Environmental Assessment of Demolition Tools Used in Townhouse Demolition: System Dynamics Modeling

Abstract

:1. Introduction

2. Literature Review

2.1. Townhouse Demolition in Bangkok

2.2. Demolition Tools Used in Demolition in Thailand

2.3. Environmental Impacts of Demolition Tools Used in Demolition

2.4. Importance Weights of the Environmental Impacts

3. Research Methodology

3.1. System Dynamics Modeling Approach

3.2. Data Collection Method

3.2.1. Secondary Data Collection

3.2.2. Primary Data Collection

4. Development of an SD Model of the Environmental Impact of Demolition Tools Used in Townhouse Demolition

4.1. Townhouse Demolition Sub-Model

4.2. CO2 Equivalent Emission Percentage Sub-Model

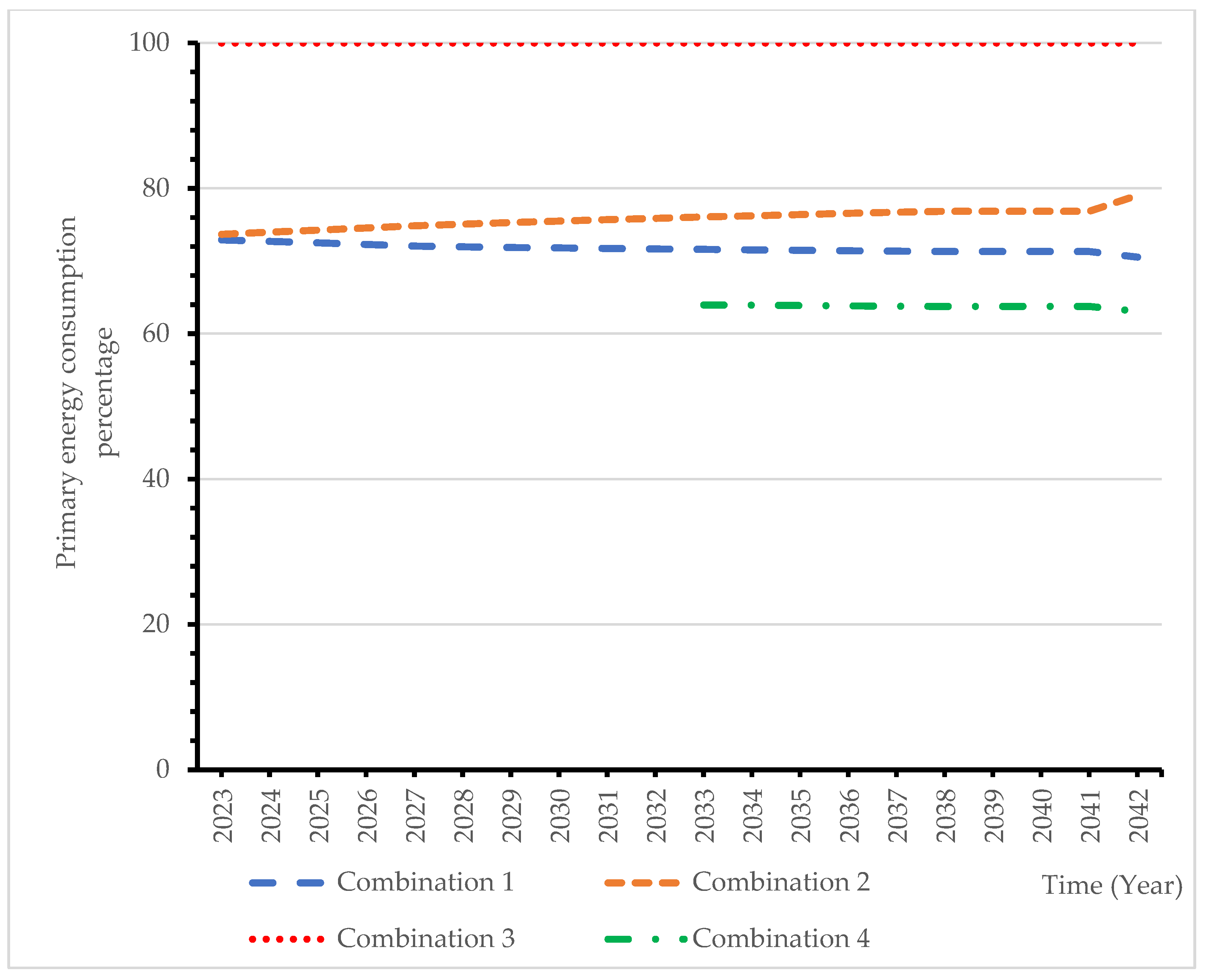

4.3. Primary Energy Consumption Percentage Sub-Model

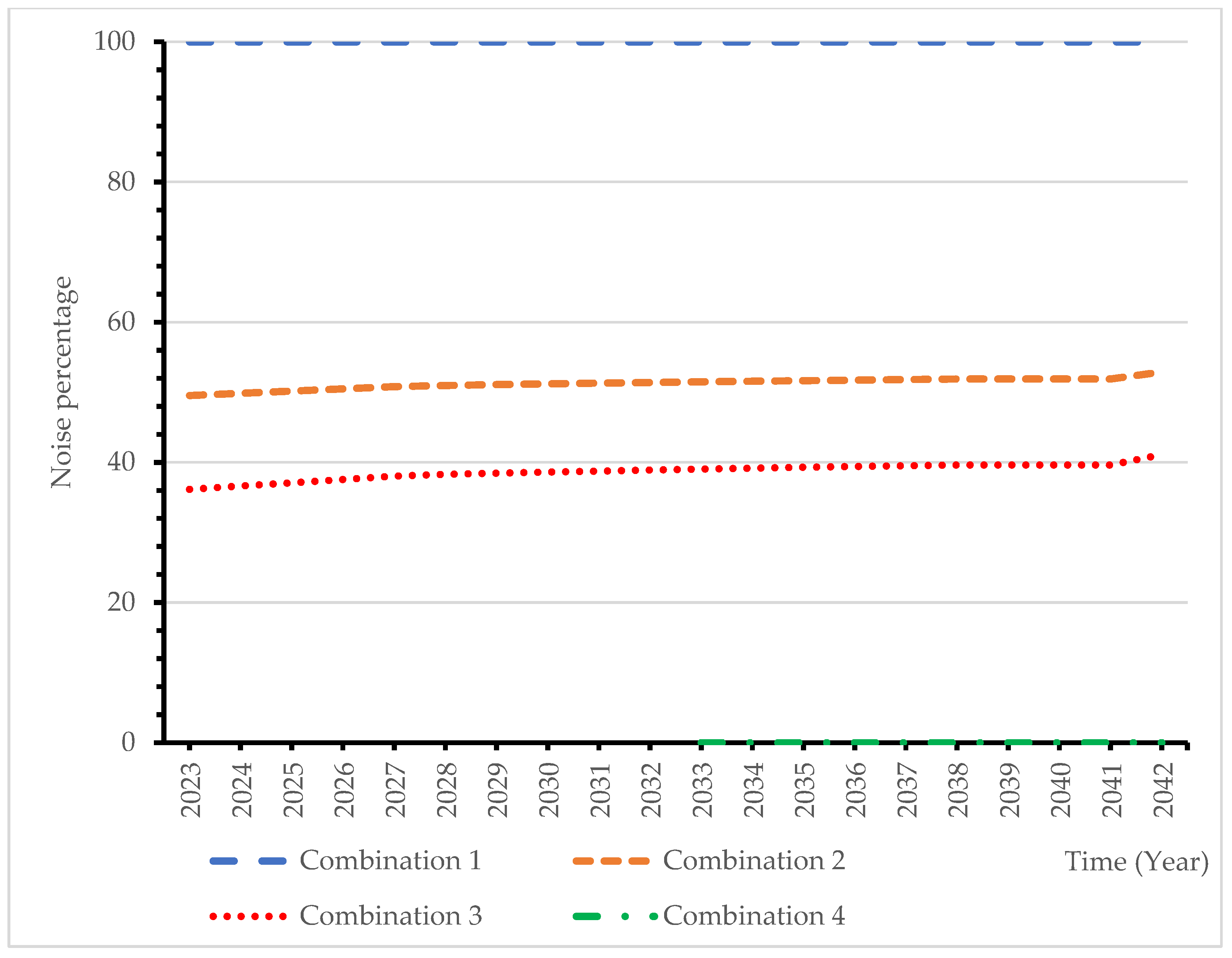

4.4. Noise Percentage Sub-Model

4.5. Dust Percentage Sub-Model

