Modeling the Dynamic Behavior of Recycled Concrete Aggregate-Virgin Aggregates Blend Using Artificial Neural Network

Abstract

:1. Introduction

2. Materials and Method

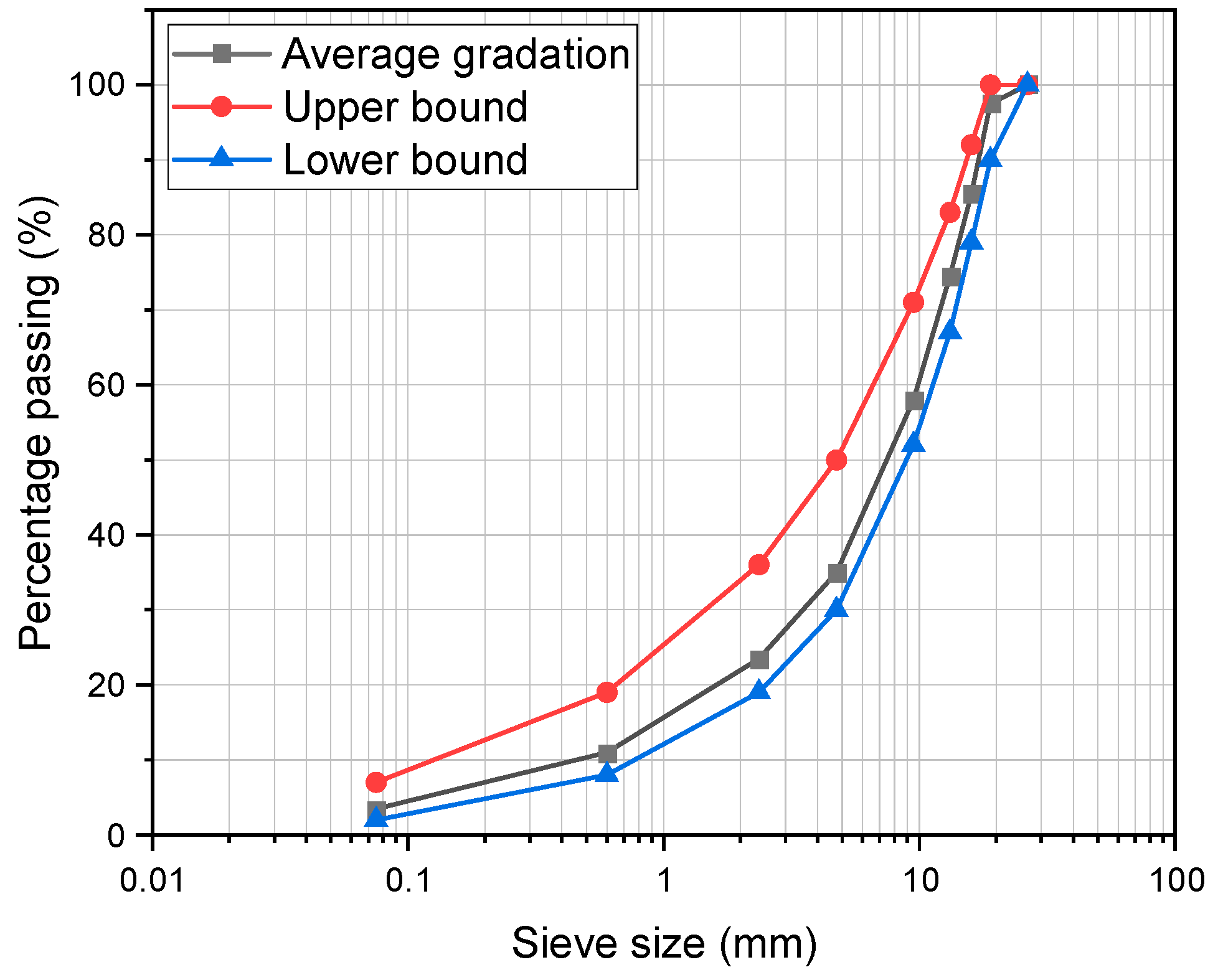

2.1. Tested Materials

2.2. Repeated Load Triaxial Test

3. Laboratory Testing Results

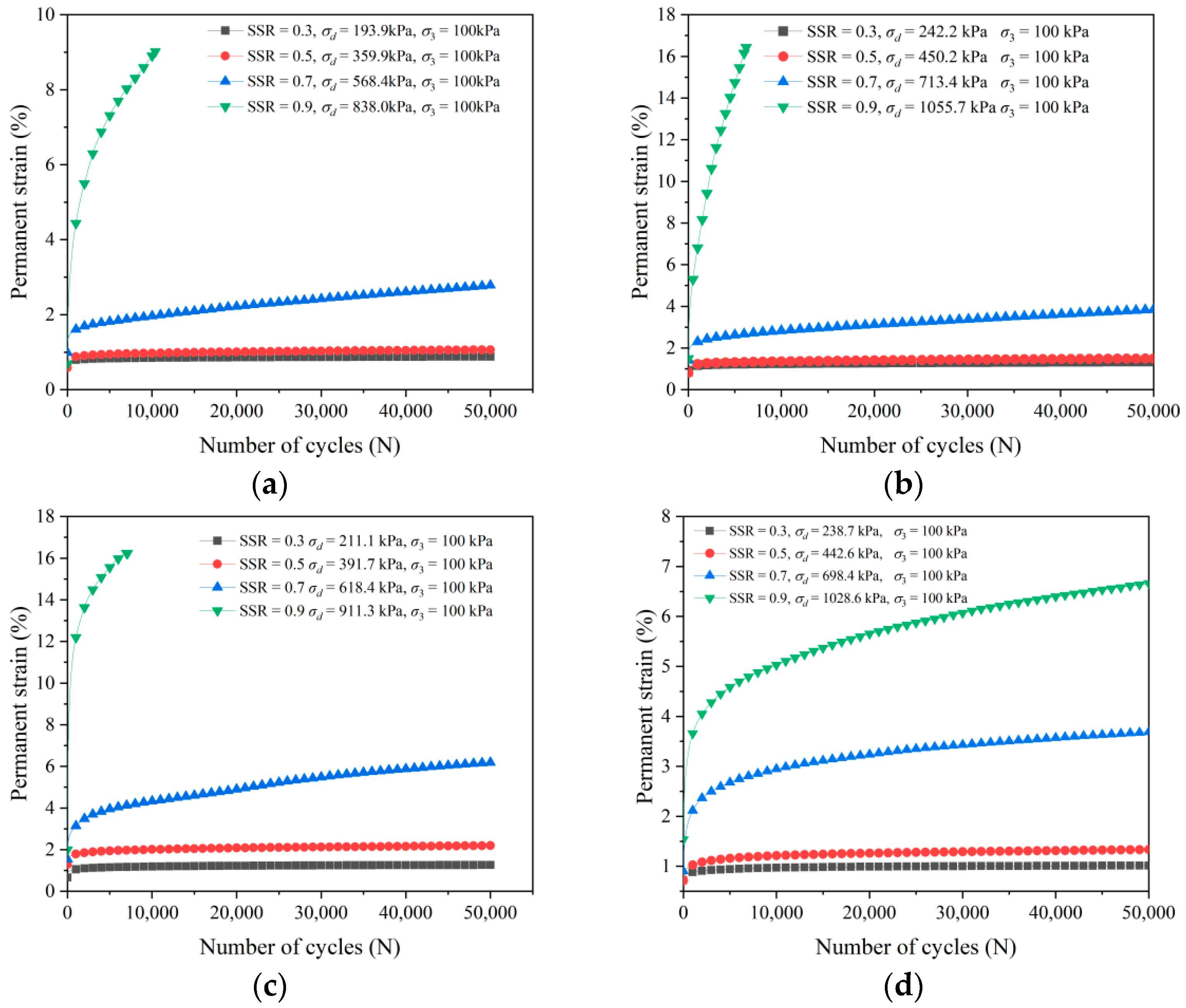

3.1. Effect of Shear Stress Ratio

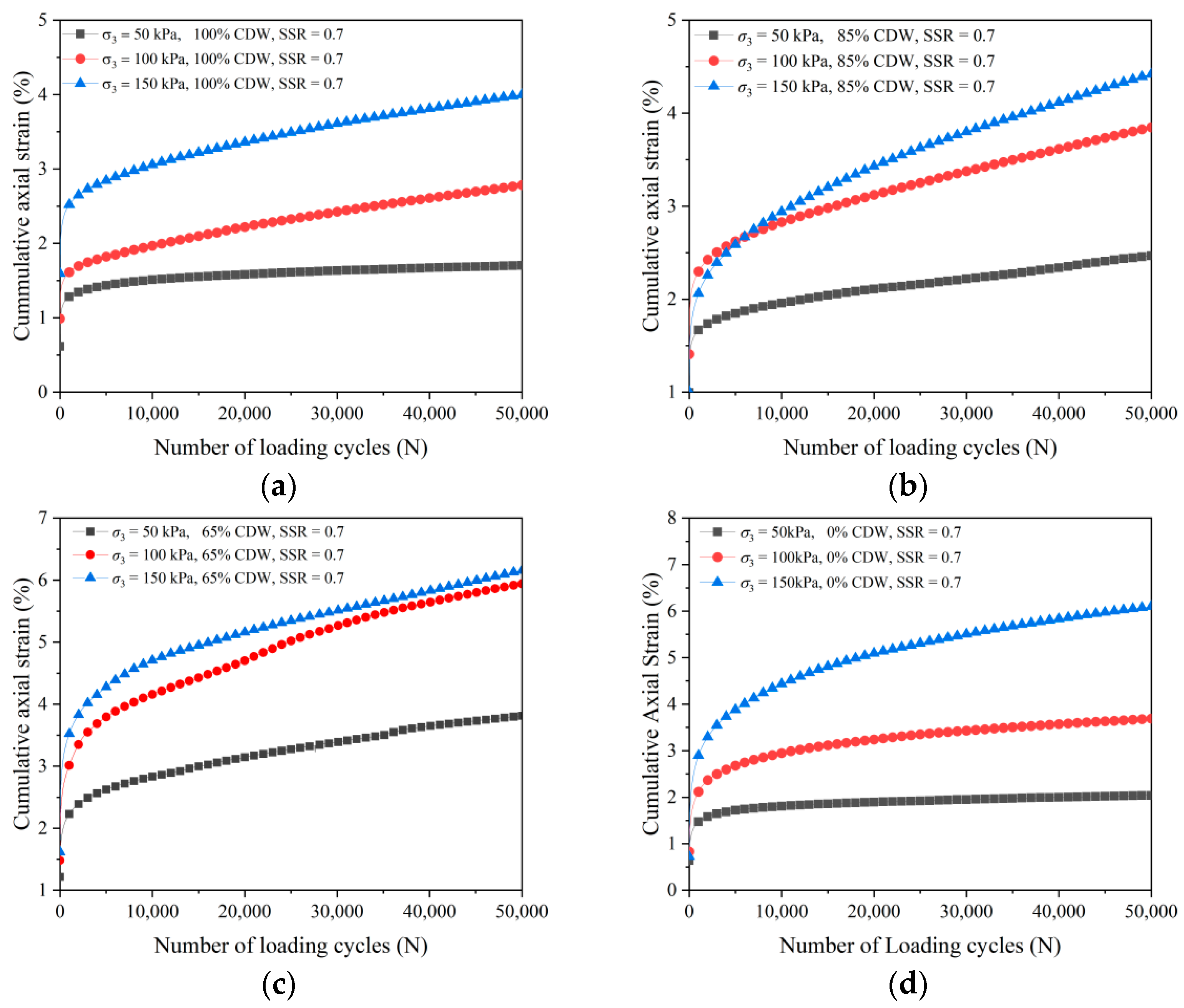

3.2. Effect of Confining Pressure

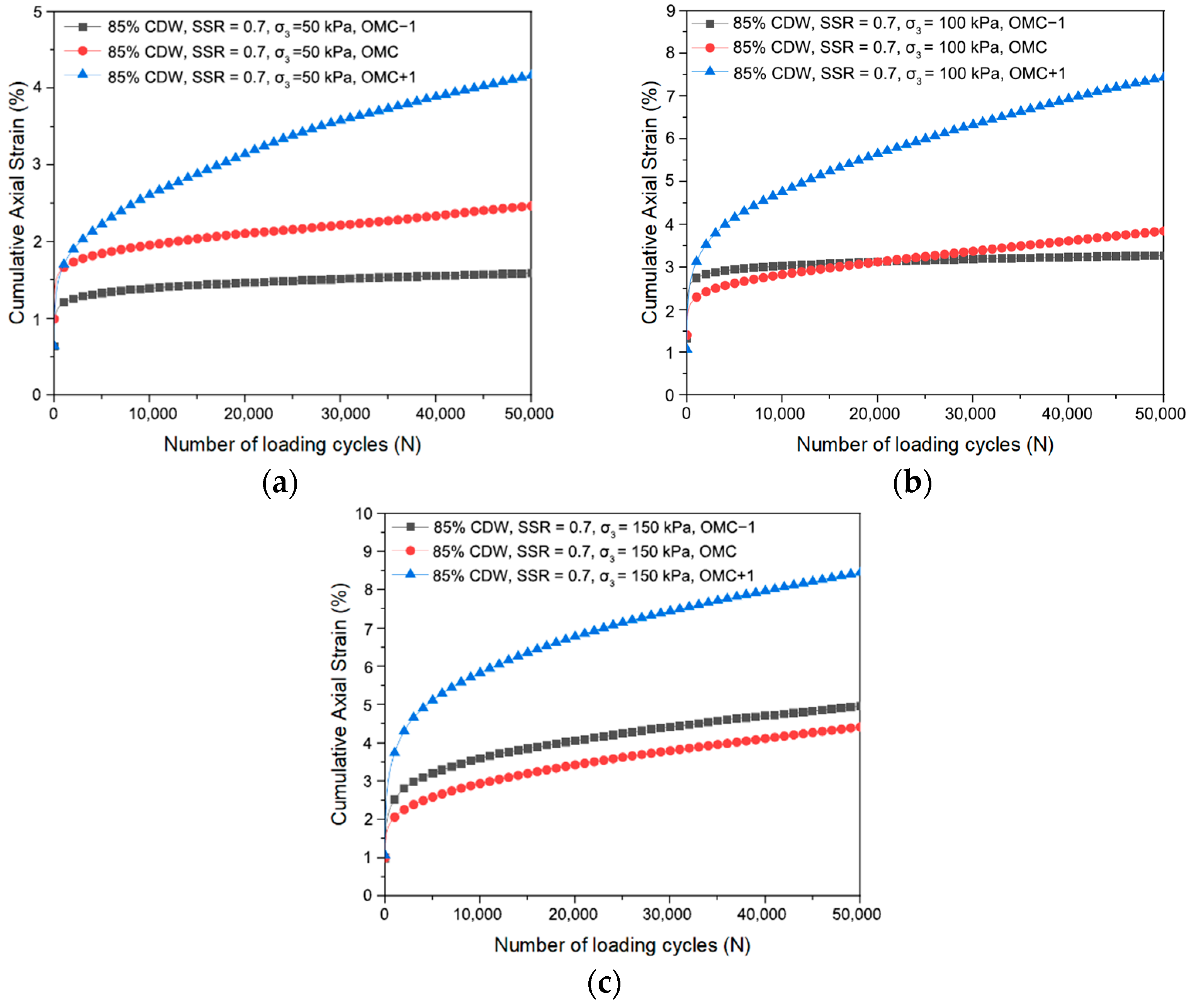

3.3. Effect of Moisture Content Variation

4. ANN Model Development

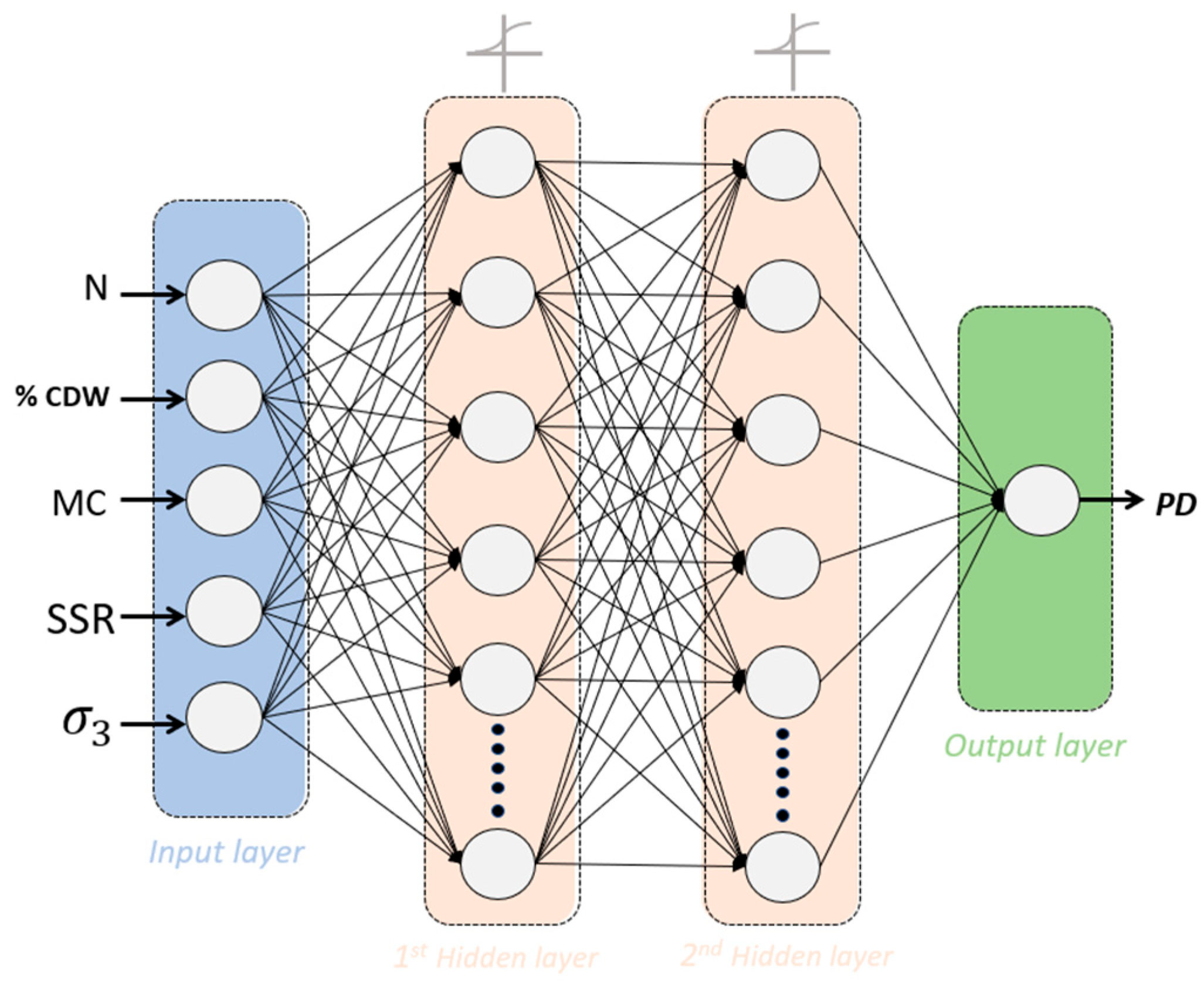

4.1. ANN Model Architecture

4.2. Data Preprocessing

4.3. ANN Learning Algorithm

4.4. Transfer Function

4.5. Stopping Criteria

4.6. ANN Model Performance Criteria

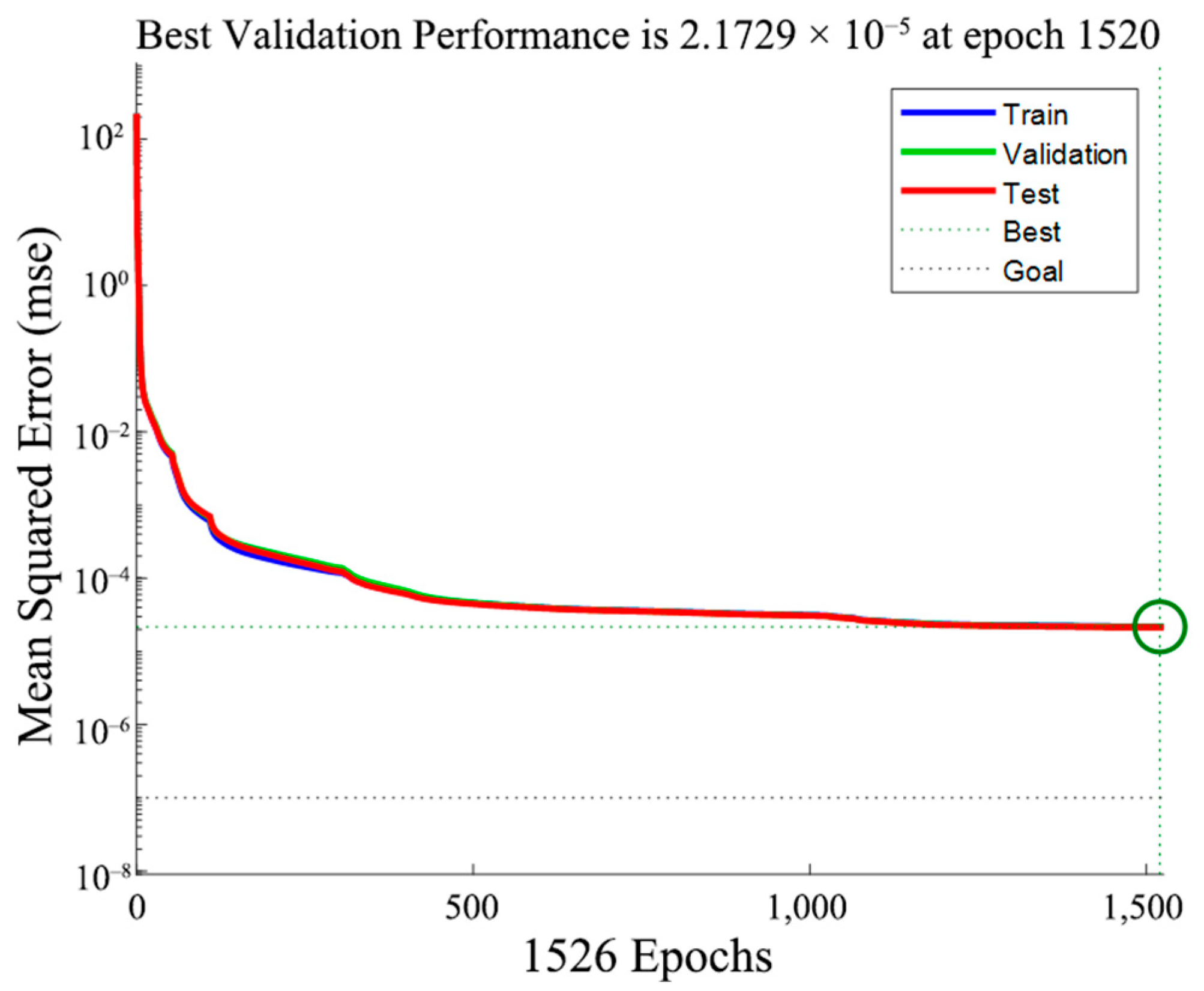

4.7. Optimum ANN Model Architecture

5. Result and Discussion

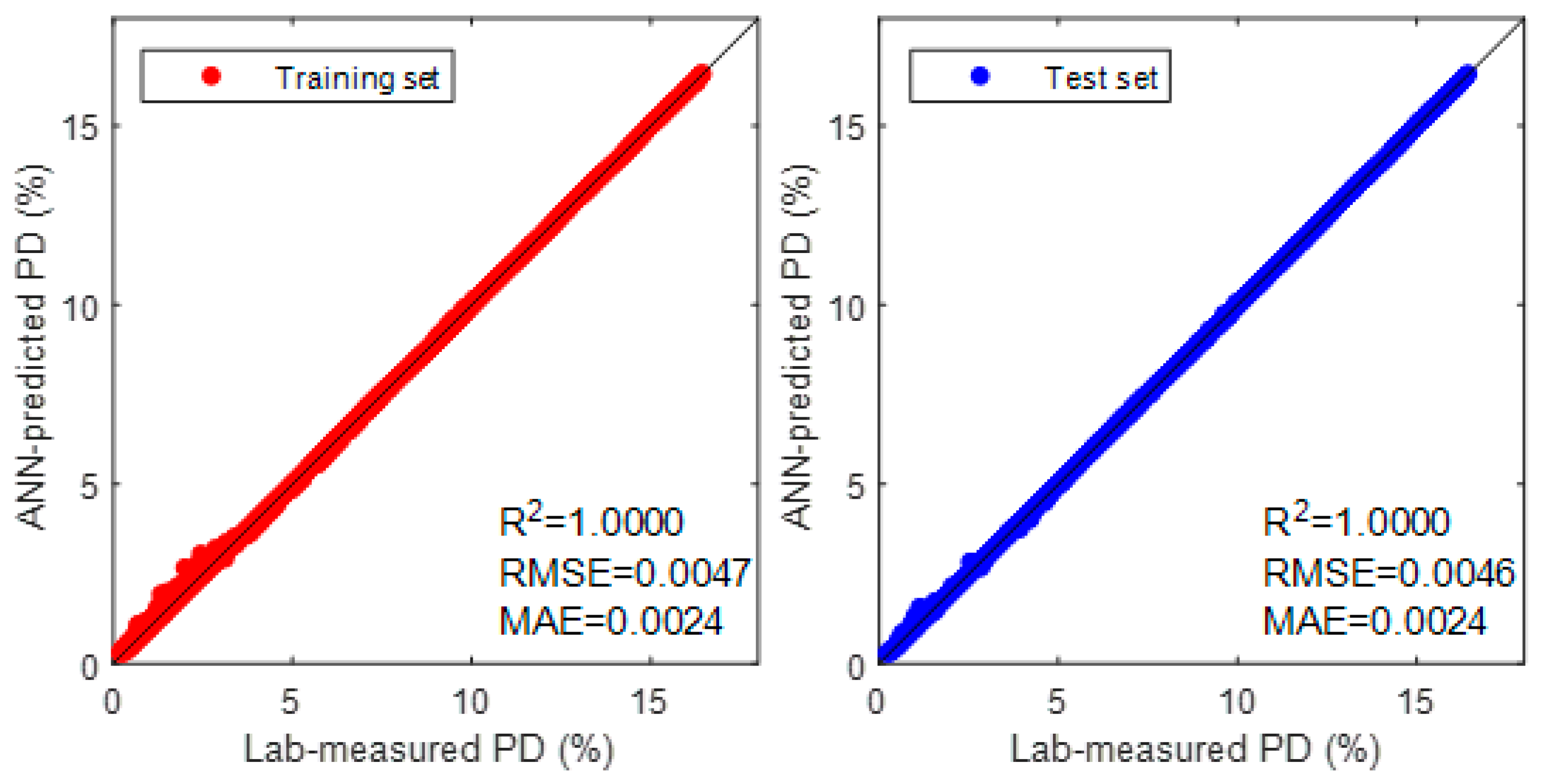

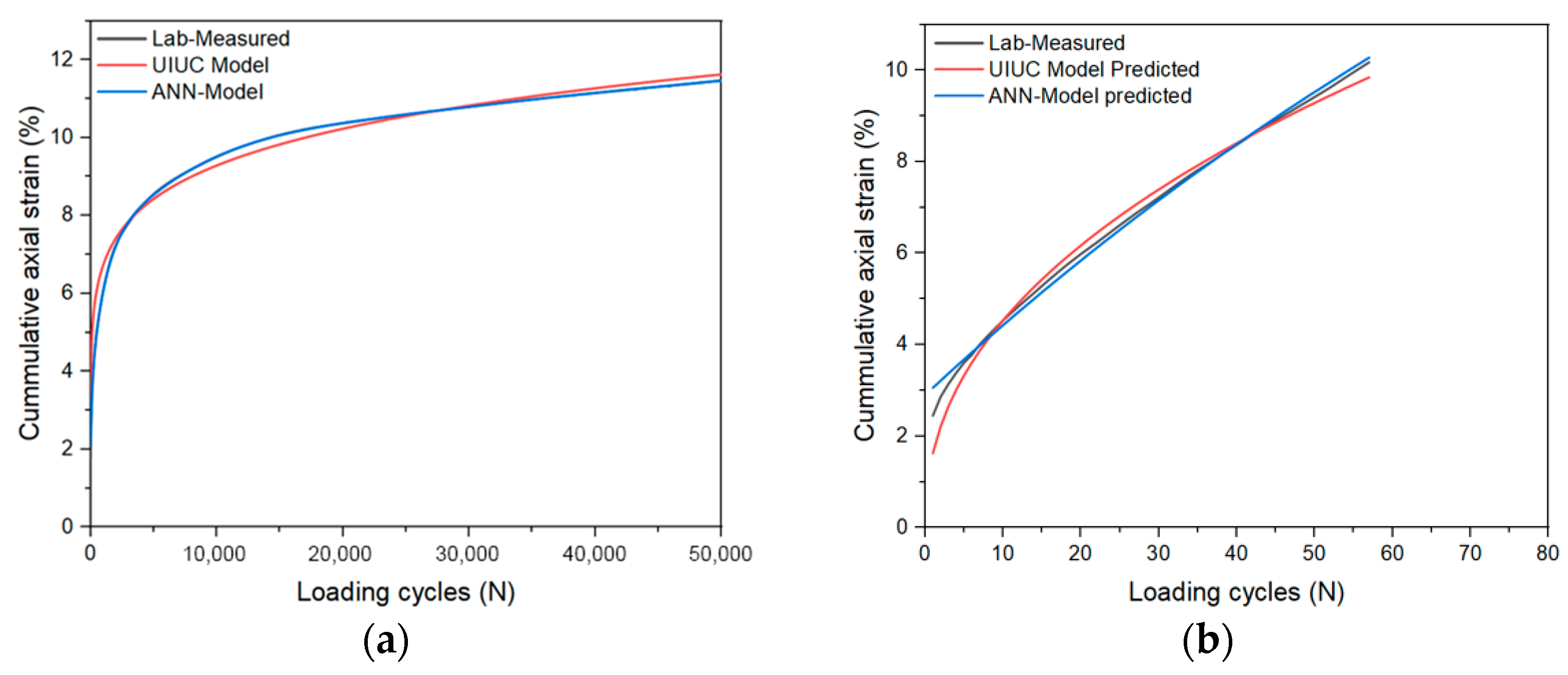

5.1. ANN Model Performance

5.2. Comparison between the ANN Model and a Multiple Regression Model

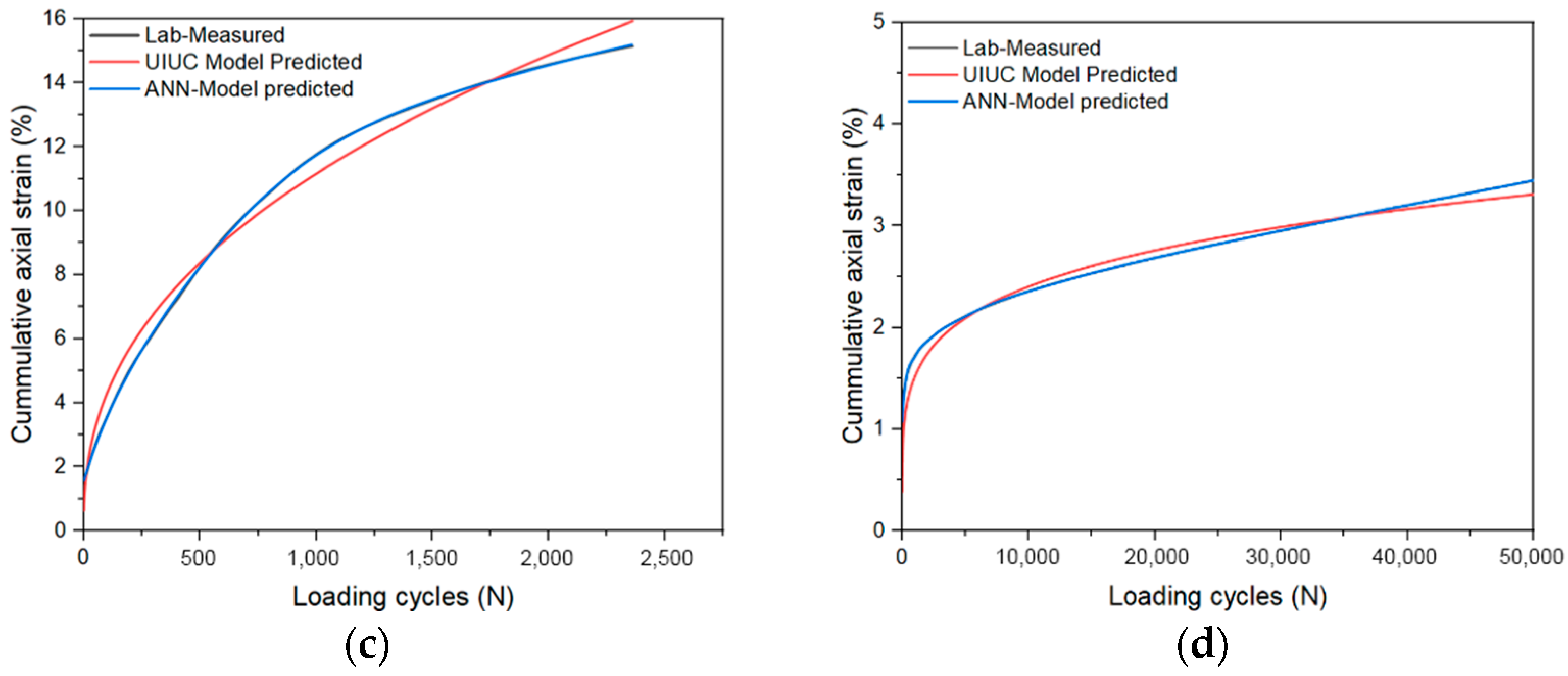

6. Sensitivity Analysis

Garson Algorithm

7. Conclusions

- The repeated load triaxial tests indicated that the newly developed matrix of blended aggregates could serve adequately as base or subbase materials under traffic loading. The SSR and deviator stress significantly influence the deformation behavior of the CDW materials. The effects of deviator stress, confining pressure, and moisture content are more noticeable at a high SSR (e.g., SSR = 0.7) compared to a lower SSR (e.g., SSR = 0.5). The blended materials showed sensitivity to moisture variation, with moisture content above the optimum producing considerable permanent strain.

