Motivations and Challenges for Food Companies in Using IoT Sensors for Reducing Food Waste: Some Insights and a Road Map for the Future

Abstract

:1. Introduction to Food Waste

2. Literature Review—Minimizing Food Waste in Agrifood Supply Chains

Technological Options

3. Methodology

4. Results—Insights on the Motivations of Businesses

4.1. Benefits to Organizations in Food Supply Chains

4.2. Motivations

4.2.1. Food Quality

4.2.2. Reliability

4.2.3. Legal

4.2.4. Green Image

4.2.5. Pressures from Stakeholders

4.2.6. Economic Factors and Survival

4.3. Challenges

4.3.1. Data Security, Data Sharing, Threat from Hackers

4.3.2. Privacy

4.3.3. Technological Challenges

4.3.4. Trust Issues

5. Exploring the Future of Use of Modern Digital Technologies for FWR—Business Models, Sustainability Plans and Roadmaps

5.1. Business Models for Supporting the Use of Digital Technologies in Food Supply Chain Companies

5.2. Sustainability Plans

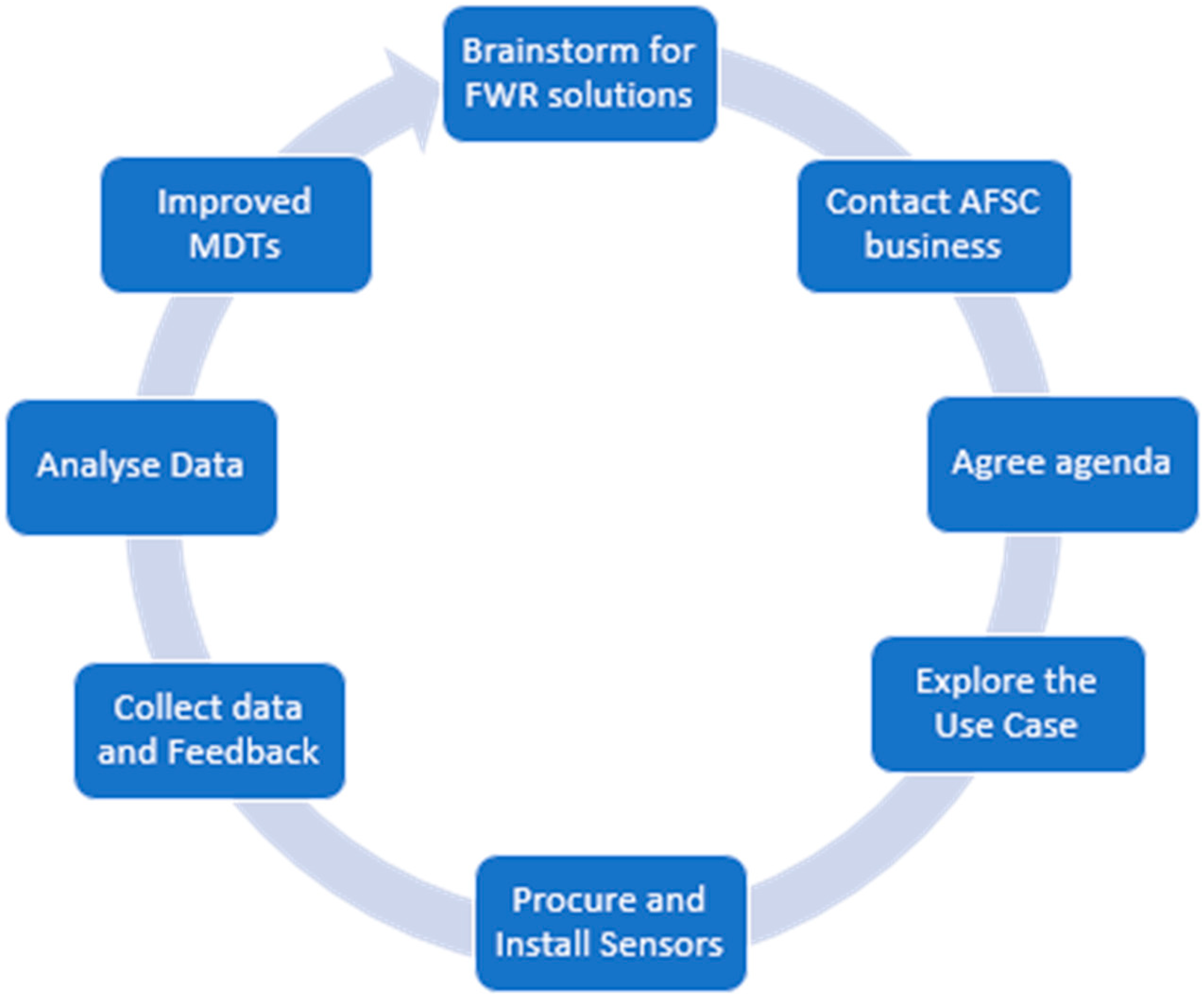

5.3. Roadmaps

- Keep abreast of the latest developments in modern digital technologies and utilize the most cost-effective technologies.

- Showcase a number of demonstrator applications of the use of modern digital technologies for FWR in selected companies. Bring out all the elements of a sustainable business model (including the value proposition, creation and delivery dimensions).

- Use the success of the demonstrators to reach out to more food companies. Explain the food waste saved, the carbon emissions avoided, and the social benefits derived from each demonstration case.

- Reach out to more food companies. There is potential to reduce 107 tonnes of carbon emissions by working with meat companies each time a warning signal is sent. This can translate to significant tons of carbon emissions over a year. By reaching more meat companies, this saving can be much larger. For example, if 100 such companies are reached in one year, there is a potential saving of 10,700 tonnes of carbon emissions per year. Therefore, it is imperative to scale up the technology adoption by involving more companies in the next few years and save as much carbon emissions as possible.

