Superhydrophobic Microchannel Heat Exchanger for Electric Vehicle Heat Pump Performance Enhancement

Abstract

:1. Introduction

2. Methodology

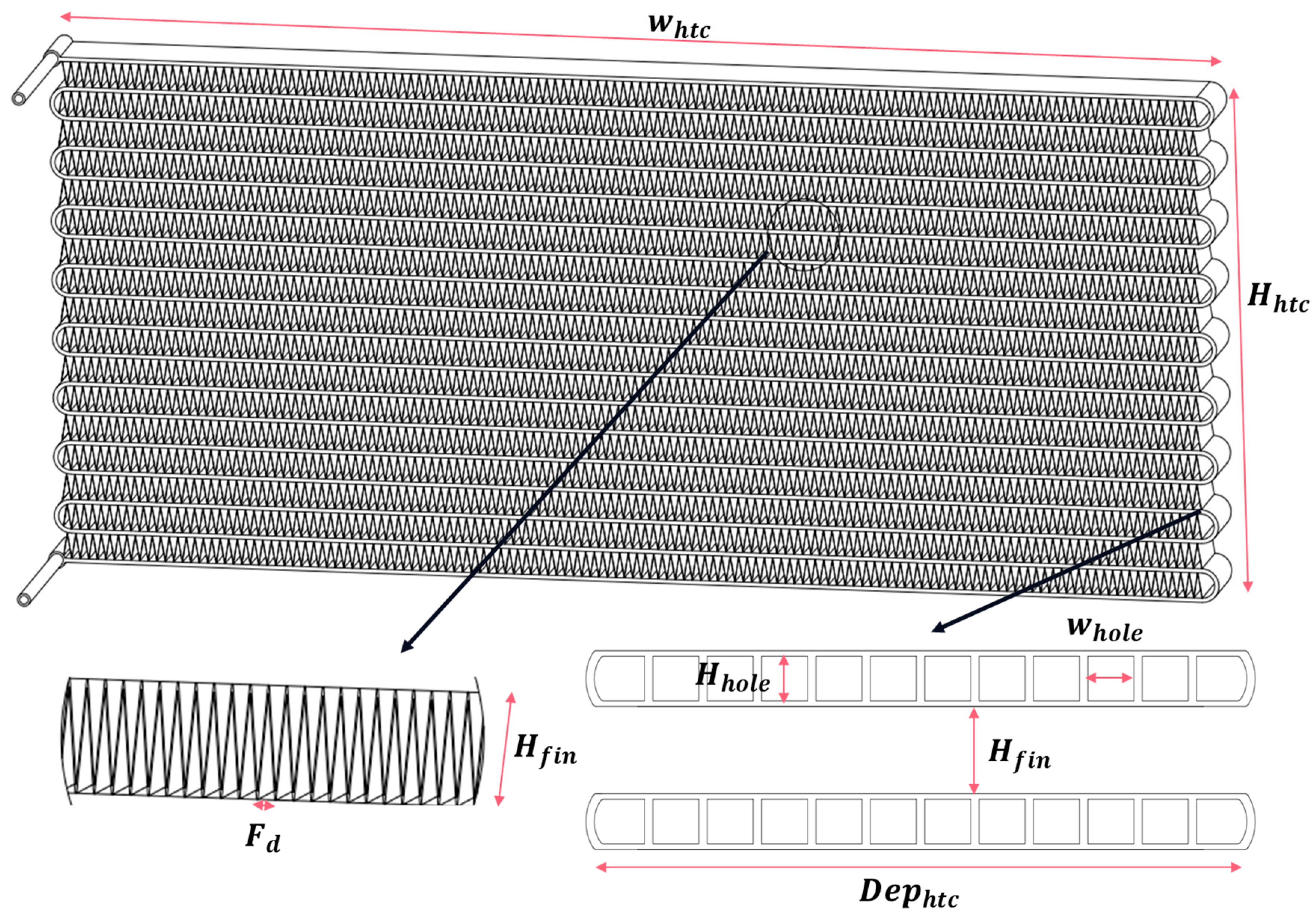

2.1. Microchannel Heat Exchanger Model

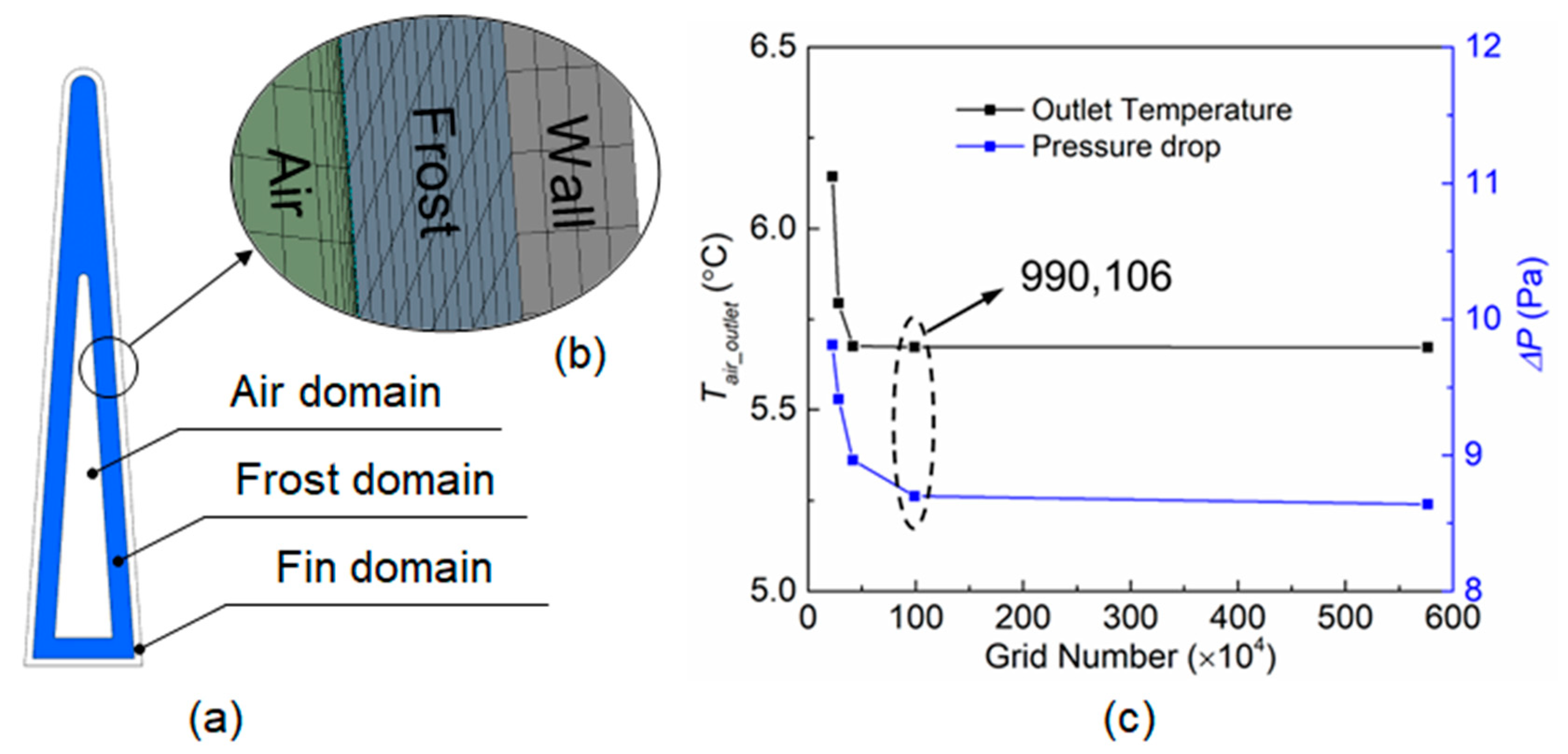

2.2. Air-Side CFD Simulation

- The frost distribution is homogeneous and uniform on the surface of the heat exchanger.

- The thermal conductively of the frost (f) is considered to be a function of the frost density as follows [33]:where ρf is the frost density, which is considered to be 1000 kg/m3 in this work.

- The heat radiation between the air and frost layer is negligible.

