SPOT: A Strategic Life-Cycle-Assessment-Based Methodology and Tool for Cosmetic Product Eco-Design

Abstract

:1. Introduction

2. Context of SPOT Development

2.1. Company Sustainable Commitments

2.2. Prior Experience in Eco-Design

2.3. Goals of SPOT

3. Description of SPOT Methodology for Environmental Impacts

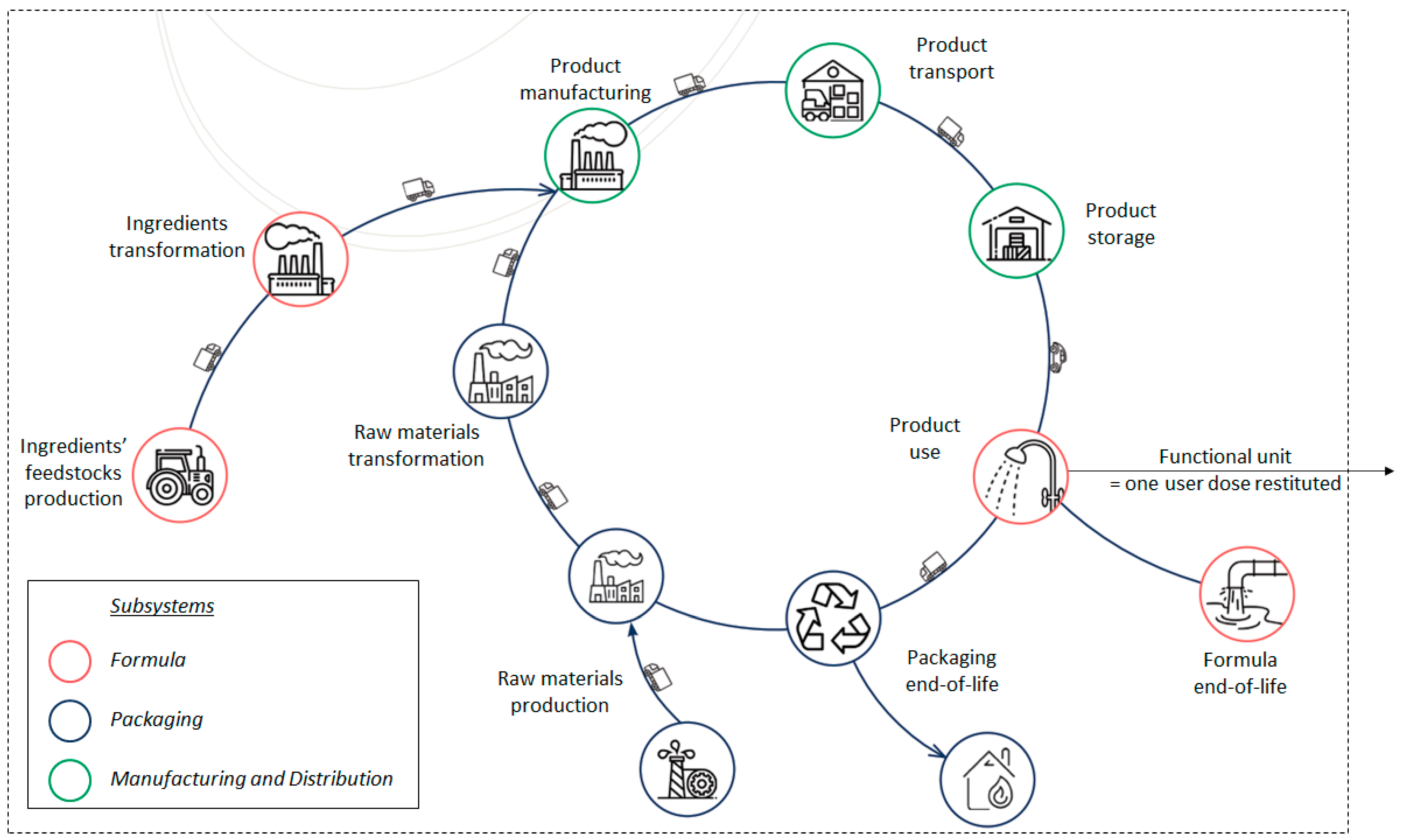

3.1. Scope of the SPOT Methodology

3.2. System Boundaries and Functional Units

3.3. Collection of Life Cycle Inventory (LCI) Data

3.4. Life Cycle Impact Assessment (LCIA) toward Single Footprint

3.4.1. Characterization of Environmental Indicators

3.4.2. LAIM: Adapted LCIA Method for Freshwater Ecotoxicity

3.4.3. Normalization and Weighting

3.5. Environmental Ratings and Sustainability Index

3.5.1. Environmental Rating

3.5.2. Product Sustainability Index

4. Application of SPOT for Cosmetic Eco-Design to Mitigate Environmental Impacts

4.1. Interpretation of Environmental Ratings for Eco-Design

4.2. Levers for Eco-Design Available in the SPOT

4.3. Eco-Design Case Studies

5. Implementation of the SPOT at L’Oréal

5.1. SPOT Functionalities and Structure

5.2. Integration of SPOT in the Innovation Process

5.3. Support for SPOT Users

5.4. SPOT Updates and Continuous Development

5.5. Links with Other Sustainable Initiatives

6. Discussion

6.1. Challenges during SPOT Development and Implementation

- Tool development team: Big data management expertise was required but was missing in the company. The development of this new skill in the tool development team forced team members to systematize and adapt their work method to align with big data requirements. Beyond the expertise in data management, the provision of all the necessary data in the right format and at the right time was also a challenge for the development of this tool.

- Data availability: There was a lack of specific LCI data for cosmetics, and the company had to develop its own datasets, especially for cosmetic ingredient production.

- Implementation of eco-design in the existing procedure: When the SPOT was launched, having to include environmental and social criteria in the decision process of the product launch added additional complexity to the management of the classical criteria, which are quality, cost, and timing. Teams realized that before, they had not always been doing everything right, which can be perceived as learning or as judgment, depending on the people. Therefore, this shift needed to be accompanied by training sessions, user support, as well as the appropriate wording not to emphasize what was done badly, but what can be improved now.

