Effect of Biochar Application and Mineral Fertilization on Biomass Production and Structural Carbohydrate Content in Forage Plant Mixture

Abstract

:1. Introduction

2. Materials and Methods

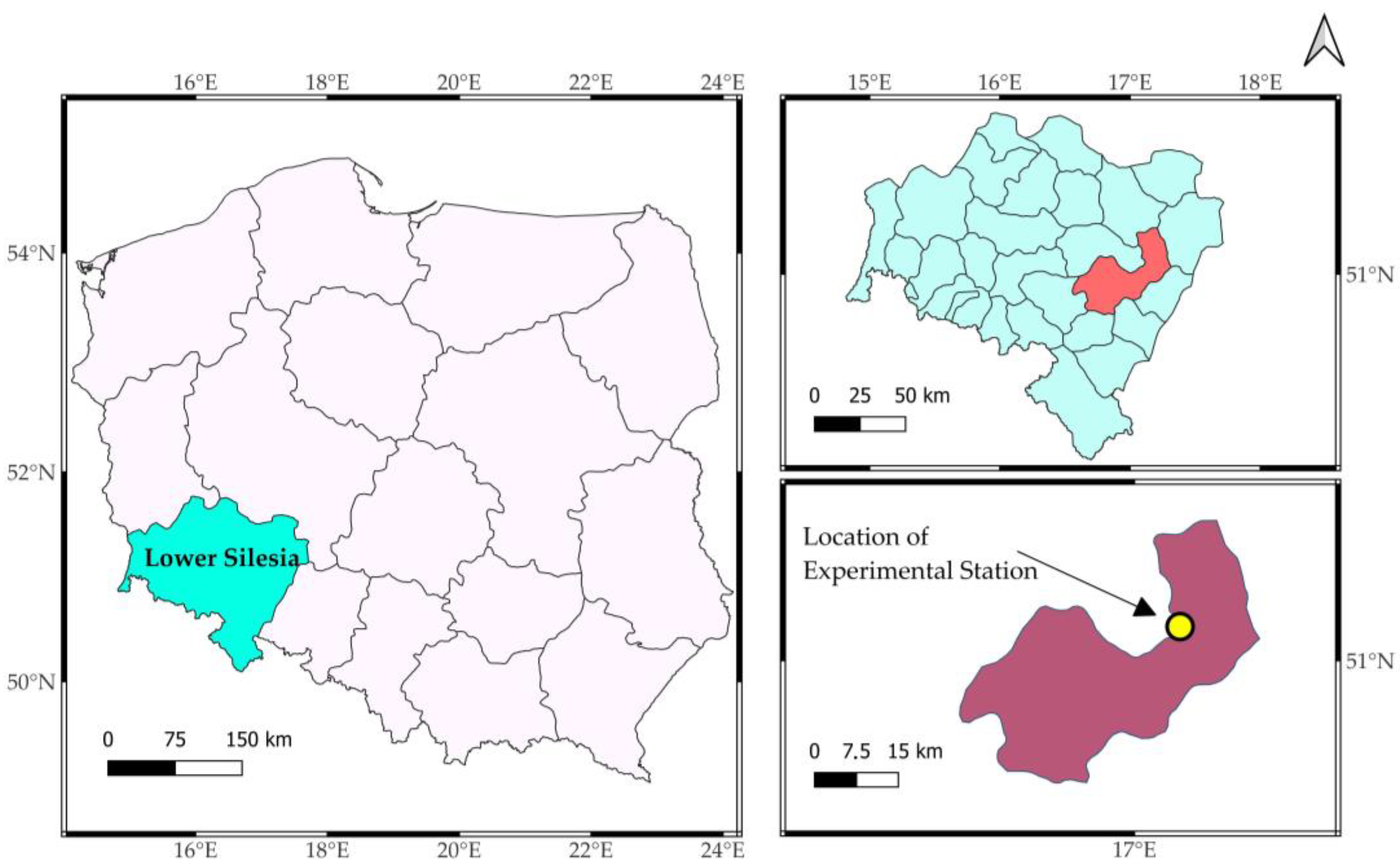

2.1. Study Area Characteristics

2.2. Description of the Biochar (BC)

2.3. Grass–Legume Mixture

2.4. Study Design and Conduct

2.5. Analytical Methods Used

2.6. Statistical Analysis

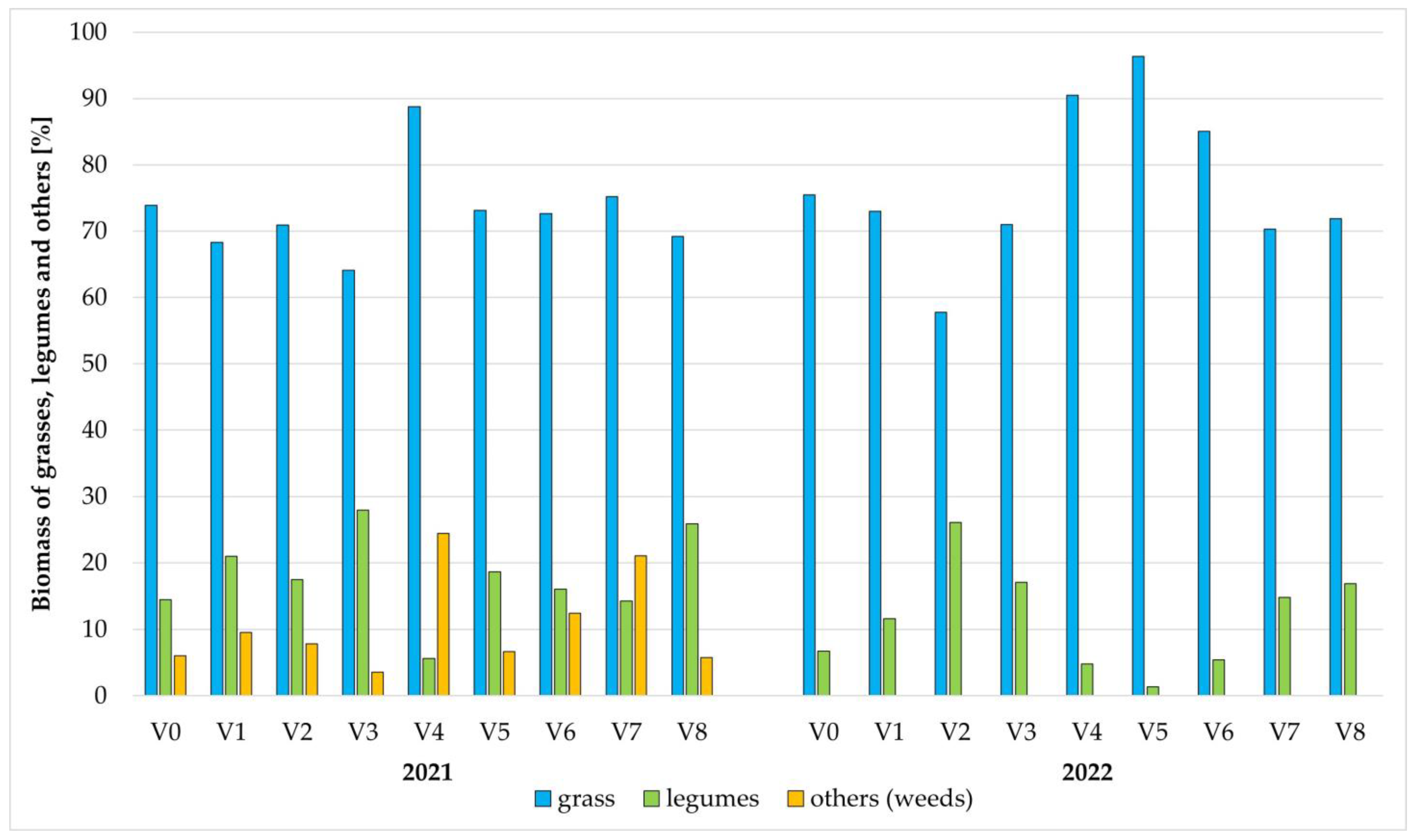

3. Results

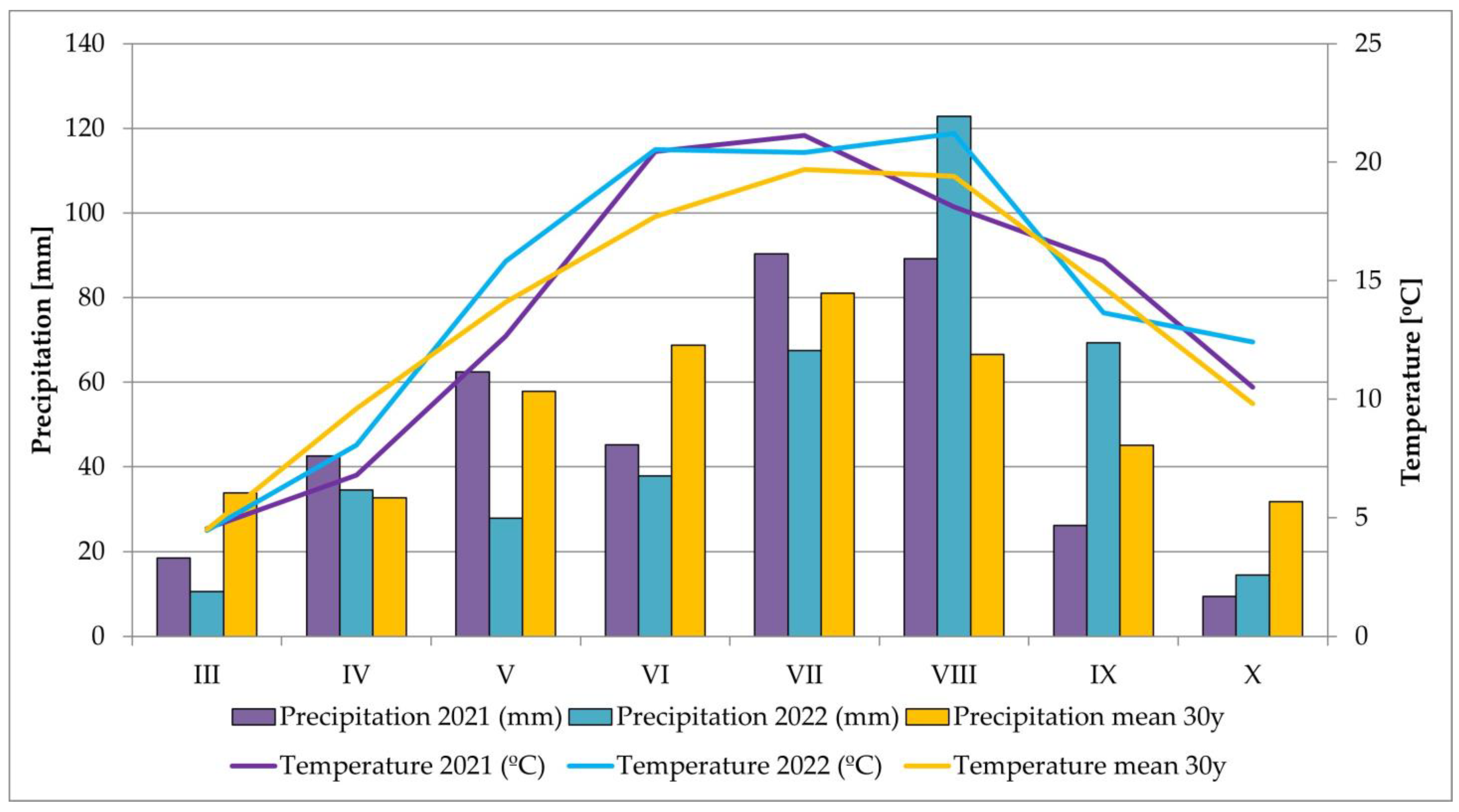

3.1. Weather Conditions

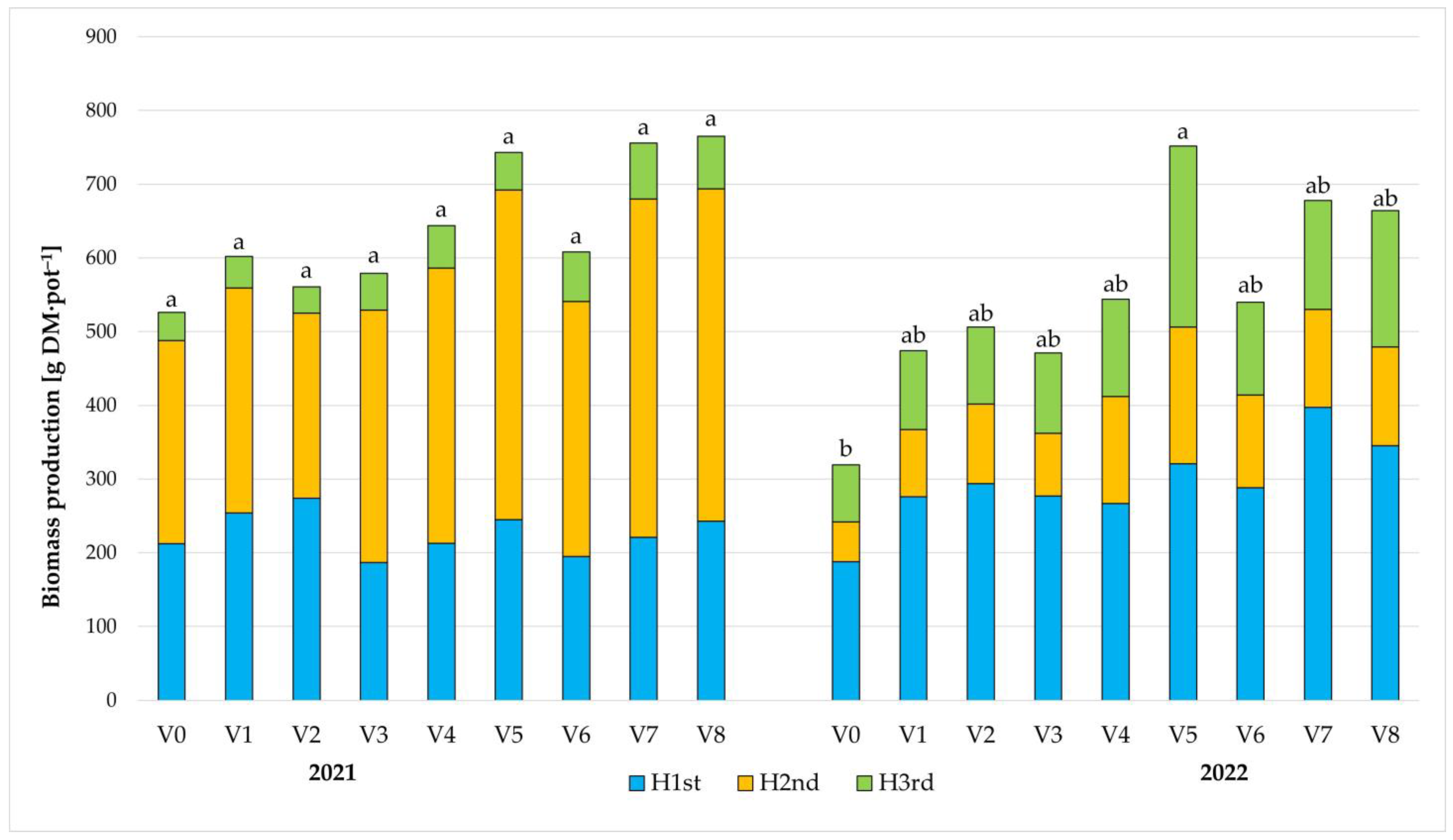

3.2. Biomass Production

3.3. Structural Carbohydrate Content

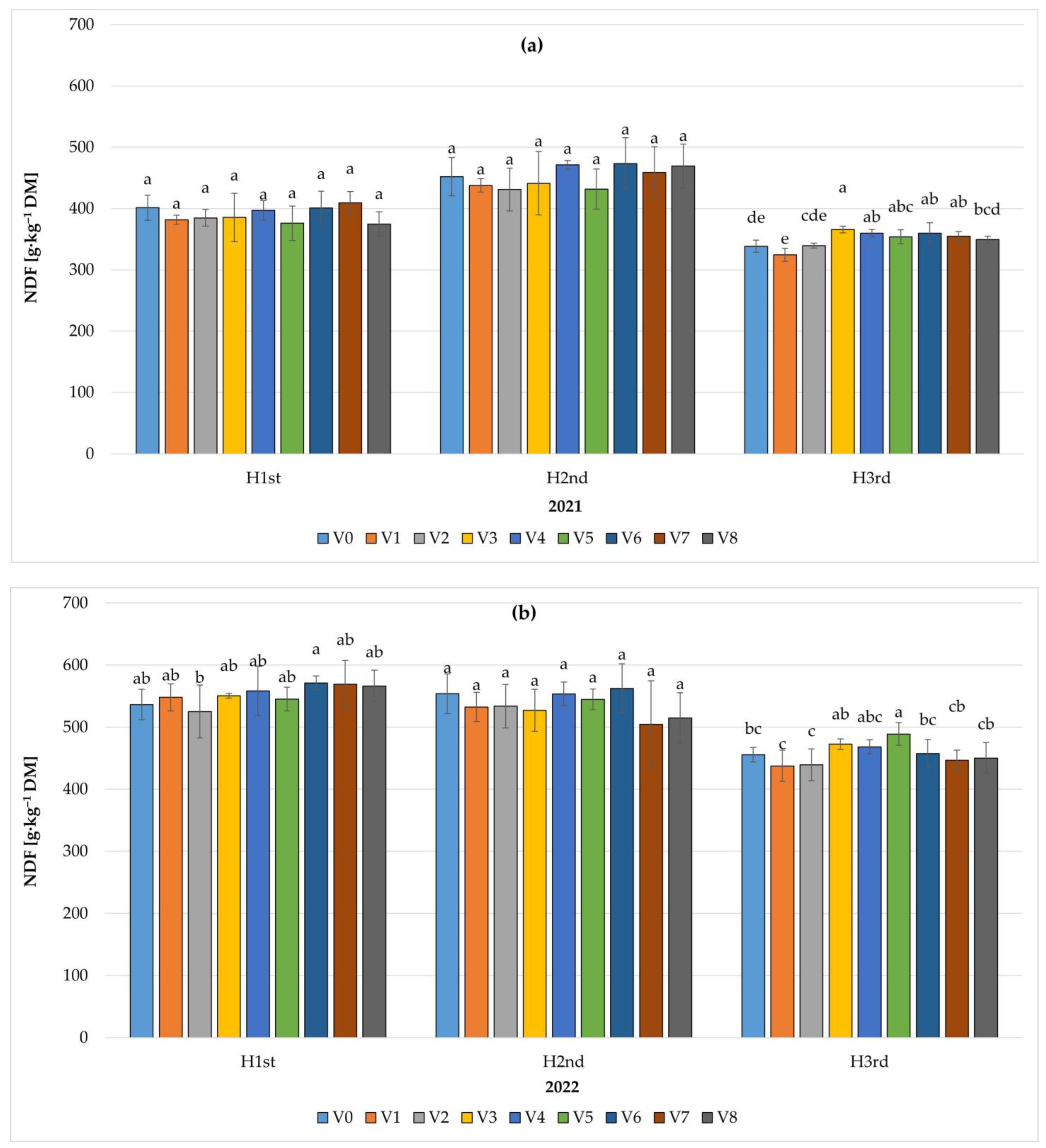

3.3.1. Neutral Detergent Fiber (NDF)

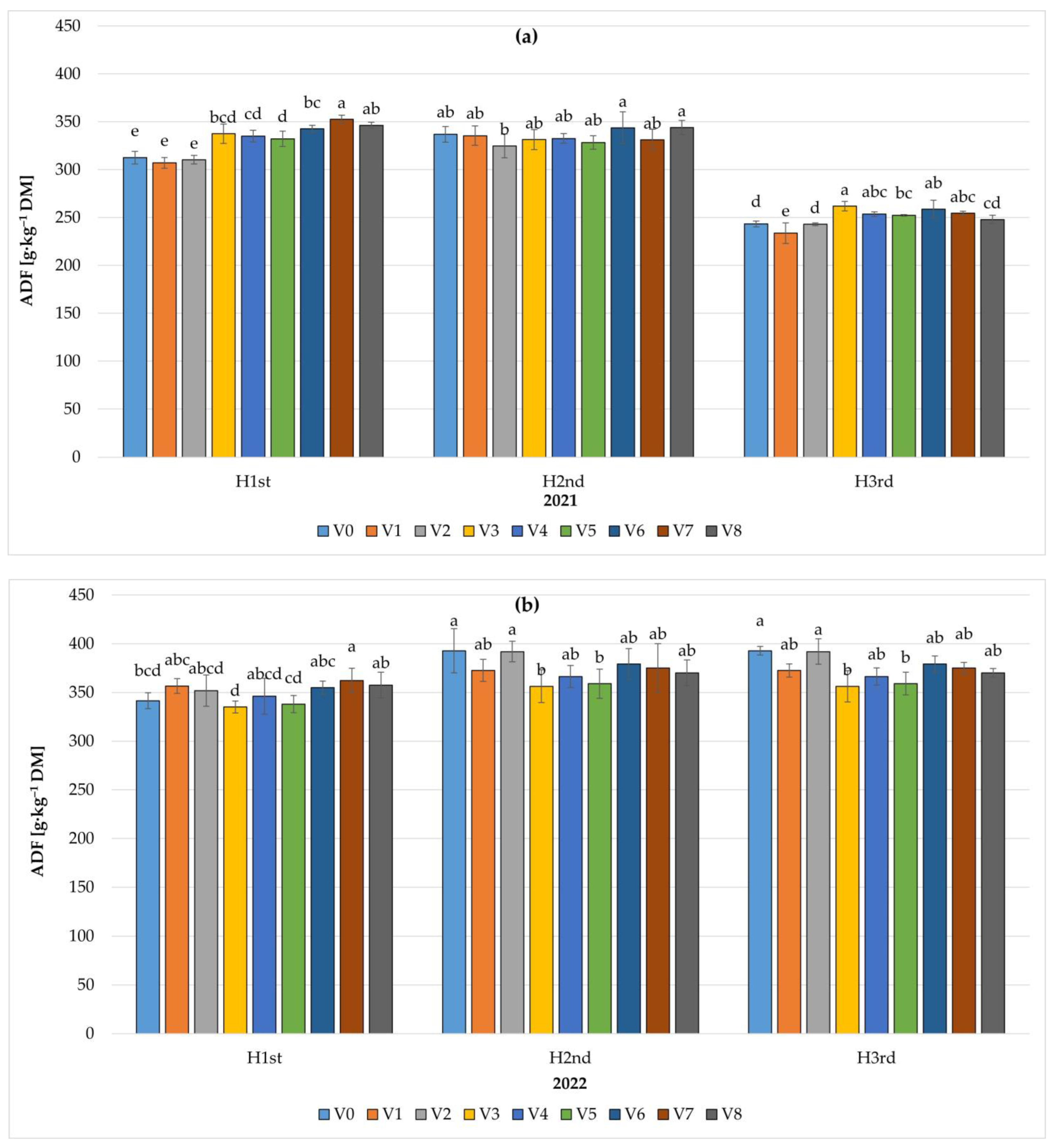

3.3.2. Acid Detergent Fiber (ADF)

3.3.3. Acid Detergent Lignin (ADL)

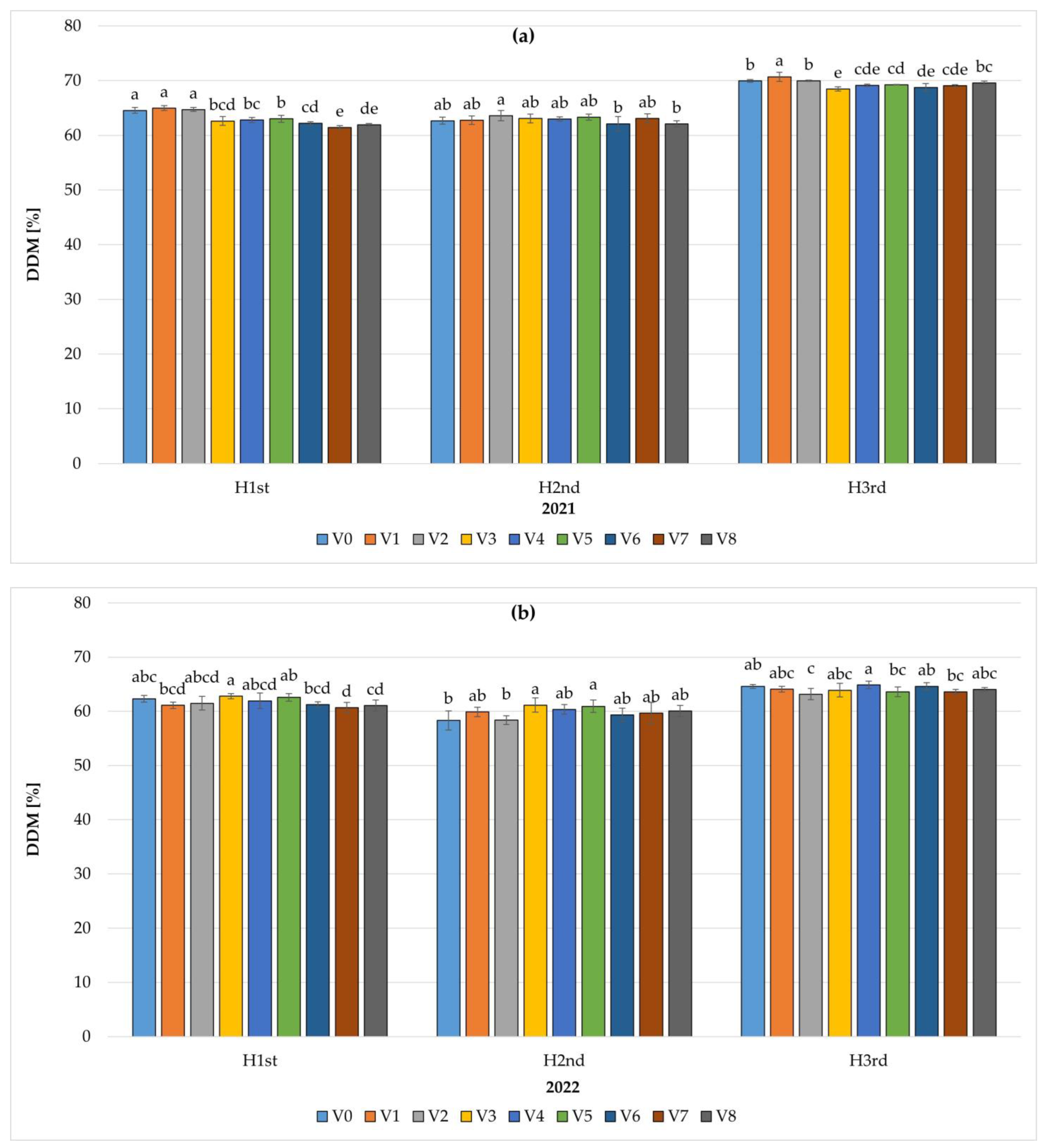

3.3.4. Digestible Dry Matter (DDM)

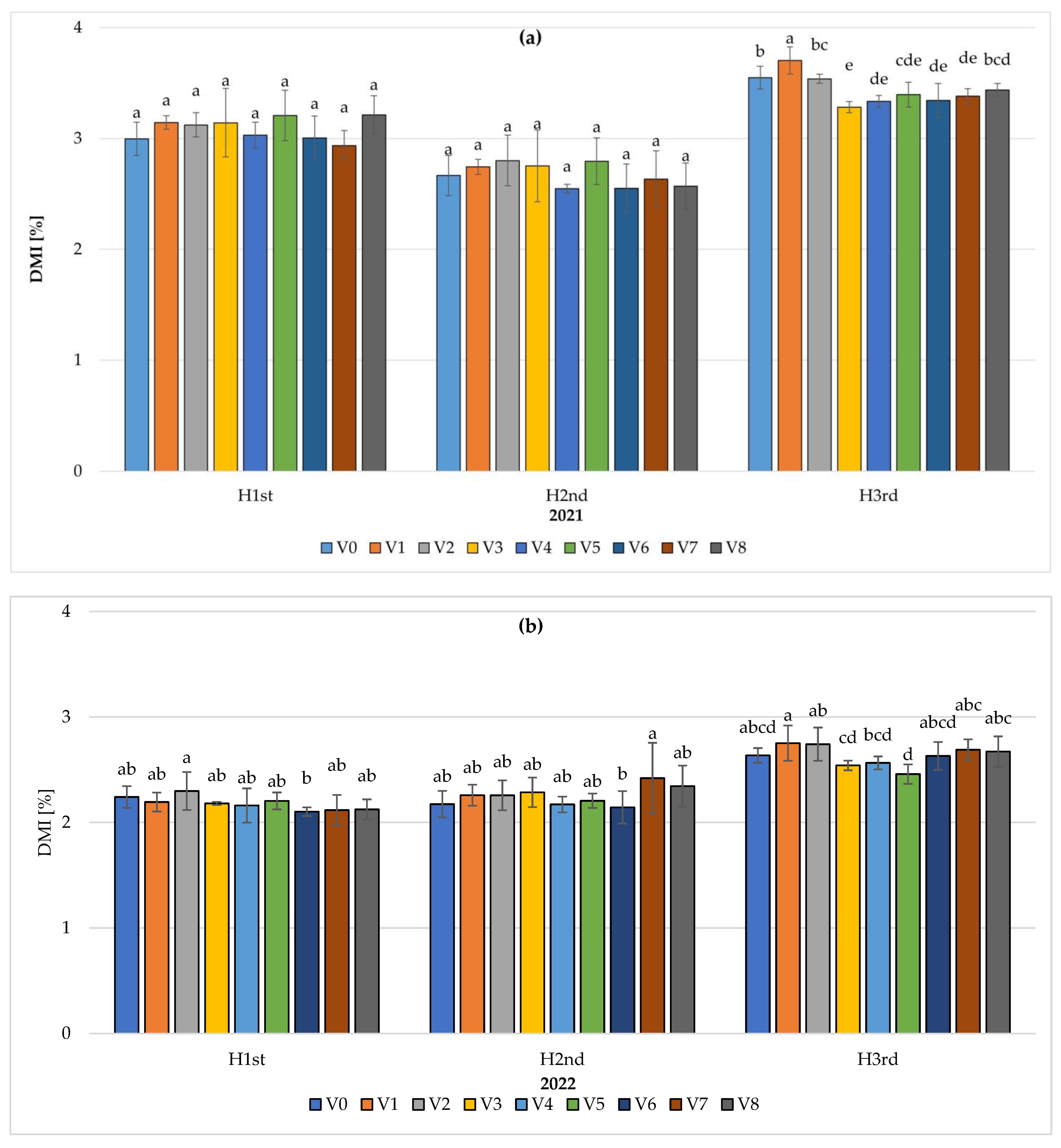

3.3.5. Dry Matter Intake (DMI)

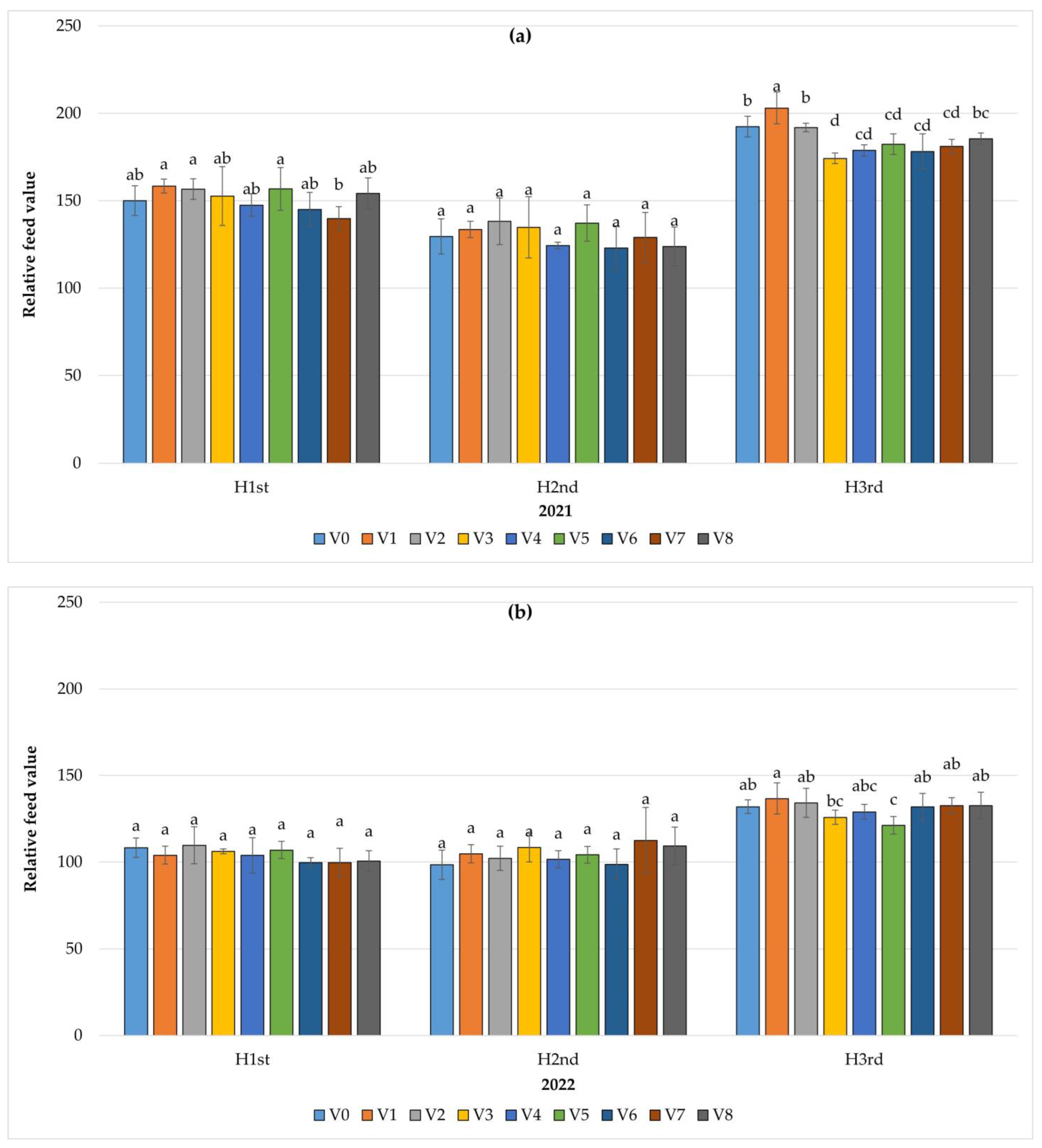

3.3.6. Relative Feed Value (RFV) and Quality Class

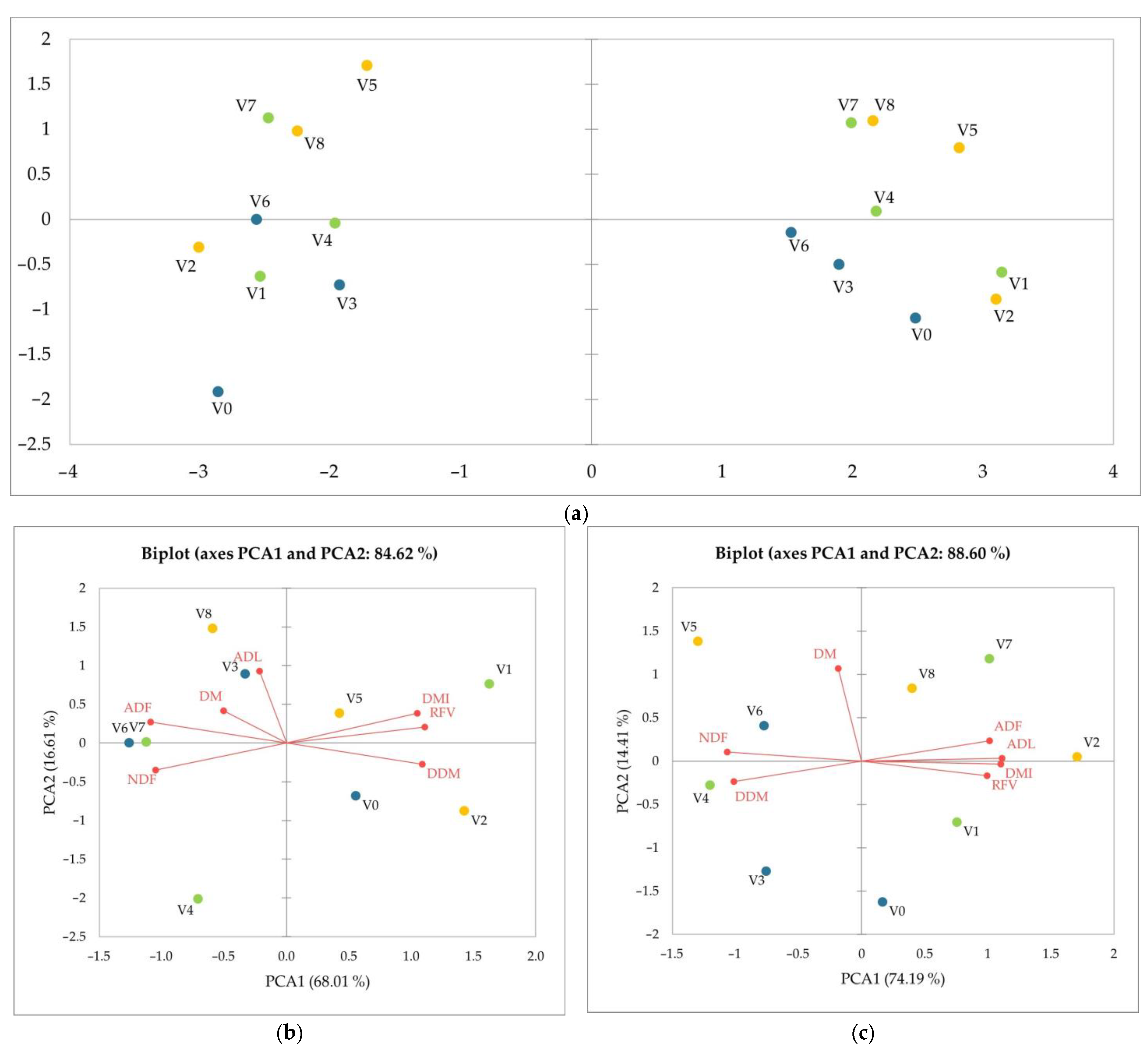

