The Principles and Evaluation of Green Construction of Tunnels in Frigid Plateau Regions

Abstract

:1. Introduction

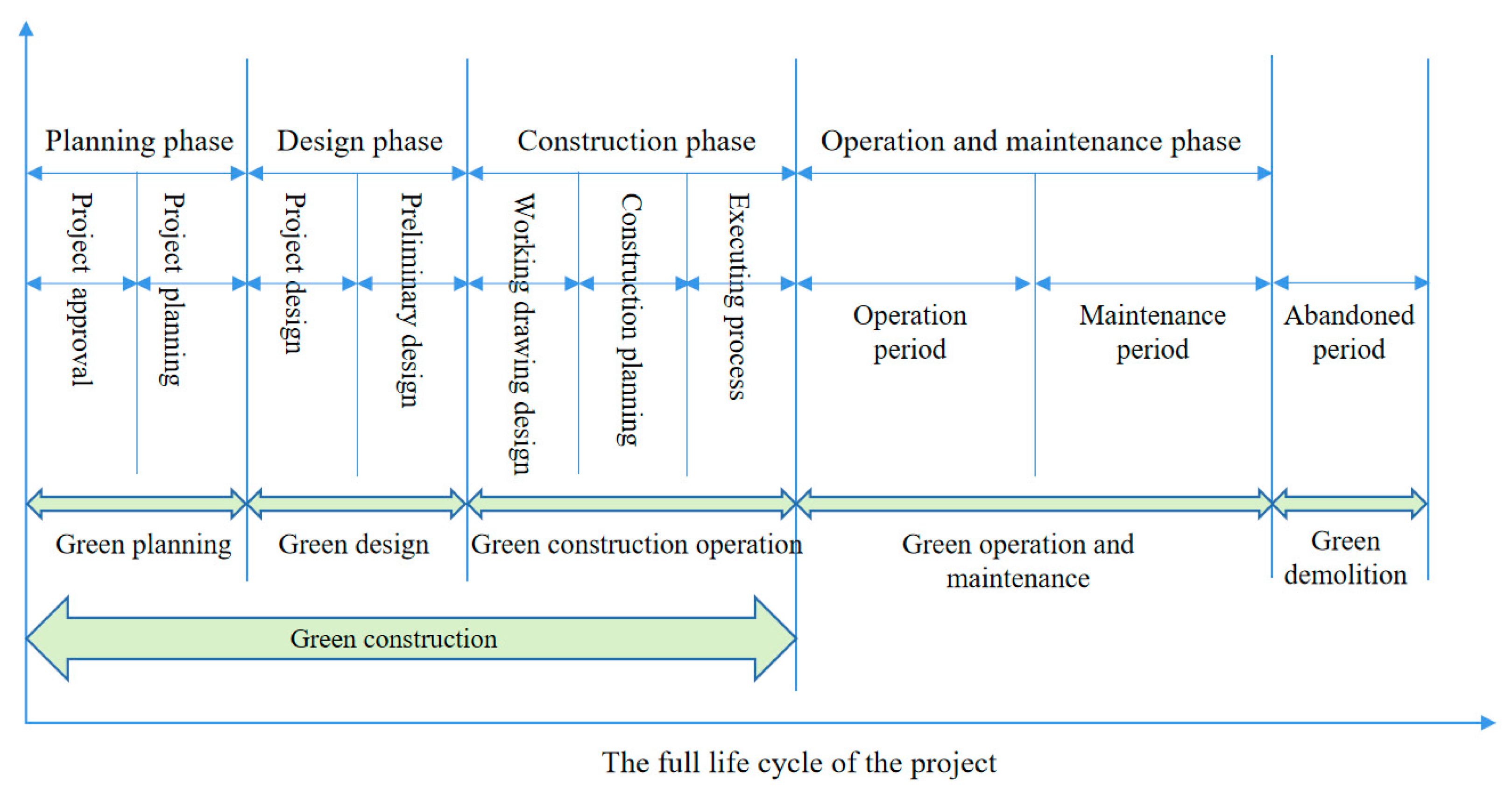

2. Green Construction

2.1. Concept and Connotation of Green Construction

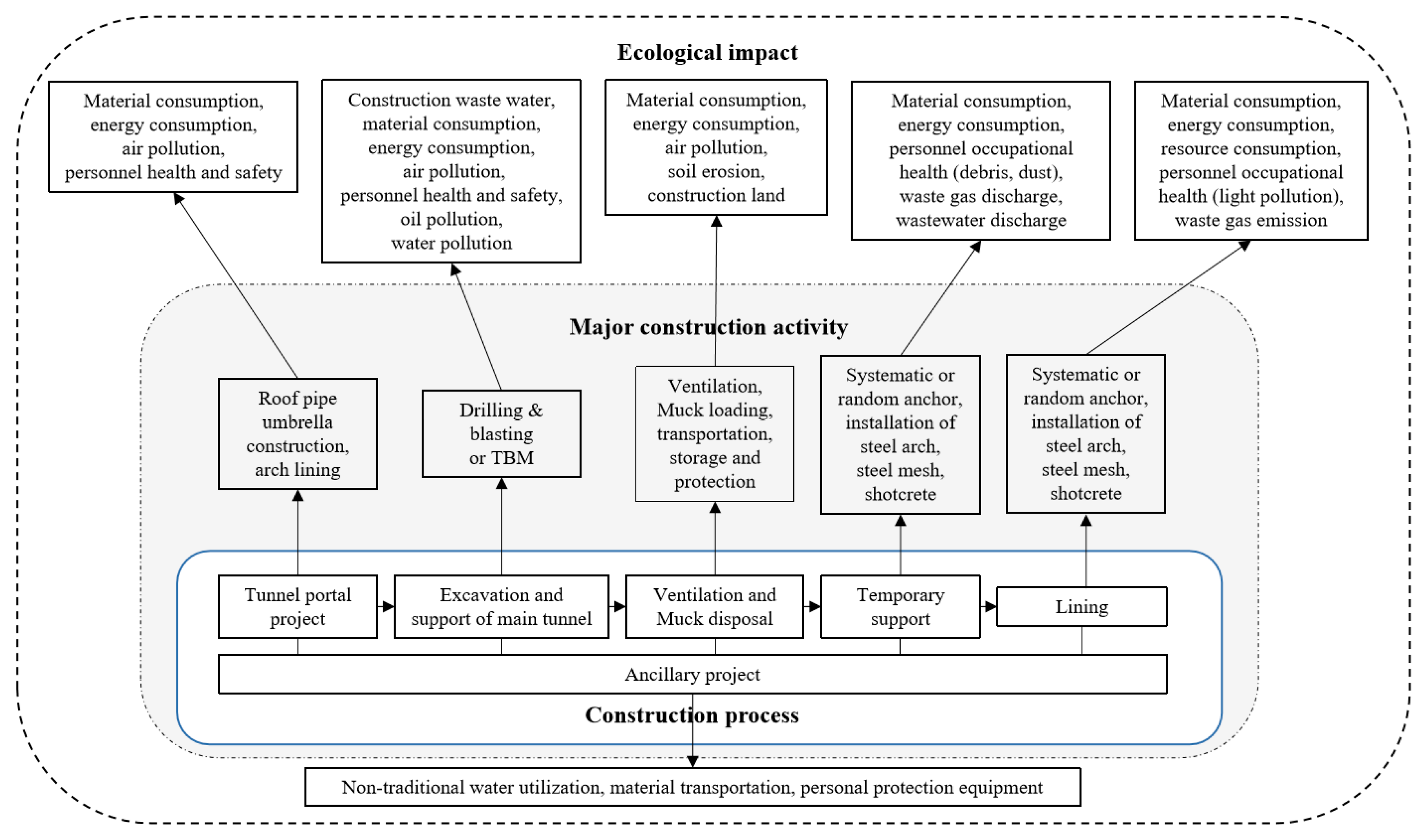

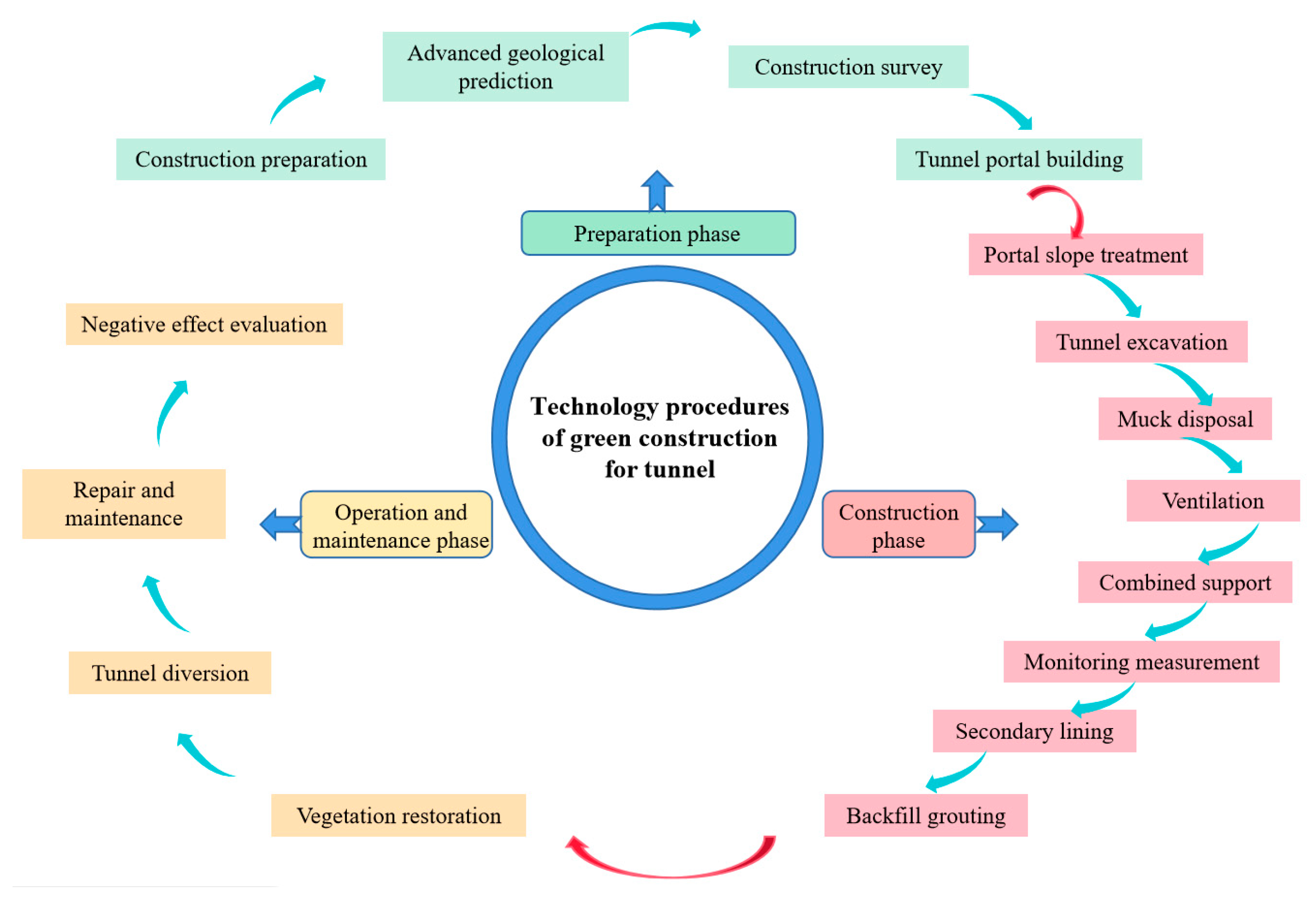

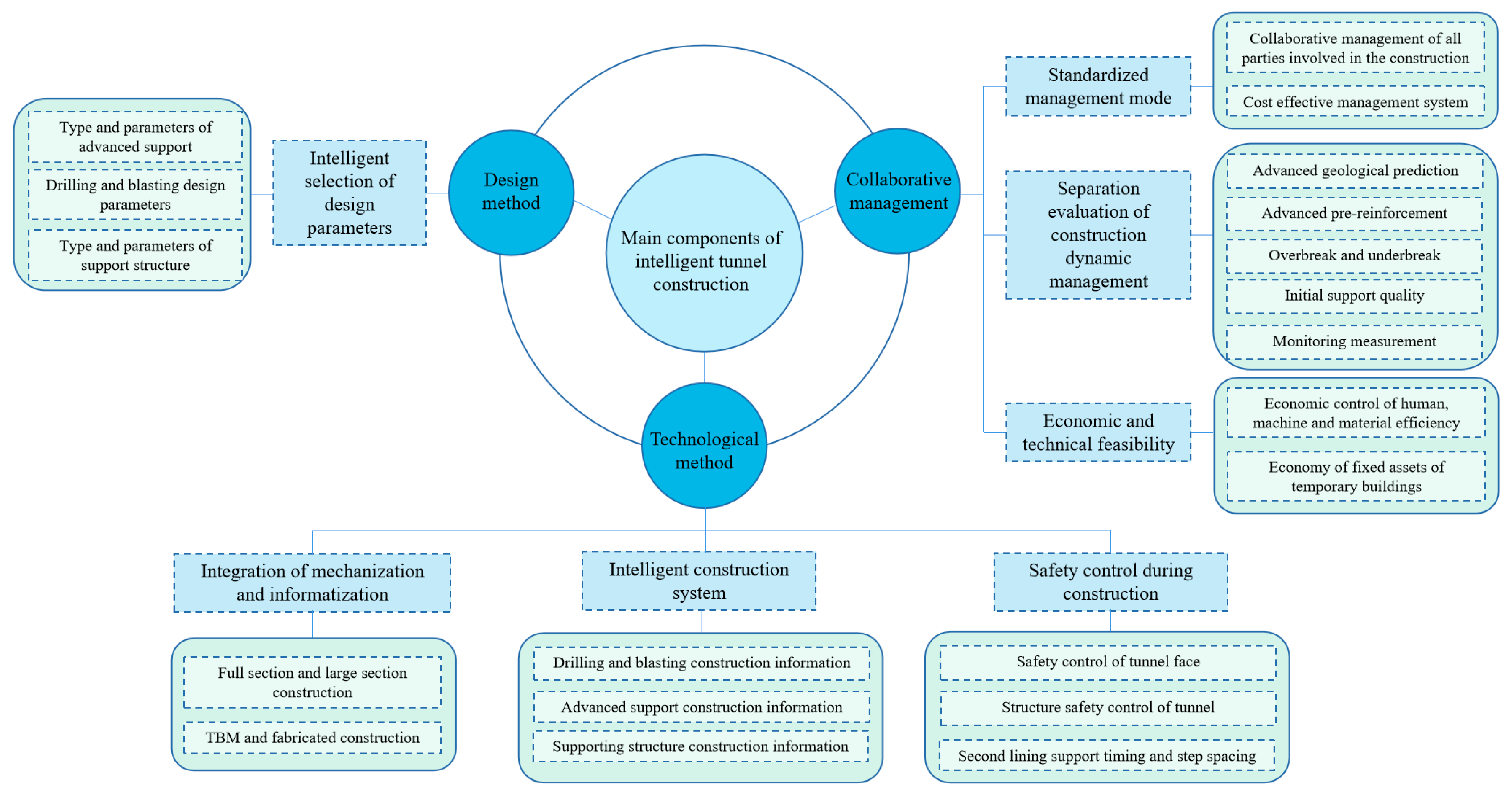

2.2. Green Construction Technology for Tunneling

2.3. Key Points of Green Construction for Tunnels

2.3.1. Refined Classification and Safety Evaluation of Surrounding Rock

