Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design

Abstract

:1. Introduction

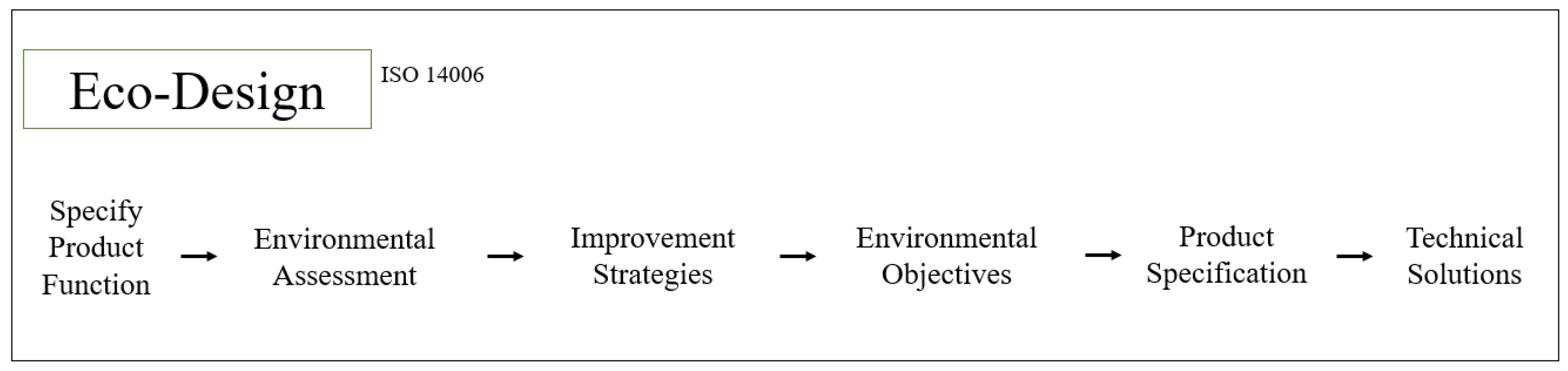

1.1. Eco-Design Overview

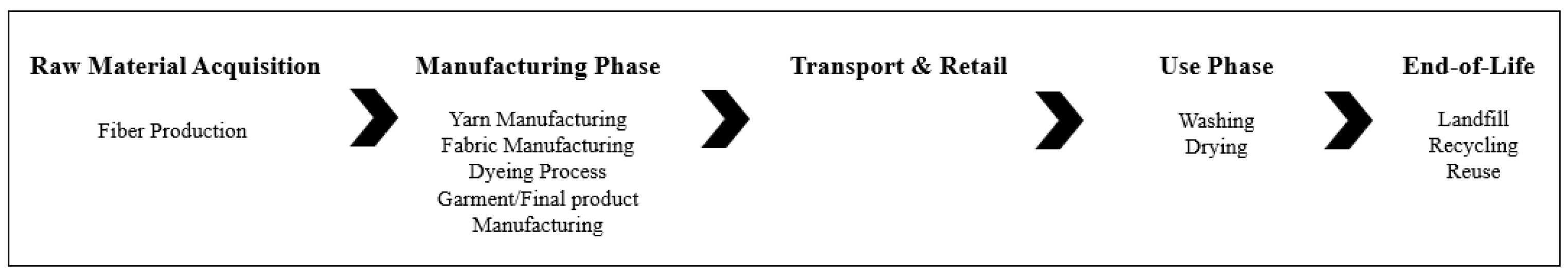

1.2. LCA Overview

- (i)

- Execution of a qualitative evaluation of the literature.

- (ii)

- Quantification of outcomes linked to climate change/global warming potential.

- (iii)

- Analyze the variability inherent in the above-mentioned impact category’s reported results.

- (i)

- Identification of the core raw materials utilized in LCA studies pertinent to the textile industry.

- (ii)

- Quantitative assessment of outcomes derived from diverse studies.

- (iii)

- Identification of hotspots within the life cycle phase of products.

