Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment, Sewage Sludge Digestion and Biogas Upgrading: A Review

Abstract

:1. Introduction

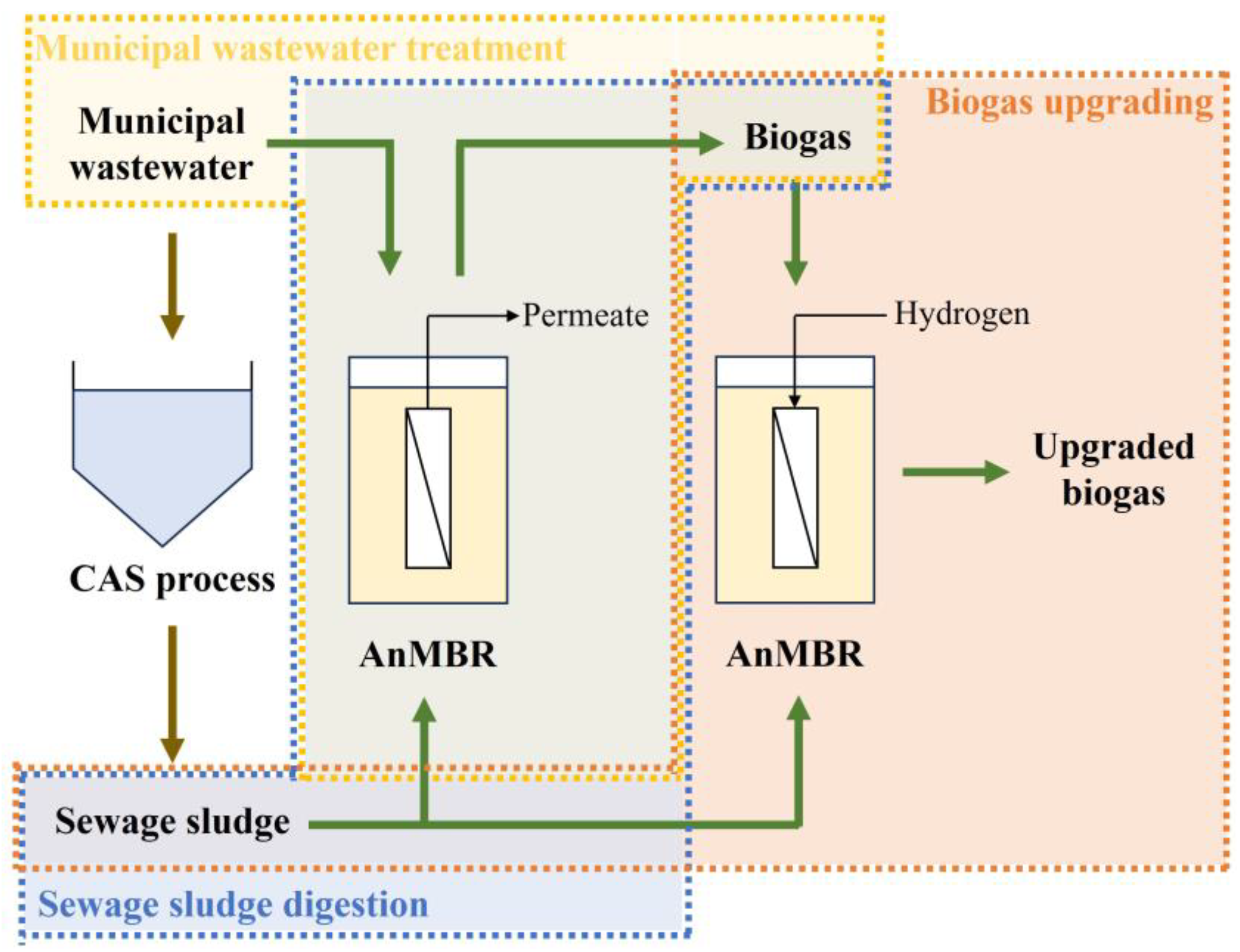

2. Application of AnMBRs

2.1. Configurations of AnMBRs

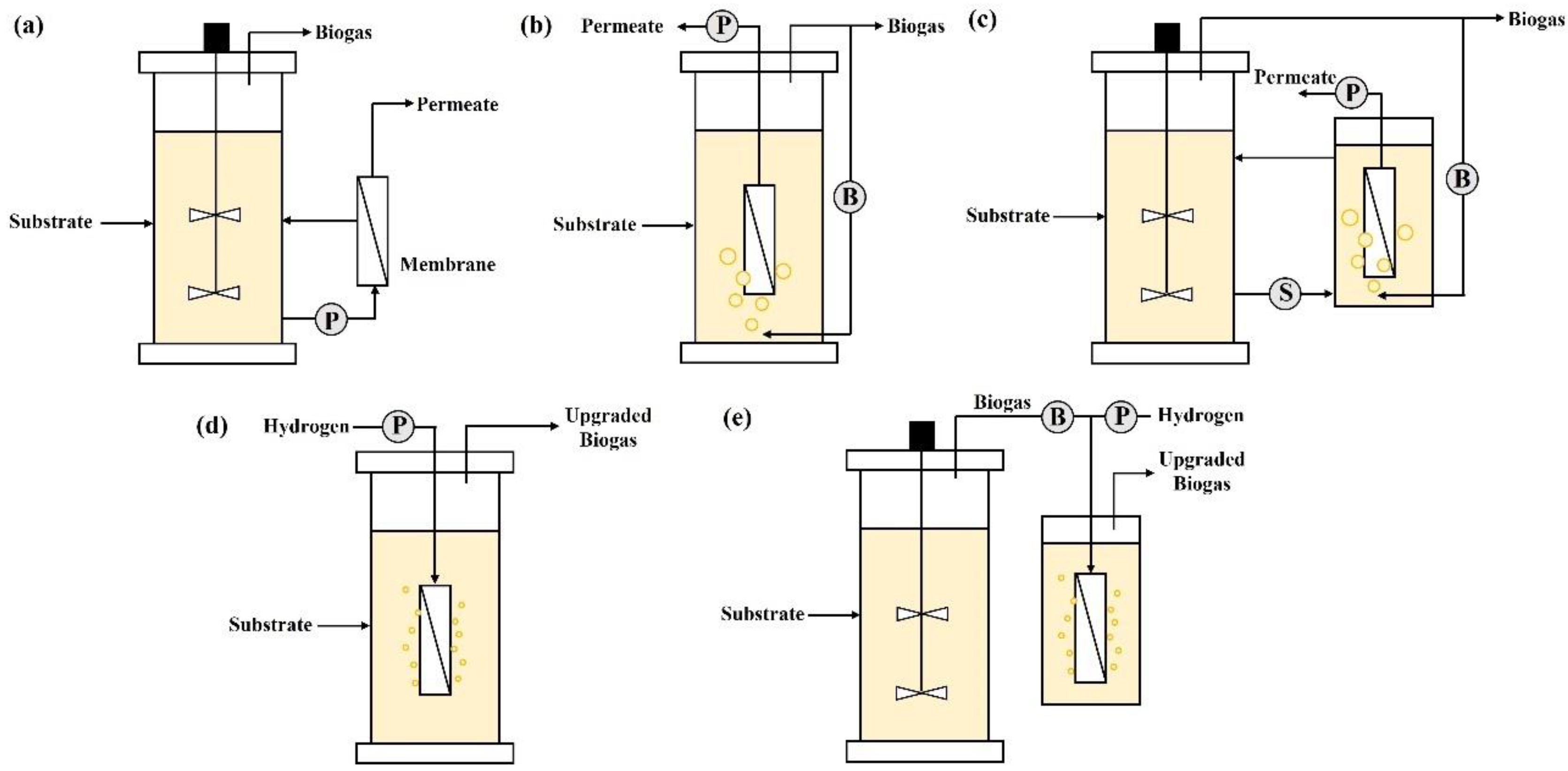

2.1.1. Membrane for Filtration

2.1.2. Membrane for Injection

2.2. AnMBRs for Municipal Wastewater Treatment

2.2.1. Effects of Operating Parameters

| System Configuration * | Scale (L) | Temperature (°C) | CODinfluent (mg/L) | HRT (h) | SRT (d) | Methane Yield (L/g-COD) | COD Removal Efficiency (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| S-FS-AnMBR | 40 | 18/24 | 428–477 | 48–12 | 50 | - | 69–89 | [24] |

| S-HF-AnMBR | 20 | 15 | 412 | 6–24 | 21–491 | 0.21–0.23 | 90.5 | [26] |