- Tool adoption by users: User buy-in was difficult at the beginning as the tool was new, sometimes perceived as too complex, and required additional workload for the user, even if the tool automation made it easier. Specific measures put in place helped to overcome this challenge like the involvement of top management with the introduction of the sustainability KPI, the increase in top management accountability, the specific training sessions organized for operational teams, and the technical support. As the SPOT encompasses a wide variety of eco-design levers, the improvement in the product rating associated with the activation of a lever was sometimes not up to the user’s expectations; training and explanation were then required. In addition, all efforts were made to make the tool user-friendly and intuitive for its adoption by non-experts in LCA, while keeping the methodology scientifically robust.

- User accessibility: Finding a reasonable balance between the precision of data and results and tool complexity was a challenge. Trials and errors, as well as user feedback, were crucial to tackling that issue. Involving users (like former formulators and packagers) in the tool development team was also a good way to guide development by accounting for user constraints from the beginning.

- User support: Communicating the complexity of the approach based on LCA in a way that is understandable to operational teams required efforts for pedagogy during training sessions and user support.

- Data evolution management: Data evolution influences the results, which can cause difficulties for users in integrating changes that may affect their work. There is a need for user support to keep a critical mind and to accompany changes carefully by explaining the resulting differences to users (transparency). In addition, performing regular audits is key to reinforcing tool credibility.

- Tool adaptation capacity: Dealing with disruptive innovation (i.e., development that creates a break with the current market based on innovative use, innovative technology, or both) is challenging because of the difficulty of determining what they are being compared to in terms of environmental progress as no baseline product is available. In addition, a committee is responsible for the creation of new product categories and specific expertise to determine the corresponding baseline products.

6.2. Strategies for SPOT Implementation Compared with the Literature

6.3. Main Methodological Limitations of SPOT

6.4. Other Eco-Design Levers for Cosmetic Products

6.5. Future Perspectives for SPOT Development

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Details on SPOT Methodology

Appendix A.1. Formula End-of-Life

Appendix A.2. Influence of Dose-Related Parameters on the Number of Units of Services

Appendix A.3. Main Differences between the SPOT Methodology and the PEF Requirements

| Topic | PEF | SPOT 2023 |

|---|---|---|

| Indicators and characterization methods |

|

|

| Normalization |

|

|

| Weighting |

|

|

| LCI database |

|

|

Appendix B. LAIM Method

- -

- Chronic data available:

- o

- EC10chr or NOECchr on standard regulatory species available

- o

- EF = 1000 × 0.05/((Lowest EC10chr/SF) × Extrapolation factor) with:

- ▪

- ∆PAF = 0.05 for 5% of affected species

- ▪

- SF = safety factor (10 for 1 EC10chr or NOECchr available, 5 for 2 EC10chr or NOECchr and 1 for 3 EC10chr or NOECchr)

