Study on the Stress Distribution and Stability Control of Surrounding Rock of Reserved Roadway with Hard Roof

Abstract

:1. Introduction

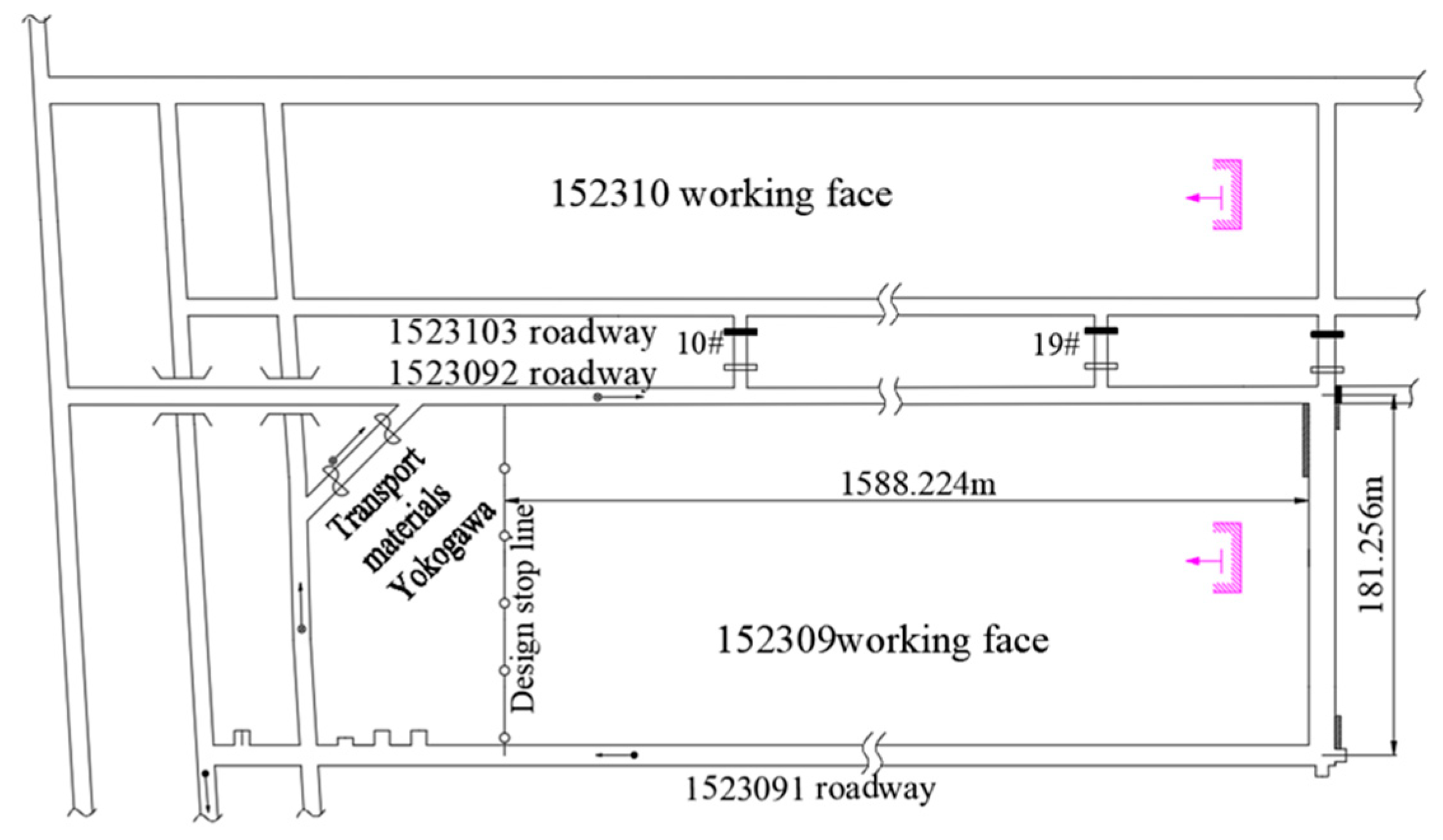

2. Project Overview

2.1. Geological Overview

2.2. Overview of the Roadway

3. Cause Analysis of Surrounding Rock Failure of Reserved Roadway

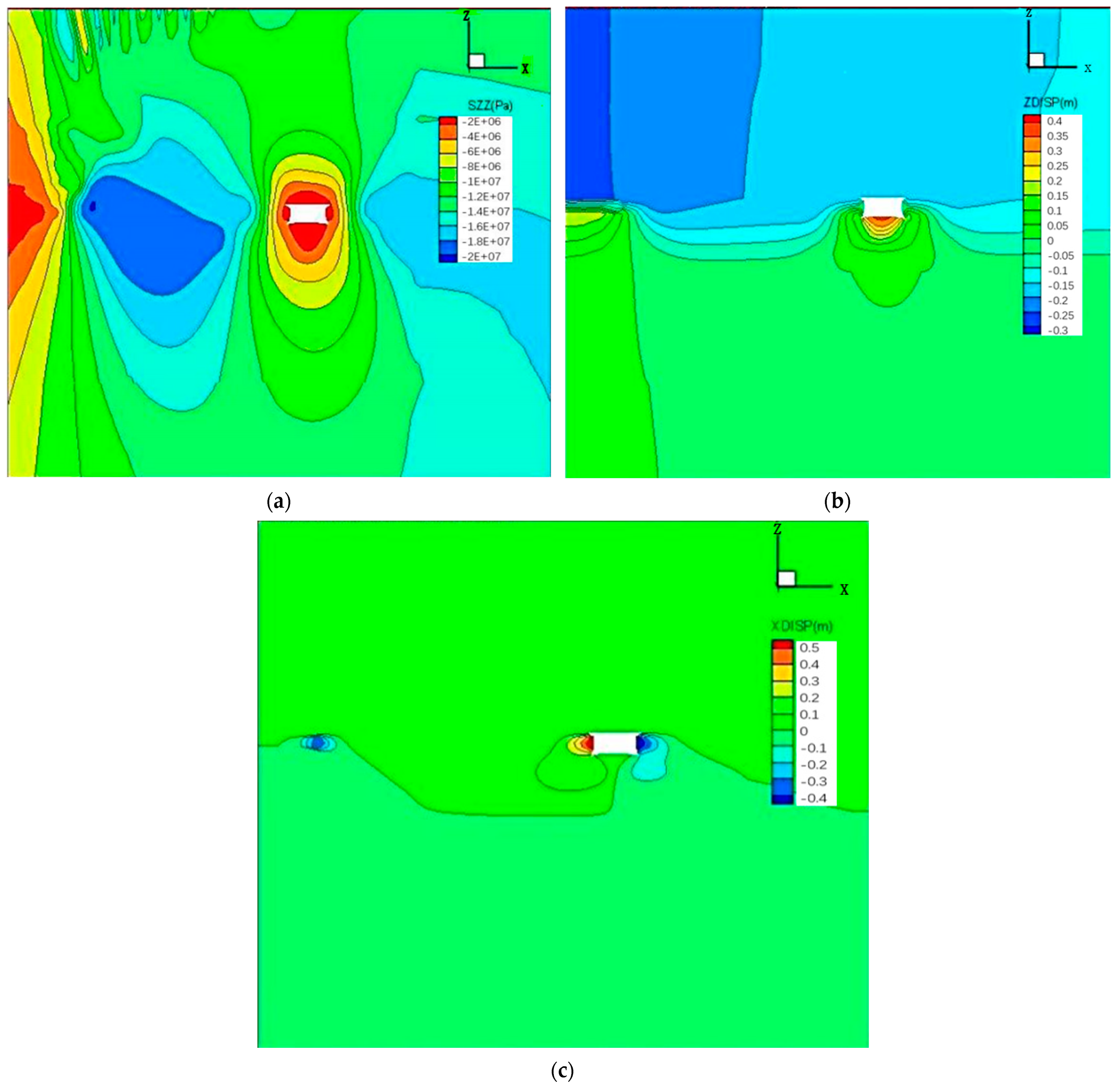

3.1. Justification of the Geomechanical Model

3.2. The Influence of Lateral Support Pressure on Working Face

3.3. Influence of Rock Mass Strength

3.4. The Influence of Supporting Method

