Treatment of Direct Red 28 Dye through Phoenix dactylifera L. Fruit Seed Biochar: Equilibrium, Kinetics, Thermodynamics, and Phytotoxicity Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Date Fruit Seed Biochar Production

2.2. Materials and Preparation of Reagents

2.3. Batch Experiments

2.4. Point Zero of Charge

2.5. Characterization of Date Fruit Seed Biochar

2.6. Adsorption Isotherm

2.6.1. Langmuir Isotherm

2.6.2. Freundlich Isotherm

2.6.3. Temkin Isotherm

2.7. Kinetics of Sorption Phenomenon

2.8. Thermodynamics Parameters

2.9. Estimation of Reusability Capacity

2.10. Assessment of Phytotoxicity

2.11. Analyses of Biochemical Constituents

2.12. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analyses of Sorbent

3.2. Characterization of Date Fruit Seed Biochar

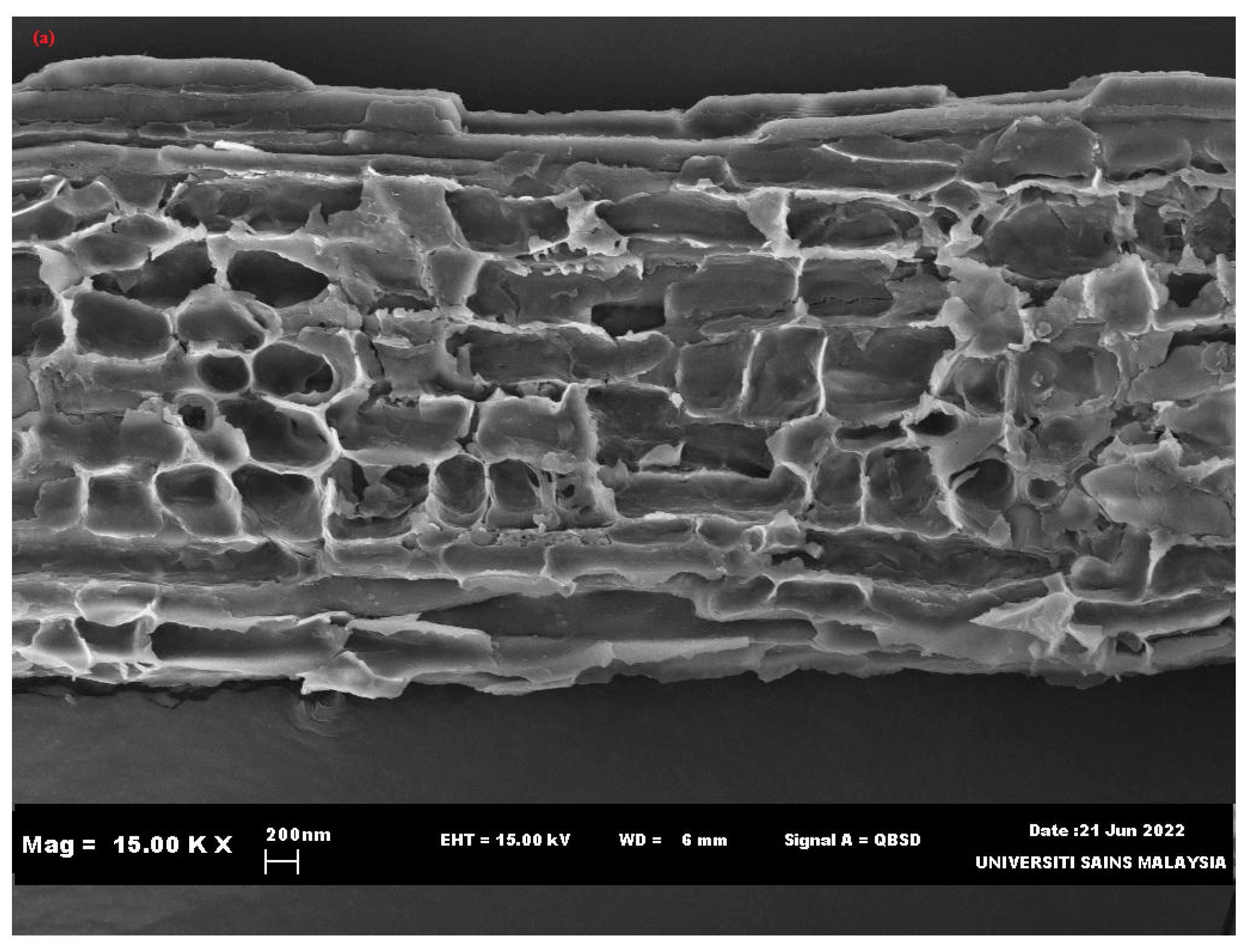

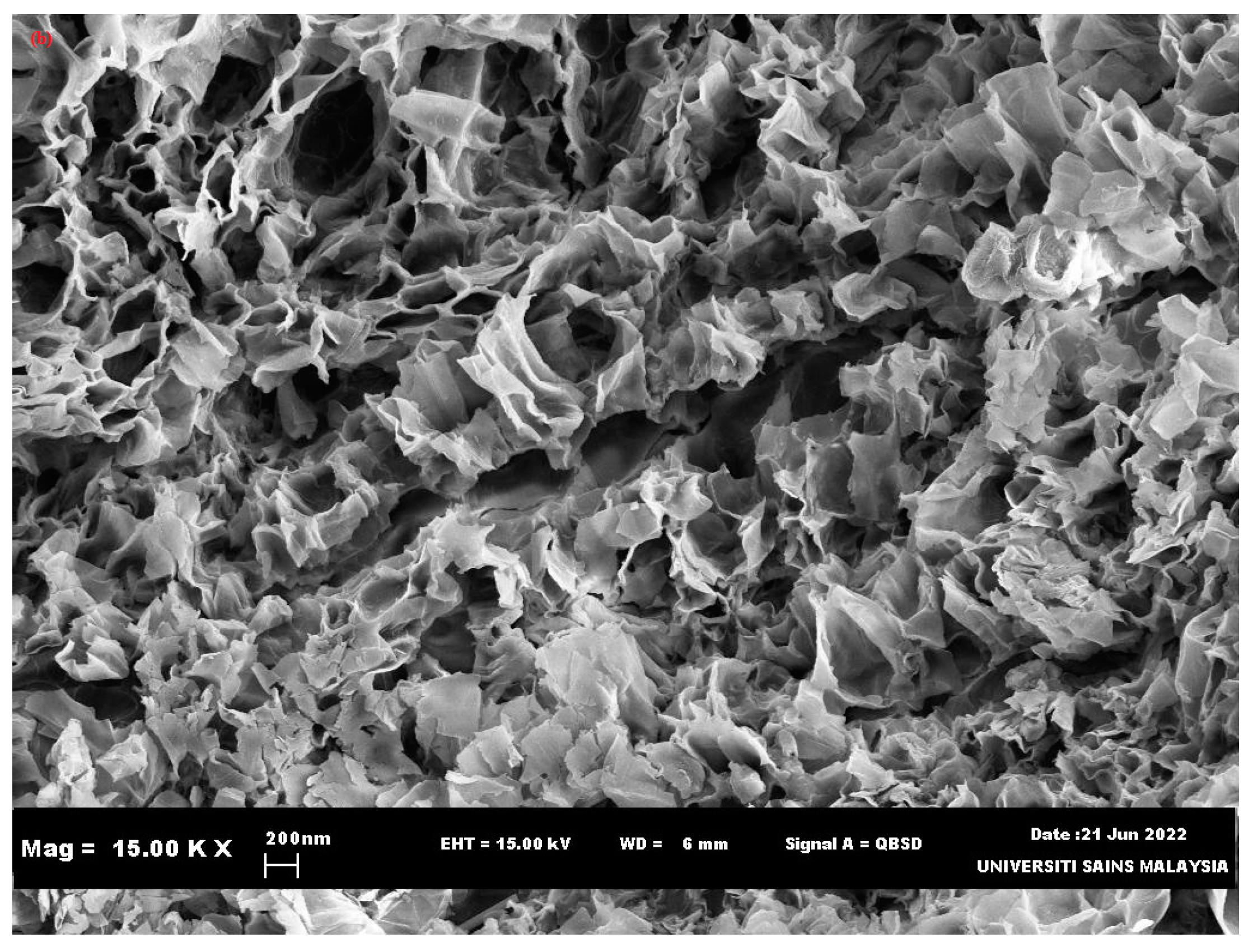

3.3. Batch Experiments

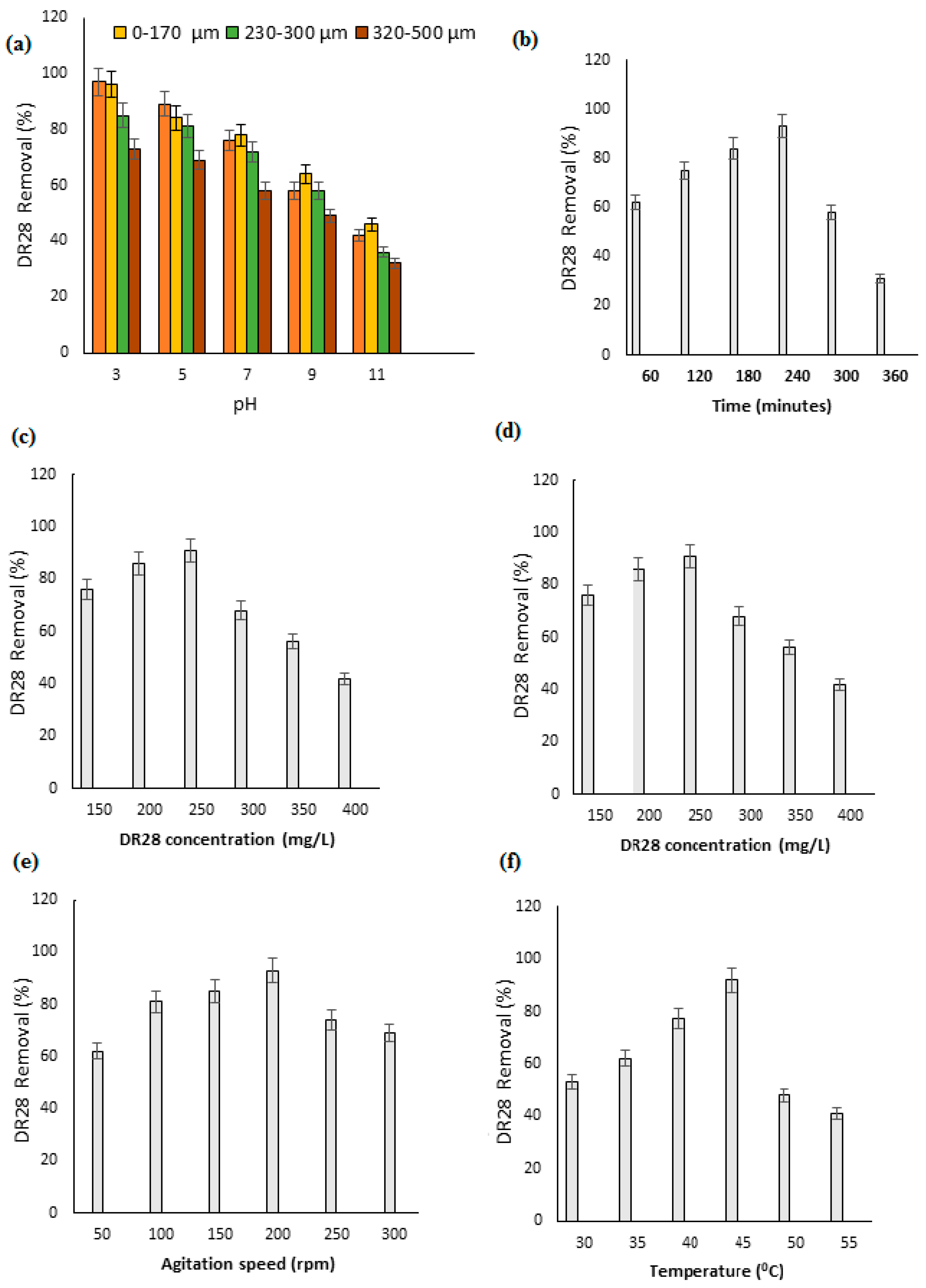

3.3.1. Impact of pH

3.3.2. Particle Size

3.3.3. Contact Period

3.3.4. Dose of Adsorbent

3.3.5. Concentration of Dye

3.3.6. Agitation Speed

3.3.7. Temperature

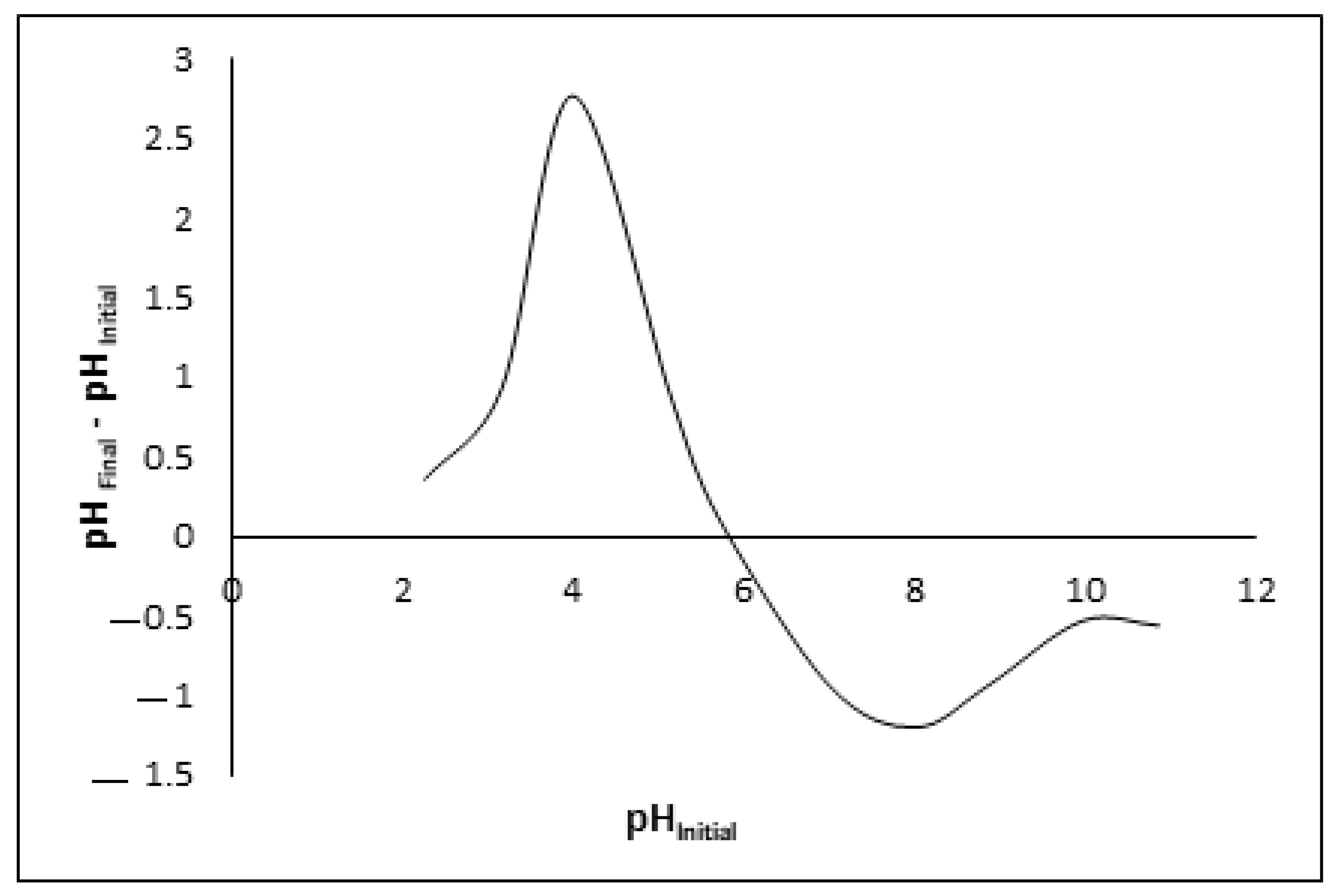

3.3.8. Point of Zero Charge

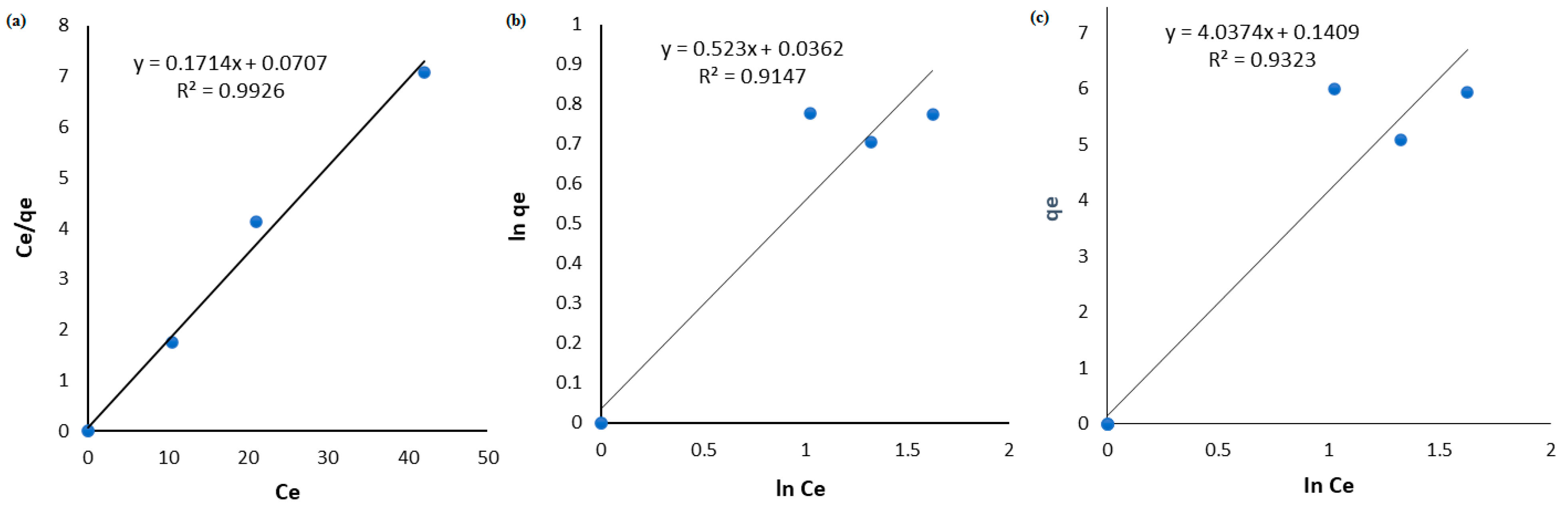

3.3.9. Equilibrium Modeling

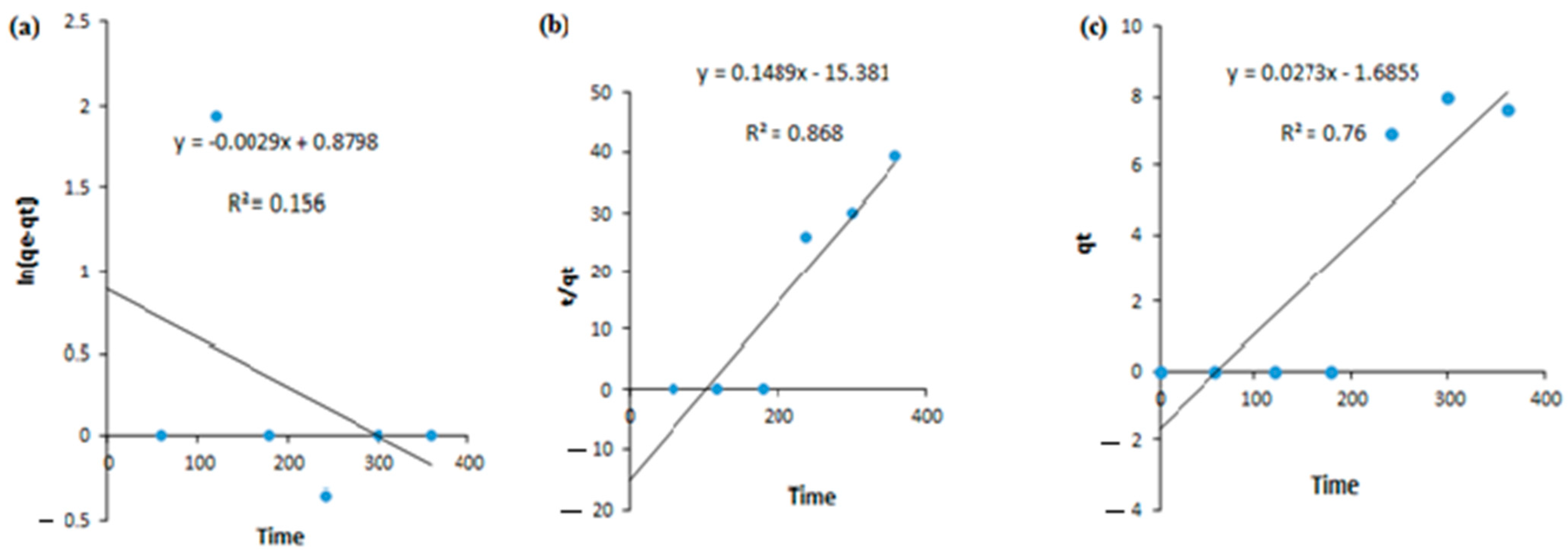

3.3.10. Kinetics of Adsorption

3.3.11. Thermodynamic Analysis

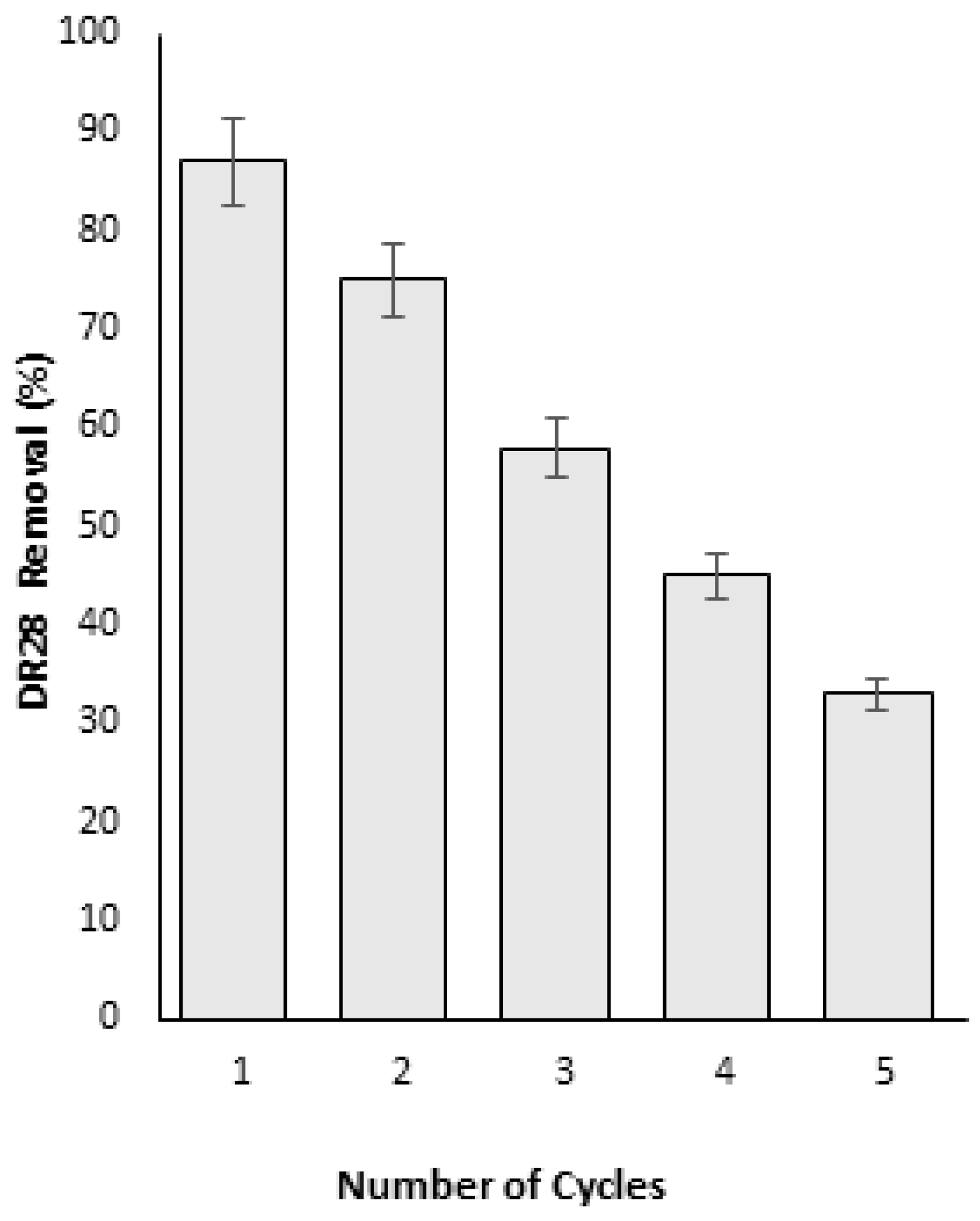

3.3.12. Regeneration Analysis

3.3.13. Evaluation of Phytotoxic Effects

3.3.14. Performance of Date Fruit Seed Biochar

