Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture

Abstract

:1. Introduction

1.1. Background

1.2. Novelty

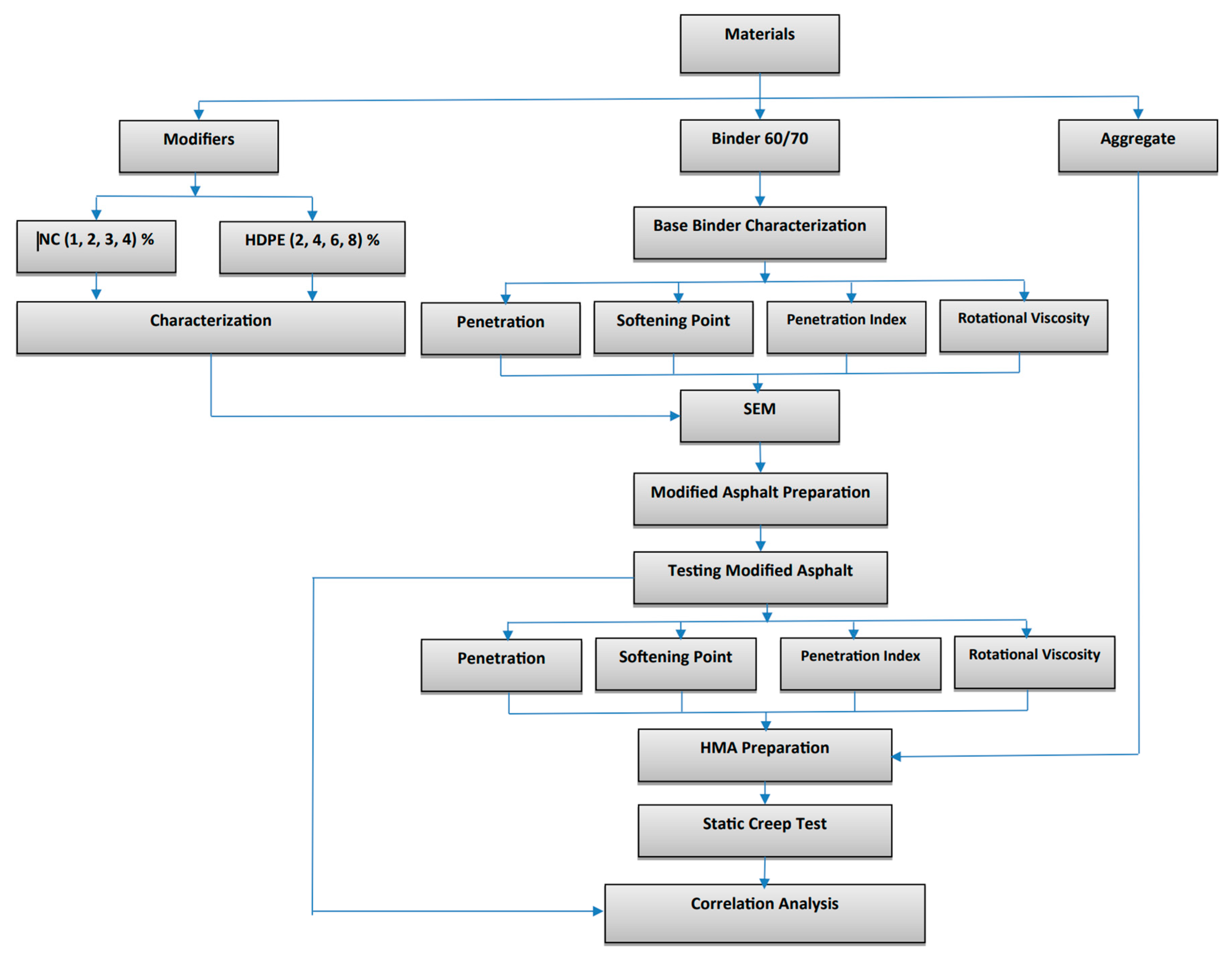

1.3. Objective and Research Approach

- First, study the rheological properties of HDPE-, NC-modified binders;

- Next, based on static creep testing, evaluate the susceptibility of the HDPE-, NC-modified asphalt mixtures to rutting that is essential for designing and constructing durable and long-lasting asphalt pavements;

- Finally, analyze the relationship between creep parameters and basic properties of modified binders using correlation analysis.

