojan Žlender, Cahit Gürer, Rok Varga, Tamara Bračko, Murat V. Taciroğlu, Burak E. Korkmaz, Şule Yarcı, and Borut Macuh. 2023. "Potential of Using Waste Materials in Flexible Pavement Structures Identified by Optimization Design Approach" Sustainability 15, no. 17: 13141. https://doi.org/10.3390/su151713141