Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location of the Study and Treatments

2.2. Soil Sampling and Analyses

2.3. Spatial Dependence of Preconsolidation Pressure

3. Results and Discussion

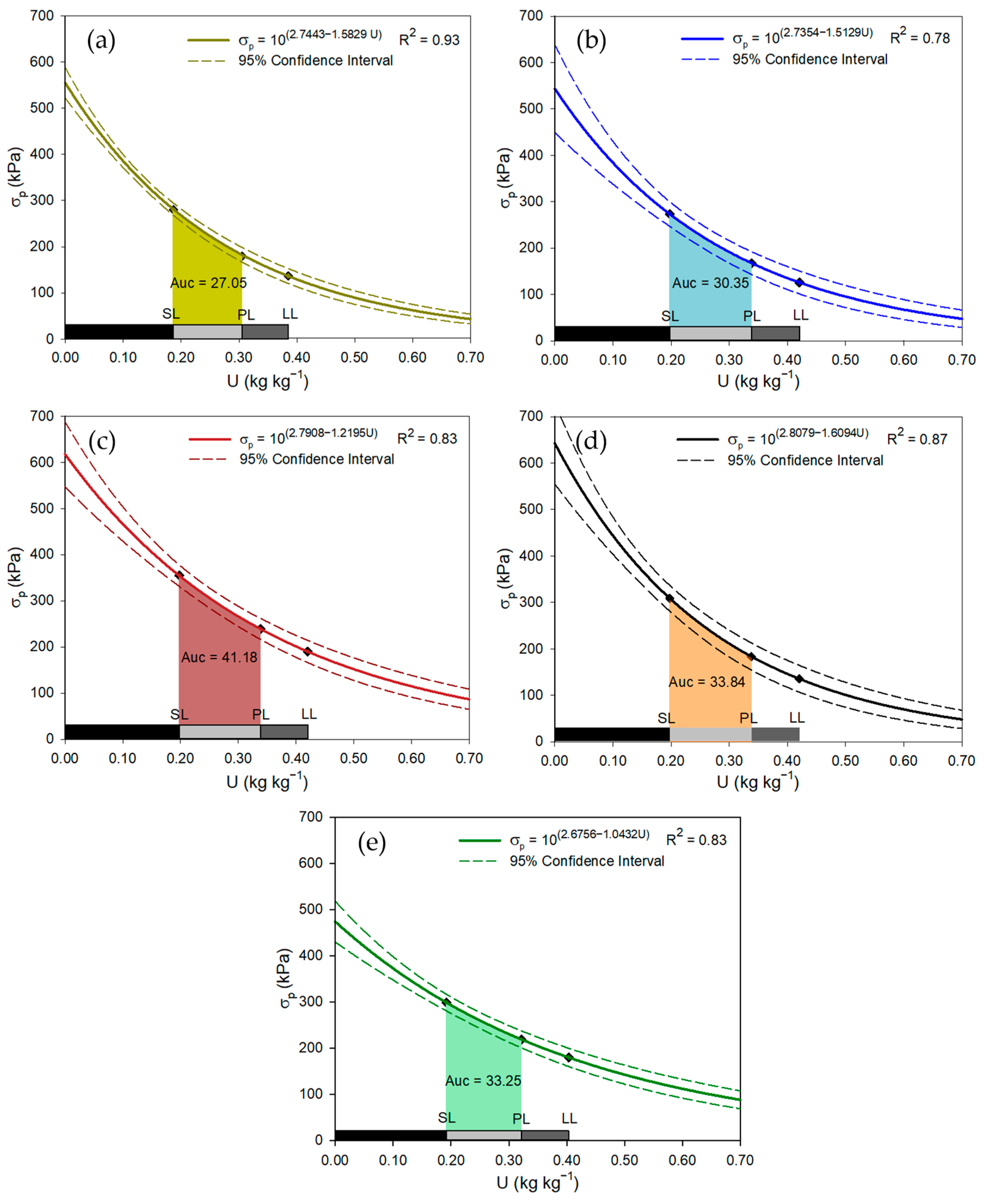

3.1. Soil Load-Bearing Capacity

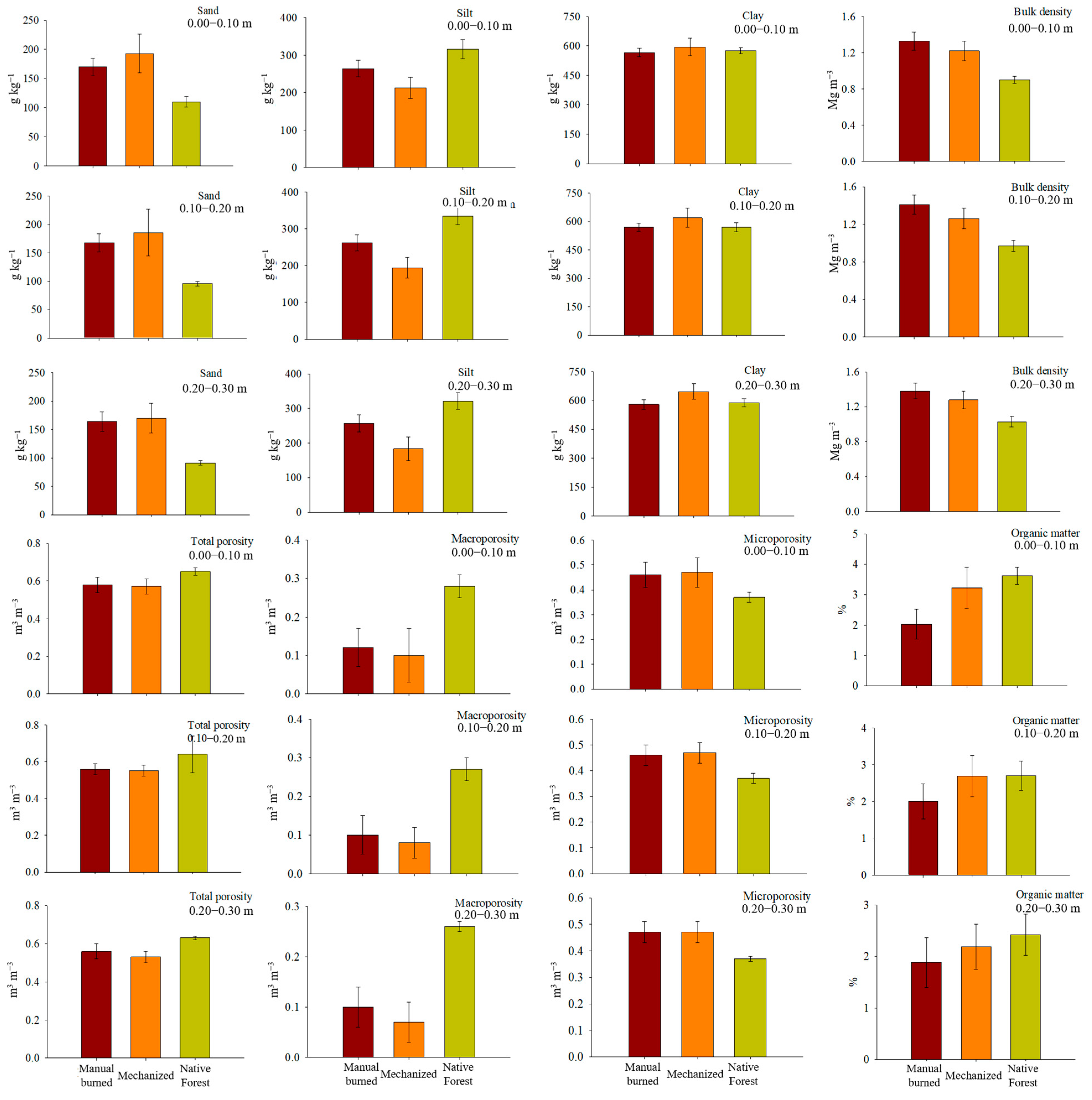

3.2. Physical Attributes and Preconsolidation Pressure

3.3. Spatial Variability of Preconsolidation Pressure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Conab—Companhia Nacional De Abastecimento. Acompanhamento De Safra Brasileira: Cana-De-Açúcar, Safra 2022/23, v.9—Terceiro levantamento, n.3, Brasília. 2022; pp. 1–58. Available online: https://www.conab.gov.br/info-agro/safras/cana?view=default (accessed on 22 February 2023).

