Cyclic Loading and Unloading of Weakly Consolidated Sandstone with Various Water Contents

Abstract

:1. Introduction

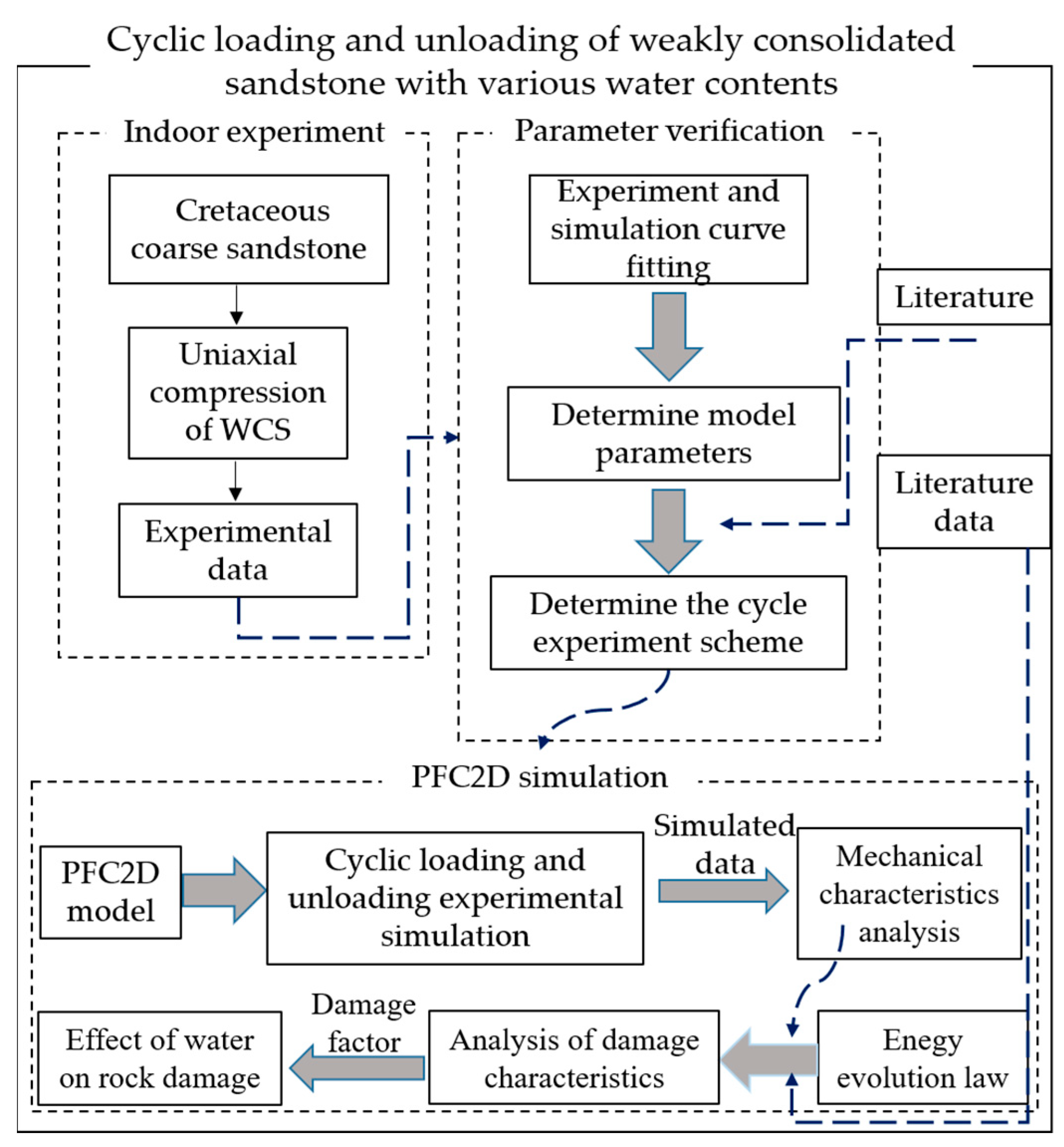

2. Numerical Simulation of WCS with Various Water Contents under Cyclic Loading and Unloading

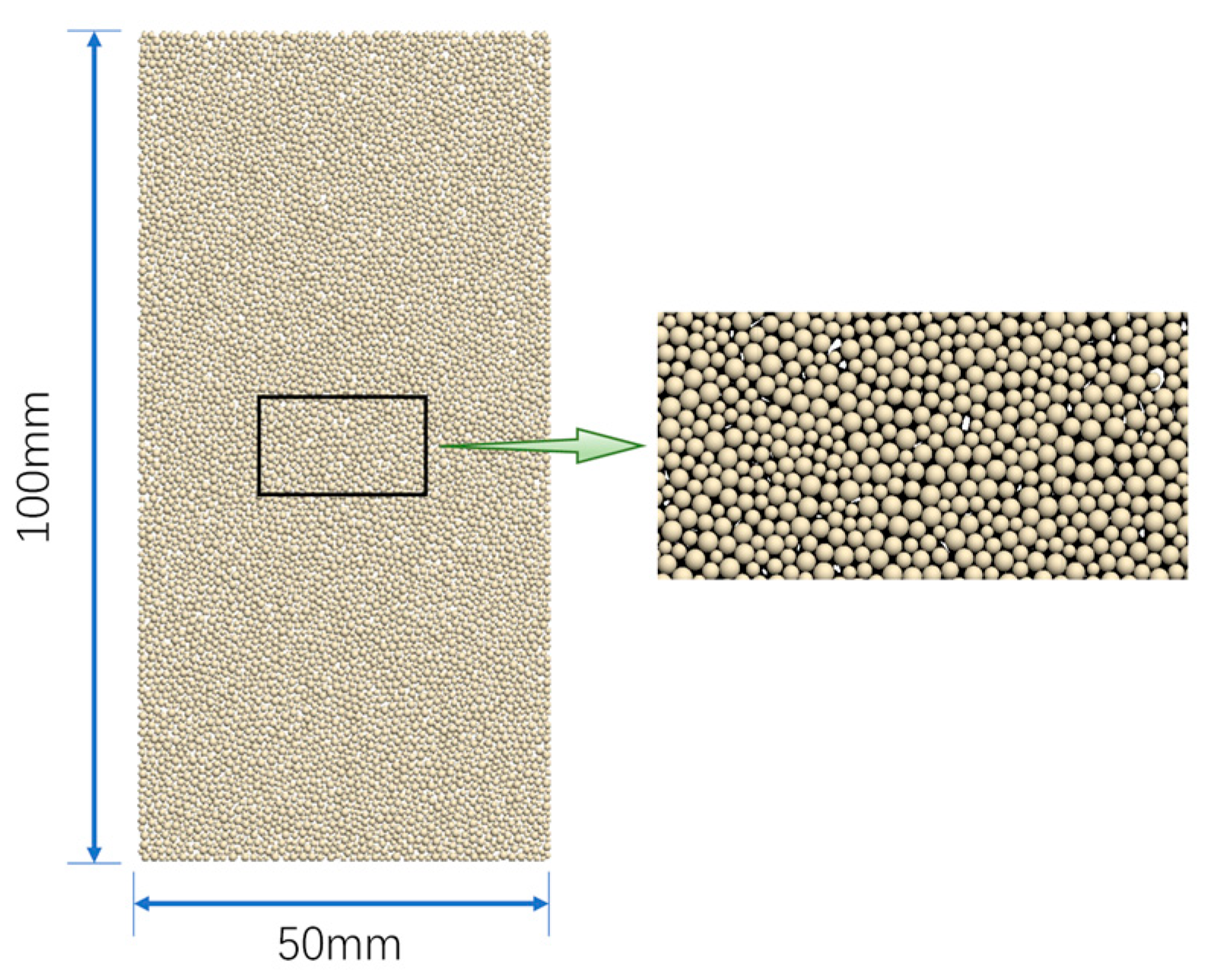

2.1. Numerical Modeling of Particle Flow

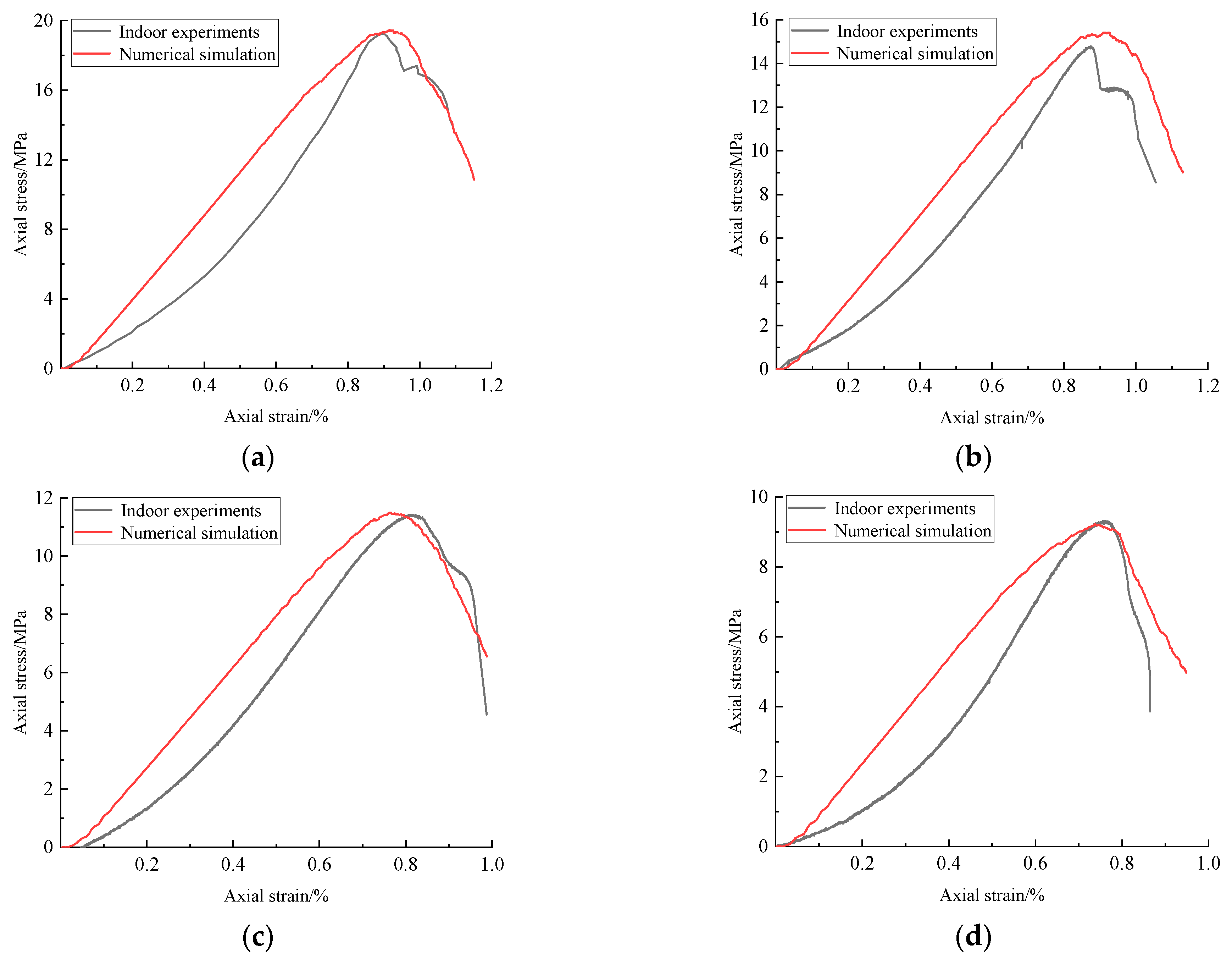

2.2. Verification of the Fine-View Parameters

