Development of Energy-Saving Battery Pre-Cooling System for Electric Vehicles

Abstract

:1. Introduction

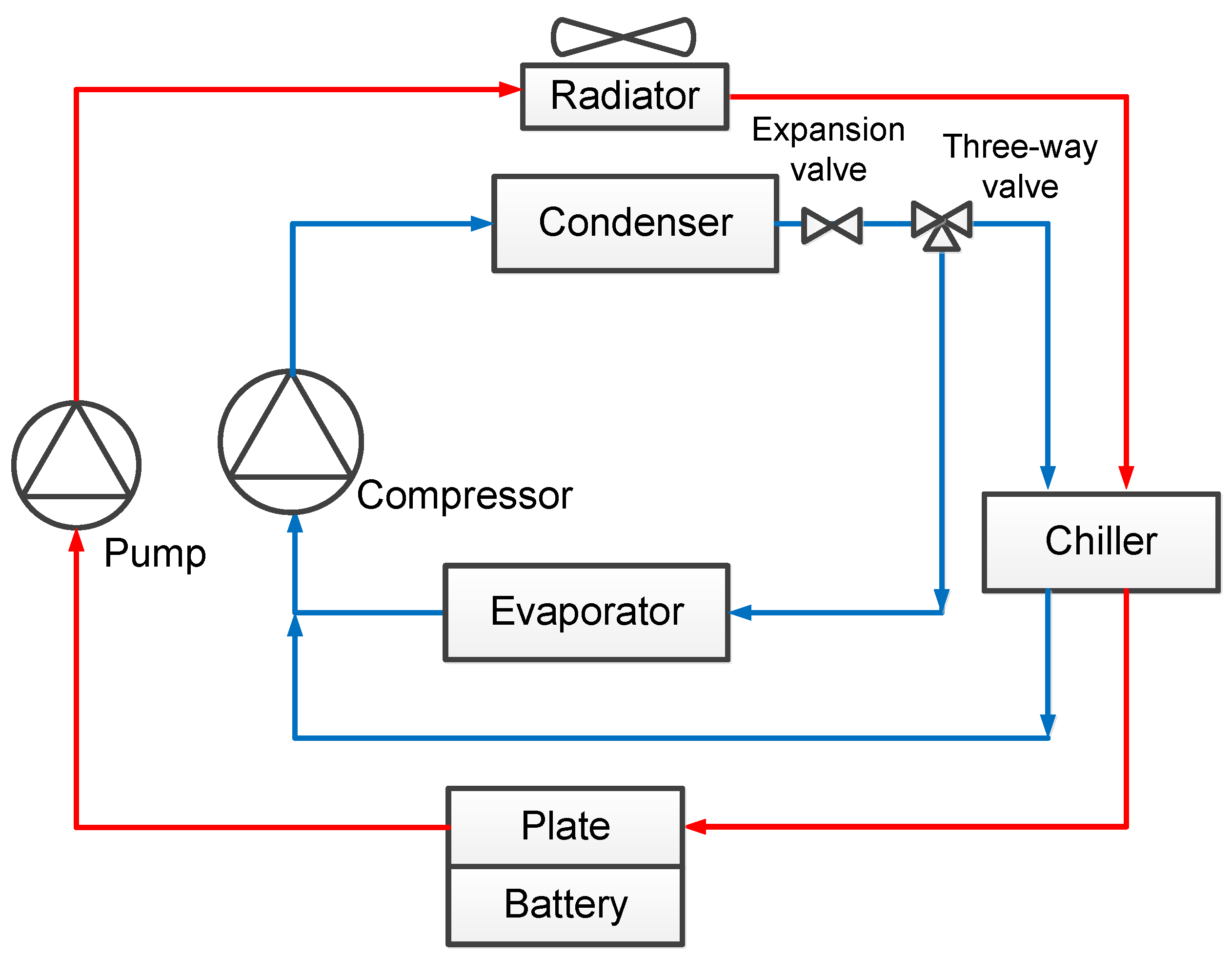

2. Experimental Apparatus

2.1. Cooling Water Loop