- ▪

- Extrapolation factor (EC10chr or NOECchr to EC50chr) = 5 from Payet [60]

- o

- EF = 10/(Lowest EC10chr or NOECchr/SF)

- -

- Acute data available:

- o

- EC50acu on standard regulatory species available

- o

- EF = 1000 × 0.05/((Lowest EC50acu/SF)/Extrapolation factor) with:

- ▪

- ∆PAF = 0.05 for 5% of affected species

- ▪

- SF = safety factor (10 for 1 EC50 available, 5 for 2 EC50 and 1 for 3 EC50)

- ▪

- Extrapolation factor (EC50acu to EC50chr) = 2 for organics; 20 for metals and organometallics. Same values as used in USEtox.

- o

- Metals and organometallics: EF = 1000/(Lowest EC50acu/SF)

- o

- Others (including organics): EF = 100/(Lowest EC50acu/SF)

Appendix C. Additional Results for Eco-Design Case Studies

Appendix D. Additional Information about the Implementation of SPOT at L’Oréal

References

- Bom, S.; Jorge, J.; Ribeiro, H.M.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Kröhnert, H.; Stucki, M. Life cycle assessment of a plant-based, regionally marketed shampoo and analysis of refill options. Sustainability 2021, 13, 8478. [Google Scholar] [CrossRef]

- Golsteijn, L.; Lessard, L.; Campion, J.-F.; Capelli, A.; D’Enfert, V.; King, H.; Kremer, J.; Krugman, M.; Orliac, H.; Furnemont, S.R.; et al. Developing Product Environmental Footprint Category Rules (PEFCR) for shampoos: The basis for comparable life cycle assessment. Integr. Environ. Assess. Manag. 2018, 14, 649–659. [Google Scholar] [CrossRef] [PubMed]

- Łopaciuk, A.; Łoboda, M. Global Beauty Industry Trends in the 21st Century. In Proceedings of the Management, Knowledge and Learning International Conference, Zadar, Croatia, 19–21 June 2013; pp. 1079–1087. [Google Scholar]

- Morea, D.; Fortunati, S.; Martiniello, L. Circular economy and corporate social responsibility: Towards an integrated strategic approach in the multinational cosmetics industry. J. Clean. Prod. 2021, 315, 128232. [Google Scholar] [CrossRef]

- ISO:14006; Environmental Management Systems d Guidelines for Incorporating Ecodesign. ISO: Geneva, Switzerland, 2010.

- Secchi, M.; Castellani, V.; Collina, E.; Mirabella, N.; Sala, S. Assessing eco-innovations in green chemistry: Life Cycle Assessment (LCA) of a cosmetic product with a bio-based ingredient. J. Clean. Prod. 2016, 129, 269–281. [Google Scholar] [CrossRef]

- Bovea, M.D.; Pérez-Belis, V. A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. J. Clean. Prod. 2012, 20, 61–71. [Google Scholar] [CrossRef]

- Bhander, G.S.; Hauschild, M.; McAloone, T. Implementing Life Cycle Assessment in Product Development. Environ. Prog. 2003, 22, 255–267. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Ligthart, T.N.; van Velzen, E.U.T.; Brouwer, M. EnvPack an LCA-based tool for environmental assessment of packaging chains. Part 1: Scope, methods and inventory of tool. Int. J. Life Cycle Assess. 2019, 24, 900–914. [Google Scholar] [CrossRef]

- Ligthart, T.N.; Ansems, T.M. EnvPack, an LCA-based tool for environmental assessment of packaging chains: Part 2: Influence of assessment method on ranking of alternatives. Int. J. Life Cycle Assess. 2019, 24, 915–925. [Google Scholar] [CrossRef]

- Verghese, K.L.; Horne, R.; Carre, A. PIQET: The design and development of an online ‘streamlined’ LCA tool for sustainable packaging design decision support. Int. J. Life Cycle Assess. 2010, 15, 608–620. [Google Scholar] [CrossRef]

- Sustainable Packaging Initiative for CosmEtics. Introducing the SPICE Tool. 2020. Available online: https://open-spice.com/tool/ (accessed on 15 July 2022).

- The Sustainability Consortium. Beauty and Personal Care Product Sustainability Rating System. 2019. Available online: https://sustainabilityconsortium.org/project/beauty-and-personal-care-product-sustainability-rating-system/ (accessed on 15 July 2022).

- Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability 2020, 12, 1437. [Google Scholar] [CrossRef]

- Baldassarre, B.; Keskin, D.; Diehl, J.C.; Bocken, N.; Calabretta, G. Implementing sustainable design theory in business practice: A call to action. J. Clean. Prod. 2020, 273, 123113. [Google Scholar] [CrossRef]

- Boks, C. The soft side of ecodesign. J. Clean. Prod. 2006, 14, 1346–1356. [Google Scholar] [CrossRef]

- Pigosso, D.C.; Rozenfeld, H.; McAloone, T.C. Ecodesign maturity model: A management framework to support ecodesign implementation into manufacturing companies. J. Clean. Prod. 2013, 59, 160–173. [Google Scholar] [CrossRef]

- Brones, F.A.; de Carvalho, M.M.; Zancul, E.d.S. Reviews, action and learning on change management for ecodesign transition. J. Clean. Prod. 2017, 142, 8–22. [Google Scholar] [CrossRef]

- Kemp, R.; Loorbach, D.; Rotmans, J. Transition management as a model for managing processes of co-evolution towards sustainable development. Int. J. Sustain. Dev. World Ecol. 2009, 14, 78–91. [Google Scholar] [CrossRef]

- L’Oréal. Sustainable Sourcing Guidebook for Raw Materials Suppliers; L’Oréal: Paris, France, 2022; pp. 1–27. [Google Scholar]

- Philippe, M.; Didillon, B.; Gilbert, L. Industrial commitment to green and sustainable chemistry: Using renewable materials & developing eco-friendly processes and ingredients in cosmetics. Green Chem. 2012, 14, 952–956. [Google Scholar] [CrossRef]

- Philippe, M.; Didillon, B.; Gilbert, L. Naturalness: Its assessment in the development of sustainable and green chemistry ingredients. An industrial commitment 1. Ann. Des Falsif. De L’expertise Chim. Toxicol. 2016, 985, 36–43. [Google Scholar]

- L’Haridon, J.; Martz, P.; Chenéble, J.-C.; Campion, J.-F.; Colombe, L. Ecodesign of cosmetic formulae: Methodology and application. Int. J. Cosmet. Sci. 2018, 40, 165–177. [Google Scholar] [CrossRef]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Chomkhamsri, K.; de Souza, D.M. Product Environmental Footprint (PEF) Guide; European Commission—Joint Research Centre: Ispra, Italy, 2012. [Google Scholar]

- ISO14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006; Volume 2006.

- Morizet, D.; Aguiar, M.; Campion, J.; Pessel, C.; De Lantivy, M.; Godard, C.; Dezeure, J. Water consumption by rinse-off cosmetic products: The case of the shower. Int. J. Cosmet. Sci. 2023, 1–9. [Google Scholar] [CrossRef] [PubMed]

- SCCS (Scientific Committee on Consumer Safety). SCCS Notes of Guidance for the Testing of Cosmetic Ingredients and Their Safety Evaluation 9th Revision. 29 September 2015, SCCS/1564/15, Revision of 25 April 2016. 2015, p. 151. Available online: https://ec.europa.eu/health/scientific_committees/consumer_safety/docs/sccs_o_190.pdf (accessed on 15 June 2022).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Colomb, V.; Amar, S.A.; Mens, C.B.; Gac, A.; Gaillard, G.; Koch, P.; Mousset, J.; Salou, T.; Tailleur, A.; van der Werf, H.M. AGRIBALYSE®, the French LCI Database for agricultural products: High quality data for producers and environmental labelling. OCL 2015, 22, D104. [Google Scholar] [CrossRef]

- Nemecek, T.; Bengoa, X.; Rossi, V.; Humbert, S.; Lansche, J.; Mouron, P. World Food LCA Database: Methodological Guidelines for the Life Cycle Inventory of Agricultural Products. Version 3.5. 2019, p. 88. Available online: https://simapro.com/wp-content/uploads/2020/11/WFLDB_MethodologicalGuidelines_v3.5.pdf (accessed on 1 June 2022).