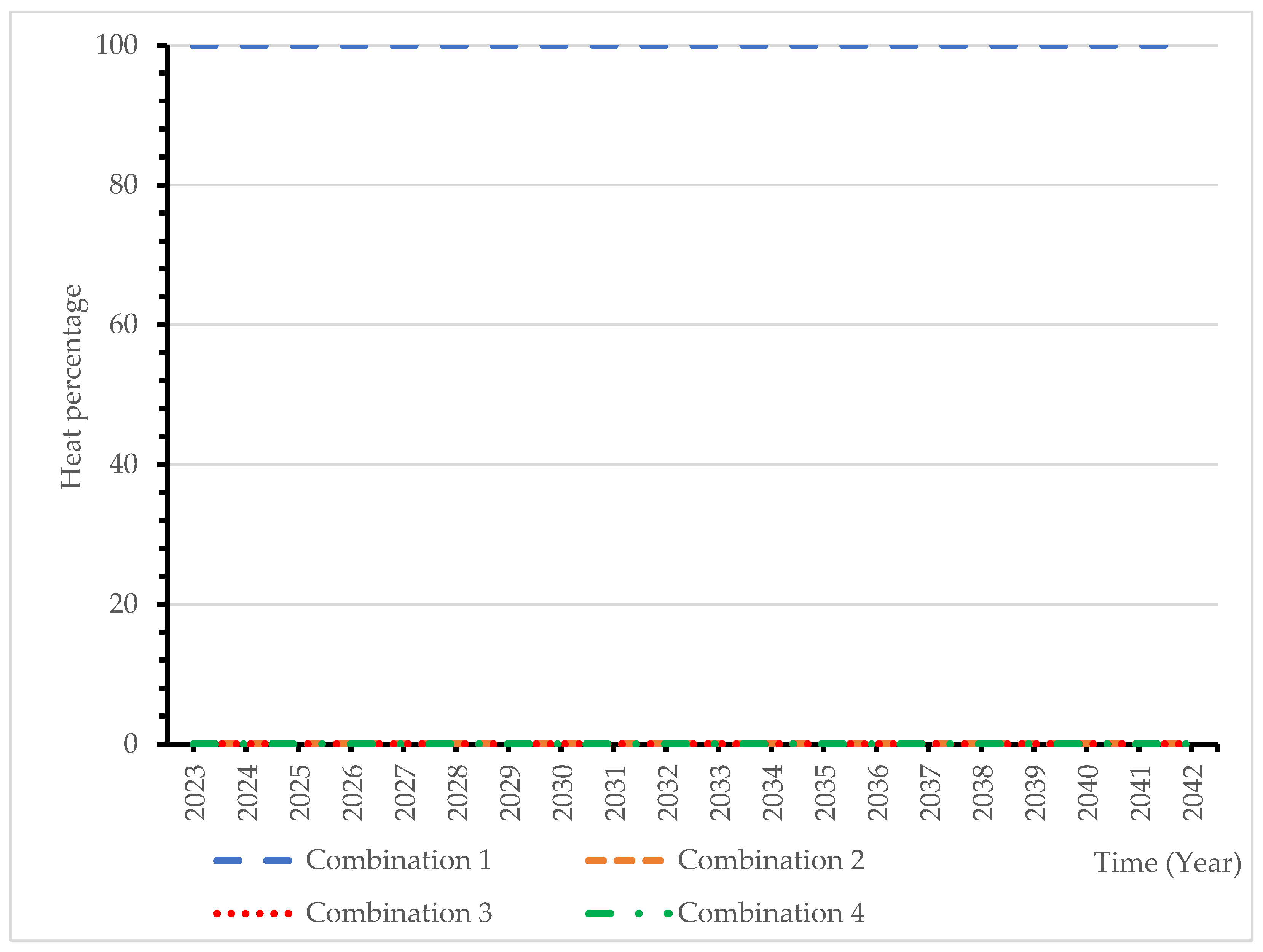

4.6. Heat Percentage Sub-Model

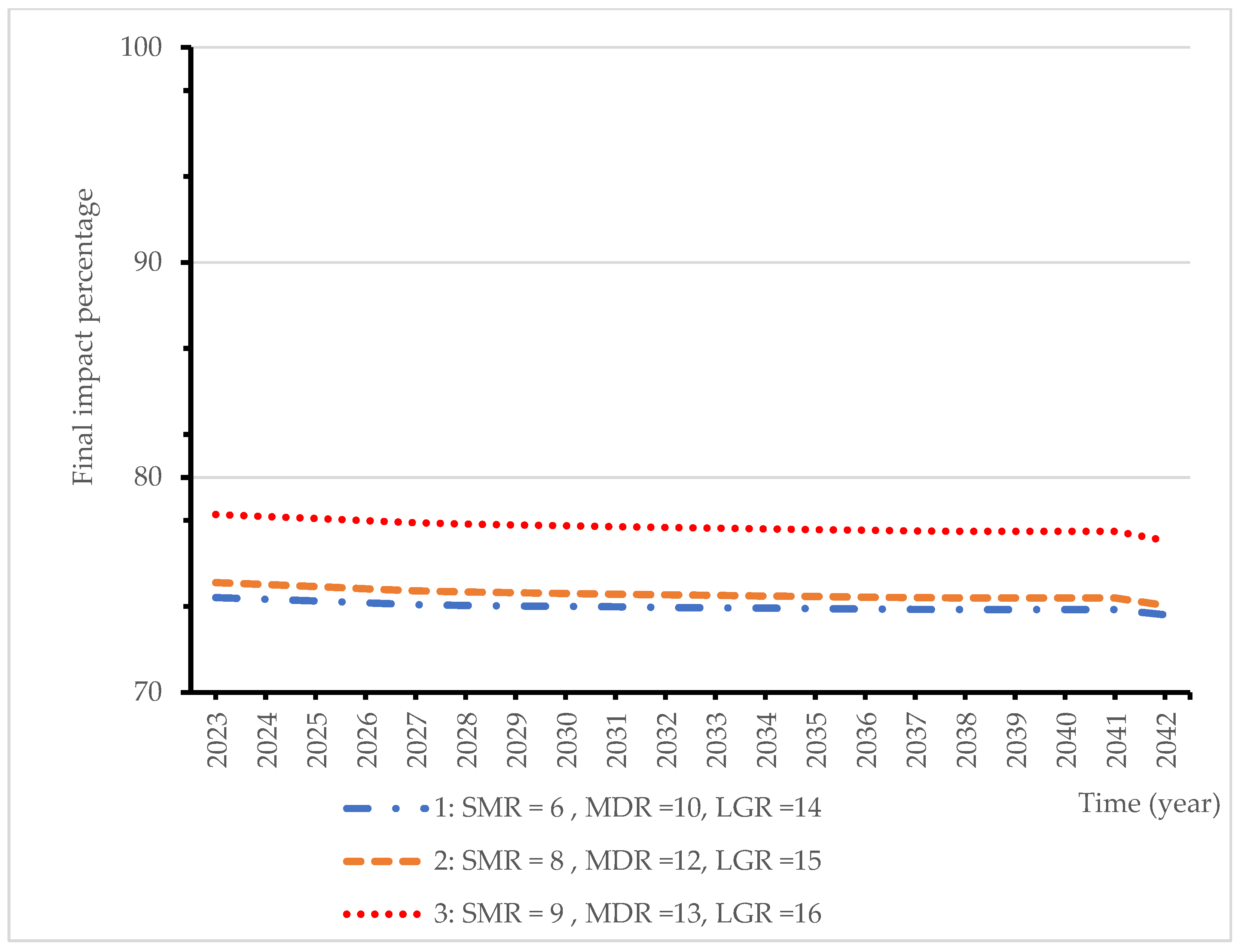

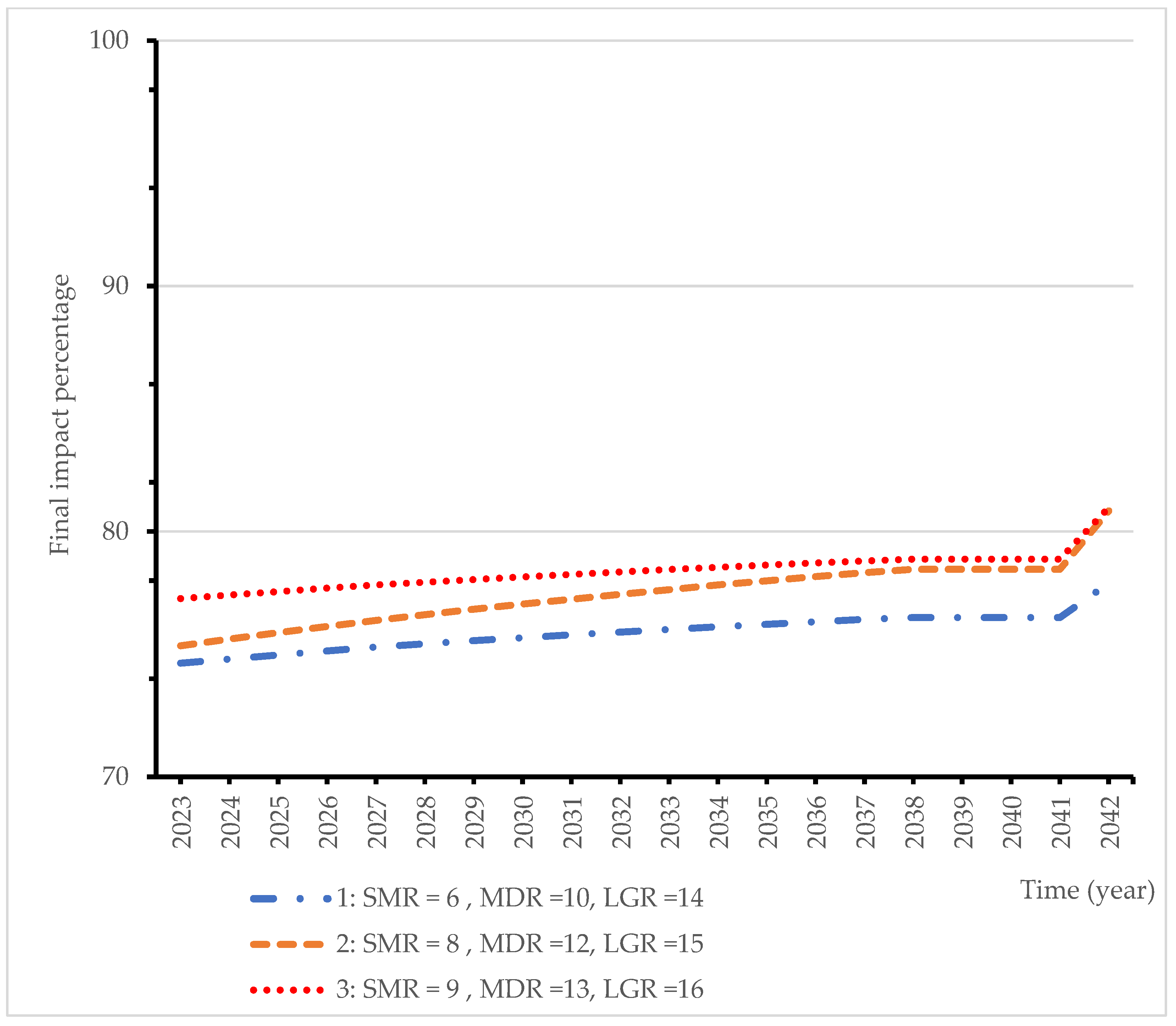

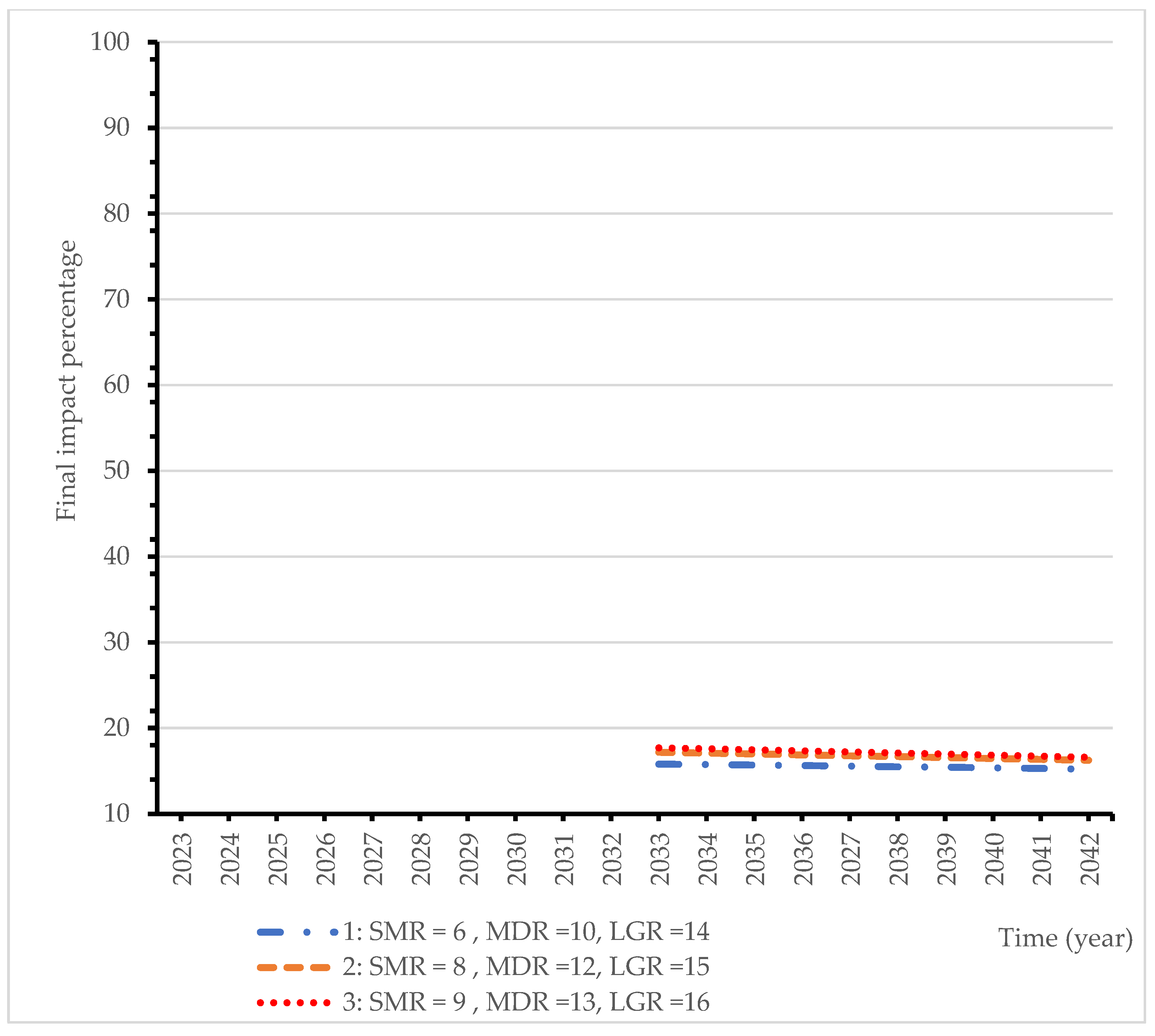

4.7. Final Impact Percentage Sub-Model

5. Results

5.1. Simulation Results

5.2. Model Validation and Sensitivity Analysis

- Its size is more compact than its traditional counterparts, such as excavators and mechanical jackhammering, while its power is much greater.

- It can work continuously without interruption or breaks.

- The remote-controlled aspect of demolition robots provides additional control to features, thus enhancing flexibility and efficiency. It also ensures the safety of operators as it can be controlled from a safe distance from the demolition sites.

- It can engage in high-risk demolition operations and reduce casualties.

- It requires fewer workers, resulting in reduced costs and more safety.