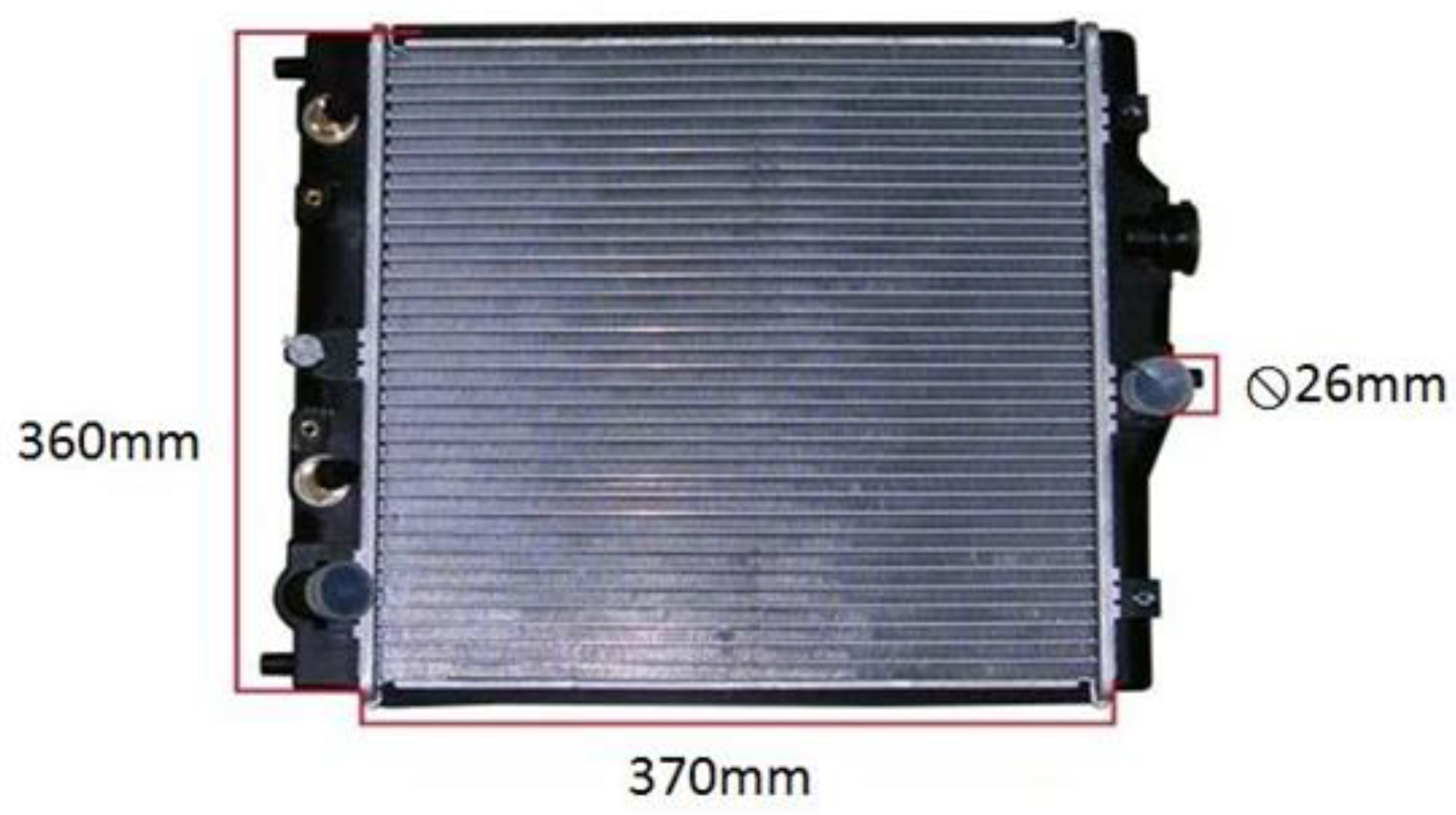

2.2. Radiator and Fan Module

2.3. Heater

2.4. Temperature and Humidity Test Chamber

2.5. Measuring Equipment

2.6. Data Acquisition System

2.7. Data Analysis