3.4. Principal Component Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EUROSTAT. Share of Main Land Types in Utilised Agricultural Area (UAA) by NUTS 2 Regions (Tai05). Available online: https://ec.europa.eu/eurostat/cache/metadata/en/tai05_esmsip2.htm (accessed on 9 February 2023).

- Yan, Y.; Jarvie, S.; Liu, Q.; Zhang, Q. Effects of fragmentation on grassland plant diversity depend on the habitat specialization of species. Biol. Conserv. 2022, 275, 109773. [Google Scholar] [CrossRef]

- Gallé, R.; Happe, A.-K.; Baillod, A.B.; Tscharntke, T.; Batáry, P. Landscape configuration, organic management, and within-field position drive functional diversity of spiders and carabids. J. Appl. Ecol. 2019, 56, 63–72. [Google Scholar] [CrossRef]

- Milazzo, F.; Fernández, P.; Peña, A.; Vanwalleghem, T. The Resilience of Soil Erosion Rates under Historical Land Use Change inAgroecosystems of Southern Spain. Sci. Total Environ. 2022, 822, 153672. [Google Scholar] [CrossRef] [PubMed]

- Han, F.; Ren, L.; Zhang, X.C. Effect of biochar on the soil nutrients about different grasslands in the Loess Plateau. Catena 2016, 137, 554–562. [Google Scholar] [CrossRef]