2. Materials and Methods

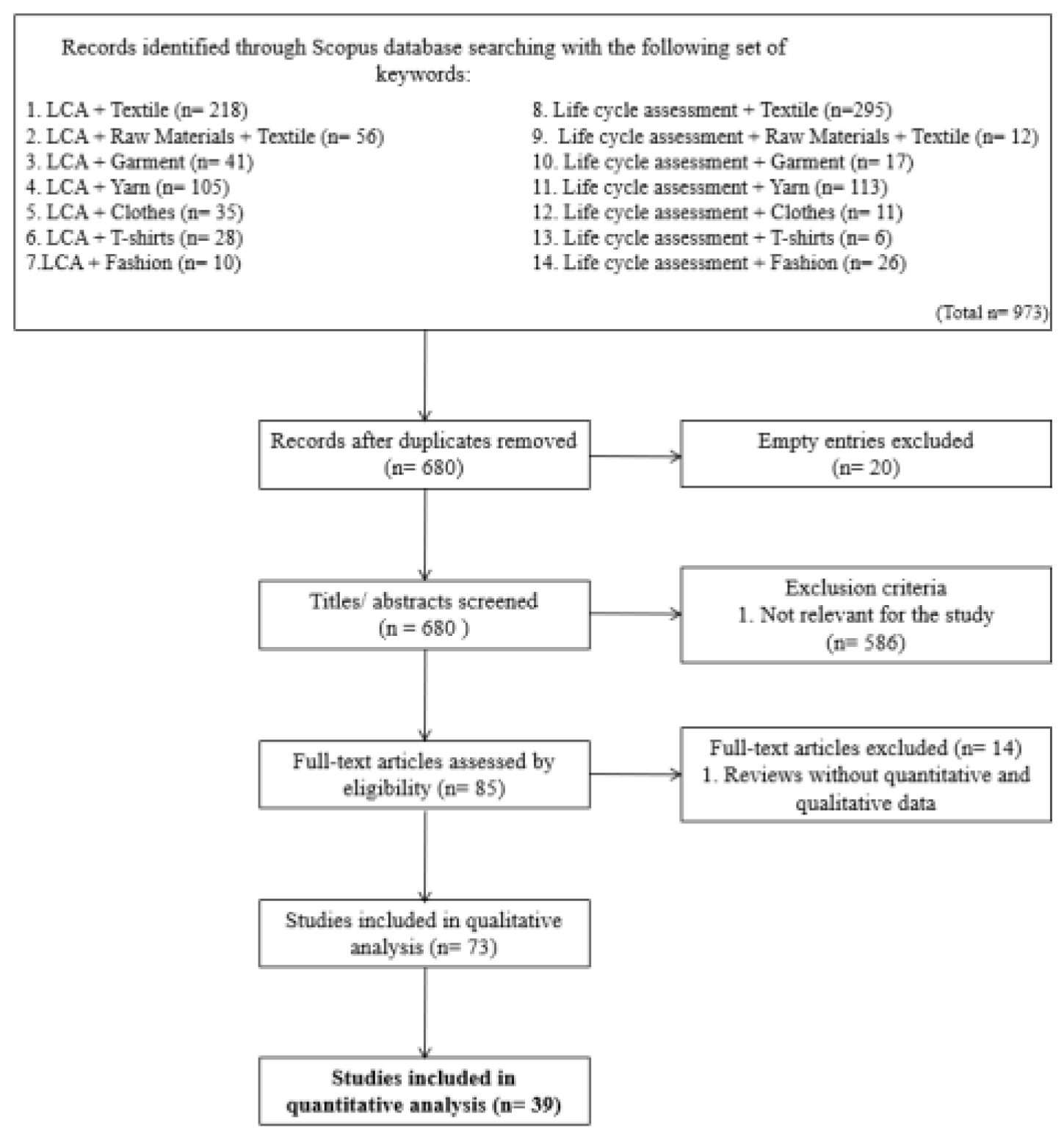

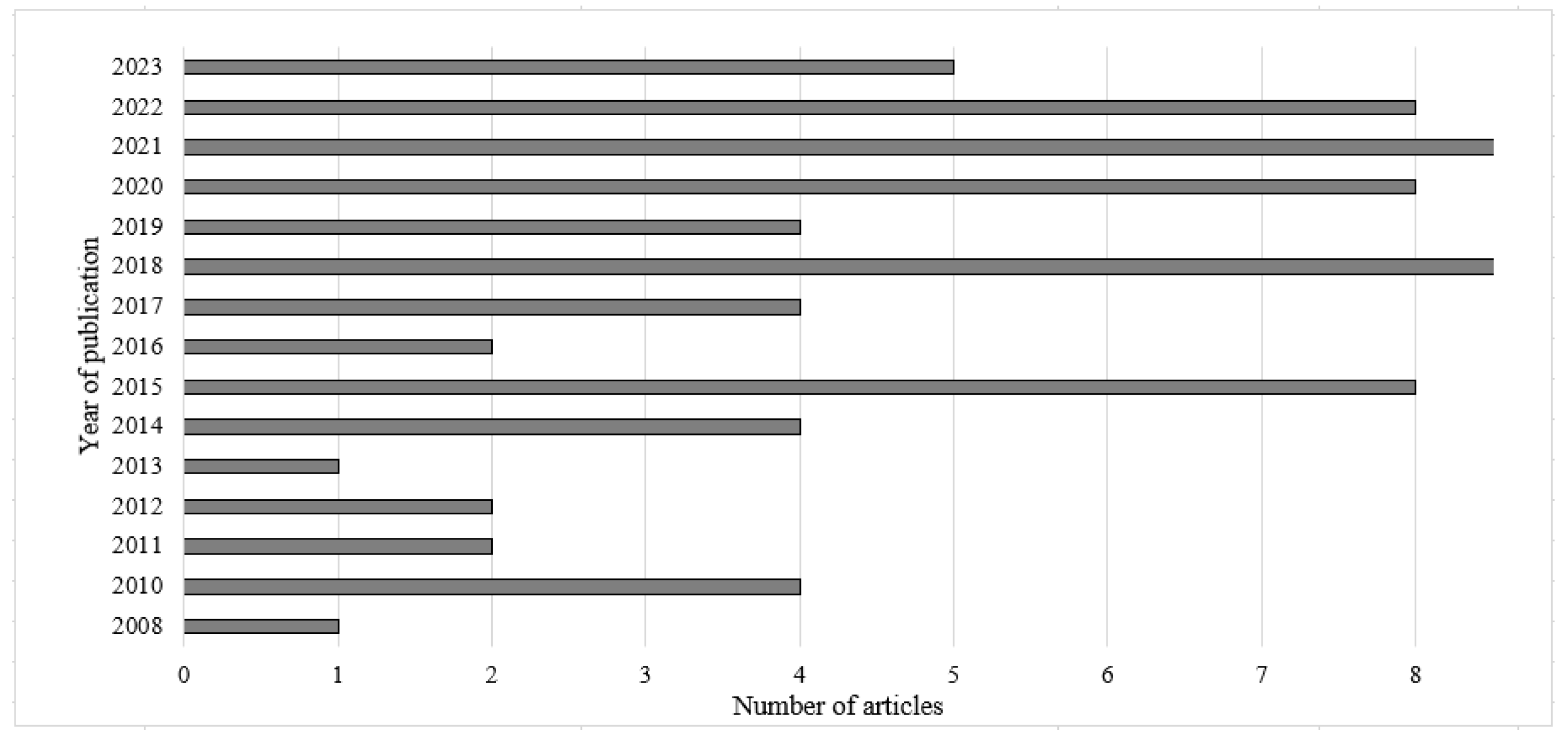

2.1. Bibliographic Research

2.2. Quantitative Analysis

3. Results

| Reference | Year | System Boundaries | Software | Impact Assessment Method |

|---|---|---|---|---|

| [43] * | 2021 | Cradle-to-Gate | SimaPro 9.0 | TRACI |

| [44] * | 2017 | Gate-to-Gate | EIME | NA |

| [45] * | 2014 | Cradle-to-Gate | Simapro 8.0.2 | CED, IPCC, Blue water footprint (BWF), and ReCiPe |

