Factors Influencing Ground Settlement during Tunnel Proximity Construction

Abstract

:1. Introduction

2. Materials and Approach

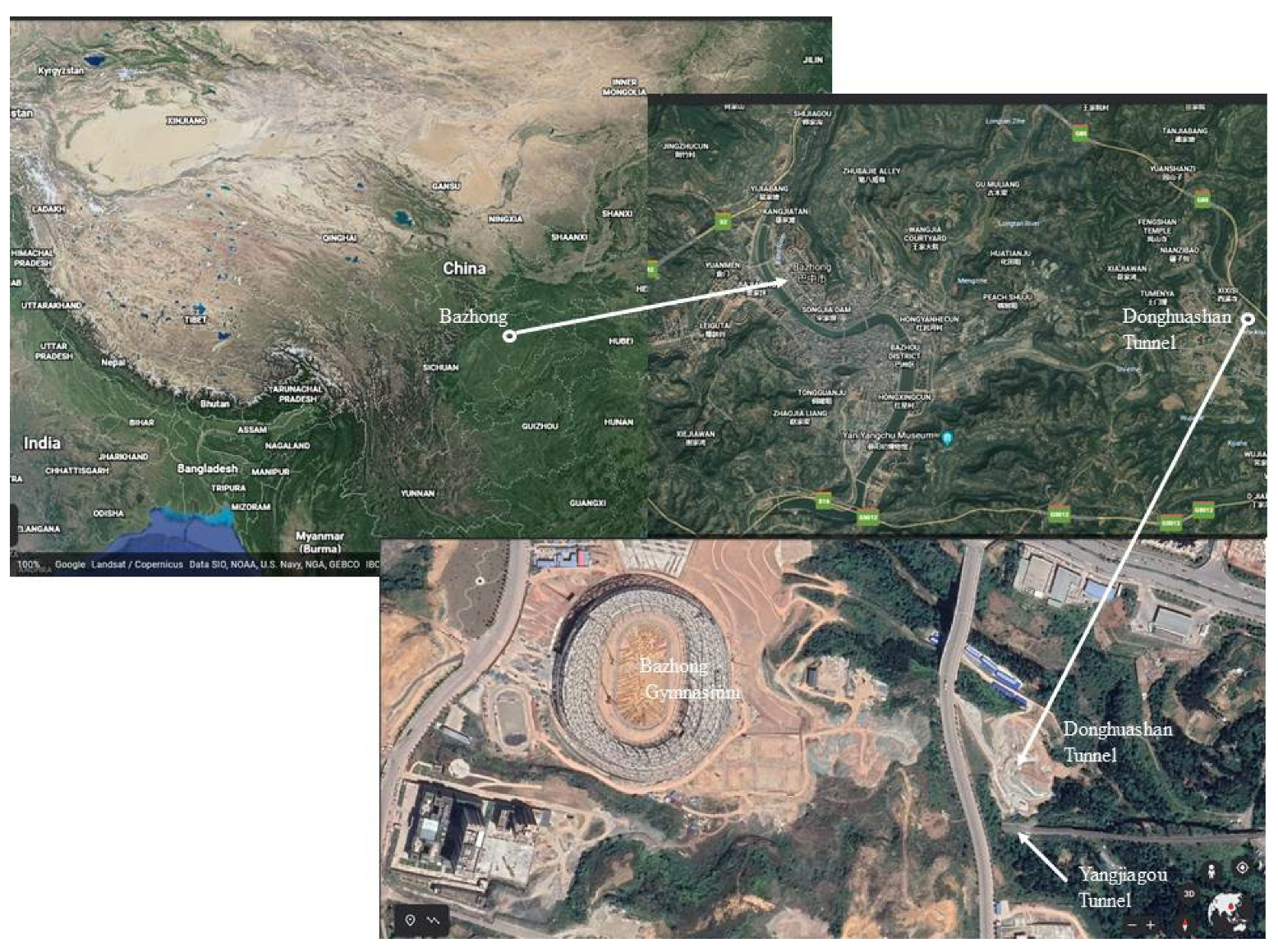

2.1. Project Overview

2.2. Orthogonal Test Design

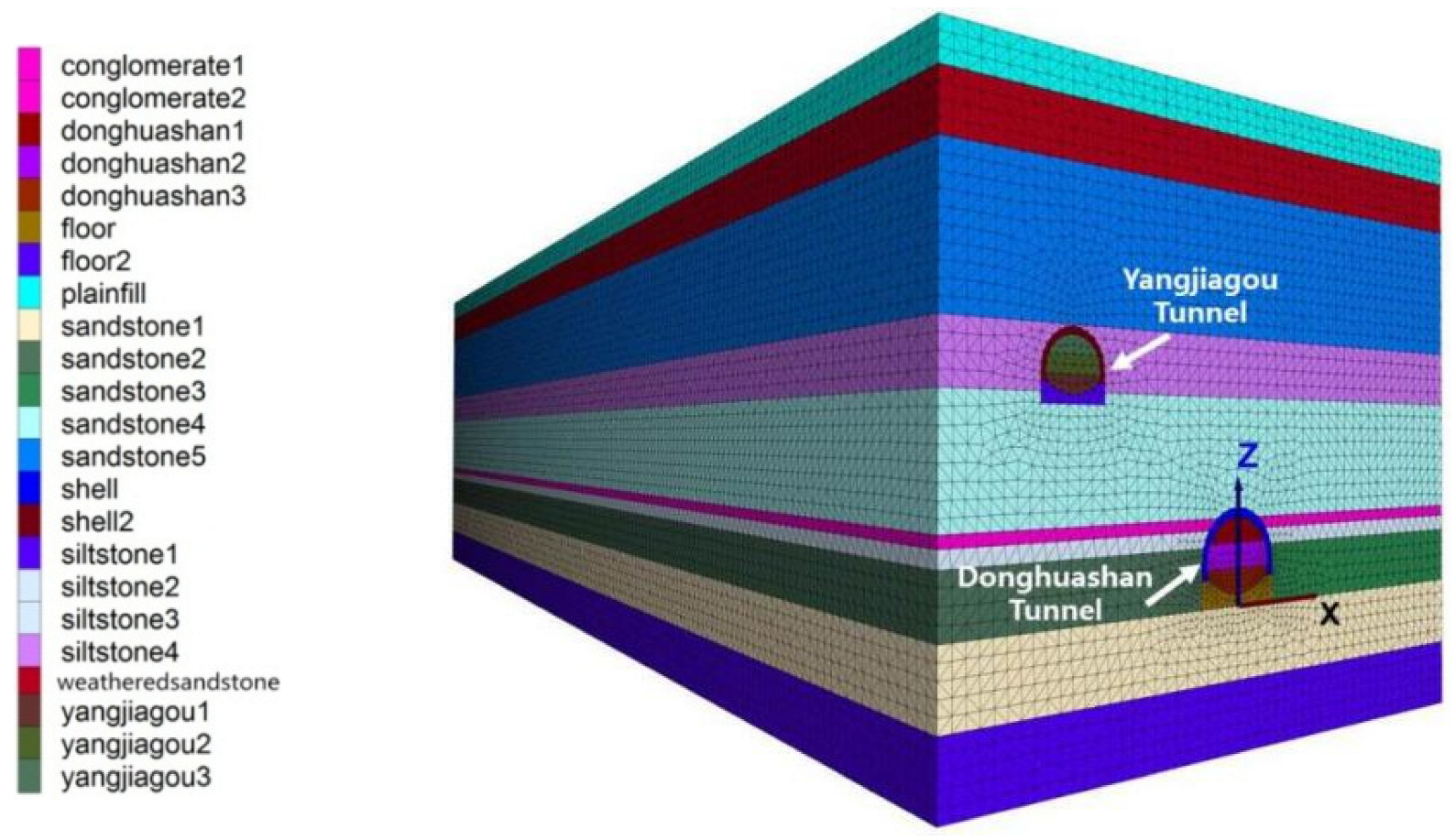