- Bai, Y.; Cotrufo, M.F. Grassland soil carbon sequestration: Current understanding, challenges, and solutions. Science 2022, 377, 603–608. [Google Scholar] [CrossRef]

- Gabryszuk, M.; Barszczewski, J.; Wróbel, B. Characteristics of grasslands and their use in Poland. J. Water Land Dev. 2021, 51, 243–249. [Google Scholar] [CrossRef]

- Wróbel, B.; Zielewicz, W.; Staniak, M. Challenges of Pasture Feeding Systems—Opportunities and Constraints. Agriculture 2023, 13, 974. [Google Scholar] [CrossRef]

- Sosnowski, J.; Wróbel, B.; Truba, M. Effect of Tytanit on selected morphological, physiological and chemical characteristics of Lolium multiflorum dry matter. J. Water Land Dev. 2023, 56, 7–13. [Google Scholar] [CrossRef]

- Wróbel, B.; Zielewicz, W.; Paszkiewicz-Jasińska, A.; Spychalski, B.; Jakubowska, Z. Effect of harvest date on structural carbohydrates and lignin content in meadow sward in different pluvio-thermal conditions. J. Water Land Dev. 2022, 55, 60–66. [Google Scholar] [CrossRef]

- EEA. The European Environment—State and Outlook 2020 Knowledge for Transition to a Sustainable Europe; European Environment Agency (EEA): Luxembourg, UK, 2019.