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Slama, H.B.; Chenari Bouket, A.; Pourhassan, Z.; Alenezi, F.N.; Silini, A.; Cherif-Silini, H.; Oszako, T.; Luptakova, L.; Golińska, P.; Belbahri, L. Diversity of synthetic dyes from textile industries, discharge impacts and treatment methods. Appl. Sci. 2021, 11, 6255. [Google Scholar] [CrossRef]

- Enache, A.C.; Cojocaru, C.; Samoila, P.; Ciornea, V.; Apolzan, R.; Predeanu, G.; Harabagiu, V. Adsorption of brilliant green dye onto a mercerized biosorbent: Kinetic, thermodynamic, and molecular docking studies. Molecules 2023, 28, 4129. [Google Scholar] [CrossRef] [PubMed]

- Daud, Z.; Detho, A.; Rosli, M.A.; Abubakar, M.H.; Samo, K.A.; Rais, N.F.M.; Halim, A.A.; Tajarudin, H.A. Ammoniacal nitrogen and COD removal from stabilized landfill leachate using granular activated carbon and green mussel (Perna viridis) shell powder as a composite adsorbent. Desalination Water Treat 2020, 192, 111–117. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Pazdzior, K. Recent achievements in dyes removal focused on advanced oxidation processes integrated with biological methods. Molecules 2021, 26, 870. [Google Scholar] [CrossRef] [PubMed]

- Benkhaya, S.; Mrabet, S.; El Harfi, A. Classifications, properties, recent synthesis and applications of azo dyes. Heliyon 2020, 6, e03271. [Google Scholar] [CrossRef] [PubMed]

- Parthasarathy, P.; Sajjad, S.; Saleem, J.; Alherbawi, M.; Mckay, G.A. Review of the removal of dyestuffs from effluents onto biochar. Separations 2022, 9, 139. [Google Scholar] [CrossRef]