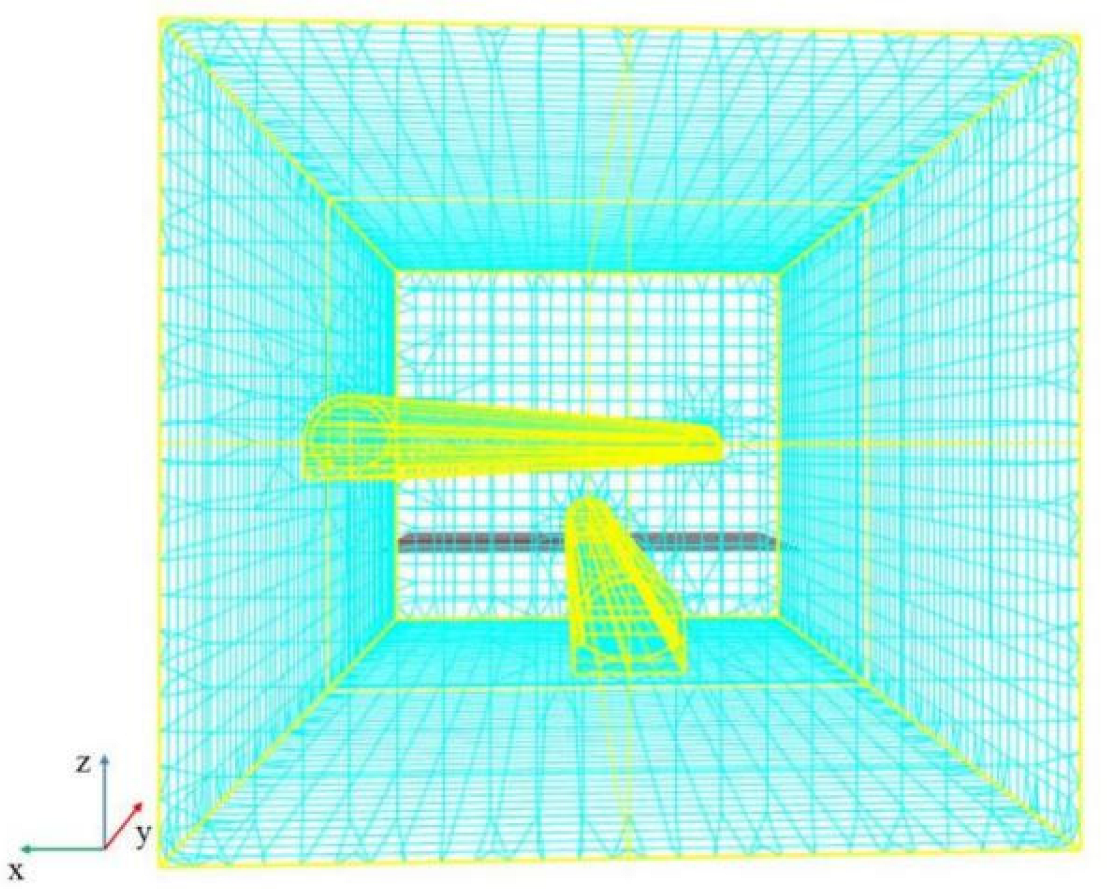

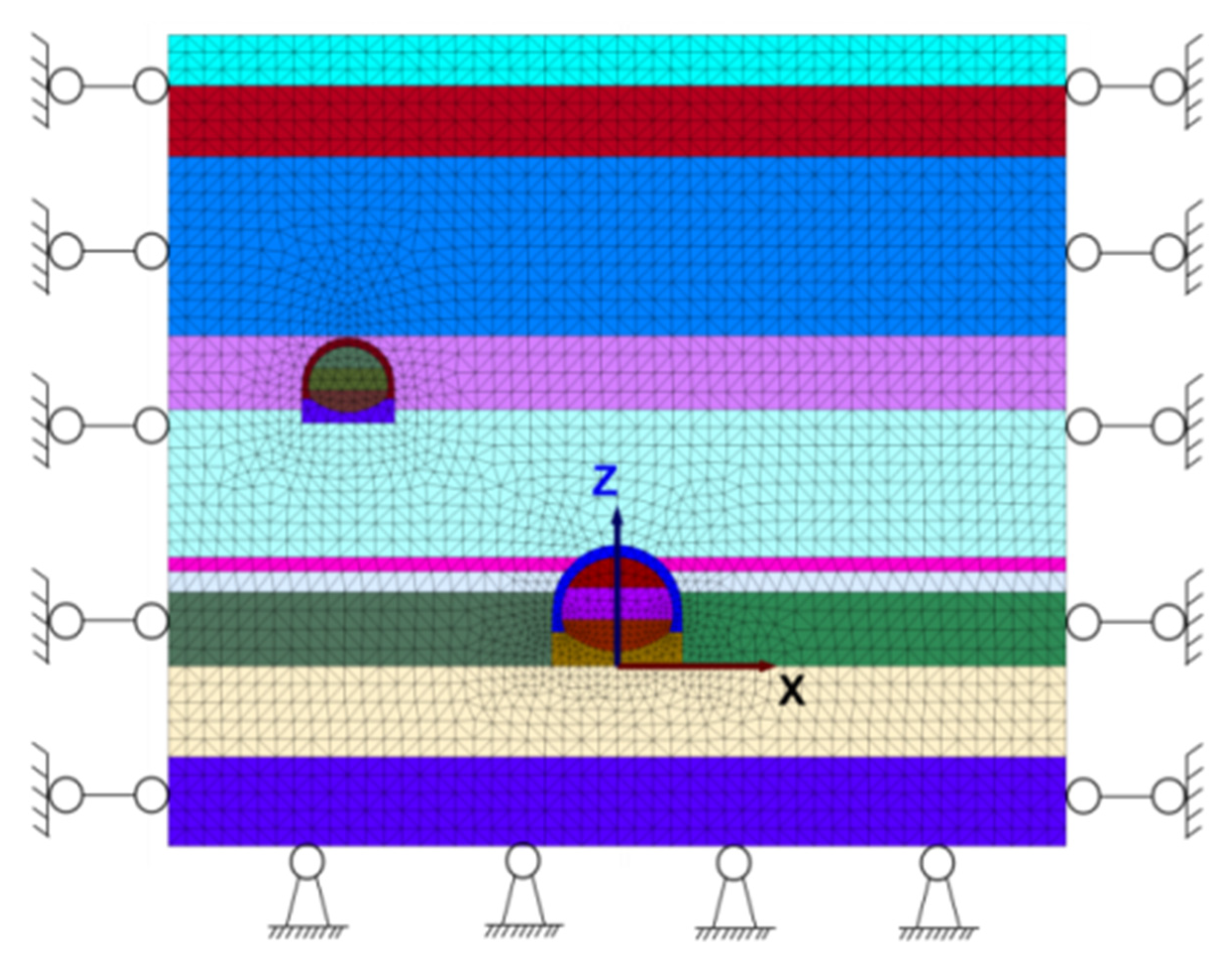

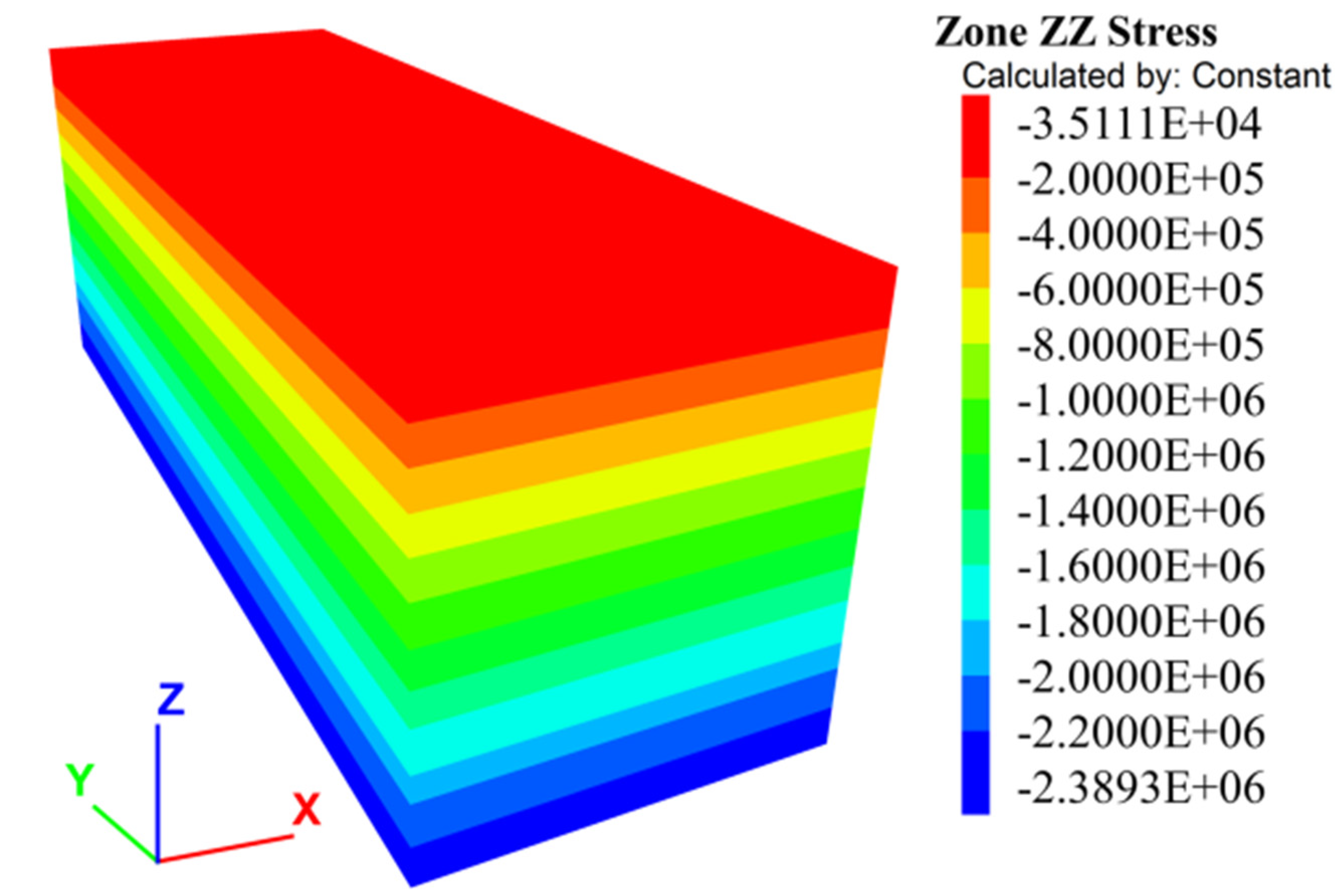

2.3. Simulation Model

3. Results

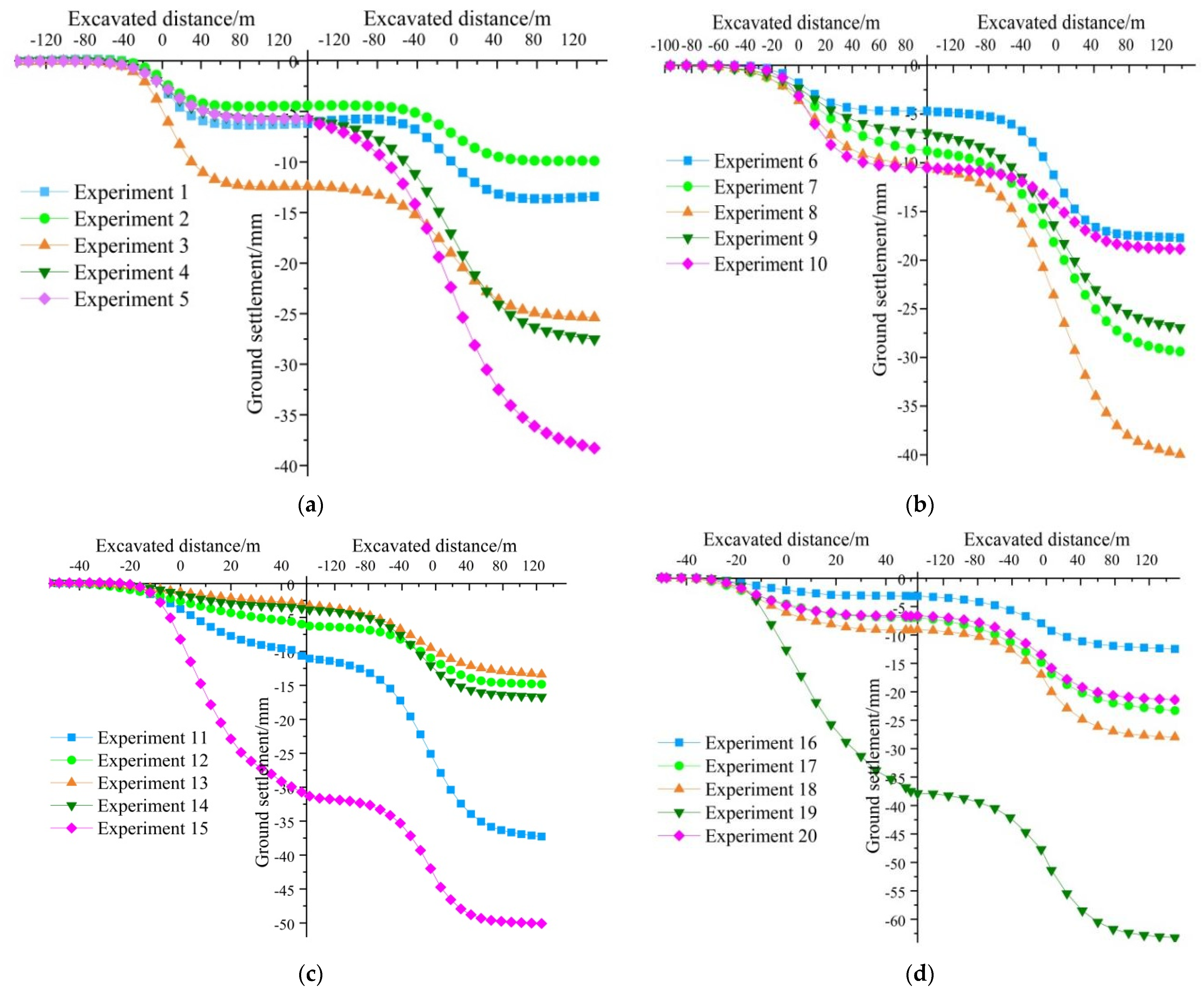

3.1. Results of Orthogonal Tests

3.2. Results of Impact Parameter Analysis

- (1)

- Impact factors on ground subsidence (W)

- (2)

- Impact factors on horizontal movement (U)

- (3)

- Impact factors on tilt (i)

- (4)

- Impact factors on curvature (K)

- (5)

- Impact factors on horizontal deformation (ε)