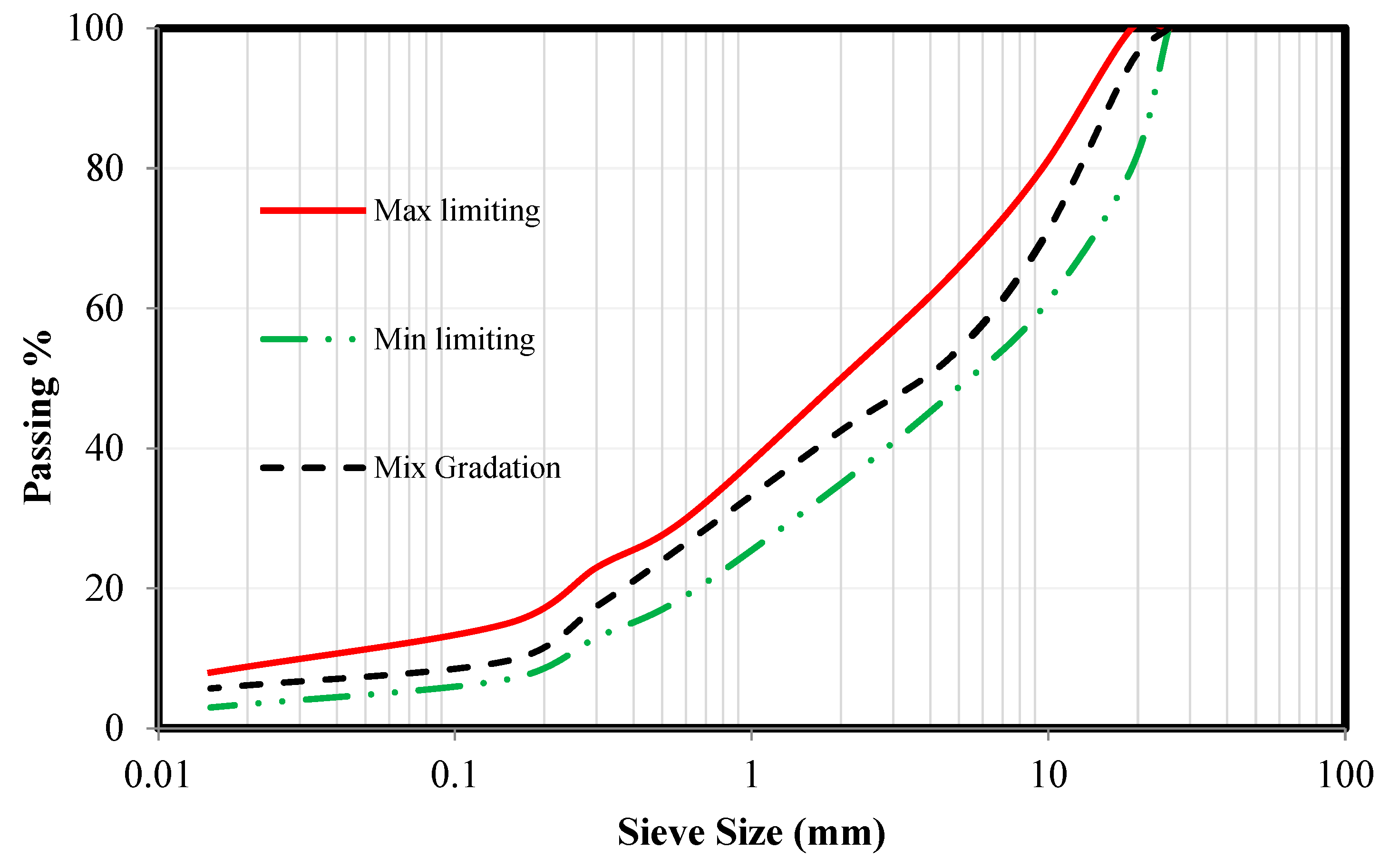

2. Material Properties and Sample Preparations

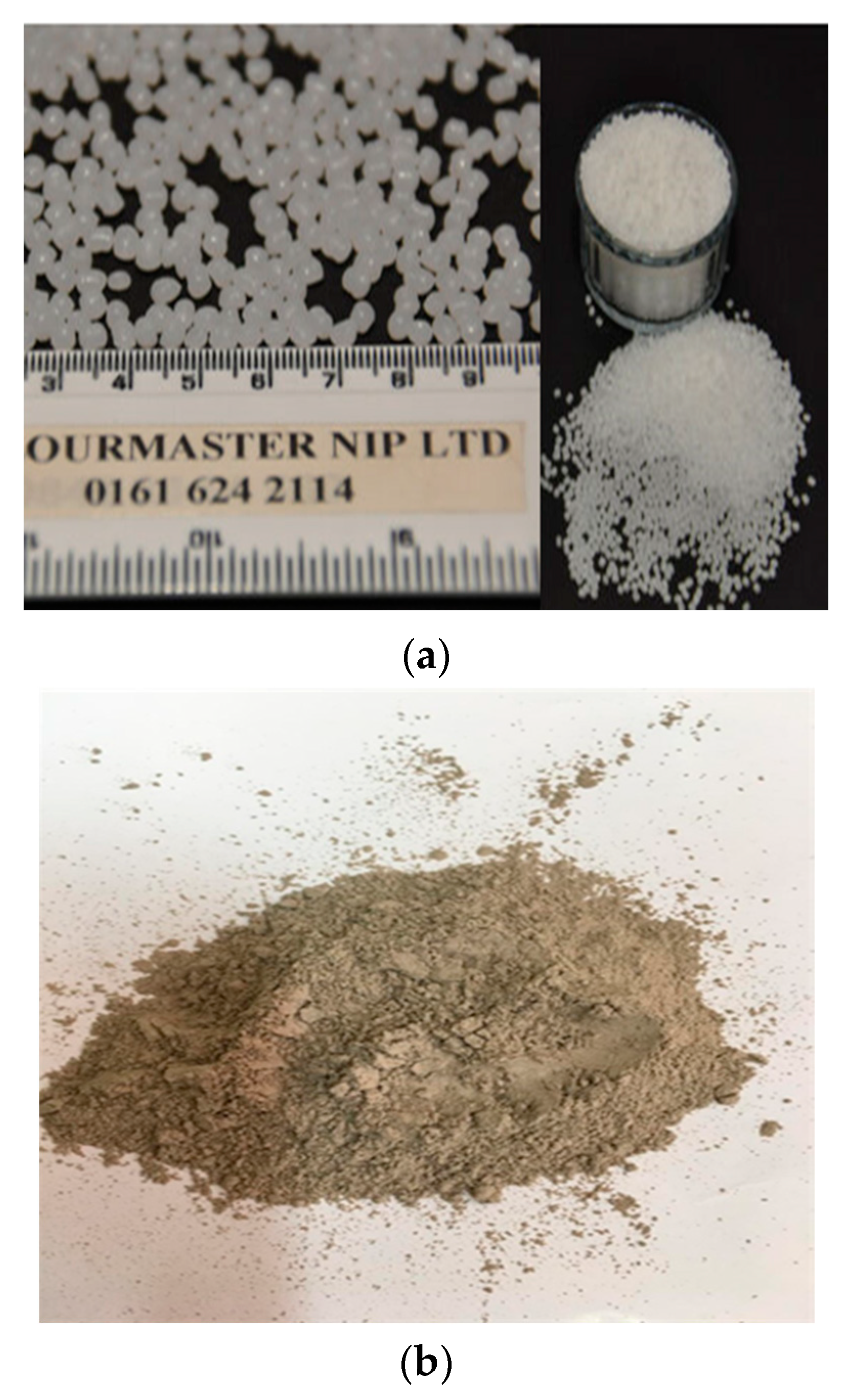

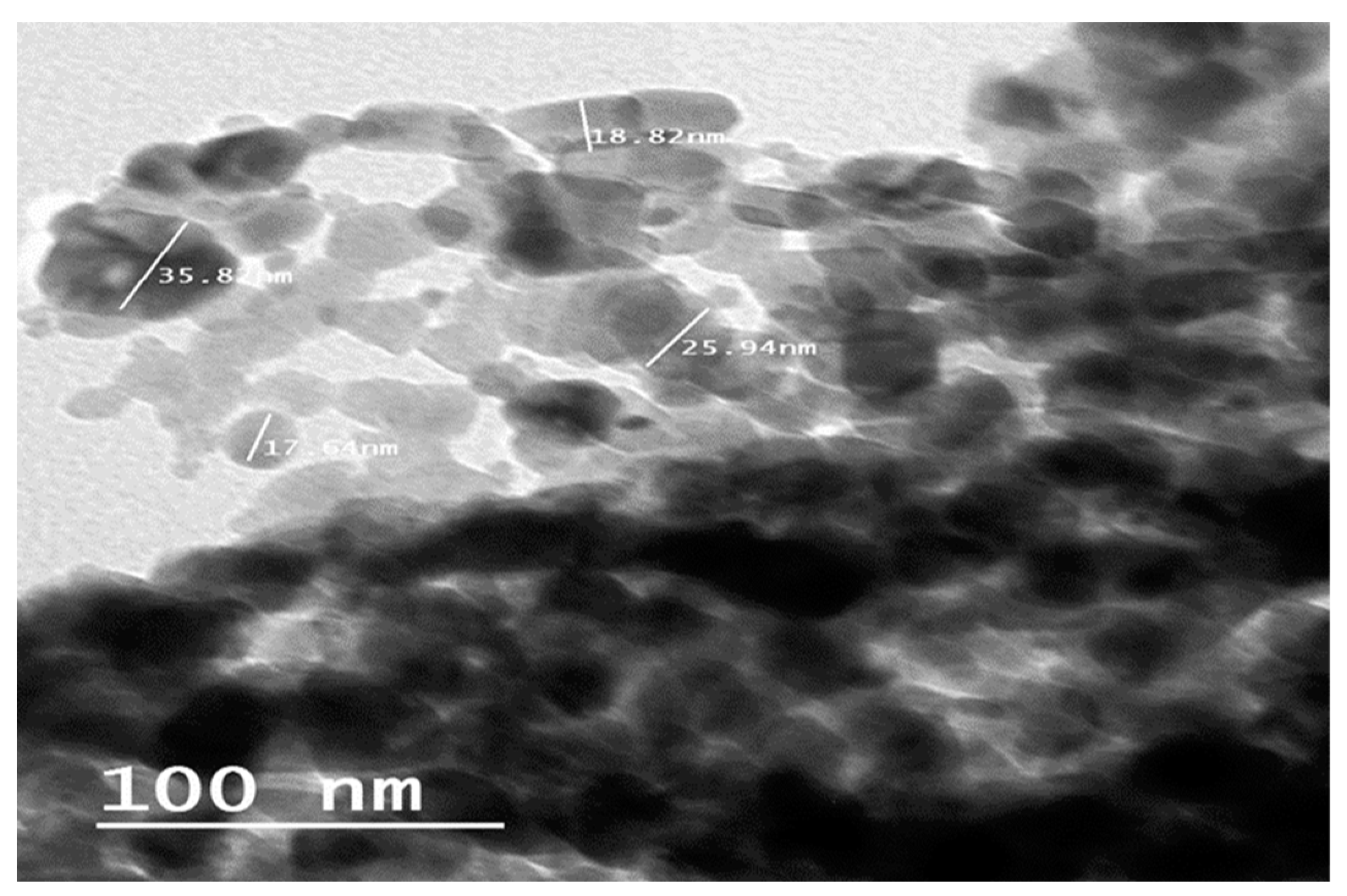

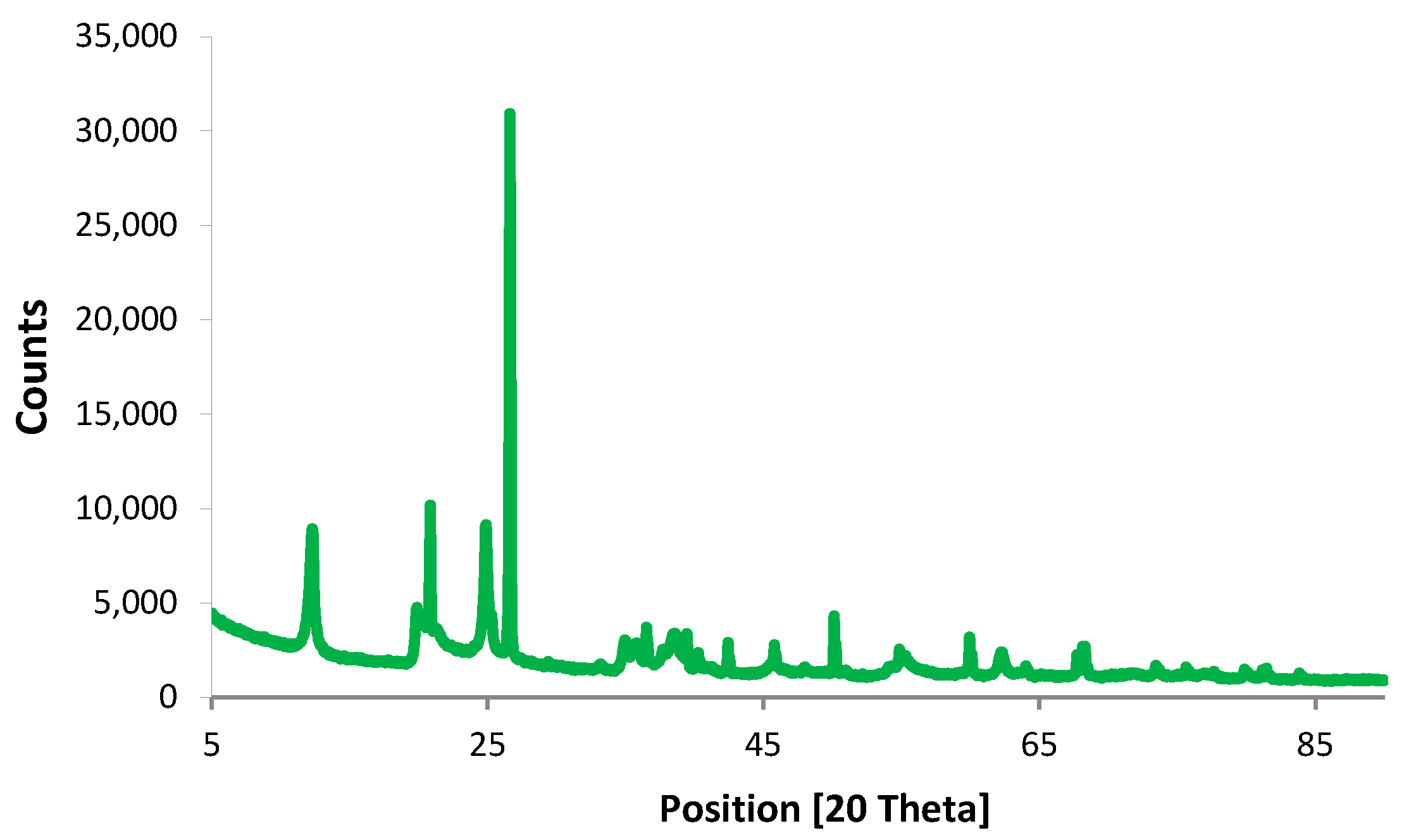

2.1. Material Properties

2.2. Binder and Mixture Preparations

3. Experimental Work

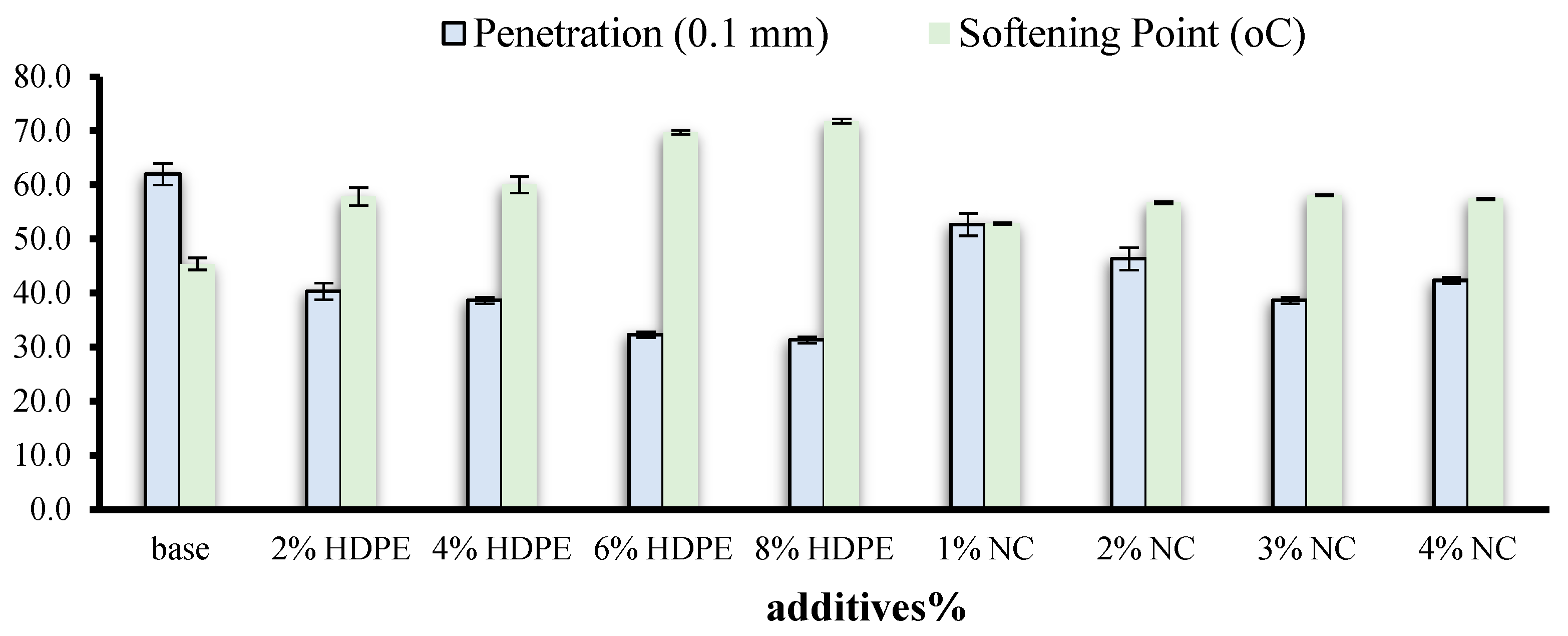

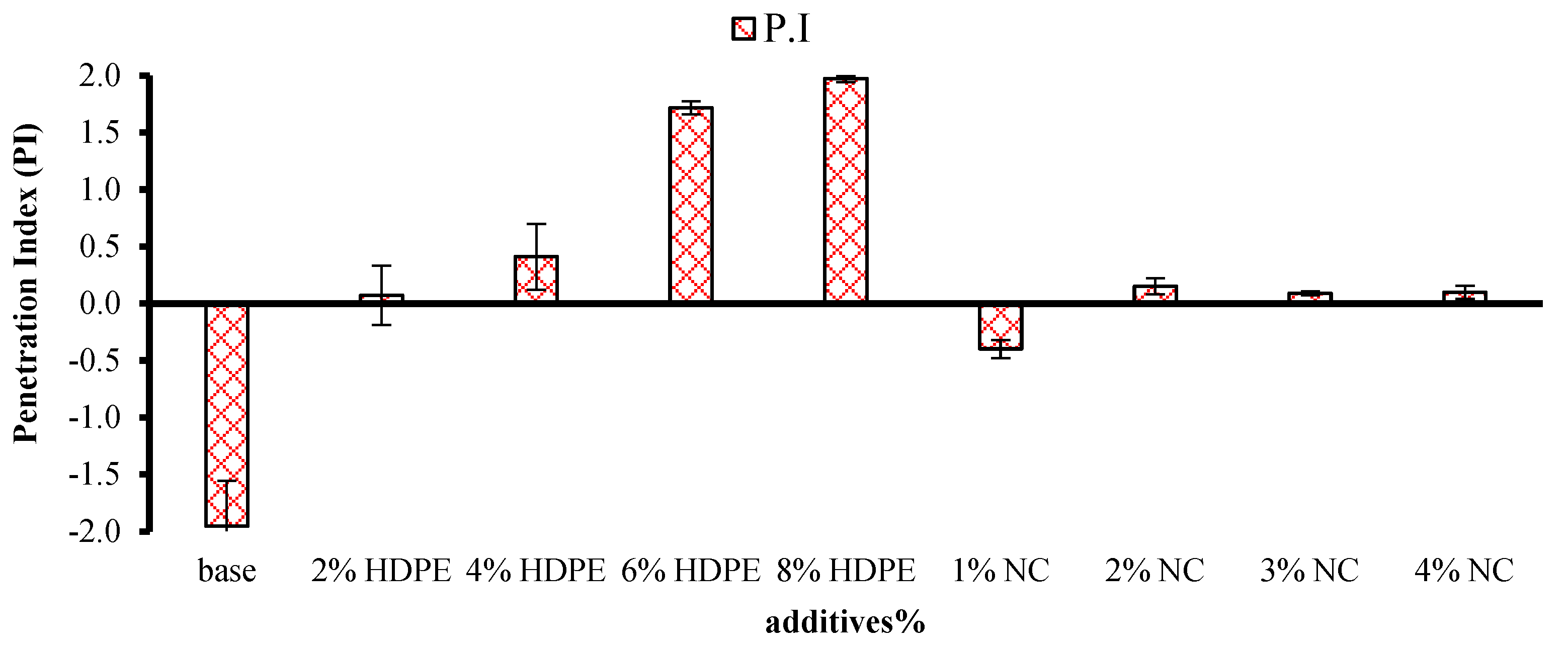