2.3. Heat Pump Cycle Model

2.4. Model Validation

3. Air-Side Flow and Heat Transfer Characteristics with Frost Growth

3.1. The Heat Transfer Coefficients with and without SHST

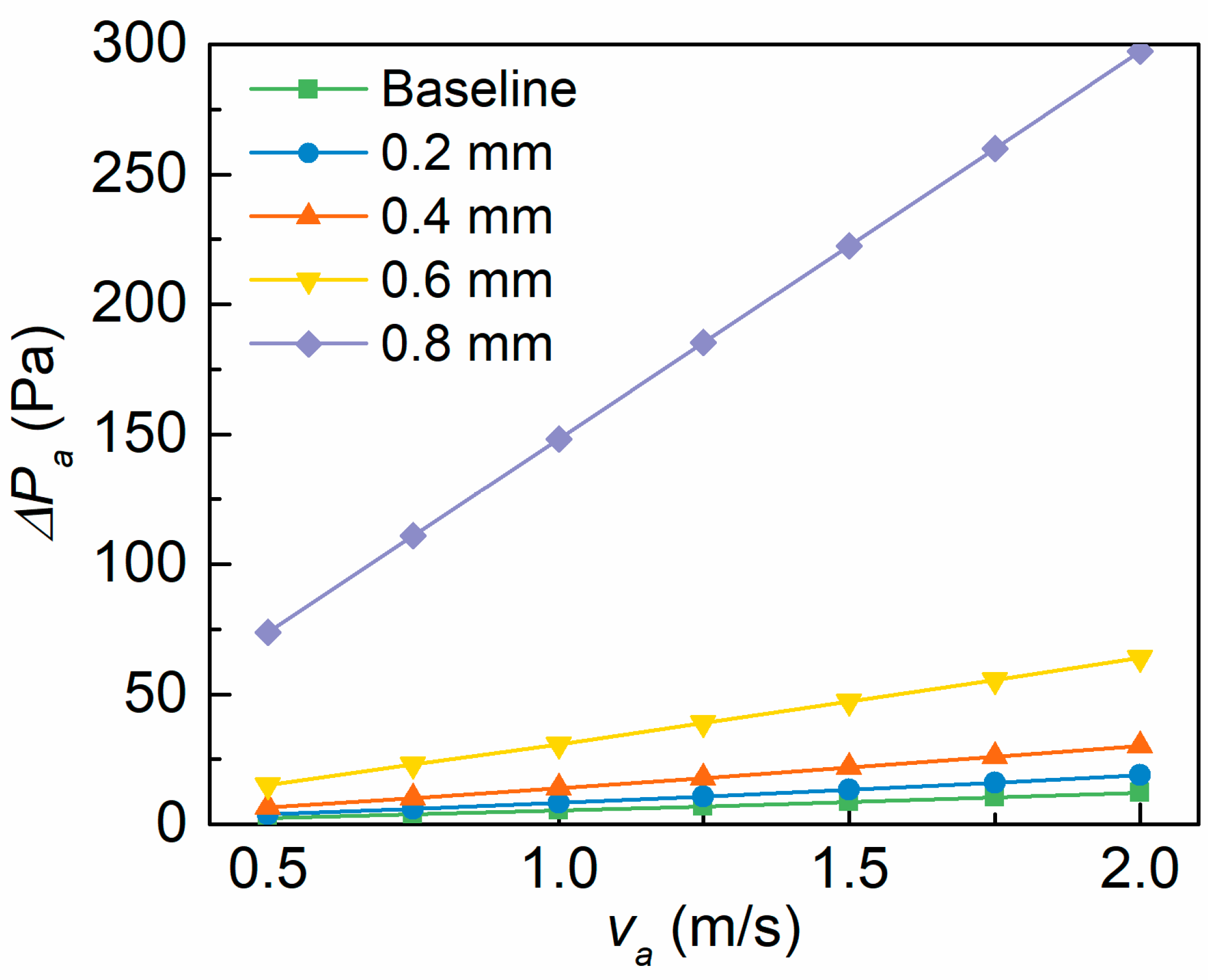

3.2. The Pressure Drops with and without SHST

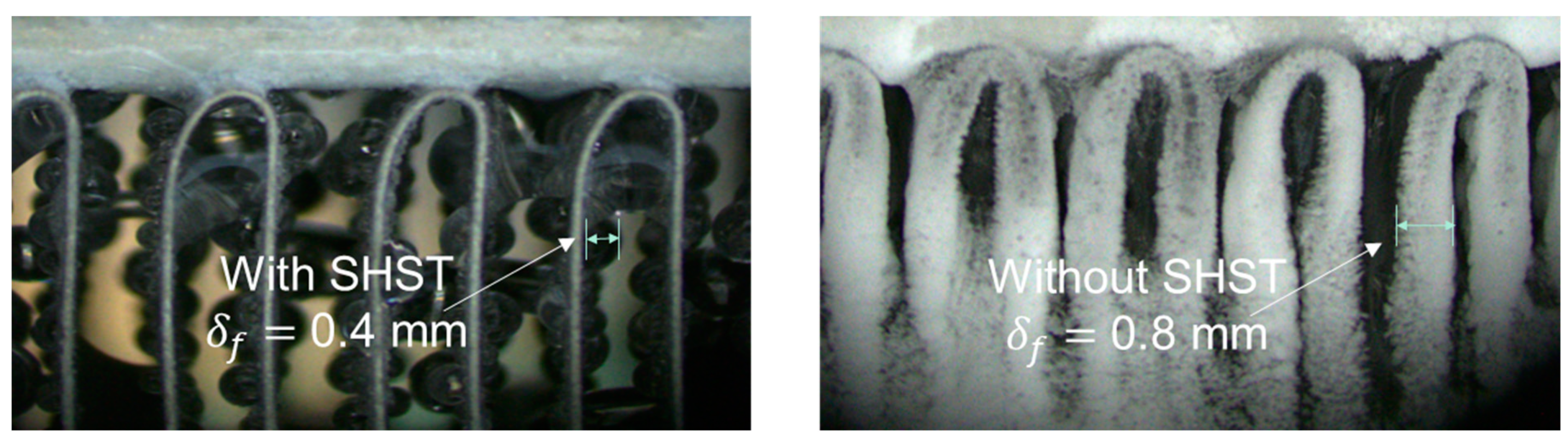

4. Experiment on Microchannel Heat Exchangers with SHST

5. Cycle Performance of Heat Pump with Frost Accumulation

6. Performance Comparison of EVs Using Different Heating Methods

7. Conclusions

- (1)

- The validated CFD model demonstrates that frost growth significantly affects the heat transfer characteristics of MHEs. When the frost layer thickness is 0.8 mm at a given air-side velocity of 1.0 m/s, the air-side heat transfer coefficient can be reduced by about 75%, and the air-side pressure drop sharply increases by 28.4 times.

- (2)

