Optimal Predictive Torque Distribution Control System to Enhance Stability and Energy Efficiency in Electric Vehicles

Abstract

:1. Introduction

2. The Vehicle Simulator Model

3. Torque Distribution System

4. Designing the Control System

4.1. Overall Control System Diagram

4.2. Longitudinal Slip Control Based on a Five-Degree-of-Freedom Vehicle Model

Evaluation of the Longitudinal Stability Control Law

4.3. Control of Four-Wheel Vehicle Model

4.3.1. Reference Model for Vehicle Wheel Rate

4.3.2. Wheel Torque Controller

4.3.3. Force Distribution Algorithm

- Mzt = Mz: In this case, the vehicle exhibits stable behavior, and no corrective external torque is required. Thus, the torque distribution system, with an equal distribution of tire forces resulting from the initial wheel torques, provides maximum acceleration for the vehicle, allowing it to continue along its initial path.

- Mzt > Mz: In this case, considering the necessary sign of the required external torque, the torque distribution system becomes active to generate the desired torque. With an appropriate distribution of traction forces resulting from the output torque of each independent motor connected to the wheels, the system ensures the stability of the vehicle. For example, in the case of an understeering vehicle rotating to the right, the active torque distribution system initially reduces the traction force of the inner wheels and increases the traction force of the outer wheels to create the corrective torque. It is worth mentioning that during acceleration, the load transfer occurs from the front axle to the rear axle, so the rear wheels have a greater traction capacity. Therefore, to improve the acceleration performance, the traction force is initially increased for the rear wheels and decreased for the front wheels.

- Mzt < Mz: This case is similar to the second case, with the difference that the positions of the tire forces are swapped. With the knowledge of the traction forces for each wheel, torque distribution is performed among the wheels in a way that the calculated forces from the distribution algorithm are achieved. To do this, the longitudinal slips corresponding to each force are calculated using the inverse model of tire forces. The calculated longitudinal slips are then used as desired values for the longitudinal slip controller (16) to calculate the motor torques for tracking them.