2.8. Uncertainty Analysis

3. Results and Discussion

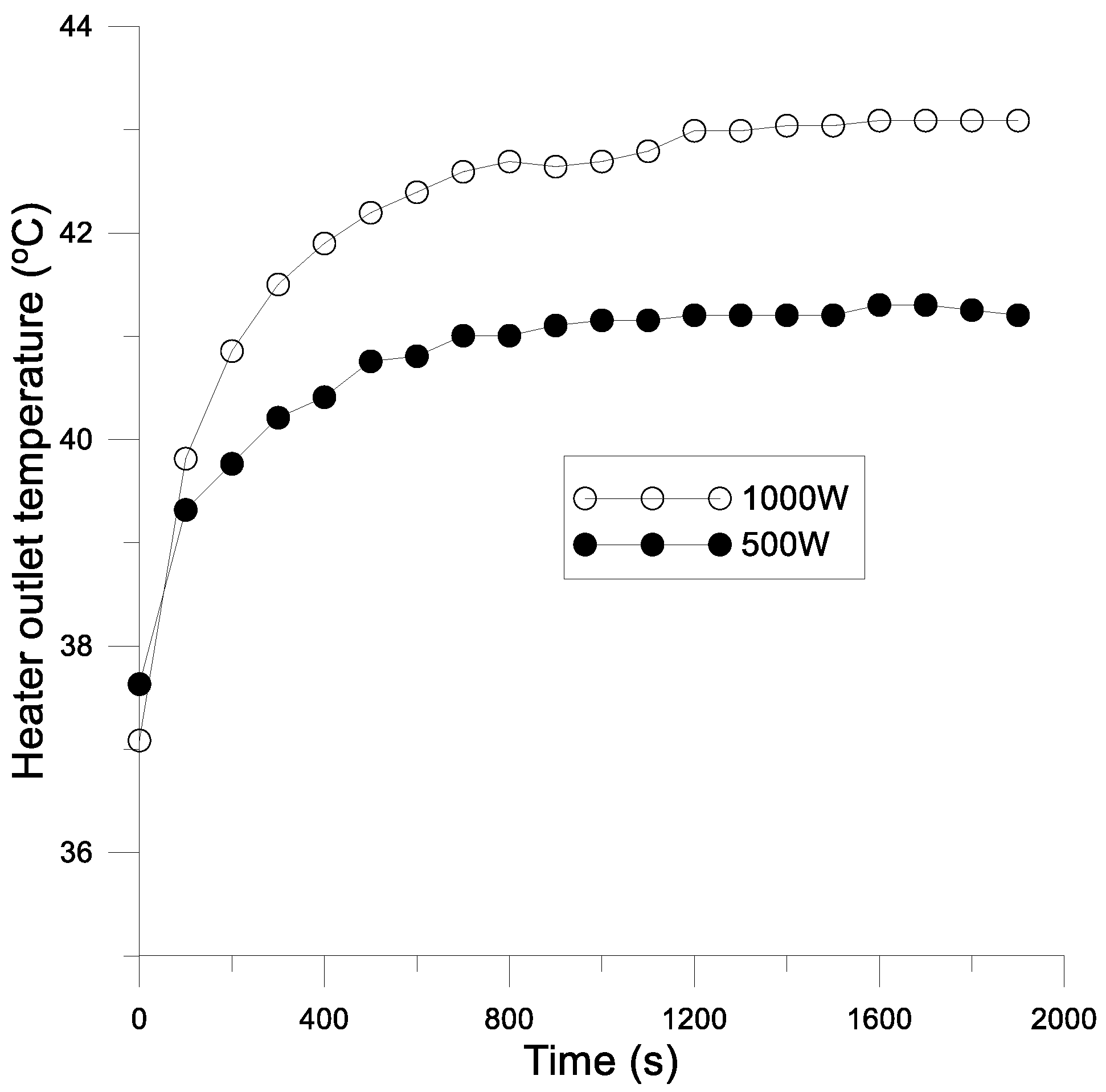

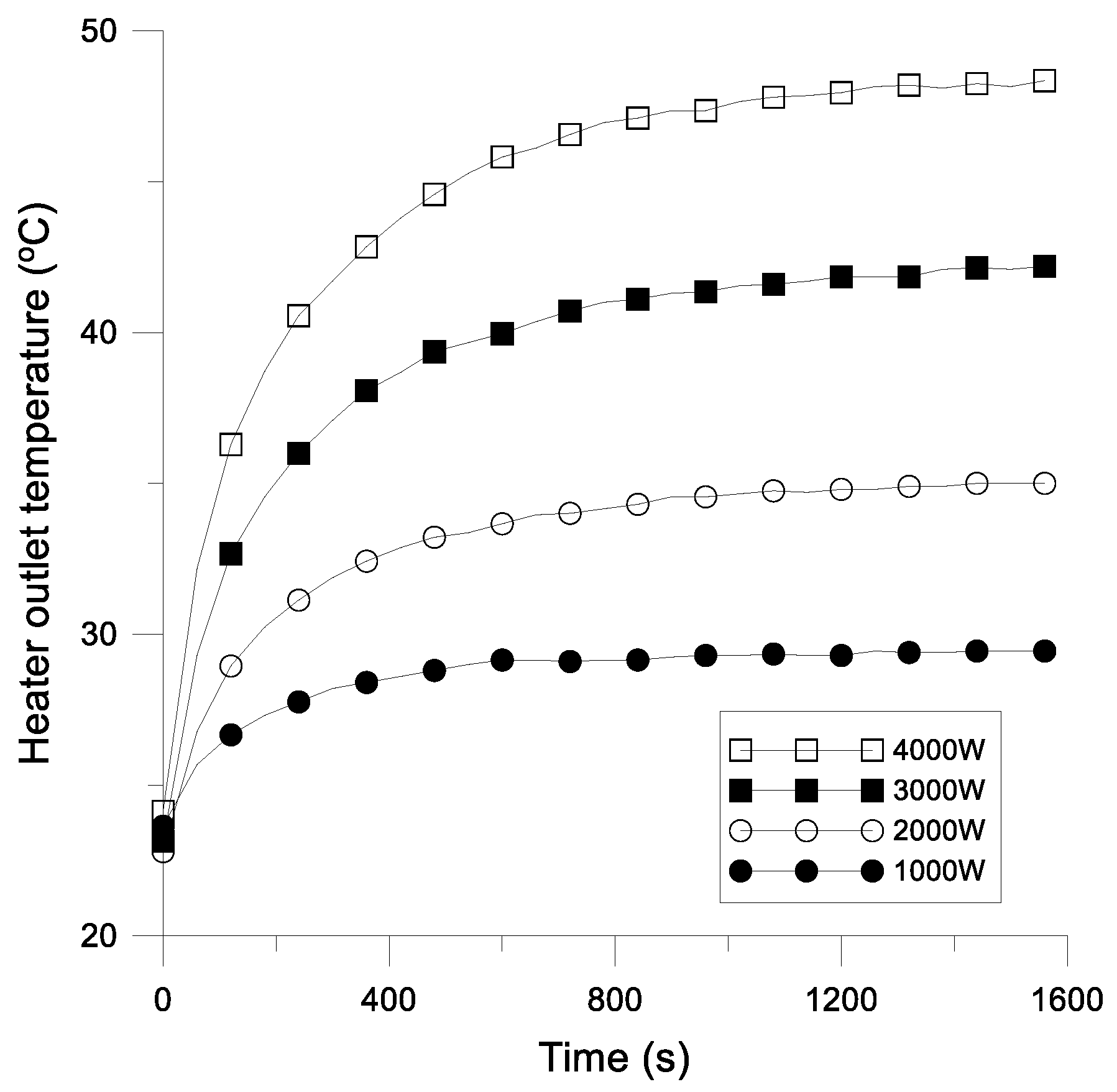

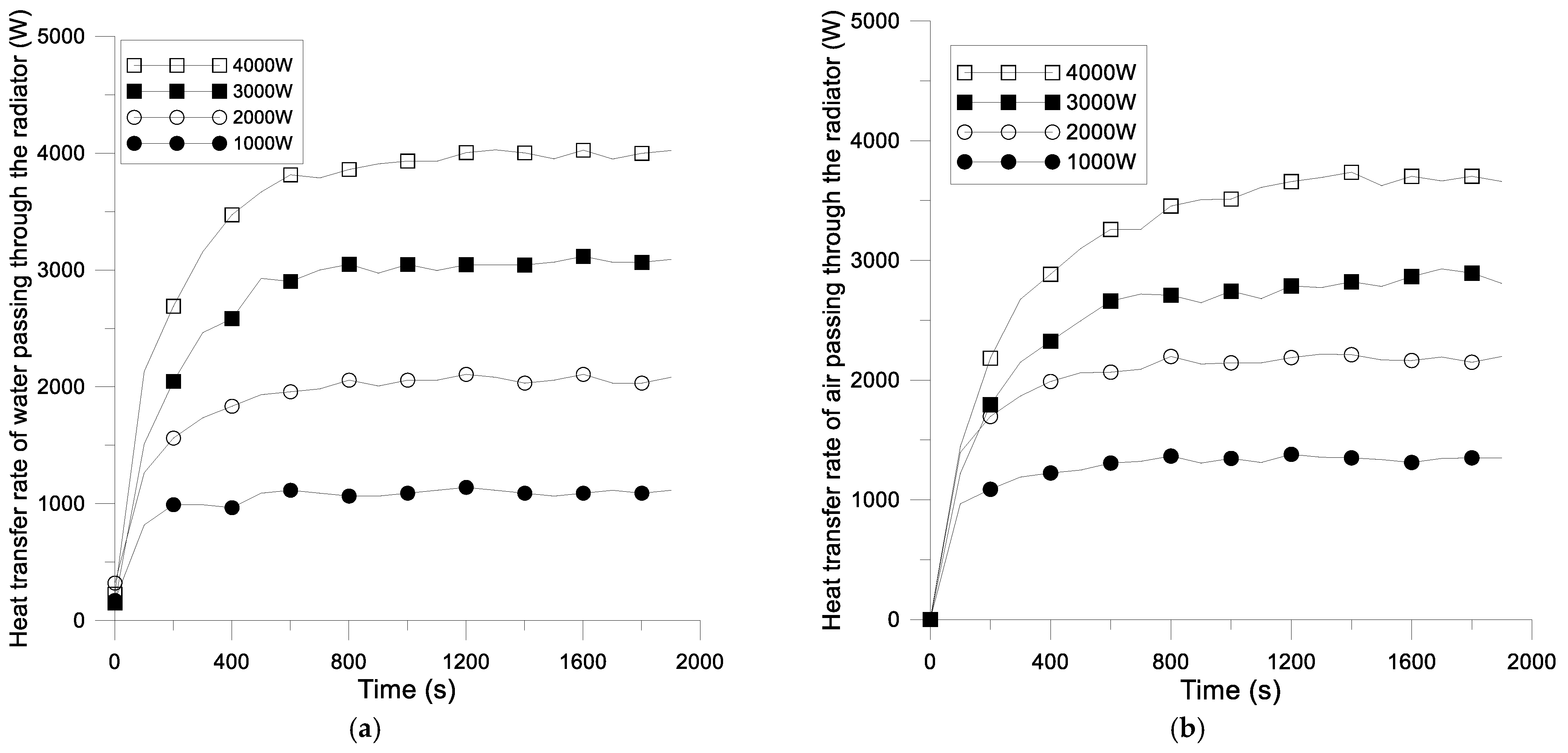

3.1. High Summer Experimental Results

