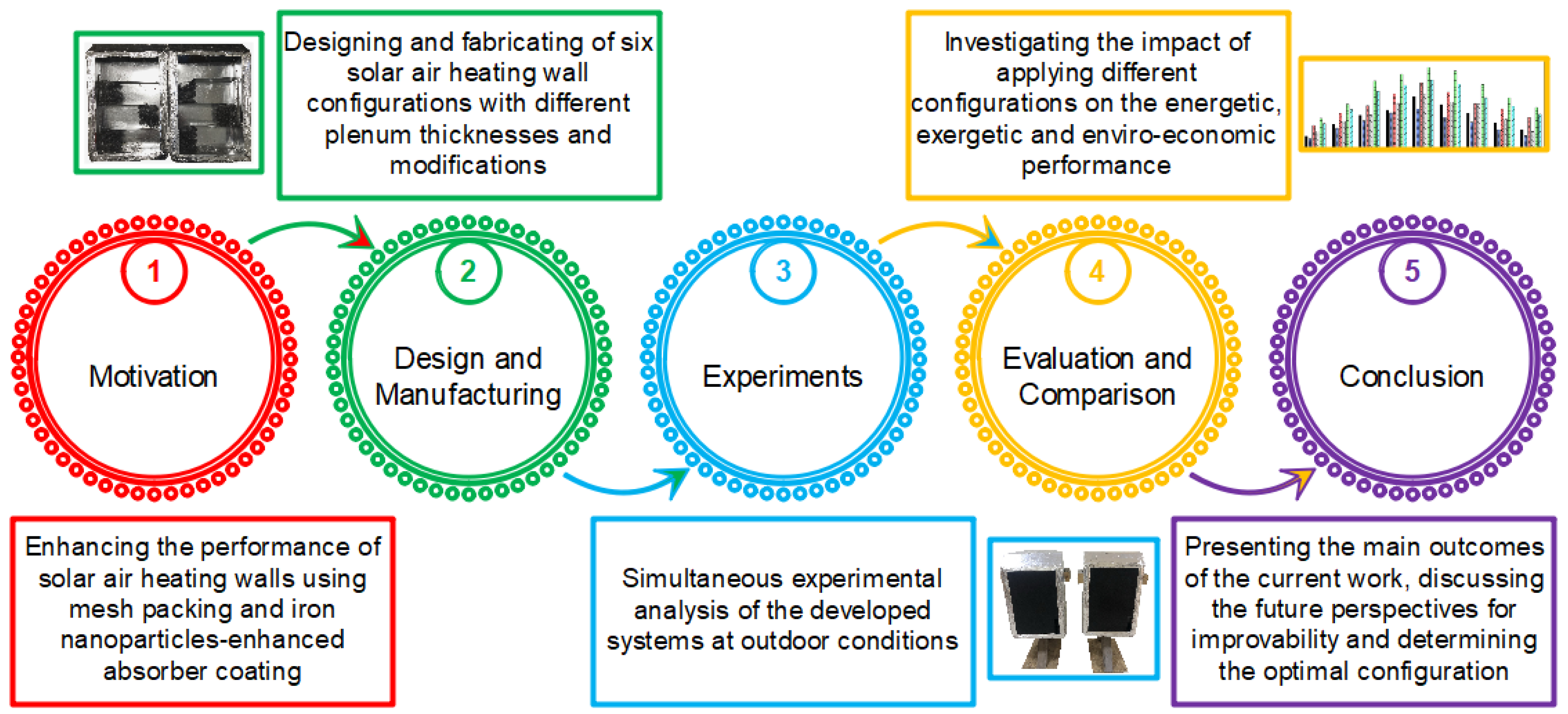

Improving the Performance of Unglazed Solar Air Heating Walls Using Mesh Packing and Nano-Enhanced Absorber Coating: An Energy–Exergy and Enviro-Economic Assessment