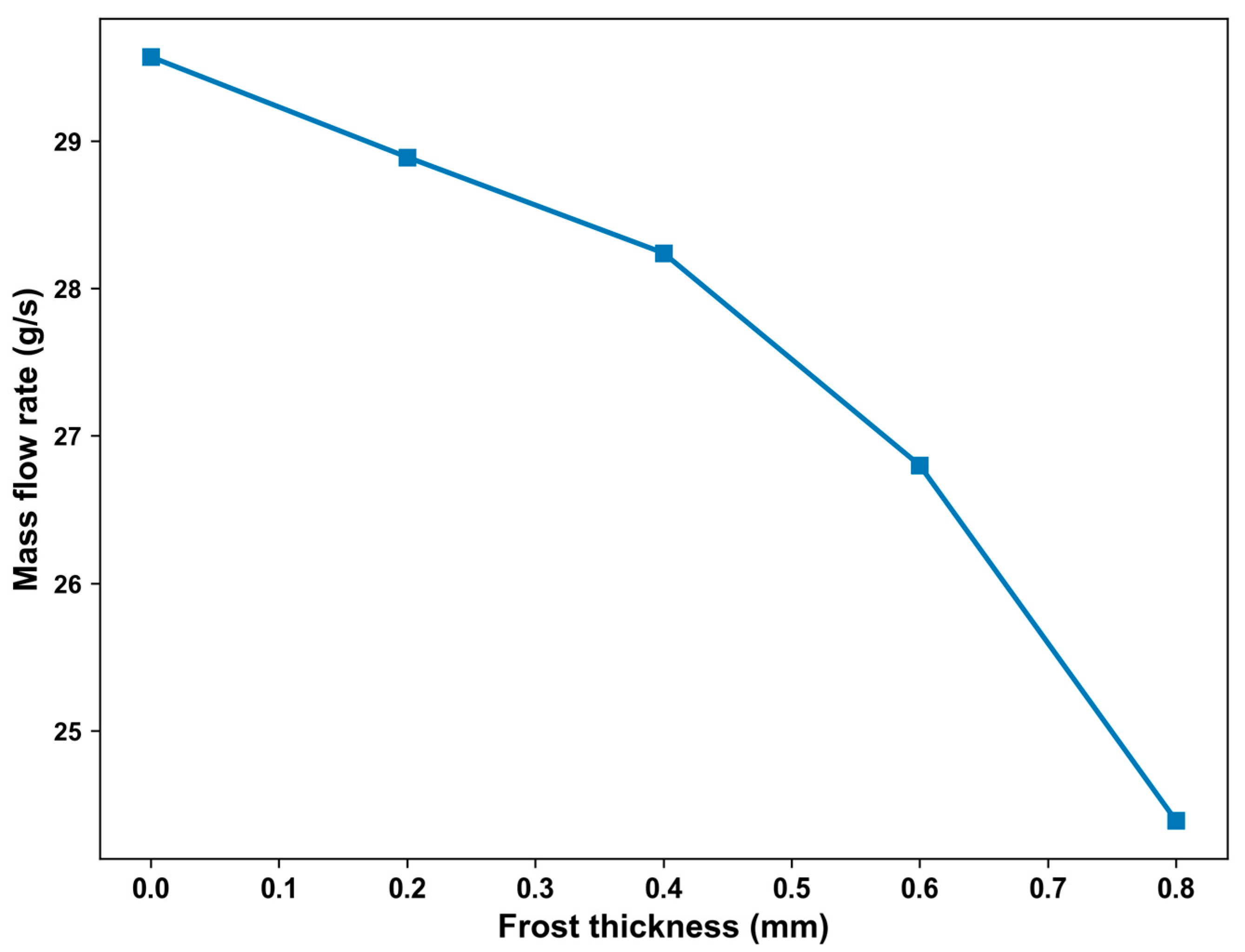

- As the frost thickness increases from 0 to 0.8 mm, the heating output decreases from 3.97 to 1.82 kW, and the system COP declines from 3.17 to 2.30. When frost thickness exceeds 0.4 mm, both the heating output and COP decrease dramatically.

- (3)

- After 30 min of operation, the frost thickness on the MHE treated with SHST is approximately 0.4 mm, while the MHE without SHST attains a frost thickness of about 0.8 mm. These results confirm the defrosting capability of superhydrophobic coatings. Once the frost thickness reaches 0.8 mm, the frost can obstruct the flow areas of the MHE, leading to a rapid decrease in the air-side heat transfer coefficient and COP.

- (4)

- With the MHE using SHST, the heat pump system achieves a heating COP of 2.93 and a cooling COP of 2.72. Compared to an untreated MHE, the air-side flow resistance and heating power consumption of the proposed system are reduced by 90.1% and 48.7%, owing to the defrosting capability of the SHST. Additionally, the single-charge driving distance of the heat pump with SHST extends to 327.27 km, which is 8.99% longer than a heat pump without SHST and 28.0% longer than a traditional positive temperature coefficient heating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| area: m2 | |

| specific heat capacity, kJ/(kgK) | |

| hydraulic diameter, m | |

| height, m | |

| specific enthalpies, kJ/kg | |

| mass flow rate, kg/s | |

| pressure, kPa | |

| heat transfer rate, kW | |

| t | temperature, °C |

| power, kW | |

| convective heat transfer coefficient, W/(m2·K) | |

| density, kg/m3 | |

| dynamic viscosity, Pa·s | |

| efficiency | |

| thermal conductivity, W/(m·K) | |

| thickness, m | |

| Abbreviations | |

| COP | coefficient of performance |

| CFD | computational fluid dynamics |

| EV | electric vehicle |

| MAPE | mean absolute percentage error |

| MHE | microchannel heat exchanger |

| PTC | positive temperature coefficient |

| SHST | superhydrophobic surface treatment |

| Subscripts | |

| a | air side |

| comp | compressor |

| dis | discharge |

| ex | expansion valve |

| ext | external |

| fan | fan |

| htc | heat exchanger |

| in | inlet |

| int | internal |

| is | isentropic |

| me | mechanical |

| out | outlet |

| sys | system |

References

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2019, 182, 824–839. [Google Scholar] [CrossRef]

- Rajper, S.Z.; Albrecht, J. Prospects of electric vehicles in the developing countries: A literature review. Sustainability 2020, 12, 1906. [Google Scholar] [CrossRef]