- Beck, T.; Bos, U.; Wittstock, B.; Baitz, M.; Fischer, M.; Sedlbauer, K. LANCA®—Land Use Indicator Value Calculation in Life Cycle Assessment; Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2010. [Google Scholar] [CrossRef]

- Fantke, P.; Evans, J.; Hodas, N.; Apte, J.; Jantunen, M.; Jolliet, O.; McKone, T.E. Health impacts of fine particulate matter. In Global Guidance for Life Cycle Impact Assessment Indicators Volume 1; United Nations Environment Programme: Nairobi, Kenya, 2016. [Google Scholar]

- Van Zelm, R.; Huijbregts MA, J.; Den Hollander, H.A.; Van Jaarsveld, H.A.; Sauter, F.J.; Struijs, J.; Van Wijnen, H.J.; Van De Meent, D. European characterization factors for human health damage of PM 10 and ozone in life cycle impact assessment. Atmos. Environ. 2008, 42, 441–453. [Google Scholar] [CrossRef]

- Fantke, P.; Ernstoff, A.S.; Huang, L.; Csiszar, S.A.; Jolliet, O. Coupled near-field and far-field exposure assessment framework for chemicals in consumer products. Environ. Int. 2016, 94, 508–518. [Google Scholar] [CrossRef]

- Fantke, P.; Chiu, W.A.; Aylward, L.; Judson, R.; Huang, L.; Jang, S.; Gouin, T.; Rhomberg, L.; Aurisano, N.; McKone, T.; et al. Exposure and toxicity characterization of chemical emissions and chemicals in products: Global recommendations and implementation in USEtox. Int. J. Life Cycle Assess. 2021, 26, 899–915. [Google Scholar] [CrossRef]

- Owsianiak, M.; Hauschild, M.Z.; Posthuma, L.; Saouter, E.; Vijver, M.G.; Backhaus, T.; Douziech, M.; Schlekat, T.; Fantke, P. Ecotoxicity characterization of chemicals: Global recommendations and implementation in USEtox. Chemosphere 2022, 310, 136807. [Google Scholar] [CrossRef]

- European Commission. Commission Recommendation of 16.12.2021 on the Use of the Environmental Footprint Methods; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Saouter, E.; Biganzoli, F.; Ceriani, L.; Versteeg, D.; Crenna, E.; Zampori, L.; Sala, S.; Pant, R. Environmental footprint: Update of Life Cycle Impact Assessment Methods—Ecotoxicity Freshwater, Human Toxicity Cancer, and Non-Cancer; Publications office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Pizzol, M.; Laurent, A.; Sala, S.; Weidema, B.; Verones, F.; Koffler, C. Normalisation and weighting in life cycle assessment: Quo vadis? Int. J. Life Cycle Assess. 2017, 22, 853–866. [Google Scholar] [CrossRef]

- Crenna, E.; Secchi, M.; Benini, L.; Sala, S. Global environmental impacts: Data sources and methodological choices for calculating normalization factors for LCA. Int. J. Life Cycle Assess. 2019, 24, 1851–1877. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 1979, 347, 1259855. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- Sala, S.; Cerutti, A.K.; Pant, R. Development of a Weighting Approach for the Environmental Footprint; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- Vargas-Gonzalez, M.; Witte, F.; Martz, P.; Gilbert, L.; Humbert, S.; Jolliet, O.; van Zelm, R.; L’Haridon, J. Operational Life Cycle Impact Assessment weighting factors based on Planetary Boundaries: Applied to cosmetic products. Ecol. Indic. 2019, 107, 105498. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Introducing carrying capacity-based normalisation in LCA: Framework and development of references at midpoint level. Int. J. Life Cycle Assess. 2015, 20, 1005–1018. [Google Scholar] [CrossRef]

- Beltran, A.M.; Prado, V.; Vivanco, D.F.; Henriksson, P.J.G.; Guinée, J.B.; Heijungs, R. Quantified Uncertainties in Comparative Life Cycle Assessment: What Can Be Concluded? Environ. Sci. Technol. 2018, 52, 2152–2161. [Google Scholar] [CrossRef] [PubMed]

- Science-Based Target Initiative. Over 100 Global Corporations Using Science-Based Targets to Align Strategies with Paris Agreement. 2018. Available online: https://sciencebasedtargets.org/news/over-100-global-corporations-using-science-based-targets-to-align-strategies-with-paris-agreement (accessed on 1 June 2022).

- L’Oréal. Product Environmental & Social Labelling Methodologies; L’Oréal: Paris, France, 2020; pp. 1–32. [Google Scholar]

- L’Oréal. The EcoBeautyScore Consortium is Now Live with 50 Industry Players in a Breakthrough Initiative to Enable More Sustainable Consumer Choices. 2022. Available online: https://www.loreal.com/en/press-release/commitments/ecobeautyscore-consortium/ (accessed on 1 May 2022).