- Cherubin, M.R.; Karlen, D.L.; Franco, A.L.C.; Tormena, C.A.; Cerri, C.E.P.; Davies, C.A.; Cerri, C.C. Soil physical quality response to sugarcane expansion in Brazil. Geoderma 2016, 267, 156–168. [Google Scholar] [CrossRef]

- Cavalcanti, R.Q.; Rolim, M.M.; Lima, R.P.; Tavares, U.E.; Pedrosa, E.M.R.; Cherubin, M.R. Soil physical changes induced by sugarcane cultivation in the Atlantic Forest biome, northeastern Brazil. Geoderma 2020, 370, e114353. [Google Scholar] [CrossRef]

- Guimarães Júnnyor, W.S.; Diserens, E.; De Maria, I.C.; Araujo-Junior, C.F.; Farhate, C.V.V.; Souza, Z.M. Prediction of soil stresses and compaction due to agricultural machines in sugarcane cultivation systems with and without crop rotation. Sci. Total Environ. 2019, 681, 424–434. [Google Scholar] [CrossRef]

- Esteban, D.A.; Souza, Z.M.; Silva, R.B.; Lim, E.S.; Lovera, L.H.; Oliveira, I.N. Impact of permanent traffic lanes on the soil physical and mechanical properties in mechanized sugarcane fields with the use of automatic steering. Geoderma 2020, 363, E114097. [Google Scholar] [CrossRef]

- Castioni, G.A.F.; Lima, R.P.; Cherubin, M.R.; Bordonal, R.O.; Rolim, M.R.; Carvalho, J.L.N. Machinery traffic in sugarcane straw removal operation: Stress transmitted and soil compaction. Soil Tillage Res. 2021, 213, E105122. [Google Scholar] [CrossRef]

- An, J.; Zhang, Y.; Yu, N. Quantifying the effect of soil physical properties on the compressive characteristics of two arable soils using uniaxial compression tests. Soil Tillage Res. 2015, 145, 216–223. [Google Scholar] [CrossRef]

- Peixoto, D.S.; Silva, B.M.; Oliveira, G.S.; Moreira, S.G.; Silva, F.; Curi, N.A. Soil compaction diagnosis method for occasional tillage recommendation under continuous no tillage system in Brazil. Soil Tillage Res. 2019, 194, E104307. [Google Scholar] [CrossRef]

- Shaheb, M.R.; Venkatesh, R.; Shearer, S.A. A review on the effect of soil compaction and its management for sustainable crop production. Biosyst. Eng. 2021, 46, 417–439. [Google Scholar] [CrossRef]

- Lima, R.P.; Rolim, M.M.; Oliveira, V.S.; Silva, A.R.; Pedrosa, E.M.R.; Ferreira, R.L.C. Load-bearing capacity and its relationships with the physical and mechanical attributes of cohesive soil. J. Terramech. 2015, 58, 51–58. [Google Scholar] [CrossRef]

- Souza, G.S.; Souza, Z.M.; Silva, R.B.; Araujo, F.S.; Barbosa, R.S. Compressibilidade do solo e sistema radicular da cana-de-açúcar em manejo com e sem controle de tráfego. Pesqui. Agropecu. Bras. 2012, 47, 603–612. [Google Scholar] [CrossRef]

- Luca, E.F.; Chaplotb, V.; Mutemac, M.; Ferreirae, M.L.; Cerri, C.C.; Cout, H.T.Z. Effect of conversion from sugarcane preharvest burning to residues green-trashing on soc stocks and soil fertility status: Results from different soil conditions in Brazil. Geoderma 2018, 310, 238–248. [Google Scholar] [CrossRef]

- Silva, R.B.; Iori, P.; Souza, Z.M.; Pereira, D.M.G.; Vischi Filho, O.J.; Silva, F.A.M. Contact pressures and the impact of farm equipment on Latosol with the presence and absence of sugarcane straw. Ciênc. Agrotec. 2016, 40, 265–278. [Google Scholar] [CrossRef]

- Luz, F.B.; Castioni, G.A.F.; Tormena, C.A.; Freitas, R.S.; Carvalho, J.L.N.; Cherubin, M.R. Soil tillage and machinery traffic influence soil water availability and air fluxes in sugarcane fields. Soil Tillage Res. 2022, 223, E105459. [Google Scholar] [CrossRef]

- Tavares, U.E.; Rolim, M.M.; Oliveira, S.; Pedrosa, E.M.R.; Siqueira, G.M.; Magalhães, A.G. Spatial dependence of physical attributes and mechanical properties of Ultisol in a sugarcane field. Sci. World J. 2015, 2015, 531231. [Google Scholar] [CrossRef] [PubMed]