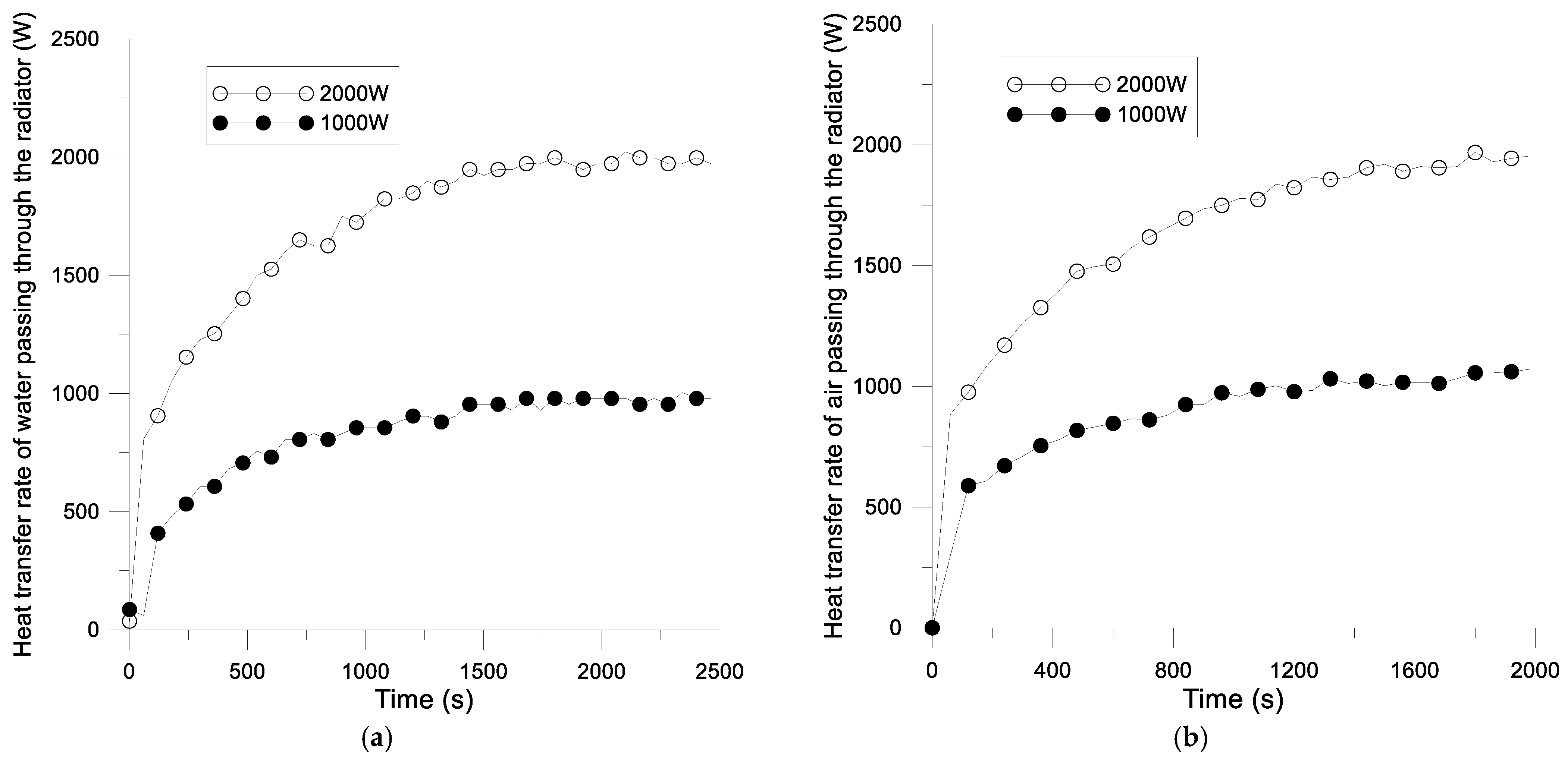

3.2. Mean Summer Experimental Results

3.3. Spring and Fall Experimental Results

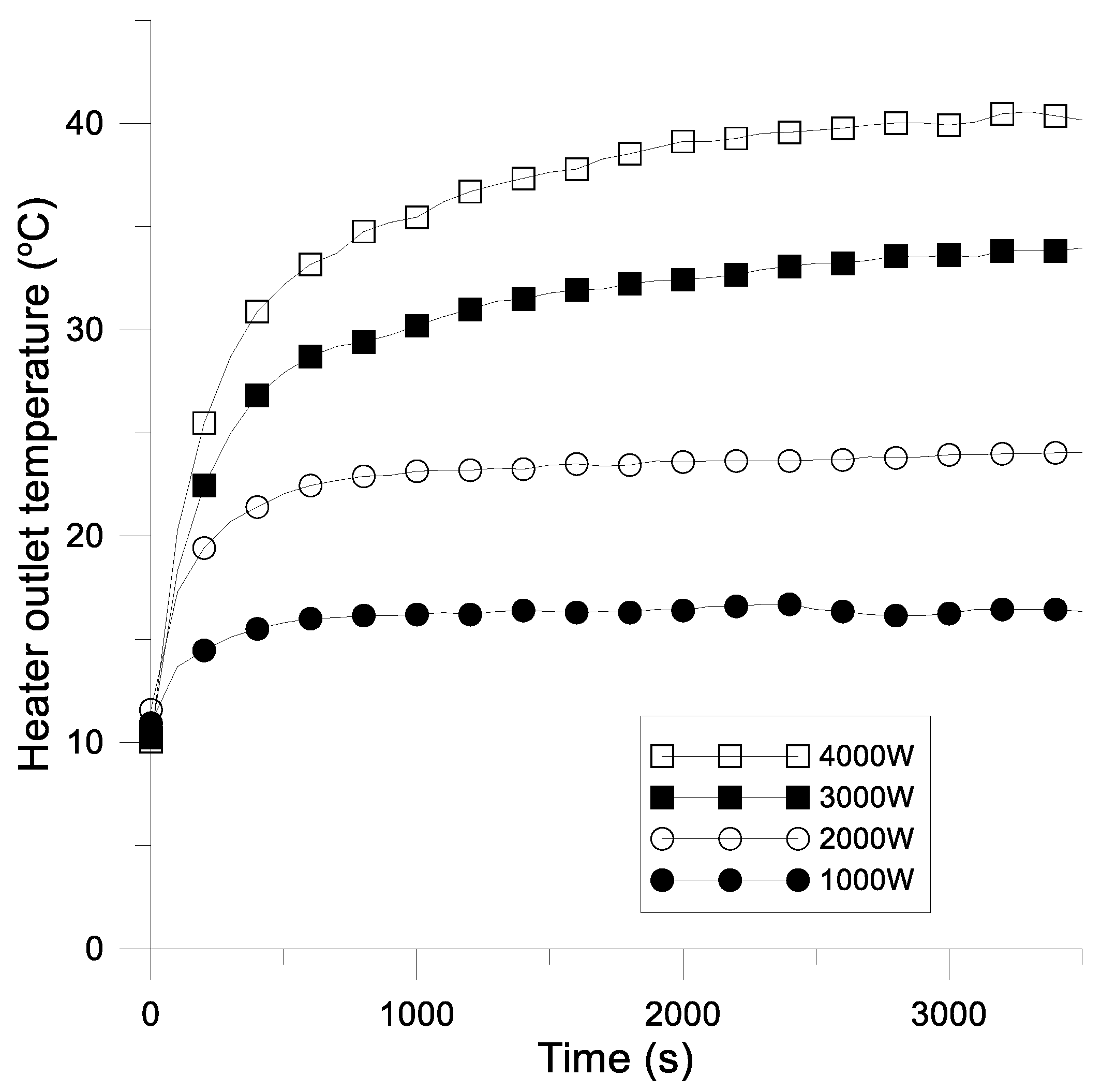

3.4. Winter Experimental Results

4. Conclusions

- The radiator in the cooling water loop and chiller in the air-conditioning loop are connected in series rather than in parallel. Consequently, the cooling water first flows through the radiator to dissipate heat and then enters the chiller of the air-conditioning system. As a result, the cooling load (and hence the energy consumption) of the air-conditioning system is significantly reduced.