- It reduces the time require for demolition, thereby speeding up the redevelopment process.

6. Discussion and Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Description | Unit |

| BHU | Bangkok housing units | units/year |

| CO2eqDR4 | CO2 equivalent emissions of demolition robots used in Combination 4 | kgCO2eq |

| CO2eqEX1 | CO2 equivalent emissions of excavators used in Combination 1 | kgCO2eq |

| CO2eqEX2 | CO2 equivalent emissions of excavators used in Combination 2 | kgCO2eq |

| CO2eqEX3 | CO2 equivalent emissions of excavators used in Combination 3 | kgCO2eq |

| CO2eqJH1 | CO2 equivalent emissions of jackhammers used in Combination 1 | kgCO2eq |

| CO2eqJH2 | CO2 equivalent emissions of jackhammers used in Combination 2 | kgCO2eq |

| CO2eqHS2 | CO2 equivalent emissions of hydraulic splitters used in Combination 2 | kgCO2eq |

| CO2eqHS3 | CO2 equivalent emissions of hydraulic splitters used in Combination 3 | kgCO2eq |

| CO2eqHS4 | CO2 equivalent emissions of hydraulic splitters used in Combination 4 | kgCO2eq |

| DEX1 | Dust of excavators used in Combination 1 | mg/m3 |

| DEX2 | Dust of excavators used in Combination 2 | mg/m3 |

| DEX3 | Dust of excavators used in Combination 3 | mg/m3 |

| DJH1 | Dust of jackhammers used in Combination 1 | mg/m3 |

| DJH2 | Dust of jackhammers used in Combination 2 | mg/m3 |

| F1C1 | Final impact percentage of Combination 1 | % |

| LTHP | Large townhouses portion from total townhouses | units/year |

| NEX1 | Noise of excavators used in Combination 1 | decibels |

| NEX2 | Noise of jackhammers used in Combination 2 | decibels |

| NEX3 | Noise of excavators used in Combination 3 | decibels |

| NJH1 | Noise of jackhammers used in Combination 1 | decibels |

| MAXTCO2eq | Maximum CO2 equivalent emissions | kgCO2eq |

| MAXTD | Maximum dust | mg/m3 |

| MAXTH | Maximum heat | kJ |

| MAXTN | Maximum noise | decibels |

| MAXTP | Maximum primary energy consumption | kgoe |

| MTHP | Medium townhouses portion from total townhouses | units/year |

| PEX1 | Primary energy consumption of excavators used in Combination 1 | kgoe |

| PEX2 | Primary energy consumption of excavators used in Combination 2 | kgoe |

| PEX3 | Primary energy consumption of excavators used in Combination 3 | kgoe |

| PDR4 | Primary energy consumption of demolition robots used in Combination 4 | kgoe |

| PFC1 | Primary energy consumption of flame cutters used in Combination 1 | kgoe |

| PJH1 | Primary energy consumption of jackhammers used in Combination 1 | kgoe |

| PJH2 | Primary energy consumption of hydraulic splitters used in Combination 2 | kgoe |

| PJH3 | Primary energy consumption of hydraulic splitters used in Combination 3 | kgoe |

| PJH4 | Primary energy consumption of hydraulic splitters used in Combination 4 | kgoe |