- Barathi, S.; Karthik, C.; Nadanasabapathi, S.; Padikasan, I.A. Biodegradation of textile dye reactive blue 160 by Bacillus firmus (Bacillaceae: Bacillales) and non-target toxicity screening of their degraded products. Toxicol. Rep. 2020, 7, 16–22. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Divyapriya, G.; Titchou, F.E.; Hamdani, M. Treatment of textile wastewater by sulfate radical based advanced oxidation processes. Sep. Purif. Technol. 2022, 293, 121115. [Google Scholar] [CrossRef]

- Han, Q.; Yang, Y.; Wang, R.; Zhang, K.; Liu, N.; Hong, M. Biochar derived from agricultural wastes as a means of facilitating the degradation of azo dyes by sulfides. Catalysts 2021, 11, 434. [Google Scholar] [CrossRef]

- Sackey, E.A.; Song, Y.; Yu, Y.; Zhuang, H. Biochars derived from bamboo and rice straw for sorption of basic red dyes. PLoS ONE 2021, 16, e0254637. [Google Scholar] [CrossRef]

- Sait, H.H.; Hussain, A.; Bassyouni, M.; Ali, I.; Kanthasamy, R.; Ayodele, B.V.; Elhenawy, Y. Anionic dye removal using a date palm seed-derived activated carbon/chitosan polymer microbead biocomposite. Polymers 2022, 14, 2503. [Google Scholar] [CrossRef] [PubMed]

- Nindjio, G.F.K.; Tagne, R.F.T.; Jiokeng, S.L.Z.; Fotsop, C.G.; Bopda, A.; Doungmo, G.; Temgoua, R.C.T.; Doench, I.; Njoyim, E.T.; Tamo, A.K.; et al. Lignocellulosic-based materials from bean and pistachio pod wastes for dye-contaminated water treatment: Optimization and modeling of indigo carmine sorption. Polymers 2022, 14, 3776. [Google Scholar] [CrossRef] [PubMed]

- Albahnasawi, A.; Yüksel, E.; Gürbulak, E.; Duyum, F. Fate of aromatic amines through decolorization of real textile wastewater under anoxic-aerobic membrane bioreactor. J. Environ. Chem. Eng. 2020, 8, 104226. [Google Scholar] [CrossRef]

- Abd-Elhamid, A.I.; Emran, M.; El-Sadek, M.H.; El-Shanshory, A.A.; Soliman, H.M.; Akl, M.A.; Rashad, M. Enhanced removal of cationic dye by eco-friendly activated biochar derived from rice straw. Appl. Water Sci. 2020, 10, 1–11. [Google Scholar] [CrossRef]

- Santoso, E.; Ediati, R.; Kusumawati, Y.; Bahruji, H.; Sulistiono, D.O.; Prasetyoko, D. Review on recent advances of carbon based adsorbent for methylene blue removal from waste water. Mater. Today Chem. 2020, 16, 100233. [Google Scholar] [CrossRef]

- Vadivel, V.K.; Cikurel, H.; Mamane, H. Removal of indigo dye by CaCO3/Ca(OH)2 composites and resource recovery. Ind. Eng. Chem. Res. 2021, 60, 10312–10318. [Google Scholar] [CrossRef]

- Alsukaibi, A.K. Various approaches for the detoxification of toxic dyes in wastewater. Processes 2022, 10, 1968. [Google Scholar] [CrossRef]

- Xiang, H.; Min, X.; Tang, C.J.; Sillanpää, M.; Zhao, F. Recent advances in membrane filtration for heavy metal removal from wastewater: A mini review. J. Water Process Eng. 2022, 49, 103023. [Google Scholar] [CrossRef]

- Zainudin, N.F.; Sam, S.T.; Wong, Y.S.; Ismail, H.; Walli, S.; Inoue, K.; Kawamura, G.; Tan, W.K. Degradation of diazo congo red dye by using synthesized poly-ferric-silicate-sulphate through co-polymerization process. Polymers 2023, 15, 237. [Google Scholar] [CrossRef]

- Hamad, H.N.; Idrus, S. Recent developments in the application of bio-waste-derived adsorbents for the removal of methylene blue from wastewater: A review. Polymers 2022, 14, 783. [Google Scholar] [CrossRef]

- Değermenci, G.D.; Değermenci, N.; Ayvaoğlu, V.; Durmaz, E.; Çakır, D.; Akan, E. Adsorption of reactive dyes on lignocellulosic waste; characterization, equilibrium, kinetic and thermodynamic studies. J. Clean. Prod. 2019, 225, 1220–1229. [Google Scholar] [CrossRef]

- Mokhtar, N.; Johari, M.A.M.; Tajarudin, H.A.; AlGheethi, A.A.; AlgaifiA, H.A. Sustainable enhancement of bio-cement using immobilised Bacillus sphaericus: Optimization, microstructural properties, and techno-economic analysis for a cleaner production of bio-cementitious mortars. J. Clean. Prod. 2021, 318, 128470. [Google Scholar] [CrossRef]

- Kaab, A.; Sharifi, M.; Mobli, H.; Nabavi-Pelesaraei, A.; Chau, K.W. Combined life cycle assessment and artificial intelligence for prediction of output energy and environmental impacts of sugarcane production. Sci. Total Environ. 2019, 664, 1005–1019. [Google Scholar] [CrossRef] [PubMed]

- Goswami, L.; Kushwaha, A.; Kafle, S.R.; Kim, B.S. Surface modification of biochar for dye removal fromwastewater. Catalysts 2022, 12, 817. [Google Scholar] [CrossRef]

- Kim, D.Y.; Jung, G.B. Effects of pyrolysis and ball-milling on the physicochemical and rhodamine b removal characteristics of rice-bran-derived biochar. Appl. Sci. 2023, 13, 4288. [Google Scholar] [CrossRef]

- Kapoor, R.T.; Rafatullah, M.; Siddiqui, M.R.; Khan, M.A.; Sillanpää, M. Removal of reactive black 5 dye by banana peel biochar and evaluation of its phytotoxicity on tomato. Sustainability 2022, 14, 4176. [Google Scholar] [CrossRef]

- Kapoor, R.T.; Rafatullah, M.; Aljuwayid, A.M.; Habila, M.A.; Wabaidur, S.M.; Alam, M. Removal of patent blue dye using Ananas comosus-derived biochar: Equilibrium, kinetics, and phytotoxicity studies. Separations 2022, 9, 426. [Google Scholar] [CrossRef]

- Ying, Z.; Chen, X.; Li, H.; Liu, X.; Zhang, C.; Zhang, J.; Yi, G. Efficient adsorption of methylene blue by porous biochar derived from soybean dreg using a one-pot synthesis method. Molecules 2021, 26, 661. [Google Scholar] [CrossRef]

- Kali, A.; Amar, A.; Loulidi, I.; Hadey, C.; Jabri, M.; Alrashdi, A.A.; Lgaz, H.; Sadoq, M.; El-Kordy, A.; Boukhlifi, F. Efficient adsorption removal of an anionic azo dye by lignocellulosicwaste material and sludge recycling into combustible briquettes. Colloids Interfaces 2022, 6, 22. [Google Scholar] [CrossRef]