- Work with policymakers to incentivize food companies to use modern digital technologies to reduce food waste in their supply chains. This can be done, for example, by formulating guidelines, policy briefs, regulations, taxes and incentives and via appropriate labeling mechanisms confirming ‘pro-active food waste reduction status’. This will encourage much wider deployment of modern digital technologies in food supply chains and will help avoid more food waste and reduce more carbon emissions in the future.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cattaneo, A.; Federighi, G.; Vaz, S. The environmental impact of reducing food loss and waste: A critical assessment. Food Policy 2021, 98, 101890. [Google Scholar] [CrossRef]

- UNDP. Sustainable Development Goal 12—Responsible Consumption and Production; UNDP: New York, NY, USA, 2022; Available online: https://www.undp.org/sustainable-development-goals#responsible-consumption-and-production (accessed on 6 September 2022).

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef] [PubMed]

- Lemaire, A.; Limbourg, S. How can food loss and waste management achieve sustainable development goals? J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Chauhan, C.; Dhir, A.; Akram, M.U.; Salo, J. Food loss and waste in food supply chains. A systematic literature review and framework development approach. J. Clean. Prod. 2021, 295, 126438. [Google Scholar] [CrossRef]

- Mena, C.; Terry, L.A.; Williams, A.; Ellram, L. Causes of waste across multi-tier supply networks: Cases in the UK food sector. Int. J. Prod. Econ. 2014, 152, 144–158. [Google Scholar] [CrossRef]

- van der Vorst, J.G.; van Kooten, O.; Luning, P.A. Towards a diagnostic instrument to identify improvement opportunities for quality controlled logistics in agrifood supply chain networks. Int. J. Food Syst. Dyn. 2011, 2, 94–105. [Google Scholar]

- Karki, S.T.; Bennett, A.C.; Mishra, J.L. Reducing food waste and food insecurity in the UK: The architecture of surplus food distribution supply chain in addressing the sustainable development goals (Goal 2 and Goal 12.3) at a city level. Ind. Mark. Manag. 2021, 93, 563–577. [Google Scholar] [CrossRef]

- Ali, I.M.; Satie, S.A.; Thai, V.I. Adopting Industry 4.0 technologies in agri-food supply chains. In Supply Chain 4.0: Improving Supply Chains with Analytics and Industry 4.0 Technologies; Kogan Page: London, UK, 2021; Volume 3, p. 209. [Google Scholar]