3.1. Binder Consistency and Flow

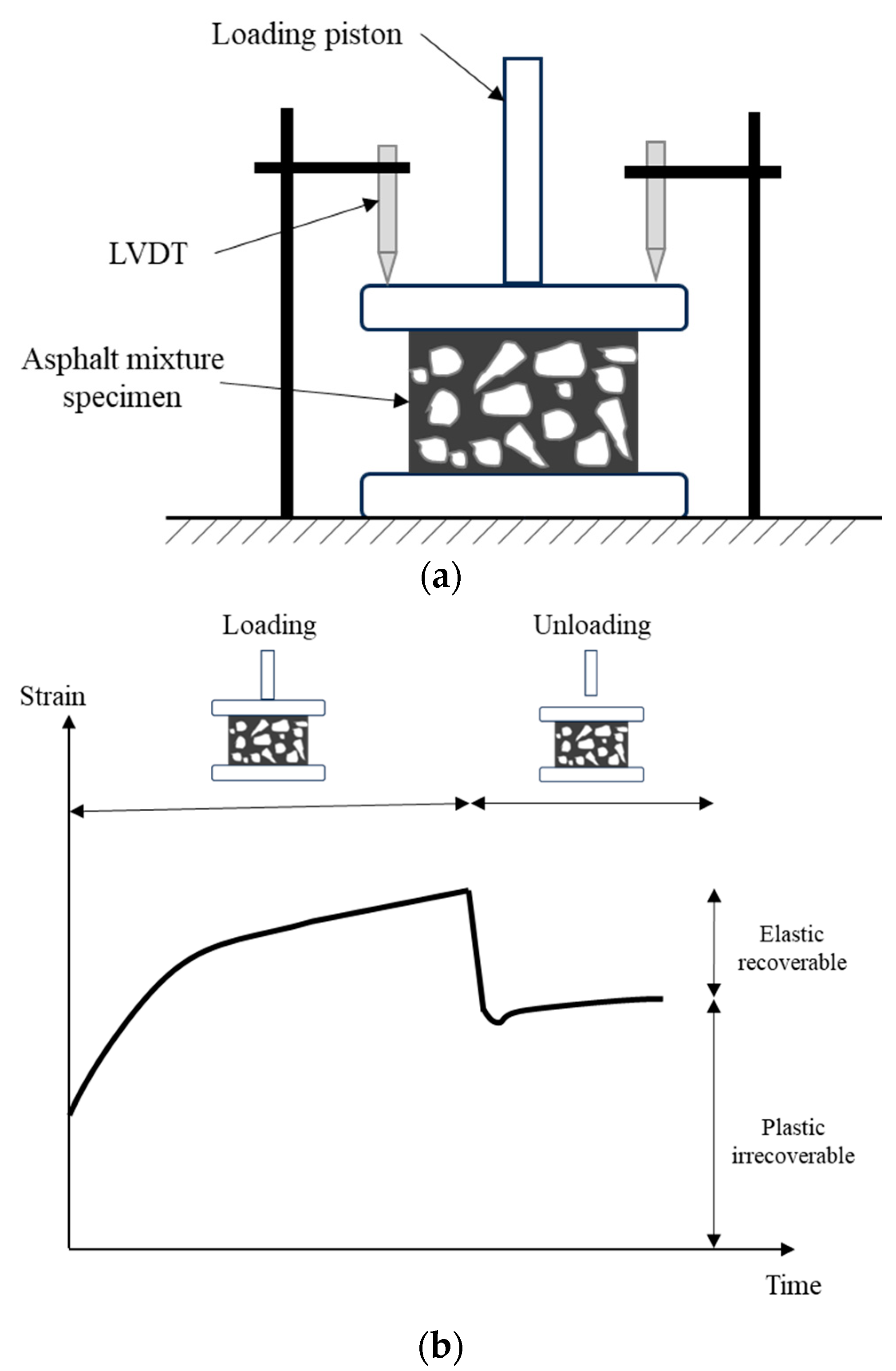

3.2. Rutting Characteristics of Asphalt Mixture

- Testing temperature: 40 °C;

- Vertical stress: 0.1 MPa;

- Loading time: 3600 s;

- Unloading time: 1800 s;

- Specimen dimensions: 64 mm height and 102 mm diameter;

- Curing: Specimens were placed at 40 °C for four hours before testing.