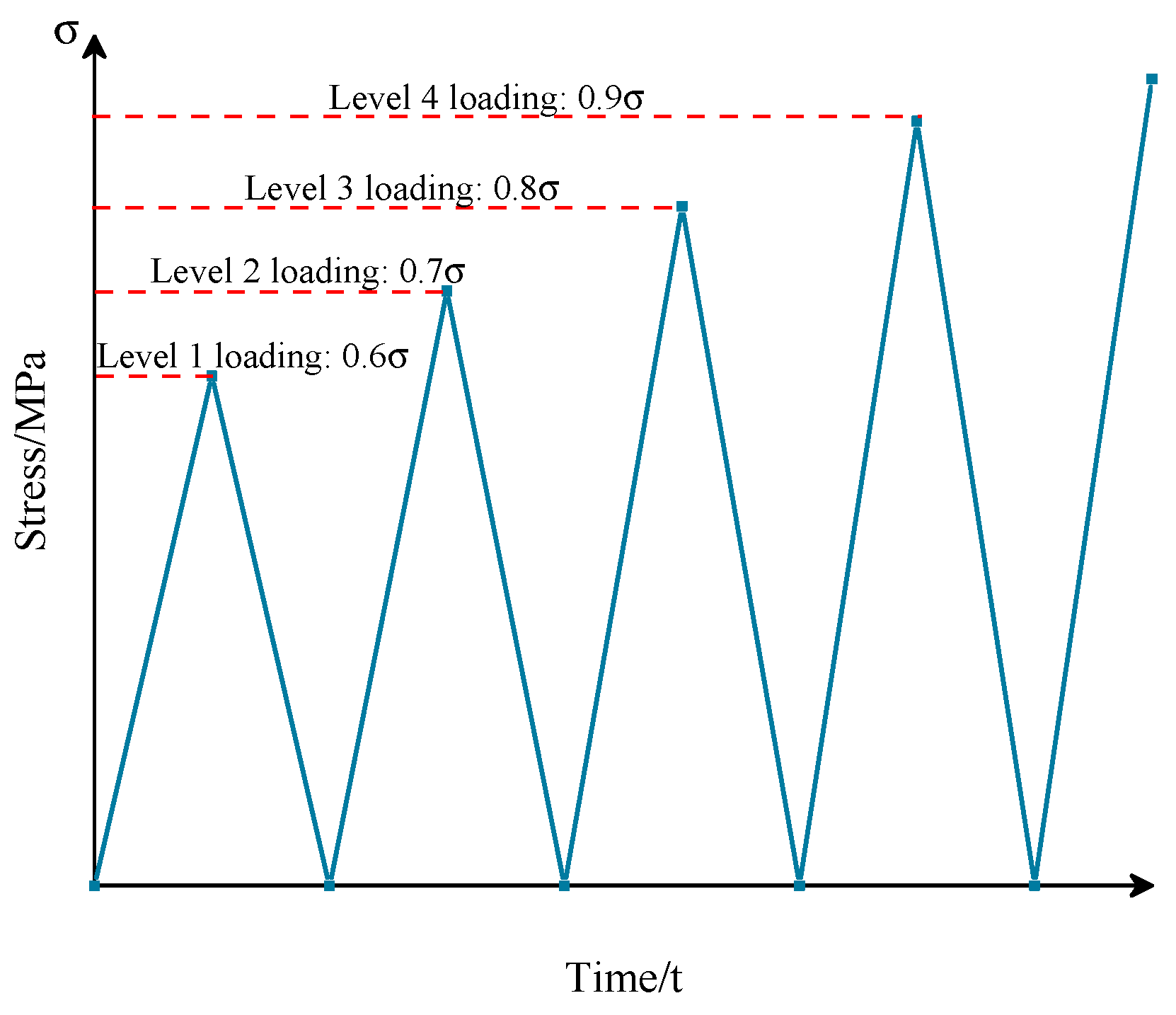

2.3. Simulation of WCS with Various Water Contents under Cyclic Loading and Unloading

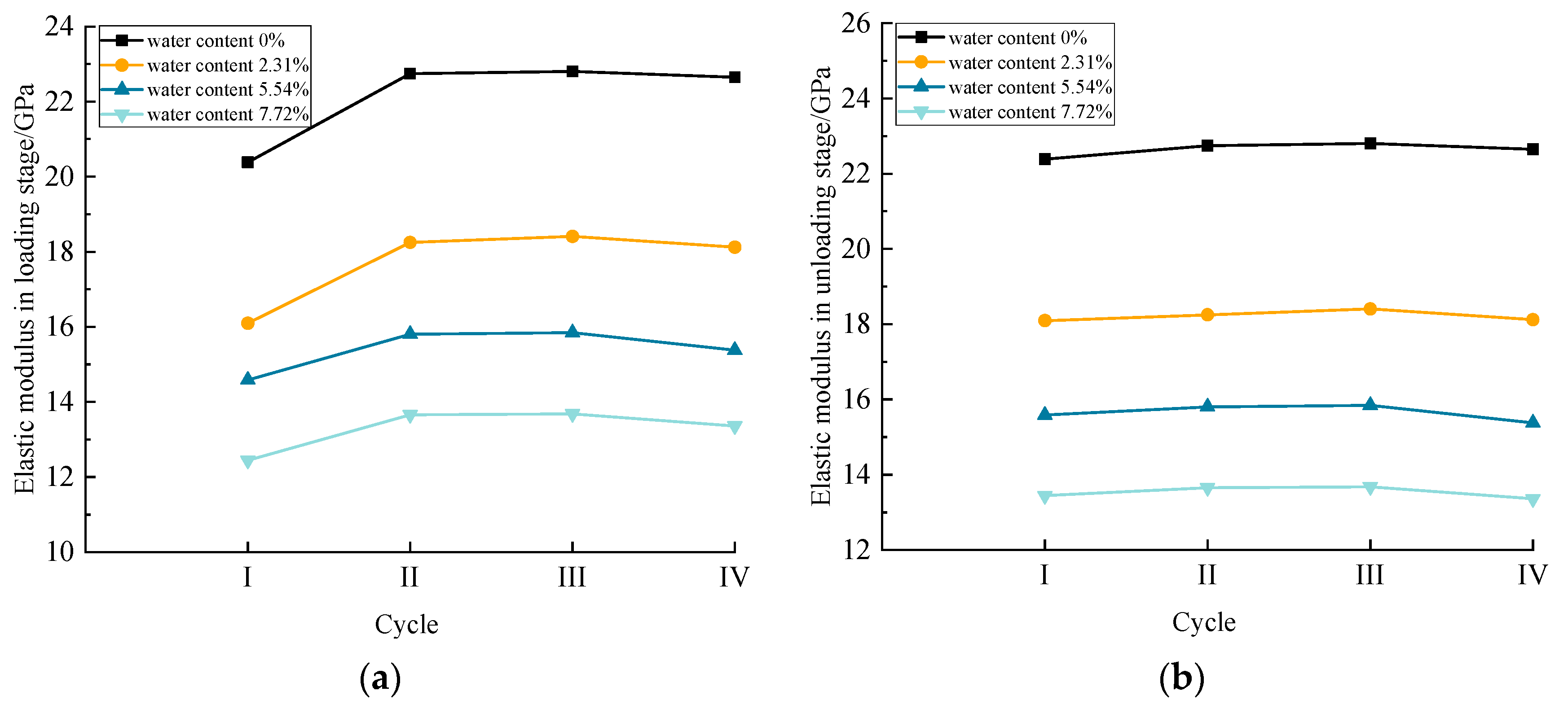

3. Effects of Water Content on the Mechanical Properties of WCS under Cyclic Loading and Unloading

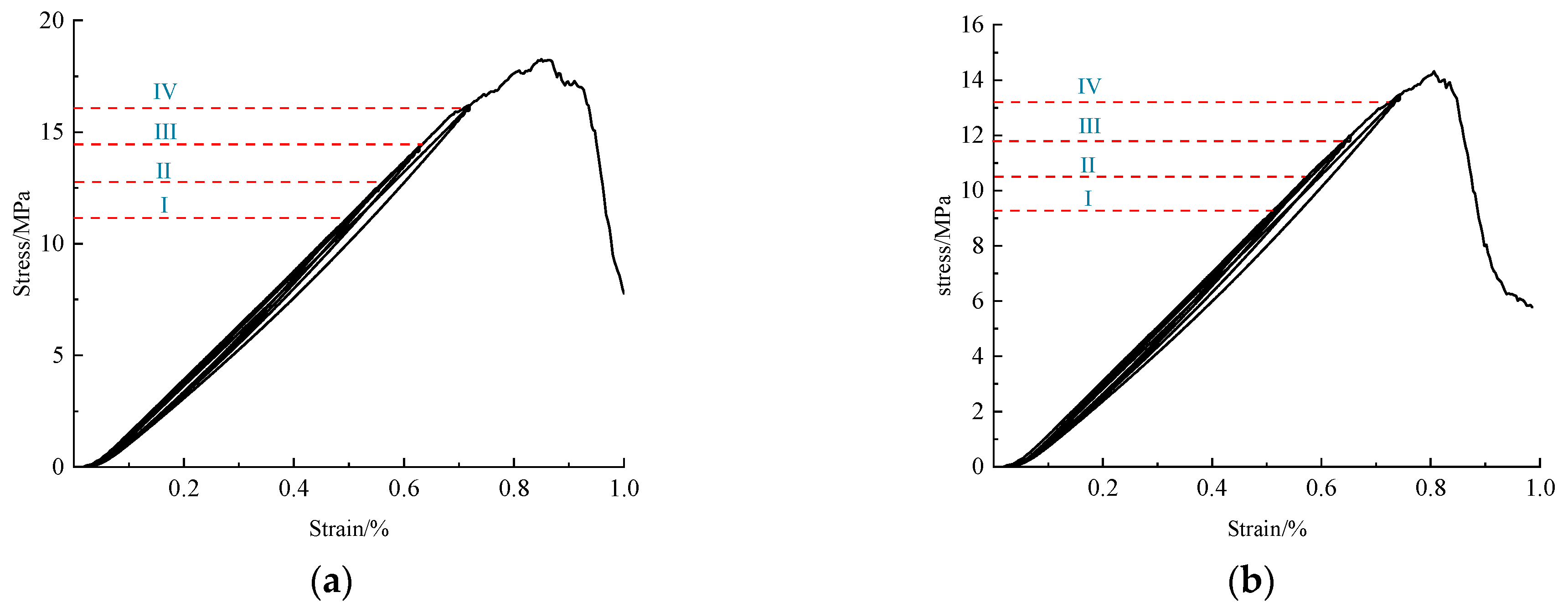

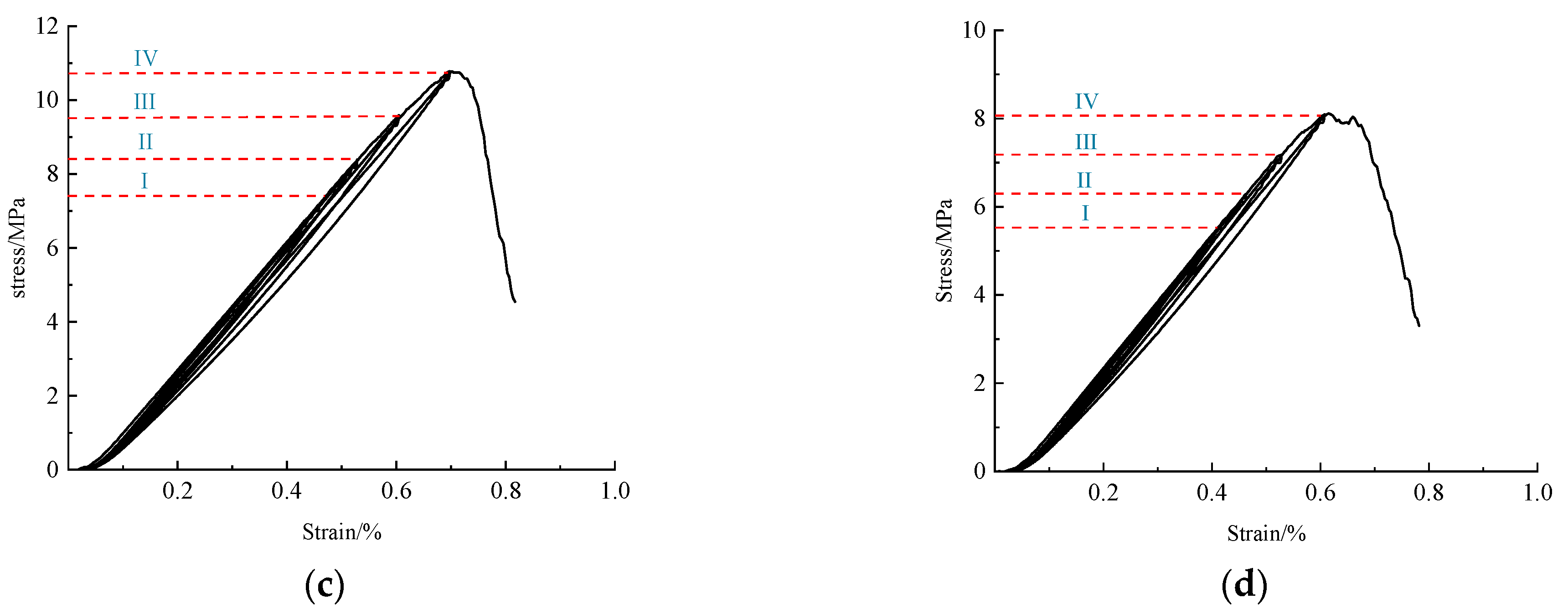

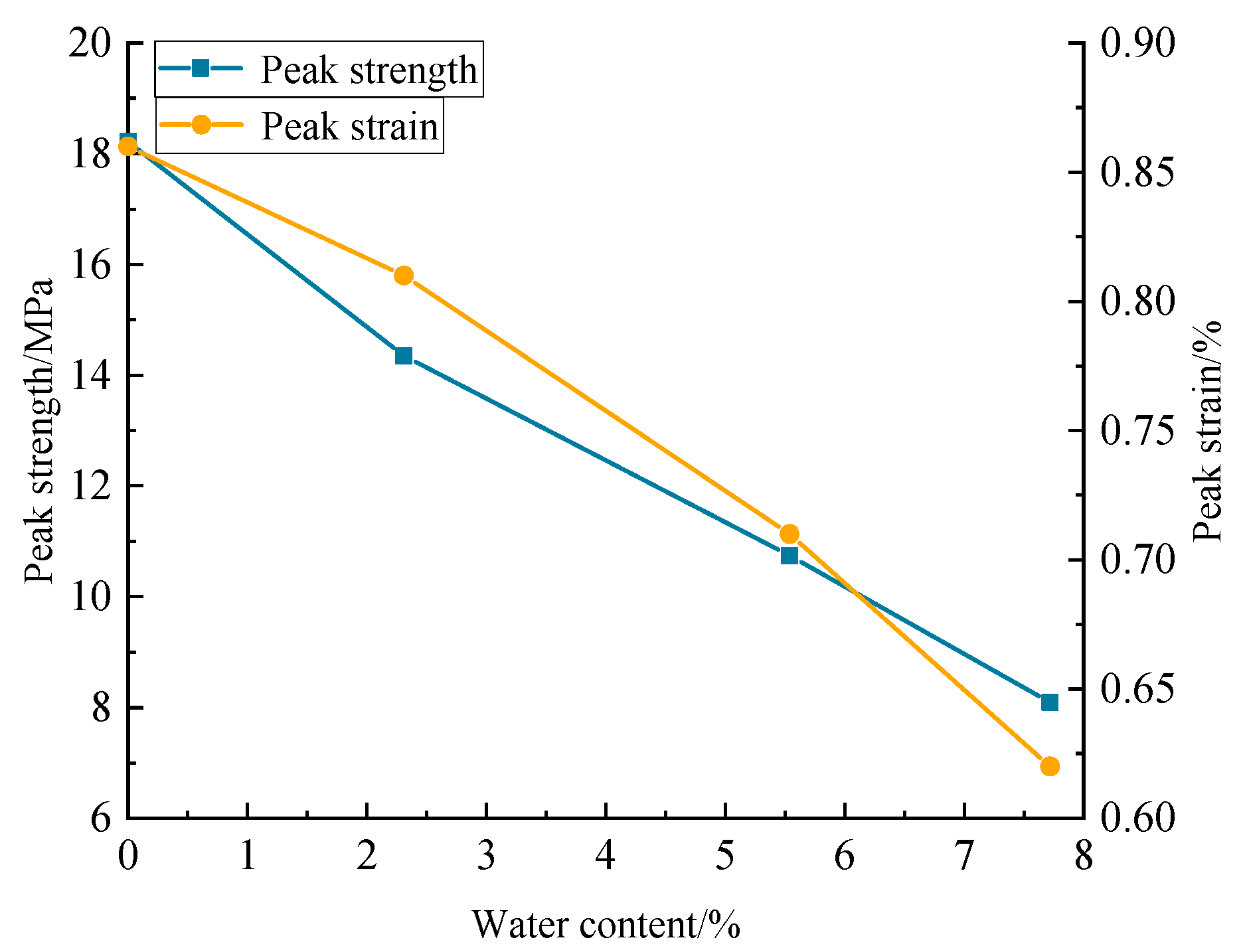

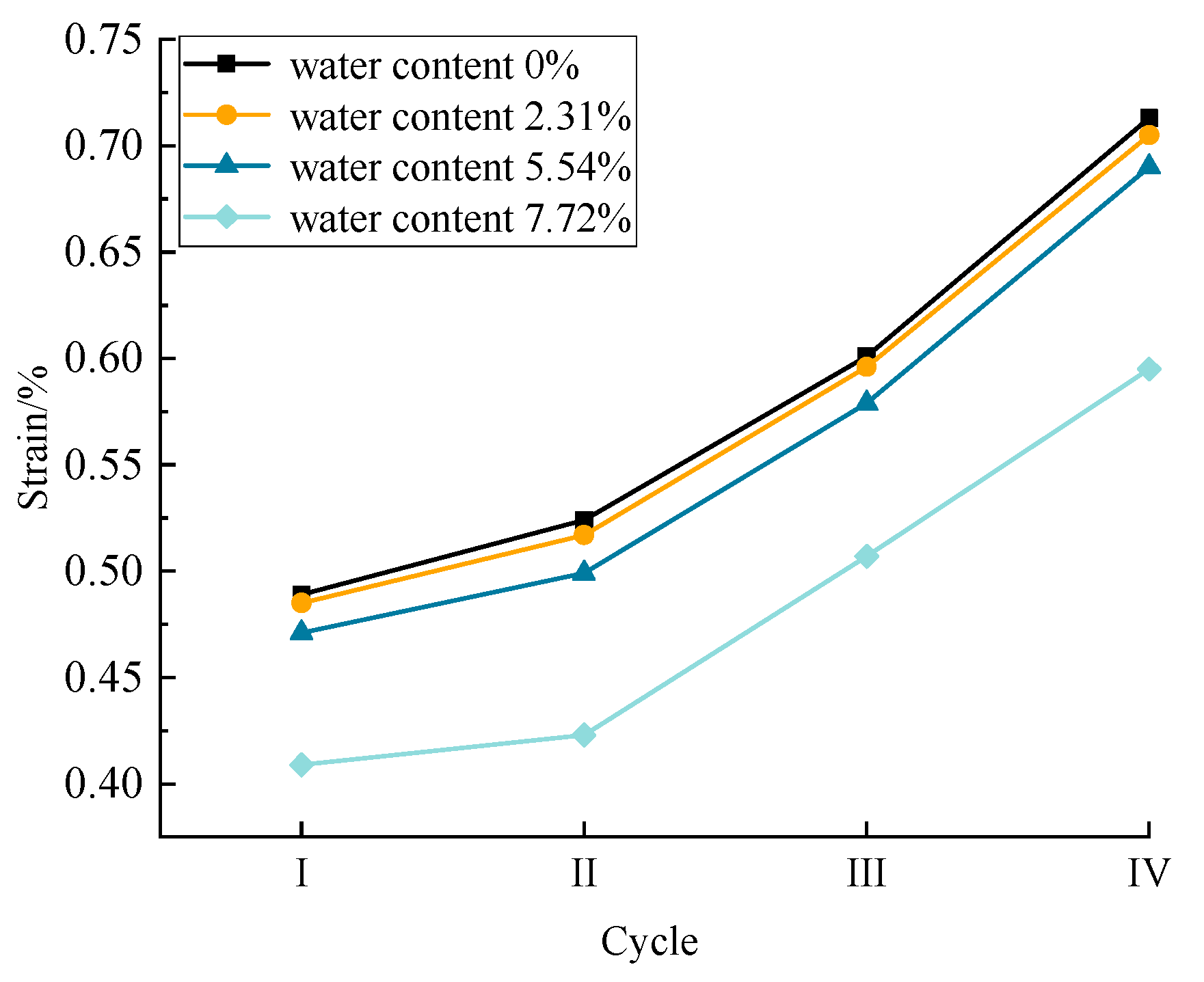