- Attaran, M. Digital technology enablers and their implications for supply chain management. In Supply Chain Forum: An International Journal; Taylor & Francis: Abingdon, UK, 2020; Volume 21, pp. 158–172. [Google Scholar]

- da Costa, T.P.; Gillespie, L.; Cama-Moncunill, X.; Ward, S.; Condell, J.; Ramanathan, R.; Murphy, F. A systematic review of real-time monitoring technologies and its potential application to reduce food loss and waste: Key elements of food supply chains and IoT technologies. Sustainability 2023, 15, 614. [Google Scholar] [CrossRef]

- REAMIT. Benefits to Stakeholders for Participating in the REAMIT Project. 2022. Available online: https://www.nweurope.eu/projects/project-search/reamit-improving-resource-efficiency-of-agribusiness-supply-chains-by-minimising-waste-using-big-data-and-internet-of-things-sensors/#tab-7 (accessed on 29 August 2022).

- Kayıkcı, Y.; Gözaçan, N.; Lafcı, Ç.; Kazançoğlu, Y. A conceptual framework for food loss and waste in agri-food supply chains: Circular economy perspective. In Challenges and Opportunities of Circular Economy in Agri-Food Sector; Springer: Singapore, 2021; pp. 41–53. [Google Scholar]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [Green Version]

- Aramyan, L.; Grainger, M.; Logatcheva, K.; Piras, S.; Setti, M.; Stewart, G.; Vittuari, M. Food waste reduction in supply chains through innovations: A review. Meas. Bus. Excell. 2021, 25, 475–492. [Google Scholar] [CrossRef]

- Martin-Rios, C.; Demen-Meier, C.; Gössling, S.; Cornuz, C. Food waste management innovations in the foodservice industry. Waste Manag. 2018, 79, 196–206. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Mangla, S.K.; Luthra, S.; Kumar, A. Exploring the application of Industry 4.0 technologies in the agricultural food supply chain: A systematic literature review. Comput. Ind. Eng. 2022, 169, 108304. [Google Scholar] [CrossRef]

- Li, X.; Liu, P.C. Based on RFID Food Supply Chain Traceability System Framework Design. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 474, pp. 2150–2154. [Google Scholar]

- Sparrow, R.; Howard, M. Robots in agriculture: Prospects, impacts, ethics, and policy. Precis. Agric. 2021, 22, 818–833. [Google Scholar] [CrossRef]

- Tiwari, U. Application of blockchain in agri-food supply chain. Br. Int. Exact Sci. (BIoEx) J. 2020, 11, 574–589. [Google Scholar] [CrossRef]

- Kopanaki, E.; Stroumpoulis, A.; Oikonomou, M. The impact of blockchain technology on food waste management in the hospitality industry. ENTRENOVA-Enterp. Res. Innov. 2021, 7, 428–437. [Google Scholar] [CrossRef]

- Marin, M.P.; Marin, I.; Vidu, L. Learning about the reduction of food waste using blockchain technology. arXiv 2021, arXiv:2101.02026. [Google Scholar]

- Panghal, A.; Vern, P.; Mor, R.S.; Panghal, D.; Sindhu, S.; Dahiya, S. A study on adoption enablers of 3D printing technology for sustainable food supply chain. Manag. Environ. Qual. Int. J. 2022; ahead-of-print. [Google Scholar]

- Prakash, S.; Bhandari, B.R.; Godoi, F.C.; Zhang, M. Future outlook of 3D food printing. In Fundamentals of 3D Food Printing and Applications; Academic Press: Cambridge, MA, USA, 2019; pp. 373–381. [Google Scholar]

- Verdouw, C.N.; Robbemond, R.M.; Verwaart, T.; Wolfert, J.; Beulens, A.J. A reference architecture for IoT-based logistic information systems in agri-food supply chains. Enterp. Inf. Syst. 2018, 12, 755–779. [Google Scholar] [CrossRef]

- Kumar, T.B.; Prashar, D. Review on efficient food waste management system using internet of things. Int. J. Cur Res. Rev. 2021, 13, 143. [Google Scholar] [CrossRef]

