Research on the Whole Life Cycle of a Furniture Design and Development System Based on Sustainable Design Theory

Abstract

:1. Introduction

2. Related Research

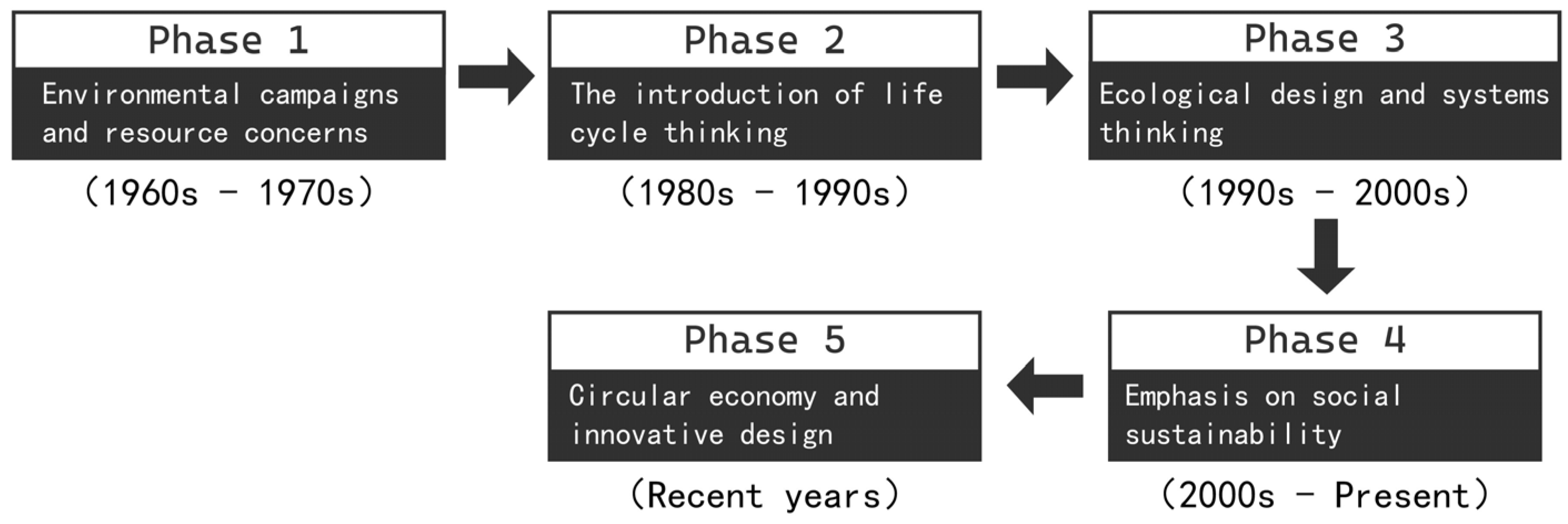

2.1. Sustainable Furniture Design

2.2. AHP Method

2.3. QFD Method

2.4. Axiomatic Design Method

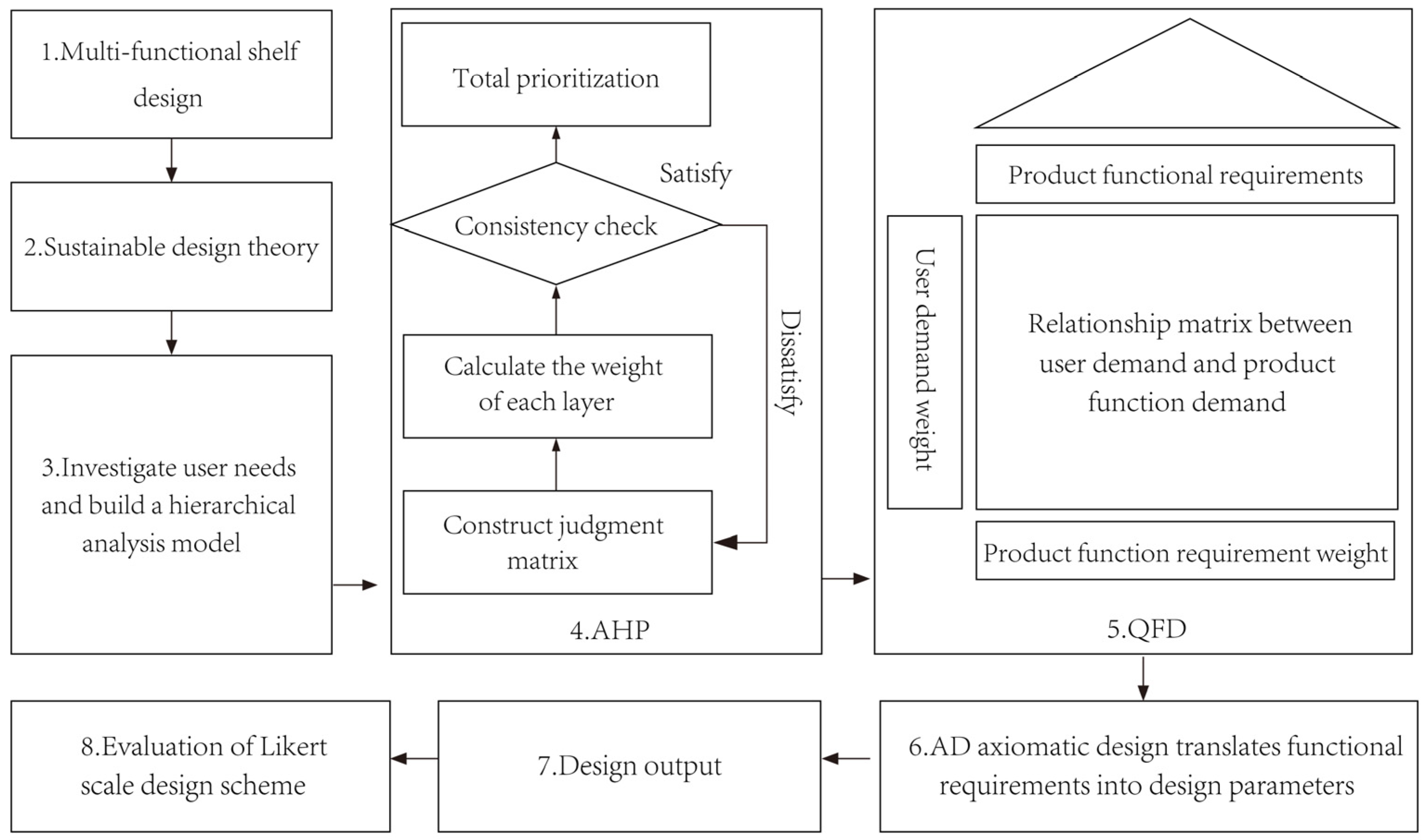

3. Research Method

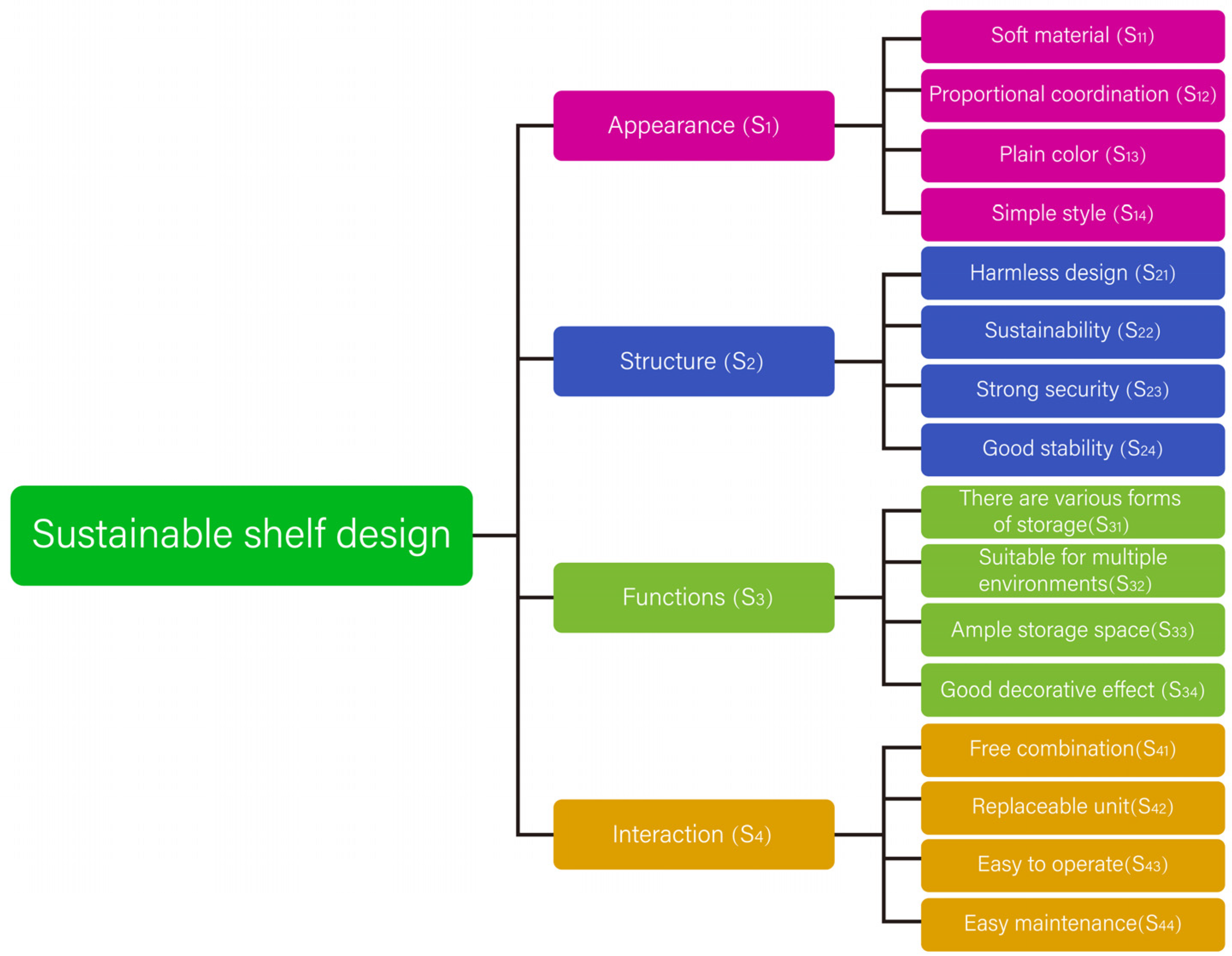

3.1. User and Market Research

3.2. AHP User Demand Analysis

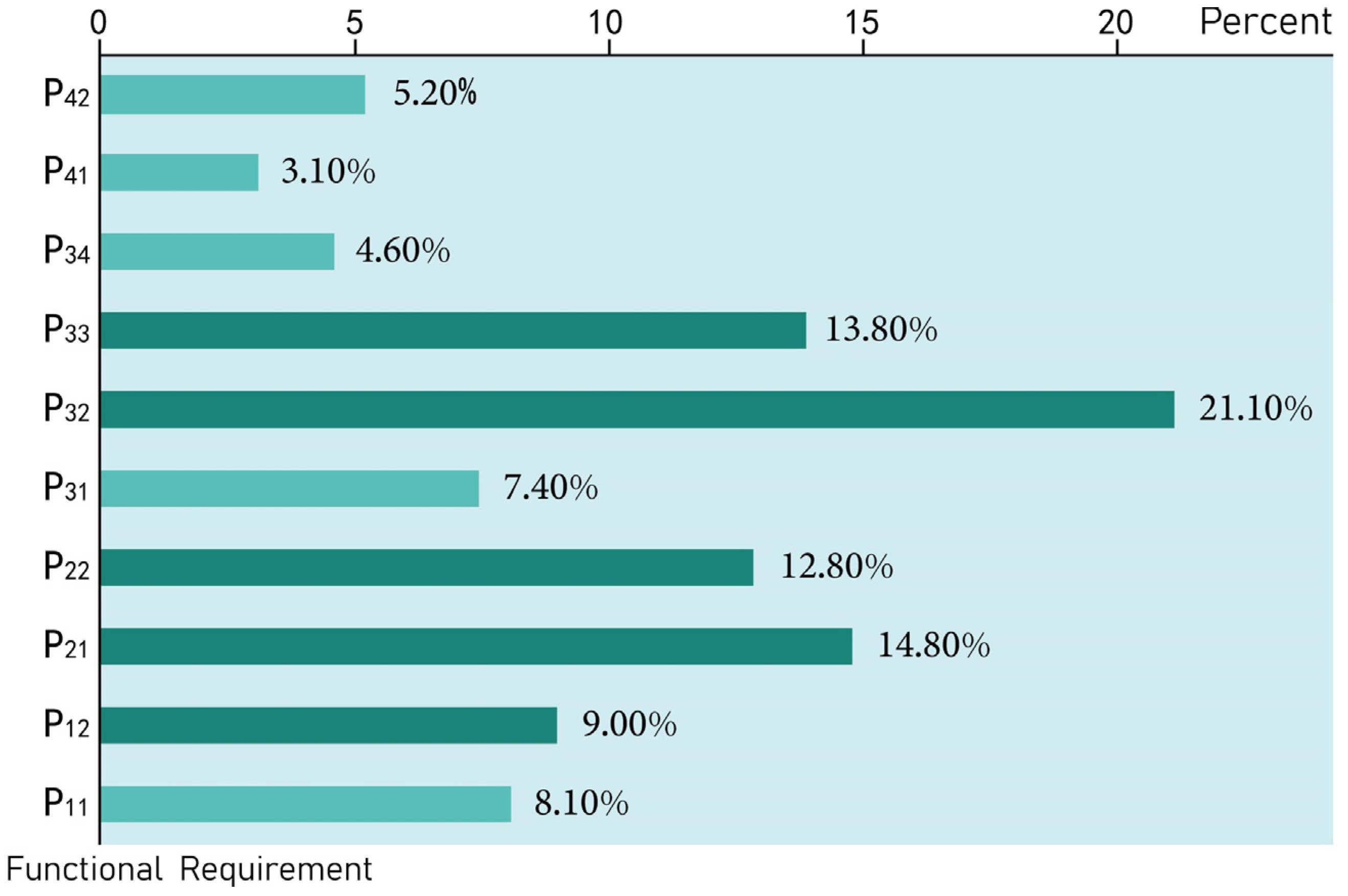

3.3. QFD Transforms Functional Requirements

3.4. AD Design Independence Axiom Proof

4. Case Study

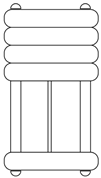

4.1. Sustainable Modeling Design

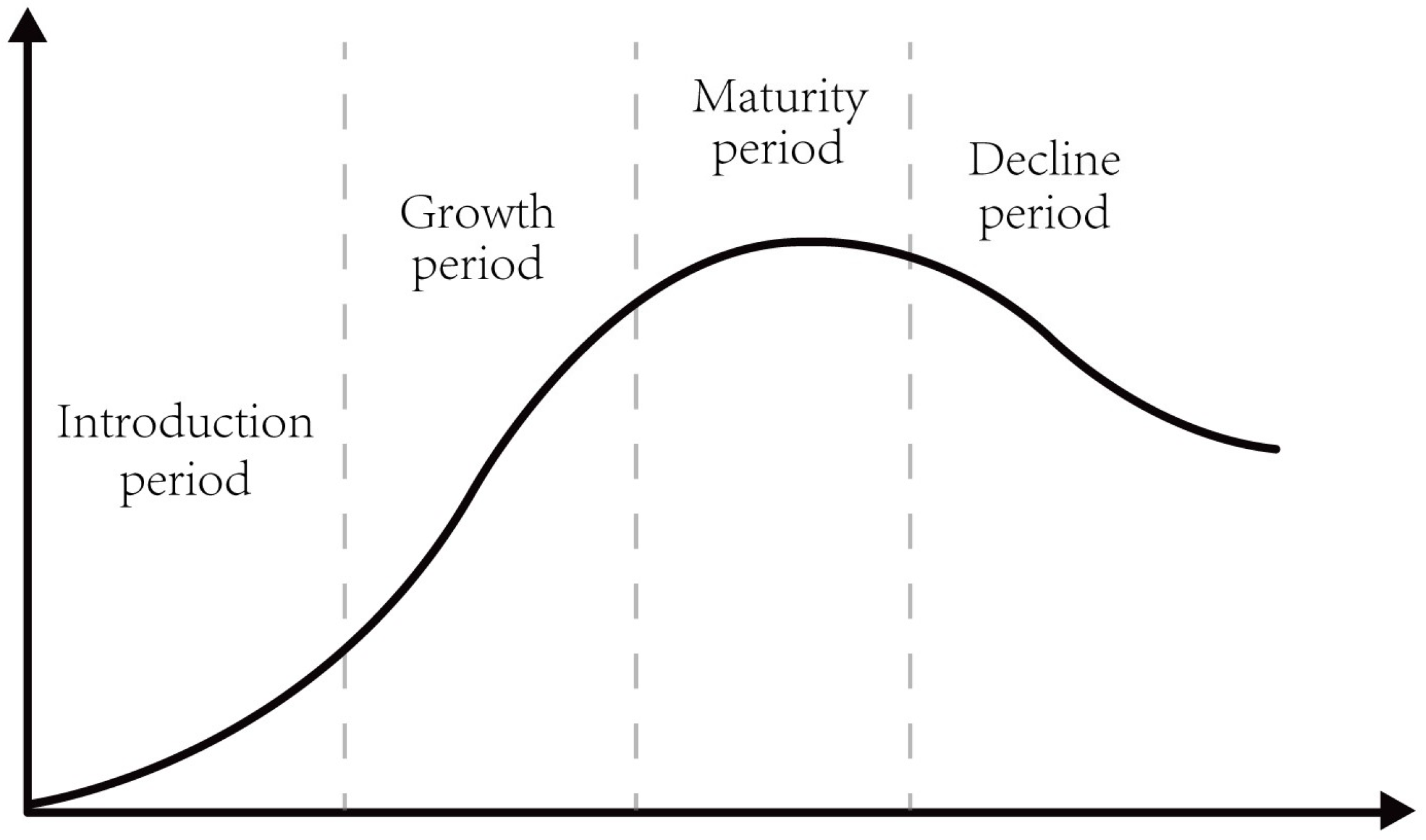

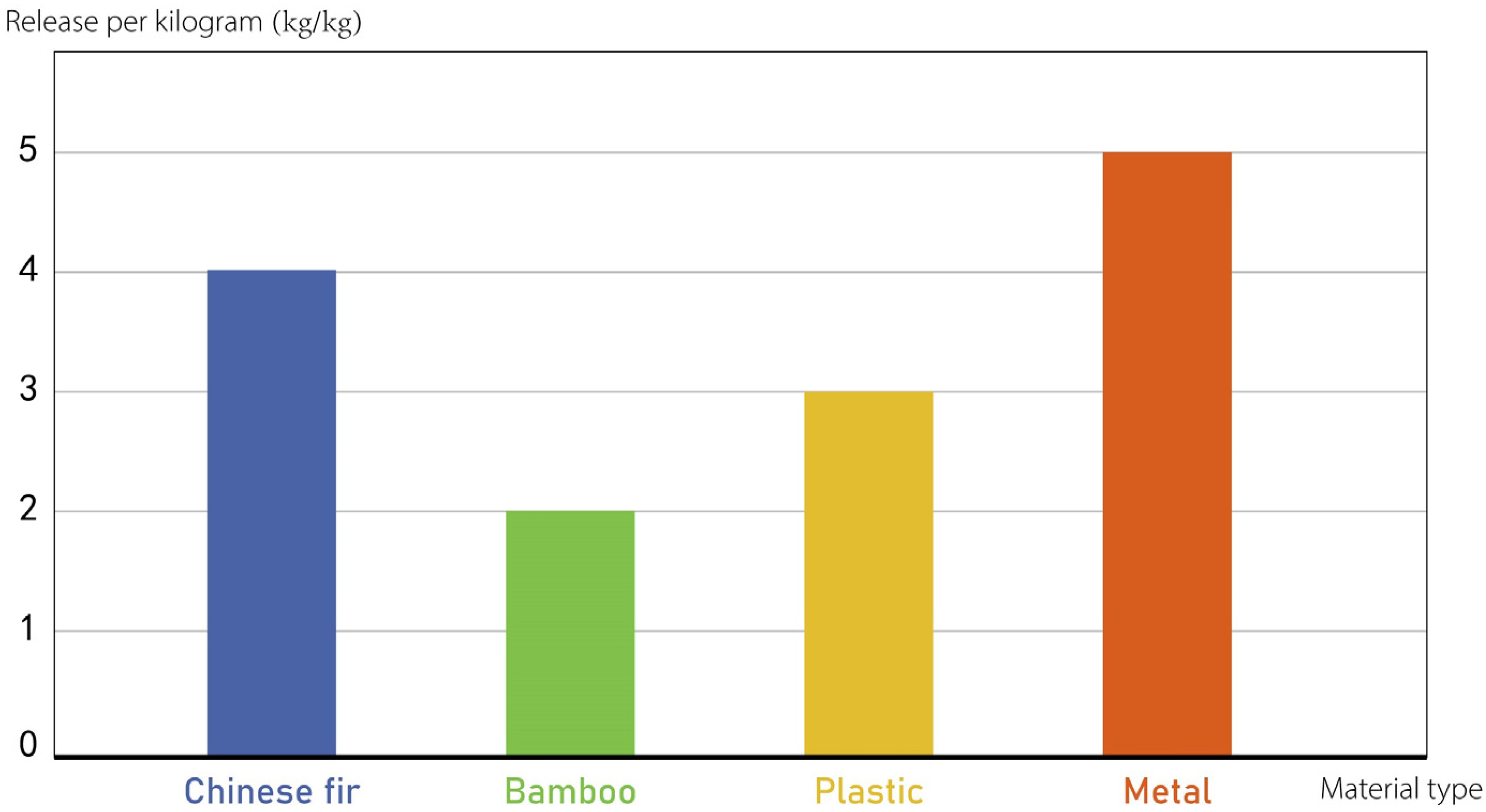

4.2. Sustainable Product Life Cycle Design

4.3. Evaluation of Design Scheme

4.4. Discussions

5. Conclusions