| S-HF-AnMBR | 1650 | 25 | 762 | 11–21 | 100 | 0.2 | 92 | [37] |

| ES-HF-AnMBR | 34,400 | 10–27 | 755–1403 | 25–41 | 70 | 0.07–0.17 | 93 | [9] |

| S-HF-AnMBR | 5000 | 15–25 | 203–490 | 8 | 20–71 | 0.205–0.244 | 77–93 | [27] |

| ES-TM-AnMBR/UASB | 160 + 150 | 18 | 892 | 7–17 | - | 0.199–0.235 | 73–90 | [38] |

2.2.2. Co-Digestion

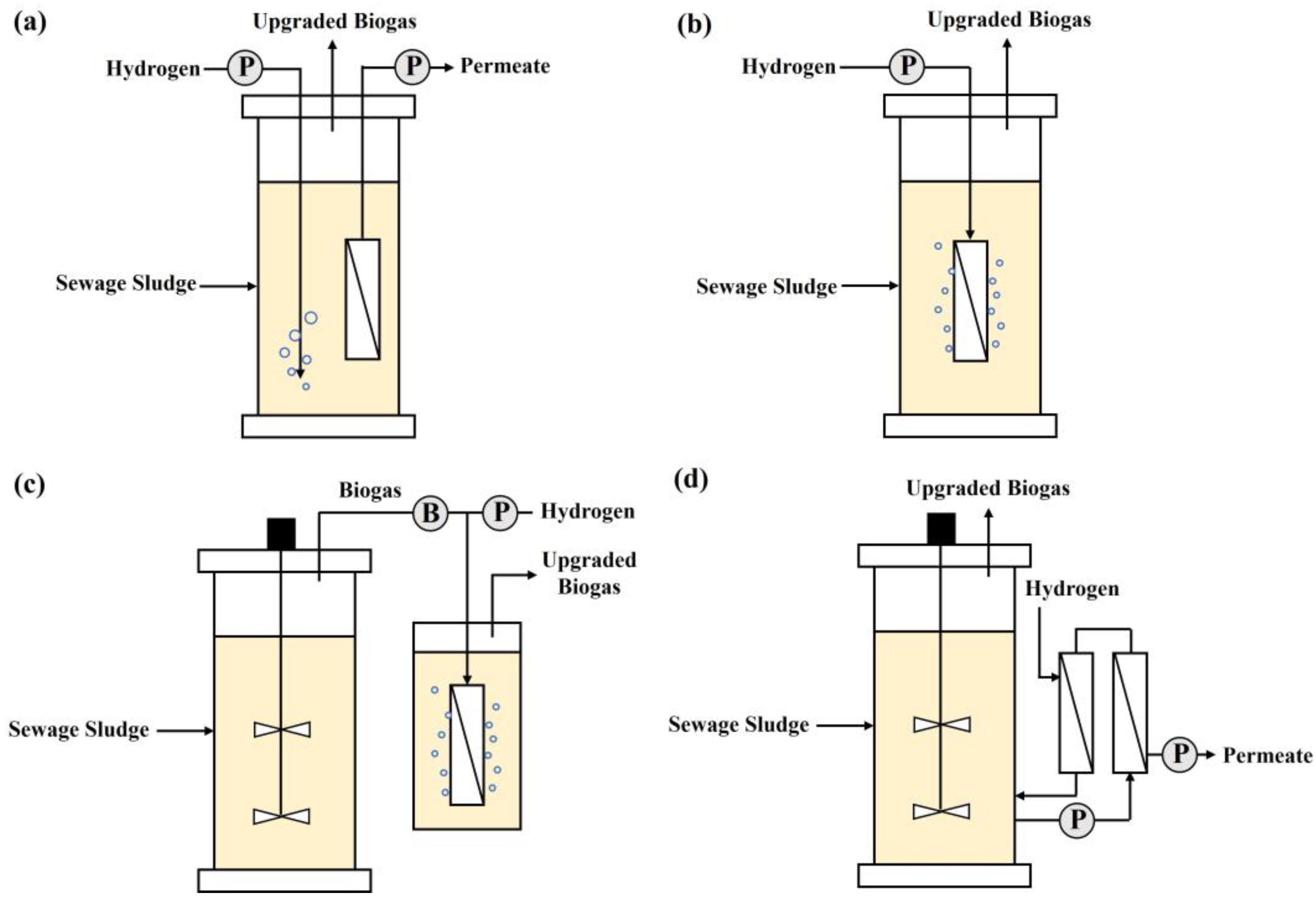

2.3. AnMBRs for Sewage Sludge Treatment

2.3.1. Effects of Operating Parameters

| System Configuration * | Scale (L) | Temperature (°C) | OLR (g-COD/L/d) | HRT (d) | SRT (d) | Methane Yield | COD Removal (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| ES-HF-AnMBR/CSTR | 15 | 35 | 1.72–3.72 | 15–30 | 25–60 | 0.239 L/g-VS | 99.0 | [50] |

