Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete

Abstract

:1. Introduction

2. Experimental design

2.1. Materials

2.2. General Philosophy and Mixture Proportioning of Pervious Concrete

2.3. Mixing, Casting, and Compacting Procedures

2.4. Test Methods

2.4.1. Tests on Fresh Concrete

2.4.2. Tests of Mechanical Properties and Abrasion Resistance

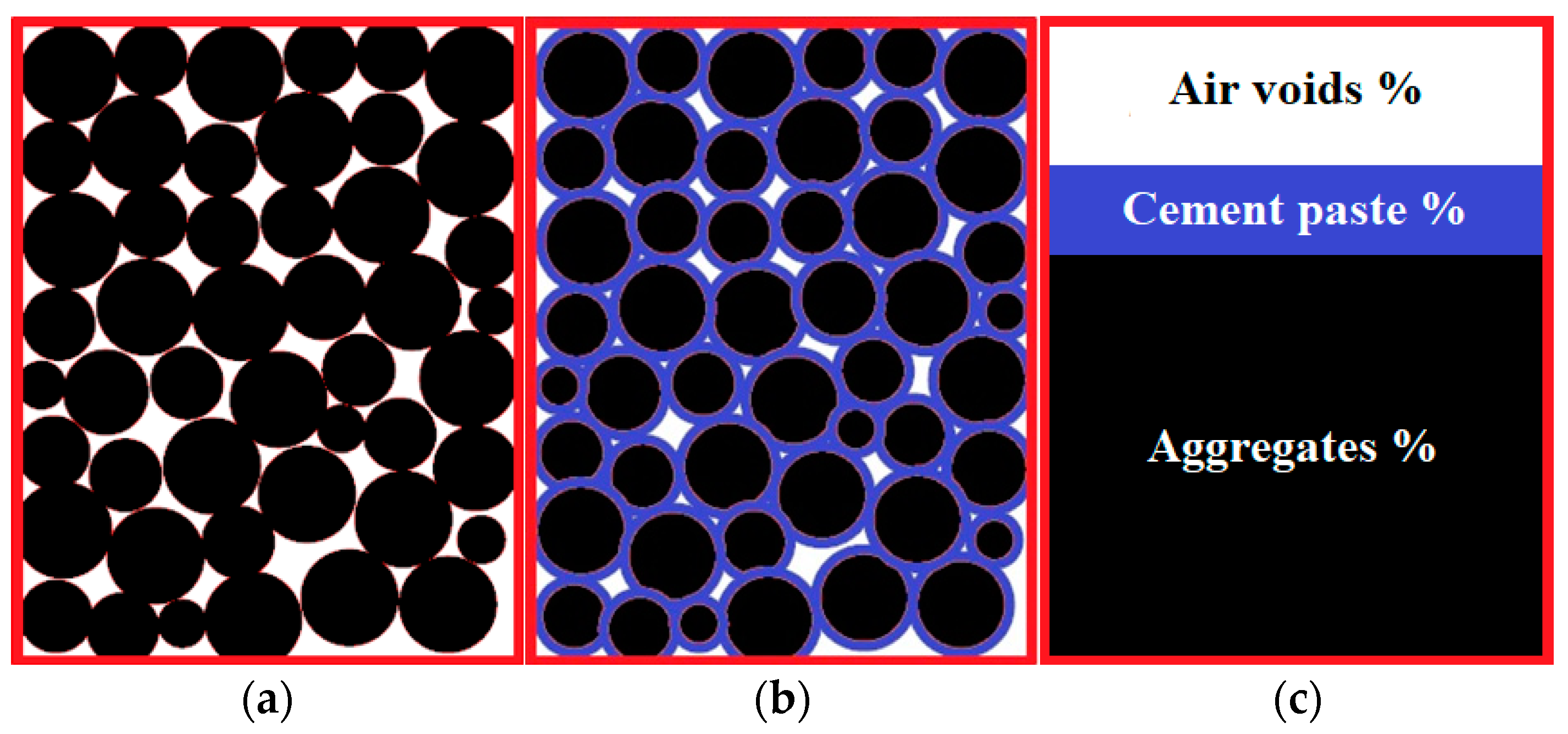

2.4.3. Tests on Porosity and Hydraulic Conductivity

3. Results and Discussion

3.1. Properties of Fresh Pervious Concrete

3.2. Properties of Hardened Pervious Concrete

3.2.1. Hardened Concrete Density

3.2.2. Compressive Strength

3.2.3. Splitting Tensile Strength

3.2.4. Abrasion Resistance

3.3. Porosity and Hydraulic Conductivity

4. Conclusions

- The workability of the pervious concrete was significantly affected by the binder content rather than the aggregate size. The results obtained from the compacting factor test are within the range of 0.70–0.98, which shows that this test method is suitable for testing fresh pervious concrete and can be used for pavement and other reinforced concrete works.

- The applied compaction energy influenced the density of the concrete; the density increased by around 9% as the applied specific energy increased from 99.3 KJ/m3 to 496.9 KJ/m3.

- The compressive strength was notably affected by the aggregate size; the compressive strength of the concrete samples with 8/16 mm aggregates exhibited 20–40% lower values than the samples with 4/8 mm aggregates.

- The test results exhibited a good correlation between the strength and the density of the concrete samples. The strength increased as the density of the pervious concrete sample increased.

- The cement and void contents played a more significant role in determining the splitting tensile strength than the size of the aggregates. The improvement in strength ranged from 25% to 75% as the cement content increased by 35–78 kg/m3.

- The concrete with 8/16 mm aggregates possessed lower abrasion resistance (90–220%) compared with the samples produced with smaller aggregates. Hence, the effect of aggregate size on the abrasion resistance of the pervious concrete is more prominent.