- The ANN model was proposed to predict the permanent deformation of blended CDW and VA. Due to the material’s complexity and the dataset’s enormous size, the optimum neural network determined in this study was a four-layered network with two hidden layers. The complexity associated with the CDW was fully incorporated into the model. The ANN model demonstrated a high degree of accuracy, with an average coefficient of determination of 0.99.

- The performance criteria of the developed ANN model indicate its capability to predict the permanent deformation of the blended proportions with high precision and accuracy. Additional performance criteria were utilized to determine the model’s applicability to predict its performance when applied to an external dataset. The results confirmed the model’s adequacy in predicting the permanent deformation of external data.

- The comparison between the ANN-based and regression-based models revealed that the ANN model outperforms conventional regression-based models. The ANN model, accommodating various combinations of input parameters at any given loading application, can predict the accumulative permanent strain more efficiently than the regression model, with improved computation time. Most regression-based models rely on specified equations that involve tedious linear and nonlinear calculations.

- The ANN model surpasses the regression-based model by determining each input parameter’s contribution through network weights via sensitivity analysis. The result indicated that all the selected input parameters influence the accuracy of the permanent deformation model.

- Sensitivity analysis revealed that all input parameters are essential for predicting permanent deformation. Testing parameters such as the number of loading cycles, confining pressure, and SSR significantly control the permanent deformation behavior of the materials. With a total sensitivity coefficient close to 80%, the loading condition greatly affects the permanent deformation behavior of the blended CDW. The content of construction and demolition waste and moisture content also play roles in determining the material’s response.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.P. Recycling and reuse of waste concrete in China Part I. Material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Zheng, L.N.; Wu, H.Y.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Lee, J.C.; Edil, T.B.; Tinjum, J.M.; Benson, C.H. Quantitative assessment of environmental and economic benefits of recycled materials in highway construction. Transp. Res. Rec. 2010, 2158, 138–142. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z.P. The mechanical properties of asphalt mixtures with Recycled Concrete Aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ali, M.M.Y.; Piratheepan, J.; Bo, M.W. Geotechnical Properties of Waste Excavation Rock in Pavement Subbase Applications. J. Mater. Civ. Eng. 2012, 24, 924–932. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M. Reclaimed asphalt pavement and recycled concrete aggregate blends in pavement subbases: Laboratory and field evaluation. J. Mater. Civ. Eng. 2014, 26, 349–357. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Behiry, A.E.A.E.-M. Utilization of cement treated recycled concrete aggregates as base or subbase layer in Egypt. Ain Shams Eng. J. 2013, 4, 661–673. [Google Scholar] [CrossRef]

- Gabr, A.R.; Cameron, D.A. Permanent Strain Modeling of Recycled Concrete Aggregate for Unbound Pavement Construction. J. Mater. Civ. Eng. 2013, 25, 1394–1402. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Ayuso, J.; Agrela, F.; López, M.; Galvín, A.P. Utilisation of unbound recycled aggregates from selected CDW in unpaved rural roads. Resour. Conserv. Recycl. 2012, 58, 88–97. [Google Scholar] [CrossRef]

- Lim, S.; Zollinger, D.G. Estimation of the Compressive Strength and Modulus of Elasticity of Cement-Treated Aggregate Base Materials. In Proceedings of the 82nd Annual Meeting of the Transportation-Research-Board, Washington, DC, USA, 12–16 January 2003. [Google Scholar] [CrossRef]

- Melbouci, B. Compaction and shearing behaviour study of recycled aggregates. Constr. Build. Mater. 2009, 23, 2723–2730. [Google Scholar] [CrossRef]

- Vegas, I.; Ibañez, J.A.; Lisbona, A.; De Cortazar, A.S.; Frías, M. Pre-normative research on the use of mixed recycled aggregates in unbound road sections. Constr. Build. Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and Geoenvironmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Azam, A.M.; Cameron, D.A. Geotechnical Properties of Blends of Recycled Clay Masonry and Recycled Concrete Aggregates in Unbound Pavement Construction. J. Mater. Civ. Eng. 2013, 25, 788–798. [Google Scholar] [CrossRef]