2.3.2. Changes in Seepage Field Caused by Tunnel Construction

2.3.3. Establishment of a Standardized Management System for Tunnels

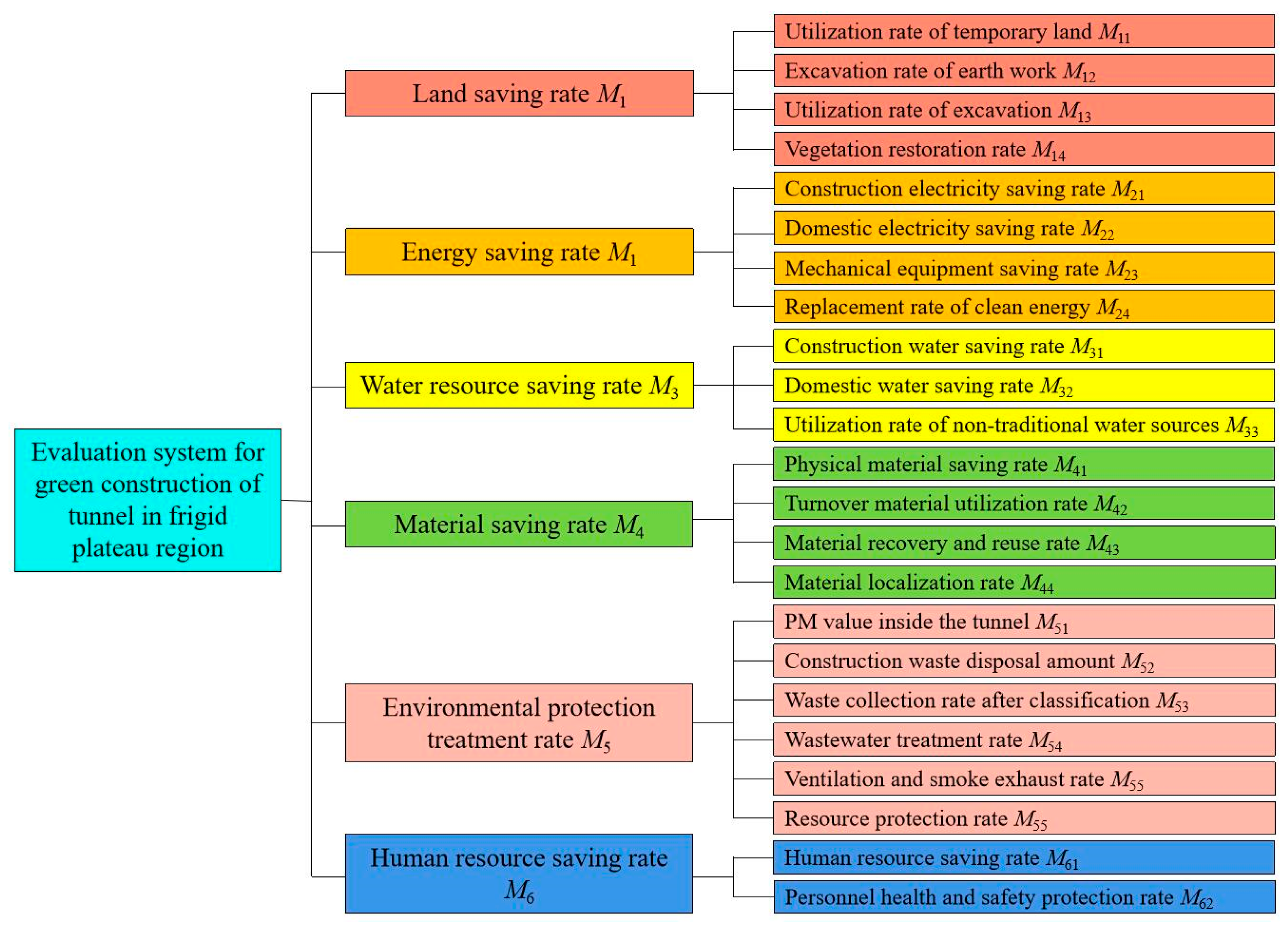

3. Evaluation for Green Construction of Tunnels in Frigid Plateau Regions

3.1. Evaluation System

3.1.1. Evaluation Indicators

- (1)

- Land resource

- (2)

- Energy

- (3)

- Water resource

- (4)

- Material

- (5)

- Environmental protection

- (6)

- Human resource, health, and safety

3.1.2. Grading Scale for Evaluation Indicators

3.2. Evaluation Model

3.2.1. Weight of Indicators

- (1)

- Establish the judgment matrix of each layer. Establish a judgment matrix M = (aij)n×m for the evaluation indicators of the same layer under a certain criterion layer based on the importance of the factors. Decision makers compare each pairwise comparison to obtain a ratio scale of measurement where aij represents the relative importance value of factor ai to aj, with values ranging from one to nine.