- The measured porosity of the concrete samples obtained using standard compaction was always less than the designed porosity, and this variation ranged from 10% to 40%.

- Even with high compaction, the samples exhibited hydraulic conductivity within the accepted range (3.5–35.2 mm/s). Hence, a designed porosity of 13.5% and above is recommended to achieve sufficient hydraulic conductivity for pervious concrete.

- The experimental investigation concluded that the utilisation of smaller aggregates (4/8 mm) in pervious concrete significantly improved the strength properties and simultaneously slightly reduces the hydraulic conductivity. The reduction in hydraulic conductivity of the samples with 4/8 mm aggregates was less significant than that observed in the samples produced with larger aggregates (8/16 mm) and was highly influenced by the porosity of the pervious concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bright Singh, S.; Murugan, M. Effect of Aggregate Size on Properties of Polypropylene and Glass Fibre-Reinforced Pervious Concrete. Int. J. Pavement Eng. 2020, 23, 2034–2048. [Google Scholar] [CrossRef]

- Ning, X.; Michelle, A.; Xianming, S. Permeable Concrete Pavements: A Review of Environmental Benefits and Durability. J. Clean. Prod. 2019, 210, 1605–1621. [Google Scholar] [CrossRef]

- Gaedicke, C.; Marines, A.; Mata, L.; Miankodila, F. Effect of Recycled Materials and Compaction Methods on the Mechanical Properties and Solar Reflectance Index of Pervious Concrete. Rev. Ing. Construcción 2015, 30, 159–167. [Google Scholar] [CrossRef] [Green Version]

- Golden, J.S.; Kaloush, K.E. Mesoscale and Microscale Evaluation of Surface Pavement Impacts on the Urban Heat Island Effects. Int. J. Pavement Eng. 2006, 7, 37–52. [Google Scholar] [CrossRef]

- Šešlija, M.M.; Radonjanin, V.S.; Radović, N.M.; Lađinović, Đ.Ž. Porosity Effect on Physical and Mechanical Properties of Pervious Concrete Pavement. In Proceedings of the IV International Conference on Road and Rail Infrastructure, Šibenik, Croatia, 23–25 May 2016; Lakušić, S., Ed.; University of Zagreb: Zagreb, Croatia, 2016; pp. 203–208. [Google Scholar]

- Putman, B.J.; Neptune, A.I. Comparison of Test Specimen Preparation Techniques for Pervious Concrete Pavements. Constr. Build. Mater. 2011, 25, 3480–3485. [Google Scholar] [CrossRef]