- Enhanced Durability and Material Firmness: Sustainable design bolsters furniture product durability and material firmness. Leveraging diverse, sustainable materials while considering their characteristics increases stability and firmness. This resilience enables products to adapt to environments, extending their service life.

- Reduced Environmental Impact via Whole Life Cycle Integration: Integrating the whole life cycle concept mitigates furniture products’ environmental impact. The sustainable design prioritizes material sustainability and uses product life cycle theory to address loss, usage time, and environmental factors. Modular design removes damaged components, reducing waste, promoting eco-friendliness, and extending product lifespan.

- Integrated AHP-QFD-AD Model for Targeted Development: Applying the AHP-QFD-AD model transforms user needs into functional demands and maps them onto design parameters. This systematic approach uses targeted technologies and axiom verification to align with user needs effectively.

- Scientific Design Evaluation and Consumer Assessment: Including the independence axiom in design evaluation and consumer feedback substantiates the design scheme’s feasibility. This approach expedites innovative, sustainable product development.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, J.; Bai, Z. Spatial and temporal changes of the ecological footprint of China’s resource-based cities in the process of urbanization. Resour. Policy 2022, 75, 102491. [Google Scholar] [CrossRef]

- Ali, K.; Kausar, N.; Amir, M. Impact of pollution prevention strategies on environment sustainability: Role of environmental management accounting and environmental proactivity. Environ. Sci. Pollut. Res. Int. 2023, 30, 88891–88904. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Jie, Z.; Wang, J.; Nepal, J.; Ullah, N.; Zhao, Z.Y.; Wang, P.Y.; Ahmad, W.; Khan, A.; Wang, W.; et al. Ecological risks of microplastics contamination with green solutions and future perspectives. Sci. Total Environ. 2023, 899, 165688. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rautela, R.; Kumar, S. Towards a sustainable future: Nexus between the sustainable development goals and waste management in the built environment. J. Clean. Prod. 2023, 415, 137865. [Google Scholar] [CrossRef]

- Vernon, R. International investment and international trade in the product cycle. Int. Exec. 1966, 8, 16. [Google Scholar] [CrossRef]

- Deng, W.; Lin, H.; Jiang, M. Research on Bamboo Furniture Design Based on D4S (Design for Sustainability). Sustainability 2023, 15, 8832. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Zhang, X.; Zeng, S. Research on Sustainable Furniture Design Based on Waste Textiles Recycling. Sustainability 2023, 15, 3601. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Yang, Q.; Osmani, M.; Demian, P. A Conceptual Blockchain Enhanced Information Model of Product Service Systems Framework for Sustainable Furniture. Buildings 2022, 13, 85. [Google Scholar] [CrossRef]

- Septiani, M.; Putri, N.C.; Verma, G.; Sasongko, N.A. Eco-design practice towards sustainable furniture: A Review. Conf. Ser. Earth Environ. Sci. 2022, 1108, 012059. [Google Scholar] [CrossRef]

- Sofiana, Y.; Wulandari, N.; Indahyani, T. Actions for Sustainability: The implementation of Recycling Thermoplastics in Furniture Design for Painting Community in Jakarta. Conf. Ser. Earth Environ. Sci. 2022, 998, 012033. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties. Materials 2022, 15, 8487. [Google Scholar] [CrossRef] [PubMed]

- Kwangsawat, K.; Rugwongwan, Y. A Furniture Design Guideline Derived from the Socio-Economic Factors of Consumers for Their Choices of Sustainable Furniture Design in Thailand. Asian Soc. Sci. 2017, 13, 182. [Google Scholar] [CrossRef]

- Reham, M.M.; Eldin, M. Sustainable Interior Design for Homes. Indian J. Sci. Technol. 2017, 10, 1–9. [Google Scholar] [CrossRef]

- Arianti, A.P.; Agus, S.; Andar, B.S. Design Adaptation of Wooden Furniture through Sustainability Design Strategy (Case Studies: Five Furniture Industries in Central Java, Indonesia). Arts Des. Stud. 2016, 45, 1–13. [Google Scholar]