Abstract

:1. Introduction

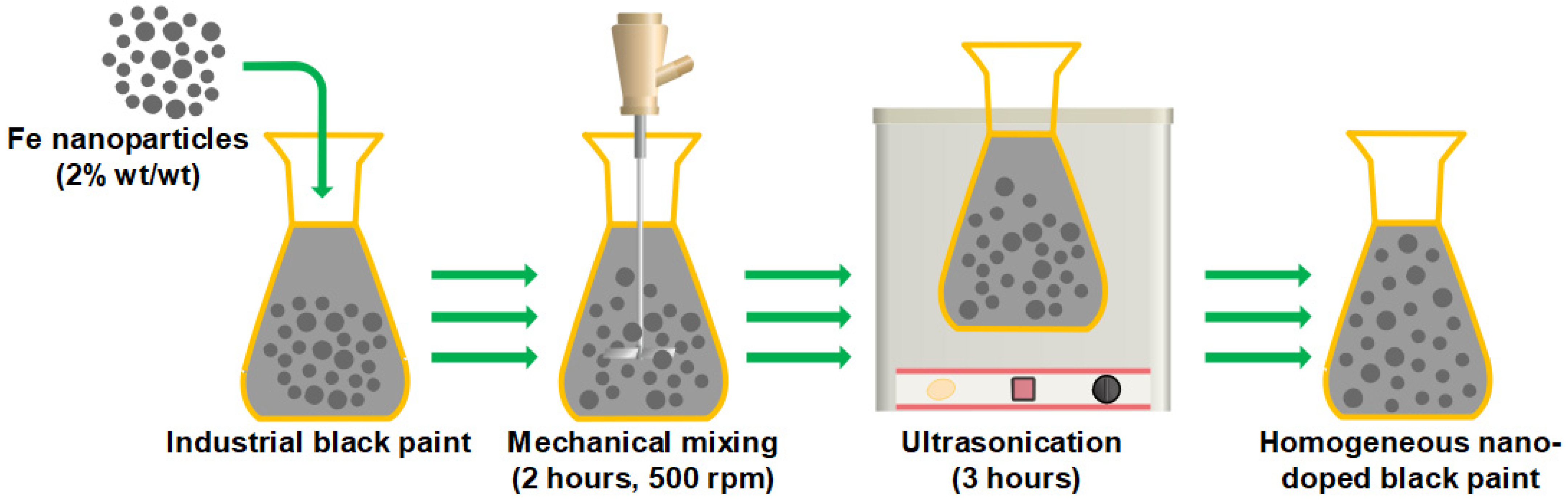

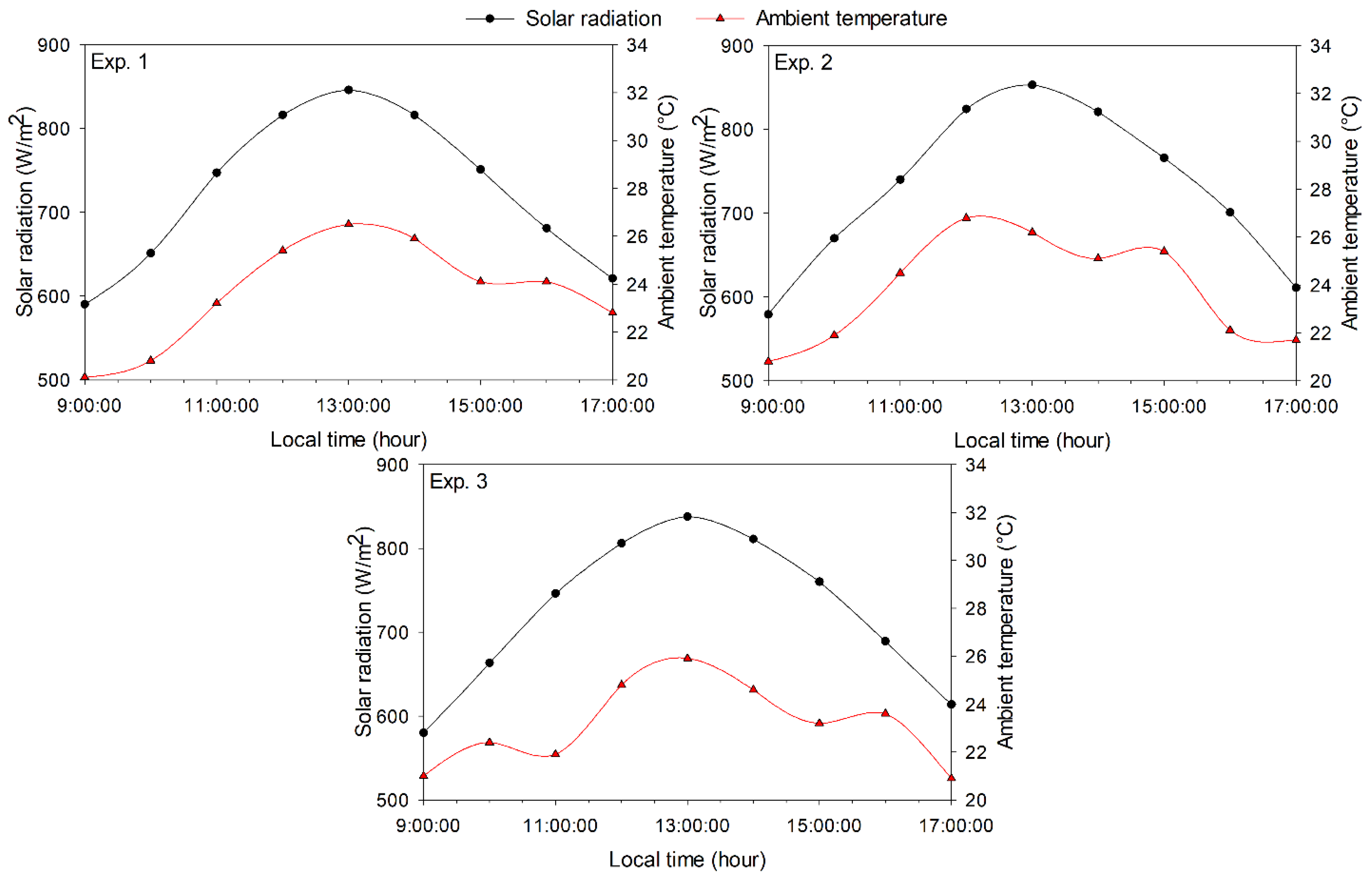

2. Materials and Methods

3. Theoretical Calculations

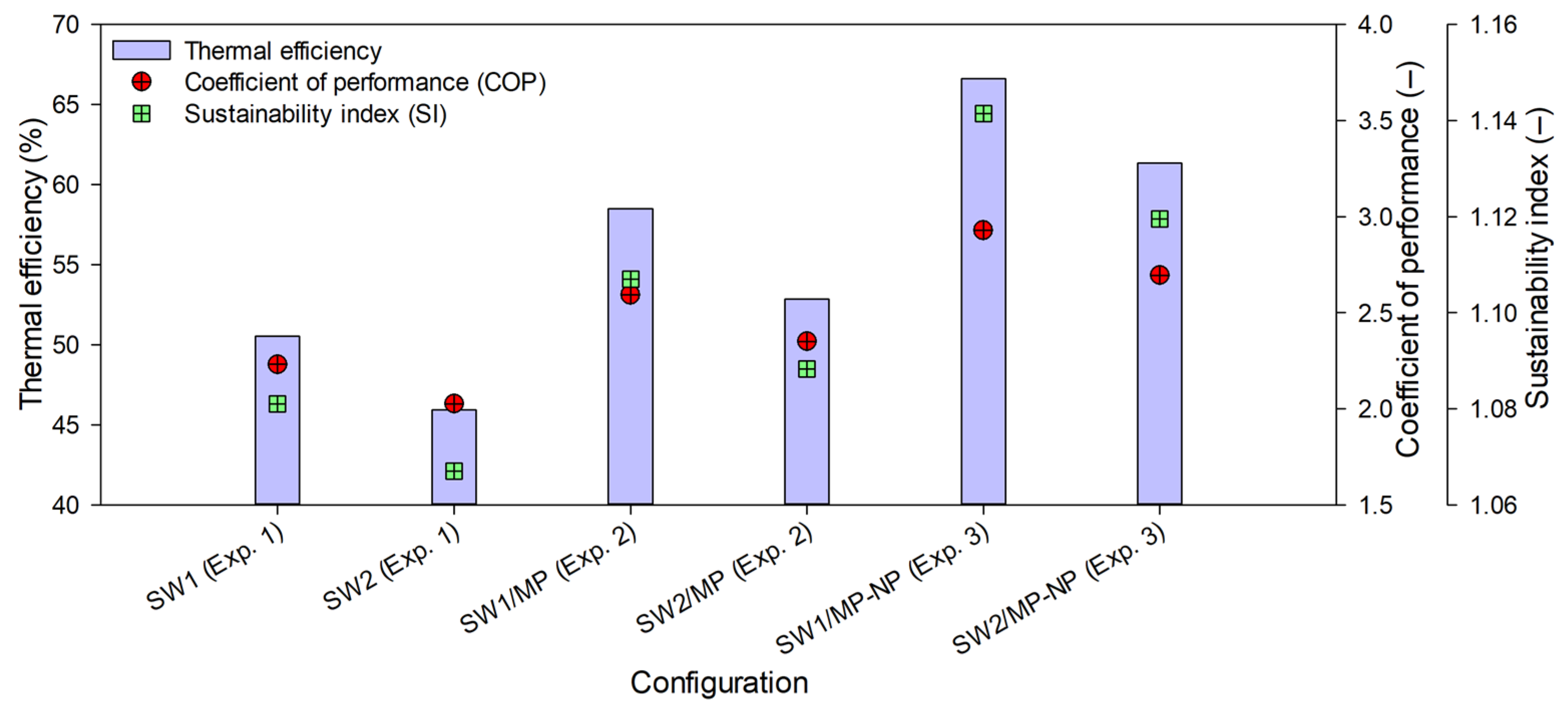

4. Results and Discussion

4.1. Thermodynamic Performance Results

4.2. Enviro-Economic Performance Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, Q.; Tapia, F.; Reith, A. Quantifying the influence of nature-based solutions on building cooling and heating energy demand: A climate specific review. Renew. Sustain. Energy Rev. 2023, 186, 113660. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, A.; Goel, V.; Sharma, R.; Sethi, M.; Tyagi, V.V. An experimental investigation of new roughness patterns (dimples with alternative protrusions) for the performance enhancement of solar air heater. Renew. Energy 2023, 211, 964–974. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Residential net-zero energy buildings: Review and perspective. Renew. Sustain. Energy Rev. 2021, 142, 110859. [Google Scholar] [CrossRef]

- Afshari, F.; Muratçobanoğlu, B.; Mandev, E.; Ceviz, M.A.; Mirzaee, Z. Effects of double glazing, black wall, black carpeted floor and insulation on thermal performance of solar-glazed balconies. Energy Build. 