- Jayakody, S.; Gallage, C.; Ramanujam, J. Effects of reclaimed asphalt materials on geotechnical characteristics of recycled concrete aggregates as a pavement material. Road Mater. Pavement Des. 2019, 20, 754–772. [Google Scholar] [CrossRef]

- Li, X.P. Recycling and reuse of waste concrete in China. Resour. Conserv. Recycl. 2009, 53, 107–112. [Google Scholar] [CrossRef]

- Silva, R.V.; Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Gomez-Meijide, B.; Pérez, I. Nonlinear elastic behavior of bitumen emulsion-stabilized materials with C&D waste aggregates. Constr. Build. Mater. 2015, 98, 853–863. [Google Scholar] [CrossRef]

- Cerni, G.; Cardone, F.; Virgili, A.; Camilli, S. Characterisation of permanent deformation behaviour of unbound granular materials under repeated triaxial loading. Constr. Build. Mater. 2012, 8, 79–87. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Bo, M.W. Dynamic characterization of recycled glass-recycled concrete blends using experimental analysis and artificial neural network modeling. Soil Dyn. Earthq. Eng. 2021, 142, 106544. [Google Scholar] [CrossRef]

- Li, Y.; Nie, R.; Yue, Z.; Leng, W.; Guo, Y. Dynamic behaviors of fine-grained subgrade soil under single-stage and multi-stage intermittent cyclic loading: Permanent deformation and its prediction model. Soil Dyn. Earthq. Eng. 2021, 142, 106548. [Google Scholar] [CrossRef]

- Nie, R.; Mei, H.; Leng, W.; Ruan, B.; Li, Y.; Chen, X. Characterization of permanent deformation of fine-grained subgrade soil under intermittent loading. Soil Dynam. Earthq. Eng. 2020, 139, 106395. [Google Scholar] [CrossRef]