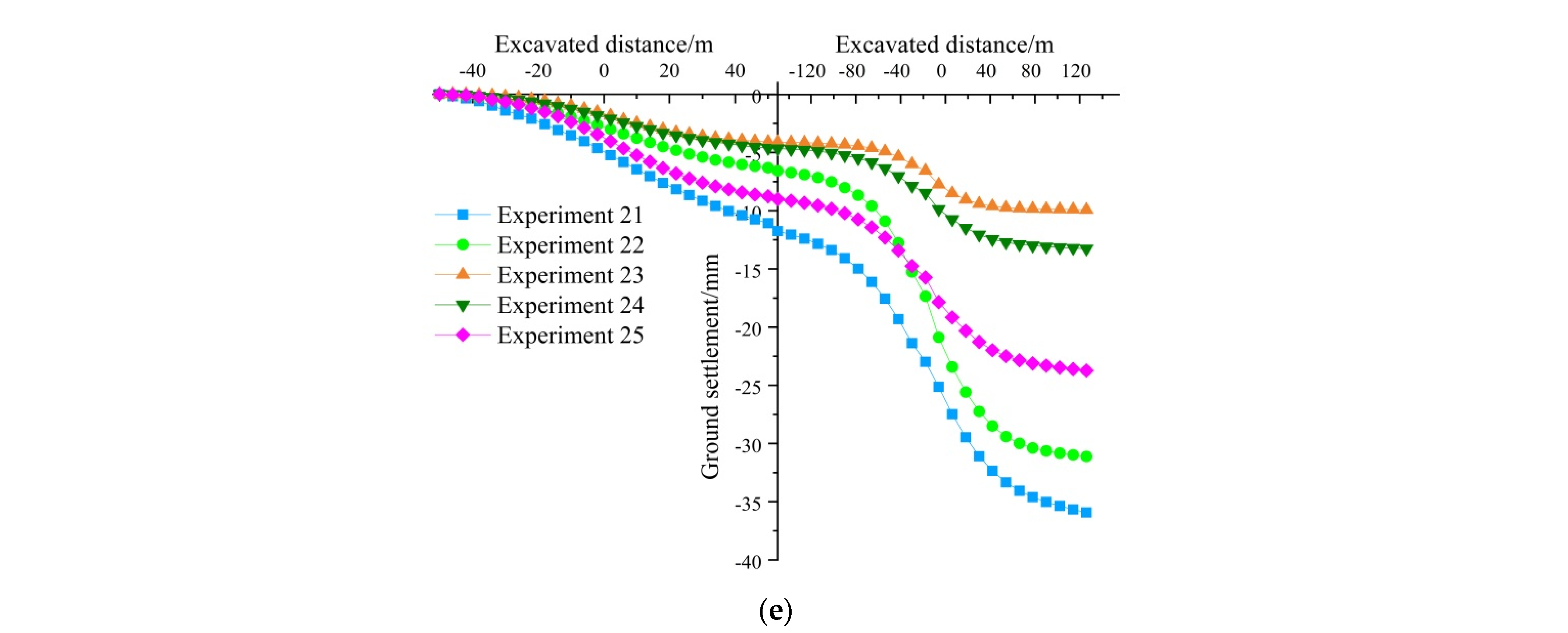

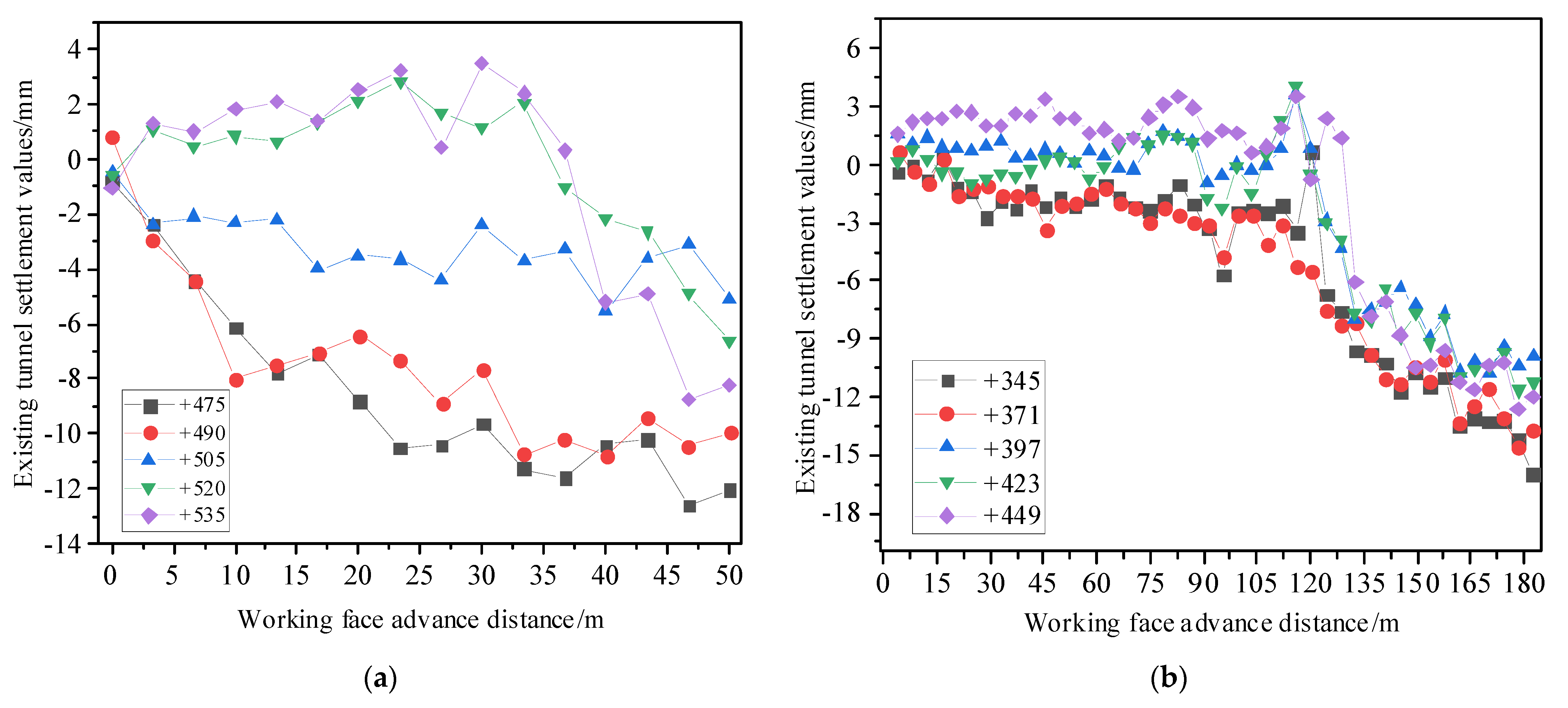

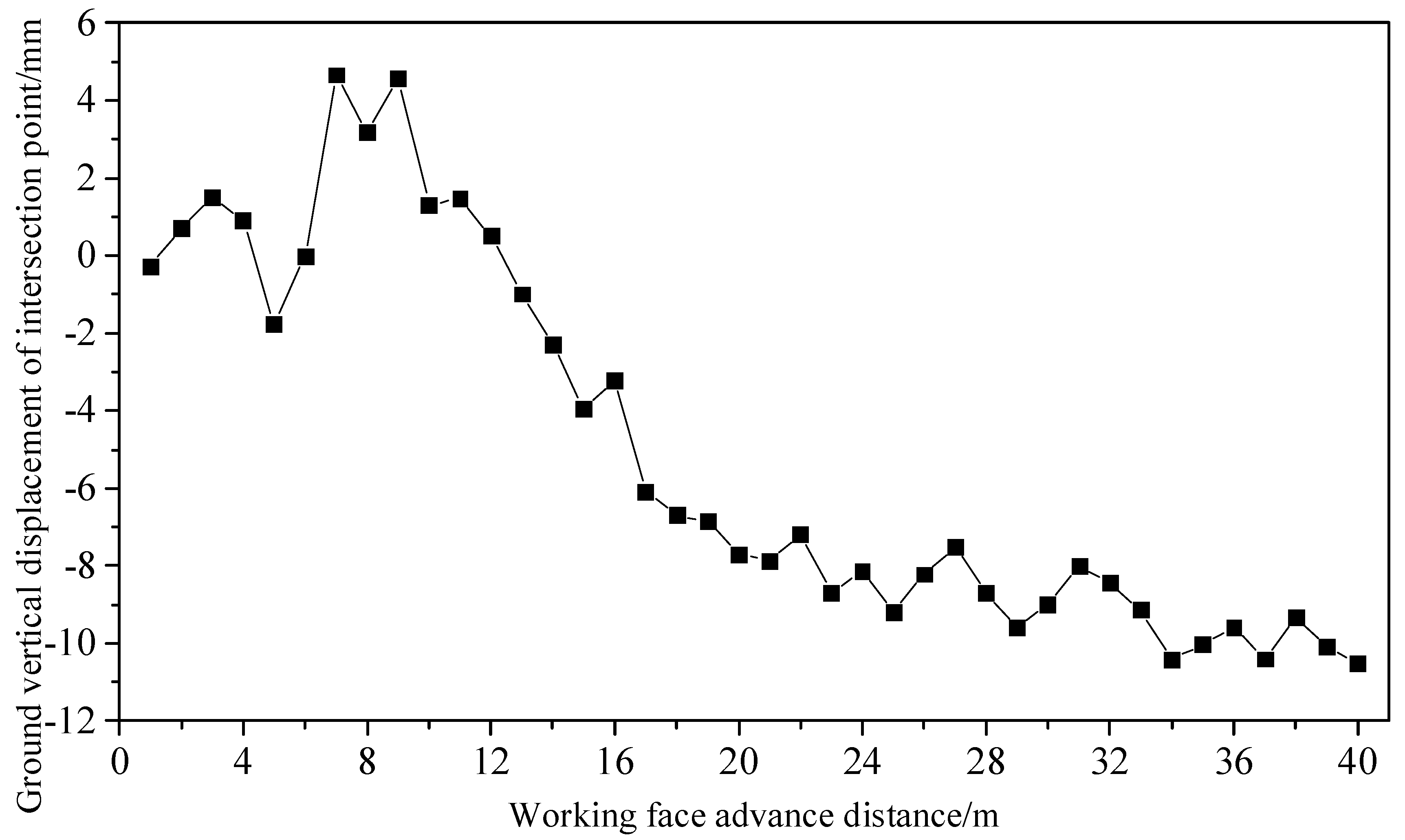

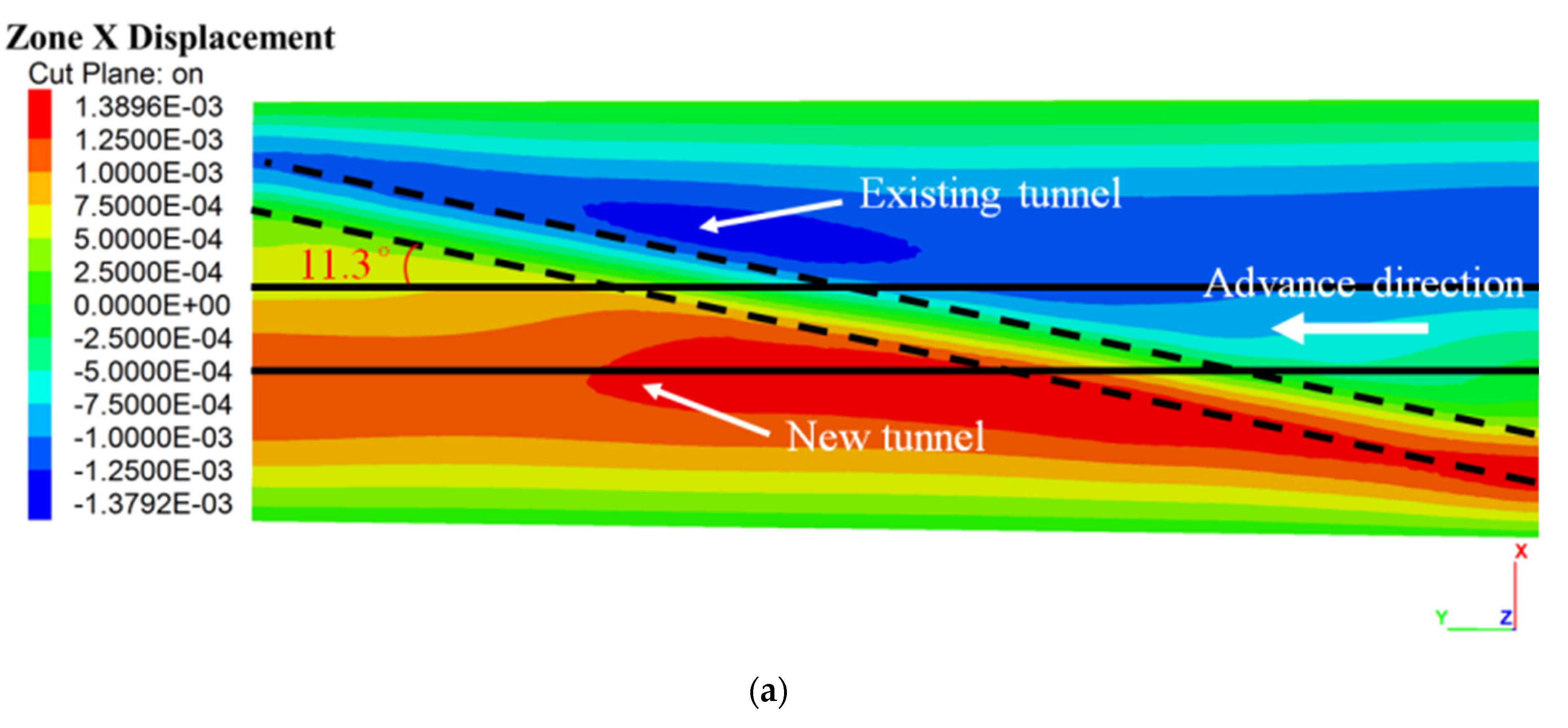

3.3. Comparison with Monitoring Data

4. Discussion

5. Conclusions

- (1)

- Of the five influential parameters, tunnel clearance has the most significant influence on ground subsidence, while the skew angle has the smallest influence. Ground settlement directly increases with the increase in tunnel clearance.

- (2)

- The skew angle is the main impact factor of ground horizontal movement, which should not be neglected during tunnel excavation that under-crosses existing tunnels. The horizontal movement of the ground induces shear stress along its direction, thus influencing the stability of existing tunnels. The intersection angle between the two tunnels is directly proportional to horizontal movement.

- (3)

- The key influential parameter of ground tilt deformation and ground horizontal deformation is the new tunnel’s buried depth. A shallower tunnel depth will induce larger tilt and horizontal deformation, which adversely affects the safety of structures on the ground. Proper measures should be taken to protect structures and buildings in shallow tunnel excavation projects.

- (4)