- Bode, F.; Burnete, N.V.; Fechete Tutunaru, L.; Nastase, I. Improving Electric Vehicle Range and Thermal Comfort through an Innovative Seat Heating System. Sustainability 2023, 15, 5534. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Feng, X.; Chang, L.; Chen, Y.; Wang, X. The solutions to electric vehicle air conditioning systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 443–463. [Google Scholar] [CrossRef]

- Qi, Z. Advances on air conditioning and heat pump system in electric vehicles–A review. Renew. Sustain. Energy Rev. 2014, 38, 754–764. [Google Scholar] [CrossRef]

- Peng, Q.; Du, Q. Progress in heat pump air conditioning systems for electric vehicles—A review. Energies 2016, 9, 240. [Google Scholar] [CrossRef]

- Jakończuk, P.; Śmierciew, K.; Gagan, J.; Butrymowicz, D. Image-Analysis-Based Approach for Identification of Air Cooler Heat Transfer Degradation during Frosting Process. Sustainability 2022, 14, 13731. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Liu, R.; Wang, D.; Shi, J.; Yu, Z.; Cheng, L.; Chen, J. Performance evaluation of secondary loop low-temperature heat pump system for frost prevention in electric vehicles. Appl. Therm. Eng. 2021, 182, 115615. [Google Scholar] [CrossRef]

- Mahvi, A.J.; Boyina, K.; Musser, A.; Elbel, S.; Miljkovic, N. Superhydrophobic heat exchangers delay frost formation and enhance efficency of electric vehicle heat pumps. Int. J. Heat Mass Transf. 2021, 172, 121162. [Google Scholar] [CrossRef]

- Badri, D.; Toublanc, C.; Rouaud, O.; Havet, M. Review on frosting, defrosting and frost management techniques in industrial food freezers. Renew. Sustain. Energy Rev. 2021, 151, 111545. [Google Scholar] [CrossRef]

- Yang, B.; Zhu, X.; Liu, M.; Lv, Z. Review on the application of machine vision in defrosting and decondensation on the surface of heat exchanger. Sustainability 2022, 14, 11606. [Google Scholar] [CrossRef]

- Song, M.; Deng, S.; Dang, C.; Mao, N.; Wang, Z. Review on improvement for air source heat pump units during frosting and defrosting. Appl. Energy 2018, 211, 1150–1170. [Google Scholar] [CrossRef]

- Gurumukhi, Y.; Chavan, S.; Sett, S.; Boyina, K.; Ramesh, S.; Sokalski, P.; Fortelka, K.; Lira, M.; Park, D.; Chen, J.-Y. Dynamic defrosting on superhydrophobic and biphilic surfaces. Matter 2020, 3, 1178–1195. [Google Scholar] [CrossRef]

- Liu, J.; Kappl, M.; Butt, H.-J. Toward passive defrosting with heterogeneous coatings. Matter 2020, 3, 981–983. [Google Scholar] [CrossRef]

- Foster, A.; Campbell, R.; Davies, T.; Evans, J. A novel passive defrost system for a frozen retail display cabinet with a low evaporator. In Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 16–22 August 2015; International Institute of Refrigeration: Paris, France, 2015. [Google Scholar]

- Amer, M.; Wang, C.-C. Review of defrosting methods. Renew. Sustain. Energy Rev. 2017, 73, 53–74. [Google Scholar] [CrossRef]

- Li, F.; Wu, S.; Ma, Z.; Zhao, R.; Huang, D. Effect of surface coating on defrosting water drainage characteristics of vertical-fin microchannel frosting evaporator. Appl. Therm. Eng. 2022, 208, 118220. [Google Scholar] [CrossRef]

- Boreyko, J.B.; Srijanto, B.R.; Nguyen, T.D.; Vega, C.; Fuentes-Cabrera, M.; Collier, C.P. Dynamic defrosting on nanostructured superhydrophobic surfaces. Langmuir 2013, 29, 9516–9524. [Google Scholar] [CrossRef]

- Shin, J.; Tikhonov, A.V.; Kim, C. Experimental study on frost structure on surfaces with different hydrophilicity: Density and thermal conductivity. J. Heat Transf. 2003, 125, 84–94. [Google Scholar] [CrossRef]

- Kadhim, M.A.; Kapur, N.; Summers, J.L.; Thompson, H. Experimental and theoretical investigation of droplet evaporation on heated hydrophilic and hydrophobic surfaces. Langmuir 2019, 35, 6256–6266. [Google Scholar] [CrossRef]