| ES-HF-AnMBR/CSTR | 15 | 55 | 4.31 | 15 | - | 0.31 L/g-VS | 96.7 | [51] |

| ET-AnMBR | 500 | 24, 35, 55 | 3.4–3.7 | 6.9–7.3 | 22–39 | 0.19–0.34 L/g-VS | - | [46] |

| ET-HF-AnMBR/CSTR | 2.37 + 0.1 | 37 | 0.21–0.27 | 30–33 | 102–107 | 0.19–0.24 L/g-VS | - | [52] |

| ET-CM-AnMBR/CSTR | 25 | 35 & 55 | 4.8–10.4 | 3–7 | 30–50 | 0.213–0.245 L/g-COD | - | [47] |

2.3.2. Co-Digestion

2.3.3. Pretreatment

2.4. AnMBRs for Biogas Upgrading

3. Membrane Fouling Mitigation

3.1. Filtration Mode

3.2. Biogas Sparging

3.3. Anaerobic Fluidized-Bed Membrane Bioreactors

3.4. Electrochemical AnMBRs

4. Future Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane Bioreactors—A Review on Recent Developments in Energy Reduction, Fouling Control, Novel Configurations, LCA and Market Prospects. J. Memb. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef]

- Xiao, K.; Liang, S.; Wang, X.; Chen, C.; Huang, X. Current State and Challenges of Full-Scale Membrane Bioreactor Applications: A Critical Review. Bioresour. Technol. 2019, 271, 473–481. [Google Scholar] [CrossRef]

- Pretel, R.; Moñino, P.; Robles, A.; Ruano, M.V.V.; Seco, A.; Ferrer, J.; Pretel, R.; Ruano, M.V.V.; Robles, A.; Ferrer, J.; et al. Economic and Environmental Sustainability of an AnMBR Treating Urban Wastewater and Organic Fraction of Municipal Solid Waste. J. Environ. Manag. 2016, 179, 83–92. [Google Scholar] [CrossRef]

- Christian, S.; Grant, S.; McCarthy, P.; Wilson, D.; Mills, D. The First Two Years of Full-Scale Anaerobic Membrane Bioreactor (AnMBR) Operation Treating High-Strength Industrial Wastewater. Water Pract. Technol. 2011, 6, wpt2011032. [Google Scholar] [CrossRef]

- Kanai, M.; Yamamoto, T.; Moro, M.; Wakahara, S.; Ferre, V. A Novel Combination of Methane Fermentation and MBR—Kubota Submerged Anaerobic Membrane Bioreactor Process. Desalination 2009, 250, 964–967. [Google Scholar] [CrossRef]

- Ji, J.; Kakade, A.; Yu, Z.; Khan, A.; Liu, P.; Li, X. Anaerobic Membrane Bioreactors for Treatment of Emerging Contaminants: A Review. J. Environ. Manag. 2020, 270, 110913. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.H.; Harb, M.; Amy, G.; Hong, P.Y.; Leiknes, T.O. Sustainable Organic Loading Rate and Energy Recovery Potential of Mesophilic Anaerobic Membrane Bioreactor for Municipal Wastewater Treatment. Bioresour. Technol. 2014, 166, 326–334. [Google Scholar] [CrossRef]

- Ozgun, H.; Dereli, R.K.; Ersahin, M.E.; Kinaci, C.; Spanjers, H.; Van Lier, J.B. A Review of Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment: Integration Options, Limitations and Expectations. Sep. Purif. Technol. 2013, 118, 89–104. [Google Scholar] [CrossRef]

- Robles, Á.; Jiménez-Benítez, A.; Giménez, J.B.; Durán, F.; Ribes, J.; Serralta, J.; Ferrer, J.; Rogalla, F.; Seco, A. A Semi-Industrial Scale AnMBR for Municipal Wastewater Treatment at Ambient Temperature: Performance of the Biological Process. Water Res. 2022, 215, 118249. [Google Scholar] [CrossRef]

- Lutze, R.; Engelhart, M. Comparison of CSTR and AnMBR for Anaerobic Digestion of WAS and Lipid-Rich Flotation Sludge from the Dairy Industry. Water Resour. Ind. 2020, 23, 100122. [Google Scholar] [CrossRef]

- Velasco, P.; Jegatheesan, V.; Thangavadivel, K.; Othman, M.; Zhang, Y. A Focused Review on Membrane Contactors for the Recovery of Dissolved Methane from Anaerobic Membrane Bioreactor (AnMBR) Effluents. Chemosphere 2021, 278, 130448. [Google Scholar] [CrossRef]

- Xu, S.; Qiao, Z.; Luo, L.; Sun, Y.; Wong, J.W.C.; Geng, X.; Ni, J. On-Site CO2 Bio-Sequestration in Anaerobic Digestion: Current Status and Prospects. Bioresour. Technol. 2021, 332, 125037. [Google Scholar] [CrossRef]

- Sun, Z.F.; Zhao, L.; Wu, K.K.; Wang, Z.H.; Wu, J.T.; Chen, C.; Yang, S.S.; Wang, A.J.; Ren, N.Q. Overview of Recent Progress in Exogenous Hydrogen Supply Biogas Upgrading and Future Perspective. Sci. Total Environ. 2022, 848, 157824. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Xie, H.; Cao, W.; Chen, R.; Kong, Z.; Zhang, Y. Insight into the Effects and Mechanism of Cellulose and Hemicellulose on Anaerobic Digestion in a CSTR-AnMBR System during Swine Wastewater Treatment. Sci. Total Environ. 2023, 869, 161776. [Google Scholar] [CrossRef] [PubMed]

- Aslam, A.; Khan, S.J.; Shahzad, H.M.A. Anaerobic Membrane Bioreactors (AnMBRs) for Municipal Wastewater Treatment- Potential Benefits, Constraints, and Future Perspectives: An Updated Review. Sci. Total Environ. 2022, 802, 149612. [Google Scholar] [CrossRef] [PubMed]