- Orosa, P.; Medina, L.; Fernández-Ruiz, J.; Pérez, I.; Pasandín, A.R. Numerical simulation of the stiffness evolution with curing of pavement sections rehabilitated using cold in-place recycling technology. Constr. Build. Mater. 2022, 335, 127487. [Google Scholar] [CrossRef]

- Sakhare, A.; Farooq, H.; Nimbalkar, S.; Dodagoudar, G.R. Dynamic Behavior of the Transition Zone of an Integral Abutment Bridge. Sustainability 2022, 14, 4118. [Google Scholar] [CrossRef]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Neural Network ToolboxTM User’s Guide; The MathWorks, Inc.: Natick, MA, USA, 2017. [Google Scholar]

- Pazuki, G.R.; Nikookar, M.; Dehnavi, M.; Al-Anazi, B. The Prediction of Permeability Using an Artificial Neural Network System. Pet. Sci. Technol. 2012, 30, 2108–2113. [Google Scholar] [CrossRef]

- Williams, C.G.; Ojuri, O.O. Predictive modelling of soils’ hydraulic conductivity using artificial neural network and multiple linear regression. SN Appl. Sci. 2021, 3, 152. [Google Scholar] [CrossRef]

- Taha, O.M.E.; Majeed, Z.H.; Ahmed, S.M. Artificial Neural Network Prediction Models for Maximum Dry Density and Optimum Moisture Content of Stabilized Soils. Transp. Infrastruct. Geotechnol. 2018, 5, 146–168. [Google Scholar] [CrossRef]

- Bahmed, I.T.; Harichane, K.; Ghrici, M.; Boukhatem, B.; Rebouh, R.; Gadouri, H. Prediction of geotechnical properties of clayey soils stabilized with lime using artificial neural networks (ANNs). Int. J. Geotech. Eng. 2019, 13, 191–203. [Google Scholar] [CrossRef]

- Sinha, S.K.; Wang, M.C. Artificial Neural Network Prediction Models for Soil Compaction and Permeability. Geotech. Geol. Eng. 2008, 26, 47–64. [Google Scholar] [CrossRef]

- Sivrikaya, O. Comparison of Artificial Neural Networks models with correlative works on undrained shear strength. Eurasian Soil Sci. 2009, 42, 1487–1496. [Google Scholar] [CrossRef]

- Mollahasani, A.; Alavi, A.H.; Gandomi, A.H.; Rashed, A. Nonlinear neural-based modeling of soil cohesion intercept. KSCE J. Civ. Eng. 2011, 15, 831–840. [Google Scholar] [CrossRef]

- Kim, S.-H.; Yang, J.; Beadles, S. Estimate of Resilient Modulus of Graded Aggregate Base in Flexible Pavement. In Proceedings of the T&DI Congress 2014, Planes, Trains, and Automobiles, Orlando, FL, USA, 8–11 June 2014; pp. 24–38. [Google Scholar] [CrossRef]

- Farh, N.K.; Awed, A.M.; El-Badawy, S.M. Artificial Neural Network Model for Predicating Resilient Modulus of Silty Subgrade Soil. Am. J. Civ. Eng. Archit. 2020, 8, 52–55. [Google Scholar]

- Kim, S.-H.; Yang, J.; Jeong, J.-H. Prediction of subgrade resilient modulus using artificial neural network. KSCE J. Civ. Eng. 2014, 18, 1372–1379. [Google Scholar] [CrossRef]

- Park, H.I.; Kweon, G.C.; Lee, S.R. Prediction of Resilient Modulus of Granular Subgrade Soils and Subbase Materials using Artificial Neural Network. Road Mater. Pavement Des. 2009, 10, 647–665. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Tatari, O. Evaluating the use of neural networks and genetic algorithms for prediction of subgrade resilient modulus. Int. J. Pavement Eng. 2013, 14, 364–373. [Google Scholar] [CrossRef]

- Ullah, S.; Tanyu, B.F.; Zainab, B. Development of an artificial neural network (ANN)-based model to predict permanent deformation of base course containing reclaimed asphalt pavement (RAP). Road Mater. Pavement Des. 2021, 22, 2552–2570. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S. Experimental and ANN analysis of temperature effects on the permanent deformation properties of demolition wastes. Transp. Geotech. 2020, 24, 100365. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Bo, M.W. Shakedown analysis of PET blends with demolition waste as pavement base/subbase materials using experimental and neural network methods. Transp. Geotech. 2021, 27, 100481. [Google Scholar] [CrossRef]

- JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- Kim, I.T. Permanent Deformation Behavior of Airport Flexible Pavement Base and Subbase Courses. Ph.D. Thesis, University of Illinois at Urbana, Champaign, IL, USA, 2005. [Google Scholar]

- Hua, W.J.; Yu, Q.D.; Xiao, Y.J.; Li, W.; Wang, M.; Chen, Y.; Li, Z. Development of Artificial-Neural-Network-Based Permanent Deformation Prediction Model of Unbound Granular Materials Subjected to Moving Wheel Loading. Materials 2022, 15, 7303. [Google Scholar] [CrossRef]

- Chow, L.C. Permanent Deformation Behavior of Unbound Granular Materials and Rutting Model Development. Master’s Thesis, University of Illinois at Urbana, Champaign, IL, USA, 2014. [Google Scholar]

- Ren, J.L.; Li, D.; Wang, S. Combined Effect of Compaction Methods and Loading Conditions on the Deformation Behaviour of Unbound Granular Material. Adv. Civ. Eng. 2020, 2020, 2419102. [Google Scholar] [CrossRef]

- Shahin, M.A.; Jaksa, M.B.; Maier, H.R. State of the Art of Artificial Neural Networks in Geotechnical Engineering. Electron. J. Geotech. Eng. 2008, 8, 1–26. [Google Scholar]

- Wang, H.; Xie, P.; Ji, R.; Gagnon, J. Prediction of airfield pavement responses from surface deflections: Comparison between the traditional backcalculation approach and the ANN model. Road Mater. Pavement Des. 2021, 22, 1930–1945. [Google Scholar] [CrossRef]

- Rahimi, M. An Artificial Neural Network Approach to Model and Predict Asphalt Deflections As a Complement to Experimental Measurements by Falling Weight Deflectometer. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2020. [Google Scholar] [CrossRef]

- Kurt, H.; Maxwell, S.; Halbert, W. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar]

- Hornik, K. Some new results on neural network approximation. Neural Netw. 1993, 6, 1069–1072. [Google Scholar] [CrossRef]

- Ashtiani, R.S.; Little, D.N.; Rashidi, M. Neural network based model for estimation of the level of anisotropy of unbound aggregate systems. Transp. Geotech. 2018, 15, 4–12. [Google Scholar] [CrossRef]

- Khademi, F.; Akbari, M.; Jamal, S.M. Prediction of compressive strength of concrete by data-driven models. Manag. J Civ. Eng. 2015, 5, 16–23. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Liu, J.; Zhao, X. Using artificial neural networks to predict the dynamic modulus of asphalt mixtures containing recycled asphalt shingles. J. Mater. Civ. Eng. 2018, 30, 04018051. [Google Scholar] [CrossRef]

- Nawari, N.O.; Liang, R.; Nusairat, J. Artificial intelligence techniques for the design and analysis of deep foundations. Electron. J. Geotech. Eng. 1999, 4, 1–21. [Google Scholar]

- Frank, I.E.; Todeschini, R. The data analysis handbook. Data Sci. Technol. 1994, 14, 1–352. [Google Scholar] [CrossRef]

- Das, S.K.; Basudhar, P.K. Undrained lateral load capacity of piles in clay using artificial neural network. Comput. Geotech. 2006, 33, 454–459. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of artificial neural network and genetic programming as predictive tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Golbraikh, A.; Tropsha, A. Beware of q(2)! J. Mol. Graph. Model. 2002, 20, 269–276. [Google Scholar] [CrossRef]

- Roy, P.P.; Roy, K. On Some Aspects of Variable Selection for Partial Least Squares Regression Models. QSAR Comb. Sci. 2008, 27, 302–313. [Google Scholar] [CrossRef]