- (2)

- Calculate the maximum eigenvalue and eigenvector of the judgment matrix. Based on the judgment matrix, calculate the eigenvector w’ corresponding to the maximum eigenvalue of M using the formula Mw = λmaxw. The normalized weight vector w’= (w’1, w’2, …, w’n) is the importance ranking of each indicator, that is, the weight of each indicator.

- (3)

- Perform consistency verification. Whether the weights obtained above are within the allowable range requires consistency testing using a testing equation.

3.2.2. Fuzzy Matter-Element

4. Case Calculation

4.1. Results

4.2. Discussion

- (1)

- Due to the harsh natural environment and fragile ecological environment in frigid plateau regions, the traditional indicator system of “Four savings and One protection” [59] is not sufficient to fully meet the green construction evaluation needs of tunnels. Considering the characteristics of the frigid plateau region, two indicators of human resource saving and personnel protection are proposed and added to form the “Five savings and Two protections” evaluation index system suitable for green construction of tunnels in the frigid plateau region. It contains six first-level evaluation indicators, including land saving, energy saving, material saving, water resource conservation, environmental protection, human resources and health and safety protection, and 23 corresponding second-level evaluation indicators.

- (2)

- The weight calculations used in this study were obtained by the AHP method. The AHP method was used to invite experts to provide scores, which determined the weights of indicators at all levels. This method has some invisible, subjective impact. However, by comparing the weights of evaluation indicators with other similar regions [55], it can be proven that the final weight values obtained are reasonable.

- (3)

- This paper adopts the established evaluation indicator system and uses the fuzzy matter-element method to evaluate the green construction grade of the Yindajihuang project. However, due to space limitations, this article did not conduct sensitivity analysis for the calculated weights and for all the grades. The impact of different factors will be further studied in the future.

- (4)

- Various green construction technologies have been adopted in the Yindajihuang project, such as adopting a non-excavated slope approach, developing and using a hydraulic tunnel secondary lining trolley, and adopting a standardized management system to ensure quality and improve production efficiency. Through scientific management and technological innovation, construction methods conducive to saving resources, protecting the environment, reducing emissions, improving efficiency, and guaranteeing quality have been adopted to realize the harmonious coexistence between humans and nature. Therefore, the green construction evaluation grade of the #11 tunnel is very good, basically consistent with the actual situation on site.

5. Concluding Remarks

- (1)

- As a particular underground tunnel structure project, the tunnel project is suitable for classification into the three stages of green planning, green design, and green construction operation based on the concept of green construction. It is necessary to clarify the implications of the green construction of tunnels and to promote practice and innovation in green construction technology, while focusing on quality assurance and environmental protection. This is an essential prerequisite for the promotion and implementation of green construction. The green construction of the tunnel project in a cold, arid, and frigid plateau area has important strategic significance in responding to green development.

- (2)

- Driven by China’s policy of vigorously promoting the construction of ecological civilization, the new concept of green construction technology for tunnels is proposed and optimized. A green construction evaluation indicator system set suitable for tunnels in frigid plateau regions has been developed. It contains six first-level evaluation indicators, including land saving, energy saving, material saving, water resource conservation, environmental protection, human resources, and health and safety protection, and 23 corresponding second-level evaluation indicators, referred to as “Five savings and Two protections”. Establishing this evaluation system is intended to make up for the shortcomings of most existing studies, which have carried out green evaluations from the aspects of soil and water conservation and environmental impact, so that tunnel construction can be coordinated with the ecological environment and achieve rapid development. It is also the inevitable result of implementing a green and sustainable development strategy for a tunnel in the frigid plateau region. Through the green construction evaluation of the tunnel of the Yindajihuang project, the evaluation grade was found to be “very good”, which is basically consistent with the actual situation. The evaluation system can provide a reference for tunnel projects in other frigid plateau regions.

- (3)

- Considering the unique climatic characteristics, natural resource characteristics, environmental characteristics, and other regional conditions of frigid plateau regions, the following key points are put forward: (a) fine grading of surrounding rock and safety evaluation, (b) changes in seepage field caused by construction, and (c) the establishment of a standardized construction system. The green evaluation results of the tunnel in the Yindajihuang Project show that adopting these green construction technologies is beneficial for the evaluation results. In order to achieve “Five savings and Two protections”, the development of intelligent construction technology should be the goal of green construction for tunnels.

- (4)

- Implementing green construction has a more profound connotation and significance. Considering the fragile and complex regional characteristics of the western frigid plateau region, the sustainable development of green construction of the tunnel in the frigid plateau region needs to advocate resource-saving, reduce energy consumption and pollution, and protect the health and safety of people and the environment as well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Energy Administration of China. Available online: http://www.nea.gov.cn/2022-07/01/c_1310636707.htm (accessed on 18 July 2023).

- Hao, J.; Gao, F.; Fang, X.; Nong, X.; Zhang, Y.; Hong, F. Multi-factor decomposition and multi-scenario prediction decoupling analysis of China’s carbon emission under dual carbon goal. Sci. Total Environ. 2022, 841, 156788. [Google Scholar] [CrossRef]

- Shi, Q.; Zuo, J.; Huang, R.; Huang, J.; Pullen, S. Identifying the Critical Factors for Green Construction—An Empirical Study in China. Habitat Int. 2013, 40, 1–8. [Google Scholar] [CrossRef]

- Xiao, X.; Feng, D. Review and promoting suggestions of green construction for buildings. Constr. Technol. 2013, 42, 12–15. [Google Scholar]

- Xiao, X.; Feng, D. Practical significance and implementation strategy of green construction in China. Constr. Technol. 2013, 42, 1–4. [Google Scholar]

- Sun, Y.; Tang, J.; Wang, M.; Niu, F.; Qiu, Q. Connotation explore and research prospects for green railway engineering. J. Railw. Sci. Eng. 2021, 18, 1–11. [Google Scholar] [CrossRef]