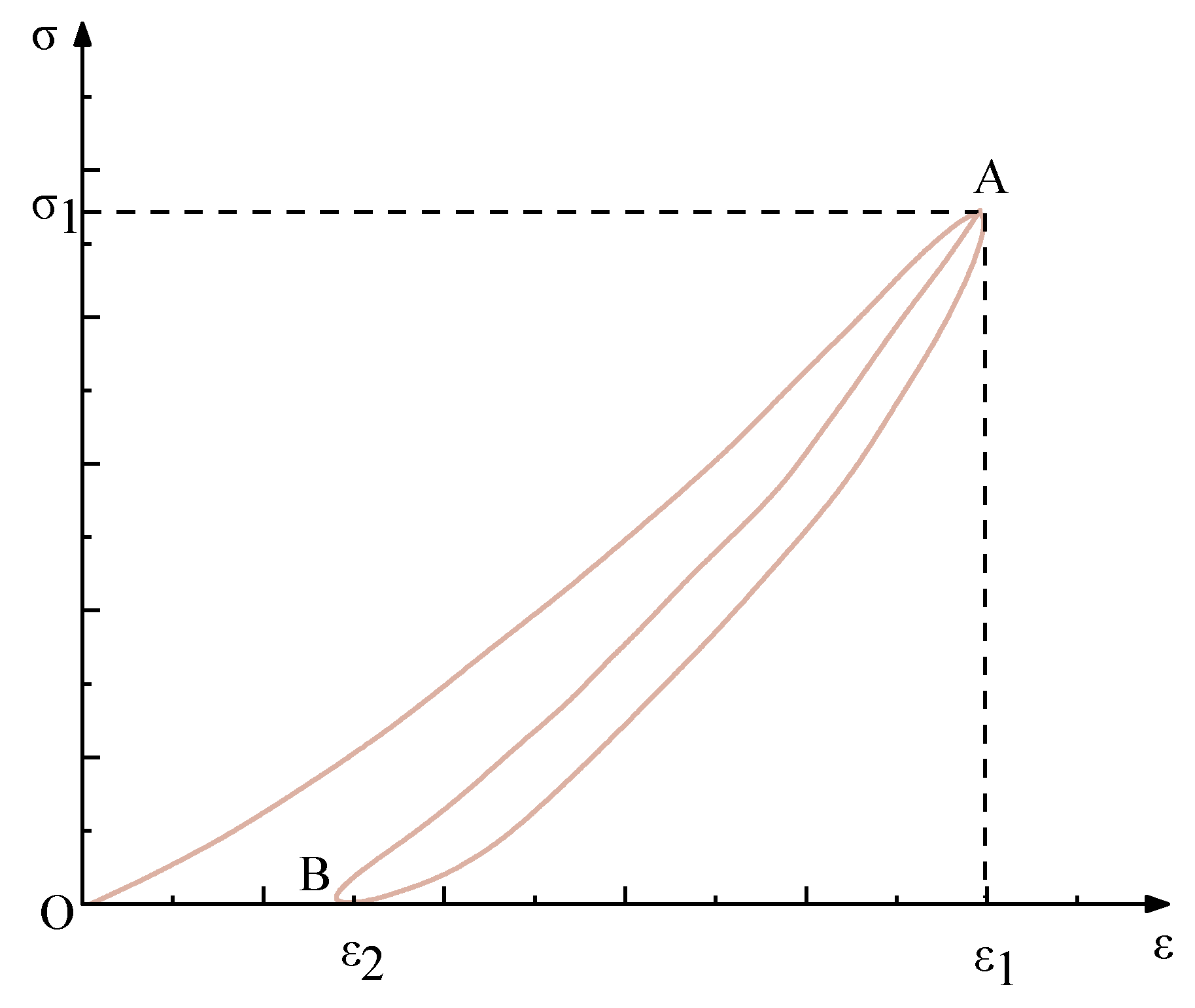

3.1. Effects of Water Content on the Stress–Strain Behavior of WCS

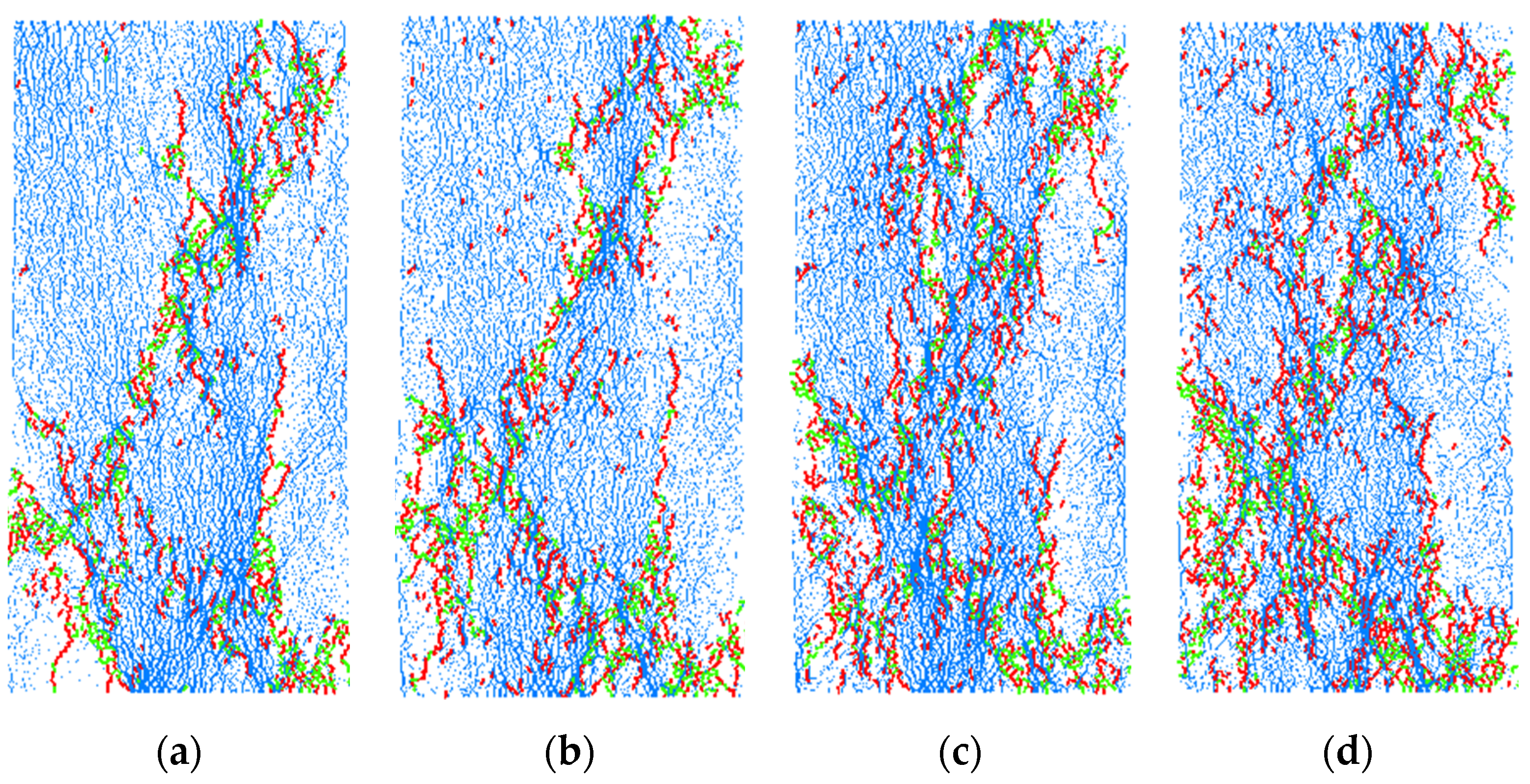

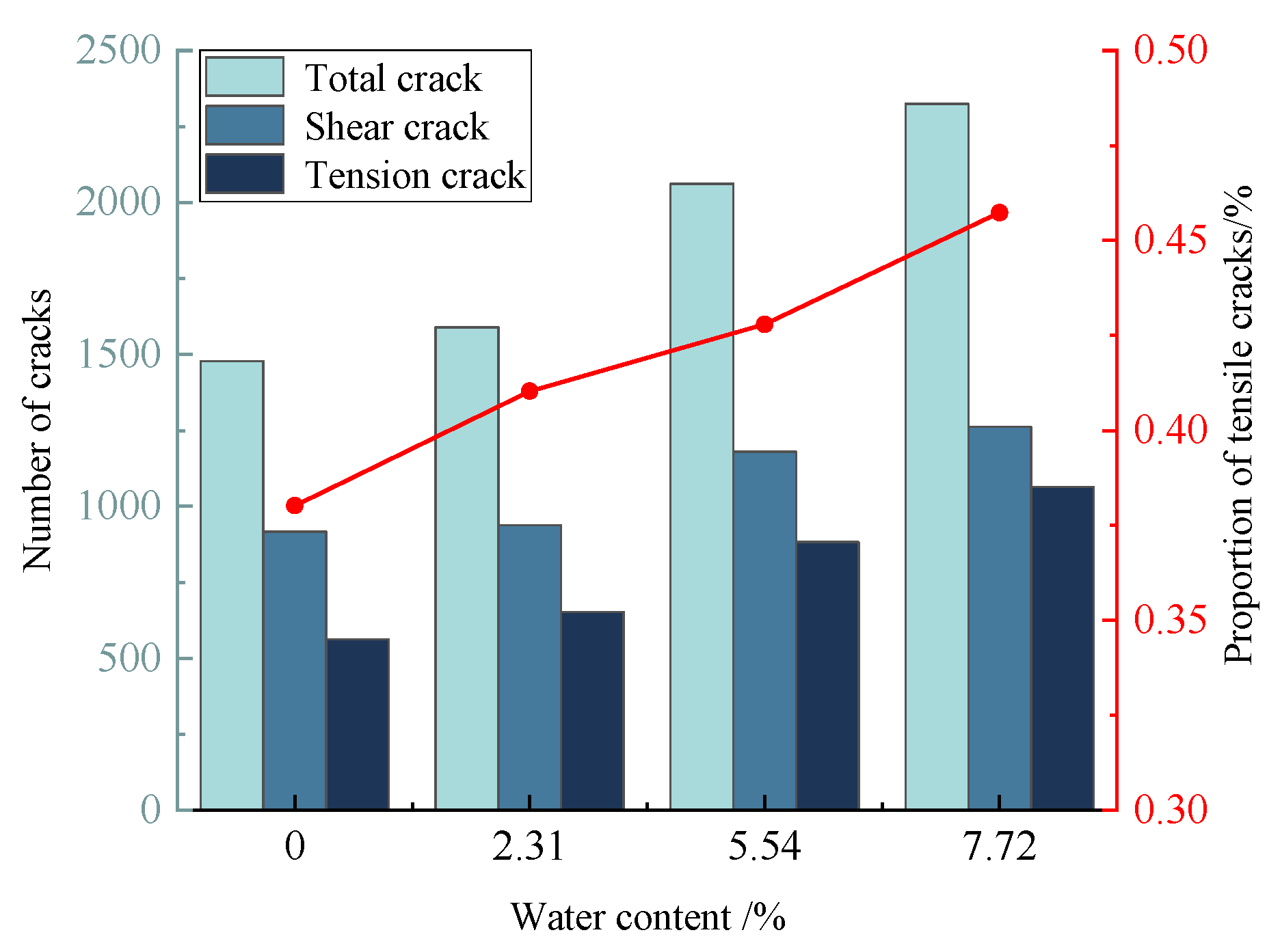

3.2. Effect of Water Content on the Fracture Morphology

4. Energy Evolution Law for WCS with Various Water Contents

4.1. Energy Calculation Methods

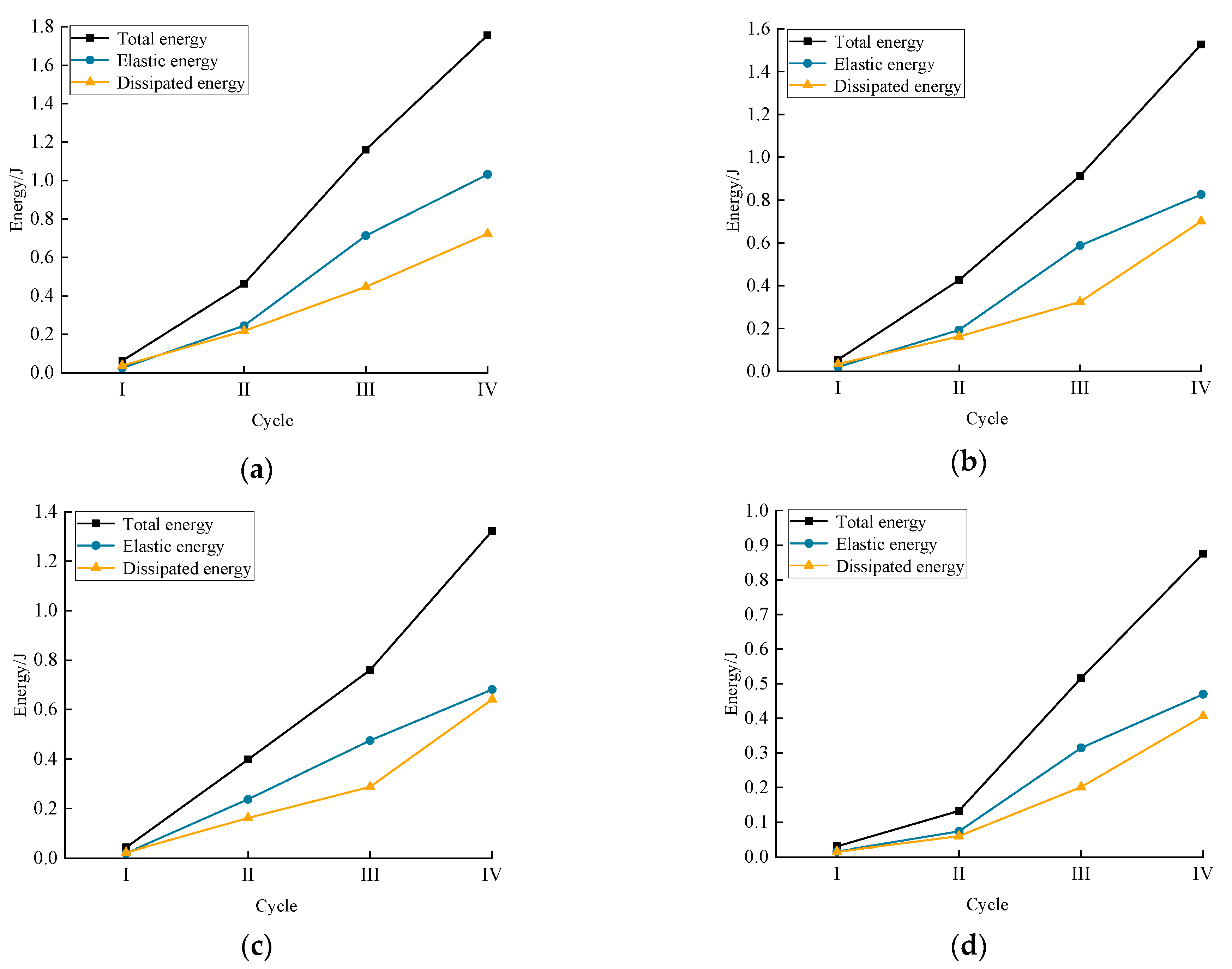

4.2. Energy Evolution Process