- Cherubin, M.R.; Franchi, M.R.A.; Lima, R.P.; Moraes, M.T.; Luz, F.B. Sugarcane straw effects on soil compaction susceptibility. Soil Tillage Res. 2021, 212, E105066. [Google Scholar] [CrossRef]

- Holtz, R.D.; Kovacs, W.D. An Introduction to Geotechnical Engineering; Englewood Cliffs: Prentice-Hall, NJ, USA, 1981; pp. 1–746. [Google Scholar]

- Araujo-Junior, C.F.; Dias Junior, M.S.; Guimarães, P.T.G.; Alcântara, E.N. Load bearing capacity and critical water content of a Latossol induced by different managements. Rev. Bras. Cienc. Solo 2011, 35, 15–31. [Google Scholar]

- Tassinari, D.; Andrade, C.; Junior, S.D.; Martins, R.P.; Rocha, W.W.; Pais, A.M. Soil compaction caused by harvesting, skidding and wood processing in eucalyptus forests on coarse-textured tropical soils. Soil Use Manag. 2019, 35, 400–411. [Google Scholar] [CrossRef]

- Severiano, E.C.; Oliveira, G.C.; Dias Junior, M.S.; Castro, M.B.; Oliveira, L.F.C.; Costa, K.P. Compactação de solos cultivados com cana-de-de-açúcar: Ii—quantificação das restrições às funções edáficas do solo em decorrência da compactação prejudicial. Eng. Agrícola 2010, 30, 414–423. [Google Scholar] [CrossRef]

- Mulla, D.J. Spatial variability in precision agriculture. In Encyclopedia of Gis; Shekhar, S., Xiong, H., Zhou, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–8. [Google Scholar]

- Barik, K.; Aksakal, E.L.; Islam, K.R.; Sari, S.; Angin, I. Spatial variability in soil compaction properties associated with field traffic operations. Catena 2014, 120, 122–133. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.S.; Gonçalves, J.L.M.; Sparovek, G. Köppen’s Climate Classification map for Brazil. Meteorol. Z. 2014, 22, 711–728. [Google Scholar] [CrossRef]

- Soil Survey Staff. Keys to Soil Taxonomy, 12th ed.; United States Department of Agriculture, Natural Resources Conservation Service: Washington, DC, USA, 2014.

- Santos, H.G.; Jacomine, P.K.T.; Anjos, L.H.C.; Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Almeida, J.A.; Araujo Filho, J.C.; Oliveira, J.B.; Cunha, T.J.F. Sistema Brasileiro de Classificação de Solos, 5th ed.; Revista e Ampliada; Embrapa: Brasília, Brazil, 2018. [Google Scholar]

- Teixeira, C.; Donagemma, G.K.; Fontana, A.; Teixeira, W.G. Manual de Métodos de Análise de Solo, 3rd ed.; Revisada e Ampliada; Embrapa: Brasília, Brazil, 2017. [Google Scholar]

- Lambe, T.W.; Whitman, R.V. Soil Mechanics; John Wile & Sons: New York, NY, USA, 1969. [Google Scholar]

- Bowles, J.A. Engineering Properties of Soils and Their Measurements, 3rd ed.; Mcgraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Sowers, C.F. Consistency. Methods of Soil Analysis, Part 1; Black, C.A., Ed.; Asa: Madison, WI, USA, 1965. [Google Scholar]

- Silva, R.B.; Lanças, K.; Miranda, E.E.; Silva, F.A.M.; Baio, F.H.R. Estimation and evaluation of dynamic properties as indicators of changes on soil structure in sugarcane fields of Sao Paulo StateBrazil. Soil Tillage Res. 2009, 103, 265–270. [Google Scholar] [CrossRef]

- Silva, R.B.; Masqueto, B.J.; Lanças, K.; Silva, F.A.M. Desenvolvimento, automação e desempenho de um consolidômetro com interface homem-máquina. Rev. Bras. Cien. Solo 2015, 39, 416–427. [Google Scholar] [CrossRef]

- Taylor, H.M. Effects of soil strength on seedling mergence, root growth and crop yield. In Compaction of Agricultural Soils; Barnes, K.K., Carleton, W.M., Throckmorton, R.I., Van Den Berg, G.E., Eds.; Asae: St. Joseph, MI, USA, 1971. [Google Scholar]