- When the water temperature at the battery outlet side is assigned a maximum permissible value of 43 °C, the heat dissipation capacity of the proposed pre-cooling system is equal to 1000 W for an ambient temperature of 35 °C, 2000 W for a temperature of 30 °C, 3167 W for a temperature of 20 °C, and more than 4000 W for a temperature of 7 °C. For a heat generation rate of the battery lower than these maximum heat dissipation values, the pre-cooling system is sufficient to maintain the outlet water temperature of the battery at the target value of 43 °C. Hence, the air-conditioning system is not required, and the cooling load is correspondingly reduced.

- In the winter (7 °C), the cooling fan of the radiator is not required and the heat energy dissipated by the battery can be used as the heat source for the air-conditioning system, thereby further reducing its energy consumption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sato, N. Thermal behavior analysis of lithium-ion batteries for electric and hybrid vehicles. Power Sources 2001, 99, 70–77. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J.M. Electrical energy storage for the grid: A battery of choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef] [PubMed]

- Meiwes, H.B.; Drillkens, J.; Lunz, B.; Muennix, J.; Rothgang, S.; Kowal, J.; Sauer, D.U. A review of current automotive battery technology and future prospects. Automob. Eng. 2013, 227, 761–776. [Google Scholar] [CrossRef]

- Bukhari, S.M.A.S.; Maqsood, J.; Baig, M.Q.; Ashraf, S.; Khan, T.A. Comparison of Characteristics—Lead Acid, Nickel Based, Lead Crystal and Lithium Based Batteries. In Proceedings of the 2015 17th UKSim-AMSS International Conference on Modelling and Simulation (UKSim), Cambridge, UK, 25–27 March 2015. [Google Scholar]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. In Materials for Sustainable Energy: A Collection of Peer-Reviewed Research and Review Articles from Nature Publishing Group; Macmillan Publishers Ltd.: London, UK, 2011; pp. 171–179. [Google Scholar]

- Sasaki, T.; Ukyo, Y.; Novák, P. Memory effect in a lithium-ion battery. Nat. Mater. 2013, 12, 569. [Google Scholar] [CrossRef]

- Etacheri, V.; Marom, R.; Elazari, R.; Salitra, G.; Aurbach, D. Challenges in the development of advanced Li-ion batteries: A review. Energy Environ. Sci. 2011, 4, 3243–3262. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Pesaran, A.; Santhanagopalan, S.; Kim, G.H. Addressing the Impact of Temperature Extremes on Large Format Li-Ion Batteries for Vehicle Applications. In Proceedings of the 30th International Battery Seminar, Fort Lauderdale, FL, USA, 11–14 March 2013. [Google Scholar]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Park, H. A design of air flow configuration for cooling lithium ion battery in hybrid electric vehicles. J. Power Sources 2013, 239, 30–36. [Google Scholar] [CrossRef]

- Chen, K.; Li, Z.; Chen, Y.; Long, S.; Hou, J.; Song, M.; Wang, S. Design of Parallel Air-Cooled Battery Thermal Management System through Numerical Study. Energies 2017, 10, 1677. [Google Scholar] [CrossRef]

- Jarrett, A.; Kim, I.Y. Design optimization of electric vehicle battery cooling plates for thermal performance. J. Power Sources 2011, 196, 10359–10368. [Google Scholar] [CrossRef]

- Jin, L.W.; Lee, P.S.; Kong, X.X.; Fan, Y.; Chou, S.K. Ultra-thin minichannel LCP for EV battery thermal management. Appl. Energy 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A.; Mathew, M.; Fowler, M. Thermal and electrical performance evaluations of series connected Li-ion batteries in a pack with liquid cooling. Appl. Therm. Eng. 2018, 129, 472–481. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Zou, H.; Jiang, B.; Wang, Q.; Tian, C.; Yan, Y. Performance analysis of a heat pump air conditioning system coupling with battery cooling for electric vehicles. Energy Procedia 2014, 61, 891–894. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J.; Tillmetz, W. Advances in Battery Technologies for Electric Vehicles; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Krueger, I.; Limperich, D.; Schmitz, G. Energy Consumption of Battery Cooling in Hybrid Electric Vehicles. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 16–19 July 2012. [Google Scholar]