- Vinardell, S.; Astals, S.; Peces, M.; Cardete, M.A.; Fernández, I.; Mata-Alvarez, J.; Dosta, J. Advances in Anaerobic Membrane Bioreactor Technology for Municipal Wastewater Treatment: A 2020 Updated Review. Renew. Sustain. Energy Rev. 2020, 130, 109936. [Google Scholar] [CrossRef]

- Dagnew, M.; Pickel, J.; Parker, W.; Seto, P. Anaerobic Membrane Bio-Reactors for Waste Activated Sludge Digestion: Tubular Versus Hollow Fiber Membrane Configuration. AIChE J. 2013, 3, 598–604. [Google Scholar] [CrossRef]

- Ruano, M.V.; Steyer, J.-P.P.; Charfi, A.; Robles, Á.; Batstone, D.J.; Heran, M.; Lesage, G.; Kim, J.; Ferrer, J.; Seco, A.; et al. A Review on Anaerobic Membrane Bioreactors (AnMBRs) Focused on Modelling and Control Aspects. Bioresour. Technol. 2018, 270, 612–626. [Google Scholar] [CrossRef]

- Rattier, M.; Jimenez, J.A.; Miller, M.W.; Dhanasekar, A.; Willis, J.; Keller, J.; Batstone, D. Long-Term Comparison of Pilot UASB and AnMBR Systems Treating Domestic Sewage at Ambient Temperatures. J. Environ. Chem. Eng. 2022, 10, 108489. [Google Scholar] [CrossRef]

- Li, Y.; Ni, J.; Cheng, H.; Guo, G.; Zhang, T.; Zhu, A.; Qin, Y.; Li, Y.Y. Enhanced Digestion of Sludge via Co-Digestion with Food Waste in a High-Solid Anaerobic Membrane Bioreactor: Performance Evaluation and Microbial Response. Sci. Total Environ. 2023, 899, 165701. [Google Scholar] [CrossRef]

- Luo, G.; Angelidaki, I. Hollow Fiber Membrane Based H2 Diffusion for Efficient in Situ Biogas Upgrading in an Anaerobic Reactor. Appl. Microbiol. Biotechnol. 2013, 97, 3739–3744. [Google Scholar] [CrossRef] [PubMed]

- Deschamps, L.; Imatoukene, N.; Lemaire, J.; Mounkaila, M.; Filali, R.; Lopez, M.; Theoleyre, M.A. In-Situ Biogas Upgrading by Bio-Methanation with an Innovative Membrane Bioreactor Combining Sludge Filtration and H2 Injection. Bioresour. Technol. 2021, 337, 125444. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Liu, L.; Liu, W.; Yu, L.; Dong, J.; Han, F.; Wang, H.; Chen, Z.; Ge, H.; Jiang, B.; et al. Improvement of Sludge Characteristics and Mitigation of Membrane Fouling in the Treatment of Pesticide Wastewater by Electrochemical Anaerobic Membrane Bioreactor. Water Res. 2022, 213, 118153. [Google Scholar] [CrossRef] [PubMed]

- Plevri, A.; Mamais, D.; Noutsopoulos, C. Anaerobic MBR Technology for Treating Municipal Wastewater at Ambient Temperatures. Chemosphere 2021, 275, 129961. [Google Scholar] [CrossRef]

- Kong, Z.; Wu, J.; Rong, C.; Wang, T.; Li, L.; Luo, Z.; Ji, J.; Hanaoka, T.; Sakemi, S.; Ito, M.; et al. Large Pilot-Scale Submerged Anaerobic Membrane Bioreactor for the Treatment of Municipal Wastewater and Biogas Production at 25 °C. Bioresour. Technol. 2021, 319, 124123. [Google Scholar] [CrossRef]

- Ji, J.; Du, R.; Ni, J.; Chen, Y.; Hu, Y.; Qin, Y.; Hojo, T.; Li, Y.Y. Submerged Anaerobic Membrane Bioreactor Applied for Mainstream Municipal Wastewater Treatment at a Low Temperature: Sludge Yield, Energy Balance and Membrane Filtration Behaviors. J. Clean. Prod. 2022, 355, 131831. [Google Scholar] [CrossRef]

- Rong, C.; Wang, T.; Luo, Z.; Hu, Y.; Kong, Z.; Qin, Y.; Hanaoka, T.; Ito, M.; Kobayashi, M.; Li, Y.Y. Pilot Plant Demonstration of Temperature Impacts on the Methanogenic Performance and Membrane Fouling Control of the Anaerobic Membrane Bioreactor in Treating Real Municipal Wastewater. Bioresour. Technol. 2022, 354, 127167. [Google Scholar] [CrossRef]

- Smith, A.L.; Skerlos, S.J.; Raskin, L. Psychrophilic Anaerobic Membrane Bioreactor Treatment of Domestic Wastewater. Water Res. 2013, 47, 1655–1665. [Google Scholar] [CrossRef]

- Cookney, J.; Mcleod, A.; Mathioudakis, V.; Ncube, P.; Soares, A.; Jefferson, B.; McAdam, E.J. Dissolved Methane Recovery from Anaerobic Effluents Using Hollow Fibre Membrane Contactors. J. Membr. Sci. 2016, 502, 141–150. [Google Scholar] [CrossRef]

- Crone, B.C.; Garland, J.L.; Sorial, G.A.; Vane, L.M. Significance of Dissolved Methane in Effluents of Anaerobically Treated Low Strength Wastewater and Potential for Recovery as an Energy Product: A Review. Water Res. 2016, 104, 520–531. [Google Scholar] [CrossRef]

- Puyol, D.; Batstone, D.J.; Hülsen, T.; Astals, S.; Peces, M.; Krömer, J.O. Resource Recovery from Wastewater by Biological Technologies: Opportunities, Challenges, and Prospects. Front. Microbiol. 2017, 7, 1–23. [Google Scholar] [CrossRef]

- Smith, A.L.; Stadler, L.B.; Love, N.G.; Skerlos, S.J.; Raskin, L. Perspectives on Anaerobic Membrane Bioreactor Treatment of Domestic Wastewater: A Critical Review. Bioresour. Technol. 2012, 122, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.S.; Moon, C.; Kang, S.; Kim, D.H. Continuous Performance of Hydrogenotrophic Methanogenic Mixed Cultures: Kinetic and SMP Analysis. Int. J. Hydrogen Energy 2017, 42, 27767–27773. [Google Scholar] [CrossRef]