4. Control Countermeasures of Roadway Stability

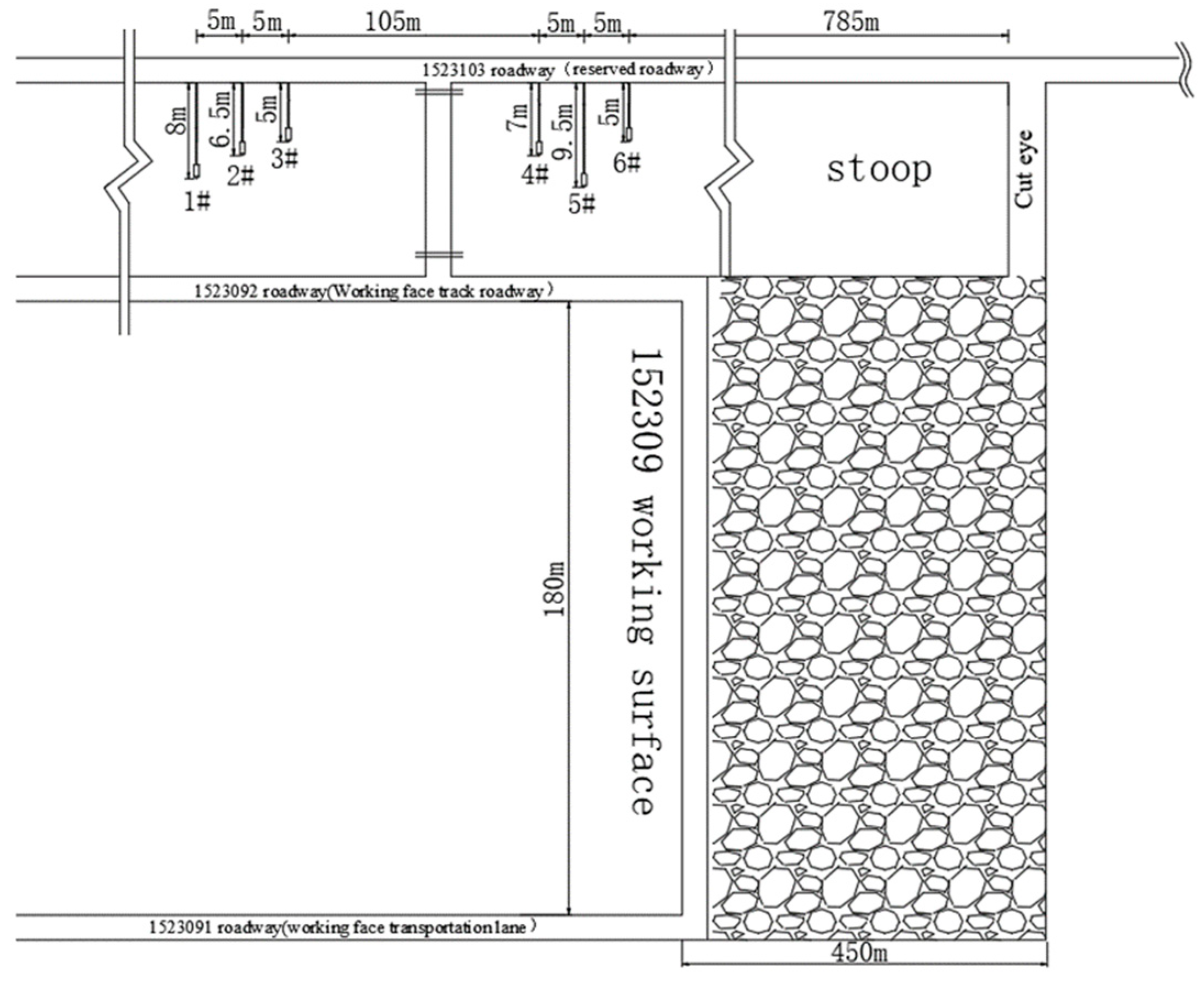

5. Design of Surrounding Rock Control Scheme of Reserved Roadway 1523103

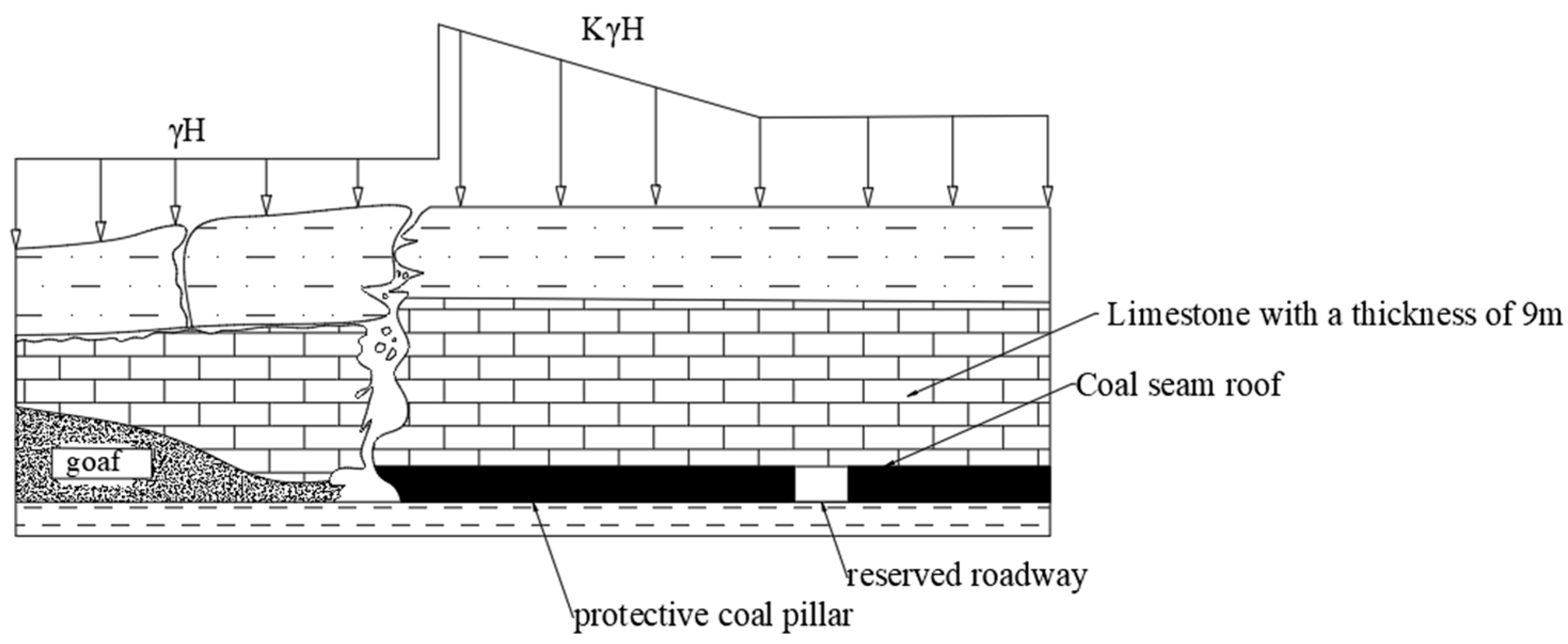

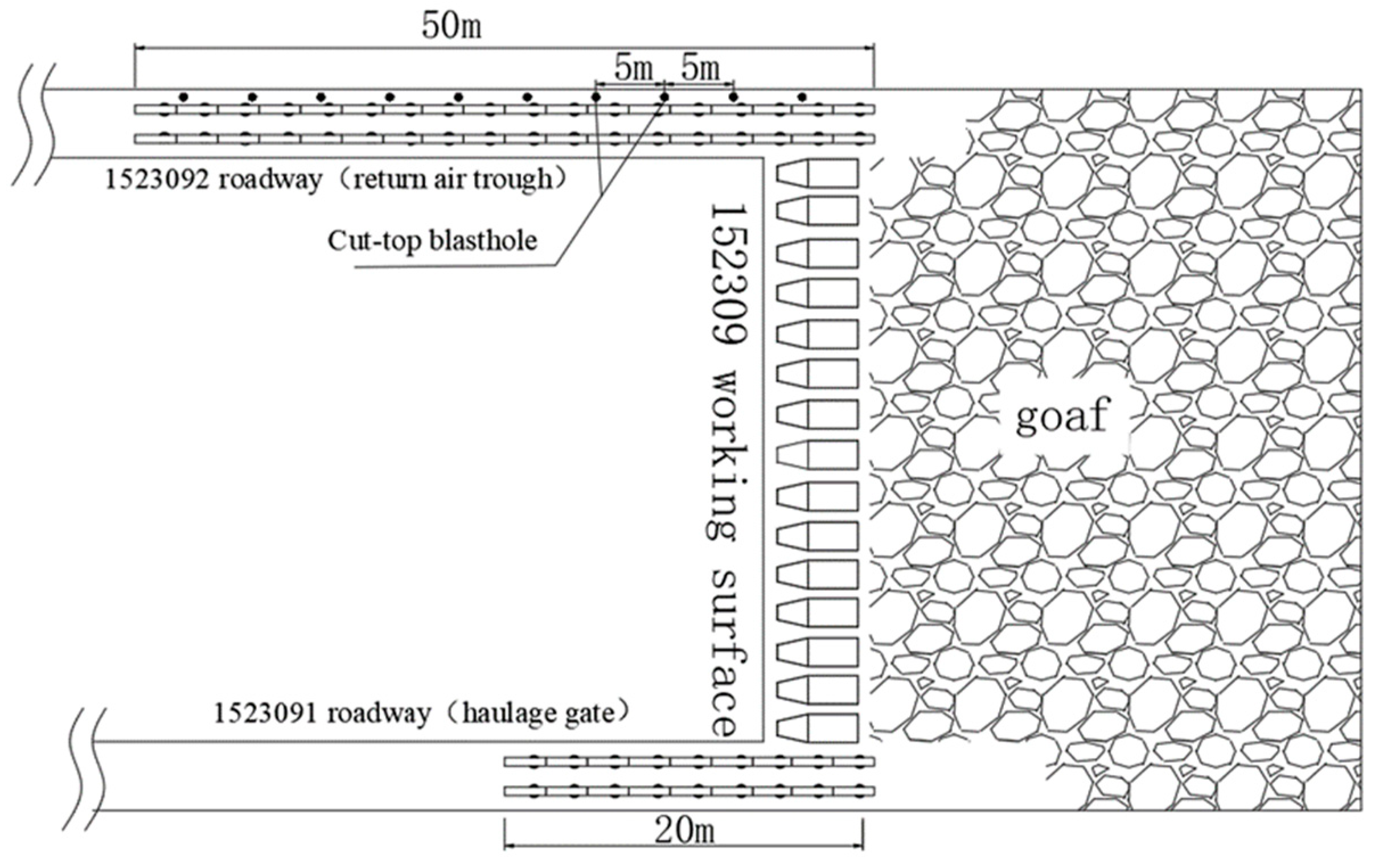

5.1. 152309 Face-Cutting Top Pressure Relief Technology

5.1.1. Cutting Top Pressure Relief Principle

5.1.2. The Main Technical Parameters of Cutting Top Pressure Relief

5.2. 1523092 Roadway Roof Weakening Technology

5.2.1. Principle of Advanced Deep Hole Pre-Splitting Blasting Technology