- Khademi, F.; Akbari, M.; Jamal, S.M.; Nikoo, M. Multiple linear regression, artificial neural network, and fuzzy logic prediction of 28 days compressive strength of concrete. Front. Struct. Civ. Eng. 2017, 11, 90–99. [Google Scholar] [CrossRef]

| Size | Gravel | Mortar | Brick | Others (Tiles, Wood, Nails, and Others) |

|---|---|---|---|---|

| 5–10 | 65.78 | 24.65 | 8.34 | 1.23 |

| 10–20 | 69.58 | 17.80 | 7.93 | 4.69 |

| 20–40 | 68.93 | 23.72 | 5.21 | 2.14 |

| Percentage of CDW (%) | Specific Gravity | Absorption (%) | Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) | Apparent Cohesion c’ (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|

| 0 | 2.697 | 0.302 | 2.238 | 5.5 | 87.4 | 51.7 |

| 65 | 2.406 | 3.715 | 2.040 | 7.0 | 59.1 | 52.1 |

| 85 | 2.402 | 3.763 | 2.063 | 6.0 | 59.5 | 54.8 |

| 100 | 2.370 | 3.945 | 1.958 | 6.4 | 41.2 | 52.4 |

| Test Method | Specimen Height (cm) | Specimen Volume (cm3) | Sub-Layers | Blows per Sub-Layer | Hammer Weight (kg) | Falling Height (mm) | Maximum Particle Size (mm) |

|---|---|---|---|---|---|---|---|

| Heavy II-2 | 12 | 2177 | 3 | 98 | 4.5 | 450 | 40 |

| Specimen Designation | Moisture Condition (%) | Confining Pressure σ3 (kPa) | Shear Stress Ratio (SSR) | Deviator Stress σd (kPa) | No. of Load Applications (N) |

|---|---|---|---|---|---|

| 100% CDW | wopt | 50 | 0.3/0.5/0.7/0.9 | 120.3/223.3/352.6/519.9 | 50,000 |

| 100% CDW | wopt | 100 | 0.3/0.5/0.7/0.9 | 193.9/359.9/568.4/838.0. | 50,000 |

| 100% CDW | wopt | 150 | 0.3/0.5/0.7/0.9 | 267.5/496.5/784.1/1156.1 | 50,000 |

| 85% CDW + 15% VA | wopt | 50 | 0.3/0.5/0.7/0.9 | 156.9/291.8/462.1/683.9 | 50,000 |

| 85% CDW + 15% VA | wopt | 100 | 0.3/0.5/0.7/0.9 | 242.2/450.4/713.4/1055.7 | 50,000 |

| 85% CDW + 15% VA | wopt | 150 | 0.3/0.5/0.7/0.9 | 327.4/609.0/964.6/1427 | 50,000 |

| 65% CDW + 35% VA | wopt | 50 | 0.3/0.5/0.7/0.9 | 138.8/257.6/406.6/599.3 | 50,000 |

| 65% CDW + 35% VA | wopt | 100 | 0.3/0.5/0.7/0.9 | 211.1/391.7/618.4/911.3 | 50,000 |

| 65% CDW + 35% VA | wopt | 150 | 0.3/0.5/0.7/0.9 | 283.5/25.8/830.1/1223.4 | 50,000 |

| 0% CDW | wopt | 50 | 0.3/0.5/0.7/0.9 | 168.1/311.7/491.8/724.4 | 50,000 |

| 0% CDW | wopt | 100 | 0.3/0.5/0.7/0.9 | 238.7/442.6/698.4/1028.6 | 50,000 |

| 0% CDW | wopt | 150 | 0.3/0.5/0.7/0.9 | 309.3/573.6/905.0/1332.9 | 50,000 |

| 85% CDW + 15% VA | wopt ± 1 | 50 | 0.3/0.5/0.7 | 156.9/291.8/462.1 | 50,000 |

| 85% CDW + 15% VA | wopt ± 1 | 100 | 0.3/0.5/0.7 | 242.2/450.4/713.4 | 50,000 |

| 85% CDW + 15% VA | wopt ± 1 | 150 | 0.3/0.5/0.7 | 327.4/609.0/964.6 | 50,000 |

| 65% CDW + 35% VA | wopt ± 1 | 50 | 0.3/0.5/0.7 | 138.8/257.6/406.6 | 50,000 |

| 65% CDW + 35% VA | wopt ± 1 | 100 | 0.3/0.5/0.7 | 211.1/391.7/618.4 | 50,000 |

| 65% CDW + 35% VA | wopt ± 1 | 150 | 0.3/0.5/0.7 | 283.5/25.8/830.1 | 50,000 |

| Model | Hidden Layer 1 | Hidden Layer 2 | MSE | RMSE | R2 Value | ||

|---|---|---|---|---|---|---|---|

| Transfer Function | Number of Neurons | Transfer Function | Number of Neurons | ||||