- Albers, A.; Collet, P.; Benoist, A.; Hélias, A. Back to the future: Dynamic full carbon accounting applied to prospective bioenergy scenarios. Int. J. Life Cycle Assess. 2020, 25, 1242–1258. [Google Scholar] [CrossRef]

- Woods, J.S.; Verones, F.; Jolliet, O.; Vázquez-Rowe, I.; Boulay, A.-M. A framework for the assessment of marine litter impacts in life cycle impact assessment. Ecol. Indic. 2021, 129, 107918. [Google Scholar] [CrossRef]

- European Chemicals Agency. Committee for Risk Assessment (RAC) Committee for Socio-economic Analysis (SEAC) Background Document to the Opinion on the Annex XV Report Proposing Restrictions on Intentionally Added Microplastics; European Chemicals Agency: Helsinki, Finland, 2022; p. 207. [Google Scholar]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—the UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Cycleco, “Environmental Footprinting with USEtox—Characterization Factors for Cosmetic, Detergent, Pesticide. 2014. Available online: http://efwithusetox.tools4env.com/dashboard (accessed on 14 December 2022).

- Echa. Chapter R.10: Characterisation of dose [concentration]-response for environment. In Guidance on Information Requirements and Chmical Safety Assessment; European Chemicals Agency: Helsinki, Finland, 2008; pp. 1–65. [Google Scholar]

- EU. Regulation (EC) No 66/2010 of the European Parliament and of the Council of 25 November 2009 on the EU Ecolabel. 2010. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32010R0066 (accessed on 19 December 2022).

- Payet, J. Assessing Toxic Impacts on Aquatic Ecosystems in Life Cycle Assessment (LCA). Ph.D. Thesis, École Polytechnique Fédérale De Lausanne, Lausanne, Switzerland, 2004. [Google Scholar]

- ECHA. Understanding REACH. 2022. Available online: https://echa.europa.eu/en/regulations/reach/understanding-reach (accessed on 19 December 2022).

| LCIA Indicators | Impact Method | Indicator Unit | Normalization Factor (Unit per Person per Year) | Weighting Factors |

|---|---|---|---|---|

| Climate Change | GWP 100 years from IPCC 2013 | kg CO2 eq. | 8.10 × 103 | 25.50% |

| Water Scarcity | AWaRe 100 | L of water eq. of deprived water | 1.15 × 107 | 1.40% |

| Freshwater Ecotoxicity | For emissions in water during formula end-of-life: LAIMFor other emissions: USEtox v1.01 | CTUe | 99.00 × 103 | 2.31% |

| Freshwater Eutrophication | EUTREND model | kg P eq. | 1.61 × 100 | 8.78% |

| Marine Eutrophication | EUTREND model | kg N eq. | 1.95 × 101 | 1.50% |

| Acidification | Accumulated Exceedance model | mol H+ eq. | 15.56 × 101 | 1.45% |

| Land Use | Soil Organic Matter (SOM) model, LANCA [34] | points | 8.19 × 105 | 25.43% |

| Terrestrial Eutrophication | Accumulated Exceedance model | mol N eq. | 1.77 × 102 | 0.83% |

| Resource Depletion (Mineral and Fossil) | CML2002 ADP fossil and mineral, reserve base | kg Sb eq. | 1.93 × 10−1 | 11.12% |

| Human Toxicity | Human toxicity (cancer and non-cancer) from USEtox v1.01 | CTUh | 5.87 × 10−4 | 3.16% |

| Particulate Matter | RiskPoll, UNEP recommended model [35] expressed in kg PM2.5 eq. | kg PM2.5 eq. | 2.50 × 100 | 16.27% |

| Ionizing Radiation | Human Health effect model | kBq U235 eq. | 4.22 × 103 | 0.03% |

| Photochemical Ozone Formation | LOTOS-EUROS model [36] as applied in ReCiPe) | kg NMVOC eq. | 44.06 × 101 | 1.47% |

| Ozone Depletion | EDIP model based on the ODPs of the World Meteorological Organization (WMO) over an infinite time horizon. | kg CFC11 eq. | 5.36 × 10−2 | 0.76% |

| Subsystem Optimized | Design Change on the New Finished Product | Example |

|---|---|---|

| Formula | Composition | formula ingredients |

| Quantity of ingredient | ingredients concentration | |

| Quantity of water for rinsing one dose | 7 L to 5 L for shampoo | |

| User dose by increasing formula efficiency | 10.46 g for liquid shampoo to 2.59 g for solid shampoo | |