- You, X. State-of-art and prospectives of urban utility tunnels in China. Tunn. Constr. 2018, 38, 1603–1611. [Google Scholar]

- You, X.; Hua, D.; Wang, H. Effective measures for green construction of utility tunnel. Tunn. Constr. 2018, 38, 1423–1427. [Google Scholar]

- You, X.; Qu, L.; Luo, C. Urban Utility Tunnels in China: Experience, Problems and Suggestions. Tunn. Constr. 2020, 40, 621–628. [Google Scholar]

- Rooshdi, R.R.R.M.; Rahman, N.A.; Baki, N.Z.U.; Majid, M.Z.A.; Ismail, F. An Evaluation of Sustainable Design and Construction Criteria for Green Highway. Procedia Environ. Sci. 2014, 20, 180–186. [Google Scholar] [CrossRef]

- You, X. Green Construction Concept and Technology of Shield Engineering. Archit. Technol. 2019, 50, 644–646. [Google Scholar]

- Zhang, Y. Research on Green Evaluation Index System and Evaluation Results of High-speed Railway. Master Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Jiang, Z.; Xue, P.; Ma, X.; Xie, J.; Liu, J. Evaluation System of Green Highway Tunnels. Tunn. Constr. 2022, 42, 586–593. [Google Scholar]

- Luo, W.; Sandanayake, M.; Hou, L.; Tan, Y.; Zhang, G. A systematic review of green construction research using scientometrics methods. J. Clean. Prod. 2022, 366, 132710. [Google Scholar] [CrossRef]

- Qiu, W.; Liu, Y.; Lu, F.; Huang, G. Establishing a Sustainable Evaluation Indicator System for Railway Tunnel in China. J. Clean. Prod. 2020, 268, 122150. [Google Scholar] [CrossRef]

- García-Trenas, T.; López, J.C.; Peña-García, A. Proposal to Forest Alpine Tunnels Surroundings to Enhance Energy Savings from the Lighting Installations. Towards a Standard Procedure. Tunn. Undergr. Space Technol. 2018, 78, 1–7. [Google Scholar] [CrossRef]

- Lehner, P.; Hrabová, K. Evaluation of Degradation and Mechanical Parameters and Sustainability Indicators of Zeolite Concretes. Constr. Build. Mater. 2023, 371, 130791. [Google Scholar] [CrossRef]

- Chi, B.; Lu, W.; Ye, M.; Bao, Z.; Zhang, X. Construction waste minimization in green building: A comparative analysis of LEED-NC 2009 certified projects in the US and China. J. Clean. Prod. 2020, 256, 120749. [Google Scholar] [CrossRef]

- Li, H.; Huang, F.; Wang, Z.; Luo, X.; Yuan, Z.; Yi, Z.; Xie, Y. Review of Material Technology Used in Green Railway Tunnel Engineering. Tunn. Constr. 2021, 41, 1992–2000. [Google Scholar]

- Barla, M.; Insana, A. Energy Tunnels as an Opportunity for Sustainable Development of Urban Areas. Tunn. Undergr. Space Technol. 2023, 132, 104902. [Google Scholar] [CrossRef]

- Phillips, J. A Quantitative Evaluation of the Sustainability or Unsustainability of Three Tunnelling Projects. Tunn. Undergr. Space Technol. 2016, 51, 387–404. [Google Scholar] [CrossRef]

- De La Fuente, A.; Blanco, A.; Armengou, J.; Aguado, A. Sustainability Based-Approach to Determine the Concrete Type and Reinforcement Configuration of TBM Tunnels Linings. Case Study: Extension Line to Barcelona Airport T1. Tunn. Undergr. Space Technol. 2017, 61, 179–188. [Google Scholar] [CrossRef]

- Hrabova, K.; Vorechovska, D.; Teply, B. Potential for the Inclusion of Sustainability Aspects in Limit States for Concrete; STEF92 Technology: Sofia, Bulgaria, 2020; pp. 411–418. [Google Scholar] [CrossRef]

- Li, W. Application Research on Green Construction in Metro Engineering. Master Thesis, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Wan, Z. Study on Green Construction Technology and Cost Risk Management of Water Supply Project. Master Thesis, Southeast University, Nanjing, China, 2017. [Google Scholar]

- Yin, Z. Metallurgical Industry Project Green Construction Techniques and Cost Risk Management. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2014. [Google Scholar]

- Guo, C.; Xu, J.; Yang, L.; Guo, X.; Liao, J.; Zheng, X.; Zhang, Z.; Chen, X.; Yang, K.; Wang, M. Life Cycle Evaluation of Greenhouse Gas Emissions of a Highway Tunnel: A Case Study in China. J. Clean. Prod. 2019, 211, 972–980. [Google Scholar] [CrossRef]

- Lv, Y.; Jiang, Y.; Hu, W.; Cao, M.; Mao, Y. A review of the effects of tunnel excavation on the hydrology, ecology, and environment in karst areas: Current status, challenges, and perspectives. J. Hydrol. 2020, 586, 124891. [Google Scholar] [CrossRef]

- Islam, M.S.; Iskander, M. Twin tunnelling induced ground settlements: A review. Tunn. Undergr. Space Technol. 2021, 110, 103614. [Google Scholar] [CrossRef]

- Xiao, X. State and development strategy for green construction. Constr. Technol. 2018, 47, 1–4+40. [Google Scholar]

- Department of Transport of Guangdong Province. Available online: http://td.gd.gov.cn/dtxw_n/gdjrxw/content/post_4118665.html (accessed on 18 July 2023).

- GB 50487-2008; Code for Engineering Geological Investigation of Water Resources and Hydropower. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- GB/T 50218-2014; Standard for Engineering Classification of Rock Mass. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

- Yin, H.; Zhang, Y.; Zhou, H.; Zhong, Z. Review on the Classification of Engineering Rock Mass. J. Yangtze River Sci. Res. Inst. 2011, 28, 59–66. [Google Scholar]

- Cai, B. Discussion about several problems of the use of standard for engineering classification of rock masses. Rock Soil Mech. 2003, S1, 74–76. [Google Scholar] [CrossRef]

- Hao, Z. Review and suggestions on China’s current rock mass classification system. Met. Mine 2005, 9, 59–62+73. [Google Scholar]

- TB 10003-2016; Code for Design of Railway Tunnel. National Railway Administration of People’s Republic of China: Beijing, China, 2017.