- Tian, Z.; Gan, W.; Zhang, X.; Gu, B.; Yang, L. Investigation on an integrated thermal management system with battery cooling and motor waste heat recovery for electric vehicle. Appl. Therm. Eng. 2018, 136, 16–27. [Google Scholar] [CrossRef]

- Cen, J.; Jiang, F. Li-ion power battery temperature control by a battery thermal management and vehicle cabin air conditioning integrated system. Energy Sustain. Dev. 2020, 57, 141–148. [Google Scholar] [CrossRef]

- CNS 14464; Non-Ducted Air Conditioners and Heat Pumps—Testing and Rating for Performance. Taiwan National Standard: Taipei City, Taiwan, 2020. Available online: http://cns-standards.org/CNS_standard_cn.asp?CODE=CNS%2014464 (accessed on 13 June 2021).

- Taiwan Central Weather Bureau. Monthly Mean Temperature. 2020. Available online: https://www.cwb.gov.tw/V8/E/C/Statistics/monthlymean.html (accessed on 13 June 2021).

- JIS C 9220; Household Heat Pump Water Heater. Japanese Industrial Standards: Tokyo, Japan, 2018. Available online: https://www.catalabo.org/iportal/CatalogDownload.do?method=downloadPdfCatalogPage&type=downloadPdfCatalogPage&volumeID=CATALABO&categoryID=&catalogID=&catalogCategoryID=&pageGroupID=&pageID=57667940000 (accessed on 1 June 2023).

- Holman, J.P. Experimental Methods for Engineers; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Chang, T.-B.; Sheu, J.-J.; Huang, J.-W. High-Efficiency HVAC System with Defog/Dehumidification Function for Electric Vehicles. Energies 2021, 14, 46. [Google Scholar] [CrossRef]

| Current (A) | Voltage (DC V) | Fan Diameter (mm) | Average Wind Speed (km/h) | Maximum Volume Flow Rate (m3/h) |

|---|---|---|---|---|

| 7.8 | 12 | 320 | 10 | 820 |

| Model | Current (A) | Voltage (V) | Power (kW) | Weight (kg) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|

| NC5-LB | 40 | 220 | 8.8 | 2.6 | 314 | 240 | 137 |

| Length (m) | Width (m) | Height (m) | Temperature Range (°C) | Temperature Accuracy (°C) | Humidity Range (%) | Humidity Accuracy (%) |

|---|---|---|---|---|---|---|

| 2.2 | 1.8 | 2.1 | 30~50 | ±0.3 | 10~90 | ±2.5 |

| Summer (35 °C) | Summer (30 °C) | Spring and Fall (20 °C) | Winter (7 °C) | |

|---|---|---|---|---|

| Dry bulb temperature | 35 °C | 30 °C | 20 °C | 7 °C |

| Wet bulb temperature | 24 °C | 27 °C | 17.7 °C | 6 °C |

| Specification | CNS14464, T1 | Weather data from Taiwan Central Weather Bureau | Weather data from Taiwan Central Weather Bureau | JIS C 9920 |

| No. | Apparatus | Measurement Parameters | Accuracy |

|---|---|---|---|

| 1 | Thermocouple | Temperature | ±0.2 °C |

| 2 | Ultrasonic flowmeter | Mass flow rate of cooling water | ±1% |

| 3 | Air capture hood | Volume flow rate of air | ±3% |

| Climate | Ambient Temperature | Heat Dissipation Capacity (Reduced Cooling Load for A/C System) | Energy Saving of A/C System |

|---|---|---|---|

| High summer | 35 °C | 1000 W | 400 W |

| Mean summer | 30 °C | 2000 W | 800 W |

| Spring and fall | 20 °C | 3167 W | 1267 W |

| Winter | 7 °C | 4485 W | 1794 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, T.-B.; Xiao, Y.-Z.; Liu, Y.-F. Development of Energy-Saving Battery Pre-Cooling System for Electric Vehicles. Sustainability 2023, 15, 13182. https://doi.org/10.3390/su151713182

Chang T-B, Xiao Y-Z, Liu Y-F. Development of Energy-Saving Battery Pre-Cooling System for Electric Vehicles. Sustainability. 2023; 15(17):13182. https://doi.org/10.3390/su151713182

Chicago/Turabian StyleChang, Tong-Bou, Yi-Zong Xiao, and You-Fan Liu. 2023. "Development of Energy-Saving Battery Pre-Cooling System for Electric Vehicles" Sustainability 15, no. 17: 13182. https://doi.org/10.3390/su151713182

APA StyleChang, T.-B., Xiao, Y.-Z., & Liu, Y.-F. (2023). Development of Energy-Saving Battery Pre-Cooling System for Electric Vehicles. Sustainability, 15(17), 13182. https://doi.org/10.3390/su151713182