- Dias Junior, M.S.; Pierce, F.J. A simple procedure for estimating preconsolidation pressure from soil compression curves. Soil Technol. 1995, 8, 139–151. [Google Scholar] [CrossRef]

- Snedecor, G.W.; Cochran, W.G. Statistical Methods, 8th ed.; Iowa State University Press: Ames, IA, USA, 1989. [Google Scholar]

- Moraes, M.T.; Luz, F.B.; Debiasi, H.; Franchini, J.C.; Silva, V.R. Soil load support capacity increases with time without soil mobilization as a result of age-hardening phenomenon. Soil Tillage Res. 2019, 186, 128–134. [Google Scholar] [CrossRef]

- Vieira, S.R. Geoestatistica em estudos de variabilidade espacial do solo. In Tópicos em Ciência do Solo; Novais, F., Alvarez, H., Schaefer, C.E.G.R., Eds.; SBCS: Viçosa, Brazil, 2000. [Google Scholar]

- Cambardella, C.A.; Moorman, T.B.; Novak, J.M.; Parkin, T.B.; Karlen, D.L.; Turco, R.F.; Konopka, A.E. Field scale variability of soil properties in central Iowa soils. Soil Sci. Soc. Am. J. 1994, 58, 1501–1511. [Google Scholar] [CrossRef]

- Robertson, G.P. Gs+: Geostatistics for the Environmental Sciences (Version 5.1 For Windows); Gamma Design Software: Plainwell, MI, USA, 1998. [Google Scholar]

- Golden Software Inc. (Golden, Estates Unidos). Surfer For Windows: Release 7.0, Contouring and 3d Surface Mapping for Scientist’s Engineers User’s Guide, New York; Golden Software, Inc.: Golden, CO, USA, 1999. [Google Scholar]

- Kunde, R.J.; Lima, C.L.R.; Silva, S.D.A.; Pilon, C.N. Tensile strength, friability, aggregation, and soil organic matter physical fractions of an Oxisol cultivated with sugarcane. Pesqui. Agropecu. Bras. 2018, 53, 487–494. [Google Scholar] [CrossRef]

- Toledo, M.S.; Rolim, M.M.; Lima, R.P.; Cavalcanti, R.Q.; Ortiz, F.S.; Cherubin, M.R. Strength, swelling and compressibility of unsaturated sugarcane soils. Soil Tillage Res. 2021, 212, E105072. [Google Scholar] [CrossRef]

- Vasconcelos, R.F.B.; Cantalice, J.R.B.; Moura, G.B.A.; Rolim, M.M.; Montenegro, C.E. Compressibilidade de um Latossolo Amarelo distrocoeso não saturado sob diferentes sistemas de manejo da cana-de-açúcar. Rev. Bras. Cien. Solo 2012, 36, 525–536. [Google Scholar] [CrossRef]

- Hillel, D. Fundamentals of Soil Physics; Academic Press: New York, NY, USA, 1980. [Google Scholar]

- Rossetti, K.V.; Centurion, J.F.; Oliveira, P.R.; Andrioli, I. Atributos físicos no tempo de adoção de manejos em Latossolos cultivado com soja. Ver. Bras. Cien. Solo 2012, 36, 367–376. [Google Scholar] [CrossRef]

- Severiano, E.C.; Oliveira, G.C.; Dias Junior, M.S.; Curi, N.; Costa, K.A.P.; Carducci, C.E. Preconsolidation pressure, soil water retention characteristics, and texture of Latosols in the Brazilian Cerrado. Soil Res. 2013, 51, 193–202. [Google Scholar] [CrossRef]

- Silva, V.R.; Reinert, D.J.; Reichert, J.M.; Soares, J.M. Fatores controladores da compressibilidade de um Argissolo Vermelho amarelo distrófico arênico e de um Latossolo Vermelho distrófico típico. I—estado inicial de compactação. Ver. Bras. Cien. Solo 2002, 26, 1–8. [Google Scholar] [CrossRef]

- Otto, R.; Silva, A.P.; Franco, H.J.C.; Oliveira, E.C.A.; Trivelin, P.C.O. High soil penetration resistance reduces sugarcane root system development. Soil Tillage Res. 2011, 117, 201–210. [Google Scholar] [CrossRef]