| 1 | Tansig | 22 | - | - | 0.005200 | 0.0724 | 0.9990 |

| 2 | Logsig | 24 | - | - | 0.005100 | 0.0711 | 0.9989 |

| 3 | Tansig | 16 | Tansig | 4 | 0.008600 | 0.0929 | 0.9981 |

| 4 | Tansig | 16 | Tansig | 8 | 0.039600 | 0.1990 | 0.9915 |

| 5 | Tansig | 20 | Tansig | 4 | 0.000850 | 0.9998 | 0.9998 |

| 6 | Tansig | 20 | Tansig | 8 | 0.000150 | 1.0000 | 0.9999 |

| 7 | Tansig | 20 | Tansig | 12 | 0.000069 | 0.0083 | 0.9999 |

| 8 | Tansig | 24 | Tansig | 4 | 0.000150 | 0.0122 | 0.9999 |

| 9 | Tansig | 24 | Tansig | 8 | 0.000360 | 0.0189 | 0.9999 |

| 10 | Tansig | 24 | Tansig | 12 | 0.000210 | 0.0143 | 1.0000 |

| 11 | Logsig | 20 | Logsig | 4 | 0.029900 | 0.1728 | 0.9936 |

| 12 | Logsig | 20 | Logsig | 8 | 0.000103 | 0.0102 | 0.9999 |

| 13 | Logsig | 20 | Logsig | 12 | 0.000056 | 0.0075 | 0.9999 |

| 14 | Logsig | 24 | Logsig | 4 | 0.000750 | 0.0273 | 0.9998 |

| 15 | Logsig | 24 | Logsig | 8 | 0.000076 | 0.0087 | 0.9999 |

| 16 | Logsig | 24 | Logsig | 12 | 0.000022 | 0.0047 | 0.9999 |

| Criterion | Limit | Result Obtained |

|---|---|---|

| It should be close to R2 | 1.000 | |

| It should be close to R2 | 1.000 | |

| −8.0614 × 10−6 | ||

| −8.0614 × 10−6 | ||

| 0.997 | ||

| 1.000 | ||

| 1.000 |

| No. of Neurons | Bias | |||||

|---|---|---|---|---|---|---|

| 1 | −0.1094 | 5.6973 | −2.6239 | −4.1142 | −2.2875 | −5.8412 |

| 2 | −2.6531 | −1.9948 | −2.8745 | −9.1333 | −3.1458 | 7.2169 |

| 3 | −0.6294 | −1.6299 | 2.0106 | 3.6315 | 6.4585 | 2.3361 |

| 4 | 0.1171 | 0.5023 | −0.0272 | −2.4416 | 4.2335 | −0.4899 |

| 5 | 0.3365 | 2.2900 | 4.2364 | −5.0357 | −3.2842 | −5.2766 |

| 6 | 0.0737 | 1.0322 | 0.1258 | 0.0464 | 9.2983 | 9.7301 |

| 7 | −0.3636 | 9.7478 | −2.4388 | 14.0586 | 9.6219 | 3.9302 |

| 8 | 0.8907 | 2.1307 | 1.3836 | 7.1531 | 0.5404 | −2.2487 |

| 9 | 0.4206 | −8.8326 | 0.7155 | −9.0036 | −16.4121 | 12.2490 |

| 10 | 0.1758 | −21.1393 | −0.4254 | 0.5450 | −1.1629 | 5.7882 |

| 11 | 0.5968 | 2.6394 | 0.1605 | −1.1610 | −2.2575 | 0.6746 |

| 12 | 0.2026 | 2.4468 | 3.5302 | −8.1728 | −4.4705 | −1.2732 |

| 13 | −0.1958 | −12.5005 | −8.0251 | 3.4476 | −2.0155 | 0.9297 |

| 14 | −0.2200 | 12.5328 | −27.6076 | −2.1199 | −9.5615 | −5.8104 |

| 15 | 0.1520 | 2.9182 | −3.3135 | −9.2082 | 0.7358 | −5.6332 |

| 16 | −0.6329 | 0.7560 | −0.1534 | −5.0035 | 0.9725 | 1.6679 |

| 17 | 4.2473 | −0.0495 | 0.2003 | −1.0546 | −1.1639 | 6.2983 |

| 18 | 0.0824 | −5.6410 | −0.7707 | −11.1252 | 13.6619 | 3.9059 |

| 19 | −5.0133 | 3.6679 | −0.6048 | 9.6750 | 1.8379 | −12.1019 |

| 20 | −0.0327 | 11.2124 | −5.7675 | −1.7260 | 10.8888 | −7.9320 |

| 21 | 0.3489 | −6.3274 | 1.1552 | −5.0078 | −19.4570 | 18.2258 |

| 22 | 27.8994 | −1.3200 | −0.7075 | −3.6271 | 0.7454 | 30.8751 |

| 23 | −17.6869 | 0.3266 | 0.8284 | 4.1171 | 0.2390 | −22.2180 |

| 24 | −73.0825 | −0.1119 | 0.5436 | 0.9321 | 1.0957 | −76.1978 |

| Number of Neurons | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 0.7146 | −0.3988 | 2.4250 | 6.6116 | 0.6890 | −6.9594 | 1.7063 | −1.2343 | −5.2970 | −0.6711 | 3.0982 | 0.0161 | 4.2159 | −1.1533 | −0.5488 |

| 2. | −16.4659 | 2.2190 | 0.7273 | 6.7797 | 4.0228 | −7.5493 | 0.9441 | −15.6412 | 3.8110 | −14.0547 | −5.8514 | −5.2285 | −9.8674 | 1.9195 | 11.1362 |

| 3. | 1.8968 | −1.5852 | 1.8603 | 1.9031 | 2.4132 | 13.2439 | 2.0927 | 3.3924 | −4.3266 | −4.1764 | 0.4465 | 1.1636 | −1.2214 | −2.1732 | −0.1646 |

| 4. | −2.7318 | −0.2603 | −1.1354 | −0.2528 | 0.0820 | −7.5951 | 1.4863 | −0.2839 | −3.3794 | 0.2096 | −0.6990 | −1.2705 | 0.1842 | −1.1036 | 1.5444 |

| 5. | −0.5293 | −3.8654 | 2.2891 | 10.5591 | −9.9651 | 18.1215 | −12.1999 | 1.7446 | −1.7580 | −2.7056 | 2.5688 | −1.0575 | −5.9527 | 6.1044 | −5.4290 |

| 6. | 2.6677 | −3.0737 | 2.0298 | 6.9112 | 3.4642 | −11.3896 | 3.7019 | −6.1639 | 14.5756 | 2.4095 | 1.7059 | 1.0439 | −4.5989 | 2.8452 | 0.1966 |

| 7. | 0.5566 | −5.5456 | −2.8597 | 11.5208 | 2.0721 | 2.8176 | 1.2168 | 8.0306 | −2.9587 | −3.7244 | 2.1402 | 2.8904 | −1.3286 | 1.0611 | −5.0067 |

| 8. | −3.2716 | 1.5978 | −1.6496 | 0.8116 | −5.7029 | −0.4009 | −0.8204 | −0.5505 | 4.5118 | −1.3713 | −3.8134 | 3.9949 | −4.9466 | 1.7123 | 0.9079 |

| 9. | −4.7425 | −3.0986 | −7.1215 | −12.1448 | −0.3192 | −14.2148 | 1.4936 | 2.0335 | 7.2961 | 2.3999 | −2.0665 | −1.4892 | 0.0024 | 4.1281 | 2.5828 |

| 10. | −1.6457 | 0.8667 | −0.9029 | −7.0424 | −2.0925 | 1.0502 | −2.9149 | 0.8246 | 3.7235 | −3.6903 | 1.8387 | 1.0353 | 10.1864 | −0.3438 | −0.4639 |

| 11. | −4.0954 | −0.6293 | 11.3081 | −3.0892 | 2.3912 | −10.0275 | −7.3025 | 7.9210 | 2.4526 | −8.9789 | −1.8385 | 4.7274 | 12.4830 | −2.8821 | 0.2723 |

| 12. | 3.3456 | −0.1275 | 0.6344 | 4.2034 | 4.5033 | −4.8560 | 3.1607 | −1.7153 | 2.0473 | 8.8093 | 6.8159 | −5.3400 | −5.6144 | 2.4990 | −34.1919 |

| Number of Neurons | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | −0.6536 | −0.4666 | −1.6391 | 0.8160 | −1.7547 | 5.8938 | −0.8661 | −7.3072 | 2.1186 | 6.8634 |

| 2. | −7.1168 | 4.2295 | −6.3028 | −4.7430 | −4.0240 | −5.8181 | 2.9287 | −4.2561 | −2.9766 | 24.5150 |

| 3. | 6.0359 | 0.3560 | −2.1268 | 2.4940 | −3.2969 | 3.4366 | −2.0608 | −12.7921 | −1.5496 | −15.0832 |

| 4. | −1.8965 | 0.1715 | −1.2868 | −0.6701 | 0.4239 | 3.2045 | 0.0236 | −2.8066 | −0.1310 | 11.0606 |

| 5. | 8.4488 | 3.2800 | −7.7378 | −6.8762 | 9.1786 | 2.8125 | 1.4265 | −5.9075 | −11.6221 | −19.0318 |

| 6. | −5.4748 | −0.8150 | −0.4198 | 2.0685 | −1.8596 | −15.2934 | 0.0932 | −7.4596 | 2.5995 | 6.5697 |

| 7. | −8.1357 | 12.6468 | 3.6756 | −4.3331 | −0.9245 | 6.7587 | 26.3563 | 26.0665 | −60.2009 | −24.0241 |

| 8. | 3.3867 | −2.0912 | 0.9286 | −1.8435 | −0.5058 | −2.0781 | −0.7201 | −2.3558 | 2.4062 | 3.5620 |

| 9. | 5.5772 | −2.9913 | 6.6608 | −2.5804 | 4.0340 | −4.3462 | 0.2886 | 19.7329 | 7.1202 | 6.1357 |

| 10. | 3.2732 | 0.7859 | 7.6699 | −1.0107 | −0.3832 | −4.0689 | −0.2181 | −2.7736 | −2.3277 | −4.8548 |

| 11. | −0.1646 | 7.6401 | −10.1064 | 3.2279 | 1.0123 | −12.8508 | 1.2497 | 3.9537 | −4.1822 | −0.8310 |

| 12. | −2.8282 | 1.8739 | −0.4615 | 3.6850 | −2.3380 | −5.9040 | −0.1491 | −3.9433 | 0.0691 | −2.2141 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhi, X.; Aminu, U.F.; Hua, W.; Huang, Y.; Li, T.; Deng, P.; Chen, Y.; Xiao, Y.; Ali, J. Modeling the Dynamic Behavior of Recycled Concrete Aggregate-Virgin Aggregates Blend Using Artificial Neural Network. Sustainability 2023, 15, 14228. https://doi.org/10.3390/su151914228

Zhi X, Aminu UF, Hua W, Huang Y, Li T, Deng P, Chen Y, Xiao Y, Ali J. Modeling the Dynamic Behavior of Recycled Concrete Aggregate-Virgin Aggregates Blend Using Artificial Neural Network. Sustainability. 2023; 15(19):14228. https://doi.org/10.3390/su151914228

Chicago/Turabian StyleZhi, Xiao, Umar Faruk Aminu, Wenjun Hua, Yi Huang, Tingyu Li, Pin Deng, Yuliang Chen, Yuanjie Xiao, and Joseph Ali. 2023. "Modeling the Dynamic Behavior of Recycled Concrete Aggregate-Virgin Aggregates Blend Using Artificial Neural Network" Sustainability 15, no. 19: 14228. https://doi.org/10.3390/su151914228