- Shi, Y.; Huang, J.; Zeng, G.; Gu, Y.; Chen, Y.; Hu, Y.; Tang, B.; Zhou, J.; Yang, Y.; Shi, L. Exploiting Extracellular Polymeric Substances (EPS) Controlling Strategies for Performance Enhancement of Biological Wastewater Treatments: An Overview. Chemosphere 2017, 180, 396–411. [Google Scholar] [CrossRef]

- Gao, D.W.; Wen, Z.D.; Li, B.; Liang, H. Membrane Fouling Related to Microbial Community and Extracellular Polymeric Substances at Different Temperatures. Bioresour. Technol. 2013, 143, 172–177. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, Z.; Liang, Z.; Hou, X.; Li, Z.; Mu, D.; Ge, C.; Zhang, C.; Jin, C. Long-Term Investigation into the Membrane Fouling Behavior in Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment Operated at Two Different Temperatures. Membranes 2020, 10, 231. [Google Scholar] [CrossRef]

- Lim, Z.K.; Liu, T.; Zheng, M.; Rattier, M.; Keller, J.; Yuan, Z.; Guo, J.; Hu, S. Membrane Reciprocation as Energy-Efficient Fouling Control with High Biogas Recovery in a Pilot-Scale Anaerobic Membrane Bioreactor. Resour. Conserv. Recycl. 2023, 190, 106849. [Google Scholar] [CrossRef]

- Gouveia, J.; Plaza, F.; Garralon, G.; Fdz-polanco, F.; Peña, M. Long-Term Operation of a Pilot Scale Anaerobic Membrane Bioreactor (AnMBR) for the Treatment of Municipal Wastewater under Psychrophilic Conditions. Bioresour. Technol. 2015, 185, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Guven, H.; Ozgun, H.; Ersahin, M.E.; Dereli, R.K.; Sinop, I.; Ozturk, I. High-Rate Activated Sludge Processes for Municipal Wastewater Treatment: The Effect of Food Waste Addition and Hydraulic Limits of the System. Environ. Sci. Pollut. Res. 2019, 26, 1770–1780. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, J.; Bai, W. A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic-Environmental and Social Sustainability. Sustainability 2023, 15, 5620. [Google Scholar] [CrossRef]

- Macintosh, C.; Astals, S.; Sembera, C.; Ertl, A.; Drewes, J.E.; Jensen, P.D.; Koch, K. Successful Strategies for Increasing Energy Self-Sufficiency at Grüneck Wastewater Treatment Plant in Germany by Food Waste Co-Digestion and Improved Aeration. Appl. Energy 2019, 242, 797–808. [Google Scholar] [CrossRef]

- Moñino, P.; Aguado, D.; Barat, R.; Jiménez, E.; Giménez, J.B.; Seco, A.; Ferrer, J. A New Strategy to Maximize Organic Matter Valorization in Municipalities: Combination of Urban Wastewater with Kitchen Food Waste and Its Treatment with AnMBR Technology. Waste Manag. 2017, 62, 274–289. [Google Scholar] [CrossRef] [PubMed]

- Robles, A.; Capson-Tojo, G.; Ruano, M.V.V.; Seco, A.; Ferrer, J.; Capson-Tojo, G.; Ruano, M.V.V.; Robles, A.; Capson-Tojo, G.; Ruano, M.V.V.; et al. Real-Time Optimization of the Key Filtration Parameters in an AnMBR: Urban Wastewater Mono-Digestion vs. Co-Digestion with Domestic Food Waste. Waste Manag. 2018, 80, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Liew Abdullah, A.G.; Idris, A.; Ahmadun, F.R.; Baharin, B.S.; Emby, F.; Megat Mohd Noor, M.J.; Nour, A.H. A Kinetic Study of a Membrane Anaerobic Reactor (MAR) for Treatment of Sewage Sludge. Desalination 2005, 183, 439–445. [Google Scholar] [CrossRef]

- Dagnew, M.; Parker, W. Impact of AnMBR Operating Conditions on Anaerobic Digestion of Waste Activated Sludge. Water Environ. Res. 2021, 93, 703–713. [Google Scholar] [CrossRef] [PubMed]

- Pileggi, V.; Parker, W.J. AnMBR Digestion of Mixed WRRF Sludges: Impact of Digester Loading and Temperature. J. Water Process Eng. 2017, 19, 74–80. [Google Scholar] [CrossRef]

- Meabe, E.; Déléris, S.; Soroa, S.; Sancho, L. Performance of Anaerobic Membrane Bioreactor for Sewage Sludge Treatment: Mesophilic and Thermophilic Processes. J. Memb. Sci. 2013, 446, 26–33. [Google Scholar] [CrossRef]

- Abdelrahman, A.M.; Ozgun, H.; Dereli, R.K.; Isik, O.; Ozcan, O.Y.; van Lier, J.B.; Ozturk, I.; Ersahin, M.E. Anaerobic Membrane Bioreactors for Sludge Digestion: Current Status and Future Perspectives. Crit. Rev. Environ. Sci. Technol. 2020, 51, 1–39. [Google Scholar] [CrossRef]

- Hafuka, A.; Mashiko, R.; Odashima, R.; Yamamura, H.; Satoh, H.; Watanabe, Y. Digestion Performance and Contributions of Organic and Inorganic Fouling in an Anaerobic Membrane Bioreactor Treating Waste Activated Sludge. Bioresour. Technol. 2019, 272, 63–69. [Google Scholar] [CrossRef]

- Guo, G.; Li, Y.; Zhou, S.; Chen, Y.; Urasaki, K.; Qin, Y.; Kubota, K.; Li, Y.Y. Long Term Operation Performance and Membrane Fouling Mechanisms of Anaerobic Membrane Bioreactor Treating Waste Activated Sludge at High Solid Concentration and High Flux. Sci. Total Environ. 2022, 846, 157435. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, H.; Guo, G.; Zhang, T.; Qin, Y.; Li, Y.-Y. High Solid Mono-Digestion and Co-Digestion Performance of Food Waste and Sewage Sludge by a Thermophilic Anaerobic Membrane Bioreactor. Bioresour. Technol. 2020, 310, 123433. [Google Scholar] [CrossRef]

- Hafuka, A.; Fujino, S.; Kimura, K.; Oshita, K.; Konakahara, N.; Takahashi, S. In-Situ Biogas Upgrading with H2 Addition in an Anaerobic Membrane Bioreactor (AnMBR) Digesting Waste Activated Sludge. Sci. Total Environ. 2022, 828, 154573. [Google Scholar] [CrossRef]