- de Boer, I.J.; van Ittersum, M.K. Circularity in Agricultural Production; Wageningen University &Research: Wageningen, The Netherlands, 2018. [Google Scholar]

- van Loon, M.P.; Vonk, W.J.; Hijbeek, R.; van Ittersum, M.K.; ten Berge, H.F. Circularity indicators and their relation with nutrient use efficiency in agriculture and food systems. Agric. Syst. 2023, 207, 103610. [Google Scholar] [CrossRef]

- Blanco-Pastor, J.L.; Manel, S.; Barre, P.; Roschanski, A.M.; Willner, E.; Dehmer, K.J.; Hegarty, M.; Muylle, H.; Ruttink, T.; Roldán-Ruiz, I.; et al. Pleistocene climate changes, and not agricultural spread, accounts for range expansion and admixture in the dominant grassland species Lolium perenne L. J. Biogeogr. 2019, 46, 1451–1465. [Google Scholar] [CrossRef]

- Abel, S.; Gislum, B.; Boelt, B. Path and correlation analysis of perennial ryegrass (Lolium perenne L.) seed yield components. J. Agron. Crop Sci. 2017, 203, 338–344. [Google Scholar] [CrossRef]

- Rafińska, K.; Pomastowski, P.; Wrona, O.; Ryszard Górecki, R.; Buszewski, B. Medicago sativa as a source of secondary metabolites for agriculture and pharmaceutical industry. Phytochem. Lett. 2017, 20, 520–539. [Google Scholar] [CrossRef]

- Acharya, J.P.; Lopez, Y.; Gouveia, B.T.; de Bem Oliveira, I.; Resende, M.F.R., Jr.; Muñoz, P.R.; Rios, E.F. Breeding Alfalfa (Medicago sativa L.) Adapted to Subtropical Agroecosystems. Agronomy 2020, 10, 742. [Google Scholar] [CrossRef]

- Barszczewski, J.; Jankowska-Huflejt, H.; Twardy, S. Metody odnawiania łąk i pastwisk. In Racjonalne Wykorzystanie Potencjału Produkcyjnego Trwałych Użytków Zielonych w Polsce w Różnych Warunkach Glebowych i Systemach Gospodarowania; Barszczewski, J., Ed.; Pub. ITP: Falenty, Poland, 2015; Volume 40. [Google Scholar]

- Marquard, E.; Weigelt, A.; Temperton, V.M.; Roscher, C.; Schumacher, J.; Buchmann, N.; Schmid, B. Plant species richness and functional composition drive overyielding in a six-year grassland experiment. Ecology 2009, 90, 3290–3302. [Google Scholar] [CrossRef]

- Bullock, J.M.; Pywell, R.F.; Walker, K.J. Long-term enhancement of agricultural production by restoration of biodiversity. J. Appl. Ecol. 2007, 44, 6–12. [Google Scholar] [CrossRef]