- The ground curvature deformation is significantly influenced by new tunnel clearance. However, the clearance ratio between the two tunnels makes the smallest contribution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shin, H.S.; Kim, C.Y.; Kim, K.Y.; Bae, G.J.; Hong, S.W. A new strategy for monitoring of adjacent structures to tunnel construction in urban area. Tunn. Undergr. Sp. Tech. 2006, 21, 461–462. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, R.; Wu, H.; Meng, F. A simplified method for estimating the longitudinal and circumferential behaviors of the shield-driven tunnel adjacent to a braced excavation. Comput. Geotech. 2020, 123, 103595. [Google Scholar] [CrossRef]

- Boldini, D.; Losacco, N.; Bertolin, S.; Amorosi, A. Finite Element modelling of tunneling-induced displacements on framed structures. Tunn. Undergr. Sp. Tech. 2018, 80, 222–231. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Han, Y.; Wang, Z.; Zhang, R.; Wang, S. Analytical solution for the response of an existing tunnel induced by above-crossing shield tunneling. Comput. Geotech. 2020, 124, 103624. [Google Scholar] [CrossRef]

- Mohammad, A.; Mostafa, S.; Kourosh, S.; Hamed, J. Interaction of twin tunnels and shallow foundation at Zand underpass, Shiraz metro, Iran. Tunn. Undergr. Sp. Tech. 2011, 26, 356–363. [Google Scholar]