- Vinardell, S.; Astals, S.; Koch, K.; Mata-Alvarez, J.; Dosta, J. Co-Digestion of Sewage Sludge and Food Waste in a Wastewater Treatment Plant Based on Mainstream Anaerobic Membrane Bioreactor Technology: A Techno-Economic Evaluation. Bioresour. Technol. 2021, 330, 124978. [Google Scholar] [CrossRef]

- Serna-García, R.; Mora-Sánchez, J.F.; Sanchis-Perucho, P.; Bouzas, A.; Seco, A. Anaerobic Membrane Bioreactor (AnMBR) Scale-up from Laboratory to Pilot-Scale for Microalgae and Primary Sludge Co-Digestion: Biological and Filtration Assessment. Bioresour. Technol. 2020, 316, 123930. [Google Scholar] [CrossRef] [PubMed]

- Serna-García, R.; Borrás, L.; Bouzas, A.; Seco, A. Insights into the Biological Process Performance and Microbial Diversity during Thermophilic Microalgae Co-Digestion in an Anaerobic Membrane Bioreactor (AnMBR). Algal Res. 2020, 50, 101981. [Google Scholar] [CrossRef]

- Dereli, R.K.; Heffernan, B.; Grelot, A.; Van Der Zee, F.P.; Van Lier, J.B. Influence of High Lipid Containing Wastewater on Filtration Performance and Fouling in AnMBRs Operated at Different Solids Retention Times. Sep. Purif. Technol. 2015, 139, 43–52. [Google Scholar] [CrossRef]

- Qiao, W.; Takayanagi, K.; Li, Y.-Y.; Niu, Q.; Shofie, M.; Yu, H.Q. Thermophilic Anaerobic Digestion of Coffee Grounds with and without Waste Activated Sludge as Co-Substrate Using a Submerged AnMBR: System Amendments and Membrane Performance. Bioresour. Technol. 2013, 150, 249–258. [Google Scholar] [CrossRef]

- Elalami, D.; Carrere, H.; Monlau, F.; Abdelouahdi, K.; Oukarroum, A.; Barakat, A. Pretreatment and Co-Digestion of Wastewater Sludge for Biogas Production: Recent Research Advances and Trends. Renew. Sustain. Energy Rev. 2019, 114, 109287. [Google Scholar] [CrossRef]

- Niu, C.; Pan, Y.; Lu, X.; Wang, S.; Zhang, Z.; Zheng, C.; Tan, Y.; Zhen, G.; Zhao, Y.; Li, Y.-Y. Mesophilic Anaerobic Digestion of Thermally Hydrolyzed Sludge in Anaerobic Membrane Bioreactor: Long-Term Performance, Microbial Community Dynamics and Membrane Fouling Mitigation. J. Memb. Sci. 2020, 612, 118264. [Google Scholar] [CrossRef]

- Wandera, S.M.; Qiao, W.; Jiang, M.; Gapani, D.E.; Bi, S.; Dong, R. AnMBR as Alternative to Conventional CSTR to Achieve Efficient Methane Production from Thermal Hydrolyzed Sludge at Short HRTs. Energy 2018, 159, 588–598. [Google Scholar] [CrossRef]

- Wandera, S.M.; Qiao, W.; Jiang, M.; Mahdy, A.; Yin, D.; Dong, R. Enhanced Methanization of Sewage Sludge Using an Anaerobic Membrane Bioreactor Integrated with Hyperthermophilic Biological Hydrolysis. Energy Convers. Manag. 2019, 196, 846–855. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An Overview of Biogas Production and Utilization at Full-Scale Wastewater Treatment Plants (WWTPs) in the United States: Challenges and Opportunities towards Energy-Neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Niu, K.; Wu, J.; Qi, L.; Niu, Q. Energy Intensity of Wastewater Treatment Plants and Influencing Factors in China. Sci. Total Environ. 2019, 670, 961–970. [Google Scholar] [CrossRef] [PubMed]

- Sarangi, P.K.; Srivastava, R.K.; Singh, A.K.; Sahoo, U.K.; Prus, P.; Sass, R. Municipal-Based Biowaste Conversion for Developing and Promoting Renewable Energy in Smart Cities. Sustainability 2023, 15, 12737. [Google Scholar] [CrossRef]

- Casasso, A.; Puleo, M.; Panepinto, D.; Zanetti, M. Economic Viability and Greenhouse Gas (Ghg) Budget of the Biomethane Retrofit of Manure-Operated Biogas Plants: A Case Study from Piedmont, Italy. Sustainability 2021, 13, 7979. [Google Scholar] [CrossRef]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A Review on the State-of-the-Art of Physical/Chemical and Biological Technologies for Biogas Upgrading. Rev. Environ. Sci. Biotechnol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- Alfaro, N.; Fdz-Polanco, M.; Fdz-Polanco, F.; Díaz, I. H2 Addition through a Submerged Membrane for In-Situ Biogas Upgrading in the Anaerobic Digestion of Sewage Sludge. Bioresour. Technol. 2019, 280, 1–8. [Google Scholar] [CrossRef]

- Díaz, I.; Pérez, C.; Alfaro, N.; Fdz-Polanco, F. A Feasibility Study on the Bioconversion of CO2 and H2 to Biomethane by Gas Sparging through Polymeric Membranes. Bioresour. Technol. 2015, 185, 246–253. [Google Scholar] [CrossRef]

- Cheng, D.; Ngo, H.H.; Guo, W.; Liu, Y.; Chang, S.W.; Nguyen, D.D.; Nghiem, L.D.; Zhou, J.; Ni, B. Anaerobic Membrane Bioreactors for Antibiotic Wastewater Treatment: Performance and Membrane Fouling Issues. Bioresour. Technol. 2018, 267, 714–724. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, B.; Zhang, J.; Zhai, X.; Liu, Z.; Yang, Q.; Liu, H.; Hou, Z.; Sano, D.; Chen, R. Virus Removal during Sewage Treatment by Anaerobic Membrane Bioreactor (AnMBR): The Role of Membrane Fouling. Water Res. 2022, 211, 118055. [Google Scholar] [CrossRef]