- Kim, T.H.; Chung, S.Y.; Senapathi, V.; Sekar, S.; Elzain, H.E. Groundwater Decrease and Contamination around Subway Tunnels in a Coastal Area of Busan City, Korea. Environ. Earth Sci. 2021, 80, 550. [Google Scholar] [CrossRef]

- Chen, K.-L.; Wu, H.-N.; Cheng, W.-C.; Zhang, Z.; Chen, J. Geological Characteristics of Strata in Chongqing, China, and Mitigation of the Environmental Impacts of Tunneling-Induced Geo-Hazards. Environ. Earth Sci. 2017, 76, 10. [Google Scholar] [CrossRef]

- Liu, J.; Liu, D.; Song, K. Evaluation of the Negative Effects on Groundwater Environment Resulted by Geleshan Tunnel Drainage. Mod. Tunn. Technol. 2012, 49, 178–183. [Google Scholar] [CrossRef]

- Vincenzi, V.; Gargini, A.; Goldscheider, N. Using Tracer Tests and Hydrological Observations to Evaluate Effects of Tunnel Drainage on Groundwater and Surface Waters in the Northern Apennines (Italy). Hydrogeol. J. 2009, 17, 135–150. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, M. Research on Evaluation Technique of Interaction Between Shibanshan Tunnel and Groundwater Environment. China Civ. Eng. J. 2015, 48 (Suppl. 1), 321–325. [Google Scholar]

- Liu, Y.; Yu, C.; Cao, S.; Song, M.; Lin, J. Study on Comprehensive Assessment Method of Water Quality in Dong’e Groundwater Source. J. Water Resour. Water Eng. 2015, 26, 99–103. [Google Scholar]

- Ferreira, A.; Pinheiro, M.D.; Brito, J.D.; Mateus, R. A Critical Analysis of LEED, BREEAM and DGNB as Sustainability Assessment Methods for Retail Buildings. J. Build. Eng. 2023, 66, 105825. [Google Scholar] [CrossRef]

- Luo, K.; Scofield, J.H.; Qiu, Y. Water Savings of LEED-Certified Buildings. Resour. Conserv. Recycl. 2021, 175, 105856. [Google Scholar] [CrossRef]

- Derek, J.P.; Bradford, F.T. Design for Sustainable and Economical Tunnels. In North American Tunneling: 2010 Proceedings; Society for Mining, Metallurgy, and Exploration, Inc.: Littleton, CO, USA, 2010; pp. 183–190. [Google Scholar]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. A Methodology for Predicting the Severity of Environmental Impacts Related to the Construction Process of Residential Buildings. Build. Environ. 2009, 44, 558–571. [Google Scholar] [CrossRef]

- Kim, Y.-D.; Cha, H.-S.; Kim, K.-R.; Shin, D.-W. Evaluation Method of Green Construction Technologies Using Integrated LCC and LCA Analysis. Korean J. Constr. Eng. Manag. 2011, 12, 91–100. [Google Scholar] [CrossRef]

- Bao, X.; Yang, S.; Wang, Q. Research on the grade evaluation for railway green construction based on grey clustering methods. J. Railw. Eng. Soc. 2016, 33, 106–110. [Google Scholar]

- Chen, J.; Jiskani, I.M.; Lin, A.; Zhao, C.; Jing, P.; Liu, F.; Lu, M. A Hybrid Decision Model and Case Study for Comprehensive Evaluation of Green Mine Construction Level. Environ. Dev. Sustain. 2022, 25, 3823–3842. [Google Scholar] [CrossRef]

- GB/T 50378-2019; Assessment Standard for Green Building. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- GB/T 50434-2018; Standard of Soil Erosion Control for Production and Construction Projects. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Li, X. Key Technology for Expressway Land Intensive Economical Use and Comprehensive Evaluation on Its Effect. Ph.D. Thesis, Chang’an University, Xi’an, China, 2013. [Google Scholar]

- Wang, H.; Wu, F.; Gong, L. Evaluating the Green-grade of Railway Passenger Stations Based on Whole Life Cycle. J. China Railw. Soc. 2012, 34, 14–21. [Google Scholar]

- Bao, X. Study on Application and Formation of Railway Green Construction Grade Evaluation Systems for Cold and Arid Areas in Northwest China. Ph.D. Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2017. [Google Scholar]

- Thungngern, J.; Wijitkosum, S.; Sriburi, T.; Sukhsri, C. A Review of the Analytical Hierarchy Process (AHP): An Approach to Water Resource Management in Thailand. App. Envi. Res. 2015, 37, 13–32. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, X.; Cheng, Y.; Jing, J.; Jia, S.; Sun, D. Evaluation of water resources carrying capacity and water resources security in Gansu section of Yellow River Basin. J. Drain. Irrig. Mach. Eng. 2021, 39, 897–903. [Google Scholar]

- Wu, X.; Wang, H.; He, Y. Excavation stability evaluation of Karst tunnel based on fuzzy matter-element. China Saf. Sci. J. 2018, 28, 99–104. [Google Scholar] [CrossRef]

- Bao, X.; Zhang, J.; Wang, Q. Study on Grade Evaluation of Green Construction in Northwest Cold and Arid Areas. J. China Railw. Soc. 2019, 41, 33–39. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review on China’s tunnel engineering research: 2015. China J. Highw. Transp. 2015, 28, 1–65. [Google Scholar]

- Tian, S.; Wang, W.; Gong, J. Development and prospect of railway tunnels in China (Including statistics on China railway tunnels by the end of 2020) Tunnel Construction. Tunn. Constr. 2021, 41, 308–325. [Google Scholar]

- Hong, K.; Feng, H. Development trends and views of highway tunnels in China over the past decade. China J. Highw. Transp. 2020, 33, 62–76. [Google Scholar] [CrossRef]

- Yan, J. Achievements and challenges of tunneling technology in China over past 40 years. Tunn. Constr. 2019, 39, 537–544. [Google Scholar]

- Wang, T. Development Status and Prospect of Intelligent Construction Technology for Railway Tunnel in China. China Railw. 2020, 12, 1–9. [Google Scholar] [CrossRef]

| SN | Construction Stage | Method or Countermeasures | Goals | Five Savings or Two Protections |

|---|---|---|---|---|

| 1 | Pre-excavation | Using the comprehensive geological forecast to optimize the pre-support and excavation parameters | Improve the efficiency of the excavation, slow the loss, and extend the service life of construction machinery | Energy, Personal health and safety |

| 2 | Tunnel excavation | Improving the drilling techniques and parameters | Reduce the overbreak in excavation, reduce the consumption of explosives, detonators, and other blasting materials, improve the blasting and crushing effect and loading and transportation efficiency | Energy, Material, Personal health and safety |

| 3 | Ventilation | Selecting the ventilation fan and supporting air duct that are conducive to energy saving and environmental protection | Establish a ventilation system that meets the health requirements of the construction environment | Energy, Personal health and safety, Environmental protection |