- Chen, F.; Wang, L.; Zhang, W. Reliability assessment on stability of tunneling perpendicularly beneath an existing tunnel considering spatial variabilities of rock mass properties. Tunn. Undergr. Sp. Tech. 2019, 88, 276–289. [Google Scholar] [CrossRef]

- Lai, H.P.; Zheng, H.W.; Chen, R.; Kang, Z.; Liu, Y. Settlement behaviors of existing tunnel caused by obliquely under-crossing shield tunneling in close proximity with small intersection angle. Tunn. Undergr. Sp. Tech. 2020, 97, 103258. [Google Scholar] [CrossRef]

- Lee, C.L.; Shou, K.J.; Chen, S.S.; Zhou, W.C. Numerical analysis of tunneling in slates with anisotropic time-dependent behavior. Tunn. Undergr. Sp. Tech. 2019, 84, 281–294. [Google Scholar] [CrossRef]

- Huang, M.S.; Zhou, X.C.; Yu, J.; Leung, C.F.; Tan, J.Q.W. Estimating the effects of tunneling on existing jointed pipelines based on Winkler model. Tunn. Undergr. Sp. Tech. 2019, 86, 89–99. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, M.; Wang, F.; Ling, T.; Yang, X. The failure mechanism of surrounding rock around an existing shield tunnel induced by an adjacent excavation. Comput. Geotech. 2020, 117, 103236. [Google Scholar] [CrossRef]

- Ali, S.M.; Mangi, N.; Xiong, H.; Kumar, M.; Ali, M.D. Centrifuge and numerical modelling of stress transfer mechanisms and settlement of pile group due to twin stacked tunneling with different construction sequences. Comput. Geotech. 2020, 121, 103449. [Google Scholar]