- Wang, W.; Xie, L.; Luo, G.; Zhou, Q.; Angelidaki, I. Performance and Microbial Community Analysis of the Anaerobic Reactor with Coke Oven Gas Biomethanation and in Situ Biogas Upgrading. Bioresour. Technol. 2013, 146, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Wang, W.; Angelidaki, I. Anaerobic Digestion for Simultaneous Sewage Sludge Treatment and CO Biomethanation: Process Performance and Microbial Ecology. Environ. Sci. Technol. 2013, 47, 10685–10693. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Q.; Yu, S.J.; Zhang, F.; Xia, X.Y.; Zeng, R.J. Enhancement of Acetate Productivity in a Thermophilic (55 °C) Hollow-Fiber Membrane Biofilm Reactor with Mixed Culture Syngas (H2/CO2) Fermentation. Appl. Microbiol. Biotechnol. 2017, 101, 2619–2627. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Jiang, J.; Li, J.; He, C.; Luo, Y.; Wei, L. Anaerobic Membrane Bioreactors for Wastewater Treatment: Mechanisms, Fouling Control, Novel Configurations, and Future Perspectives. Environ. Eng. Res. 2022, 28, 210575. [Google Scholar] [CrossRef]

- De Vela, R.J. A Review of the Factors Affecting the Performance of Anaerobic Membrane Bioreactor and Strategies to Control Membrane Fouling; Springer: Dordrecht, The Netherlands, 2021; Volume 20, ISBN 0123456789. [Google Scholar]

- Zhang, Y.P.; Law, A.W.K.; Fane, A.G. Determination of Critical Flux by Mass Balance Technique Combined with Direct Observation Image Analysis. J. Memb. Sci. 2010, 365, 106–113. [Google Scholar] [CrossRef]

- Robles, A.; Ruano, M.V.; García-Usach, F.; Ferrer, J. Sub-Critical Filtration Conditions of Commercial Hollow-Fibre Membranes in a Submerged Anaerobic MBR (HF-SAnMBR) System: The Effect of Gas Sparging Intensity. Bioresour. Technol. 2012, 114, 247–254. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.L.; Stadler, L.B.; Cao, L.; Love, N.G.; Raskin, L.; Skerlos, S.J. Navigating Wastewater Energy Recovery Strategies: A Life Cycle Comparison of Anaerobic Membrane Bioreactor and Conventional Treatment Systems with Anaerobic Digestion. Environ. Sci. Technol. 2014, 48, 5972–5981. [Google Scholar] [CrossRef]

- Cheng, H.; Li, Y.; Kato, H.; Li, Y.-Y. Enhancement of Sustainable Flux by Optimizing Filtration Mode of a High-Solid Anaerobic Membrane Bioreactor during Long-Term Continuous Treatment of Food Waste. Water Res. 2020, 168, 115195. [Google Scholar] [CrossRef]

- Hu, Y.; Du, R.; Nitta, S.; Ji, J.; Rong, C.; Cai, X.; Qin, Y.; Li, Y.Y. Identification of Sustainable Filtration Mode of an Anaerobic Membrane Bioreactor for Wastewater Treatment towards Low-Fouling Operation and Efficient Bioenergy Production. J. Clean. Prod. 2021, 329, 129686. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Rout, P.R.; Aslam, M.; Fuwad, A.; Choi, Y.; Banu, J.R.; Park, J.H.; Kumar, G. A Brief Review of Anaerobic Membrane Bioreactors Emphasizing Recent Advancements, Fouling Issues and Future Perspectives. J. Environ. Manag. 2020, 270, 110909. [Google Scholar] [CrossRef]

- Yue, X.; Koh, Y.K.K.; Ng, H.Y. Membrane Fouling Mitigation by NaClO-Assisted Backwash in Anaerobic Ceramic Membrane Bioreactors for the Treatment of Domestic Wastewater. Bioresour. Technol. 2018, 268, 622–632. [Google Scholar] [CrossRef] [PubMed]

- Vera, L.; González, E.; Ruigómez, I.; Gómez, J.; Delgado, S. Influence of Gas Sparging Intermittence on Ultrafiltration Performance of Anaerobic Suspensions. Ind. Eng. Chem. Res. 2016, 55, 4668–4675. [Google Scholar] [CrossRef]

- Li, N.; Hu, Y.; Lu, Y.Z.; Zeng, R.J.; Sheng, G.P. In-Situ Biogas Sparging Enhances the Performance of an Anaerobic Membrane Bioreactor (AnMBR) with Mesh Filter in Low-Strength Wastewater Treatment. Appl. Microbiol. Biotechnol. 2016, 100, 6081–6089. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.J.; Han, M.N.; Xu, C.; Liao, B.Q.; Hong, Y.; Cumin, J.; Dagnew, M. Performance of Submerged Anaerobic Membrane Bioreactor for Thermomechanical Pulping Wastewater Treatment. J. Water Process Eng. 2016, 13, 70–78. [Google Scholar] [CrossRef]

- Fox, R.A.; Stuckey, D.C. The Effect of Sparging Rate on Transmembrane Pressure and Critical Flux in an AnMBR. J. Environ. Manag. 2015, 151, 280–285. [Google Scholar] [CrossRef]

- Zhang, Q.; Victor Tan, G.H.; Stuckey, D.C. Optimal Biogas Sparging Strategy, and the Correlation between Sludge and Fouling Layer Properties in a Submerged Anaerobic Membrane Bioreactor (SAnMBR). Chem. Eng. J. 2017, 319, 248–257. [Google Scholar] [CrossRef]

- Trzcinski, A.P.; Stuckey, D.C. Effect of Sparging Rate on Permeate Quality in a Submerged Anaerobic Membrane Bioreactor (SAMBR) Treating Leachate from the Organic Fraction of Municipal Solid Waste (OFMSW). J. Environ. Manag. 2016, 168, 67–73. [Google Scholar] [CrossRef]

- Pretel, R.; Robles, A.; Ruano, M.V.; Seco, A.; Ferrer, J. Filtration Process Cost in Submerged Anaerobic Membrane Bioreactors (AnMBRs) for Urban Wastewater Treatment. Sep. Sci. Technol. 2016, 51, 517–524. [Google Scholar] [CrossRef]

- Kwon, D.; Beirns, E.; Yoon, J.; Lam, T.Y.C.; Tan, G.Y.A.; Lee, P.H.; Kim, J. Polyaniline-Coated Conductive Media Promotes Direct Interspecies Electrons Transfer (DIET) and Kinetics Enhancement of Low-Strength Wastewater Treatment in Anaerobic Fluidized Bed Membrane Bioreactor (AFMBR). Chem. Eng. J. 2022, 446, 136711. [Google Scholar] [CrossRef]