5.2.2. Main Technical Parameters of Advanced Deep Hole Pre-Splitting Blasting

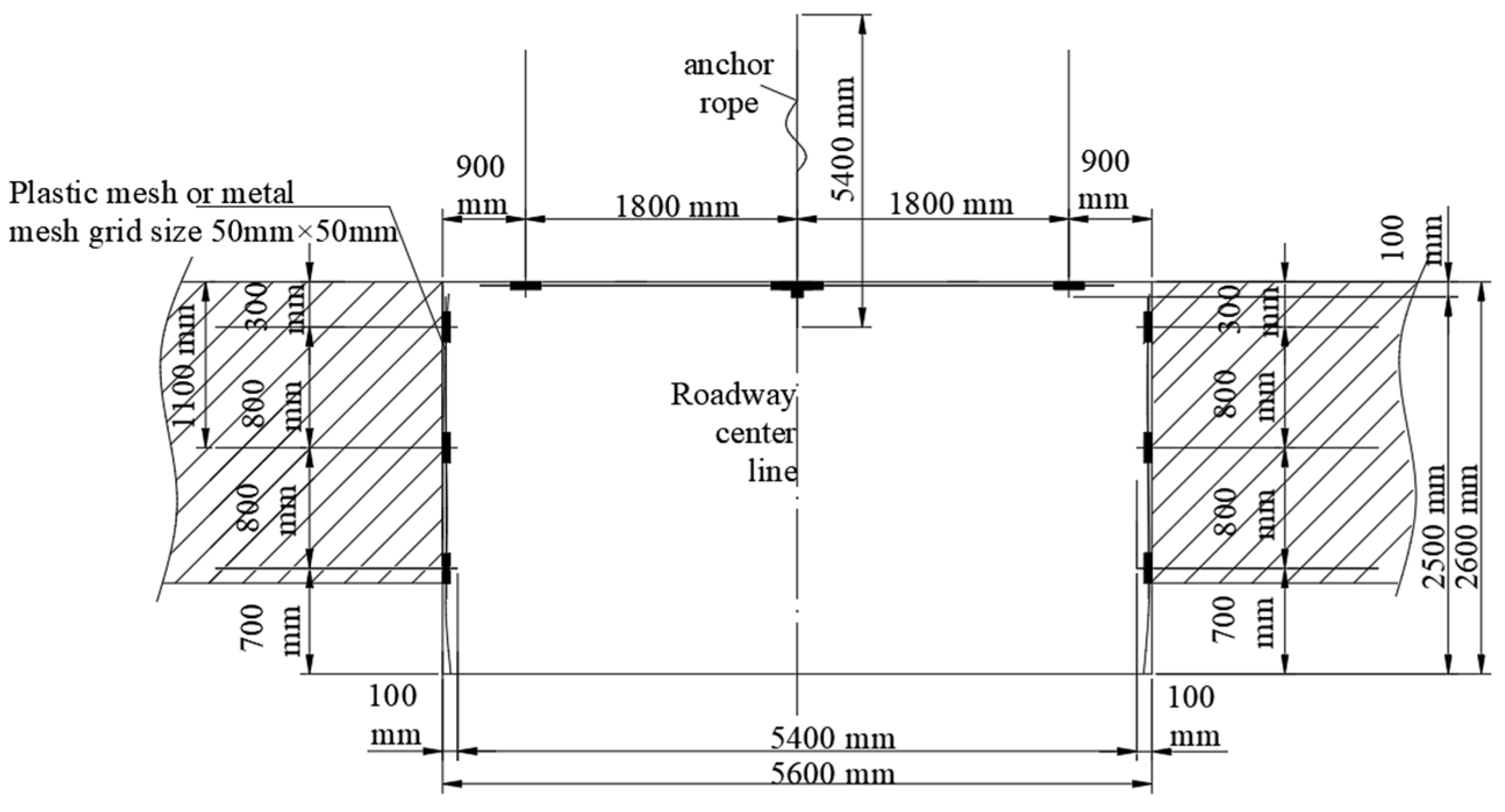

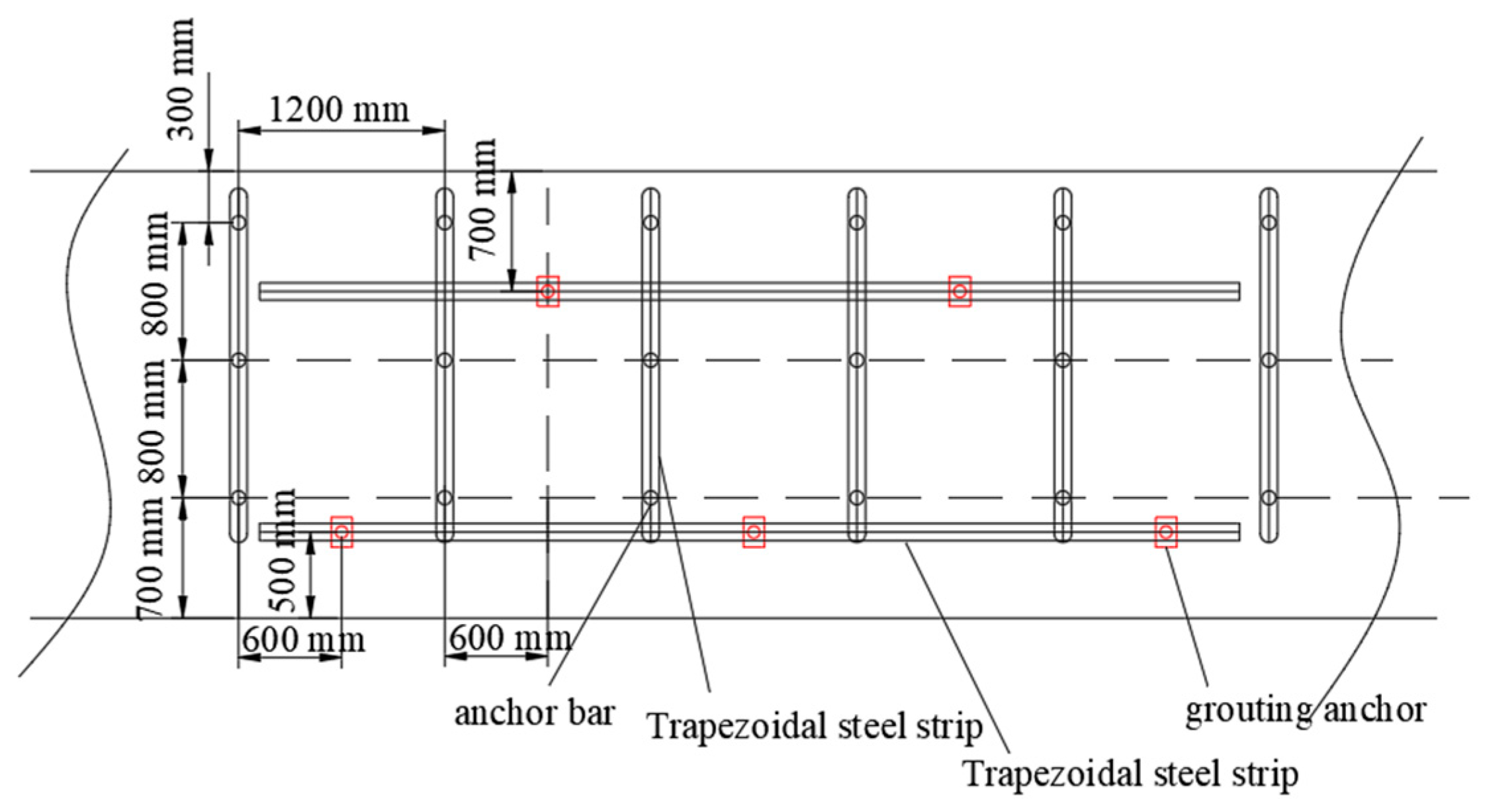

5.3. Grouting Anchor Cable Support Technology

5.3.1. Supporting Principle of Grouting Anchor Cable

5.3.2. Layout Scheme and Main Technical Parameters of Grouting Anchor Cable

6. Analysis of Monitoring Results of Surrounding Rock Control in Reserved Roadway

6.1. Analysis of Monitoring Results of Lateral Support Pressure of Coal Pillar