2023, 285, 112919. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Lipu, M.S.H.; Saad, M.H.M.; Hussain, A. A review of monitoring technologies for solar PV systems using data processing modules and transmission protocols: Progress, challenges and prospects. Sustainability 2021, 13, 8120. [Google Scholar] [CrossRef]

- Hajjaj, S.S.H.; Aqeel, A.A.K.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. Review of recent efforts in cooling Photovoltaic Panels (PVs) for enhanced performance and better impact on the Environment. Nanomaterials 2022, 12, 1664. [Google Scholar] [CrossRef]

- Kannan, N.; Vakeesan, D. Solar energy for future world:—A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Krese, G.; Butala, V.; Stritih, U. Thermochemical seasonal solar energy storage for heating and cooling of buildings. Energy Build. 2018, 164, 239–253. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pathak, S.K.; Sharma, R.K.; Mansor, M.; Goel, V.; Sari, A. 5E analysis of a novel designed hot water storage header integrated vacuum tube solar water heater. Therm. Sci. Eng. Prog. 2023, 42, 101929. [Google Scholar] [CrossRef]

- Bellos, E.; Papavasileiou, L.; Kekatou, M.; Karagiorgas, M. A Comparative Energy and Economic Analysis of Different Solar Thermal Domestic Hot Water Systems for the Greek Climate Zones: A Multi-Objective Evaluation Approach. Appl. Sci. 2022, 12, 4566. [Google Scholar] [CrossRef]

- Seddegh, S.; Wang, X.; Henderson, A.D.; Xing, Z. Solar domestic hot water systems using latent heat energy storage medium: A review. Renew. Sustain. Energy Rev. 2015, 49, 517–533. [Google Scholar] [CrossRef]

- Herrando, M.; Wang, K.; Huang, G.; Otanicar, T.; Mousa, O.B.; Agathokleous, R.A.; Ding, Y.; Kalogirou, S.; Ekins-Daukes, N.; Taylor, R.A.; et al. A review of solar hybrid photovoltaic-thermal (PV-T) collectors and systems. Prog. Energy Combust. Sci. 2023, 97, 101072. [Google Scholar] [CrossRef]

- Monghasemi, N.; Vadiee, A. A review of solar chimney integrated systems for space heating and cooling application. Renew. Sustain. Energy Rev. 2018, 81, 2714–2730. [Google Scholar] [CrossRef]

- Choudhury, P.K.; Baruah, D.C. Solar air heater for residential space heating. Energy Ecol. Environ. 2017, 2, 387–403. [Google Scholar] [CrossRef]

- Singh, A.P.; Kumar, A.; Singh, O.P. Effect of integrating high flow naturally driven dual solar air heaters with Trombe wall. Energy Convers. Manag. 2021, 249, 114861. [Google Scholar] [CrossRef]