- Singh, A.; Kumari, S.; Malekpoor, H.; Mishra, N. Big data cloud computing framework for low carbon supplier selection in the beef supply chain. J. Clean. Prod. 2018, 202, 139–149. [Google Scholar] [CrossRef]

- Mustapha, U.F.; Alhassan, A.W.; Jiang, D.N.; Li, G.L. Sustainable aquaculture development: A review on the roles of cloud computing, internet of things and artificial intelligence (CIA). Rev. Aquac. 2021, 13, 2076–2091. [Google Scholar] [CrossRef]

- Funchal, G.; Melo, V.; Leitão, P. Cloud-enabled Integration of IoT Applications within the Farm to Fork to Reduce the Food Waste. In Proceedings of the 2022 IEEE 31st International Symposium on Industrial Electronics (ISIE), Anchorage, AK, USA, 1–3 June 2022; pp. 824–829. [Google Scholar]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, big data and artificial intelligence in agriculture and food industry. IEEE Internet Things J. 2020, 9, 6305–6324. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable innovations in the food industry through artificial intelligence and big data analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C. Study and analysis of the implementation of 4.0 technologies in the agri-food supply chain: A state of the art. Agronomy 2021, 11, 2526. [Google Scholar] [CrossRef]

- Seiler, R.; Fankhauser, D.; Keller, T. Reducing food waste with virtual reality (VR) training—A prototype and A/B-test in an online experiment. In Proceedings of the 20th International Conference e-Society 2022, Virtual, 12–14 March 2022; IADIS. pp. 179–186. [Google Scholar]

- Elg, M.; Gremyr, I.; Halldorsson, Á.; Wallo, A. Service action research: Review and guidelines. J. Serv. Mark. 2020, 34, 87–99. [Google Scholar] [CrossRef]

- Ivankova, N.; Wingo, N. Applying mixed methods in action research: Methodological potentials and advantages. Am. Behav. Sci. 2018, 62, 978–997. [Google Scholar] [CrossRef]

- Erro-Garcés, A.; Alfaro-Tanco, J.A. Action research as a meta-methodology in the management field. Int. J. Qual. Methods 2020, 19. [Google Scholar] [CrossRef] [Green Version]

- Argyris, C.; Schön, D.A. Participatory action research and action science compared: A commentary. In Participatory Action Research; Whyte, W.F., Ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 1991; pp. 85–96. [Google Scholar] [CrossRef]

- Ramanathan, U.; Pelc, K.; da Costa, T.P.; Ramanathan, R.; Shenker, N. A Case Study of Human Milk Banking with Focus on the Role of IoT Sensor Technology. Sustainability 2023, 15, 243. [Google Scholar] [CrossRef]

- Ramanathan, U.; Ramanathan, R.; Adefisan, A.; da Costa, T.P.; Cama, X.; Samriya, G. Adapting digital technologies to reduce food waste and improve operational efficiency of a frozen food company—The case of Yumchop Foods in the UK. Sustainability 2022, 14, 16614. [Google Scholar] [CrossRef]

- Powell, T.C. Total quality management as competitive advantage: A review and empirical study. Strateg. Manag. J. 1995, 16, 15–37. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling faults in the industry 4.0 era—A survey of machine-learning solutions and key aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, N.; Jain, U.; Soni, S. Sensors for food quality monitoring. In Nanoscience for Sustainable Agriculture; Springer: Cham, Switzerland, 2019; pp. 601–626. [Google Scholar]

- Lopez-Torres, G.C.; Montejano-García, S.; Alvarez-Torres, F.J.; Perez-Ramos, M.d.J. Sustainability for competitiveness in firms—A systematic literature review. Meas. Bus. Excell. 2022, 26, 433–450. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M.; Rolínek, L.; Bednář, J. Sustainability outcomes of green processes in relation to industry 4.0 in manufacturing: Systematic review. Sustainability 2020, 12, 5968. [Google Scholar] [CrossRef]

- Freudenreich, B.; Lüdeke-Freund, F.; Schaltegger, S. A stakeholder theory perspective on business models: Value creation for sustainability. J. Bus. Ethics 2020, 166, 3–18. [Google Scholar] [CrossRef]