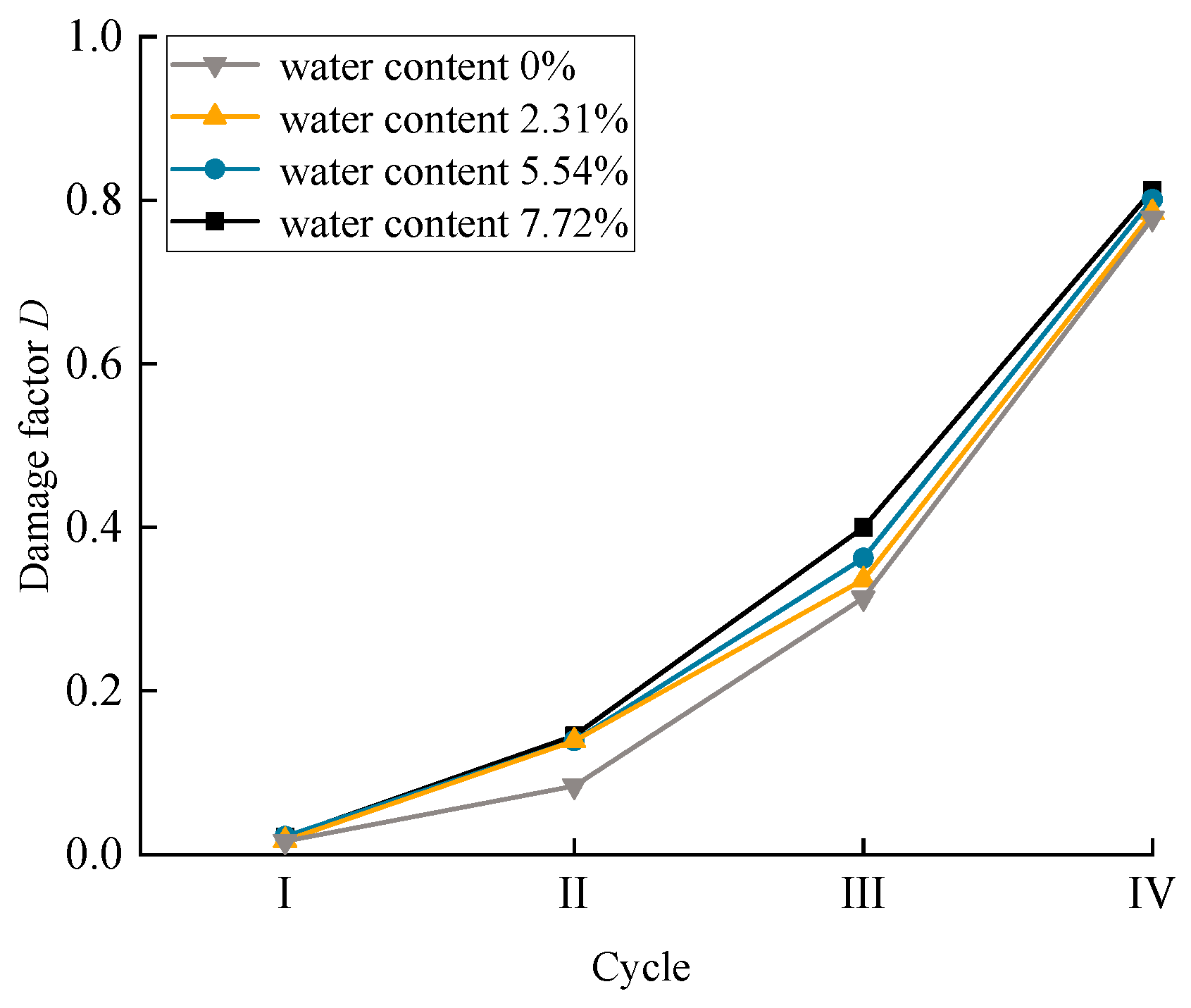

4.3. Damage Characterization

5. Conclusions

- With an increase in the water content, the peak strength of the cyclic loading and unloading of WCS gradually decreased. Compared with the dry state (0%), the peak strengths decreased by 21.32%, 25.03%, and 24.64% for water contents of 2.31%, 5.54%, and 7.72%, respectively. The elastic modulus of the cyclic loading stage increased with the increase in the number of cycles; this increase was the largest before the second cycle, while the overall change in the elastic modulus in the unloading stage was small.

- When the water content was low (≤2.31%), rock fractures were caused by the generation of a single inclined main crack, which resulted in overall splitting failures. Clear secondary cracks developed around the main crack, which was typical of the shear failure mode. As the water content increased (>2.31%), the fracture pattern gradually changed from single inclined surface failure to a combination of tensile and shear slip failures.

- As the number of cyclic loadings and unloadings increased, the elastic, dissipated, and total energies of WCS with various water contents gradually increased. During the initial loading phase, the dissipated energy was dominant; variations in the total strain, elastic, and dissipated energies were relatively small; and the dissipated energy was slightly greater than the elastic energy. As the number of cycles increased, the rock entered the elastoplastic stage; the growth rate of the elastic energy increased and it gradually exceeded the dissipated energy. Near the peak stress, there was a noticeable difference in the variations in the elastic and dissipated energies.