- Paraschiv, S.; Bărbuţă-Mişu, N.; Paraschiv, L.S. Technical and economic analysis of a solar air heating system integration in a residential building wall to increase energy efficiency by solar heat gain and thermal insulation. Energy Rep. 2020, 6, 459–474. [Google Scholar] [CrossRef]

- Xu, L.; Luo, K.; Ji, J.; Yu, B.; Li, Z.; Huang, S. Study of a hybrid BIPV/T solar wall system. Energy 2020, 193, 116578. [Google Scholar] [CrossRef]

- Qi, X.; Lin, S.; Tao, S.; Patchigolla, K. Numerical study on the impact of wall structure on the thermal performance of double-channel porous solar wall. Sci. Rep. 2022, 12, 15144. [Google Scholar] [CrossRef]

- Charvát, P.; Klimeš, L.; Pech, O.; Hejčík, J. Solar air collector with the solar absorber plate containing a PCM–Environmental chamber experiments and computer simulations. Renew. Energy 2019, 143, 731–740. [Google Scholar] [CrossRef]

- Hong, X.; Leung, M.K.; He, W. Effective use of venetian blind in Trombe wall for solar space conditioning control. Appl. Energy 2019, 250, 452–460. [Google Scholar] [CrossRef]

- Luo, K.; Ji, J.; Xu, L.; Li, Z. Seasonal experimental study of a hybrid photovoltaic-water/air solar wall system. Appl. Therm. Eng. 2020, 169, 114853. [Google Scholar] [CrossRef]

- Khanlari, A.; Sözen, A.; Afshari, F.; Tuncer, A.D.; Ağbulut, Ü.; Aytaç Yılmaz, Z. Numerical and experimental analysis of parallel-pass forced convection solar air heating wall with different plenum and absorber configurations. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 978–1001. [Google Scholar] [CrossRef]

- Habib, N.A.; Ali, A.J.; Chaichan, M.T.; Kareem, M. Carbon nanotubes/paraffin wax nanocomposite for improving the performance of a solar air heating system. Therm. Sci. Eng. Prog. 2021, 23, 100877. [Google Scholar] [CrossRef]

- Gandjalikhan Nassab, S.A.; Moein Addini, M. Performance augmentation of solar air heater for space heating using a flexible flapping guide winglet. Iran. Iran. J. Energy Environ. 2021, 12, 161–172. [Google Scholar]

- Moghadasi, M.; Ghadamian, H.; Khodsiani, M.; Pourbafrani, M. A comprehensive experimental investigation and dynamic energy modeling of a highly efficient solar air heater with octagonal geometry. Sol. Energy 2022, 242, 298–311. [Google Scholar] [CrossRef]

- Hatamleh, R.I.; Abu-Hamdeh, N.H.; Bantan, R.A. Integration of a solar air heater to a building equipped with PCM to reduce the energy demand. J. Build. Eng. 2022, 48, 103948. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Alsulami, R.A.; Hatamleh, R.I. A case study in the field of building sustainability energy: Performance enhancement of solar air heater equipped with PCM: A trade-off between energy consumption and absorbed energy. J. Build. Eng. 2022, 48, 103903. [Google Scholar] [CrossRef]

- Rajarajeswari, K.; Sreekumar, A. Matrix solar air heaters—A review. Renew. Sustain. Energy Rev. 2016, 57, 704–712. [Google Scholar] [CrossRef]

- Türkakar, G. Performance analysis and optimal charging time investigation of solar air heater with packed bed sensible heat storage device. Sol. Energy 2016, 224, 718–729. [Google Scholar] [CrossRef]

- Baig, W.; Ali, H.M. An experimental investigation of performance of a double pass solar air heater with foam aluminum thermal storage medium. Case Stud. Therm. Eng. 2019, 14, 100440. [Google Scholar] [CrossRef]

- Karthikeyan, R.; Kumar, R.A.; Manikandan, P.; Senthilnathan, A.K. Investigation of solar air heater with phase change materials using packed bed absorber plate. Mater. Today Proc. 2021, 45, 1360–1365. [Google Scholar] [CrossRef]

- Singh, S.; Dhruw, L.; Chander, S. Experimental investigation of a double pass converging finned wire mesh packed bed solar air heater. J. Energy Storage 2019, 21, 713–723. [Google Scholar] [CrossRef]

- Nowzari, R.; Saygin, H.; Aldabbagh, L.B.Y. Evaluating the performance of a modified solar air heater with pierced cover and packed mesh layers. J. Sol. Energy Eng. 2021, 143, 011006. [Google Scholar] [CrossRef]