- Tilman, D. Biodiversity: Population versus ecosystem stability. Ecology 1996, 77, 350–363. [Google Scholar] [CrossRef]

- Picasso, V.D.; Brummer, E.C.; Liebman, M.; Dixon, P.M.; Wilsey, B.J. Crop species diversity affects productivity and weed suppression in perennial polycultures under two management strategies. Crop Sci. 2008, 48, 331–342. [Google Scholar] [CrossRef]

- Furey, G.N.; Tilman, D. Plant biodiversity and the regeneration of soil fertility. Proc. Natl. Acad. Sci. USA 2021, 118, e2111321118. [Google Scholar] [CrossRef]

- Yan, H.; Gu, S.; Li, S.; Shen, W.; Zhou, X.; Yu, H.; Lu, G. Grass-legume mixtures enhance forage production via the bacterial community. Agric. Ecosyst. Environ. 2022, 338, 108087. [Google Scholar] [CrossRef]

- Dhakal, D.; Islam, M.A. Grass-legume mixtures for improved soil health in cultivated agroecosystem. Sustainability 2018, 10, 2718. [Google Scholar] [CrossRef]

- Nyfeler, D.; Huguenin-Elie, O.; Suter, M.; Frossard, E.; Lüscher, A. Grass–legume mixtures can yield more nitrogen than legume pure stands due to mutual stimulation of nitrogen uptake from symbiotic and non-symbiotic sources. Agric. Ecosyst. Environ. 2011, 140, 155–163. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, P.; Zhang, H.; Yuan, W. Biochar production and applications in agro and forestry systems: A review. Sci. Total Environ. 2020, 723, 137775. [Google Scholar] [CrossRef] [PubMed]

- Chi, N.T.L.; Anto, S.; Ahamed, T.S.; Kumar, S.S.; Shanmugam, S.; Samuel, M.S.; Pugazhendhi, A. A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel 2021, 287, 119411. [Google Scholar] [CrossRef]

- Cha, J.S.; Park, S.H.; Jung, S.C.; Ryu, C.; Jeon, J.K.; Shin, M.C.; Park, Y.K. Production and utilization of biochar: A review. J. Ind. Eng. Chem. 2016, 40, 1–15. [Google Scholar] [CrossRef]

- Paustian, K.; Lehmann, J.; Ogle, S.; Reay, D.; Robertson, G.P.; Smith, P. Climate-smart soils. Nature 2016, 532, 49–57. [Google Scholar] [CrossRef]

- Purakayastha, T.J.; Das, K.C.; Gaskin, J.; Harris, K.; Smith, J.L.; Kumari, S. E_ect of pyrolysis temperatures onstability and priming e_ects of C3 and C4 biochars applied to two di_erent soils. Soil. Tillage Res. 2016, 155, 107–115. [Google Scholar] [CrossRef]

- He, L.; Zhong, Z.; Yang, H. E_ects on soil quality of biochar and straw amendment in conjunction withchemical fertilizers. J. Integr. Agric. 2017, 16, 704–712. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, W.; Liang, G.; Song, D.; Zhang, X. Characteristics of maize biochar with di_erent pyrolysis temperatures and its e_ects on organic carbon, nitrogen and enzymatic activities after addition to fluvo-aquic soil. Sci. Total Environ. 2015, 538, 137–144. [Google Scholar] [CrossRef]

- Głąb, T.; Gondek, K.; Mierzwa-Hersztek, M.; Szewczyk, W. Effects of straw and biochar amendments on grassland productivity and root morphology. Agronomy 2020, 10, 1794. [Google Scholar] [CrossRef]

- Shamim, M.I.A.; Dijkstra, F.A.; Abuyusuf, M.; Hossain, A.I. Synergistic effects of biochar and NPK fertilizer on soybean yield in an alkaline soil. Pedosphere 2015, 25, 713–719. [Google Scholar] [CrossRef]

- Ullah, I.; Muhammad, D.; Mussarat, M.; Khan, S.; Adnan, M.; Fahad, S.; Solaiman, Z. Comparative effects of biochar and NPK on wheat crops under different management systems. Crop Pasture Sci. 2022, 74, 31–40. [Google Scholar] [CrossRef]

- Sarwar, N.; Abbas, N.; Farooq, O.; Akram, M.; Hassan, M.W.; Mubeen, K.; Khaliq, A. Biochar Integrated Nutrient Application Improves Crop Productivity, Sustainability and Profitability of Maize–Wheat Cropping System. Sustainability 2023, 15, 2232. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Phillips, C.L.; Meyer, K.M.; Trippe, K.M. Is biochar applied as surface mulch beneficial for grassland restoration? Geoderma 2020, 375, 114457. [Google Scholar] [CrossRef]

- Graber, E.R.; Meller Harel, Y.; Kolton, M.; Cytryn, E.; Silber, A.; Rav David, D.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Yan, X.; Li, J.; Jiao, N.; Hu, S. Biochar amendments increase the yield advantage of legume-based intercropping systems over monoculture. Agric. Ecosyst. Environ. 2017, 237, 16–23. [Google Scholar] [CrossRef]

- Maiti, S.K.; Ahirwal, J. Ecological restoration of coal mine degraded lands: Topsoil management, pedogenesis, carbon sequestration, and mine pit limnology. In Phytomanagement of Polluted Sites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 83–111. [Google Scholar] [CrossRef]

- United Nations. Department of Economic and Social Affairs. Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 17 March 2023).

- Gaskin, J.W.; Speir, R.A.; Harris, K.; Das, K.C.; Lee, R.D.; Morris, L.A.; Fisher, D.S. Effect of peanut hull and pine chip biochar on soil nutrients, corn nutrient status, and yield. Agron. J. 2010, 102, 623–633. [Google Scholar] [CrossRef]

- Domene, X.; Mattana, S.; Hanley, K.; Enders, A.; Lehmann, J. Medium-term effects of corn biochar addition on soil biota activities and functions in a temperate soil cropped to corn. Soil. Biol. Biochem. 2014, 72, 152–162. [Google Scholar] [CrossRef]

- Feng, W.; Yang, F.; Cen, R.; Liu, J.; Qu, Z.; Miao, Q.; Chen, H. Effects of straw biochar application on soil temperature, available nitrogen and growth of corn. J. Environ. Manag. 2021, 277, 111331. [Google Scholar] [CrossRef] [PubMed]

- Rogovska, N.; Laird, D.A.; Karlen, D.L. Corn and soil response to biochar application and stover harvest. Field Crops Res. 2016, 187, 96–106. [Google Scholar] [CrossRef]

- Lentz, R.D.; Ippolito, J.A.; Spokas, K.A. Biochar and manure effects on net nitrogen mineralization and greenhouse gas emissions from calcareous soil under corn. Soil Sci. Soc. Am. J. 2014, 78, 1641–1655. [Google Scholar] [CrossRef]

- Rafiq, M.K.; Bai, Y.; Aziz, R.; Rafiq, M.T.; Mašek, O.; Bachmann, R.T.; Joseph, S.; Shahbaz, M.; Qayyum, A.; Shang, Z.; et al. Biochar amendment improves alpine meadows growth and soil health in Tibetan plateau over a three year period. Sci. Total Environ. 2020, 717, 135296. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.W.; Chadwick, D.R.; Bott, T.; West, H.M.; Wilson, P.; Hodgins, G.R.; Snape, C.E.; Jones, D.L. Biochar application to temperate grasslands: Challenges and opportunities for delivering multiple ecosystem services. Biochar 2023, 5, 33. [Google Scholar] [CrossRef] [PubMed]

- Mak-Mensah, E.; Zhao, W.; Zhou, X.; Zhang, D.; Zhao, X.; Wang, Q.; Obour, P.B. Influence of tied-ridge with maize straw biochar on alfalfa fodder yield, nutritional quality, and production economics. J. Soil. Sci. Plant Nutr. 2023, 23, 339–350. [Google Scholar] [CrossRef]

- Choudhary, P.; Prasad, M.; Choudhary, M.; Kumar, A.; Kumar, S.; Srinivasan, R.; Mahawer, S.K. Exploring invasive weed biochar as soil amendment: A study on fodder oats productivity and soil biological properties. Environ. Res. 2023, 216, 114527. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Zheng, H.; Jiang, Z.; Xing, B. Combined effects of biochar properties and soil conditions on plant growth: A meta-analysis. Sci. Total Environ. 2020, 713, 136635. [Google Scholar] [CrossRef]

- Linn, J.G.; Martin, N.P. Forage Quality Tests and Interpretations (Revised 1989); University Minnesota, Agricultural Extension Service: Minneapolis, MN, USA, 1989; Available online: https://conservancy.umn.edu/handle/11299/207442 (accessed on 10 February 2023).

- Institute of Meteorology and Water Management—National Research Institute. Available online: https://imgw.pl/ (accessed on 20 February 2023).