- Soomro, M.A.; Kumar, M.; Xiong, H.; Mangnejo, D.A.; Mangi, N. Investigation of effects of different construction sequences on settlement and load transfer mechanism of single pile due to twin stacked tunneling. Tunn. Undergr. Sp. Tech. 2020, 96, 103171. [Google Scholar] [CrossRef]

- Sohaei, H.; Hajihassani, M.; Namazi, E.; Marto, A. Experimental study of surface failure induced by tunnel construction in sand. Eng. Fail. Anal. 2020, 118, 104897. [Google Scholar] [CrossRef]

- Nematollahi, M.; Dias, D. Interaction between an underground parking and twin tunnels—Case of the Shiraz subway line. Tunn. Undergr. Sp. Tech. 2020, 95, 103150. [Google Scholar] [CrossRef]

- Zakhem, A.M.; El, N.H. Three-dimensional investigation of how newly constructed buildings supported on raft foundations affect pre-existing tunnels. Transp. Geotech. 2020, 22, 100324. [Google Scholar] [CrossRef]

- Li, C.; Zhong, Z.; He, G.; Liu, X. Response of the ground and adjacent end-bearing piles due to side-by-side twin tunneling in compound rock strata. Tunn. Undergr. Sp. Tech. 2019, 89, 91–108. [Google Scholar] [CrossRef]

- Johannes, T.; Mats, K.; Anders, K.; Minna, K. Modelling the construction and long-term response of Gota Tunnel. Comput. Geotech. 2020, 134, 104027. [Google Scholar]

- Zhang, Z.X.; Liu, C.; Huang, X.; Kwok, C.Y.; Teng, L. Three-dimensional finite-element analysis on ground responses during twin-tunnel construction using the URUP method. Tunn. Undergr. Sp. Tech. 2016, 58, 133–146. [Google Scholar] [CrossRef]

- Yao, A.; Yang, X.; Dong, L. Numerical Analysis of the Influence of Isolation Piles in Metro Tunnel Construction of Adjacent Buildings. Procedia Earth Planet Sci. 2012, 5, 150–154. [Google Scholar] [CrossRef]

- Lueprasert, P.; Jongpradist, P.; Jongpradist, P.; Suwansawat, S. Numerical investigation of tunnel deformation due to adjacent loaded pile and pile-soil-tunnel interaction. Tunn. Undergr. Sp. Tech. 2017, 70, 166–181. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W. Investigation on passive pile responses subject to adjacent tunneling in anisotropic clay. Comput. Geotech. 2020, 127, 103782. [Google Scholar] [CrossRef]

- Liu, J.; Shi, C.; Lei, M.; Cao, C.; Lin, Y. Improved analytical method for evaluating the responses of a shield tunnel to adjacent excavations and its application. Tunn. Undergr. Sp. Tech. 2020, 98, 103339. [Google Scholar] [CrossRef]

- Li, X.; Cao, W.; Tao, M.; Zhou, Z.; Chen, Z. Influence of unloading disturbance on adjacent tunnels. Int. J. Rock Mech. Min. Sci. 2016, 84, 10–24. [Google Scholar] [CrossRef]

- Chang, S.H.; Chen, C.S.; Wang, T.T. Sediment Sluice Tunnel of Zengwen Reservoir and construction of section with huge underground excavation adjacent to neighboring slope. Eng. Geol. 2019, 260, 105227. [Google Scholar] [CrossRef]

- Fulvio, T. ADECO full-face tunnel excavation of two 260 m2 tubes in clays with sub-horizontal jet-grouting under minimal urban cover. Tunn. Undergr. Sp. Tech. 2011, 26, 253–266. [Google Scholar]

- Peng, F.; Ma, S. Analysis of experimental data on the effect of double-line parallel shield tunneling on the deformation of adjacent buildings. Alexandria Eng. J. 2021, 60, 3957–3963. [Google Scholar] [CrossRef]

- Chen, R.; Meng, F.; Li, Z.; Ye, Y.; Ye, J. Investigation of response of metro tunnels due to adjacent large excavation and protective measures in soft soils. Tunn. Undergr. Sp. Tech. 2016, 58, 224–235. [Google Scholar] [CrossRef]

- Liang, R.; Wu, W.; Yu, F.; Jiang, G.; Liu, J. Simplified method for evaluating shield tunnel deformation due to adjacent excavation. Tunn. Undergr. Sp. Tech. 2018, 71, 94–105. [Google Scholar] [CrossRef]

- Liang, R. Simplified analytical method for evaluating the effects of overcrossing tunneling on existing shield tunnels using the nonlinear Pasternak foundation model. Soils Found. 2019, 59, 1711–1727. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M.; Wang, W. Evaluation of deformation response for adjacent tunnels due to soil unloading in excavation engineering. Tunn. Undergr. Sp. Tech. 2013, 38, 244–253. [Google Scholar] [CrossRef]

- Zhang, J.F.; Chen, J.J.; Wang, J.H.; Zhu, Y.F. Prediction of tunnel displacement induced by adjacent excavation in soft soil. Tunn. Undergr. Sp. Tech. 2013, 36, 24–33. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, Z.; Jiang, Z. Key protection techniques adopted and analysis of influence on adjacent buildings due to the Bund Tunnel construction. Tunn. Undergr. Sp. Tech. 2014, 41, 24–34. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, D.W.; Yang, C.Z.; Qian, B. Long-term performance of metro tunnels induced by adjacent large deep excavation and protective measures in Nanjing silty clay. Tunn. Undergr. Sp. Tech. 2020, 95, 103147. [Google Scholar] [CrossRef]

- Li, X.; Yuan, D.; Jin, D.; Yu, J.; Li, M. Twin neighboring tunnel construction under an operating airport runway. Tunn. Undergr. Sp. Tech. 2018, 81, 534–546. [Google Scholar] [CrossRef]

- Q/CR9218:2015; Technical Regulations for Monitoring and Measurement of Railway Tunnels. China Railway Press: Beijing, China, 2015.