- Chen, M.; Lyu, J.H. Aesthetic evaluation of furniture design based on ANP method. Appl. Mech. Mater. 2014, 574, 318–323. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, X.; Chen, Y.; Kong, Q. Evaluation and Design of Dining Room Chair Based on Analytic Hierarchy Process (AHP) and Fuzzy AHP. BioResources 2023, 18, 2574–2588. [Google Scholar] [CrossRef]

- Scholz, S.W.; Decker, R. Measuring the impact of wood species on consumer preferences for wooden furniture by means of the Analytic Hierarchy Process. For. Prod. J. 2007, 57, 23. [Google Scholar]

- Liu, L.; Zhang, X.; Li, P. Design of Bronze Drum Furniture Based on AHP-GUCDR Model. China For. Prod. Ind. 2023, 60, 56–61. [Google Scholar]

- Chen, M.; Lyu, J.; Chen, J. Applying a Hybrid. Approach Based on Analytic Hierarchy Process and Artificial Neural Network to Upholstered Furniture Design. Int. J. Smart Home 2016, 10, 347–360. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B. QFD/TRIZ Based Mechanical Structure Design of Elderly Walker. J. Phys. Conf. Ser. 2023, 2542, 012006. [Google Scholar] [CrossRef]

- Fang, M.; Yang, W.; Li, H.; Pan, Y. Enhancing User Experience through Optimization Design Method for Elderly Medication Reminder Mobile Applications: A QFD-Based Research Approach. Electronics 2023, 12, 2860. [Google Scholar] [CrossRef]

- Wang, T.; Yang, L. Combining GRA with a Fuzzy QFD Model for the New Product Design and Development of Wickerwork Lamps. Sustainability 2023, 15, 4208. [Google Scholar] [CrossRef]

- Angtuaco, D.S.; Barria, N.M.A.; Lee, J.M.C.; Tangsoc, J.C.; Chiu, A.S.F.; Mutuc, J.E. A redesign of the toothpaste tube using green QFD II for improved usability and sustainability. J. Clean. Prod. 2023, 393, 136279. [Google Scholar] [CrossRef]

- Wei, W.; Wang, Z. An Improved QFD Method for Rapid Response to Customer Requirements in Product Optimization Design. Procedia CIRP 2023, 119, 474–480. [Google Scholar] [CrossRef]

- Liu, J.; Wan, F.; Zou, J.; Wang, L. Developing an ANP-QFD Approach for Balers’ Appearance Design: A Case Study. Int. J. New Dev. Eng. Soc. 2022, 6, 16–23. [Google Scholar]

- Zhu, T.; Li, Y.; Wu, C.; Yue, H.; Zhao, Y. Research on the Design of Surgical Auxiliary Equipment Based on AHP, QFD and PUGH Decision Matrix. Math. Probl. Eng. 2022, 2022, 4327390. [Google Scholar] [CrossRef]

- Taifa, I.W.; Desai, D.A. Quality Function Deployment integration with Kano model for ergonomic product improvement (Classroom furniture)—A review. J. Multidiscip. Eng. Sci. Technol. 2015, 2, 2484–2491. [Google Scholar]

- Kuang, F.C.; Wu, Z.H.; Liu, X. A Study on Furniture Innovative Theory Based on QFD and TRIZ. Adv. Mater. Res. 2013, 753, 1437–1441. [Google Scholar] [CrossRef]

- Lyu, J.; Chen, R.; Yang, L.; Wang, J.; Chen, M. Applying a Hybrid Kano/Quality Function Deployment Integration Approach to Wood Desk Designs for Open-Plan Offices. Forests 2022, 13, 1825. [Google Scholar] [CrossRef]

- Erdil, A. Evaluation Product Development, Product design for the furniture-wood industry via Quality Function Deployment and Pareto Analysis. Sigma J. Eng. Nat. Sci. 2020, 11, 203–217. [Google Scholar]

- Yi, X.; Liang, J.; Liang, Z.; Wang, Q. Research on the Innovative Design of Children’s Rocking Chair Based on the Integration of QFD/TRIZ/FEM. China For. Prod. Ind. 2021, 58, 17–22. [Google Scholar]

- Marianna, M.; Ian, A.F. Addressing the Adaptive Customization of Timber Prefabricated Housing through Axiomatic Design. Procedia CIRP 2015, 34, 199–205. [Google Scholar]

- Shi, D.Y.; Liu, S. Enhancing the Ideality of Innovation by AD/TOC/TRIZ. Key Eng. Mater. 2010, 450, 145–148. [Google Scholar] [CrossRef]

- Basar, O.; Mine, I.; Secil, E. Multi-Criteria Decision Aid for Sustainable Energy Prioritization Using Fuzzy Axiomatic Design. Int. J. Energy Optim. Eng. 2013, 2, 1–20. [Google Scholar]

- Park, S.; Yoon, J.; An, H.; Park, J.; Park, G. Integration of axiomatic design and design structure matrix for the modular design of automobile parts. Proc. Inst. Mech. Eng. 2022, 236, 296–306. [Google Scholar] [CrossRef]

- Xu, J. A Computer-Supported Axiomatic Design System Integrating TRIZ. Adv. Mater. Res. 2014, 3349, 1066–1069. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making—The Analytic Hierarchy and Network Processes (AHP/ANP). Syst. Sci. Syst. Eng. 2004, 13, 35. [Google Scholar] [CrossRef]