- Joseph, S.; Cowie, A.L.; Van Zwieten, L.; Bolan, N.; Budai, A.; Buss, W.; Cayuela, M.L.; Graber, E.R.; Ippolito, J.A.; Kuzyakov, Y.; et al. How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenergy 2021, 13, 1731–1764. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M. Biochar effects on crop yields with and without fertilizer: A meta-analysis of field studies using separate controls. Soil. Use Manag. 2020, 36, 2–18. [Google Scholar] [CrossRef]

- Awad, Y.M.; Wang, J.; Igalavithana, A.D.; Tsang, D.C.; Kim, K.-H.; Lee, S.S.; Ok, Y.S. Biochar effects on rice paddy: Meta-analysis. Adv. Agron. 2018, 148, 1–32. [Google Scholar] [CrossRef]

- Biederman, L.A.; Harpole, W.S. Biochar and its effects on plant productivity and nutrient cycling: A meta-analysis. GCB Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Crane-Droesch, A.; Abiven, S.; Jeffery, S.; Torn, M.S. Heterogeneous global crop yield response to biochar: A meta-regression analysis. Environ. Res. Lett. 2013, 8, 044049. [Google Scholar] [CrossRef]

- Jeffery, S.; Abalos, D.; Prodana, M.; Bastos, A.C.; Van Groenigen, J.W.; Hungate, B.A.; Verheijen, F. Biochar boosts tropical but not temperate crop yields. Environ. Res. Lett. 2017, 12, 053001. [Google Scholar] [CrossRef]

- Nielsen, S.; Minchin, T.; Kimber, S.; van Zwieten, L.; Gilbert, J.; Munroe, P.; Joseph, S.; Thomas, T. Comparative analysis of the microbial communities in agricultural soil amended with en-hanced biochars or traditional fertilisers. Agric. Ecosyst. Environ. 2014, 191, 73–82. [Google Scholar] [CrossRef]

- Prommer, J.; Wanek, W.; Hofhansl, F.; Trojan, D.; Offre, P.; Urich, T.; Schleper, C.; Sassmann, S.; Kitzler, B.; Soja, G.; et al. Biochar Decelerates Soil Organic Nitrogen Cycling but Stimulates Soil Nitrification in a Temperate Arable Field Trial. PLS ONE 2014, 9, e86388. [Google Scholar] [CrossRef]

- Kammann, C.I.; Schmidt, H.-P.; Messerschmidt, N.; Linsel, S.; Steffens, D.; Müller, C.; Koyro, H.-W.; Conte, P.; Joseph, S. Plant growth improvement mediated by nitrate capture in co-composted biochar. Sci. Rep. 2015, 5, 11080. [Google Scholar] [CrossRef]

- van Zwieten, L.; Kimber, S.; Morris, S.; Downie, A.; Berger, E.; Rust, J.; Scheer, C. Influence of biochars on flux of N2O and CO2 from Ferrosol. Aust. J. Soil. Res. 2010, 48, 555–568. [Google Scholar] [CrossRef]

- Reiné, R.; Ascaso, J.; Barrantes, O. Nutritional Quality of Plant Species in Pyrenean Hay Meadows of High Diversity. Agronomy 2020, 10, 883. [Google Scholar] [CrossRef]

- Paszkiewicz-Jasińska, A.; Wróbel, B.; Stopa, W.; Jakubowska, Z.; Steinhoff-Wrześniewska, A.; Zielewicz, W. Nutritional Status of Wood Melick (Melica uniflora Retz.) in a Natural Forest Stand in South-Western Poland. Forests 2023, 14, 1605. [Google Scholar] [CrossRef]

- Buxton, D.R.; Brasche, M.R. Digestibility of structural carbohydrates in cool-season grass and legume forages. Crop Sci. 1991, 31, 1338–1345. [Google Scholar] [CrossRef]

- Kuoppala, K.; Ahvenjarvi, S.; Rinne, M.; Vanhatalo, A. Effects of feeding grass or red clover silage cut at two maturity stages in dairy cows. P. 2. Dry matter intake and cell wall digestion kinetics. J. Dairy. Sci. 2009, 92, 5634–5644. [Google Scholar] [CrossRef] [PubMed]

- Schlegel, P.; Wyss, U.; Arrigo, Y.; Hess, H.D. Mineral concentrations of fresh herbage from mixed grassland as influenced by botanical composition, harvest time and growth stage. Anim. Feed. Sci. Technol. 2016, 219, 226–233. [Google Scholar] [CrossRef]

- Buxton, D.R. Quality-related characteristics of forages as influenced by plant environment and agronomic factors. Anim. Feed. Sci. Technol. 1996, 59, 37–49. [Google Scholar] [CrossRef]

- Rinne, M.; Nykanen, A. Timing of primary growth harvest affects the yield and nutritive value of timothy-red clover mixtures. Agric. Food Sci. Finl. 2000, 9, 121–134. [Google Scholar] [CrossRef]

- Barry, H.; Major, J. Commercial scale agricultural biochar field trial in Québec, Canada over two years: Effects of biochar on soil fertility, biology and crop productivity and quality. Dynamotive Energy Syst. 2010, 1–35. [Google Scholar]

- McDonald, I.; Baral, R.; Min, D. Effects of alfalfa and alfalfa-grass mixtures with nitrogen fertilization on dry matter yield and forage nutritive value. J. Anim. Sci. Technol. 2021, 63, 305–318. [Google Scholar] [CrossRef]

- Dumont, B.; Andueza, D.; Niderkorn, V.; Luscher, A.; Porqueddu, C.; Picon-Cochard, C. A meta-analysis of climate change effects on forage quality in grasslands: Specificities of mountain and Mediterranean areas. Grass Forage Sci. 2015, 70, 239–254. [Google Scholar] [CrossRef]

- Niyigena, V.; Ashworth, A.J.; Nieman, C.; Acharya, M.; Coffey, K.P.; Philipp, D.; Meadors, L.; Sauer, T.J. Factors Affecting Sugar Accumulation and Fluxes in Warm- and Cool-Season Forages Grown in a Silvopastoral System. Agronomy 2021, 11, 354. [Google Scholar] [CrossRef]

- Truba, M.; Sosnowski, J. The effect of Tytanit on fibre fraction content in Medicago x varia T. Martyn and Trifolium pratense L. cell walls. Agriculture 2022, 12, 191. [Google Scholar] [CrossRef]

- Truba, M.; Jankowski, K.; Wiśniewska-Kadżajan, B.; Sosnowski, J.; Malinowska, E. The effect of soil conditioners on the quality of selected forage grasses. Appl. Ecol. Environ. Res. 2020, 18, 5123–5133. [Google Scholar] [CrossRef]

- Bis, Z.; Kobyłecki, R.; Ścisłowska, M.; Zarzycki, R. Biochar–Potential tool to combat climate change and drought. Ecohydrol. Hydrobiol. 2018, 18, 441–453. [Google Scholar] [CrossRef]

- Dickinson, D.; Balduccio, L.; Buysse, J.; Ronsse, F.; Van Huylenbroeck, G.; Prins, W. Cost-benefit analysis of using biochar to improve cereals agriculture. GCB Bioenergy 2015, 7, 850–864. [Google Scholar] [CrossRef]

- Maroušek, J.; Minofar, B.; Maroušková, A.; Strunecký, O.; Gavurová, B. Environmental and economic advantages of production and application of digestate biochar. Environ. Technol. Innov. 2023, 30, 103109. [Google Scholar] [CrossRef]

- Campion, L.; Bekchanova, M.; Malina, R.; Kuppens, T. The costs and benefits of biochar production and use: A systematic review. J. Clean. Prod. 2023, 408, 137138. [Google Scholar] [CrossRef]

- Xiao, L.; Feng, L.; Yuan, G.; Wei, J. Low-cost field production of biochars and their properties. Environ. Geochem. Health 2020, 42, 1569–1578. [Google Scholar] [CrossRef]

| Characteristics | Quantity | Units |

|---|---|---|

| Ash content (550 °C) | 7.9 | % (w/w) |

| Phosphorus (P) | 0.2 | % (w/w) |

| Potassium (K) | 1.8 | % (w/w) |

| Sodium (Na) | <0.1 | % (w/w) |

| Magnesium (Mg) | 0.5 | % (w/w) |

| Iron (Fe) | <0.1 | % (w/w) |

| Sulphur (S) | <0.1 | % (w/w) |

| Silicon (SI) | 0.1 | % (w/w) |

| Grasses | Share in the Mixture % Weight | Legumes | Share in the Mixture % Weight |