- Wang, F.; Liang, C.; Yang, M.; Fan, C.; Zhang, X. Effects of surface characteristic on frosting and defrosting behaviors of fin-tube heat exchangers. Appl. Therm. Eng. 2015, 75, 1126–1132. [Google Scholar] [CrossRef]

- Liu, Z.; Gou, Y.; Wang, J.; Cheng, S. Frost formation on a super-hydrophobic surface under natural convection conditions. Int. J. Heat Mass Transf. 2008, 51, 5975–5982. [Google Scholar] [CrossRef]

- Kim, A.; Lee, C.; Kim, H.; Kim, J. Simple approach to superhydrophobic nanostructured Al for practical antifrosting application based on enhanced self-propelled jumping droplets. ACS Appl. Mater. Interfaces 2015, 7, 7206–7213. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.G.; Fartaj, A. A review on microchannel heat exchangers and potential applications. Int. J. Energy Res. 2011, 35, 553–582. [Google Scholar] [CrossRef]

- Wang, C.-N.; Yang, F.-C.; Nguyen, V.T.T.; Vo, N.T. CFD analysis and optimum design for a centrifugal pump using an effectively artificial intelligent algorithm. Micromachines 2022, 13, 1208. [Google Scholar] [CrossRef] [PubMed]

- VO, T.M.N. Centrifugal pump design: An optimization. Eurasia Proc. Sci. Technol. Eng. Math. 2022, 17, 136–151. [Google Scholar]

- Wu, X.; Ma, Q.; Chu, F.; Hu, S. Phase change mass transfer model for frost growth and densification. Int. J. Heat Mass Transf. 2016, 96, 11–19. [Google Scholar] [CrossRef]

- Sui, Z.G.; Wu, W. A comprehensive review of membrane-based absorbers/desorbers towards compact and efficient absorption refrigeration systems. Renew. Energy 2022, 201, 563–593. [Google Scholar] [CrossRef]

- Kim, M.-H.; Bullard, C.W. Air-side performance of brazed aluminum heat exchangers under dehumidifying conditions. Int. J. Refrig. 2002, 25, 924–934. [Google Scholar] [CrossRef]

- Qasem, N.A.; Zubair, S.M. Compact and microchannel heat exchangers: A comprehensive review of air-side friction factor and heat transfer correlations. Energy Convers. Manag. 2018, 173, 555–601. [Google Scholar] [CrossRef]

- Siddiqui, F.A.; Dasgupta, E.S.; Fartaj, A. Experimental investigation of air side heat transfer and fluid flow performances of multi-port serpentine cross-flow mesochannel heat exchanger. Int. J. Heat Fluid Flow 2012, 33, 207–219. [Google Scholar] [CrossRef]

- Boeng, J.; Marcon, A.A.; Hermes, C.J. Air-side heat transfer and pressure drop characteristics of microchannel evaporators for household refrigerators. Int. J. Heat Mass Transf. 2020, 147, 118913. [Google Scholar] [CrossRef]

- Yang, D.-K.; Lee, K.-S.; Song, S. Modeling for predicting frosting behavior of a fin–tube heat exchanger. Int. J. Heat Mass Transf. 2006, 49, 1472–1479. [Google Scholar] [CrossRef]

- Fluent, A. ANSYS Fluent Theory Guide, Release 18.0; Ansys. Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

- Ding, Z.; Wu, W.; Huang, S.-M.; Huang, H.; Bai, Y.; He, Z. A novel compression-assisted energy storage heat transformer for low-grade renewable energy utilization. Energy 2023, 263, 125681. [Google Scholar] [CrossRef]

- Sui, Y.; Ding, Z.; Zhai, C.; Lin, H.; Wu, W. Crystallization-free and low-cost deep eutectic solvents for absorption thermal battery utilizing ultra-low-grade energy. Energy Convers. Manag. 2023, 284, 116984. [Google Scholar] [CrossRef]

- Omidi, M.; Liu, S.-J.; Mohtaram, S.; Lu, H.-T.; Zhang, H.-C. Improving centrifugal compressor performance by optimizing the design of impellers using genetic algorithm and computational fluid dynamics methods. Sustainability 2019, 11, 5409. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Zacharis, A.; Ziozas, N.; Bellos, E.; Iliadis, P.; Lampropoulos, I.; Chatzigeorgiou, E.; Angelakoglou, K.; Nikolopoulos, N. Dynamic Energy Analysis of Different Heat Pump Heating Systems Exploiting Renewable Energy Sources. Sustainability 2023, 15, 11054. [Google Scholar] [CrossRef]