- Zeghioud, H.; Fryda, L.; Djelal, H.; Assadi, A.; Kane, A. A comprehensive review of biochar in removal of organic pollutants from wastewater: Characterization, toxicity, activation/functionalization and influencing treatment factors. J. Water Process Eng. 2022, 47, 102801. [Google Scholar] [CrossRef]

- Ramos, R.; Abdelkader-Fernández, V.K.; Matos, R.; Peixoto, A.F.; Fernandes, D.M. Metal-supported biochar catalysts for sustainable biorefinery, electrocatalysis, and energy storage applications: A review. Catalysts 2022, 12, 207. [Google Scholar] [CrossRef]

- Siddiqui, S.I.; Allehyani, E.S.; Al-Harbi, S.A.; Hasan, Z.; Abomuti, M.A.; Rajor, H.K.; Oh, S. Investigation of congo red toxicity towards different living organisms: A review. Processes 2023, 11, 807. [Google Scholar] [CrossRef]

- Chawla, S.; Uppal, H.; Yadav, M.; Bahadur, N.; Singh, N. Zinc peroxide nanomaterial as an adsorbent for removal of congo red dye from waste water. Ecotoxicol. Environ. Saf. 2017, 135, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Hua, Z.; Pan, Y.; Hong, Q. Adsorption of congo red dye in water by orange peel biochar modified with CTAB. RSC Adv. 2023, 13, 12502–12508. [Google Scholar] [CrossRef] [PubMed]

- Naseem, K.; Farooqi, Z.H.; Begum, R.; Irfan, A. Removal of congo red dye from aqueous medium by its catalytic reduction using sodium borohydride in the presence of various inorganic nano-catalysts: A review. J. Clean. Prod. 2018, 187, 296–307. [Google Scholar] [CrossRef]

- Echegaray, N.; Gullón, B.; Pateiro, M.; Amarowicz, R.; Misihairabgwi, J.M.; Lorenzo, J.M. Date fruit and its by-products as promising source of bioactive components: A review. Food Rev. Int. 2021, 39, 1411–1432. [Google Scholar] [CrossRef]

- Fernández-López, J.; Viuda-Martos, M.; Sayas-Barberá, E.; Navarro-Rodríguez de Vera, C.; Pérez-Álvarez, J.Á. Biological, nutritive, functional and healthy potential of date palm fruit (Phoenix dactylifera): Current research and future prospects. Agronomy 2022, 12, 876. [Google Scholar] [CrossRef]

- Rybicka, I.; Kiewlicz, J.; Kowalczewski, P.L.; Gliszczynska-’Swigło, A. Selected dried fruits as a source of nutrients. Eur. Food Res. Technol. 2021, 247, 2409–2419. [Google Scholar] [CrossRef]

- Al-Shankiti, A.; Gill, S. Biochar from date palm and Conocarpus waste for improvement of soil quality and biomass production. Biosalinity New 2014, 15, 8–9. [Google Scholar]

- Jeevarathinam, G.; Chelladurai, V. Pigeon pea. In Pulses; Springer: Berlin/Heidelberg, Germany, 2020; pp. 275–296. [Google Scholar]

- Gargi, B.; Semwal, P.; Jameel Pasha, S.B.; Singh, P.; Painuli, S.; Thapliyal, A.; Cruz-Martins, N. Revisiting the nutritional, chemical and biological potential of Cajanus cajan (L.) Millsp. Molecules 2022, 27, 6877. [Google Scholar] [CrossRef]

- Cebrian, G.; Condon, S.; Manas, P. Physiology of the inactivation of vegetative bacteria by thermal treatments: Mode of action, influence of environmental factors and inactivation kinetics. Foods 2017, 6, 107. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Utrilla, J.; Bautista-Toledo, I.; Ferro-García, M.A.; Moreno-Castilla, C. Activated carbon surface modifications by adsorption of bacteria and their effect on aqueous lead adsorption. J. Chem. Technol. Biotechnol. 2001, 76, 1209–1215. [Google Scholar] [CrossRef]

- Bharathi, K.S.; Ramesh, S.P.T. Fixed-bed column studies on biosorption of crystal violet from aqueous solution by Citrullus lanatus rind and Cyperus rotundus. Appl. Water Sci. 2013, 3, 673–687. [Google Scholar] [CrossRef]

- Ng, J.C.Y.; Cheung, W.H.; McKay, G. Equilibrium studies of the sorption of Cu (II) ions onto chitosan. J. Colloid Interface Sci. 2002, 255, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Temkin, M.I.; Pyzhev, V. Kinetics of ammonia synthesis on promoted iron catalyst. Acta Phys. Chim. USSR 1940, 12, 327–356. [Google Scholar]

- Lagergren, S. About the theory of so-called adsorption of soluble substances. K. Sven. Vetenskapsakademiens Handl. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.S.; Mckay, G. Pseudo-second-order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Weber, W.J.; Morris, J.C. Kinetics of adsorption on carbon from solution. J. Sanit. Eng. Div. 1963, 89, 31–60. [Google Scholar] [CrossRef]

- Kapoor, R.T.; Selvaraju Sivamani, S. Exploring the potential of Eucalyptus citriodora biochar against direct red 31 dye and its phytotoxicity assessment. Biomass Convers. Biorefin. 2021, 13, 8011–8022. [Google Scholar] [CrossRef]

- ISTA. International Rules for Seed Testing; International Seed Testing Association, ISTA Secretariat: Bassersdorf, Switzerland, 2008. [Google Scholar]

- Lichtenthaler, H.K. Chlorophylls and carotenoids: Pigments of photosynthetic biomembranes. Methods Enzymol. 1987, 148, 350–382. [Google Scholar]

- Hedge, J.E.; Hofreiter, B.T. Carbohydrate Chemistry 17; Whistler, R.L., Be Miller, J.N., Eds.; Academic Press: New York, NY, USA, 1962; pp. 17–22. [Google Scholar]

- Bates, L.S.; Waldren, R.P.; Teare, I.D. Rapid determination of free proline for water-stress studies. Plant Soil 1973, 39, 205–207. [Google Scholar] [CrossRef]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, A.; Rani, R.; Kumar, S.; Thomas, T.; David, A.A.; Ahmed, M. A new insight to adsorption and accumulation of high lead concentration by exopolymer and whole cells of lead-resistant bacterium Acinetobacter junii L. Pb1 isolated from coal mine dump. Environ. Sci. Pollut. Res. 2017, 24, 10652–10661. [Google Scholar] [CrossRef] [PubMed]

- Wisniewska, M.; Chibowski, S.; Wawrzkiewicz, M.; Onyszko, M.; Bogatyrov, V.C.I. Basic Red 46 removal from sewage by carbon and silica based composite: Equilibrium, kinetic and electrokinetic studies. Molecules 2022, 27, 1043. [Google Scholar] [CrossRef]