| [46] * | 2020 | Cradle-to-Gate | SimaPro 9.0.0 | ILCD |

| [47] | 2022 | Gate-to-Gate | OpenLCA 1.10.3 | NA |

| [48] | 2018 | Cradle-to-Grave | GaBi 5 | IPCC |

| [49] | 2015 | Cradle-to-Grave | GaBi 5 | IPCC |

| [50] * | 2019 | Cradle-to-Grave | SimaPro 8.1.1 | ReCiPe |

| [51] * | 2014 | Cradle-to-Gate | NA | IPCC, and Ecoindicator99 |

| [52] * | 2022 | Gate-to-Gate | SimaPro 9.2 | Environmental Footprint (EF) |

| [53] * | 2010 | Cradle-to-Gate | Simapro 7 | IPCC |

| [54] | 2016 | Cradle-to-Gate | Simapro 8 | CED, IPCC, and ReCIPe |

| [55] | 2021 | Gate-to-Gate | SimaPro | ReCiPe |

| [56] | 2012 | Cradle-to-Gate | GaBi 4 | CML |

| [57] | 2017 | Cradle-to-Gate | GaBi | IPCC |

| [58] | 2010 | Cradle-to-Grave | GaBi | EDIP |

| [59] * | 2021 | Cradle-to-Gate | SimaPro 8.4.1 | IPCC, CML-IA, and CED |

| [60] * | 2010 | Cradle-to-Gate | SimaPro 7.0 | CML |

| [61] * | 2023 | Cradle-to-Gate | SimaPro 7.1 | ReCiPe |

| [62] * | 2023 | Cradle-to-Grave | Excel | Environmental Footprint (EF) |

| [63] * | 2020 | Cradle-to-Grave | GaBi 8.0 | CML |

| [64] * | 2019 | Cradle-to-Gate | SimaPro 8.0.5.13 | CML |

| [65] | 2018 | Cradle-to-Grave | GaBi 4 | IPCC and ReCiPe |

| [66] | 2018 | Cradle-to-Gate | SimaPro | ReCiPe |

| [67] * | 2020 | Cradle-to-Gate | GaBi | ReCiPe |

| [68] * | 2023 | Gate-to-Gate | SimaPro 9.1 | ReCiPe |

| [69] | 2015 | Cradle-to-Grave | SimaPro 7.3.0 | IPCC and ReCiPe |

| [70] * | 2021 | Cradle-to-Gate | OpenLCA 2.1 | ILCD |

| [71] | 2011 | Cradle-to-Grave | SimaPro 7.1.8 | TRACI |

| [72] * | 2018 | Cradle-to-Grave | Open LCA | CML |

| [73] | 2018 | Cradle-to-Grave | NA | NA |

| [74] * | 2021 | Cradle-to-Grave | OpenLCA | ReCiPe and CML |

| [75] | 2020 | Cradle-to-Gate | NA | IPCC |

| [76] * | 2012 | Cradle-to-Gate | SimaPro 7.3 | IPCC |

| [77] * | 2018 | Gate-to-Gate | SimaPro 1.11 | ReCiPe |

| [78] * | 2015 | Gate-to-Gate | SimaPro 7.3.3 | CML |

| [79] * | 2017 | Cradle-to-Gate | NA | ReCiPe |

| [80] | 2019 | Cradle-to-Grave | GaBi | ReCiPe |

| [81] | 2013 | Cradle-to-Gate | NA | NA |

| [82] * | 2023 | Cradle-to-Grave | Simapro 9.2.02 | CML-IA |

| [83] * | 2010 | Cradle-to-Gate | NA | IPCC and CML |

| [84] | 2022 | Cradle-to-Grave | SimaPro 8 | ReCiPe |

| [85] | 2018 | Cradle-to-Grave | NA | NA |

| [42] * | 2021 | Cradle-to-Grave | NA | ReCiPe |

| [86] * | 2021 | Cradle-to-Grave | SimaPro 8.5.2 | TRACI |

| [87] | 2014 | Cradle-to-Gate | SimaPro 7.3 | ReCiPe and CML |

| [88] | 2015 | Cradle-to-Grave | SimaPro 8 | IPCC and ILCD |

| [89] | 2014 | Cradle-to-Grave | NA | NA |

| [90] * | 2008 | Cradle-to-Gate | SimaPro 1.1 | IPCC |

| [91] * | 2011 | Cradle-to-Gate | NA | IPCC |

| [92] * | 2015 | Cradle-to-gate | NA | IPCC |

| [93] * | 2019 | Cradle-to-Gate | SimaPro 8 | IPCC |

| [94] | 2019 | Cradle-to-Gate | SimaPro 8.3.0 | IPCC and ReCiPe |

| [95] * | 2015 | Cradle-to-Gate | NA | IPCC |

| [96] * | 2020 | Cradle-to-Grave | SimaPro 9.0 | IPCC |

| [11] * | 2022 | Cradle-to-Grave | SimaPro 9.1 | IPCC |

| [97] * | 2022 | Cradle-to-Grave | SimaPro 9.3 | IPCC |

| [98] * | 2020 | Cradle-to-Grave | NA | NA |

| [99] | 2016 | Cradle-to-Gate | SimaPro 7.1 | Ecoindicator99 |

| [100] | 2020 | Cradle-to-Gate | NA | NA |

| [101] * | 2020 | Cradle-to-Gate | GaBi | ReCiPe |

| [16] | 2018 | Cradle-to-Gate | GaBi 5 | CML |

| [102] | 2023 | Gate-to-Gate | GaBi 10.6 | ReCiPe |

| [103] * | 2015 | Cradle-to-Grave | GaBi 6.0 | CML |

| [104] | 2018 | Cradle-to-Grave | GaBi | CML |

| [105] | 2021 | Cradle-to-Grave | SimaPro 9.1.1.1 | Environmental Footprint (EF) |