| Manufacturing and distribution | Zone of sales | North America to Western Europe |

| Zone of company manufacturing site | North Asia to Western Europe | |

| Weight claim | 40 mL to 50 mL | |

| Quantity of raw material for packaging | 22 g to 18 g | |

| Packaging | Type of raw material for packaging | PET to HDPE |

| Quantity of raw material for packaging | 22 g to 18 g | |

| Rate of restitution | 85% to 90% | |

| Dispensing improvement rate (DIR) | 1 to 1.5 | |

| Percentage of recycled material | 0% to 100% | |

| Percentage of bio-sourced material | 0% to 100% | |

| Weight claim | 40 mL to 50 mL | |

| Process type | Injection to extrusion | |

| Type of finishing process | Metallization to None | |

| Decorated surface | 10 cm2 to 5 cm2 | |

| Country of supplier | France to Spain | |

| Presence of disruptor | Yes to No | |

| Presence of a main material | No to Yes | |

| Is rechargeable/refillable | No to Yes | |

| Number of recharge cycles | 1 to 5 | |

| Is a recharge | No to Yes | |

| The fact that packaging is designed to be reusable (while considering when relevant impacts from transport/clean/refill of the reused primary packaging) | No to Yes | |

| Zone of company manufacturing site | North Asia to Western Europe |

| Subsystem Optimized | Referent Product | Eco-Design Levers Activated | Renovated Product |

|---|---|---|---|

| Formula and packaging | (A) a rinse-off hair conditioner for sensitive hair |

| (A*) a leave-on hair conditioner for sensitive hair with an eco-designed packaging |

| Formula and packaging | (B) a deodorant with an aerosol delivering packaging |

| (B*) an eco-designed deodorant with an aerosol-delivering packaging |

| Tools Related Barriers | Proposed Strategies from Rossi et al. [10] | Strategies Adopted by L’Oréal during SPOT Implementation | |

|---|---|---|---|

| The high number and high specificity of eco-design tools | Selection of tools adequate for the company and project objective | 🗸 | Tool and method selection guided by an advisory stakeholder panel composed of internal and external experts |

| Use of customized eco-design tools | 🗸 | Creation of SPOT eco-design tool specifically adapted to cosmetics in the L’Oréal context | |

| Use of integrated tools | 🗸 | Integration of SPOT results into the existing product development tools | |

| Use of tools integrated with traditional design tools | 🗸 | SPOT has been implemented while continuing consistently to build on other previously developed tools to deploy the use of key eco-design levers of formulas and packaging | |

| Use of simplified tools | 🗸 | SPOT is an operational and automatic eco-design tool allowing the user to perform a simplified LCA with little data but based on a full LCA modeling, which strongly reduces the workload for users compared to other approaches | |

| Use of tools that consider the entire life cycle of products | 🗸 | SPOT is an LCA-based tool including all life cycle steps | |

| Selection of tools that can conduct multi-criteria analysis | 🗸 | SPOT is based on the multi-criteria indicators recommended by the PEF initiative [27] | |

| Establishment of a close relationship with suppliers | 🗸 | SPOT uses data collected from suppliers | |

| Development of a good international network | 🗸 | Consultation of a stakeholder panel composed of internal and external sustainability experts | |

| Good involvement of supplier expertise in the product development process | 🗸 | Suppliers are actors in the product development process by proposing new formula ingredients or packaging that meet eco-design needs | |

| Analysis of the complete supply chain to identify criticalities | 🗸 | All product life cycle steps are included | |

| Resources (time, economic, staff) | Timing re-organization to train personnel | 🗸 | All SPOT users are trained |

| Good level of education and training provided to personnel | 🗸 | Different tools available for user support (onboarding training, hotline, newsletters) help to improve user skills and foster user involvement | |

| Establishment of clear environmental goals | 🗸 | Definition of a measurable sustainability target for eco-design at the product, brand, and company levels | |

| Address environmental considerations as business issues | 🗸 | Preserving the environment is identified among the company’s top objectives | |

| Development of cross-functional teams | 🗸 | The tool development team is a cross-functional team (product developers + sustainability experts + IT): the main stakeholders are involved in the tool development to better meet the needs, and a steering committee ensures governance | |

| Support from environmental experts in the design and development activities | 🗸 | Sustainability relies on product development teams and operational teams | |

| Establishment of good contacts between departments about environmental issues | 🗸 | Collaborative work in product development teams (formulators, packagers, product developers, and marketers)Technical teams play an important role in educating the marketing team | |