- Chanzu, H.A.; Onyari, J.M.; Shiundu, P.M. Brewers’ spent grain in adsorption of aqueous congo red and malachite green dyes: Batch and continuous flow systems. J. Hazard. Mater. 2019, 380, 120897. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Xu, S.; Chen, J.; Miao, X.; Zhu, J. Oxalate enhanced degradation of orange II in heterogeneous UV-fenton system catalyzed by Fe3O4@Γ-Fe2O3 composite. Chemosphere 2018, 199, 147–153. [Google Scholar] [PubMed]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G. Adsorptive removal of dye using biochar derived from residual algae after in-situ transesterification: Alternate use of waste of biodiesel industry. J. Environ. Manag. 2016, 182, 187–197. [Google Scholar]

- Rehman, R.; Murtaza, S.; Zaman, W.; Shafique, U. Comparative removal of congo red dye from water by adsorption on Grewia asiatica leaves, Raphanus sativus peels and activated charcoal. J. Chem. Soc. Pak. 2012, 34, 112. [Google Scholar]

- Yang, G.; Wu, L.; Xian, Q.; Shen, F.; Wu, J.; Zhang, Y. Removal of congo red and methylene blue from aqueous solutions by vermicompost-derived biochars. PLoS ONE 2016, 11, e0154562. [Google Scholar] [CrossRef]

- Salameh, Y.; Albadarin, A.B.; Allen, S.; Walker, G.; Ahmad, M.N.M. Arsenic (III, V) adsorption onto charred dolomite: Charring optimization and batch studies. Chem. Eng. J. 2015, 259, 663–671. [Google Scholar] [CrossRef]

- Jamali-Behnam, F.; Najafpoor, A.A.; Davoudi, M.; Rohani-Bastami, T.; Alidadi, H.; Esmaily, H.; Dolatabadi, M. Adsorptive removal of arsenic from aqueous solutions using magnetite nanoparticles and silica-coated magnetite nanoparticles. Environ. Prog. Sustain. Energy 2018, 37, 951–960. [Google Scholar] [CrossRef]

- Joardder, M.U.H.; Uddin, M.S.; Islam, M.N. The utilization of waste date seed as bio-oil and activated carbon by pyrolysis process. Adv. Mech. Eng. 2012, 4, 316806. [Google Scholar] [CrossRef]

- Enaime, G.; Baçaoui, A.; Yaacoubi, A.; Lübken, M. Biochar for wastewater treatment-conversion technologies and applications. Appl. Sci. 2020, 10, 3492. [Google Scholar] [CrossRef]

- Kaya, N.; Yıldız, Z.; Ceylan, S. Preparation and characterisation of biochar from hazelnut shell and its adsorption properties for methylene blue dye. Politek. Derg. 2018, 21, 765–776. [Google Scholar] [CrossRef]

- Neupane, S.; Ramesh, S.T.; Gandhimathi, R.; Nidheesh, P.V. Pineapple leaf (Ananas comosus) powder as a biosorbent for the removal of crystal violet from aqueous solution. Desalination Water Treat. 2015, 54, 2041–2054. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; van Hullebusch, E.D.; Amrane, A.; Rtimi, S. Mechanisms and adsorption capacities of biochar for the removal of organic and inorganic pollutants from industrial wastewater. Int. J. Environ. Sci. Technol. 2021, 18, 3273–3294. [Google Scholar]

- Wu, K.; Pan, X.; Zhang, J.; Zhang, X.; Salah Zene, A.; Tian, Y. Biosorption of congo red from aqueous solutions based on self-immobilized mycelial pellets: Kinetics, isotherms, and thermodynamic studies. ACS Omega 2020, 5, 24601–24612. [Google Scholar] [PubMed]

- Bao, Y.; Zhang, G. study of adsorption characteristics of methylene blue onto activated carbon made by Salix psammophila. Energy Procedia 2012, 16, 1141–1146. [Google Scholar] [CrossRef]

- Bashanaini, M.S.; Al-Douh, M.H.; Al-Ameri, H.S. Removal of malachite green dye from aqueous solution by adsorption using modified and unmodified local agriculture waste. Sci. J. Anal. Chem. 2019, 7, 42–56. [Google Scholar]

- Rubangakene, N.O.; Elwardany, A.; Fujii, M.; Sekiguchi, H.; Elkady, M.; Shokry, H. Biosorption of congo red dye from aqueous solutions using pristine biochar and ZnO biochar from green pea peels. Chem. Eng. Res. Des. 2023, 189, 636–651. [Google Scholar]

- Duarte Neto, J.F.; Pereira, I.D.S.; Da Silva, V.C.; Ferreira, H.C.; Neves, D.G.A.; Menezes, R.R. Study of equilibrium and kinetic adsorption of rhodamine B onto purified bentonite clays. Ceramica 2018, 64, 598–607. [Google Scholar] [CrossRef]

- Perez-Calderon, J.; Santos, M.V.; Zaritzky, N. Reactive red 195 dye removal using chitosan coacervated particles as bio-sorbent: Analysis of kinetics, equilibrium and adsorption mechanisms. J. Environ. Chem. Eng. 2018, 6, 6749–6760. [Google Scholar] [CrossRef]

- Karthick, K.; Namasivayam, C.; Pragasam, L.A. Removal of direct red 12B from aqueous medium by ZnCl2 activated Jatropha husk carbon: Adsorption dynamics and equilibrium studies. Ind. J. Chem. Technol. 2017, 24, 73–81. [Google Scholar]

- Khan, N.; Chowdhary, P.; Ahmad, A.; Giri, B.S.; Chaturvedi, P. Hydrothermal liquefaction of rice husk and cow dung in mixed-bed-rotating pyrolyzer and application of biochar for dye removal. Bioresour. Technol. 2020, 309, 123294. [Google Scholar] [CrossRef] [PubMed]

- Ghaedi, M.; Tavallali, H.; Sharifi, M.; Kokhdan, S.N.; Asghari, A. Preparation of low cost activated carbon from Myrtus communis and pomegranate and their efficient application for removal of congo red from aqueous solution. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2012, 86, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Chong, K.Y.; Chia, C.H.; Zakaria, S.; Sajab, M.S. Vaterite calcium carbonate for the adsorption of congo red from aqueous solutions. J. Environ. Chem. Eng. 2014, 2, 2156–2161. [Google Scholar]

- Alarifi, I.M.; Al-ghamdi, Y.O.; Darwesh, R.; Omaish, M.; Kashif, M. Properties and application of MoS2 nanopowder: Characterization, congo red dye adsorption, and optimization. J. Mater. Res. Technol. 2021, 13, 1169–1180. [Google Scholar] [CrossRef]