| [106] | 2017 | Cradle-to-Grave | SimaPro 8.0.1 | TRACI |

| [107] | 2015 | Cradle-to-Grave | NA | NA |

| [108] | 2021 | Cradle-to-Gate | NA | IPCC |

| [109] * | 2023 | Cradle-to-Gate | NA | Environmental Footprint (EF) |

| [110] | 2022 | Cradle-to-Grave | Excel | ReCiPe |

| [111] | 2022 | Cradle-to-Gate | SimaPro 7.1.8 | CML and ReCiPe |

| [112] | 2018 | Cradle-to-Gate | OpenLCA | CML |

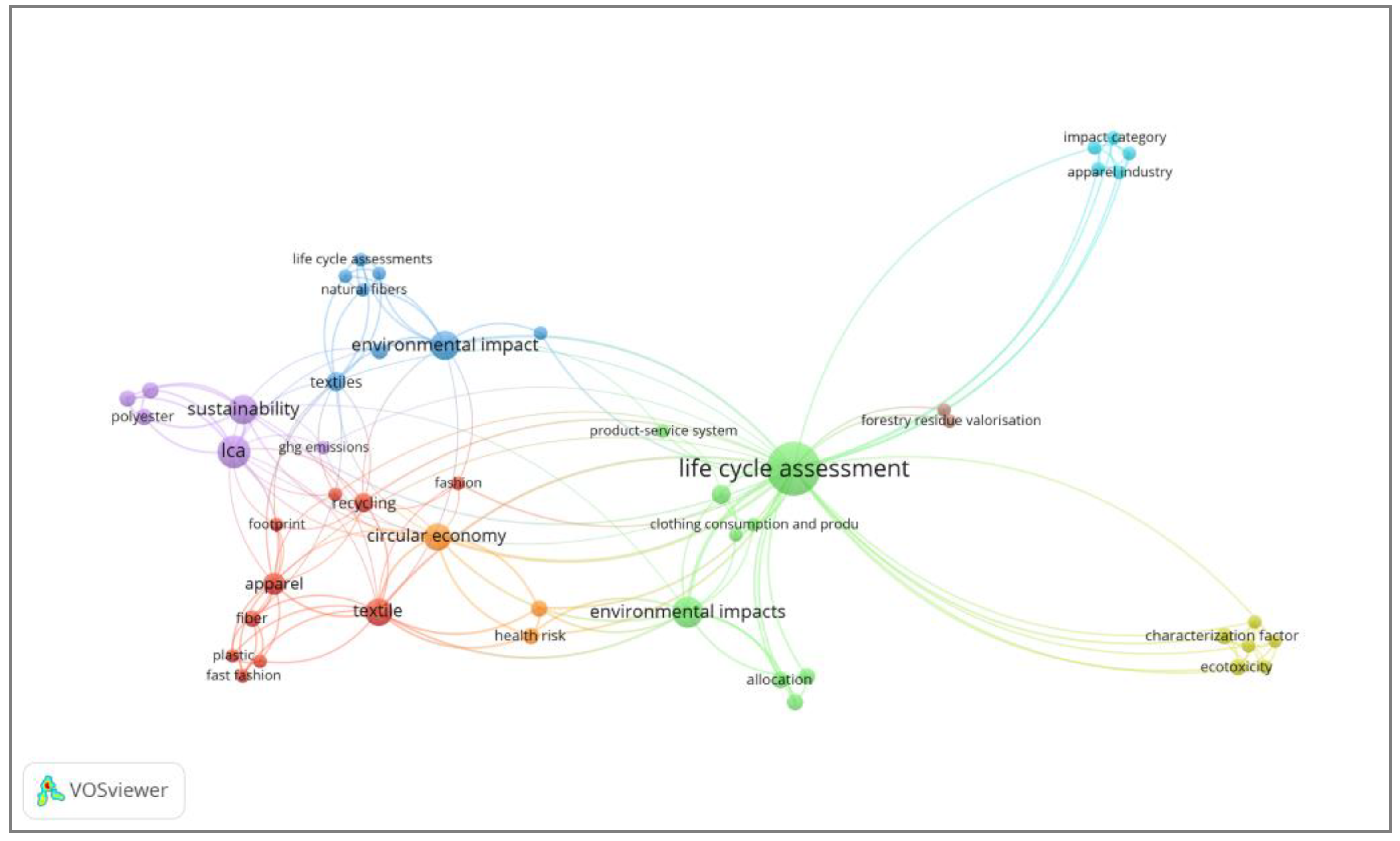