| 4 | Monitoring measurement | Based on the integrated information platform, carrying out research on the accurate and rational management of labor, machinery, and equipment, updating and analyzing critical data such as labor, machinery and equipment, various resources, materials, and construction quality in real-time | Realize dynamic monitoring and optimization of mechanized construction and refined management | Energy, Personal health and safety, Human resource, Land resource, Material, Water resource |

| 5 | Negative effect evaluation | Strengthening the construction management and safety supervision, optimizing construction organization, management, and design, improving the emission detection and disposal of three wastes (wastewater, waste gases, and residues) | Reduce environmental pollution and ecological disturbance, evaluate the negative effects on the ecological environment | Environmental protection |

| Second-Level Evaluation Indicator | Equation | Explanation |

|---|---|---|

| The utilization rate of temporary land M11 | Where X11a is the actual temporary land area, X11p is the planned temporary land area. | |

| Excavation rate of earth work M12 | Where X12 is the control amount of earthwork over-excavation and under-excavation, X12t is the total amount of earthwork excavation. | |

| The utilization rate of excavation M13 | Where X13 is the backfilling volume of excavation, and X13t is the total amount of earthwork excavation. | |

| Vegetation restoration rate M14 | Where X14a is the actual vegetation restoration area, X14p is the planned total area of vegetation restoration. | |

| Construction electricity saving rate M21 | Where X21p is the planned electricity consumption during construction, X21a is the actual electricity consumption during construction. | |

| Domestic electricity saving rate M22 | Where X22 is the amount of energy-saving lighting fixtures of zoning, timing, and automatic sensing, X22t is the total amount of domestic lighting fixtures. | |

| Mechanical equipment saving rate M23 | Where X23 is the saving amount of mechanical equipment, X23t is the total consumption of mechanical equipment | |

| The replacement rate of clean energy M24 | Where X24c is the energy saving of clean energy, X24n is the consumption of non-clean energy | |

| Construction water saving rate M31 | Where X31p is the planned water consumption during construction, X31a is the actual water consumption during construction. | |

| Domestic water saving rate M32 | Where X32 is the number of water-saving devices, X32t is the total amount of domestic water devices. | |

| The utilization rate of non-traditional water sources M33 | Where X33 is the usage of non-traditional water sources, X33t is the total amount of water used during construction. | |

| Physical material saving rate M41 | Where X41 is the amount of physical material savings, X41t is the total amount of physical material usage. | |

| Turnover material utilization rate M42 | Where X42 is the amount of turnover materials, X42t is the total amount of material usage, and N is the usage count of the turnover materials. | |

| Material recovery and reuse rate M43 | Where X43 is the amount of material recycling and reuse, X43t is the total amount of material usage. | |

| Material localization rate M44 | Where X44 is the amount of local materials usage, X44t is the total amount of material usage. | |

| PM value inside the tunnel M51 | - | Using PM10 exposure concentration to represent the air quality inside the tunnel. |

| Construction waste disposal amount M52 | - | A large amount of construction waste is generated during the construction process, including residual concrete lumps, concrete and soil bonding blocks, etc. |

| Waste collection rate after classification M53 | Where X53 is the classified collection amount of waste, X53t is the total amount of waste. | |

| Wastewater treatment rate M54 | Where X54 is the amount of wastewater that has been tested to be qualified after treatment, X54t is the total amount of wastewater. | |

| Ventilation and smoke exhaust rate M55 | - | Estimate the ventilation and smoke exhaust rate based on the ventilation conditions of the construction site, on-site cafeteria, vehicles, and equipment exhaust. |

| Resource protection rate M56 | - | Estimate the resource protection rate based on the protection conditions of cultural relics, groundwater, and pipelines within the tunnel construction scope. |

| Human resource saving rate M61 | Where X61a is the actual number of workers, X61p is the planned number of workers (excluding management personnel). | |

| Personnel health and safety protection rate M62 | - | Estimate the value of personal health and safety protection rate based on the use of on-site protective measures, such as safety helmets, safety nets, wearing glasses during welding, dust prevention measures during shotcrete, as well as safety education and operation training before construction. |

| First-Level Evaluation Indicator | Second-Level Evaluation Indicator | Grade | ||||

|---|---|---|---|---|---|---|

| Very Poor (I) | Poor (II) | Moderate (III) | Good (IV) | Very Good (V) | ||

| Land resource | The utilization rate of temporary land/% | <60 | 60–70 | 70–80 | 80–90 | >90 |

| Excavation rate of earth work/% | <5 | 5–10 | 10–15 | 15–20 | >20 | |

| The utilization rate of excavation/% | <30 | 30–50 | 50–70 | 70–80 | >80 | |

| Vegetation restoration rate/% | <60 | 60–75 | 75–85 | 85–95 | >95 | |

| Energy | Construction electricity saving rate/% | <10 | 10–15 | 15–20 | 20–25 | >25 |

| Domestic electricity saving rate/% | <50 | 50–60 | 60–70 | 70–80 | >80 | |

| Mechanical equipment saving rate/% | <10 | 10–15 | 15–20 | 20–25 | >25 | |

| The replacement rate of clean energy/% | <5 | 5–10 | 10–20 | 20–30 | >30 | |

| Water resource | Construction water saving rate/% | <10 | 10–20 | 20–30 | 30–40 | >40 |

| Domestic water saving rate/% | <60 | 60–70 | 70–80 | 80–90 | >90 | |

| The utilization rate of non-traditional water sources/% | <10 | 10–15 | 15–20 | 20–30 | >30 | |

| Material | Physical material saving rate/% | <5 | 5–10 | 10–20 | 20–30 | >30 |

| Turnover material utilization rate/% | <30 | 30–40 | 40–50 | 50–60 | >60 | |

| Material recovery and reuse rate/% | <5 | 5–10 | 10–15 | 15–20 | >20 | |

| Material localization rate/% | <30 | 30–40 | 40–50 | 50–60 | >60 | |

| Environmental protection | PM value inside the tunnel/(mg·m−3) | >12 | 3–12 | 1.4–3 | 1–1.4 | <1 |

| Construction waste disposal amount /[t/(104 m2)] | >200 | 150–200 | 100–150 | 50–100 | <50 | |

| Waste collection rate after classification/% | <10 | 10–20 | 20–30 | 30–40 | >40 | |

| Wastewater treatment rate/% | <60 | 60–70 | 70–80 | 80–90 | >90 | |

| Ventilation and smoke exhaust rate/% | <60 | 60–70 | 70–80 | 80–90 | >90 | |

| Resource protection rate/% | <40 | 40–60 | 60–70 | 70–90 | >90 | |

| Human resource, health, and safety | Human resource saving rate/% | <15 | 15–30 | 30–45 | 45–60 | >60 |