- Roy, T.K.; Mondal, N.K. Biosorption of congo red from aqueous solution onto burned root of Eichhornia crassipes biomass. Appl. Water Sci. 2017, 7, 1841–1854. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, M.; Wang, Y.; Chen, J.; Zhang, J. Biochars prepared from rabbit manure for the adsorption of rhodamine B and congo red: Characterisation, kinetics, isotherms and thermodynamic studies. Water Sci. Technol. 2020, 81, 436–444. [Google Scholar] [CrossRef]

| Stuff | Congo Red 4B, Cosmos Red, Direct Red Y |

|---|---|

| C.I. Number | 11313 |

| Color | Red-Brown |

| Type Melting point | Anionic dye >360 °C |

| Solubility | Water-soluble and less soluble in organic solvents |

| IUPAC name | disodium;4-amino-3-[[4-[4-[(1-amino-4-sulfonatonaphthalen-2-yl)diazenyl]phenyl]phenyl]diazenyl]naphthalene-1-sulfonate |

| Formula | C32H22N6Na2O6S2 |

| Molecular weight Application | 696.7 g mol−1 Used in textile and printing industry |

| Structure |  |

| λmax | 497 nm |

| S. No. | DFSB | Weight (%) |

|---|---|---|

| 1. | Volatile matter | 66.55 |

| 2. | Fixed carbon | 25.20 |

| 3. | Moisture | 5.50 |

| 4. | Ash | 2.75 |

| Isotherm | Equation | Variables | Value |

|---|---|---|---|

| Langmuir | qm (mg g−1) KL (l mg−1) R2 | 5.83 0.0021 0.9926 | |

| Freundlich | n KF (mg g−1) R2 | 1.9120 1.0369 0.9147 | |

| Temkin | qe = RT/bT In(AT) + RT/bT In (Ce) | bT (J mole−1) AT (L mole−1) R2 | 4.0374 1.03552 0.9323 |

| Model | Equation | Variables | Value |

|---|---|---|---|

| Pseudo first order | 1K1 (min−1) | 0.0029 | |

| qe (mg g−1) | 2.41042 | ||

| R2 | 0.1569 | ||

| Pseudo second order | K2 (g mg−1 min−1) | 0.00144 | |

| qe (mg g−1) | 6.7159 | ||

| R2 | 0.8685 | ||

| Weber–Morris intraparticle diffusion | qt = kdiff t1/2+ C | Kdiff C R2 | 0.0273 1.6855 0.769 |

| S. No. | Temperature (°C) | (∆G°) (kJ mol−1) | ΔH° (kJ mol−1) | ΔS° (J K−1) |

|---|---|---|---|---|

| 1. | 30 | −5377.67 | −31.889 | 90.752 |

| 2. | 35 | −4976.33 | ||

| 3. | 40 | −3822.26 | ||

| 4. | 45 | −1388.72 | ||

| 5. | 50 | −2361.86 | ||

| 6. | 55 | −4256.75 |

| Treatment | Germination (%) | Radicle Length (cm) | Plumule Length (cm) | Vigour Index |

|---|---|---|---|---|

| Control | 98 ± 0.56 a | 3.65 ± 0.15 a | 10.21 ± 0.71 a | 13,582.8 |

| DR28 dye solution (250 mg/L) | 12 ± 0.33 c | 0.87 ± 0.01 c | 2.75 ± 0.10 c | 434.4 |

| DFSB treated DR28 dye solution | 83 ± 0.67 b | 1.94 ± 0.03 b | 8.10 ± 0. 34 b | 8333.2 |

| Treatment | Chlorophyll (mg g−1 FW) | Sugar (mg g−1 DW) | Protein (mg g−1 FW) |

|---|---|---|---|

| Control | 2.89 ± 0.05 a | 3.95 ± 0.09 a | 24.12 ± 0.05 a |

| DR28 dye solution (250 mg/L) | 0.94 ± 0.02 c | 1.15 ± 0.22 c | 5.11 ± 0.38 c |

| DFSB treated DR28 dye solution | 1.67 ± 0.06 b | 2.42 ± 0.08 b | 16.09 ± 0.43 b |

| Adsorbent Material | Experimental Conditions | qmax (mg g−1) | References |

|---|---|---|---|

| Activated charcoal | pH = 2, exposure time = 0.67 h, Dose = 1 g | 0.93 | Rehman et al. [61] |

| Raphanus sativus peel | pH = 3, exposure time = 0.33 h, Dose = 2 g | 0.07 | Rehman et al. [61] |

| Grewia asiatica leaves | pH = 7, exposure time = 0.5 h, Dose = 0.5 g | 0.057 | Rehman et al. [61] |

| Vermicompost-derived biochar | pH =7, exposure time = 2 h, Dose = 0.3 g | 31 | Yang et al. [62] |

| Cow dung biochar | pH = 7, exposure time = 84 h, Dose = 5 g | 13 | Khan et al. [77] |

| Rice husk biochar | pH = 7, exposure time = 84 h, Dose = 5 g | 15.8 | Khan et al. [77] |

| Pomegranate | pH = 7, exposure time = 0.5 h, Dose = 1 g | 19.23 | Ghaedi et al. [78] |

| Vaterite calcium carbonate | pH = 7, exposure time = 3 h, Dose = 0.2 mg | 17 | Chong et al. [79] |

| Molybdenum disulfide nanopowder | pH = 3, exposure time = 3 h, Dose = 0.1 g | 81 | Alarifi et al. [80] |

| Eichhornia crassipes biomass | pH = 7, exposure time = 0.75 h, Dose = 0.125 g | 14 | Roy and Mondal [81] |

| Rabbit manure biochar | pH = 5, exposure time = 3.5 h, Dose = 0.15 g | 28.4 | Huang et al. [82] |

| Algal biochar | pH = 2, exposure time = 0.17 h, Dose = 0.2 g | 51.3 | Nautiyal et al. [60] |

| Date fruit seed biochar | pH = 3, exposure time = 4 h, Dose = 3 g | 5.83 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapoor, R.T.; Rafatullah, M.; Tajarudin, H.A.; Siddiqui, M.R.; Alam, M. Treatment of Direct Red 28 Dye through Phoenix dactylifera L. Fruit Seed Biochar: Equilibrium, Kinetics, Thermodynamics, and Phytotoxicity Studies. Sustainability 2023, 15, 15266. https://doi.org/10.3390/su152115266

Kapoor RT, Rafatullah M, Tajarudin HA, Siddiqui MR, Alam M. Treatment of Direct Red 28 Dye through Phoenix dactylifera L. Fruit Seed Biochar: Equilibrium, Kinetics, Thermodynamics, and Phytotoxicity Studies. Sustainability. 2023; 15(21):15266. https://doi.org/10.3390/su152115266

Chicago/Turabian StyleKapoor, Riti Thapar, Mohd Rafatullah, Husnul Azan Tajarudin, Masoom Raza Siddiqui, and Mahboob Alam. 2023. "Treatment of Direct Red 28 Dye through Phoenix dactylifera L. Fruit Seed Biochar: Equilibrium, Kinetics, Thermodynamics, and Phytotoxicity Studies" Sustainability 15, no. 21: 15266. https://doi.org/10.3390/su152115266

APA StyleKapoor, R. T., Rafatullah, M., Tajarudin, H. A., Siddiqui, M. R., & Alam, M. (2023). Treatment of Direct Red 28 Dye through Phoenix dactylifera L. Fruit Seed Biochar: Equilibrium, Kinetics, Thermodynamics, and Phytotoxicity Studies. Sustainability, 15(21), 15266. https://doi.org/10.3390/su152115266