| STHP | Small townhouses portion from total townhouses | units/year |

| TCO2eq1 | Total CO2 equivalent emissions of Combination 1 | kgCO2eq |

| TCO2eq2 | Total CO2 equivalent emissions of Combination 2 | kgCO2eq |

| TCO2eq3 | Total CO2 equivalent emissions of Combination 3 | kgCO2eq |

| TCO2eq4 | Total CO2 equivalent emissions of Combination 4 | kgCO2eq |

| TCO2eq1N | Total CO2 equivalent emissions percentage of Combination 1 | % |

| TD1 | Total dust of Combination 1 | mg/m3 |

| TD1N | Total dust percentage of Combination 1 | % |

| TD2 | Total dust of Combination 2 | mg/m3 |

| TD3 | Total dust of Combination 3 | mg/m3 |

| TD4 | Total dust of Combination 4 | mg/m3 |

| TH1 | Total heat of Combination 1 | kJ |

| TH1N | Total heat percentage of Combination 1 | % |

| TH2 | Total heat of Combination 2 | kJ |

| TH3 | Total heat of Combination 3 | kJ |

| TH4 | Total heat of Combination 4 | kJ |

| THD | Townhouses demolished | Units/year |

| THU | Townhouse units | Units/year |

| TN1 | Total noise of Combination 1 | decibels |

| TN2 | Total noise of Combination 2 | decibels |

| TN3 | Total noise of Combination 3 | decibels |

| TN4 | Total noise of Combination 4 | decibels |

| TP1 | Total primary energy consumption of Combination 1 | kgoe |

| TP1N | Total primary energy consumption percentage of Combination 1 | % |

| TP2 | Total primary energy consumption of Combination 2 | kgoe |

| TP3 | Total primary energy consumption of Combination 3 | kgoe |

| TP4 | Total primary energy consumption of Combination 4 | kgoe |

| Yr | Count year | years |

Appendix A

References

- Thailand Essential, Thailand Construction Market Report Overview. 2022. Available online: https://www.marketresearch.com/seek/Construction-Thailand/105/1245/1.html (accessed on 3 September 2023).

- National Housing Authority (NHA). Data Collection Survey on Housing Sector in Thailand; Japan International Cooperation Agency (JICA), International Development Center of Japan, Inc.: Tokyo, Japan, 2013. [Google Scholar]

- Klinmalai, S.; Kiyoko, K. Characteristic of sustainable location for townhouse development in Bangkok and greater metropolitan region, Thailand. In Spatial Planning and Sustainable Development; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar] [CrossRef]

- The Constructor. Demolition Methods and Process for Building Structure. Building Technology Guide. 2022. Available online: https://theconstructor.org/structures/demolition-methods-process-buildings-structures/13941/ (accessed on 3 September 2023).

- Jing, Z.; Wenzhong, Z.; Chonghao, X.; Yiqiang, S. Green Demolition of Reinforced Concrete Structures: Review of Research Findings. Glob. J. Res. Eng. E Civ. Struct. Eng. 2019, 19, 1–18. [Google Scholar]

- Shweta, O.R.; Khandvi, P.V. Demolition of Building an overview. Int. J. Adv. Eng. Res. Dev. 2014, 1, 131–139. [Google Scholar]

- Singh, V.; Rawat, V.; Chavan, O.; Jadhav, R. Selection of Suitable Techniques, Scope and Regulations for Demolition of Rcc Building. Int. J. Res. Eng. Appl. Manag. 2018, 180–184. [Google Scholar]

- Takashima. Demolition Project Report. 2023. Available online: https://courses.nus.edu.sg/course/bdgchewm/PF2107%20%20Demolition/Demolition%20Project%20Report%20Tutorial%204%20Presentation%20Group%202.pdf (accessed on 3 September 2023).

- Rexcon. Building Demolition. 2022. Available online: https://rexcon.business.site/ (accessed on 3 September 2023).

- Aymen, A. Guidelines for Civil Structures Demolition Method selection to enhance Environmental Protection. Int. J. Emerg. Trends Eng. Res. 2020, 8, 11822020. [Google Scholar]

- Abdullah, A.; Anumba, C.J. Decision criteria for the selection of demolition techniques. In Proceeding of the Second International Postgraduate Research Conference, Salford, UK, 11–12 April 2002; Blackwell Publishers: Oxford, UK, 2002; pp. 410–419. [Google Scholar]

- Anumba, J.; Abdulla, A.; Ruika, K. An Integrated System for Demolition Techniques Selection. Archit. Eng. Des. Manag. 2008, 4, 130–148. [Google Scholar] [CrossRef]

- Oryza, S.; Wahyu, T.; Munif, A. Selection Model of Building Demolition Method Based on Expert System. In Proceedings of the Third International Conference on Sustainable Innovation 2019—Technology and Engineering, Yogyakarta, Indonesia, 30–31 July 2019; p. 187. [Google Scholar]

- Macrotrends. Bangkok, Thailand Metro Area Population 1950–2023. Available online: https://www.macrotrends.net/cities/22617/Bangkok/population (accessed on 3 September 2023).

- Bangkok Post. Townhouse Revival. 2023. Available online: https://www.bangkokpost.com/business/1473689/townhouse-revival (accessed on 3 September 2023).

- Risland Thailand. Housing Project by Type. 2023. Available online: https://risland.co.th/en/ (accessed on 3 September 2023).

- Poombete, T.; Krichkanok, S.; Tusanee, T. Waste generated in high-rise buildings. Construction. A current situation in Thailand. Energy Procedia 2017, 138, 411–416. [Google Scholar]

- Abdullah, A. Intelligent Selection of Demolition Techniques. Ph.D. Thesis, Loughborough University, Leicestershire, UK, 2003. [Google Scholar]

- Ronix, Rotary and Demolition Hammers. 2023. Available online: https://ronixtools.com/en/power-tools/rotary-demolition-hammers/ (accessed on 3 September 2023).