- Reichert, J.M.; Susuki, L.E.A.; Reinert, D.J. Compactação do solo em sistemas agropecuários e florestais: Identificação, efeitos, limites críticos e mitigação. Top. Ciên. Solo 2007, 5, 49–134. [Google Scholar]

- Mendonça, V.Z.; Mello, L.M.; Andreotti, L.; Pereira, R.C.; Lima, F.C.B.L.; Valério Filho, W.V.V.; Yano, E.H. Avaliação dos atributos físicos do solo em consórcio com forrageiras e milho em sucessão com soja em região do cerrado. Ver. Bras. Cien. Solo 2013, 37, 251–259. [Google Scholar] [CrossRef]

- Reichert, J.M.; Mentges, M.I.; Rodrigues, M.F.; Cavalli, J.P.; Awe, G.O.; Mentges, L.R. Compressibility and elasticity of subtropical no-till soils varying in granulometry organic matter, bulk density and moisture. Catena 2018, 165, 345–357. [Google Scholar] [CrossRef]

- Isaaks, E.H.; Srivastava, R.M. An Introduction to Applied Geostatistics; Oxford University: New York, NY, USA, 1989. [Google Scholar]

| Management System | Soil Layer | Model Parameters | ||

|---|---|---|---|---|

| Linear Coefficient, a | Angular Coefficient, b | R2 | ||

| Burned harvest sugarcane | 0.00–0.10 m | 2.7095 * | −1.5567 * | 0.90 * |

| 0.10–0.20 m | 2.7892 * | −1.7969 * | 0.96 * | |

| 0.20–0.30 m | 2.7437 * | −1.4356 * | 0.97 * | |

| 0.00–0.30 m | 2.7443 * | −1.5829 * | 0.93 * | |

| Mechanized harvest sugarcane | 0.00–0.10 m | 2.7354 * | −1.5129 * | 0.78 * |

| 0.10–0.20 m | 2.7908 * | −1.2195 * | 0.93 * | |

| 0.20–0.30 m | 2.8079 * | −1.6094 * | 0.87 * | |

| Native forest | 0.00–0.10 m | 2.6654 * | −0.9691 * | 0.80 * |

| 0.10–0.20 m | 2.6820 * | −0.9823 * | 0.88 * | |

| 0.20–0.30 m | 2.6678 * | −1.1414 * | 0.81 * | |

| 0.00–0.30 m | 2.6756 * | −1.0432 * | 0.83 * | |

| Comparison of Models between Layers within the Management System | Data Homogeneity | F-Test | ||

|---|---|---|---|---|

| Linear Coefficient, a | Angular Coefficient, b | |||

| 0.00–0.10 vs. 0.10–0.20 | H | ns | ns | |

| Burned harvest | 0.00–0.10 vs. 0.20–0.30 | H | ns | ns |

| 0.10–0.20 vs. 0.20–0.30 | H | ns | ns | |

| 0.00–0.10 vs. 0.10–0.20 | NH | ns | ** | |

| Mechanized harvest | 0.00–0.10 vs. 0.20–0.30 | NH | ns | ns |

| 0.10–0.20 vs. 0.20–0.30 | NH | ns | ns | |

| 0.00–0.10 vs. 0.10–0.20 | H | ns | ns | |

| Native forest | 0.00–0.10 vs. 0.20–0.30 | H | ns | ns |

| 0.10–0.20 vs. 0.20–0.30 | H | ns | ns | |

| Comparison of the resulting models between management systems | ||||

| Burned harvest (0.00–0.30 m) vs. Native Forest (0.00–0.30 m) | NH | ** | ** | |

| Mechanized harvest (0.00–0.10 m) vs. Burned harvest (0.00–0.30 m) | NH | ns | ns | |

| Mechanized harvest (0.10–0.20 m) vs. Burned harvest (0.00–0.30 m) | H | ** | ns | |

| Mechanized harvest (0.20–0.30 m) vs. Burned harvest (0.00–0.30 m) | H | * | ns | |

| Mechanized harvest (0.00–0.10 m) vs. Native Forest (0.00–0.30 m) | H | * | ns | |

| Mechanized harvest (0.10–0.20 m) vs. Native Forest (0.00–0.30 m) | H | ns | * | |

| Mechanized harvest (0.20–0.30 m) vs. Native Forest (0.00–0.30 m) | H | ns | ** | |