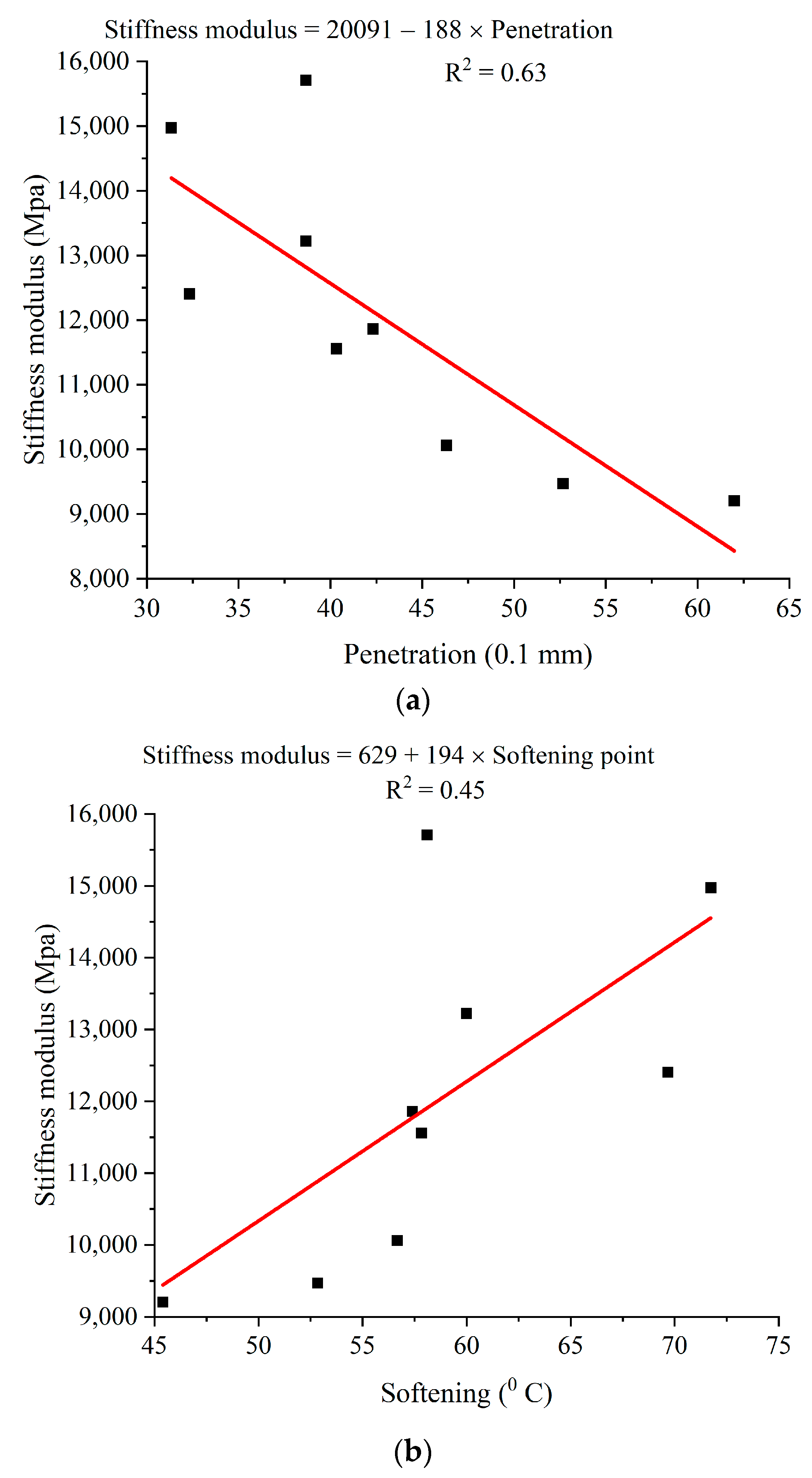

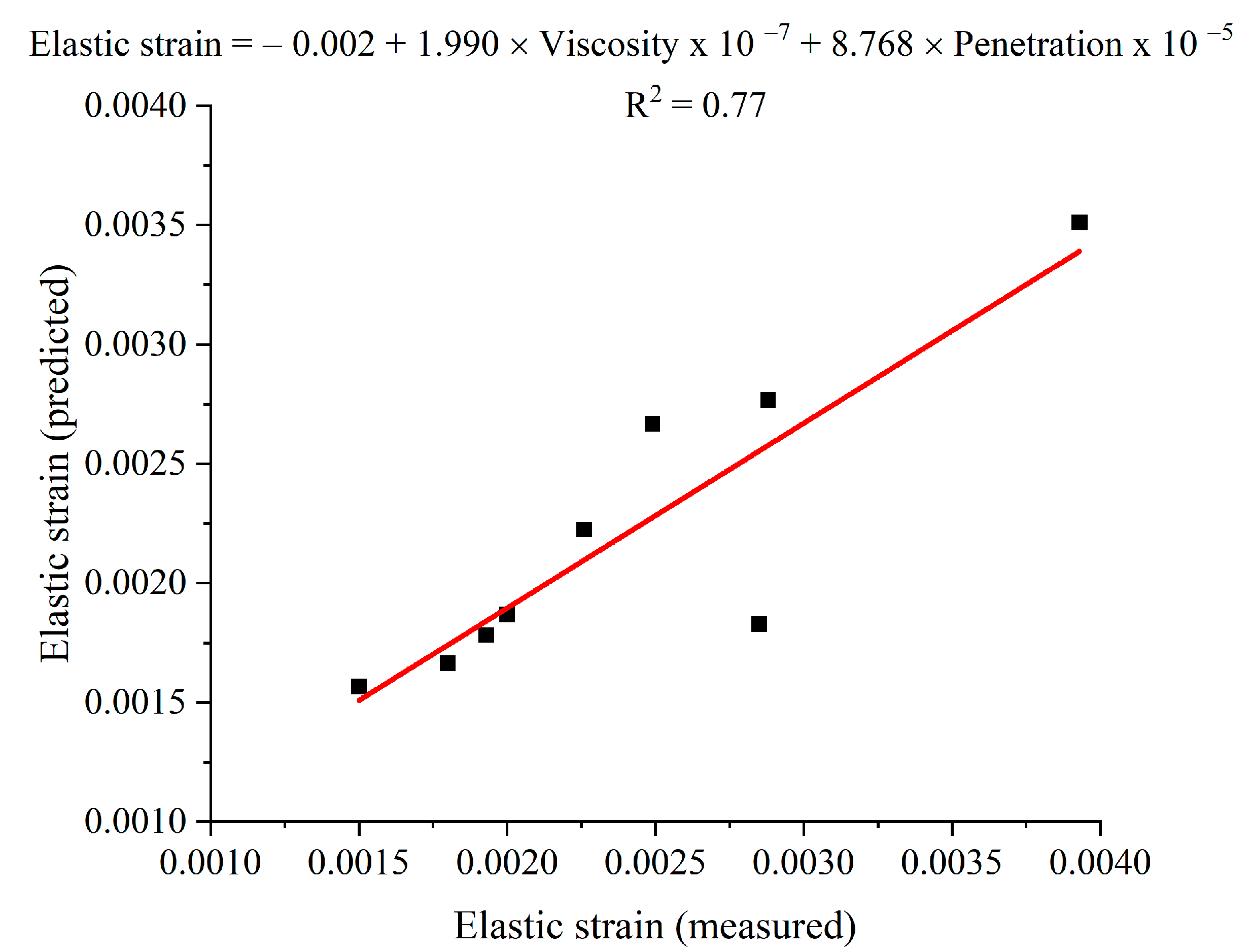

3.3. Correlation Analysis

4. Results

4.1. Binder Evaluation Results

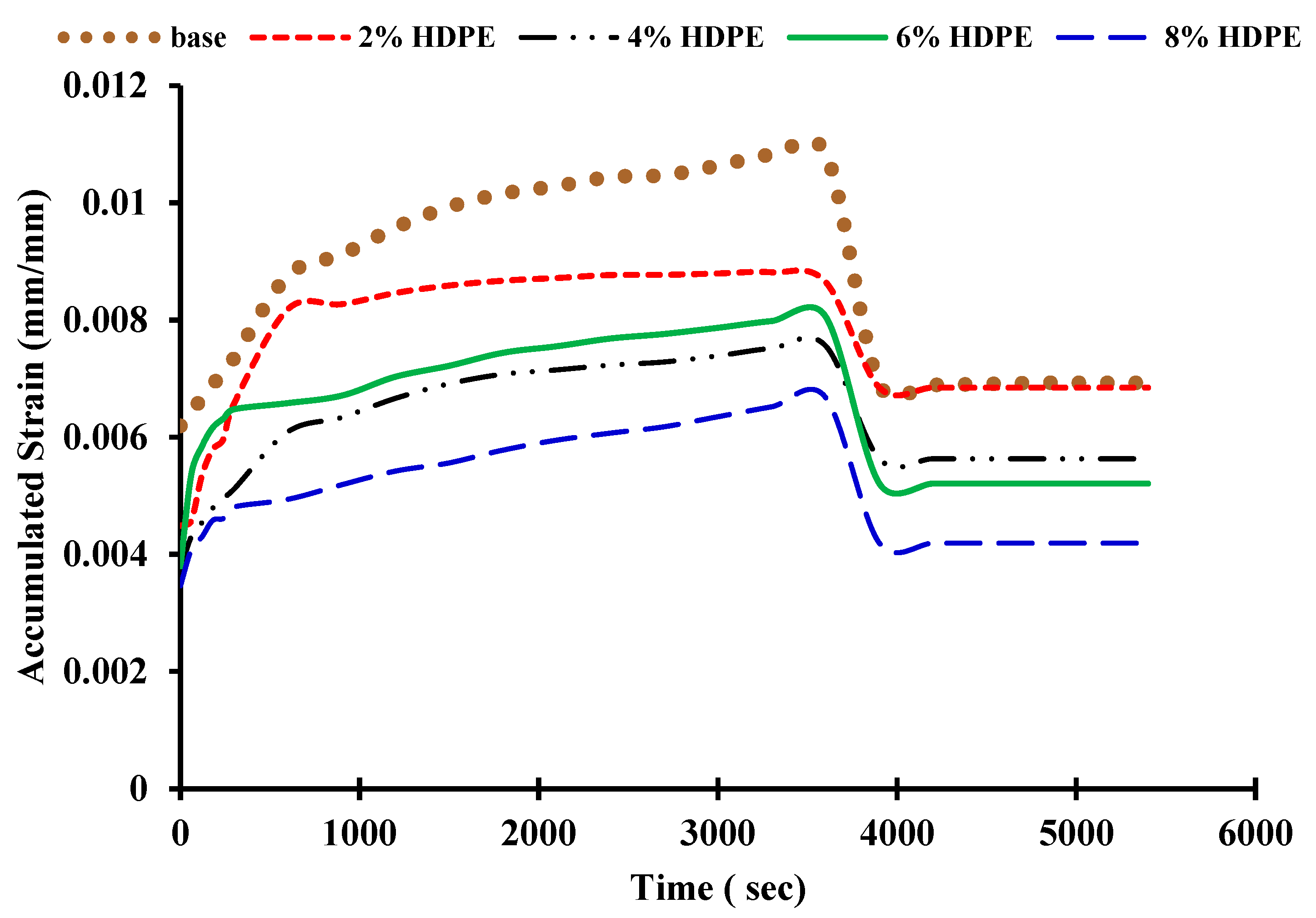

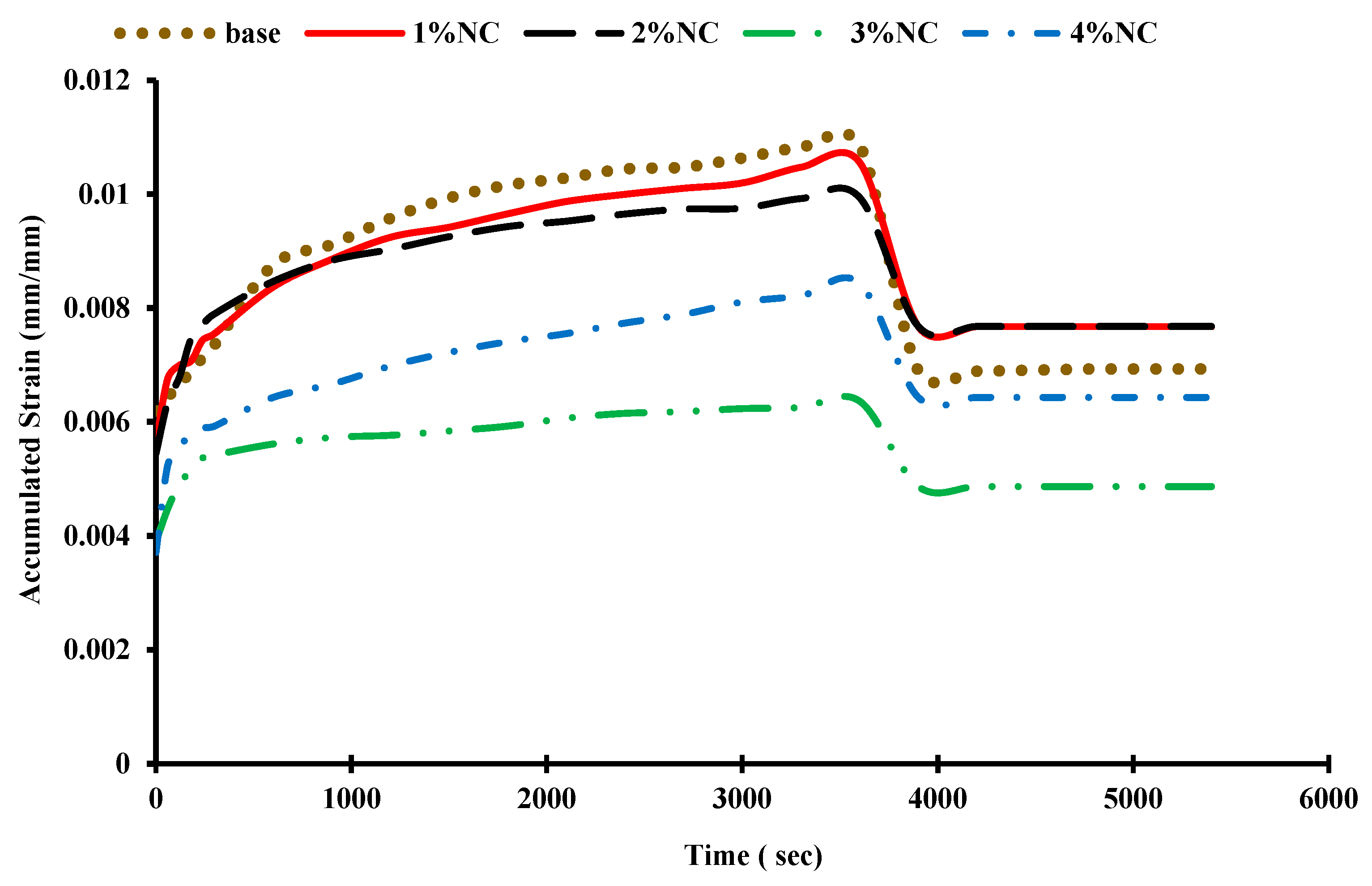

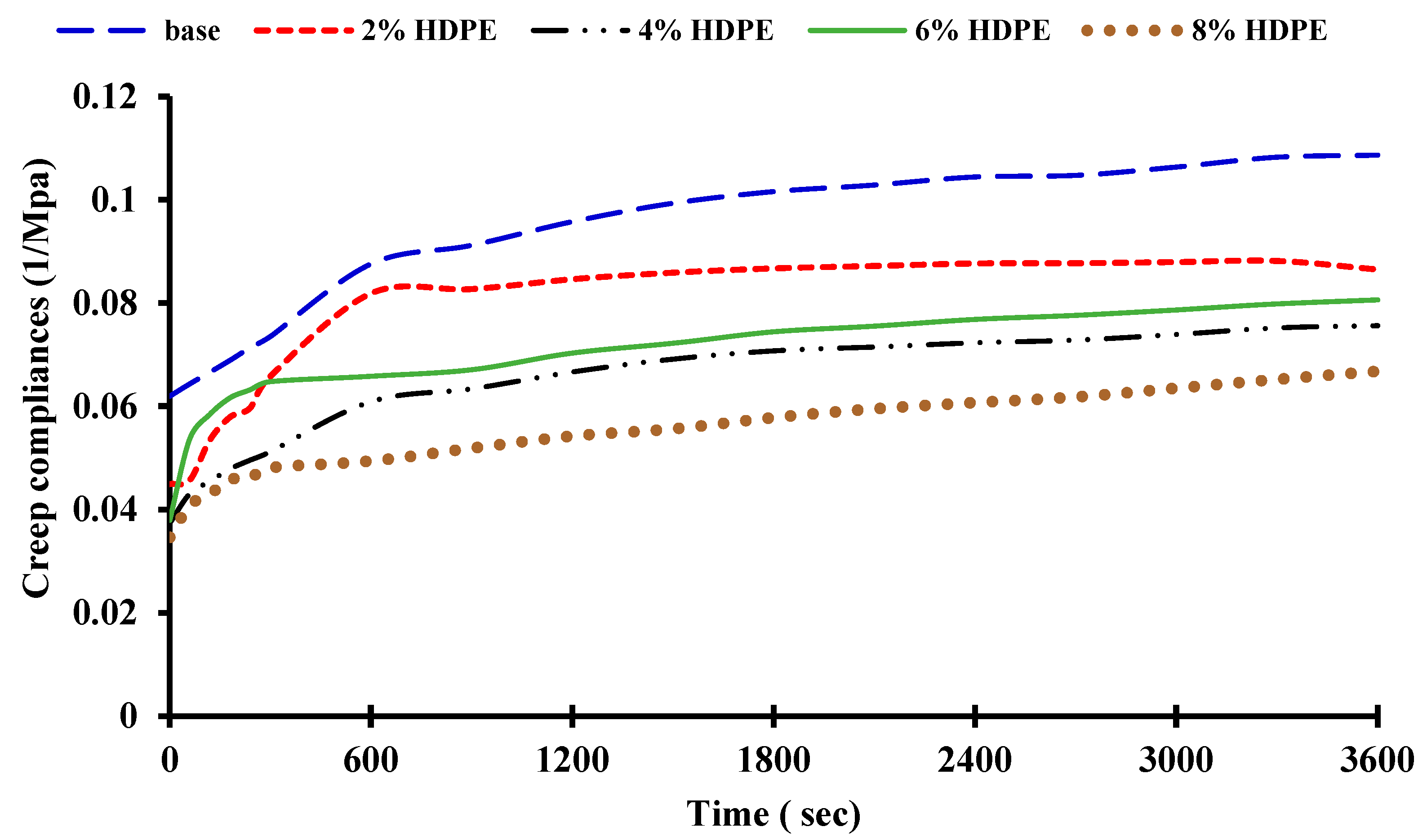

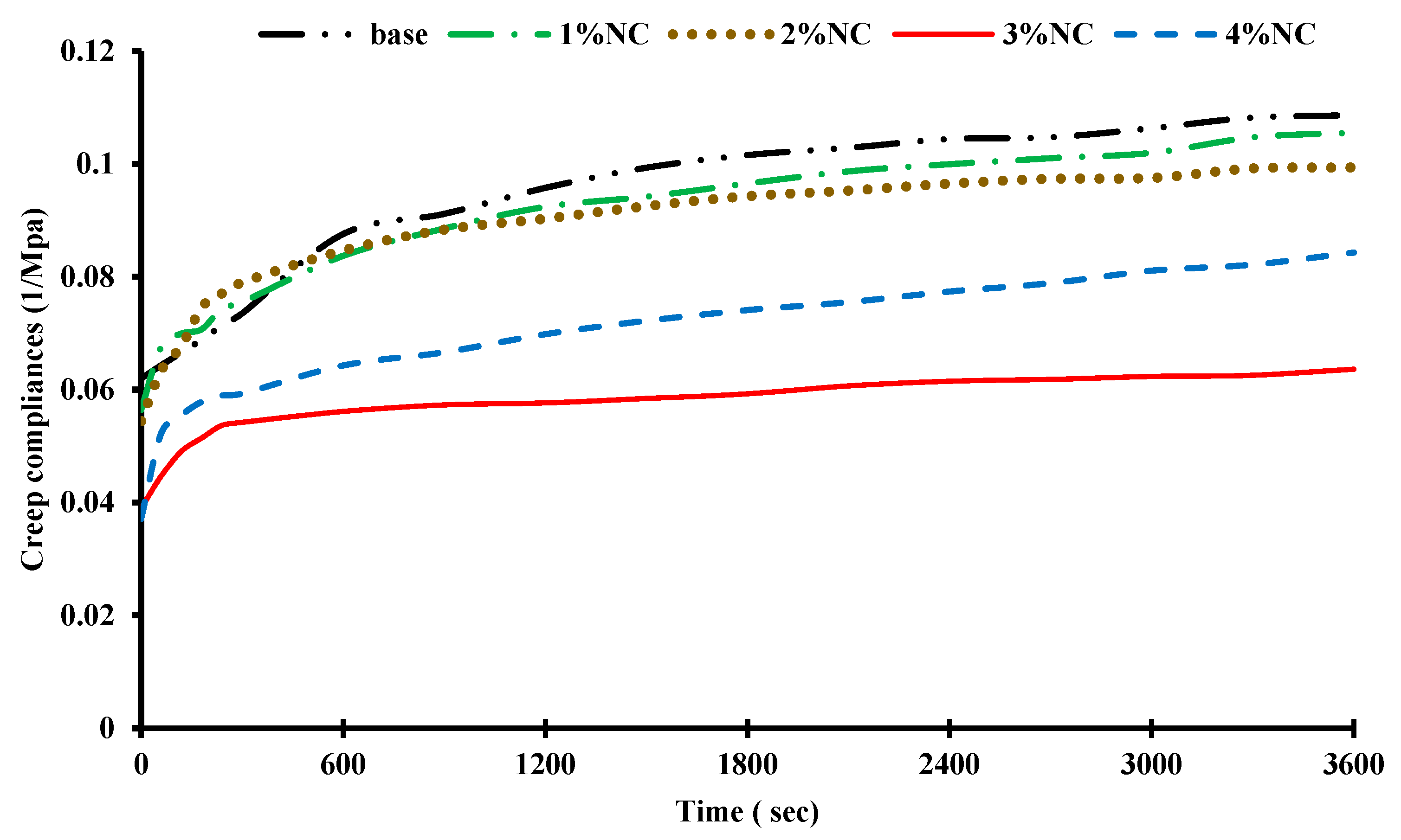

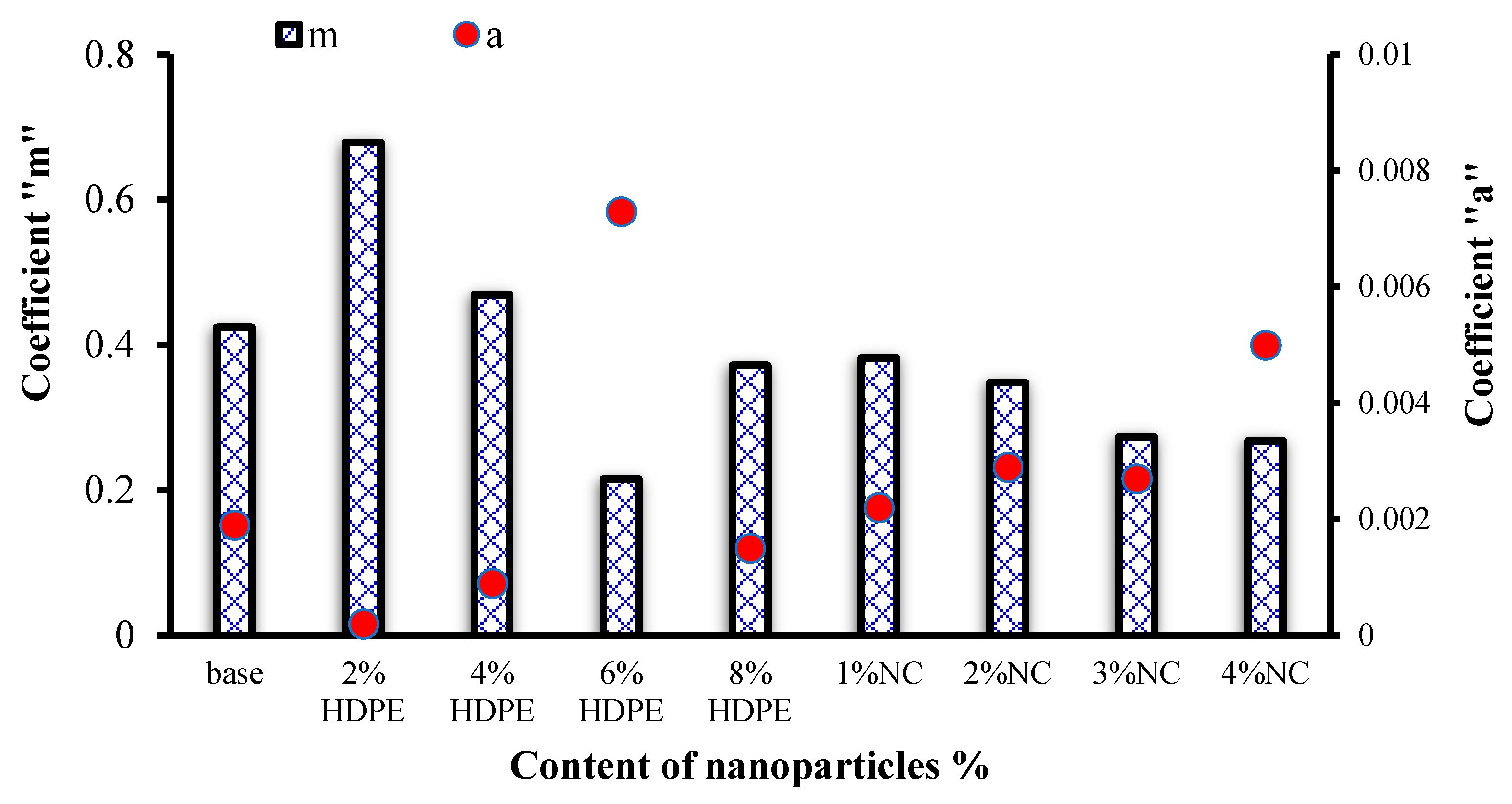

4.2. Creep Resistance of Asphalt Mixture

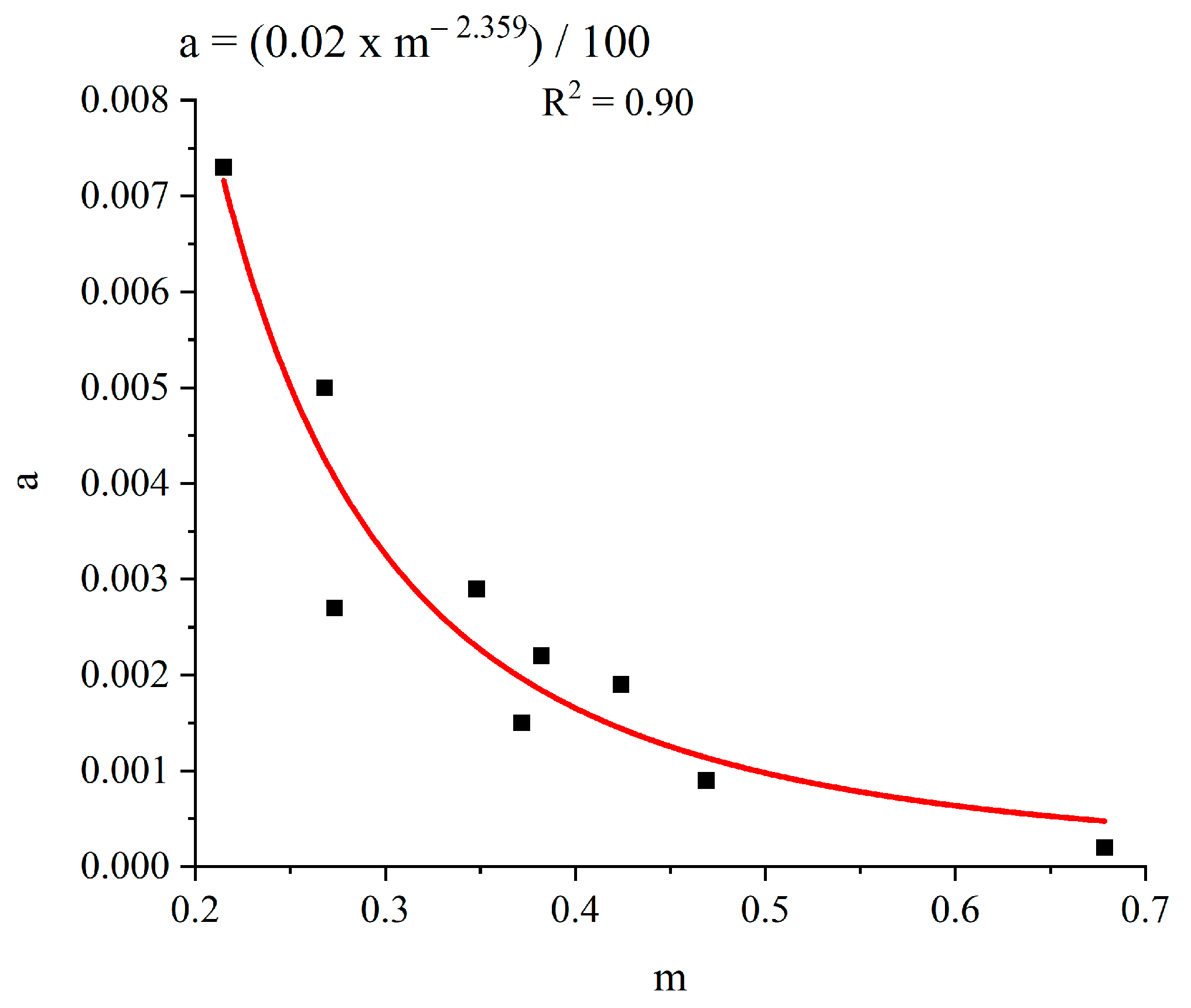

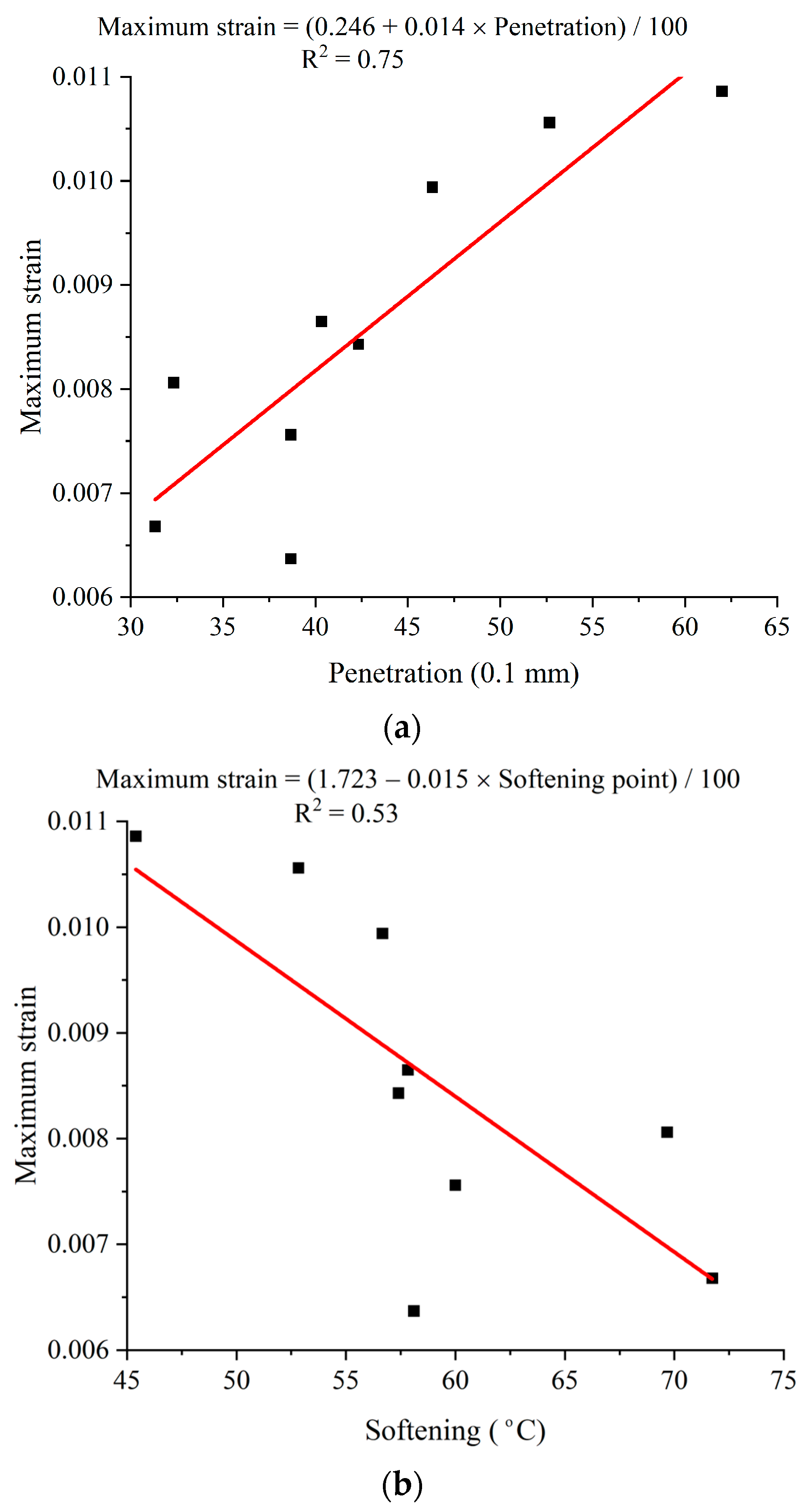

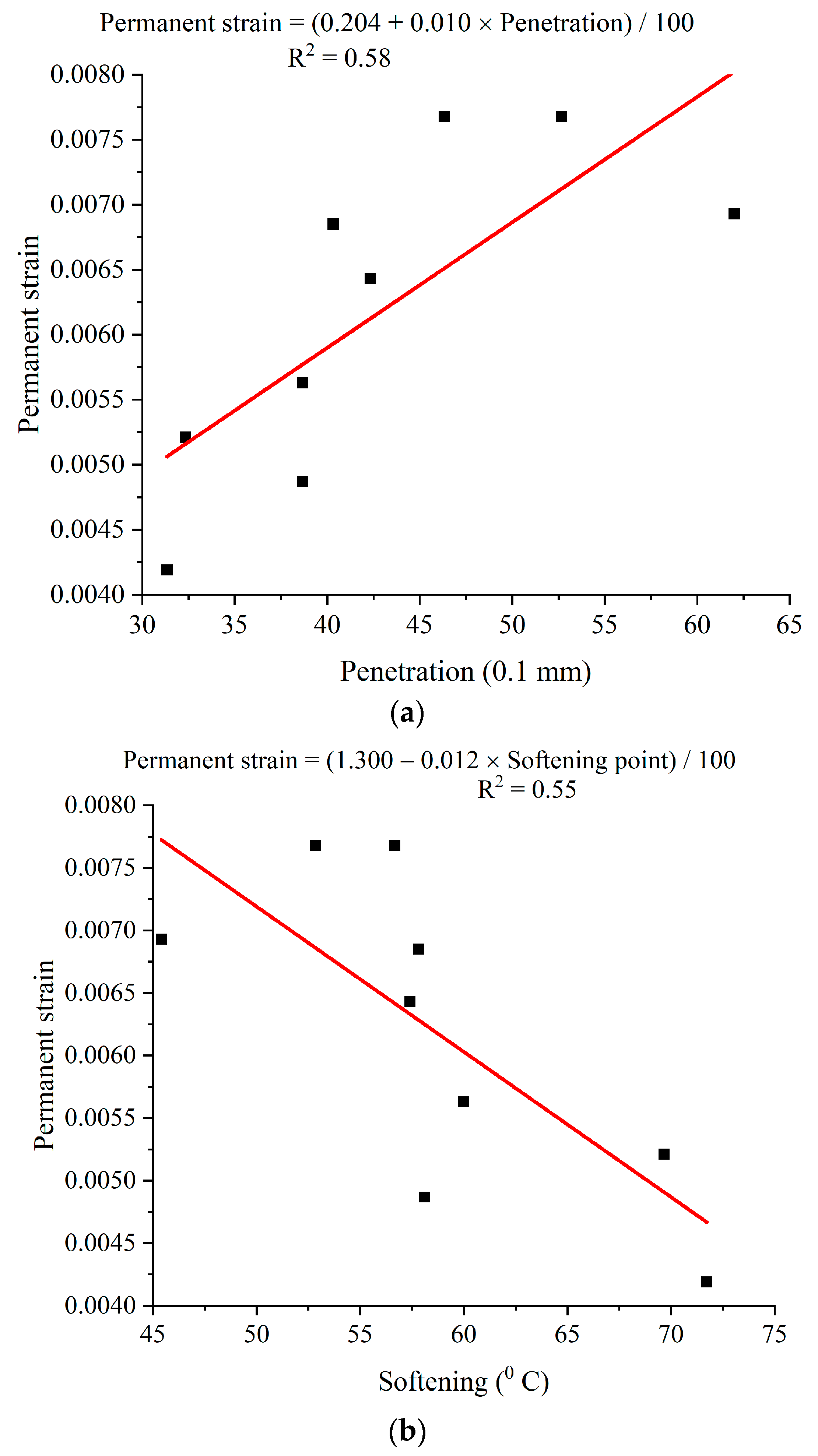

4.3. Impact of Binder Basic Characteristics on Creep Performance of Asphalt Mixture

5. Conclusions

- The HDPE and NC modifications for asphalt binder reduce the penetration value and elevate the softening point of the asphalt binder;

- The asphalt binder modification by HDPE and NC can greatly improve the creep resistance of the asphalt mixture. Under the axial loading, asphalt mixtures of 8% HDPE and 3% NC have permanent strains two times lower than the mixture of the virgin binder;

- The maximum strain at the end of the loading stage and the permanent strain at the end of the unloading stage are highly correlated to the binder basic properties. The higher the penetration value and the lower the softening point of the asphalt binder, the smaller the strains provoked in the asphalt mixture under loading;

- To sum up, future research should focus on establishing correlations between the results of large-scale field investigations. It is crucial to remember that there are several options for low-carbon and sustainable technologies in asphalt pavement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, Z.; Zaman, M.; Hawa, T.; Saha, M.C. Evaluation of Moisture Susceptibility of Nanoclay-Modified Asphalt Binders through the Surface Science Approach. J. Mater. Civ. Eng. 2015, 27, 4014261. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.; Dulaimi, A.; Shanbara, H.K.; Al Nageim, H. The impact of cement kiln dust and cement on cold mix asphalt characteristics at different climate. Sustainability 2022, 14, 4173. [Google Scholar] [CrossRef]

- Singh, A.K.; Sahoo, J.P. Rutting prediction models for flexible pavement structures: A review of historical and recent developments. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 315–338. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating effective maintenance policies for urban networks of residential cities by using optimum and sensitivity analyses. Can. J. Civ. Eng. 2020, 47, 691–703. [Google Scholar] [CrossRef]

- Nicholls, J.C. Asphalt Surfacings; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Abdel-Wahed, T.; Rashwan, N.K.; Maurice, A.E. The physical properties of bitumen modified with ilmenite and bentonite nanoparticles. HBRC J. 2020, 16, 335–350. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Z.; Song, W. Performance and overall evaluation of nano-alumina-modified asphalt mixture. Nanotechnol. Rev. 2022, 11, 2891–2902. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Li, J.; Tang, F. Effects of two metal nanoparticles on performance properties of asphalt binder and stone matrix asphalt mixtures containing waste high density polyethelene. Constr. Build. Mater. 2023, 401, 132787. [Google Scholar] [CrossRef]

- Kalantar, Z.; Mahrez, A.; Karim, M.R. Properties of Bituminous Binder Modified with High Density Penetration Test Results. Int. Eng. Conv. 2009, 11–14. [Google Scholar]

- Putri, E.E.; Vasilsa, O. Improve the Marshall stability of porous asphalt pavement with HDPE addition. In MATEC Web of Conferences; EDP Sciences: Lessulis, France, 2019; p. 3005. [Google Scholar]

- Hinislioglu, S.; Agar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Kamada, K.; Mukai, M.; Matsumoto, Y. Electrophoretic deposition assisted by soluble anode. Mater. Lett. 2003, 57, 2348–2351. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Isa, M.T. Rheological properties of polyethylene and polypropylene modified bitumen. Int. J. Civ. Environ. Eng. 2011, 3, 96–100. [Google Scholar]

- AL-Harbi, S.M.A.; Ahmed, N.Y.; AL-Harbi, A.S.M. Effect of Density of the Polyethylene Polymer on the Asphalt Mixtures. J. Univ. Babylon 2014, 22, 674–683. [Google Scholar]

- Nejad, F.M.; Gholami, M.; Naderi, K.; Rahi, M. Evaluation of rutting properties of high density polyethylene modified binders. Mater. Struct. 2015, 48, 3295–3305. [Google Scholar] [CrossRef]

- Steyn, W.J. Applications of nanotechnology in road pavement engineering. In Nanotechnology in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2011; pp. 49–83. [Google Scholar]

- Gou, J.; Wang, G.; Al-Tamimi, H.M.; Alkhalifah, T.; Alturise, F.; Ali, H.E. Application of aluminum oxide nanoparticles in asphalt cement toward non-polluted green environment using linear regression. Chemosphere 2023, 321, 137925. [Google Scholar] [CrossRef]

- Jaffur, N.; Kumar, G.; Jeetah, P.; Ramakrishna, S.; Bhatia, S.K. Current advances and emerging trends in sustainable polyhydroxyalkanoate modification from organic waste streams for material applications. Int. J. Biol. Macromol. 2023, 253, 126781. [Google Scholar] [CrossRef]