| Personnel health and safety protection rate/% | <70 | 70–80 | 80–90 | 90–95 | >95 | |

| First-Level Evaluation Indicator | Second-Level Evaluation Indicator | Indicator Value | Fuzzy Matter Element of Green Construction | ||||

|---|---|---|---|---|---|---|---|

| Very Poor (I) | POOR (II) | Moderate (III) | Good (IV) | Very Good (V) | |||

| Land resource | The utilization rate of temporary land/% | 86 | 0.0894 | 0.0000 | 0.0349 | 0.9727 | 0.1059 |

| Excavation rate of earth work/% | 14 | 0.0000 | 0.0092 | 0.7792 | 0.2571 | 0.3999 | |

| The utilization rate of excavation/% | 65 | 0.0005 | 0.0131 | 0.8409 | 0.0625 | 0.0131 | |

| Vegetation restoration rate/% | 96 | 0.0349 | 0.0000 | 0.0008 | 0.3686 | 0.7792 | |

| Energy | Construction electricity saving rate/% | 18 | 0.0092 | 0.0349 | 0.9727 | 0.1059 | 0.3768 |

| Domestic electricity saving rate/% | 85 | 0.0185 | 0.0000 | 0.0000 | 0.0625 | 0.8409 | |

| Mechanical equipment saving rate/% | 27 | 0.0000 | 0.0000 | 0.0000 | 0.1059 | 0.5374 | |

| The replacement rate of clean energy/% | 11 | 0.0003 | 0.2571 | 0.6418 | 0.0044 | 0.1921 | |

| Water resource | Construction water saving rate/% | 38 | 0.0000 | 0.0000 | 0.0092 | 0.7792 | 0.4545 |

| Domestic water saving rate/% | 88 | 0.0750 | 0.0000 | 0.0092 | 0.7792 | 0.2571 | |

| The utilization rate of non-traditional water sources/% | 16 | 0.0349 | 0.2571 | 0.7792 | 0.1059 | 0.2571 | |

| Material | Physical material saving rate/% | 18 | 0.0000 | 0.0000 | 0.7792 | 0.2571 | 0.2866 |

| Turnover material utilization rate/% | 38 | 0.1960 | 0.7792 | 0.2571 | 0.0003 | 0.0471 | |

| Material recovery and reuse rate/% | 13 | 0.0000 | 0.0349 | 0.9727 | 0.1059 | 0.3841 | |

| Material localization rate/% | 48 | 0.0349 | 0.0092 | 0.7792 | 0.2571 | 0.1696 | |

| Environmental protection | PM value inside the tunnel/(mg·m−3) | 1.2 | 0.2329 | 0.2571 | 0.3386 | 1.0000 | 0.2571 |

| Construction waste disposal amount /[t/(104 m2)] | 66 | 0.0000 | 0.0000 | 0.0211 | 0.9141 | 0.1550 | |

| Waste collection rate after classification/% | 38 | 0.0000 | 0.0000 | 0.0092 | 0.7792 | 0.4545 | |

| Wastewater treatment rate/% | 88 | 0.0750 | 0.0000 | 0.0092 | 0.7792 | 0.2571 | |

| Ventilation and smoke exhaust rate/% | 91 | 0.0570 | 0.0000 | 0.0008 | 0.3686 | 0.6418 | |

| Resource protection rate/% | 80 | 0.0020 | 0.0020 | 0.0020 | 1.0000 | 0.0020 | |

| Human resource, health, and safety | Human resource saving rate/% | 47 | 0.0000 | 0.0006 | 0.3289 | 0.6889 | 0.1515 |

| Personnel health and safety protection rate/% | 97 | 0.1136 | 0.0000 | 0.0185 | 0.1059 | 0.9727 | |

| First-Level Evaluation Indicator | Weight of First-Level Evaluation Indicator | Second-Level Evaluation Indicator | Weight of Second-Level Evaluation Indicator | Ultimate Weight |

|---|---|---|---|---|

| Land resource | 0.3553 | The utilization rate of temporary land | 0.0481 | 0.0171 |

| Excavation rate of earthwork | 0.2387 | 0.0848 | ||

| The utilization rate of excavation | 0.1703 | 0.0605 | ||

| Vegetation restoration rate | 0.5429 | 0.1929 | ||

| Energy | 0.0976 | Construction electricity saving rate | 0.4829 | 0.0471 |

| Domestic electricity saving rate | 0.0882 | 0.0086 | ||

| Mechanical equipment saving rate | 0.1570 | 0.0153 | ||

| The replacement rate of clean energy | 0.2720 | 0.0265 | ||

| Water resource | 0.2119 | Construction water saving rate | 0.6483 | 0.1374 |

| Domestic water saving rate | 0.1220 | 0.0259 | ||

| The utilization rate of non-traditional water sources | 0.2297 | 0.0487 | ||

| Material | 0.1056 | Physical material saving rate | 0.4900 | 0.0517 |

| Turnover material utilization rate | 0.1128 | 0.0119 | ||

| Material recovery and reuse rate | 0.0897 | 0.0095 | ||

| Material localization rate | 0.3075 | 0.0325 | ||

| Environmental protection | 0.0826 | PM value inside the tunnel | 0.3331 | 0.0275 |

| Construction waste disposal amount | 0.1880 | 0.0155 | ||

| Waste collection rate after classification | 0.0988 | 0.0082 | ||

| Wastewater treatment rate | 0.2229 | 0.0184 | ||

| Ventilation and smoke exhaust rate | 0.0730 | 0.0060 | ||

| Resource protection rate | 0.0842 | 0.0070 | ||

| Human resource, health, and safety | 0.1470 | Human resource saving rate | 0.2500 | 0.0368 |

| Personnel health and safety protection rate | 0.7500 | 0.1103 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liang, Q.; Zhao, T.; Li, H.; Zhou, C.; Xue, X. The Principles and Evaluation of Green Construction of Tunnels in Frigid Plateau Regions. Sustainability 2023, 15, 15153. https://doi.org/10.3390/su152015153

Li J, Liang Q, Zhao T, Li H, Zhou C, Xue X. The Principles and Evaluation of Green Construction of Tunnels in Frigid Plateau Regions. Sustainability. 2023; 15(20):15153. https://doi.org/10.3390/su152015153

Chicago/Turabian StyleLi, Jing, Qingguo Liang, Tao Zhao, Haining Li, Caigui Zhou, and Xiaopan Xue. 2023. "The Principles and Evaluation of Green Construction of Tunnels in Frigid Plateau Regions" Sustainability 15, no. 20: 15153. https://doi.org/10.3390/su152015153