6.2. Analysis of Surface Displacement Monitoring Results of Reserved Roadway

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; He, M.; Wang, Y.; Liu, J.; Xue, H. Research progress and prospect of automatically formed roadway by roof cutting and pressure relief without pillars. J. Min. Saf. Eng. 2023, 40, 429–447. [Google Scholar]

- Wang, Z.; Cai, X.; Liu, Z. Survival and Revival: Transition Path of the Chinese Construction Industry during the COVID-19 Pandemic. Eng. Manag. J. 2022, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Liu, J. Innovation strategy or policy pressure? The motivations of BIM adoption in China’s AEC enterprises. J. Asian Arch. Build. Eng. 2021, 21, 1578–1589. [Google Scholar] [CrossRef]

- Wan, F. Application research on roof-cutting pressure relief blasting technology in gob-side entry retaining. China Energy Environ. Prot. 2018, 40, 4. [Google Scholar]

- Ma, J.; Chen, J.; Chen, W.; Huang, L. A coupled thermal-elastic-plastic-damage model for concrete subjected to dynamic loading. Int. J. Plast. 2022, 153, 103279. [Google Scholar] [CrossRef]

- Ma, J.; Ding, W.; Lin, Y.; Chen, W.; Huang, L. A fast and efficient particle packing generation algorithm with controllable gradation for discontinuous deformation analysis. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 1–27. [Google Scholar] [CrossRef]

- Ma, J.; Zhao, J.; Lin, Y.; Liang, J.; Chen, J.; Chen, W.; Huang, L. Study on Tamped Spherical Detonation-Induced Dynamic Responses of Rock and PMMA Through Mini-chemical Explosion Tests and a Four-Dimensional Lattice Spring Model. Rock Mech. Rock Eng. 2023. [Google Scholar] [CrossRef]