- Jasim Mahmood, A. Thermal evaluation of a double-pass unglazed solar air heater with perforated plate and wire mesh layers. Sustainability 2020, 12, 3619. [Google Scholar] [CrossRef]

- Chouksey, V.K.; Singh Yadav, A.; Raha, S.; Shrivastava, V.; Shrivas, S.P. A theoretical parametric analysis to optimize the bed depth of packed bed solar air collector. Int. J. Green Energy 2022, 19, 775–785. [Google Scholar] [CrossRef]

- Krittacom, B.; Bunchan, S.; Luampon, R. Heat transfer enhancement of solar collector by placing wire mesh stainless porous material on the solar absorber plate of indirect forced convection solar dryer. Therm. Sci. Eng. Prog. 2022, 32, 101304. [Google Scholar] [CrossRef]

- John, M.K.; Bandaru, R.; Muraleedharan, C. Experimental analysis of wavy mesh assisted solar drying system with a survey of common drying technologies employed by farmers. Sustain. Energy Technol. Assess. 2023, 56, 103049. [Google Scholar] [CrossRef]

- Afshari, F.; Mandev, E.; Rahimpour, S.; Muratçobanoğlu, B.; Şahin, B.; Manay, E.; Teimuri-Mofrad, R. Experimental and numerical study on air-to-nanofluid thermoelectric cooling system using novel surface-modified Fe3O4 nanoparticles. Microfluid. Nanofluidics 2023, 27, 26. [Google Scholar] [CrossRef]

- Aytaç, İ. Determination of the Thermal Behavior Of Water-Based Fe3O4 Nanofluid Using Thermophysical Property Models. Heat Transf. Res. 2022, 53, 57–75. [Google Scholar] [CrossRef]

- Aytaç, İ. Experimental Investigation on Heat Transfer Performance Of Fe2O3/Water And Fe3O4/Water Nanofluids In A Plate Heat Exchanger. Heat Transf. Res. 2022, 53, 69–93. [Google Scholar] [CrossRef]

- Mandev, E.; Muratçobanoğlu, B.; Manay, E.; Sahin, B.; Teimuri-Mofrad, R.; Rahimpour, S.; Afshari, F. Performance Analysis of Thermo-Electric Cooling Systems Equipped with Surface-Modified and Recycled Nanofluids. J. Enhanc. Heat Transf. 2023, 30, 33–50. [Google Scholar] [CrossRef]

- Öztürk, M.; Çiftçi, E. Upgrading the performance of a solar air collector with flexible aluminum air ducts and graphene nanoplatelet-enhanced absorber coating. Therm. Sci. Eng. Prog. 2023, 40, 101760. [Google Scholar] [CrossRef]

- Chandrika, V.S.; Isaac, J.S.; Daniel, J.; Kathiresan, K.; Muthiah, C.T.; Raj, E.F.I.; Subbiah, R. Experimental investigation of the solar distiller using nano-black paint for different water depths. Mater. Today Proc. 2022, 56, 1406–1410. [Google Scholar] [CrossRef]

- Dharmaraj, S.K.; Ramasubbu, H.; Rajendran, V.; Ravichandran, P. Effect of graphene nanopaint on performance of solar air heater attached with inclined and winglet baffles. Environ. Sci. Pollut. Res. 2023, 30, 87330–87342. [Google Scholar] [CrossRef] [PubMed]

- Khanlari, A.; Tuncer, A.D.; Sözen, A.; Aytaç, İ.; Çiftçi, E.; Variyenli, H.İ. Energy and exergy analysis of a vertical solar air heater with nano-enhanced absorber coating and perforated baffles. Renew. Energy 2022, 187, 586–602. [Google Scholar] [CrossRef]

- Sivakumar, S.; Velmurugan, C.; Dhas, D.E.J.; Solomon, A.B.; Wins, K.L.D. Effect of nano cupric oxide coating on the forced convection performance of a mixed-mode flat plate solar dryer. Renew. Energy 2020, 155, 1165–1172. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, S.K.; Sharma, V.K. Performance enhancement analysis of triangular solar air heater coated with nanomaterial embedded in black paint. Mater. Today Proc. 2020, 26, 2528–2532. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Ismaeel, A.A.; Baheta, A.T.; Aurybi, M.A. Performance enhancement of solar vortex power generator by Al2O3-in-black paint coating. J. Clean. Prod. 2021, 316, 128303. [Google Scholar] [CrossRef]