- Brake, N.A.; Allahdadi, H.; Adam, F. Flexural Strength and Fracture Size Effects of Pervious Concrete. Constr. Build. Mater. 2016, 113, 536–543. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 522R-10 Report on Pervious Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Chandrappa, A.K.; Biligiri, K.P. Investigation on Flexural Strength and Stiffness of Pervious Concrete for Pavement Applications. Adv. Civ. Eng. Mater. 2018, 7, 223–242. [Google Scholar] [CrossRef]

- Lee, M.-G.; Wang, W.-C.; Wang, Y.-C.; Hsieh, Y.-C.; Lin, Y.-C. Mechanical Properties of High-Strength Pervious Concrete with Steel Fiber or Glass Fiber. Buildings 2022, 12, 620. [Google Scholar] [CrossRef]

- Liu, R.; Chi, Y.; Jiang, Q.; Meng, X.; Wu, K.; Li, S. Physical and Mechanical Properties of Pervious Concrete with Multi-Admixtures. Mag. Concr. Res. 2021, 73, 448–463. [Google Scholar] [CrossRef]

- Seifeddine, K.; Amziane, S.; Toussaint, E. State of the Art on the Mechanical Properties of Pervious Concrete. Eur. J. Environ. Civ. Eng. 2021, 26, 7727–7755. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K.; Tsai, C.-Y. Mix Design and Mechanical Properties of High-Performance Pervious Concrete. Materials 2019, 12, 2577. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of Aggregate Size on Compressive Strength of Pervious Concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Chen, J.; Du, W.; Zhao, G.; Shi, M.; Xue, B. Effect of Aggregate Size and Water/Cement on Compressive Strength and Physiological Performance of Planting Concrete. Materials 2022, 15, 6685. [Google Scholar] [CrossRef] [PubMed]

- Sahdeo, S.K.; Ransinchung, G.D.R.N.; Rahul, K.L.; Debbarma, S. Effect of Mix Proportion on the Structural and Functional Properties of Pervious Concrete Paving Mixtures. Constr. Build. Mater. 2020, 255, 119260. [Google Scholar] [CrossRef]

- Juradin, S.; Mihanovic, F.; Ostojic-Škomrlj, N.; Rogošic, E. Pervious Concrete Reinforced with Waste Cloth Strips. Sustainability 2022, 14, 2723. [Google Scholar] [CrossRef]

- Kevern, J.T.; Biddle, D.; Cao, Q. Effects of Macrosynthetic Fibers on Pervious Concrete Properties. J. Mater. Civil Eng. 2015, 27, 06014031. [Google Scholar] [CrossRef]

- Guo, L.; Guan, Z.; Guo, L.; Shen, W.; Xue, Z.; Chen, P.; Li, M. Effects of Recycled Aggregate Content on Pervious Concrete Performance. J. Renew. Mater. 2020, 8, 1711–1727. [Google Scholar] [CrossRef]

- Deb, P.; Debnath, B.; Hasan, M.; Alqarni, A.S.; Alaskar, A.; Alsabhan, A.H.; Khan, M.A.; Alam, S.; Hashim, K.S. Development of Eco-Friendly Concrete Mix Using Recycled Aggregates: Structural Performance and Pore Feature Study Using Image Analysis. Materials 2022, 15, 2953. [Google Scholar] [CrossRef]

- Kaplan, G.; Gulcan, A.; Cagdas, B.; Bayraktar, O.Y. The Impact of Recycled Coarse Aggregates Obtained from Waste Concretes on Lightweight Pervious Concrete Properties. Environ. Sci. Pollut. Res. 2021, 28, 17369–17394. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Lu, Q.; Yang, J.; Wang, T. Effect of Different Admixtures on Pore Characteristics, Permeability, Strength, and Anti-Stripping Property of Porous Concrete. Buildings 2022, 12, 1020. [Google Scholar] [CrossRef]

- Sahdeo, S.K.; Chandrappa, A.; Biligiri, K.P. Effect of Compaction Type and Compaction Efforts on Structural and Functional Properties of Pervious Concrete. Transp. Dev. Econ. 2021, 7, 19. [Google Scholar] [CrossRef]

- Ansari, A.; Mahajan, M. Influence of Compaction Methods on Functional and Structural Performance of Pervious Concrete. Int. J. Civ. Eng. Technol. 2020, 11, 94–105. [Google Scholar] [CrossRef]

- Anburuvel, A.; Subramaniam, D.N. Influence of Aggregate Gradation and Compaction on Compressive Strength and Porosity Characteristics of Pervious Concrete. Int. J. Pavement Eng. 2022, 1–14. [Google Scholar] [CrossRef]

- HRN EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Croatian Standards Institute: Zagreb, Croatia, 2012.