- Han, S.B.; Chen, S.K.; Ebrahimpour, M.; Sodhi, M.S. A conceptual QFD planning model. Int. J. Qual. Reliab. Manag. 2001, 18, 796–812. [Google Scholar] [CrossRef]

- Suh, N.P. The Principles of Design; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Quinn, E.C.; Knauer, K.M.; Beckham, G.T.; Chen, E. Mono-material product design with bio-based, circular, and biodegradable polymers. One Earth 2023, 6, 582–586. [Google Scholar] [CrossRef]

- Umeda, Y.; Fukushige, S.; Tonoike, K.; Kondoh, S. Product modularity for life cycle design. CIRP Ann. 2008, 57, 13–16. [Google Scholar] [CrossRef]

| Material Type | Species | Advantage | Shortcoming |

|---|---|---|---|

| 1. Hardwood | From sustainable forests, durable, long life. | Natural beauty, high texture appearance. | Deforestation impacts limited supply. |

| 2. Artificial panels | Made of recycled wood fiber, environmentally friendly. | Cost-effective, less waste. | Some adhesives may contain harmful chemicals. |

| 3. Metal materials | Recyclable, long life. | Solid, modern design style. | Energy-intensive production processes. |

| 4. Organic materials | Made of renewable materials and biodegradable. | Environmentally friendly, natural and uniquely designed. | Material selection is limited and may not be very durable. |

| 5. Bio-based materials | Made of biodegradable materials, environmentally friendly. | Sustainable, reducing reliance on plastics. | Emerging technology, limited market supply. |

| 6 Recyclable materials | Designed for easy disassembly and recycling. | Reduce waste and promote a circular economy. | Design options are limited, and durability issues may arise. |

| Layer | Requirement |

|---|---|

| Appearance | Soft material |

| Proportional coordination | |

| Plain color | |

| Simple style | |

| Structure | Harmless design |

| Sustainability | |

| Strong security | |

| Good stability | |

| Functions | Various forms of storage |

| Suitable for multiple environments | |

| Ample storage space | |

| Good decorative effect | |

| Interaction | Free combination |

| Replaceable unit | |

| Easy to operate | |

| Easy maintenance |

| Scale | Expression |

|---|---|

| 1 | Of equal importance |

| 3 | Slightly more important |

| 5 | Obviously always |

| 7 | Strongly important |

| 9 | Extremely important |

| 2, 4, 6, 8 | Median value of two adjacent values determined |

| Count backwards | Inverse value |

| Target Layer | S1 | S2 | S3 | S4 | ω |

|---|---|---|---|---|---|

| S1 | 1 | 1/4 | 1/6 | 1/4 | 0.06 |

| S2 | 4 | 1 | 1/3 | 1/2 | 0.18 |

| S3 | 6 | 3 | 1 | 3 | 0.51 |

| S4 | 4 | 2 | 1/3 | 1 | 0.25 |

| S1 | S11 | S12 | S13 | S14 | ω1 |

|---|---|---|---|---|---|

| S11 | 1 | 1/3 | 2 | 1 | 0.21 |

| S12 | 3 | 1 | 3 | 1 | 0.40 |

| S13 | 1/2 | 1/3 | 1 | 1/2 | 0.12 |

| S14 | 1 | 1 | 2 | 1 | 0.27 |

| S2 | S21 | S22 | S23 | S24 | ω2 |

|---|---|---|---|---|---|

| S21 | 1 | 1/2 | 1/4 | 1/3 | 0.10 |

| S22 | 2 | 1 | 1/2 | 3 | 0.29 |

| S23 | 4 | 2 | 1 | 2 | 0.42 |

| S24 | 3 | 1/3 | 1/2 | 1 | 0.19 |

| S3 | S31 | S32 | S33 | S34 | ω3 |

|---|---|---|---|---|---|

| S31 | 1 | 1/2 | 3 | 2 | 0.18 |

| S32 | 2 | 1 | 2 | 1 | 0.29 |

| S33 | 1/3 | 1/2 | 1 | 1 | 0.44 |

| S34 | 1/2 | 1 | 2 | 1 | 0.09 |

| S4 | S41 | S42 | S43 | S44 | ω4 |

|---|---|---|---|---|---|

| S41 | 1 | 1 | 3 | 4 | 0.40 |

| S42 | 1 | 1 | 2 | 3 | 0.34 |

| S43 | 1/3 | 1/2 | 1 | 2 | 0.16 |

| S44 | 1/4 | 1/3 | 1/2 | 1 | 0.10 |

| Layer | λmax | CI | RI | CR | Result |

|---|---|---|---|---|---|

| Criterion layer | 4.122 | 0.041 | 0.890 | 0.046 < 0.1 | Pass |

| S1 | 4.118 | 0.039 | 0.890 | 0.044 < 0.1 | Pass |

| S2 | 4.237 | 0.079 | 0.890 | 0.089 < 0.1 | Pass |

| S3 | 4.249 | 0.083 | 0.890 | 0.093 < 0.1 | Pass |

| S4 | 4.031 | 0.010 | 0.890 | 0.012 < 0.1 | Pass |

| Target Layer | Target Layer Weight | Criterion Layer | Weight of Each Criterion Layer | Final Weight | Priority Ranking |