- Kumar, P.M.; Kumar, C.S.; Muralidharan, K.; Muniratnam, Y.; Abraham, K.; Manikandan, V.; Prasanth, S.J. Augmenting the performance of conventional solar still through the nano-doped black paint (NDBP) coating on absorber. Mater. Today Proc. 2021, 47, 4929–4933. [Google Scholar] [CrossRef]

- Abdelkader, T.K.; Zhang, Y.; Gaballah, E.S.; Wang, S.; Wan, Q.; Fan, Q. Energy and exergy analysis of a flat-plate solar air heater coated with carbon nanotubes and cupric oxide nanoparticles embedded in black paint. J. Clean. Prod. 2020, 250, 119501. [Google Scholar] [CrossRef]

- Zare, D.; Minaei, S.; Zadeh, M.M.; Khoshtaghaza, M.H. Computer simulation of rough rice drying in a batch dryer. Energy Convers. Manag. 2006, 47, 3241–3254. [Google Scholar] [CrossRef]

- Tiwari, G.N. Solar Energy: Fundamentals, Design Modeling and Applications; CRC Press: Boca Raton, FL, USA; Narosa Publishing House: New York, NY, USA; New Delhi, India, 2022. [Google Scholar]

- Rai, S.; Chand, P.; Sharma, S.P. An analytical investigations on thermal and thermohydraulic performance of offset finned absorber solar air heater. Sol. Energy 2017, 153, 25–40. [Google Scholar] [CrossRef]

- Cortés, A.; Piacentini, R. Improvement of the efficiency of a bare solar collector by means of turbulence promoters. Appl. Energy 1990, 36, 253–261. [Google Scholar] [CrossRef]

- Abuşka, M.; Şevik, S. Energy, exergy, economic and environmental (4E) analyses of flat-plate and V-groove solar air collectors based on aluminium and copper. Sol. Energy 2017, 158, 259–277. [Google Scholar] [CrossRef]

- Das, M. Exploration of the effect of two-axis PLC solar tracking system on the thermal performance of solar air collector. Case Stud. Therm. Eng. 2021, 28, 101692. [Google Scholar] [CrossRef]

- Gupta, M.K.; Kaushik, S.C. Performance evaluation of solar air heater for various artificial roughness geometries based on energy, effective and exergy efficiencies. Renew. Energy 2009, 34, 465–476. [Google Scholar] [CrossRef]

- Markam, B.; Maiti, S. Artificial enhancer for small-scale solar air heater—A comprehensive review. Clean. Energy Syst. 2022, 4, 100046. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C. Enhancing the performance of a greenhouse dryer with natural dolomite powder-embedded latent heat thermal energy storage unit and air-to-air heat recovery system. Sol. Energy 2023, 262, 111881. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K. A review of solar air flat plate collector for drying application. Renew. Sustain. Energy Rev. 2019, 102, 333–345. [Google Scholar] [CrossRef]

- Tripathi, R.; Tiwari, G.N.; Dwivedi, V.K. Overall energy, exergy and carbon credit analysis of N partially covered photovoltaic thermal (PVT) concentrating collector connected in series. Sol. Energy 2016, 136, 260–267. [Google Scholar] [CrossRef]

- Afshari, F.; Mandev, E.; Muratçobanoğlu, B.; Yetim, A.F.; Ceviz, M.A. Experimental and numerical study on a novel fanless air-to-air solar thermoelectric refrigerator equipped with boosted heat exchanger. Renew. Energy 2023, 207, 253–265. [Google Scholar] [CrossRef]

- Gilago, M.C.; Mugi, V.R.; Chandramohan, V.P. Evaluating the environ-economic and exergy-energy impacts of drying carrots in passive and active mode solar dryers. Therm. Sci. Eng. Prog. 2023, 43, 101956. [Google Scholar] [CrossRef]

- Mugi, V.R.; Chandramohan, V.P. Energy and exergy analysis of forced and natural convection indirect solar dryers: Estimation of exergy inflow, outflow, losses, exergy efficiencies and sustainability indicators from drying experiments. J. Clean. Prod. 2021, 282, 124421. [Google Scholar] [CrossRef]

- Ceylan, İ.; Gürel, A.E. Solar-assisted fluidized bed dryer integrated with a heat pump for mint leaves. Appl. Therm. Eng. 2016, 106, 899–905. [Google Scholar] [CrossRef]