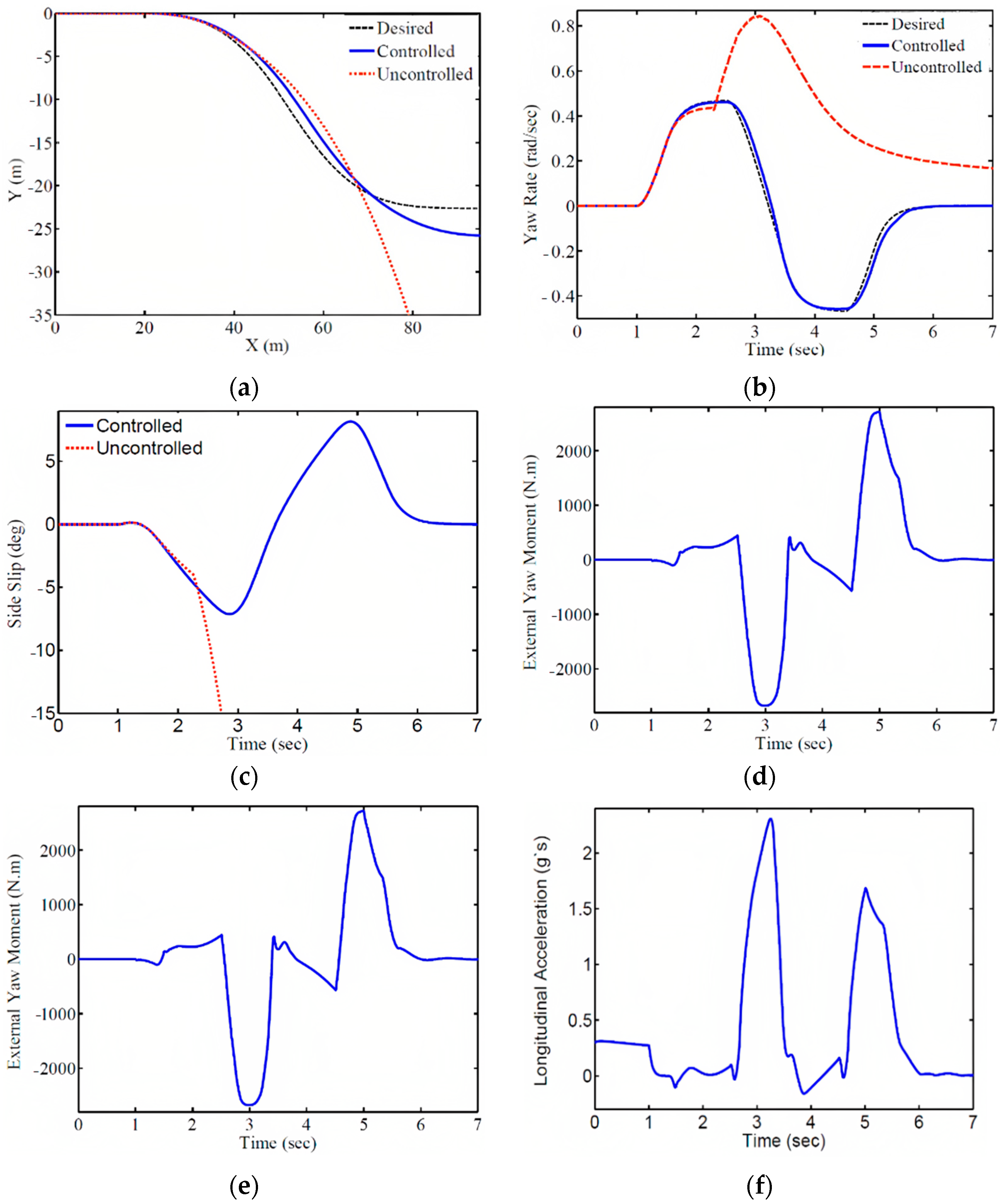

5. Simulation Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Bostanian, M.; Barakati, S.M.; Najjari, B.; Kalhori, D.M. A Genetic-Fuzzy Control Strategy for Parallel Hybrid Electric Vehicle. Int. J. Automot. Eng. 2013, 3, 482–495. [Google Scholar]

- Senol, M.; Bayram, I.S.; Naderi, Y.; Galloway, S. Electric vehicles under low temperatures: A review on battery performance, charging needs, and power grid impacts. IEEE Access 2023, 11, 39879–39912. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Zhao, C. Advanced Torque Control Strategies for Electric Vehicles: A Comprehensive Review. IEEE Trans. Veh. Technol. 2021, 70, 7956–7972. [Google Scholar]

- Lee, S.; Kim, D.; Kim, J. Real-time Torque Vectoring Control for Electric Vehicles Considering Variable Road Friction Conditions. IEEE Trans. Ind. Electron. 2021, 68, 5287–5297. [Google Scholar]

- Gan, Y.H.; Xiong, L.; Feng, Y.; Martinez, F. A Torque Vectoring Control System for Maneuverability Improvement of 4WD EV. Appl. Mech. Mater. 2013, 347–350, 899–903. [Google Scholar] [CrossRef]

- Tavasoli, A.; Naraghi, M. Comparison of static and dynamic control allocation techniques for integrated vehicle control. IFAC Proc. 2011, 44, 7180–7186. [Google Scholar] [CrossRef]

- Braghin, F.; Sabbioni, E. Development of a control strategy for improving vehicle safety in a hybrid vehicle with four independently driven in-wheel motors. In Proceedings of the International Symposium on Advanced Vehicle Control, Loughborough, UK, 22–26 August 2010. [Google Scholar]

- Rubin, D.; Arogeti, S.A. Vehicle yaw stability control using active limited-slip differential via model predictive control methods. Veh. Syst. Dyn. 2015, 53, 1315–1330. [Google Scholar] [CrossRef]

- Kasinathan, D.; Kasaiezadeh, A.; Wong, A.; Khajepour, A.; Chen, S.K.; Litkouhi, B. An Optimal Torque Vectoring Control for Vehicle Applications via Real-Time Constraints. IEEE Trans. Veh. Technol. 2015, 65, 4368–4378. [Google Scholar] [CrossRef]

- De Novellis, L.; Sorniotti, A.; Gruber, P. Wheel torque distribution criteria for electric vehicles with torque vectoring differentials. IEEE Trans. Veh. Technol. 2014, 63, 1593–1602. [Google Scholar] [CrossRef]

- Mashadi, B.; Mostaani, S.; Majidi, M. Vehicle stability enhancement by using an active differential. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2011, 225, 1098–1114. [Google Scholar] [CrossRef]

- Marino, R.; Scalzi, S. Integrated active front steering and semiactive rear differential control in rear-wheel-drive vehicles. IFAC Proc. Vol. 2008, 41, 10732–10737. [Google Scholar] [CrossRef]

- Maroonian, A.; Tamura, T.; Fuchs, R. Modeling and Simulation for the Dynamic Analysis of an Electronically Controlled Torque Coupling. Adv. Automot. Control. 2013, 46, 464–469. [Google Scholar] [CrossRef]