|---|---|---|---|

| Lolium perenne L. | 20 | Trifolium repens L. | 5 |

| Festuca arundinacea Schreb. | 15 | Medicago sativa L. | 5 |

| Dectylis glomerata L. | 15 | - | - |

| Lolium multiflorum Lam. | 10 | - | - |

| Phleum pratense L. | 10 | - | - |

| Festuca rubra L. | 10 | - | - |

| Festuca ovina L. | 5 | - | - |

| Poa pratensis L. | 5 | - | - |

| Sum | 90 | - | 10 |

| Treatment | Annual Fertilization Rates kg ha−1 | Biochar Mg ha−1 | ||

|---|---|---|---|---|

| N | P | K | BC | |

| V0 | 0 | 0 | 0 | 0 |

| V1 | 0 | 0 | 0 | 5 |

| V2 | 0 | 0 | 0 | 10 |

| V3 | 60 | 15 | 40 | 0 |

| V4 | 60 | 15 | 40 | 5 |

| V5 | 60 | 15 | 40 | 10 |

| V6 | 90 | 25 | 70 | 0 |

| V7 | 90 | 25 | 70 | 5 |

| V8 | 90 | 25 | 70 | 10 |

| Treatment | Applied NPK Rates g pot−1 | Applied NPK Rates kg ha−1 | ||

|---|---|---|---|---|

| N | P | K | BC | |

| V0, V1, V2 | 0 | 0 | 0 | 0 |

| V3, V4, V5 | 0.5 | 0.35 | 0.3 | 115 |

| V6, V7, V8 | 0.89 | 0.58 | 0.45 | 18 |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 47.6 a | 36.9 b | 42.3 b |

| 5 Mg ha−1 | 55.6 a | 47.1 ab | 51.4 ab | |

| 10 Mg ha−1 | 57.5 a | 53.4 a | 55.4 a | |

| NPK | 0 kg ha−1 | 46.9 a | 36.1 b | 41.5 b |

| 115 kg ha−1 | 54.6 a | 49.1 ab | 51.8 ab | |

| 185 kg ha−1 | 59.1 a | 52.3 a | 55.7 a | |

| H | 1st | 56.8 b | 73.7 a | 65.2 a |

| 2nd | 90.3 a | 29.5 b | 59.9 a | |

| 3rd | 13.6 c | 34.3 b | 23.9 b | |

| Average | 53.6 A | 45.8 B | ||

| Interactions | ||||

| BC | 0.452 | 0.043 | 0.041 | |

| NPK | 0.332 | 0.034 | 0.022 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.832 | 0.064 | 0.049 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 402.0 a | 520.8 a | 461.4 a |

| 5 Mg ha−1 | 399.5 a | 513.2 a | 456.3 a | |

| 10 Mg ha−1 | 389.9 a | 512.1 a | 451.0 a | |

| NPK | 0 kg ha−1 | 387.8 a | 506.9 a | 447.4 a |

| 115 kg ha−1 | 397.9 a | 523.2 a | 460.6 a | |

| 185 kg ha−1 | 405.6 a | 515.9 a | 460.8 a | |

| H | 1st | 390.1 b | 552.3 a | 471.2 b |

| 2nd | 349.5 c | 536.4 b | 494.1 a | |

| 3rd | 451.8 a | 457.4 c | 403.4 c | |

| Average | 397.1 B | 515.4 A | ||

| Interactions | ||||

| BC | 0.545 | 0.799 | 0.742 | |

| NPK | 0.315 | 0.369 | 0.461 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.777 | 0.830 | 0.938 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 307.6 a | 344.9 a | 326.3 a |

| 5 Mg ha−1 | 304.0 a | 347.8 a | 325.9 a | |

| 10 Mg ha−1 | 303.3 a | 349.2 a | 326.3 a | |

| NPK | 0 kg ha−1 | 294.1 b | 352.0 a | 323.1 a |

| 115 kg ha−1 | 307.2 ab | 339.5 b | 323.3 a | |

| 185 kg ha−1 | 313.6 a | 350.5 a | 332.0 a | |

| H | 1st | 330.7 a | 349.3 b | 340.0 b |

| 2nd | 334.3 a | 373.7 a | 354.0 a | |

| 3rd | 249.9 b | 319.0 c | 284.4 c | |

| Average | 305.0 B | 347.3 A | ||

| Interactions | ||||

| BC | 0.918 | 0.796 | 0.999 | |

| NPK | 0.124 | 0.116 | 0.320 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.829 | 0.746 | 0.967 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 41.4 a | 48.5 a | 45.0 a |

| 5 Mg ha−1 | 39.7 a | 49.7 a | 44.7 a | |

| 10 Mg ha−1 | 39.9 a | 50.6 a | 45.3 a | |

| NPK | 0 kg ha−1 | 40.1 a | 52.6 a | 46.4 a |

| 115 kg ha−1 | 39.8 a | 45.7 b | 42.8 b | |

| 185 kg ha−1 | 41.1 a | 50.6 a | 45.9 a | |

| H | 1st | 43.8 b | 44.5 b | 44.2 b |

| 2nd | 46.7 a | 59.6 a | 53.1 a | |

| 3rd | 30.5 c | 44.9 b | 37.7 c | |

| Average | 40.3 B | 49.6 A | ||

| Interactions | ||||

| BC | 0.452 | 0.043 | 0.041 | |

| NPK | 0.332 | 0.034 | 0.022 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.832 | 0.064 | 0.049 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 64.9 a | 62.0 a | 63.5 a |

| 5 Mg ha−1 | 65.2 a | 61.8 a | 63.5 a | |

| 10 Mg ha−1 | 65.3 a | 61.7 a | 63.5 a | |

| NPK | 0 kg ha−1 | 66.0 a | 61.5 b | 63.0 a |

| 115 kg ha−1 | 65.0 ab | 62.5 a | 63.7 a | |

| 185 kg ha−1 | 64.5 b | 61.6 b | 63.7 a | |

| H | 1st | 63.1 b | 61.7 b | 62.4 b |

| 2nd | 62.9 b | 59.8 c | 61.3 c | |

| 3rd | 69.4 a | 64.0 a | 66.7 a | |

| Average | 65.1 A | 61.8 B | ||

| Interactions | ||||

| BC | 0.918 | 0.796 | 0.999 | |

| NPK | 0.124 | 0.116 | 0.320 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.829 | 0.746 | 0.967 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 3.0 a | 2.3 a | 2.7 a |

| 5 Mg ha−1 | 3.1 a | 2.4 a | 2.7 a | |

| 10 Mg ha−1 | 3.1 a | 2.4 a | 2.7 a | |

| NPK | 0 kg ha−1 | 3.1 a | 2.4 a | 2.8 a |

| 115 kg ha−1 | 3.1 a | 2.3 a | 2.7 a | |

| 185 kg ha−1 | 3.0 a | 2.4 a | 2.7 a | |

| H | 1st | 3.1 b | 2.2 c | 2.5 c |

| 2nd | 2.7 c | 2.3 b | 2.6 b | |

| 3rd | 3.4 a | 2.6 a | 3.0 a | |

| Average | 3.1 A | 2.4 B | ||

| Interactions | ||||

| BC | 0.543 | 0.776 | 0.721 | |

| NPK | 0.296 | 0.292 | 0.433 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.737 | 0.768 | 0.928 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

| Factor | Level | Year | Average | |

|---|---|---|---|---|

| 2021 | 2022 | |||

| BC | 0 Mg ha−1 | 153.3 a | 112.1 a | 132.7 a |

| 5 Mg ha−1 | 155.0 a | 113.8 a | 134.4 a | |

| 10 Mg ha−1 | 158.5 a | 113.4 a | 135.9 a | |

| NPK | 0 kg ha−1 | 161.5 a | 114.4 a | 138.0 a |

| 115 kg ha−1 | 154.3 ab | 111.9 a | 133.1 a | |

| 185 kg ha−1 | 151.1 b | 113.0 a | 132.0 a | |

| H | 1st | 151.2 b | 104.3 b | 127.7 b |

| 2nd | 130.4 c | 104.4 b | 117.4 c | |

| 3rd | 185.3 a | 130.6 a | 157.9 a | |

| Average | 155.6 A | 113.1 B | ||

| Interactions | ||||

| BC | 0.670 | 0.927 | 0.816 | |

| NPK | 0.194 | 0.712 | 0.414 | |

| H | <0.001 | <0.001 | <0.001 | |

| BC*NPK | 0.759 | 0.985 | 0.954 | |

| NPK*H | <0.001 | <0.001 | <0.001 | |

| BC*H | <0.001 | <0.001 | <0.001 | |

| BC*NPK*H | <0.001 | <0.001 | <0.001 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stopa, W.; Wróbel, B.; Paszkiewicz-Jasińska, A.; Strzelczyk, M. Effect of Biochar Application and Mineral Fertilization on Biomass Production and Structural Carbohydrate Content in Forage Plant Mixture. Sustainability 2023, 15, 14333. https://doi.org/10.3390/su151914333

Stopa W, Wróbel B, Paszkiewicz-Jasińska A, Strzelczyk M. Effect of Biochar Application and Mineral Fertilization on Biomass Production and Structural Carbohydrate Content in Forage Plant Mixture. Sustainability. 2023; 15(19):14333. https://doi.org/10.3390/su151914333

Chicago/Turabian StyleStopa, Wojciech, Barbara Wróbel, Anna Paszkiewicz-Jasińska, and Maria Strzelczyk. 2023. "Effect of Biochar Application and Mineral Fertilization on Biomass Production and Structural Carbohydrate Content in Forage Plant Mixture" Sustainability 15, no. 19: 14333. https://doi.org/10.3390/su151914333