- Sui, Y.; Wu, W. Ionic liquid screening and performance optimization of transcritical carbon dioxide absorption heat pump enhanced by expander. Energy 2023, 263, 125689. [Google Scholar] [CrossRef]

- Shao, L.-L.; Yang, L.; Zhang, C.-L. Comparison of heat pump performance using fin-and-tube and microchannel heat exchangers under frost conditions. Appl. Energy 2010, 87, 1187–1197. [Google Scholar] [CrossRef]

| Symbol | Meaning | Value |

|---|---|---|

| distance between flat tubes | 12 mm | |

| port height | 1.6 mm | |

| port width | 2.2 mm | |

| distance between fins | 2 mm | |

| fin thickness | 0.15 mm | |

| number of ports per tube | 12 | |

| number of tubes | 10 | |

| HTC width | 548 mm | |

| HTC height | 258 mm | |

| HTC depth | 31.2 mm |

| Parameter | Value |

|---|---|

| Air-side inlet temperature, Ta | 7 °C |

| Air-side inlet velocity, va | 0.5–2.0 m/s |

| Wall temperature, Tw | −5 °C |

| Operating pressure, P | 101 kPa |

| Frosting thickness, δf | 0.2–0.8 mm |

| Cooling Test Conditions | Heating Test Conditions | |

|---|---|---|

| Outdoor dry-bulb temperature (°C) | 35 | 7 |

| Outdoor wet-bulb temperature (°C) | 24 | 6 |

| Mass flow rate of outdoor air (kg/s) | 4.48 | 4.10 |

| Indoor dry-bulb temperature (°C) | 27 | 20 |

| Indoor wet-bulb temperature (°C) | 19.5 | 15 |

| Mass flow rate of indoor air (kg/s) | 1.62 | 1.42 |

| Indoor humidity | 0.492 | 0.584 |

| Outdoor humidity | 0.396 | 0.866 |

| Item | Experiment Results | Simulation Results | MAPE |

|---|---|---|---|

| Cooling capacity (kW) | 23.18 | 23.08 | 0.43% |

| Total power consumption (kW) | 9.53 | 9.69 | 1.68% |

| Compressor power (kW) | 6.73 | 6.89 | 2.38% |

| COP | 2.43 | 2.38 | 2.08% |

| High-side pressure (MPa) | 2.92 | 2.97 | 1.71% |

| Low-side pressure (MPa) | 0.98 | 0.87 | 11.22% |

| Item | Experiment Results | Simulation Results | MAPE |

|---|---|---|---|

| Heating capacity (kW) | 22.23 | 23.38 | 5.17% |

| Total power consumption (kW) | 8.34 | 8.08 | 3.12% |

| Compressor power (kW) | 5.94 | 5.68 | 4.38% |

| COP | 2.67 | 2.89 | 8.56% |

| High-side pressure (MPa) | 2.58 | 2.525 | 2.13% |

| Low-side pressure (MPa) | 0.98 | 0.87 | 11.22% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, Y.; Sui, Z.; Liang, G.; Wu, W. Superhydrophobic Microchannel Heat Exchanger for Electric Vehicle Heat Pump Performance Enhancement. Sustainability 2023, 15, 13998. https://doi.org/10.3390/su151813998

Sui Y, Sui Z, Liang G, Wu W. Superhydrophobic Microchannel Heat Exchanger for Electric Vehicle Heat Pump Performance Enhancement. Sustainability. 2023; 15(18):13998. https://doi.org/10.3390/su151813998

Chicago/Turabian StyleSui, Yunren, Zengguang Sui, Guangda Liang, and Wei Wu. 2023. "Superhydrophobic Microchannel Heat Exchanger for Electric Vehicle Heat Pump Performance Enhancement" Sustainability 15, no. 18: 13998. https://doi.org/10.3390/su151813998

APA StyleSui, Y., Sui, Z., Liang, G., & Wu, W. (2023). Superhydrophobic Microchannel Heat Exchanger for Electric Vehicle Heat Pump Performance Enhancement. Sustainability, 15(18), 13998. https://doi.org/10.3390/su151813998