1. Introduction

Asphalt pavement, celebrated for its low vibrational attributes, minimal noise levels, and ease of maintenance, is extensively adopted in the construction of high-grade highways [

1]. However, in winter months, the presence of ice or snow can significantly reduce the skid resistance of asphalt surfaces, consequentially escalating the frequency of traffic accidents and the potential for casualties [

2,

3]. Currently, to ensure vehicular safety, highway maintenance departments predominantly employ chemical, mechanical, and heating methods to eradicate road ice and snow. The long-standing preferred technique has been deicer distribution, attributable to its high efficacy, cost-effectiveness, and simplicity of operation. Foreseeably, this approach will remain dominant in the near term, as alternatives are not expected to supplant it [

4]. Despite its benefits, the widespread application of deicers poses environmental challenges to the surrounding road areas and inflicts considerable damage to the pavement [

5,

6,

7].

Upon the dispersion of deicer on roadways, its solution permeates both the pavement and the surrounding environment. Prior to considerable precipitation-induced dilution, the pavement remains enveloped in an environment with a high concentration of the deicer solution [

8,

9]. This effect is particularly pronounced in areas like Northwest China, characterized by limited rainfall. Though numerous studies have focused on the impact and mechanisms of deicers on cement concrete [

10,

11,

12,

13], investigations into their effects on asphalt concrete are comparatively scarce due largely to its complex viscoelastic nature, as opposed to the simpler elastic–plastic behavior of cement concrete [

14,

15,

16,

17]. Setiadji [

18] subjected asphalt mixtures to wet–dry cycles in varied concentrations of chloride solutions, concluding that chloride may predominantly contribute to asphalt mixture damage. Similarly, Xiong [

19] suggested that crystallization erosion, instigated by salt solution seeping into the voids and cracks of the asphalt mixture, is a vital factor in asphalt mixture deterioration. Consequently, deicers lingering in the roadside environment could potentially induce significant harm to the asphalt mixture.

During frigid winters, substantial temperature disparities instigated by daily fluctuations or weather conditions can induce multiple freeze–thaw cycles of the deicer solution [

20,

21]. The salt solution infiltrating the exterior voids of the mixture can generate frost heave forces upon freezing [

22], prompting the voids within the mixture to evolve into interconnected open gaps, thereby hastening asphalt mixture degradation. Amini’s research [

23] into the impact of salt solution on asphalt mixture deterioration under freeze–thaw cycles demonstrated that the joint action of water and deicer amplifies asphalt mixture deterioration; furthermore, it was found that asphalt mixtures with a higher proportion of fine aggregates exhibit enhanced erosion resistance. Through freeze–thaw cycle testing, Feng [

24] established that salt significantly affects the low-temperature performance of asphalt mixtures. It was discerned that when salt content is below 3%, freeze–thaw cycles primarily impact the asphalt mixture’s low-temperature performance; however, when salt content exceeds 3%, salt erosion accelerates asphalt mixture degradation. According to Guo et al. [

25], the bonding interface between asphalt and aggregate under salt immersion and freeze–thaw cycles deteriorates faster than under pure water conditions. Wang’s in-depth analysis [

26], employing semi-circular bending tests, studied the effects of asphalt type, freeze–thaw cycle frequency, and deicer concentration on asphalt mixture crack resistance, indicating a gradual decrease in crack resistance with an increase in freeze–thaw cycle frequency and salt concentration. Huang Xinyan et al. [

27] found that the likelihood of asphalt film detachment increases in the presence of salt. Zhang’s [

28] research on the application of microwave heating technology in repairing microcracks resulting from freeze–thaw cycle damage, conducted on two different asphalt mixtures, suggested that freeze–thaw damage and microwave heating alter the material’s internal pore structure. As such, they proposed optimal healing times and depths for the two mixtures, offering novel insights into the damage from freeze–thaw cycles and the mechanism of microwave healing.