- HRN EN 12620:2013; Aggregates for Concrete. Croatian Standards Institute: Zagreb, Croatia, 2013.

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- HRN EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. Croatian Standards Institute: Zagreb, Croatia, 2019.

- BS EN 12350-2:2019; Testing Fresh Concrete Part 2: Slump-Test. The British Standards Institution: London, UK, 2019.

- Kevern, J.T.; Schaefer, V.R.; Wang, K. Mixture Proportion Development and Performance Evaluation of Pervious Concrete for Overlay Applications. ACI Mater. J. 2011, 108, 439–448. [Google Scholar]

- Tennis, P.D.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavement; Portland Cement Association: Skokie, IL, USA, 2004; Volume 8. [Google Scholar]

- The Concrete Promotional Group of Greater Kansas City; MO/KS American Concrete Pavement Association. Specifiers Guide to Pervious Concrete Pavements; ACPA: Lenexa, KS, USA, 2017. [Google Scholar]

- BS 1881-103:1993; Testing Concrete—Part 103: Method for Determination of Compacting Factor. The British Standards Institution: London, UK, 1993.

- HRN EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. Croatian Standards Institute: Zagreb, Croatia, 2019.

- HRN EN 12390-6:2010; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. Croatian Standards Institute: Zagreb, Croatia, 2010.

- Dong, Q.; Wu, H.; Huang, B.; Shu, X.; Kejin, W. Investigation into Laboratory Abrasion Test Methods for Pervious Concrete. J. Mater. Civ. Eng. 2013, 25, 886–892. [Google Scholar] [CrossRef]

- HRN EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. Croatian Standards Institute: Zagreb, Croatia, 2019.

- ASTM D5084-16; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2016.

- Sandoval, G.F.B.; Galobardes, I.; Teixeira, R.S.; Toralles, B.M. Comparison between the Falling Head and the Constant Head Permeability Tests to Assess the Permeability Coe Ffi Cient of Sustainable Pervious Concretes. Case Stud. Constr. Mater. 2017, 7, 317–328. [Google Scholar] [CrossRef]

- Yalley, P.P.; Sam, A. Effect of Sand Fines and Water/Cement Ratio on Concrete Properties. Civ. Eng. Res. J. 2018, 4, 555636. [Google Scholar] [CrossRef] [Green Version]

- Falade, F. Influence of Water/Cement Ratios and Mix Proportions on Workability and Characteristic Strength of Concrete Containing Laterlte Fine Aggregate. Build. Environ. 1994, 29, 237–240. [Google Scholar] [CrossRef]

- Elizondo-Martinez, E.-J.; Ossa-Lopez, A.; Rodriguez-Hernandez, J. Evaluation of the Effect of Different Compaction Methods on Porous Concrete Pavements: Correlation with Strength and Permeability. J. Mater. Civ. Eng. 2021, 33, 04021184. [Google Scholar] [CrossRef]

- IS 456:2000; reaffirmed 2021. Plain and Reinforced ConcreteCode of Practice. Bureau of Indian Standards: New Delhi, India, 2021.

- Hu, J.H.; Kuang, Y.; Zhou, T.; Zhao, F. Influence of Air Entraining Agent on Strength and Microstructure Properties of Cemented Paste Backfill. IEEE Access 2019, 7, 140899–140907. [Google Scholar] [CrossRef]

- Leon Raj, J.; Chockalingam, T. Strength and Abrasion Characteristics of Pervious Concrete. Road Mater. Pavement Des. 2020, 21, 2180–2197. [Google Scholar] [CrossRef]

- Torres, A.; Gaedicke, C.; Hu, J.; Bejugam, R.; McMasters, S. Comparing Design Void Content with Actual Void Content of Laboratory Prepared Pervious Concrete. Mater. Sci. Appl. 2018, 9, 596–613. [Google Scholar] [CrossRef]