| Identification of key roles | 🗸 | Roles related to eco-design are assigned | |

| Absence of multi-objective analysis | Standardization of the product development process | 🗸 | The product development process is standardized with checkpoints and milestones |

| Formalization of the product development process and inclusion of eco-design activities | 🗸 | The use of SPOT is included in the product development process | |

| Consideration of environmental issues at the beginning of the product design process | 🗸 | Sustainability requirements are set at the beginning of the product design | |

| Integration of environmental issues in the conventional product development process | 🗸 | Addition of a new KPI “Sustainability” based on SPOT results during a product development project | |

| Introduction of environmental checkpoints, reviews and milestones into the product development process | 🗸 | The sustainability KPI is part of the project milestones | |

| Adoption of a life cycle perspective | 🗸 | SPOT is an LCA-based tool | |

| Evaluation of the complete product life cycle | 🗸 | SPOT covers the complete product life cycle | |

| Transition Management Level | Proposed Strategies from Brones et al. [21] | Strategies Adopted by L’Oréal during SPOT Implementation | |

|---|---|---|---|

| Strategic | Define or update the long-term ambition of the organization in environmental sustainability | 🗸 | Definition of a measurable sustainability target for eco-design at the company level |

| Align product innovation strategy with the environmental ambition | 🗸 | Creation of the SPOT eco-design tool and adaptations of the innovation process to achieve the corporate sustainability target | |

| Monitor the long and midterm plan, and maintain coherence between corporate vision and business processes | 🗸 | SPOT results are used to monitor the corporate sustainability target achievement | |

| Tactical | Engage/influence the different groups involved in the deployment of environmental goals and procedures (middle management) | 🗸 | Accountability of top management for meeting sustainable targets and awareness/training of all managers and SPOT users |

| Formalize a plan for progressing toward a higher integration of environmental sustainability within Product innovation processes | ✗ | Strategy not implemented | |

| Monitor and evaluate results, progresses and gap | 🗸 | Product innovation and SPOT results are monitored and analyzed to identify progress and gaps | |

| Operational | Adapt and experiment eco-design tools and practices to company culture in pilot projects | 🗸 | Pilot projects before SPOT official implementation |

| Engage the different groups involved in product development to understand and apply eco-design principles and tools (internally and externally/supply chain and innovation partners) | 🗸 | All SPOT users are trained, and the addition of a new KPI “Sustainability” based on SPOT results during a product development project | |

| Capacity building and associated monitoring | 🗸 | Different tools available for user support (onboarding training, hotline, and newsletters) help to improve user skills and foster user involvement | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

L’Haridon, J.; Patouillard, L.; Pedneault, J.; Boulay, A.-M.; Witte, F.; Vargas-Gonzalez, M.; Bonningue, P.; Rollat, I.; Blanchard, T.; Goncalves, G.; et al. SPOT: A Strategic Life-Cycle-Assessment-Based Methodology and Tool for Cosmetic Product Eco-Design. Sustainability 2023, 15, 14321. https://doi.org/10.3390/su151914321

L’Haridon J, Patouillard L, Pedneault J, Boulay A-M, Witte F, Vargas-Gonzalez M, Bonningue P, Rollat I, Blanchard T, Goncalves G, et al. SPOT: A Strategic Life-Cycle-Assessment-Based Methodology and Tool for Cosmetic Product Eco-Design. Sustainability. 2023; 15(19):14321. https://doi.org/10.3390/su151914321

Chicago/Turabian StyleL’Haridon, Jacques, Laure Patouillard, Julien Pedneault, Anne-Marie Boulay, François Witte, Marcial Vargas-Gonzalez, Philippe Bonningue, Isabelle Rollat, Thierry Blanchard, Gabriel Goncalves, and et al. 2023. "SPOT: A Strategic Life-Cycle-Assessment-Based Methodology and Tool for Cosmetic Product Eco-Design" Sustainability 15, no. 19: 14321. https://doi.org/10.3390/su151914321

APA StyleL’Haridon, J., Patouillard, L., Pedneault, J., Boulay, A.-M., Witte, F., Vargas-Gonzalez, M., Bonningue, P., Rollat, I., Blanchard, T., Goncalves, G., Hervio, A., & Gilbert, L. (2023). SPOT: A Strategic Life-Cycle-Assessment-Based Methodology and Tool for Cosmetic Product Eco-Design. Sustainability, 15(19), 14321. https://doi.org/10.3390/su151914321