|---|---|---|---|---|---|

| Appearance (S1) | 0.06 | Soft material | 0.21 | 0.0126 | 15 |

| Proportional coordination | 0.40 | 0.0240 | 12 | ||

| Plain color | 0.12 | 0.0072 | 16 | ||

| Simple style | 0.27 | 0.0162 | 14 | ||

| Product Performance (S2) | 0.18 | Environmentally friendly materials | 0.10 | 0.0180 | 13 |

| Sustainability | 0.29 | 0.0522 | 7 | ||

| Strong security | 0.42 | 0.0756 | 6 | ||

| Good stability | 0.19 | 0.0342 | 10 | ||

| Functions (S3) | 0.51 | There are various forms of storage | 0.18 | 0.0918 | 3 |

| Suitable for multiple environments | 0.29 | 0.1479 | 2 | ||

| Ample storage space | 0.44 | 0.2244 | 1 | ||

| Good decorative effect | 0.09 | 0.0459 | 8 | ||

| Interaction (S4) | 0.25 | Free combination | 0.40 | 0.1000 | 4 |

| Replaceable unit | 0.34 | 0.0850 | 5 | ||

| Easy to operate | 0.16 | 0.0400 | 9 | ||

| Easy maintenance | 0.10 | 0.0250 | 11 |

| Primary Functional Requirement | Secondary Functional Requirement |

|---|---|

| P1 Studdle | P11 Base reinforcement |

| P12 Height adjustable | |

| P2 Laminate | P21 Mesa combination change |

| P22 Easy assembly and disassembly | |

| P3 Structure | P31 Ergonomic design |

| P32 Modularization | |

| P33 Full life cycle design | |

| P34 Avoid sharp edges | |

| P4 Appearance | P41 Simple and atmospheric |

| P42 Modeling stability and environmental protection |

| No. | Functional Requirements (FR) | No. | Design Parameters (DP) |

|---|---|---|---|

| FR1 | Modular design | DP1 | Flexible component combination design |

| FR2 | Mesa combined transform | DP2 | Suspension rod and laminate combination design |

| FR3 | Full life cycle design | DP3 | Product use process design |

| FR4 | Easy assembly and disassembly | DP4 | Joint fixation design |

| FR5 | Adjustable height | DP5 | Telescopic support rod design |

| Materials | Physical Parameter |

|---|---|

| Wood | Density: 500–800 kg/m3 |

| Elastic modulus: 10–20 GPa | |

| Tensile strength: 40–150 MPa | |

| Compressive strength: 30–80 MPa | |

| Bamboo | Density: 400–800 kg/m3 |

| Elastic modulus: 8–18 GPa | |

| Tensile strength: 70–150 MPa | |

| Compressive strength: 30–60 MPa | |

| Recycled plastics | Density: 800–1300 kg/m3 |

| Elastic modulus: 1–4 GPa | |

| Tensile strength: 20–100 MPa |

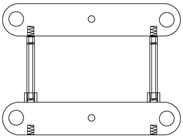

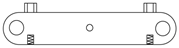

| Shelf Layer Plate Fixed Shaft Design | Shelf Laminate Combination Design | Shelf Joint Design | Shelf Support Rod Design |

|---|---|---|---|

|  |  |  |

| Part name | Blueprint |

|---|---|

| fixed shaft |  |

| suspension rod |  |

| Intermediate plate |  |

| marginal plate |  |

| support rod |  |

| non-slip cap |  |

| Stages | Sustainable Shelving | Hardwood Shelving |

|---|---|---|

| 1. Material mining | The maturity cycle of raw materials is 3–5 years | The maturity cycle of raw materials is 60–100 years |

| 2. Manufacturing phase | The manufacturing process is simple | The manufacturing process is more complex |

| 3. Use phase | Damaged disassembly can be used normally | High scrap rate due to damage |

| 4. Maintenance phase | Low maintenance cost | High maintenance cost |

| 5. Scrap disposal | Lower incineration carbon emission | Higher incineration carbon emission |

| 6. Material recycling | Bamboo charcoal can be made into economic products | The recycling rate of ash residue is low |

| No. | Appearance | Structure | Functions | Interaction |

|---|---|---|---|---|

| Adolescent males | 4 | 5 | 3 | 5 |

| Adolescent females | 4 | 4 | 5 | 4 |

| Young males | 3 | 4 | 4 | 5 |

| Young females | 5 | 5 | 5 | 4 |

| Middle-aged males | 5 | 3 | 4 | 3 |

| Middle-aged females | 3 | 5 | 3 | 5 |

| Elderly males | 5 | 3 | 5 | 4 |

| Elderly females | 5 | 3 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xiong, X.; Qu, M. Research on the Whole Life Cycle of a Furniture Design and Development System Based on Sustainable Design Theory. Sustainability 2023, 15, 13928. https://doi.org/10.3390/su151813928

Li Y, Xiong X, Qu M. Research on the Whole Life Cycle of a Furniture Design and Development System Based on Sustainable Design Theory. Sustainability. 2023; 15(18):13928. https://doi.org/10.3390/su151813928

Chicago/Turabian StyleLi, Yijie, Xingfu Xiong, and Min Qu. 2023. "Research on the Whole Life Cycle of a Furniture Design and Development System Based on Sustainable Design Theory" Sustainability 15, no. 18: 13928. https://doi.org/10.3390/su151813928

APA StyleLi, Y., Xiong, X., & Qu, M. (2023). Research on the Whole Life Cycle of a Furniture Design and Development System Based on Sustainable Design Theory. Sustainability, 15(18), 13928. https://doi.org/10.3390/su151813928