Current research predominantly focuses on the impact of deicers on the low-temperature stability of asphalt concrete, with scant attention paid to water stability. The majority of these studies emphasize single-factor alterations, resulting in a deficit of comprehensive evaluations of the multi-factor influence of deicers on the water stability of asphalt mixtures. Water stability embodies the competency of asphalt blends to preserve their physico-mechanical properties amidst water exposure. This metric provides an essential gauge for evaluating the capacity of asphalt mixtures to sustain their structural integrity, preclude material detachment, and conserve compressive and shear strength under hydric conditions, for instance, precipitation and groundwater intrusion. Water is the primary agent inducing various forms of early damage to asphalt pavements. The presence of water alters the physical and chemical properties of the asphalt binder, diminishes the adhesion between asphalt and aggregate, and, under the effect of other factors, instigates a range of pavement diseases, impacting both service performance and lifespan [

29,

30]. Consequently, it is crucial to investigate the changes in water stability of asphalt concrete after exposure to deicer erosion and freeze–thaw cycles and to identify the main factors contributing to water stability damage under multiple influences.

In the initial phase, the research team established nine monitoring points on high-grade highways in Gansu Province, China. Wind velocity and direction, precipitation, solar radiation intensity, and atmospheric humidity were procured via the CaipoBase compact weather station, whereas asphalt pavement temperatures were gauged using soil temperature sensors placed at depths of 10 cm, 20 cm, 30 cm, 40 cm, and 50 cm. These measurements were conducted on an hourly basis, revealing that the minimum internal temperature of the road infrastructure could descend to −15 °C [

21]. Concurrently, the freezing point of various deicers was assessed in the laboratory, yielding data on the freezing points of different concentrations of commonly used deicers [

20,

21]. Building upon these findings and taking into account the unique climatic and hydrological characteristics of Northwest China [

16,

31], this study selected three suitable deicer solutions for freeze–thaw cycle testing on two types of graded asphalt mixtures under three low-temperature conditions. The water stability of the asphalt concrete was examined via the Marshall water immersion test and the freeze–thaw splitting test. A statistical analysis was conducted to identify the primary factor affecting the water stability of asphalt mixtures due to deicer to prevent and reduce the economic losses caused by water damage to asphalt pavement.

6. Conclusions

Following data analysis from the Marshall water immersion test and the freeze–thaw splitting test, which scrutinized the freeze–thaw cycles of two varieties of dense-graded asphalt mixtures subjected to three distinct deicer solutions and three unique low-temperature environments, this present study concludes as follows:

- (1)

Deicer solutions, once absorbed into the asphalt mixture, can shield it from frost heaving damage, provided they remain above their freezing point. The empirical data indicates a residual stability decline of approximately 8% and a TSR reduction of around 14%, suggesting a minimal loss of water stability. However, they still inflict erosion damage on the asphalt concrete, potentially shortening the lifespan of the pavement with prolonged usage.

- (2)

When the temperature falls beneath their freezing point after the deicer solutions penetrate the asphalt mixture, frost heaving damage to the asphalt concrete occurs, culminating in a significant water stability loss. The empirical data points to a residual stability decline of approximately 19% and a TSR reduction of about 35%, severely compromising the longevity of the road surface.

- (3)

Among the three deicers studied, CH4N2O inflicts significantly more damage on the water stability of the asphalt mixture compared to NaCl and CH2CH3OH.

- (4)