- Liu, R.; Chi, Y.; Chen, S.; Jiang, Q.; Meng, X.; Wu, K.; Li, S. Influence of Pore Structure Characteristics on the Mechanical and Durability Behavior of Pervious Concrete Material Based on Image Analysis. Int. J. Concr. Struct. Mater. 2020, 14, 29. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | SO3 | Fe2O3 | MgO | Insoluble Residue | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| 59.17% | 20.22% | 5.35% | 3.00% | 2.35% | 2.50% | 0.25% | 5.00% |

| Initial Setting Time (Minutes) | Final Setting Time (Minutes) | Soundness (mm) | Specific Gravity (g/cm3) | Standard Consistency (%) | Residue on 45 µm Sieve (%) |

|---|---|---|---|---|---|

| 190 | 260 | 0 | 3.10 | 25 | 11 |

| Properties | 0/4 mm | 4/8 mm | 8/16 mm |

|---|---|---|---|

| Saturated surface dry density | 2620 kg/m3 | 2630 kg/m3 | 2620 kg/m3 |

| Water absorption | 1.4% | 1.3% | 1.1% |

| Crushing value | - | 24.3% | 24.3% |

| Shape index | - | 10 | 15 |

| Flakiness index | - | 13 | 12 |

| Mix ID | Porosity (%) | Cement (kg/m3) | Aggregate (kg/m3) | Water (kg/m3) | W/C Ratio | SP (kg/m3) | AEA (kg/m3) | ||