- Thomas, S.; LaGuardia, P.E. Concrete Decontamination and Demolition Methods; Nuclear Energy Services, Inc.: Danbury, CT, USA, 2013. [Google Scholar]

- Hemlata, P.; Verma, J.; Surya, S. Environmental Issues: Local, Regional, and Global Environmental Issues; Society of Biological Sciences and Rural Development: Prayagraj, India, 2020; pp. 234–246. [Google Scholar]

- Ram, S.; Pradeep, S. Global Environmental Problem. In Principles and Applications of Environmental Biotechnology for a Sustainable Future; Springer: Singapore, 2020; pp. 13–41. [Google Scholar]

- Chooi, M.; Takeshi, F.; Chin, S. Environmental Impacts of Construction and Demolition Waste Management Alternatives. Chem. Eng. Trans. 2018, 17, 131–139. [Google Scholar]

- Fantozzi, F.; Gargari, C.; Rovai, M.; Salvadori, G. Energy upgrading of residential building stock: Use of life cycle cost analysis to assess interventions om social housing in Italy. Sustainability 2019, 11, 1452. [Google Scholar] [CrossRef]

- Abraham, J.; Saravanakumar, R.; Ebenanjar, P.E.; Elango, K.S.; Vivek, D.; Anandaraj, S. An experimental study on concrete block using construction demolition waste and life cycle cost analysis. Mater. Today Proc. 2022, 6, 1320–1324. [Google Scholar] [CrossRef]

- Coelho, A.; Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal—Part I: Energy consumption and CO2 emissions. J. Waste. Manag. 2013, 33, 1258–1267. [Google Scholar] [CrossRef]

- Jones, M.J.; Smith, J.A. A System Dynamics Model of the Demolition Industry. J. Constr. Eng. Manag. 2005, 131, 1201–1209. [Google Scholar]

- Brown, R.L.; Smith, J.C. A System Dynamics Approach to the Selection of Demolition Methods. J. Constr. Eng. Manag. 2012, 133, 1083–1092. [Google Scholar]

- Jones, M.J.; Smith, J.C. The Impact of Demolition Methods on the Environment. Constr. Build. Mater. 2007, 21, 2559–2567. [Google Scholar]

- Brown, R.L.; Smith, J.C. The Safety of Demolition Workers. Proc. Inst. Civ. Eng. Civ. Eng. 2015, 160, 23–32. [Google Scholar]

- Chadegani, A.; Salehi, H.; Yunus, M.; Farhadi, H.; Fooladi, M.; Farhadi, M. A comparison between two main academic literature collections: Web of science and Scopus Databases. Asian Soc. Sci. 2017, 9, 18–26. [Google Scholar] [CrossRef]

- Burnham, J. Scopus database: A review. Biomed. Digit. Libr. 2006, 3, 1. [Google Scholar] [CrossRef]

- Ali, A.; Ahmad, M.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Sterman, J.D. System Dynamics Modeling for Project Management; Sloan School of Management, Massachusetts Institute of Technology: Cambridge, MA, USA, 1992. [Google Scholar]

- Doan, T.; Chinda, T. Modeling Construction and Demolition Waste Recycling Program in Bangkok: Benefit and Cost Analysis. J. Constr. Eng. Manag. 2016, 142, 05016015. [Google Scholar] [CrossRef]

- Ding, Z.; Gong, W.; Li, S.; Wu, Z. System dynamics versus Agent-based modeling: A review of complex simulation in construction waste management. Sustainability 2018, 10, 2484. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Wang, X. An environmental assessment model of construction and demolition waste based on system dynamics: A case study in Guangzhou. Environ. Sci. Pollut. Res. 2020, 27, 37237–37259. [Google Scholar] [CrossRef]

- Lampyb, B.; Sound Power Level of Powered Mechanical Equipment. Development of Road Quarry Site Investigation, Design, and Construction. 2014. Available online: https://www.epd.gov.hk/eia/register/report/eiareport/eia_2342015/Pdf/EIA/Appendix/Appendix%205.2.pdf (accessed on 3 September 2023).

- Kirkeskov, L.; Hanskov, D.; Brauer, C. Total and respirable dust exposures among carpenters and demolition workers during indoor work in Denmark. J. Occup. Med. Toxicol. 2017, 11, 45. [Google Scholar] [CrossRef]

- CEIC. Thailand Energy and Carbon Dioxide per Electricity Generation; Energy Policy and Planning Office, Ministry of Energy: Bangkok, Thailand, 2022.

- Vevor. Demolition Tools and Equipment. 2023. Available online: https://eur.vevor.com/demolition-tools-equipment-c_10984 (accessed on 3 September 2023).

- Hassanean, J.; Weizhuo, L.; Thomas, O. Quantification of Energy Consumption and Carbon Dioxide Emissions During Excavator Operations. In Proceedings of the 25th EG-ICE International Workshop 2018, Lausanne, Switzerland, 10–13 June 2018. [Google Scholar]

- Replicon. Construction Work Time. 2023. Available online: https://www.replicon.com/time-attendance/construction-time-tracking/ (accessed on 3 September 2023).

- Dworkin, L. Sample Size Policy for Qualitative Studies Using In-Depth Interviews. Arch. Sex. Behav. 2012, 41, 1319–1320. [Google Scholar] [CrossRef]

- Chontanawat, J. Relationship between Energy Consumption, CO2 Emission and Economic Growth in ASEAN: Cointegration and Causality Model. In Proceedings of the 6th International Conference on Energy and Environment Research, ICEER 2019, University of Aveiro, Aveiro, Portugal, 22–25 July 2020. [Google Scholar]

- Bala, K.; Arshad, M.; Noh, M. System Dynamics; Scenario planning and modeling series; Springer: Berlin/Heidelberg, Germany, 2016; pp. 149–162. [Google Scholar]

- Forester, J.; Senge, M. Test for building confidence in system dynamics modelling. TIMS Stud. Manag. Sci. 1980, 14, 209–228. [Google Scholar]

- Ebrahimi, B.; Wallhaum, H.; Jakobsen, D.; Booto, K. Regionalized environmental impacts of construction machinery. Int. J. Life Cycle Assess. 2020, 25, 1472–1485. [Google Scholar] [CrossRef]

- Conexpo. 5 Excavator Technologies to Improve Your Bottom Line. 2022. Available online: https://www.conexpoconagg.com/news/5-excavator-technologies-to-improve-your-bottom-li (accessed on 3 September 2023).