- Ramanathan, U.; Aluko, O.; Ramanathan, R. Supply chain resilience and business responses to disruptions of the COVID-19 pandemic. Benchmarking Int. J. 2022, 29, 2275–2290. [Google Scholar] [CrossRef]

- Tawalbeh, L.A.; Muheidat, F.; Tawalbeh, M.; Quwaider, M. IoT Privacy and security: Challenges and solutions. Appl. Sci. 2020, 10, 4102. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Haaker, T.; Ly, P.T.M.; Nguyen-Thanh, N.; Nguyen, H.T.H. Business model innovation through the application of the Internet-of-Things: A comparative analysis. J. Bus. Res. 2021, 126, 126–136. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M. A review and typology of circular economy business model patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Foss, N.J.; Saebi, T. Fifteen years of research on business model innovation: How far have we come, and where should we go? J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef] [Green Version]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, And Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 1. [Google Scholar]

- Pileggi, S.F. Knowledge interoperability and re-use in Empathy Mapping: An ontological approach. Expert Syst. Appl. 2021, 180, 115065. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Parry, A.; James, K.; LeRoux, S. Strategies to Achieve Economic and Environmental Gains by Reducing Food Waste; Waste & Resources Action Programme (WRAP): Banbury, UK, 2015; ISBN 978-1-84405-473-2. Available online: https://wrap.org.uk/sites/default/files/2020–12/Strategies-to-achieve-economic-and-environmental-gains-by-reducing-food-waste.pdf (accessed on 4 January 2022).

- Bravard, C.; Babladelis, C.; Coleman, M.; Genser, J. Assessment of Food Waste Reduction Strategies, University of Michgan. 2022. Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/172144/Food%20Waste%20Reduction%20Strategies_402.pdf (accessed on 30 September 2022).

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

| Food Produc-tion/Abattoir | Processing and Packaging | Transport and Storage | Retailing | Consumption |

|---|---|---|---|---|

|

|

|

|

|

| Technology | Main Characteristic | Applications in Food Supply Chains | Application to Support Food Waste |

|---|---|---|---|

| Radio frequency identification (RFID) | Auto-identification technology with several business uses. It uses radio frequency (RF) waves to identify, track and locate individual physical items. | Traceability has been one of the most important applications of RFID [17]; for instance, the fish food supply chain is an important area where traceability plays an important role. It also helps to ensure food safety. | Li et al. [18] considered the application of RFID in food safety. |

| Advanced robots | Robots, including drones, are being deployed in agriculture, manufacturing and delivery and are providing immense benefits. These robots can help supply chains in picking, palletizing, and unloading. They can transform businesses to help them respond faster, safer, and more productively to the external environment. They can also help during pandemic situations (e.g., COVID-19) when human beings cannot move around freely. | Applications of drones during a flood in airdrops [9]. | In Ref. [19], robots in agriculture and reducing food wastage and their prospects and impacts are discussed. |

| Blockchain technology | It is a collection of records, called ‘blocks’, across several computers linked in peer-to-peer networks. Blockchain provides security and transparency as, due to the networking feature, it cannot be corrupted. Other key characteristics of blockchain technology are decentralization, anonymity, persistence, audibility, and resistance to modification or changes to the data. | Tiwari [20] demonstrated the application of blockchain in the agrifood supply chain. | Refs. [21,22] researched the impact of blockchain technology in reducing food waste. |

| Three-dimensional printing (3D printing) (or additive manufacturing or rapid prototyping). | They are currently being used extensively in automotive, aerospace, defence, consumer products, industrial products, healthcare, and architecture. This technology increases production flexibility, reduces waste, decentralizes production and helps reduce complexity in businesses. | 3D printing is introduced as an emerging technology to support sustainable supply chain and environmental quality management [23]. | Prakash et al. [24] discussed the future of 3D food printing in the food industry; This study contains 3D food printing technologies and their working mechanisms within a broad spectrum of application areas, including the development of soft foods and sweets design. It provides a unique guide to help correlate supply materials (edible inks) and the technologies (laser-based) used during the construction of 3D shapes. |