|---|---|---|---|---|---|---|---|---|---|

| 0/4 mm | 4/8 mm | 8/16 mm | |||||||

| PC1 | 20.0 | 339.26 | - | 1530.66 | - | 108.56 | 0.32 | - | - |

| PC2 | 20.0 | 339.26 | - | - | 1524.84 | 108.56 | 0.32 | - | - |

| PC3 | 16.1 | 321.47 | 146.42 | 1464.41 | - | 122.16 | 0.38 | - | - |

| PC4 | 17.5 | 339.26 | - | 796.95 | 796.95 | 108.56 | 0.32 | - | - |

| PC5 | 15.0 | 417.07 | - | 1530.66 | - | 133.46 | 0.32 | - | - |

| PC6 | 15.0 | 417.07 | - | - | 1524.84 | 133.46 | 0.32 | - | - |

| PC7 | 20.8 | 359.00 | - | 1530.66 | - | 90.46 | 0.25 | 3.05 | - |

| PC8 | 20.8 | 359.00 | - | - | 1524.84 | 90.46 | 0.25 | 3.05 | - |

| PC9 | 13.7 | 355.97 | 146.42 | 1464.41 | - | 135.27 | 0.38 | - | - |

| PC10 | 13.5 | 400.57 | - | 796.95 | 796.95 | 128.18 | 0.32 | - | - |

| PC11 | 13.5 | 400.57 | - | 796.95 | 796.95 | 128.18 | 0.32 | - | 0.30 |

| Mix ID | Slump (mm) | Compacting Factor | Fresh Concrete Density (kg/m3) | |||

|---|---|---|---|---|---|---|

| Tamping Rod | 5 Drops | 15 Drops | 25 Drops | |||

| PC1 | 180 | 0.814 | 1848 | 1731 | 1867 | 1897 |

| PC2 | 180 | 0.804 | 1792 | 1692 | 1808 | 1846 |

| PC3 | 160 | 0.923 | 1884 | 1851 | 1961 | 1982 |

| PC4 | 160 | 0.785 | 1846 | 1740 | 1881 | 1942 |

| PC5 | 140 | 0.797 | 1962 | 1837 | 1968 | 2011 |

| PC6 | 145 | 0.777 | 1859 | 1773 | 1884 | 1909 |

| PC7 | 180 | 0.842 | 1880 | 1788 | 1888 | 1931 |

| PC8 | 175 | 0.849 | 1769 | 1729 | 1819 | 1870 |

| PC9 | 155 | 0.883 | 1895 | 1810 | 1902 | 1972 |

| PC10 | 155 | 0.784 | 1877 | 1785 | 1885 | 1960 |

| PC11 | 160 | 0.805 | 1897 | 1808 | 1920 | 1989 |

| Mix ID | Hardened Concrete Density (kg/m3) | |||

|---|---|---|---|---|

| Tamping Rod | 5 Drops | 15 Drops | 25 Drops | |

| PC1 | 1898 | 1762 | 1897 | 1928 |

| PC2 | 1813 | 1711 | 1829 | 1864 |

| PC3 | 1947 | 1891 | 2003 | 2024 |

| PC4 | 1902 | 1766 | 1910 | 1975 |

| PC5 | 2030 | 1872 | 2017 | 2050 |

| PC6 | 1921 | 1791 | 1922 | 1930 |

| PC7 | 1970 | 1835 | 1958 | 1984 |

| PC8 | 1862 | 1753 | 1843 | 1895 |

| PC9 | 1972 | 1849 | 1970 | 2011 |

| PC10 | 1973 | 1850 | 1975 | 2020 |

| PC11 | 1990 | 1865 | 1988 | 2032 |

| Mix ID | 7 Days Compressive Strength (MPa) | 28 Days Compressive Strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| Tamping Rod | 5 Drops | 15 Drops | 25 Drops | Tamping Rod | 5 Drops | 15 Drops | 25 Drops | |

| PC1 | 12.30 | 8.07 | 12.73 | 13.44 | 13.03 | 9.44 | 13.56 | 14.53 |

| PC2 | 8.95 | 6.26 | 10.03 | 9.88 | 9.70 | 7.68 | 10.58 | 11.73 |

| PC3 | 15.14 | 11.60 | 15.23 | 15.31 | 17.02 | 13.30 | 17.88 | 18.93 |

| PC4 | 10.60 | 7.82 | 11.62 | 13.06 | 12.14 | 8.40 | 13.14 | 15.87 |

| PC5 | 17.55 | 11.99 | 19.05 | 19.69 | 21.37 | 14.39 | 22.16 | 24.40 |

| PC6 | 13.48 | 9.80 | 11.72 | 12.35 | 16.32 | 10.09 | 14.13 | 13.94 |

| PC7 | 14.63 | 14.35 | 18.44 | 20.47 | 18.05 | 15.14 | 20.41 | 22.70 |

| PC8 | 9.66 | 8.30 | 12.92 | 14.72 | 11.73 | 8.94 | 13.43 | 15.34 |

| PC9 | 12.02 | 10.35 | 12.62 | 12.74 | 14.52 | 11.60 | 14.84 | 15.98 |

| PC10 | 14.38 | 11.57 | 15.14 | 15.82 | 15.71 | 12.69 | 16.02 | 17.87 |

| PC11 | 15.14 | 12.08 | 16.03 | 16.85 | 17.57 | 14.76 | 17.88 | 18.50 |

| Mix ID | 7 Days Splitting Tensile Strength (MPa) | 28 Days Splitting Tensile Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| Tamping Rod | 5 Drops | 25 Drops | Tamping Rod | 5 Drops | 25 Drops | |

| PC1 | 1.45 | 1.25 | 2.00 | 1.70 | 1.68 | 2.40 |

| PC2 | 1.60 | 1.10 | 2.00 | 1.63 | 1.95 | 2.00 |

| PC3 | 1.75 | 1.65 | 2.80 | 2.05 | 1.85 | 3.00 |

| PC4 | 1.85 | 1.60 | 2.80 | 2.03 | 1.88 | 3.10 |

| PC5 | 1.85 | 1.95 | 2.90 | 2.35 | 2.13 | 3.13 |

| PC6 | 2.05 | 2.40 | 2.70 | 2.85 | 2.53 | 3.03 |

| PC7 | 1.25 | 1.43 | 2.40 | 1.40 | 1.60 | 2.85 |

| PC8 | 1.80 | 1.75 | 2.60 | 1.98 | 2.00 | 2.88 |

| PC9 | 2.00 | 1.93 | 2.95 | 2.53 | 2.51 | 3.16 |

| PC10 | 2.45 | 2.43 | 3.00 | 2.53 | 2.44 | 3.25 |

| PC11 | 2.58 | 2.48 | 3.06 | 2.70 | 2.68 | 3.28 |

| Mix ID | Weight Loss (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Tamping Rod | 5 Drops | 25 Drops | |||||||