- With an increase in the cyclic loading and unloading times, the damage factors of WCS with different water contents gradually increased with a gradual increase in the growth rate. However, due to deteriorations in the mechanical properties of sandstone from water, the water content continued to increase and the peak value of the damage factor tended to increase, from 0.77 for a low water content to 0.81 for a high water content.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, J.H.; Zhao, X.D.; Zhou, G.Q.; Zhou, Y.X.; Jiao, W. Study in Physical and Mechanical Characteristics of Cretaceous System Weakly Cemented Sandstone in Erdos Basin. J. Mine Constr. Technol. 2021, 42, 22–28. [Google Scholar]

- Li, H.G.; Li, H.M.; Xu, G.S. Influence of water content on mechanical characteristics of weakly cemented sandstone. J. Min. Strat. Control Eng. 2021, 3, 60–66. [Google Scholar]

- Zhao, Y.C.; Yang, T.H.; Xiao, F.K.; Wang, H.; Liu, G.; Zheng, X.; Zhou, J.R.; Shen, Z.L. The variation law of plastic strain energy of western weak cemented sandstone during cyclic loading experiment. J. China Coal Soc. 2015, 40, 1813–1819. [Google Scholar]

- Ma, J.; Guan, J.; Duan, J.; Huang, L.; Liang, Y. Stability analysis on tunnels with karst caves using the distinct lattice spring model. J. Undergr. Space 2021, 6, 469–481. [Google Scholar] [CrossRef]

- Ma, J.; Zhao, J.; Lin, Y.; Liang, J.; Chen, J.; Chen, W.; Huang, L. Study on Tamped Spherical Detonation-Induced Dynamic Responses of Rock and PMMA Through Mini-chemical Explosion Tests and a Four-Dimensional Lattice Spring Model. J. Rock Mech. Rock Eng. 2023, 56, 1–19. [Google Scholar] [CrossRef]

- Li, H.Y.; Meng, L.B.; Li, T.B.; Li, P. Study on microscopic damage mechanism of sandstone under uniaxial cyclic loading in different water-bearing states. J. China Test 2023, 1–8. Available online: http://kns.cnki.net/kcms/detail/51.1714.TB.20221027.1726.002.html (accessed on 30 July 2023).

- Yang, K.; Zhang, Z.N.; Chi, X.L.; Lyu, X.; Wei, Z.; Liu, W.J. Experimental study on crack evolution and damage characteristics of water bearing sandstone under cyclic loading. J. Rock Soil Mech. 2022, 43, 1791–1802. [Google Scholar]

- Wu, Z.H.; Song, C.Y.; Tan, J.; Zhang, Y.Z.; Qi, Z.J. The evolution law of rock energy under different graded cyclic loading and unloading modes. J. Min. Saf. Eng. 2020, 37, 836–844 + 851. [Google Scholar]

- Ji, H.G.; Chen, D.S.; Su, X.B.; Quan, D.L. Analysis of elastic modulus variation and energy evolution of Granite based on triaxial loading and unloading test. J. Northeast. Univ. 2023, 44, 415–423. [Google Scholar]

- Yang, Y.; Lin, J.; Chen, X.; Yin, J.C. Mechanical characteristics analysis of weakly consolidated sandstone under dry, wet and cyclic loading and unloading conditions. J. Lanzhou Inst. Technol. 2022, 29, 7–12. [Google Scholar]

- Liu, J.; Li, J.T. Analysis on meso-damage characteristics of marble under triaxial cyclic loading and unloading based on particle flow simulation. J. Central South Univ. 2018, 49, 2797–2803. [Google Scholar]

- Tian, W.L.; Yang, S.Q.; Huang, Y.H. Particle flow analysis of mechanical behavior and meso-mechanism of sandstone under unloading confining pressure. J. Rock Soil Mech. 2016, 37, 775–782. [Google Scholar]

- Sun, L.H.; Long, Y.X.; Li, X.; Jiang, Z.; Fan, Y.; Wang, Z.; Han, X. Effect of loading rate on the mechanical properties of weakly cemented sandstone. Sustainability 2023, 15, 2750. [Google Scholar] [CrossRef]

- Sun, L.H.; Jiang, Z.X.; Long, Y.X.; Ji, Q.; Wang, Z.; Fan, Y.; Hao, Y. Influence of mesoscopic parameters of weakly cemented rocks on macroscopic mechanical properties. Sustainability 2022, 14, 13308. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Hanandeh, S. The influence of fines on the hydro-mechanical behavior of sand for sustainable compacted liner and sub-base construction applications. Asian J. Civ. Eng. 2023, 24, 1–13. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, T.; Xiang, W.; Tan, L. Influence of water content on the physical and mechanical behaviour of argillaceous siltstone and some microscopic explanations. Chin. J. Rock Mech. Eng. 2018, 37, 1618–1628. [Google Scholar]

- Feng, X.D.; Liu, G. An experimental study of cyclic loading of sandstone under different water contents. Hydrogeol. Eng. Geol. 2017, 44, 110–115. [Google Scholar]

- Xu, M.; Zhang, X.Y.; Luo, L.; Zhao, X.Y. Study on mechanical properties and energy evolution of sandstone under cyclic loading mode. Min. Res. Dev. 2021, 41, 123–128. [Google Scholar]

- Li, L.Y.; Xie, H.P.; Ju, Y. Experimental investigations of releasable energy and dissipative energy within rocks. Eng. Mech. 2011, 28, 35–40. [Google Scholar]

- Chen, X.; Lin, J.; Cao, G.Y.; Yang, Y.; Yin, J.C.; Fan, H. Energy evolution and damage characterization of sandstone under cyclic loading and unloading. Sci. Technol. Eng. 2022, 22, 5792–5799. [Google Scholar]

- Fang, K.; Zhang, J.; Tang, H.; Hu, X.; Yuan, H.; Wang, X.; An, P.; Ding, B. A quick and low-cost smartphone photogrammetry method for obtaining 3D particle size and shape. J. Eng. Geol. 2023, 322, 107170. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.; Tang, H.; Kang, J.; Wang, L.; Li, C.; Wang, D.; Liu, Z. Experimental study of the influence of wetting and drying cycles on the strength of intact rock samples from a red stratum in the Three Gorges Reservoir area. J. Eng. Geol. 2023, 314, 107013. [Google Scholar] [CrossRef]

| Moisture Content [%] | Particle Size Ratio | Minimum Particle Radius [mm] | Friction Factor | Normal Tangential Stiffness Ratio | Parallel Bond Tensile Strength [MPa] | Parallel Bond Cohesive Force [MPa] | Parallel Bond Friction Angle [°] | Parallel Bond Elastic Modulus [GPa] | Parallel Bond Stiffness Ratio |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1.66 | 0.35 | 0.5 | 1.5 | 18 | 9 | 40 | 1.6 | 1.5 |

| 2.31 | 14 | 7 | 40 | 1.4 | 1.5 | ||||

| 5.54 | 10 | 5 | 40 | 1.0 | 1.5 | ||||

| 7.72 | 8 | 4 | 40 | 0.9 | 1.5 |

| Moisture Content [%] | Peak Strength [MPa] | Elastic Modulus [GPa] | ||||

|---|---|---|---|---|---|---|

| Indoor Experiment | Numerical Simulation | Relative Error [%] | Indoor Experiment | Numerical Simulation | Relative Error [%] | |

| 0 | 19.27 | 19.43 | 0.83 | 3.18 | 3.04 | 4.4 |

| 2.31 | 14.78 | 15.42 | 4.33 | 2.23 | 2.15 | 3.5 |

| 5.54 | 11.42 | 11.51 | 0.79 | 1.61 | 1.48 | 8.1 |

| 7.72 | 9.29 | 9.18 | 1.18 | 1.49 | 1.35 | 9.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, Y.; Sun, L.; Cai, Z.; Jiang, Z.; Wang, Z.; He, Q.; Bai, Z. Cyclic Loading and Unloading of Weakly Consolidated Sandstone with Various Water Contents. Sustainability 2023, 15, 13866. https://doi.org/10.3390/su151813866

Long Y, Sun L, Cai Z, Jiang Z, Wang Z, He Q, Bai Z. Cyclic Loading and Unloading of Weakly Consolidated Sandstone with Various Water Contents. Sustainability. 2023; 15(18):13866. https://doi.org/10.3390/su151813866

Chicago/Turabian StyleLong, Yaxin, Lihui Sun, Zhenyu Cai, Zhixin Jiang, Zongze Wang, Qingfeng He, and Zhong Bai. 2023. "Cyclic Loading and Unloading of Weakly Consolidated Sandstone with Various Water Contents" Sustainability 15, no. 18: 13866. https://doi.org/10.3390/su151813866