- He, M.; Wang, Y.; Yang, J.; Zhou, P.; Gao, Q.; Gao, Y. Comparative analysis on stress field distributions in roof cutting nonpillar mining method and conventional mining method. J. China Coal Soc. 2018, 43, 626–637. [Google Scholar]

- He, M.; Chen, S.; Guo, Z.; Yang, J.; Gao, Y. Control of surrounding rock structure for gob-side entry retaining by cutting roof to release pressure and its engineering application. J. China Univ. Min. Technol. 2017, 46, 959–969. [Google Scholar]

- Ma, X.; He, M.; Li, X.; Wang, E.; Hu, C.; Gao, R. Deformation mechanism and control measures of overlying strata with gob-side entry retaining formed by roof cutting and pressure releasing. J. China Univ. Min. Technol. 2019, 48, 474–483. [Google Scholar]

- He, M.; Song, Z.; Wang, A.; Yang, H.; Qi, H.; Guo, Z. Theory of longwall mining by using roof cuting shortwall team and 110 method—The third mining science and technology reform. Coal Sci. Technol. Mag. 2017, 1, 1–9. [Google Scholar]

- He, M.; Ma, X.; Yu, B. Analysis of strata behavior process characteristics of gob-side entry retaining with roof cutting and pressure releasing based on composite roof structure. Shock. Vib. 2019, 2019, 2380342. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, Y.; Chen, T.; Ruan, X.; Wang, G. Study on breaking law of hard thick layer roof and surrounding rock control. Coal Technol. 2023, 42, 25–29. [Google Scholar]

- Chen, L.; Wang, X.; Huo, Y.; Ning, F.; Shi, J.; Di, X. Key parameters of retaining narrow coal pillar for roadway protection with deep hole roof cutting and pressure relief in hard roof. Coal Eng. 2023, 55, 13–19. [Google Scholar]

- Wang, W.; Wu, Y.; Lu, X.; Zhang, G. Study on small coal pillar in gob-side entry driving and control technology of the surrounding rock in a high-stress roadway. Front. Earth Sci. 2023, 10, 1020866. [Google Scholar] [CrossRef]

- Zhu, L.; Yao, Q.; Xu, Q.; Yu, L.; Qu, Q. Large Deformation Characteristics of Surrounding Rock and Support Technology of Shallow-Buried Soft Rock Roadway: A Case Study. Appl. Sci. 2022, 12, 687. [Google Scholar] [CrossRef]

- Qin, D.; Wang, X.; Zhang, D.; Chen, X. Study on surrounding rock-bearing structure and associated control mechanism of deep soft rock roadway under dynamic pressure. Sustainability 2019, 11, 1892. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, N.; Han, C.; Sun, C.; Song, G.; Sun, Y.; Sun, K. Stability control of deep coal roadway under the pressure relief Effect of adjacent roadway with large deformation: A case study. Sustainability 2021, 13, 4412. [Google Scholar] [CrossRef]

- Wang, F.; Wu, C.; Yao, Q.; Li, X.; Chen, S.; Li, Y.; Li, H.; Zhu, G. Instability mechanism and control method of surrounding rock of water-rich roadway roof. Minerals 2022, 12, 1587. [Google Scholar] [CrossRef]

- Xie, S.; Li, H.; Chen, D.; Feng, S.; Ma, X.; Jiang, Z.; Cui, J. New technology of pressure relief control in soft coal roadways with deep, violent mining and large deformation: A key study. Energies 2022, 15, 9208. [Google Scholar] [CrossRef]

- Xu, D.; Gao, M.; Yu, X. Dynamic Response Characteristics of Roadway Surrounding Rock and the Support System and Rock Burst Prevention Technology for Coal Mines. Energies 2022, 15, 8662. [Google Scholar] [CrossRef]

- Majcherczyk, T.; Niedbalski, Z.; Małkowski, P.; Bednarek, Ł. Analysis of Yielding Steel Arch Support with Rock Bolts in Mine Roadways Stability Aspect. Arch. Min. Sci. 2014, 59, 641–654. [Google Scholar] [CrossRef]

- Tu, H.; Tu, S.; Zhang, C.; Zhang, L.; Zhang, X. Characteristics of the Roof Behaviors and Mine Pressure Manifestations During the Mining of Steep Coal Seam. Arch. Min. Sci. 2017, 62, 871–891. [Google Scholar]

- Guo, S.; Zhu, X.; Liu, X.; Duan, H. A Case Study of Optimization and Application of Soft-Rock Roadway Support in Xiaokang Coal Mine. Adv. Civ. Eng. 2021, 2021, 3731124. [Google Scholar] [CrossRef]

- Shavarskyi, I.; Falshtynskyi, V.; Dychkovskyi, R.; Akimov, O.; Sala, D.; Buketov, V. Management of the longwall face advance on the stress-strain state of rock mass. Min. Miner. Depos. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- He, M.; Leal e Sousa, R.; Müller, A.; Vargas, E.; Ribeiro e Sousa, L.; Chen, X. Analysis of excessive deformations in tunnels for safety evaluation. Tunn. Undergr. Space Technol. 2015, 45, 190–202. [Google Scholar]