- De Novellis, L.; Sorniotti, A.; Gruber, P.; Pennycott, A. Comparison of feedback control techniques for torque-vectoring control of fully electric vehicles. IEEE Trans. Veh. Technol. 2014, 63, 3612–3623. [Google Scholar] [CrossRef]

- Rieveley, R.J.; Minaker, B. Variable Torque Distribution Yaw Moment Control for Hybrid Powertrains; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Li, J.; Yin, C.; Du, H. Optimal torque distribution control for four-independent wheel drive electric vehicles. IEEE Trans. Veh. Technol. 2015, 64, 3952–3963. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, G.; Liu, T. Robust PID Control Design for Uncertain Linear Systems: Recent Advances and Future Directions. IEEE Trans. Ind. Electron. 2021, 68, 11065–11075. [Google Scholar]

- Mousaei, A.; Peng, H. A New Control Method for the Steadiness of Electric Vehicles with 2-Motor in Rear and Front Wheels. Research Square. Int. J. Emerg. Electr. Power Syst. 2023. [Google Scholar] [CrossRef]

- Mousaei, A.; Allahyari, H. An Improved Dynamic Programming Energy Management System for Parallel Hybrid Electric Vehicles according to Battery Model. 2023. [Google Scholar] [CrossRef]

- Naderi, Y.; Hosseini, S.H.; Savaghebi, M.; Dahidah, M.; Guerrero, J.M. Multi-objective model predictive control for microgrid applications. Int. J. Electr. Power Energy Syst. 2023, 154, 109441. [Google Scholar] [CrossRef]

- Nahidi, A.; Kasaeizadeh, A.; Khosravani, S.; Khajepour, A.; Litkhouhi, B. Modular integrated longitudinal and lateral vehicle stability control for electric vehicles. Mechatronics 2017, 44, 60–70. [Google Scholar] [CrossRef]

- Li, B.; Goodarzi, A.; Khajepour, A.; Chen, S.-K.; Litkouhi, B. An optimal torque distribution control strategy for four-independent wheel drive electric vehicles. Veh. Syst. Dyn. 2015, 53, 118. [Google Scholar] [CrossRef]

- Chen, Y.; Hedrick, J.; Guo, K. A novel direct yaw moment controller for in-wheel motor electric vehicles. Veh. Syst. Dyn. 2013, 51, 925–942. [Google Scholar] [CrossRef]

- Wong, A.; Kasinathan, D.; Khajepour, A.; Chen, S.K. Integrated torque vectoring and power management framework for electric vehicles. Control Eng. Pract. 2016, 48, 22–36. [Google Scholar] [CrossRef]

- Smith, D.E.; Starkey, J.M. Effects of Model Complexity on the Performance of Automated Vehicle Steering Controllers; Model Development, Validation and Comparison. Veh. Syst. Dyn. 1995, 24, 163–181. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, J. Torque distribution strategy for a front- and rear-wheel-driven electric vehicle. IEEE Trans. Veh. Technol. 2012, 61, 3365–3374. [Google Scholar] [CrossRef]

- Mirzaeinejad, H.; Mirzaei, M. Optimization of nonlinear control strategy for anti-lock braking system with improvement of vehicle directional stability on splitmu roads. Transp. Res. Part C 2014, 46, 1–15. [Google Scholar] [CrossRef]

- Mirzaeinejad, H.; Mirzaei, M. A novel method for nonlinear control of wheel slip in anti-lock braking systems. Control Eng. Pract. 2010, 18, 918–926. [Google Scholar] [CrossRef]

- Cho, W.; Yoon, J.; Kim, J.; Hur, J.; Yi, K. An investigation into unified chassis control scheme for optimized vehicle stability and maneuverability. Veh. Syst. Dyn. 2008, 46, 87–105. [Google Scholar] [CrossRef]

- Mousaei, A.; Rostami, N.; Bannae Sharifian, M.B. Design a robust and optimal fuzzy logic controller to stabilize the speed of an electric vehicle in the presence of uncertainties and external disturbances. Trans. Inst. Meas. Control 2023. [Google Scholar] [CrossRef]

- Mousaei, A.; Gheisarnejad, M.; Khooban, M.H. Challenges and opportunities of FACTS devices interacting with electric vehicles in distribution networks: A technological review. J. Energy Storage 2023, 73, 108860. [Google Scholar] [CrossRef]

- Alhasnawi, B.N.; Jasim, B.H. A new energy management system of on-grid/off-grid using adaptive neuro-fuzzy inference system. J. Eng. Sci. Technol 2020, 15, 3903–3919. [Google Scholar]