- Çiftçi, E.; Khanlari, A.; Sözen, A.; Aytaç, İ.; Tuncer, A.D. Energy and exergy analysis of a photovoltaic thermal (PVT) system used in solar dryer: A numerical and experimental investigation. Renew. Energy 2021, 180, 410–423. [Google Scholar] [CrossRef]

- Ghiami, A.; Ghiami, S. Comparative study based on energy and exergy analyses of a baffled solar air heater with latent storage collector. Appl. Therm. Eng. 2018, 133, 797–808. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Rukman, N.S.B.; Nazri, N.S.; Mustapha, M.; Yen, C.H.; Sopian, K. Exergy and sustainability index of photovoltaic thermal (PVT) air collector: A theoretical and experimental study. Renew. Sustain. Energy Rev. 2019, 100, 44–51. [Google Scholar] [CrossRef]

- Abuşka, M. Energy and exergy analysis of solar air heater having new design absorber plate with conical surface. Appl. Therm. Eng. 2018, 131, 115–124. [Google Scholar] [CrossRef]

- Karim, M.A.; Hawlader, M.N.A. Performance evaluation of a v-groove solar air collector for drying applications. Appl. Therm. Eng. 2006, 26, 121–130. [Google Scholar] [CrossRef]

- Badescu, V.; Soriga, I.; Ciocanea, A. Solar air collector performance in transient operation under radiative regimes with different levels of stability. Sol. Energy 2019, 177, 200–212. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Khalil, A.; Shalaby, S.M.; Zayed, M.E. Investigation of the thermal performances of flat, finned, and v-corrugated plate solar air heaters. J. Sol. Energy Eng. 2016, 138, 051004. [Google Scholar] [CrossRef]

- Prasad, S.B.; Saini, J.S.; Singh, K.M. Investigation of heat transfer and friction characteristics of packed bed solar air heater using wire mesh as packing material. Sol. Energy 2009, 83, 773–783. [Google Scholar] [CrossRef]

- Abi Mathew, A.; Thangavel, V. A novel thermal storage integrated evacuated tube heat pipe solar air heater: Energy, exergy, economic and environmental impact analysis. Sol. Energy 2021, 220, 828–842. [Google Scholar] [CrossRef]

- Henein, S.M.; Abdel-Rehim, A.A. The performance response of a heat pipe evacuated tube solar collector using MgO/MWCNT hybrid nanofluid as a working fluid. Case Stud. Therm. Eng. 2022, 33, 101957. [Google Scholar] [CrossRef]

| Exp. # | Tested Systems | Plenum Thickness | Modification | Absorber Coating |

|---|---|---|---|---|

| 1 | SW1 | 10 cm | - | Conventional black paint |

| SW2 | 15 cm | - | Conventional black paint | |

| 2 | SW1/MP | 10 cm | Iron mesh packing | Conventional black paint |

| SW2/MP | 15 cm | Iron mesh packing | Conventional black paint | |

| 3 | SW1/MP-NP | 10 cm | Iron mesh packing | Nano-enhanced black paint |

| SW2/MP-NP | 15 cm | Iron mesh packing | Nano-enhanced black paint |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şirin, C.; Tuncer, A.D.; Khanlari, A. Improving the Performance of Unglazed Solar Air Heating Walls Using Mesh Packing and Nano-Enhanced Absorber Coating: An Energy–Exergy and Enviro-Economic Assessment. Sustainability 2023, 15, 15192. https://doi.org/10.3390/su152115192

Şirin C, Tuncer AD, Khanlari A. Improving the Performance of Unglazed Solar Air Heating Walls Using Mesh Packing and Nano-Enhanced Absorber Coating: An Energy–Exergy and Enviro-Economic Assessment. Sustainability. 2023; 15(21):15192. https://doi.org/10.3390/su152115192

Chicago/Turabian StyleŞirin, Ceylin, Azim Doğuş Tuncer, and Ataollah Khanlari. 2023. "Improving the Performance of Unglazed Solar Air Heating Walls Using Mesh Packing and Nano-Enhanced Absorber Coating: An Energy–Exergy and Enviro-Economic Assessment" Sustainability 15, no. 21: 15192. https://doi.org/10.3390/su152115192

APA StyleŞirin, C., Tuncer, A. D., & Khanlari, A. (2023). Improving the Performance of Unglazed Solar Air Heating Walls Using Mesh Packing and Nano-Enhanced Absorber Coating: An Energy–Exergy and Enviro-Economic Assessment. Sustainability, 15(21), 15192. https://doi.org/10.3390/su152115192