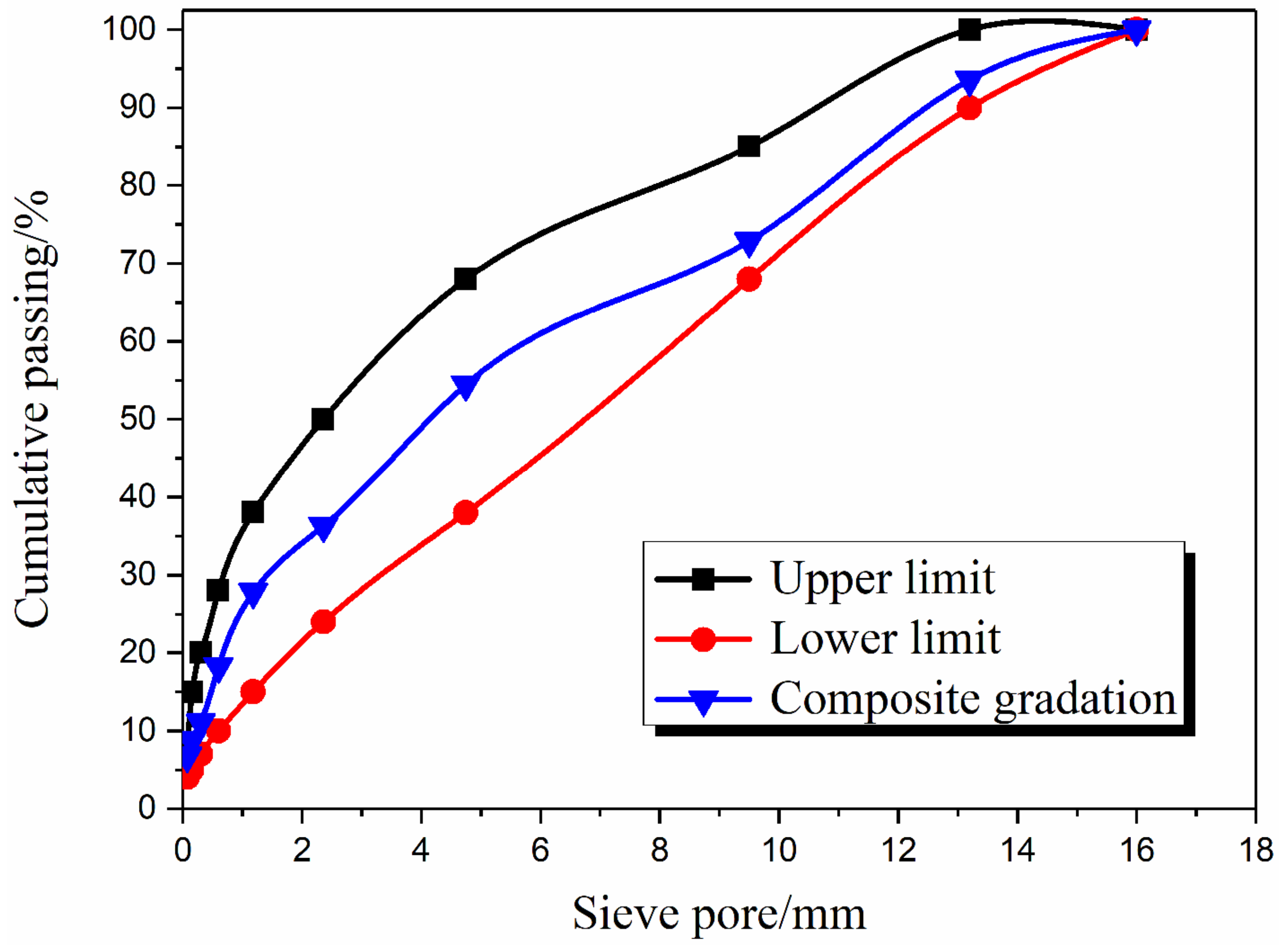

Enhancing the proportion of fine aggregate in the asphalt mixture bolsters the asphalt concrete’s resistance to deicer erosion damage and frost heaving damage.

- (5)

Variance analysis results for the two evaluation indicators indicate that gradation significantly influences the water stability of the asphalt mixture, even more so than the deicer, without considering unmodifiable factors such as weather (distinct low-temperature environments) and pavement service time (freeze–thaw cycles). Therefore, it is advisable to modify the gradation of asphalt mixtures on icy road sections. In scenarios where gradation alteration is impossible, or the road has already been constructed, the application of deicer remains an effective means to safeguard the asphalt mixture.

The present study explores the alterations in the water stability of asphalt mixtures under varying environmental conditions, ascertained through freeze–thaw cycling tests. Such findings could offer valuable references for pavement design and maintenance, particularly in colder regions. Grasping the effects of these factors on the performance of asphalt mixtures facilitates more effective pavement design and maintenance, thereby enhancing pavement longevity and vehicular safety. Nonetheless, this research has certain constraints. Primarily, the experimental scope was limited to AC-13 and AC-16 asphalt mixtures alongside three distinct types of deicers, which may not comprehensively represent all potential asphalt mixtures and deicers. Secondly, the prevailing experimental conditions may not fully encapsulate the multifaceted scenarios encountered in real road environments. Future investigations should encompass a broader variety of asphalt mixtures and deicers and take into account additional environmental variables, such as traffic load and temperature range, to more precisely gauge the effects of these factors on asphalt mixture performance.