- Nabi, M.; Liang, H.; Zhou, Q.; Cao, J.; Gao, D. In-Situ Membrane Fouling Control and Performance Improvement by Adding Materials in Anaerobic Membrane Bioreactor: A Review. Sci. Total Environ. 2023, 865, 161262. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, W.; Zhang, H.; Wang, Z.; Fan, C.; Zang, L. Recent Achievements in Enhancing Anaerobic Digestion with Carbon-Based Functional Materials. Bioresour. Technol. 2018, 266, 555–567. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Zhang, Q.; Lei, Z.; Wen, W.; Huang, X.; Chen, R. Comparing Powdered and Granular Activated Carbon Addition on Membrane Fouling Control through Evaluating the Impacts on Mixed Liquor and Cake Layer Properties in Anaerobic Membrane Bioreactors. Bioresour. Technol. 2019, 294, 122137. [Google Scholar] [CrossRef] [PubMed]

- Lei, Z.; Ma, Y.; Wang, J.; Wang, X.C.; Li, Q.; Chen, R. Biochar Addition Supports High Digestion Performance and Low Membrane Fouling Rate in an Anaerobic Membrane Bioreactor under Low Temperatures. Bioresour. Technol. 2021, 330, 124966. [Google Scholar] [CrossRef] [PubMed]

- Shin, C.; Kim, K.; McCarty, P.L.; Kim, J.; Bae, J. Integrity of Hollow-Fiber Membranes in a Pilot-Scale Anaerobic Fluidized Membrane Bioreactor (AFMBR) after Two-Years of Operation. Sep. Purif. Technol. 2016, 162, 101–105. [Google Scholar] [CrossRef]

- Charfi, A.; Aslam, M.; Kim, J. Modelling Approach to Better Control Biofouling in Fluidized Bed Membrane Bioreactor for Wastewater Treatment. Chemosphere 2018, 191, 136–144. [Google Scholar] [CrossRef] [PubMed]

- Park, J.G.; Lee, B.; Park, H.R.; Jun, H.B. Long-Term Evaluation of Methane Production in a Bio-Electrochemical Anaerobic Digestion Reactor According to the Organic Loading Rate. Bioresour. Technol. 2019, 273, 478–486. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.; Ren, H.; Fan, J.; Zhao, K.; Hu, C.; Qu, J. Membrane Fouling Mitigation by Coagulation and Electrostatic Repulsion Using an Electro-AnMBR in Kitchen Wastewater Treatment. Water Res. 2022, 222, 118883. [Google Scholar] [CrossRef] [PubMed]

- Zhen, G.; Pan, Y.; Han, Y.; Gao, Y.; Ibrahim Gadow, S.; Zhu, X.; Yang, L.; Lu, X. Enhanced Co-Digestion of Sewage Sludge and Food Waste Using Novel Electrochemical Anaerobic Membrane Bioreactor (EC-AnMBR). Bioresour. Technol. 2023, 377, 128939. [Google Scholar] [CrossRef]

| Feedstock 1 | System Configuration 2 | Membrane Material 3 | Filtration Area (m2)/Pore Size (μm) | Membrane Flux (L/m2/h) | Filtration Mode (Filtration: Relaxation; min:min) | Mixed Liquor Solid Concentration (g/L) | Biogas Sparging | Online Chemical Cleaning | Reference |

|---|---|---|---|---|---|---|---|---|---|

| S-related | M-ES-HF-AnMBR/CSTR | PTFE | 0.1/0.1 | 6 | 3:3 | 25–30 (MLTS) | Yes, 85 m/h | No | [20] |

| W-related | P-S-HF-AnMBR | PVDF | 72/0.4 | 10.8 | 4:1 | 10–12 (MLSS) | Yes, 0.75 m/h | Yes, weekly | [27] |

| S-related | T-ES-HF-AnMBR/CSTR | - | 0.1/0.1 | 5 | 3:1 | 27 (MLTS) | Yes, 74 m/h | No | [51] |

| S-related | T-S-AnMBR | CPE | 0.116/0.2 | 2.0–7.6 | 4:1 | 10–80 (MLTS) | Yes, 5 L/min | No | [57] |

| W-related | P-ES-HF-AnMBR/UASB | - | 0.93/0.045 | 0–15 | 7.5/30:0.08 | 0–5.95 (MLVS) | Yes, 25–60 m/h | Yes, 15/60 s per cycle | [38] |

| S-related | M-ET-HF-AnMBR | PVDF | 0.0016/0.1 | 1.29–1.46 | Continuously | 6–13 (MLTS) | 0/0.52 L/min | No | [52] |

| S-related | M&T-ET-CM-AnMBR | TiO2/ZrO2 | 0.0226/300 kDa | 7 | - | 20 (MLTS) | No | No | [47] |

| S-related | M-S-FS-AnMBR | Polymeric membrane | 0.232/0.22 | 3.6–10.5 | 2:1 | 38–61 (MLTS) | Yes | No | [61] |

| W-related | P-S-HF-AnMBR | - | 30/0.4 | 9.5 | - | 13–16 (MLSS) | Yes, 26 m3/h | No | [19] |

| S-related | M-ES-HF-AnMBR | PVDF | 0.44/0.03 | 3.5–10.5 | 1.5:0 | 12.3 (MLTS) | Yes, 0.15 m/h | Yes, 40 s per cycle | [54] |

| S-related | M-ES-HF-AnMBR | PVDF | 0.44/0.03 | 4.18–5.6 | 3:0.5 | 11.5 (MLTS) | Yes, 0.15–0.62 m/h | Yes, 45 s per cycle | [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Ren, Y.; Ji, J.; Li, Y.-Y.; Kobayashi, T. Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment, Sewage Sludge Digestion and Biogas Upgrading: A Review. Sustainability 2023, 15, 15129. https://doi.org/10.3390/su152015129

Li Y, Ren Y, Ji J, Li Y-Y, Kobayashi T. Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment, Sewage Sludge Digestion and Biogas Upgrading: A Review. Sustainability. 2023; 15(20):15129. https://doi.org/10.3390/su152015129

Chicago/Turabian StyleLi, Yemei, Yuanyuan Ren, Jiayuan Ji, Yu-You Li, and Takuro Kobayashi. 2023. "Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment, Sewage Sludge Digestion and Biogas Upgrading: A Review" Sustainability 15, no. 20: 15129. https://doi.org/10.3390/su152015129