| Soil Physical Attributes | σp (Burned Harvesting Sugarcane Area) | σp (Mechanized Harvesting Sugarcane Area) | ||||

|---|---|---|---|---|---|---|

| 0.00–0.10 m | 0.10–0.20 m | 0.20–0.30 m | 0.00–0.10 m | 0.10–0.20 m | 0.20–0.30 m | |

| Tp | −0.13 | −0.09 | −0.01 | 0.06 | −0.06 | −0.05 |

| MaP | −0.02 | −0.11 | −0.10 | 0.07 | 0.09 | −0.008 |

| MiP | −0.08 | 0.06 | 0.09 | −0.05 | −0.14 | −0.02 |

| Bd | 0.14 | −0.02 | 0.14 | −0.05 | 0.08 | −0.07 |

| Snd | 0.01 | 0.21 * | 0.22 * | 0.11 | −0.10 | −0.004 |

| Cly | −0.0009 | 0.005 | 0.10 | −0.09 | 0.08 | −0.04 |

| Sil | −0.01 | −0.16 | −0.26 * | 0.01 | −0.0001 | 0.05 |

| U | −0.99 ** | −0.68 ** | −0.99 ** | −0.96 ** | −0.99 ** | −0.98 * |

| SOM | −0.08 | 0.10 | −0.24 * | 0.06 | −0.08 | 0.06 |

| Parameter | Preconsolidation Pressure—σp (kPa) | Soil Water Content—U (kg kg−1) | ||||

|---|---|---|---|---|---|---|

| 0.00–0.10 m | 0.10–0.20 m | 0.20–0.30 m | 0.00–0.10 m | 0.10–0.20 m | 0.20–0.30 m | |

| Burned harvest | ||||||

| Model | Spherical | Spherical | Spherical | Spherical | Spherical | Spherical |

| C0 | 0.10 | 24.500 | 0.10 | 0.47 | 0.37 | 0.44 |

| C0 + C1 | 143.70 | 108.00 | 115.20 | 2.48 | 1.70 | 2.01 |

| a (m) | 19.30 | 17.60 | 19.40 | 17.70 | 18.90 | 17.10 |

| DSD (%) | 0.07 | 22.29 | 0.09 | 19.21 | 21.84 | 22.24 |

| R2 (%) | 84.90 | 80.70 | 88.20 | 74.30 | 82.00 | 90.10 |

| SSR | 443.00 | 114.00 | 336.00 | 0.08 | 0.03 | 0.024 |

| Mechanized harvest | ||||||

| Model | Spherical | Spherical | Spherical | Spherical | Spherical | Spherical |

| C0 | 920.00 | 127.0 | 10.0 | 1.15 | 1.37 | 1.38 |

| C0 + C1 | 12,300.00 | 543.00 | 6357.0 | 12,410.00 | 5.95 | 5.83 |

| a (m) | 18.20 | 17.20 | 17.30 | 17.10 | 17.20 | 15.30 |

| DSD (%) | 7.48 | 23.39 | 0.02 | 9.27 | 23.01 | 23.66 |

| R2 (%) | 94.50 | 93.39 | 91.10 | 93.10 | 92.30 | 94.10 |

| SSR | 619,015 | 713.00 | 299,371.0 | 0.63 | 0.11 | 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva Araújo, F.; Menezes de Souza, Z.; Soares Souza, G.; Barboza da Silva, R.; Aguilera Esteban, D.A.; Moraes Tavares, R.L. Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops. Sustainability 2023, 15, 15185. https://doi.org/10.3390/su152115185

Silva Araújo F, Menezes de Souza Z, Soares Souza G, Barboza da Silva R, Aguilera Esteban DA, Moraes Tavares RL. Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops. Sustainability. 2023; 15(21):15185. https://doi.org/10.3390/su152115185

Chicago/Turabian StyleSilva Araújo, Fernando, Zigomar Menezes de Souza, Gustavo Soares Souza, Reginaldo Barboza da Silva, Diego Alexander Aguilera Esteban, and Rose Luiza Moraes Tavares. 2023. "Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops" Sustainability 15, no. 21: 15185. https://doi.org/10.3390/su152115185

APA StyleSilva Araújo, F., Menezes de Souza, Z., Soares Souza, G., Barboza da Silva, R., Aguilera Esteban, D. A., & Moraes Tavares, R. L. (2023). Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops. Sustainability, 15(21), 15185. https://doi.org/10.3390/su152115185