- Van de Ven, M.F.C.; Molenaar, A.A.A.; Besamusca, J. Nanoclay for binder modification of asphalt mixtures. In Proceedings of the 7th International RILEM Symposium ATCBM09 on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27 May 2009; pp. 133–142. [Google Scholar]

- Sajedi, F.; Razak, H.A. Comparison of different methods for activation of ordinary Portland cement-slag mortars. Constr. Build. Mater. 2011, 25, 30–38. [Google Scholar] [CrossRef]

- Mahdi, L.M.J.; Muniandy, R.; Yunus, R.B.; Hasham, S.; Aburkaba, E. Effect of short term aging on organic montmorillonite nanoclay modified asphalt. Indian J. Sci. Technol. 2013, 6, 5434–5442. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Cao, Z.; Xu, X.; Xiao, F.; Abdel-Wahed, T. Bonding, rheological, and physiochemical characteristics of reclaimed asphalt rejuvenated by crumb rubber modified binder. J. Clean. Prod. 2022, 373, 133896. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Sadeghnejad, M.; Shafabakhsh, G. Use of Nano SiO2 and Nano TiO2 to improve the mechanical behaviour of stone mastic asphalt mixtures. Constr. Build. Mater. 2017, 157, 965–974. [Google Scholar] [CrossRef]

- ASTM D 5/D 5M; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D2170/D2170M; 18 Standard Test Method for Kinematic Viscosity of Asphalts. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D 113-07; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 92; D92 Test Method for Flash and Fire Points by Cleveland. ASTM International: West Conshohocken, PA, USA, 1989.