| Internet of Things (IoT) technology | IoT devices measure some characteristics in an application and are connected to the cloud so that the device’s reading can be externally monitored for business decisions. These devices range from smartphones, wearable devices, industrial equipment, appliances, and anything else that collects and transmits data via the internet. | Yadav et al. [17] investigated and developed an IoT-based system in food supply chains. Verdouw et al. [25] provided an IoT-based reference architecture for food supply chains. | A review of efficient food waste management systems using IoT is available in [26] |

| Cloud Computing Technology (CCT) | CCT is a cost-effective way to run applications, store data, and accomplish other IT tasks. It can help improve internal efficiencies, including capital investment savings, simplified operations, scalability, improved information visibility, sustainability, and faster deployment. | Singh et al. [27] studied big data CCT for low-carbon supplier selection of beef food supply chains. Mustapha et al. [28] reviewed sustainable agriculture development roles of CCT, IoT, and artificial intelligence. | Funchal et al. [29] explained the CCT-enabled integration of IoT applications for food waste reduction. |

| Big data analytics and artificial intelligence (BDA-AI) | Internet of Things devices and other digital technologies create a massive amount of data, often on a real-time basis. Advanced analytics, Artificial Intelligence (AI), Machine Learning (ML) and Deep Learning technologies have been designed to make use of this big data for developing important business insights and help in crucial business decisions (e.g., on product designs, manufacturing, distribution, and sales). | Misra et al. [30] investigated IoT, BDA, and AI in food supply chains. | Sharma et al. [31] discussed sustainable innovation in the food industry through AI and BDA. |

| Virtual Reality (VR), Augmented Reality (AR) and metaverse | They are adding layer upon layer of digitized overlaid information to the world around us, making it rich, meaningful, and interactive. They are useful to businesses in remote working and collaboration, maintenance issues, safety warnings, employee/customer digital experience, and more. | Morella et al. [32] demonstrated the application of VR in food supply chains. | Seiler et al. [33] studied reducing food waste with VR. |

| TD Number | Stage of the Supply Chain | Country | Food Waste Issue | MDT Deployed | Solution/REMARKS |

|---|---|---|---|---|---|

| 1. | Food processing in an abattoir | UK | Meat waste due to un-uniform temperature distribution in dry-aging chambers (fridges). | IoT temperature and humidity sensors located at multiple points to monitor uniform temperature distribution, and CCT and BDA-AI. Alerts via a smartphone and email. | Ensure uniform distribution of air in the chamber. Send warning alerts if needed. |

| 2. | Food processing in an abattoir. | Republic of Ireland | Meat waste due to un-uniform temperature distribution in dry aging chambers (fridges). | IoT temperature, humidity, and pressure sensors located at multiple points to monitor uniform temperature distribution, and CCT and BDA-AI. Alerts via a smartphone and email. | Ensure uniform distribution of air in the chamber. Send warning alerts if needed. |

| 3. | Food storage in a frozen food company | UK | Food waste due to inadequate temperature in fridges | IoT temperature sensors located in fridges to monitor temperature, and CCT and BDA-AI. Alerts via a smartphone and email. | Send alerts if the temperature is not maintained within a pre-specified threshold. |

| 4. | Milk transportation | UK | Food waste due to inadequate temperature during transport | IoT temperature sensors located in transport options to monitor the temperature, and CCT and BDA-AI. Alerts via a smartphone and email. | Send alerts if temperature is not maintained within a pre-specified threshold. |

| 5. | Transport | UK | Food waste due to temperature anomalies during transport | IoT temperature sensors located in fridge and freezer of the van to monitor temperature, and CCT and BDA-AI. Alerts via a smartphone and email. | Send alerts if the temperature is not maintained within a pre-specified threshold. |

| 6. | Transport | The Netherlands | Food waste due to the inadequate volume of icepacks used during transport | IoT temperature sensors located in the grocery transport crates to monitor the temperature, and CCT and BDA-AI. | ML model to predict quantity of ice required to maintain temperature given the weather and journey length. |