| 100 Rev. | 200 Rev. | 300 Rev. | 100 Rev. | 200 Rev. | 300 Rev. | 100 Rev. | 200 Rev. | 300 Rev. | |

| PC1 | 22.6 | 34.1 | 46.7 | 15.5 | 42.5 | 65.4 | 11.7 | 19.2 | 25.5 |

| PC2 | 35.4 | 89.0 | 100.0 | 62.9 | 100.0 | 100.0 | 12.7 | 46.9 | 80.2 |

| PC3 | 13.0 | 21.4 | 29.5 | 10.0 | 18.2 | 25.1 | 7.0 | 12.3 | 18.0 |

| PC4 | 16.7 | 31.9 | 47.1 | 17.2 | 46.7 | 73.5 | 9.6 | 15.7 | 22.0 |

| PC5 | 9.2 | 16.3 | 23.1 | 9.8 | 17.2 | 25.9 | 6.2 | 11.1 | 15.4 |

| PC6 | 13.0 | 29.7 | 91.1 | 14.7 | 42.8 | 85.3 | 8.7 | 18.7 | 36.5 |

| PC7 | 20.1 | 41.0 | 51.9 | 12.4 | 22.1 | 31.5 | 7.9 | 13.1 | 17.8 |

| PC8 | 16.1 | 45.6 | 82.5 | 34.5 | 72.8 | 92.8 | 10.6 | 17.3 | 34.1 |

| PC9 | 12.3 | 18.1 | 25.7 | 8.8 | 15.2 | 21.6 | 5.7 | 10.5 | 15.0 |

| PC10 | 15.2 | 28.7 | 42.3 | 15.3 | 43.1 | 71.4 | 8.2 | 13.1 | 19.5 |

| PC11 | 14.7 | 26.8 | 38.5 | 13.4 | 41.6 | 68.2 | 7.1 | 11.6 | 18.0 |

| Mix ID | Designed Porosity (%) | Actual Porosity (%) | Hydraulic Conductivity (mm/s) | ||||

|---|---|---|---|---|---|---|---|

| Tamping Rod | 5 Drops | 25 Drops | Tamping Rod | 5 Drops | 25 Drops | ||

| PC1 | 20.0 | 25.7 | 27.2 | 18.7 | 18.0 | 26.7 | 9.7 |

| PC2 | 20.0 | 27.9 | 27.3 | 21.0 | 22.8 | 35.2 | 13.9 |

| PC3 | 16.1 | 20.6 | 23.0 | 12.9 | 12.7 | 18.9 | 3.5 |

| PC4 | 17.5 | 22.6 | 25.1 | 15.3 | 16.5 | 23.8 | 9.1 |

| PC5 | 15.0 | 18.5 | 23.1 | 11.2 | 10.0 | 16.3 | 6.0 |

| PC6 | 15.0 | 19.1 | 21.8 | 14.4 | 11.2 | 17.9 | 9.9 |

| PC7 | 20.8 | 27.5 | 29.2 | 18.7 | 23.3 | 29.3 | 12.0 |

| PC8 | 20.8 | 26.8 | 29.6 | 18.3 | 26.0 | 34.5 | 13.8 |

| PC9 | 13.7 | 14.9 | 19.6 | 12.3 | 11.3 | 16.6 | 5.6 |

| PC10 | 13.5 | 17.0 | 19.3 | 12.1 | 13.3 | 19.5 | 6.6 |

| PC11 | 13.5 | 17.0 | 19.3 | 12.1 | 11.9 | 17.5 | 5.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferić, K.; Sathish Kumar, V.; Romić, A.; Gotovac, H. Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability 2023, 15, 1146. https://doi.org/10.3390/su15021146

Ferić K, Sathish Kumar V, Romić A, Gotovac H. Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability. 2023; 15(2):1146. https://doi.org/10.3390/su15021146

Chicago/Turabian StyleFerić, Kajo, Veerappan Sathish Kumar, Ana Romić, and Hrvoje Gotovac. 2023. "Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete" Sustainability 15, no. 2: 1146. https://doi.org/10.3390/su15021146

APA StyleFerić, K., Sathish Kumar, V., Romić, A., & Gotovac, H. (2023). Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability, 15(2), 1146. https://doi.org/10.3390/su15021146