- Adeleke, O.P.; Li, Y.; Chen, Q.; Zhou, W.; Xu, X.; Cui, X. Torque Distribution Based on Dynamic Programming Algorithm for Four In-Wheel Motor Drive Electric Vehicle Considering Energy Efficiency Optimization. World Electr. Veh. J. 2022, 13, 181. [Google Scholar] [CrossRef]

| Ref. | Key Contribution | Control Variables | Control Approach | Applications | Results |

|---|---|---|---|---|---|

| [3] | Investigated precise wheel rotational torque control in stability systems. | Wheel rotational torque | Various control methods | Vehicle stability | Improved stability through precise torque control. |

| [4] | Emphasized wheel rotational speed as a control variable in torque distribution. | Wheel rotational speed | Control based on speed | Stability control | Enhanced stability control with speed-based approach. |

| [5] | Examined the use of lateral slip angle as a control variable for stability. | Lateral slip angle | Control based on slip angle | Vehicle stability | Improved stability with slip angle control. |

| [6] | Proposed a combined approach using wheel speed and slip angle for control. | Wheel speed, slip angle | Comprehensive control strategy | Enhanced stability | Comprehensive strategy led to superior stability. |

| [7] | Developed controllers minimizing longitudinal and lateral forces for improved stability. | Longitudinal and lateral forces | Tailored control methods | Enhanced vehicle stability | Improved stability by minimizing forces effectively. |

| [12] | Addressed physical limitations to enhance controller performance. | N/A | Optimization of control performance | Control system improvement | Enhanced controller performance considering limitations. |

| [13] | Employed sliding mode control for adaptable torque computation. | External torque | Sliding mode control approach | Versatile control | Sliding mode control provided adaptable torque control. |

| [14] | Improved stability using fuzzy logic and electronic stability control. | Fuzzy logic, stability control | Hybrid control approach | Stability and maneuverability improvement | Enhanced stability and maneuverability with hybrid control. |

| [16] | Applied Model Predictive Control for precise performance optimization. | Performance variables | Model Predictive Control (MPC) | Performance optimization | Precise control of performance variables for optimization. |

| [17] | Extended torque distribution control to optimize electric vehicle performance. | Torque distribution | Advanced torque vectoring control | Electric vehicle performance enhancement | Improved electric vehicle performance and control. |

| [3] | Proposed direct yaw moment control for enhanced stability. | Yaw moment | Sliding mode control approach | Vehicle stability and maneuverability improvement | Enhanced stability and maneuverability through yaw control. |

| [18] | Developed integrated torque vectoring and power management framework. | Torque distribution | Integrated control framework | Overall vehicle performance enhancement | Enhanced overall vehicle performance through integration. |

| Parameter | Value (Unit) | Parameter | Value (Unit) |

|---|---|---|---|

| R | 0.3 (m) | m | 1280 (kg) |

| Iω | 2.1 (kg·m2) | Iz | 2500 (kg·m2) |

| Cα | 3000 (N·rad−1) | Ix | 750 (kg·m2) |

| Ci | 5000 (N·UnitSlip−1) | a | 1.203 (m) |

| εr | 0.015 | b | 1.217 (m) |

| tw | 0.444 (m) | l | 2.42 (m) |

| d | 0.2 (m) | hcg | 0.5 (m) |

| The Control Input Weighting Coefficients | The Total Torque of the Four Wheels (N·m) | The Rotational Speed Error |

|---|---|---|

| w2/w1 = 0 | 2054.4 | 0.0778 |

| w2/w1 = 1 × 10−9 | 1670.2 | 0.2234 |

| w2/w1 = 8 × 10−9 | 582.4 | 0.4011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousaei, A.; Naderi, Y. Optimal Predictive Torque Distribution Control System to Enhance Stability and Energy Efficiency in Electric Vehicles. Sustainability 2023, 15, 15155. https://doi.org/10.3390/su152015155

Mousaei A, Naderi Y. Optimal Predictive Torque Distribution Control System to Enhance Stability and Energy Efficiency in Electric Vehicles. Sustainability. 2023; 15(20):15155. https://doi.org/10.3390/su152015155

Chicago/Turabian StyleMousaei, Arash, and Yahya Naderi. 2023. "Optimal Predictive Torque Distribution Control System to Enhance Stability and Energy Efficiency in Electric Vehicles" Sustainability 15, no. 20: 15155. https://doi.org/10.3390/su152015155

APA StyleMousaei, A., & Naderi, Y. (2023). Optimal Predictive Torque Distribution Control System to Enhance Stability and Energy Efficiency in Electric Vehicles. Sustainability, 15(20), 15155. https://doi.org/10.3390/su152015155