- Conjet. Advantages of a Robotic Demolition Machine. 2023. Available online: https://www.conjet.com/advantages-of-a-robotic-demolition-machine/ (accessed on 3 September 2023).

- Pusapukdepop, J. Pengsaium, V. Measures to Reduce the Impact of Dust from Construction in Bangkok; St. Theresa International College: Nakhon Nayok, Thailand, 2018. [Google Scholar] [CrossRef]

- Department of Trade and Industry. Dust Suppression System for Use in the Demolition of Buildings. 2004. Available online: https://patentimages.storage.googleapis.com/2d/5d/e1/43721f38abbf4c/GB2396381A.pdf (accessed on 3 September 2023).

| Environmental Impact | Frequency | Importance Weight |

|---|---|---|

| CO2 equivalent emission | 65 | 21.7 |

| Primary energy consumption | 19 | 6.3 |

| Noise | 4 | 1.3 |

| Dust | 3 | 1 |

| Heat | 3 | 1 |

| Soil contamination | 0 | 0 |

| Vibration | 0 | 0 |

| Water contamination | 0 | 0 |

| Ocean acidification | 0 | 0 |

| Drought | 0 | 0 |

| Acid rain | 0 | 0 |

| Desertification | 0 | 0 |

| Total | 94 | 31.3 |

| Data | Details | Description | Reference |

|---|---|---|---|

| Housing unit |

|

| [2,3,15,16,17] |

| |||

| |||

| |||

| |||

| |||

| Demolition tools and their environmental impacts |

|

| [20,22,38,39,40,41,42,43] |

|

| ||

|

| ||

|

| ||

|

| ||

| Work time |

|

|

| Information | Interviewee | |||||||

|---|---|---|---|---|---|---|---|---|

| #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | |

| Position | Supervisor | Engineer | Engineer | Supervisor | Supervisor | Engineer | Executive | Engineer |

| Work experience | 15 years | 12 years | 10 years | 15 years | 13 years | 13 years | 15 years | 10 years |

| Involvement in building demolition | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Demolition work | Buildings and bridges | Buildings and retaining walls | Buildings | Buildings | Buildings and bridges | Buildings | Buildings | Buildings |

| Combination of demolition tools | Excavators, jackhammers, and flame cutters | Excavators, jackhammers, and flame cutters | Excavators, jackhammers, and flame cutters | Excavators, jackhammers, and hydraulic splitters | Excavators, jackhammers, and hydraulic splitters | Excavators, jackhammers, and hydraulic splitters | Excavators, and hydraulic splitters | Excavators, and hydraulic splitters |

| Demolition time for different townhouse sizes | Small: 8 days Medium: 12 days Large: 16 days | Small: 7 days Medium: 10 days Large: 15 days | Small: 8 days Medium: 12 days Large: 16 days | Small: 7 days Medium: 13 days Large: 15 days | Small: 8 days Medium: 11 days Large: 16 days | Small: 8 days Medium: 12 days Large: 16 days | Small: 6 days Medium: 12 days Large: 14 days | Small: 9 days Medium: 13 days Large: 16 days |

| Knowledge of demolition robots | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Detail | Combination | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Demolition tools |

|

|

|

|

| Number of tools used for demolition |

|

|

|

|

|

|

|

| |

|

|

|

| |

| Work rate based on total work time |

|

|

|

|

| Year | STHD (Units) | MTHD (Units) | LTHD (Units) | THD (Units) |

|---|---|---|---|---|

| 2023 | 2159 | 993 | 931 | 4083 |

| 2024 | 2295 | 1008 | 909 | 4212 |

| 2025 | 2440 | 1018 | 887 | 4345 |

| 2026 | 2594 | 1023 | 865 | 4482 |

| 2027 | 2757 | 1022 | 844 | 4623 |

| 2028 | 2861 | 1083 | 824 | 4768 |

| 2029 | 2951 | 1163 | 804 | 4918 |

| 2030 | 3044 | 1245 | 784 | 5073 |

| 2031 | 3140 | 1328 | 765 | 5233 |

| 2032 | 3239 | 1412 | 747 | 5398 |

| 2033 | 3341 | 1498 | 729 | 5568 |

| 2034 | 3446 | 1586 | 711 | 5744 |

| 2035 | 3554 | 1676 | 694 | 5924 |

| 2036 | 3667 | 1767 | 677 | 6111 |

| 2037 | 3782 | 1861 | 661 | 6304 |

| 2038 | 3901 | 1951 | 650 | 6502 |

| 2039 | 4024 | 2012 | 671 | 6707 |

| 2040 | 4151 | 2075 | 692 | 6918 |

| 2041 | 4282 | 2141 | 714 | 7136 |

| 2042 | 4417 | 2771 | 173 | 7361 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayowa, B.; Chinda, T. Environmental Assessment of Demolition Tools Used in Townhouse Demolition: System Dynamics Modeling. Sustainability 2023, 15, 14382. https://doi.org/10.3390/su151914382

Mayowa B, Chinda T. Environmental Assessment of Demolition Tools Used in Townhouse Demolition: System Dynamics Modeling. Sustainability. 2023; 15(19):14382. https://doi.org/10.3390/su151914382

Chicago/Turabian StyleMayowa, Bamisaye, and Thanwadee Chinda. 2023. "Environmental Assessment of Demolition Tools Used in Townhouse Demolition: System Dynamics Modeling" Sustainability 15, no. 19: 14382. https://doi.org/10.3390/su151914382