- ASTM D 70; Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 36; ASTM D36-06: Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2006.

- ISO-527-2; Plastics–Determination of Tensile Properties–Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 1996.

- ISO 178; 2013-09; Plastics-Determination of Flexural Properties (ISO 178: 2010+ Amd. 1: 2013). ISO: Geneva, Switzerland, 2013.

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastomete. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D3418-03 (D 3417-99); Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2003; pp. 66–72.

- ASTM D 256 ISO 180; Data Retrieved October 12. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM D 4883; Standard Test Method for Density of Polyethylene by the Ultrasound Technique 1, East. ASTM International: West Conshohocken, PA, USA, 1999; pp. 5–7.

- Zafari, F.; Rahi, M.; Moshtagh, N.; Nazockdast, H. The Improvement of Bitumen Properties by Adding NanoSilica. Study Civ. Eng. Archit. 2014, 3, 62–69. [Google Scholar]

- Moussa, G.S.; Abdel-Raheem, A.; Abdel-Wahed, T. Effect of Nanoclay Particles on the Performance of High-Density Polyethylene-Modified Asphalt Concrete Mixture. Polymer 2021, 13, 434. [Google Scholar] [CrossRef] [PubMed]

- Egyptian Code of Practice for Urban and Rural Roads Part 4: Road Material and Its Tests; Housing and Building National Research Center: Giza, Egypt, 2018.

- ASTM D5581; Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. Annual B ASTM Standard. American Society for Testing and Materials: Philadelphia, PA, USA, 1998.

- AASHTO T209; Standard Method of Test for Theoretical Maximum Specific Gravity (Gmm) and Density of Asphalt Mixtures. AASHTO: Washington, DC, USA, 2020.

- ASTM C131-06; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4791-10; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C127-12; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2012.

- Bitumen, S. The Shell Bitumen Handbook; Shell Bitumen: Cheshire, UK, 1990. [Google Scholar]

- Kumar, P.; Mehndiratta, H.C.; Singh, K.L. Comparative study of rheological behavior of modified binders for high-temperature areas. J. Mater. Civ. Eng. 2010, 22, 978–984. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, P. Optimum blending requirements for EVA modified binder. Transp. Res. Procedia 2016, 17, 98–106. [Google Scholar] [CrossRef]

- Tam, W.O.; Solaimanian, M.; Kennedy, T.W.; River, R. Development and Use of Static Creep Test to Evaluate Rut Resistance of Superpave Mixes (FHWA-TX-1250-4), Work; The University of Texas at Austin: Austin, TX, USA, 2000; Volume 7, p. 4. [Google Scholar]

- Yuan, Q.; Shi, C.; De Schutter, G.; Audenaert, K.; Deng, D. Chloride binding of cement-based materials subjected to external chloride environment—A review. Constr. Build. Mater. 2009, 23, 1–13. [Google Scholar] [CrossRef]

- Chen, S.; Xu, L.; Jia, S.; Wang, J. Characterization of the nonlinear viscoelastic constitutive model of asphalt mixture. Case Stud. Constr. Mater. 2023, 18, e01902. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Jaya, R.P.; Prasetijo, J.; Azizi, K. Effects of temperature and binder type on the dynamic creep of asphaltic concrete incorporating geometrically cubical aggregates subjected to ageing. Mod. Appl. Sci. 2009, 3, 3–14. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Xiao, F.; Hettiarachchi, C.; Abdel-Wahed, T. Bond strength in dry condition of reclaimed asphalt modified by crumb rubber modified binder. J. Adhes. 2023, 99, 691–720. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khasawneh, M.A.; Al-Rousan, T.M.; Al-Theeb, S.F. Static creep of modified superpave asphalt concrete mixtures using crumb tire rubber, microcrystalline synthetic wax, and nano-silica. Int. J. Pavement Eng. 2021, 22, 794–805. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Lu, W.; Zhang, N. Optimization Design and Mechanical Performances of Plant-Mix Hot Recycled Asphalt Using Response Surface Methodology. Materials 2023, 16, 5863. [Google Scholar] [CrossRef] [PubMed]

- Onyango, M.A. Verification of Mechanistic Prediction Models for Permanent Deformation in Asphalt Mixes Using Accelerated Pavement Testing. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2009. [Google Scholar]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating the effect of corrective maintenance on the pavement life cycle and the optimal maintenance strategies. In CICTP 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 811–822. [Google Scholar]

| Test | Test Conditions | Value | Max. Limit | Min. Limit | Standard |

|---|---|---|---|---|---|

| Penetration, dmm | 100 g, at 25 °C, 5 s | 61 | 70 | 60 | ASTM D 5/D 5M [26] |

| Penetration-index | −1.96 | 2 | −2 | ||

| Rotational viscosity, C.st | at 135 °C | 381 | 3000 | - | ASTM D 2170 [27] |

| Ductility, cm | at 25 °C, 5 cm/min | 101 | - | 100 | ASTM D 113 [28] |

| Flash-point, °C | 251 | - | 250 | ASTM D 92 [29] | |

| Density, g/cm3 | at 15 °C | 1.02 | 1.06 | 1.01 | ASTM D 70 [30] |

| Softening-Point, °C | 45.5 | 56 | 49 | ASTM D 36 [31] |

| Property | Value | Standard |

|---|---|---|

| Tensile-Stress (Yield) (MPa) | 24 | ISO 527 2/1A/50 [32] |

| Tensile-Strain (Yield) (%) | 11 | |

| Tensile-Strain (Break) (%) | >100 | |

| Flexural Modulus (MPa) | 919 | ISO 178 [33] |

| Melt Index (190 °C/2.16 kg), (g/10 min) | 21 | ASTM D 1238 [34] |

| Peak Melting Temp (°C) | 129 | ASTM D 3418 [35] |

| Notched Izod Impact Strength (kJ/m2) | 4.2 | ISO 180/1A [36] |

| Density (g/cm3) | 0.948 | ASTM D 4883 [37] |

| Property | Value |

|---|---|

| Chemical formula | Al2Si2O5(OH)4 |

| Purity, % | >99 |

| Shape | Spherical |

| Physical-state | Powder |

| Colour | White |

| Size, nm | Less than 40 |

| Compound name | Aluminum Silicate-Hydroxide |

| Specific gravity, g/cm3 | 2.6 |

| Melting Point, °C | >1500 |

| Molecular Weight, g/mole | 258.2 |

| Test | Standard | Result | Specification |

|---|---|---|---|

| Specific gravity (combined aggregate) | AASHTO T209 [42] | 2.544 | ---------- |

| Los Angeles abrasion | ASTM C131 [43] | 24% | Max 35% |

| aggregate angularity | ASTM D5821 [44] | 92.5% | Min 90% |

| Flat particles | ASTM D4791 [45] | 4.6% | Max 10% |

| Filler size | --------- | 96% passing sieve No. 100 | ----------- |

| Water absorption | ASTM C127 [46] | <1% | ----------- |

| Marshall Criteria | Value | Egyptian Highway Specification | |

|---|---|---|---|

| Max. | Min. | ||

| density, g/cm3 | 2.34 | - | - |

| Air voids (AV), % | 4.29 | 5 | 3 |

| Flow, mm | 3.79 | 4 | 2 |

| Stability, kg | 980 | - | 900 |

| Optimum-asphalt-content, % | 5 | - | - |

| Voids in mineral aggregates, % | 14.99 | - | 14 |

| Voids filled with binder, % | 71.9 | - | 71 |

| Additives % | Properties of Stain | (Smax) Mpa | ||

|---|---|---|---|---|

| (Ɛelas) | (Ɛperm) | (Ɛmax) | ||

| Conventional mixture | 0.00393 | 0.00693 | 0.01086 | 9204.65 |

| 2% high-density polyethylene | 0.00180 | 0.00685 | 0.00865 | 11558.25 |

| 4% high-density polyethylene | 0.00193 | 0.00563 | 0.00756 | 13222.59 |

| 6% high-density polyethylene | 0.00285 | 0.00521 | 0.00806 | 12403.61 |

| 8% high-density polyethylene | 0.00249 | 0.00419 | 0.00668 | 14973.00 |

| 1% nano clay | 0.00288 | 0.00768 | 0.01056 | 9472.47 |

| 2% nano clay | 0.00226 | 0.00768 | 0.00994 | 10062.89 |

| 3% nano clay | 0.00150 | 0.00487 | 0.00637 | 15709.43 |

| 4% nano clay | 0.00200 | 0.00643 | 0.00843 | 11859.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdel-Raheem, A.; Dulaimi, A.; Mohamed, A.S.; Moussa, G.S.; Özkılıç, Y.O.; Mashaan, N.; Jaya, R.P.; Abdel-Wahed, T. Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture. Sustainability 2023, 15, 13992. https://doi.org/10.3390/su151813992

Abdel-Raheem A, Dulaimi A, Mohamed AS, Moussa GS, Özkılıç YO, Mashaan N, Jaya RP, Abdel-Wahed T. Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture. Sustainability. 2023; 15(18):13992. https://doi.org/10.3390/su151813992

Chicago/Turabian StyleAbdel-Raheem, Ashraf, Anmar Dulaimi, Ahmed S. Mohamed, Ghada S. Moussa, Yasin Onuralp Özkılıç, Nuha Mashaan, Ramadhansyah Putra Jaya, and Talaat Abdel-Wahed. 2023. "Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture" Sustainability 15, no. 18: 13992. https://doi.org/10.3390/su151813992

APA StyleAbdel-Raheem, A., Dulaimi, A., Mohamed, A. S., Moussa, G. S., Özkılıç, Y. O., Mashaan, N., Jaya, R. P., & Abdel-Wahed, T. (2023). Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture. Sustainability, 15(18), 13992. https://doi.org/10.3390/su151813992