| 7. | Storage and transport in multiple stages of the supply chain | Luxembourg | Food waste is due to temperature abuse at the transport and storage stage of the supply chain. | IoT temperature and humidity sensors located at each stage of the supply chain (farm, transport, storage), and CCT and BDA-AI. | ML model for early warning of product degradation given temperature. |

| 8. | Storage and transport in multiple stages of the supply chain | Germany | Quality differences between two different producers. Wastage occurs more quickly from one than the other. | IoT temperature, humidity, and VOC sensors located in transport options, and CCT and BDA-AI. | ML model for early warning of quality warning given temperature, humidity, and VOC. |

| 9. | Storage | The Netherlands | Food waste due to pressure abuse at the storage stage of the supply chain | IoT pressure sensors located at a storage facility, and CCT and BDA-AI. Alerts via a smartphone and email. | Send alerts if pressure is not maintained within a pre-specified threshold. |

| 10. | Processing—wine manufacturing | UK | Food waste of raw material when the right temperature and flow are not maintained in the production process. | IoT temperature and flow sensors monitor temperature and other relevant parameters during production. | Discontinued after initial discussion. |

| 11. | Production—raising cattle | UK | Food waste due to unacceptable quality of meat. | Motion sensors on cattle. | Discontinued after initial discussion. |

| 12. | Transportation | UK | Food waste in international transport. | IoT temperature sensors located in transport options to monitor the temperature. | Discontinued because of the difficulties of internet connectivity in international air transport. |

| 13. | Food production, storage and transport | Germany | Food waste due to temperature anomalies during transport | IoT temperature sensors located in transport options to monitor the temperature. | Discontinued after initial discussion. |

| Impact Dimension | Key Benefits |

|---|---|

| Economic |

|

| Societal |

|

| Environmental |

|

| Major Dimensions | Sub-Categories | |

|---|---|---|

| Value proposition | Products | Smart hardware such as sensors, cloud infrastructure and software for BDA-AI. |

| Services | Timely alerts of any deviation from optimal conditions for food storage. | |

| Value delivery | Target customers | Food companies are conscious of quality and sustainability. |

| Value delivery processes | Timely alerts will help avoid food waste, connecting potential nearby demand points when there is a risk of food becoming waste soon. Mobile application for ease of operation. More efficient food production, logistics, quality control and storage opportunities for food companies. | |

| Value creation | Partners and stakeholders | Food supply chain companies, companies manufacturing IoT sensors, CCT and BDA-AI software, data-driven decision-making capabilities. |

| Value creation processes | Measurement and continuous monitoring of storage conditions, such as temperature and humidity, connecting to potential nearby demand points when there is a danger of food becoming waste soon. | |

| Value capture | Revenues | Sale of hardware and subscriptions. Dynamic pricing, pay-per-use and performance-based revenues. |

| Costs | Hardware such as sensors, cloud infrastructure, software costs for BDA-AI and staff costs, costs of training and support, and maintenance costs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramanathan, R.; Duan, Y.; Ajmal, T.; Pelc, K.; Gillespie, J.; Ahmadzadeh, S.; Condell, J.; Hermens, I.; Ramanathan, U. Motivations and Challenges for Food Companies in Using IoT Sensors for Reducing Food Waste: Some Insights and a Road Map for the Future. Sustainability 2023, 15, 1665. https://doi.org/10.3390/su15021665

Ramanathan R, Duan Y, Ajmal T, Pelc K, Gillespie J, Ahmadzadeh S, Condell J, Hermens I, Ramanathan U. Motivations and Challenges for Food Companies in Using IoT Sensors for Reducing Food Waste: Some Insights and a Road Map for the Future. Sustainability. 2023; 15(2):1665. https://doi.org/10.3390/su15021665

Chicago/Turabian StyleRamanathan, Ramakrishnan, Yanqing Duan, Tahmina Ajmal, Katarzyna Pelc, James Gillespie, Sahar Ahmadzadeh, Joan Condell, Imke Hermens, and Usha Ramanathan. 2023. "Motivations and Challenges for Food Companies in Using IoT Sensors for Reducing Food Waste: Some Insights and a Road Map for the Future" Sustainability 15, no. 2: 1665. https://doi.org/10.3390/su15021665