- Keinhorst, H. Betrachtung zur Bergschadenfrage. Gliickauf 1934, 149–155. [Google Scholar]

| Level | Factors | ||||

| Skew angle/° () | Proximity distance/m (l) | Buried depth/m (h) | Clearance/m (D) | Ratio of tunnel clearances () | |

| No. | Strata | h | ρ | φ | c | Rt | E | μ |

|---|---|---|---|---|---|---|---|---|

| m | Kg/m3 | ° | MPa | MPa | GPa | |||

| ①1Q4mlII | Artificial accumulation | 5.6 | 1939 | 33 | 0.024 | 0.01 | 0.03 | 0.29 |

| ⑨12K1bSsIVW3 | Highly weathered sandstone | 7.9 | 2245 | 43 | 0.03 | 0.14 | 0.75 | 0.15 |

| ⑨13K1bSsIVW2 | Sandstone | 19.9 | 2347 | 35 | 0.7 | 4.9 | 6 | 0.3 |

| ⑨33K1bStIVW2 | Siltstone | 8.2 | 2296 | 39 | 0.5 | 3.6 | 5 | 0.31 |

| ⑨13K1bSsIVW2 | Sandstone | 16.4 | 2143 | 35 | 0.7 | 4.9 | 6 | 0.3 |

| ⑨73K1bCgIVW2 | Conglomerate | 1.6 | 2347 | 35 | 0.7 | 4.9 | 6 | 0.3 |

| ⑨33K1bStIVW2 | Siltstone | 2.3 | 2296 | 39 | 0.5 | 3.6 | 5 | 0.31 |

| ⑨13K1bSsIVW2 | Sandstone | 8.2 | 2143 | 30 | 0.2 | 2 | 3.8 | 0.32 |

| ⑨33K1bStIVW2 | Siltstone | 10.1 | 2296 | 39 | 0.5 | 3.6 | 5 | 0.31 |

| Level | Factors | ||||

|---|---|---|---|---|---|

| Skew Angle/° ) | Proximity Distance/m (l) | Buried Depth/m (h) | Clearance/m (D) | Ratio of Tunnel Clearances ) | |

| 1 | 11.3 | 13.5 | 56.58 | 14.52 | 0.7 |

| 2 | 30 | 10 | 50 | 12 | 0.8 |

| 3 | 50 | 15 | 60 | 14 | 1.0 |

| 4 | 70 | 20 | 70 | 16 | 0.6 |

| 5 | 90 | 25 | 80 | 18 | 0.5 |

| Anchor Number of Every Ring Lining | Anchor Diameter/mm | Anchor Length/m | Anchor Bond Strength/(N/m) | Anchor Space | Anchoring Method |

|---|---|---|---|---|---|

| 5 | 90 | 12 | 1.75 × 105 | 2 | Extended anchorage |

| Experiment Group | Factors | Results | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| /° | l/m | h/m | D/m | W/ mm | U/ mm | K mm/m2 | i mm/m | ε mm/m | ||

| 1 | 11.3 | 13.5 | 56.58 | 14.52 | 0.7 | −13.6 | −0.432 | 0.0030 | 0.087 | 0.1002 |

| 2 | 11.3 | 10 | 50 | 12 | 0.8 | −9.88 | −0.454 | 0.0016 | 0.154 | 0.2603 |

| 3 | 11.3 | 15 | 60 | 14 | 1.0 | −25.4 | −1.267 | 0.0053 | 0.225 | 0.1328 |

| 4 | 11.3 | 20 | 70 | 16 | 0.6 | −27.6 | −0.634 | 0.0071 | 0.109 | 0.1327 |

| 5 | 11.3 | 25 | 80 | 18 | 0.5 | −38.4 | −0.708 | 0.0047 | 0.110 | 0.1157 |

| 6 | 30 | 13.5 | 50 | 14 | 0.6 | −17.7 | −1.108 | 0.0018 | 0.205 | 0.1972 |

| 7 | 30 | 10 | 60 | 16 | 0.5 | −29.5 | −0.033 | 0.0022 | 0.036 | 0.0045 |

| 8 | 30 | 15 | 70 | 18 | 0.7 | −40.1 | −2.698 | 0.0078 | 0.137 | 0.4346 |

| 9 | 30 | 20 | 80 | 14.52 | 0.8 | −27.1 | −2.281 | 0.0197 | 0.276 | 0.2679 |

| 10 | 30 | 25 | 56.58 | 12 | 1.0 | −18.9 | −1.950 | 0.0038 | 0.272 | 0.2193 |

| 11 | 50 | 13.5 | 60 | 18 | 0.8 | −34.7 | −3.055 | 0.0099 | 0.125 | 0.1855 |

| 12 | 50 | 10 | 70 | 14.52 | 1.0 | −14.9 | −1.792 | 0.0021 | 0.011 | 0.0341 |

| 13 | 50 | 15 | 80 | 12 | 0.6 | −13.4 | −0.874 | 0.0007 | 0.022 | 0.0296 |

| 14 | 50 | 20 | 56.58 | 14 | 0.5 | −16.7 | 0.994 | 0.0042 | 0.088 | 0.1072 |

| 15 | 50 | 25 | 20 | 16 | 0.7 | −50.1 | −5.611 | 0.0264 | 0.815 | 0.5950 |

| 16 | 70 | 13.5 | 70 | 12 | 0.5 | −12.5 | −1.002 | 0.0015 | 0.029 | 0.0309 |

| 17 | 70 | 10 | 80 | 14 | 0.7 | −23.4 | −1.744 | 0.0016 | 0.025 | 0.0412 |

| 18 | 70 | 15 | 56.58 | 16 | 0.8 | −28.1 | −2.379 | 0.0006 | 0.089 | 0.1176 |

| 19 | 70 | 20 | 50 | 18 | 1.0 | −63.2 | −4.914 | 0.0206 | 0.265 | 0.2988 |

| 20 | 70 | 25 | 60 | 14.52 | 0.6 | −21.4 | −1.810 | 0.0055 | 0.042 | 0.0985 |

| 21 | 90 | 13.5 | 80 | 16 | 1.0 | −36.1 | −4.130 | 0.0017 | 0.041 | 0.0359 |

| 22 | 90 | 10 | 56.58 | 18 | 0.6 | −31.2 | −2.319 | 0.0050 | 0.098 | 0.1363 |

| 23 | 90 | 15 | 50 | 14.52 | 0.5 | −9.94 | −1.448 | 0.0011 | 0.043 | 0.0449 |

| 24 | 90 | 20 | 60 | 12 | 0.7 | −13.3 | −1.741 | 0.0001 | 0.041 | 0.0481 |

| 25 | 90 | 25 | 70 | 14 | 0.8 | −23.8 | −3.794 | 0.0025 | 0.036 | 0.0506 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Wang, H.; Kang, S.; Liu, C.; Chen, Y.; Zhou, X.; Wu, C.; Zhu, H.; Yang, C.; Zhu, Y.; et al. Factors Influencing Ground Settlement during Tunnel Proximity Construction. Sustainability 2023, 15, 13270. https://doi.org/10.3390/su151713270

Yuan X, Wang H, Kang S, Liu C, Chen Y, Zhou X, Wu C, Zhu H, Yang C, Zhu Y, et al. Factors Influencing Ground Settlement during Tunnel Proximity Construction. Sustainability. 2023; 15(17):13270. https://doi.org/10.3390/su151713270

Chicago/Turabian StyleYuan, Xun, Hongchao Wang, Shun Kang, Changwu Liu, Yulin Chen, Xianliang Zhou, Chengzhe Wu, Haowei Zhu, Changyu Yang, Yong Zhu, and et al. 2023. "Factors Influencing Ground Settlement during Tunnel Proximity Construction" Sustainability 15, no. 17: 13270. https://doi.org/10.3390/su151713270