- Wang, S.; Wang, J.; Dai, Y. Numerical analysis on movement and failure of coal and strees condition of support structures in mechanized top-coal caving in steep thick seam. Chin. J. Rock Mech. Eng. 2004, 23, 4531–4534. [Google Scholar]

- Hashikawa, H.; Mao, P.; Sasaoka, T.; Hamanaka, A.; Shimada, H.; Batsaikhan, U.; Oya, J. Numerical simulation on pillar design for longwall mining under weak immediate roof and floor strata in indonesia. Sustainability 2022, 14, 16508. [Google Scholar] [CrossRef]

- Yue, X.; Tu, M.; Li, Y.; Chang, G.; Li, C. Stability and Cementation of the Surrounding Rock in Roof-Cutting and Pressure-Relief Entry under Mining Influence. Energies 2022, 15, 951. [Google Scholar] [CrossRef]

- Mondal, D.; Roy, P.N.S.; Kumar, M. Monitoring the strata behavior in the Destressed Zone of a shallow Indian longwall panel with hard sandstone cover using Mine-Microseismicity and Borehole Televiewer data. Eng. Geol. 2020, 271, 105593. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.; Zhang, X.; Song, Q. Overlying strata movement rules and safety mining technology for the shallow depth seam proximity beneath a room mining goaf. Int. J. Min. Sci. Technol. 2015, 25, 139–143. [Google Scholar] [CrossRef]

- Ou, X.-F.; Ouyang, L.-X.; Xu, X.-X.; Wang, L. Case study on floor heave failure of highway tunnels in gently inclined coal seam. Eng. Fail. Anal. 2022, 136, 106224. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Yan, Y.; Pang, J.; Zhao, S. Floor heave in the west wing track haulage roadway of the Tingnan Coal Mine: Mechanism and control. Int. J. Min. Sci. Technol. 2012, 22, 295–299. [Google Scholar] [CrossRef]

- He, W.; He, F.; Zhao, Y. Field and simulation study of the rational coal pillar width in extra-thick coal seams. Energy Sci. Eng. 2019, 8, 627–646. [Google Scholar] [CrossRef]

- Liu, Q.; Xue, Y.; Ma, D.; Li, Q. Failure Characteristics of the Water-Resisting Coal Pillar under Stress-Seepage Coupling and Determination of Reasonable Coal Pillar Width. Water 2023, 15, 1002. [Google Scholar] [CrossRef]

- Shuang-Chun, J.; Jia-chen, W.; Jian-ming, Z. Calculation and Application on Elastic-Plastic Coal Pillar Width of the Stope. Procedia Eng. 2011, 26, 1116–1124. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, H.; Jiang, B.; Li, S.; He, M.; Wang, D.; Lu, W.; Qin, Q.; Gao, S.; Yu, H. Research on reasonable coal pillar width of roadway driven along goaf in deep mine. Arab. J. Geosci. 2017, 10, 466. [Google Scholar] [CrossRef]

| Name of Rock Mass (GPa) | Bulk Modulus (Gpa) | Shear Modulus (MPa) | Tensile Strength (MPa) | Cohesion (MPa) | Angle of Internal Friction (°) | Density (Kg/m3) |

|---|---|---|---|---|---|---|

| limestone | 24.32 | 12.50 | 1.82 | 4.23 | 38 | 2760 |

| 15# coal seam | 4.41 | 2.23 | 0.56 | 0.82 | 23 | 1540 |

| fine sandstone | 13.16 | 4.92 | 1.61 | 4.12 | 36 | 2628 |

| grit stone | 10.17 | 3.26 | 1.60 | 4.05 | 36 | 2672 |

| mudstone | 5.52 | 2.54 | 1.05 | 2.03 | 26 | 2570 |

| sandy mudstone | 6.87 | 2.93 | 3.35 | 1.18 | 28 | 2707 |

| Hole Length (m) | Angle of Elevation (°) | Horizontal Angle (°) | Aperture (mm) | Charge Length (m) | Powder Charge (Kg) | Sealing Length (m) |

|---|---|---|---|---|---|---|

| 15 | 45 | 0 | 75 | 5 | 15 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, Y.; Li, M.; Wang, W.; Zhang, Z.; Li, Z. Study on the Stress Distribution and Stability Control of Surrounding Rock of Reserved Roadway with Hard Roof. Sustainability 2023, 15, 14111. https://doi.org/10.3390/su151914111

Hao Y, Li M, Wang W, Zhang Z, Li Z. Study on the Stress Distribution and Stability Control of Surrounding Rock of Reserved Roadway with Hard Roof. Sustainability. 2023; 15(19):14111. https://doi.org/10.3390/su151914111

Chicago/Turabian StyleHao, Yuxi, Mingliang Li, Wen Wang, Zhizeng Zhang, and Zhun Li. 2023. "Study on the Stress Distribution and Stability Control of Surrounding Rock of Reserved Roadway with Hard Roof" Sustainability 15, no. 19: 14111. https://doi.org/10.3390/su151914111