3.1. Goal and Scope Definition

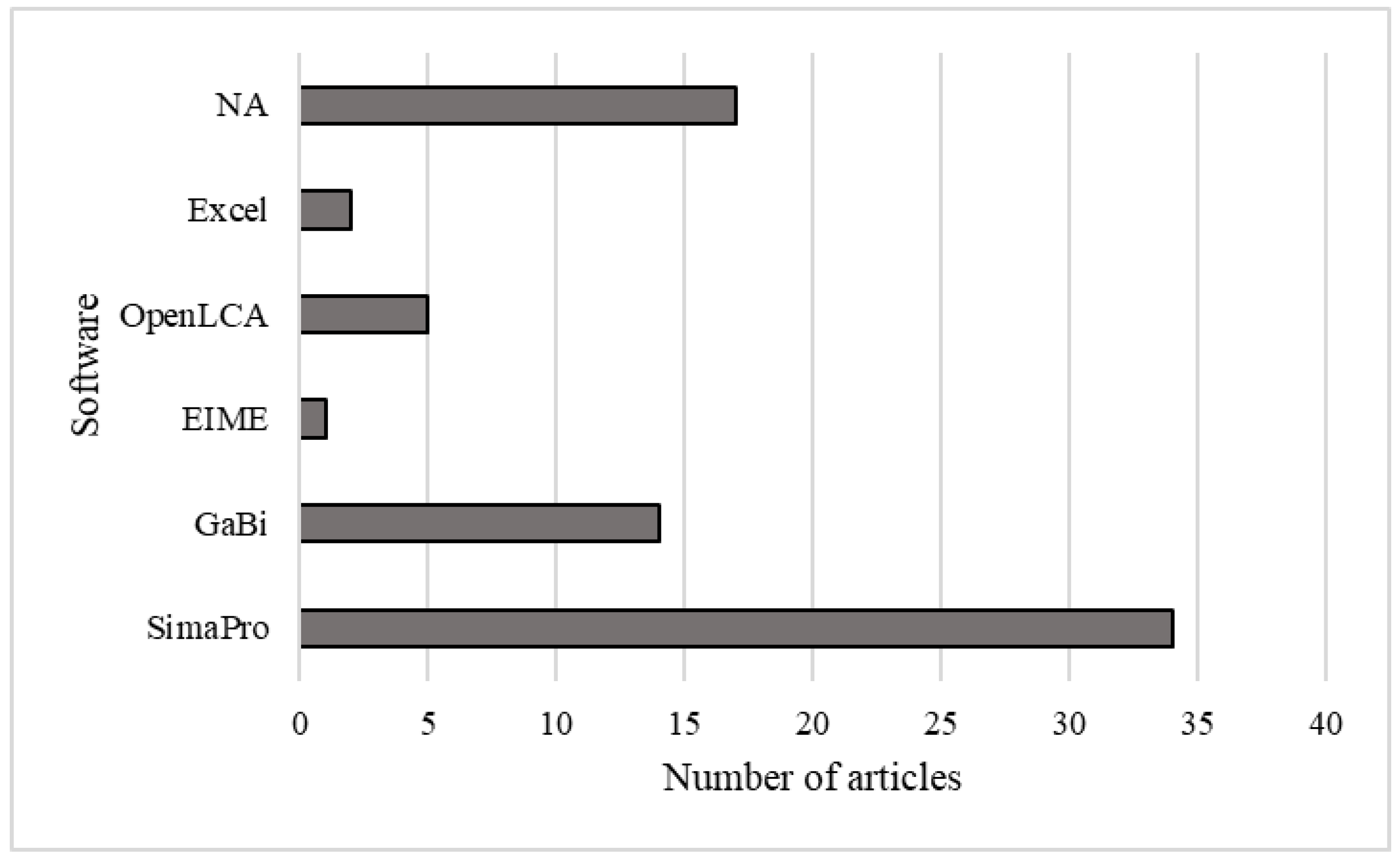

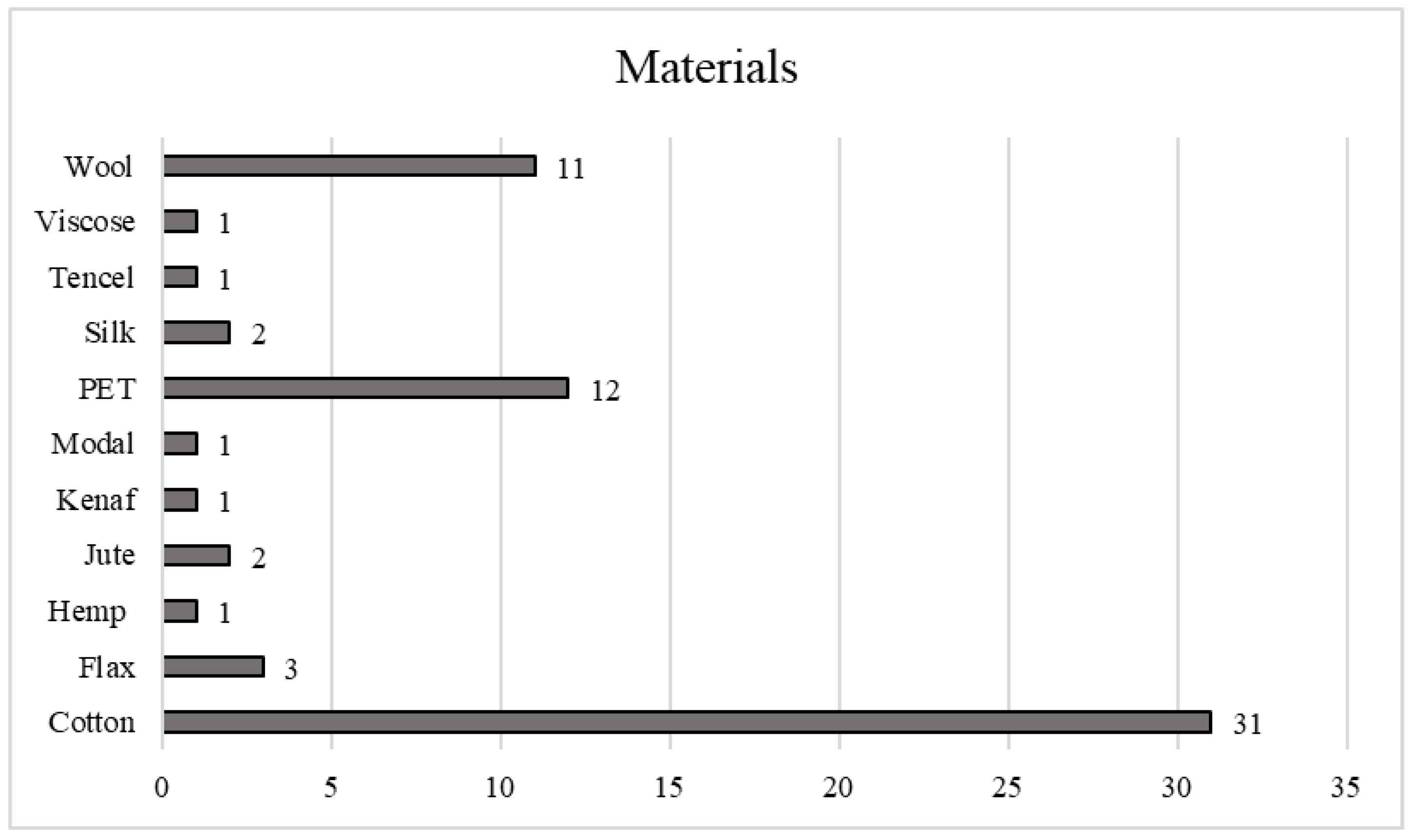

3.2. Life Cycle Inventory

3.3. Life Cycle Impact Assessment

3.4. Interpretation

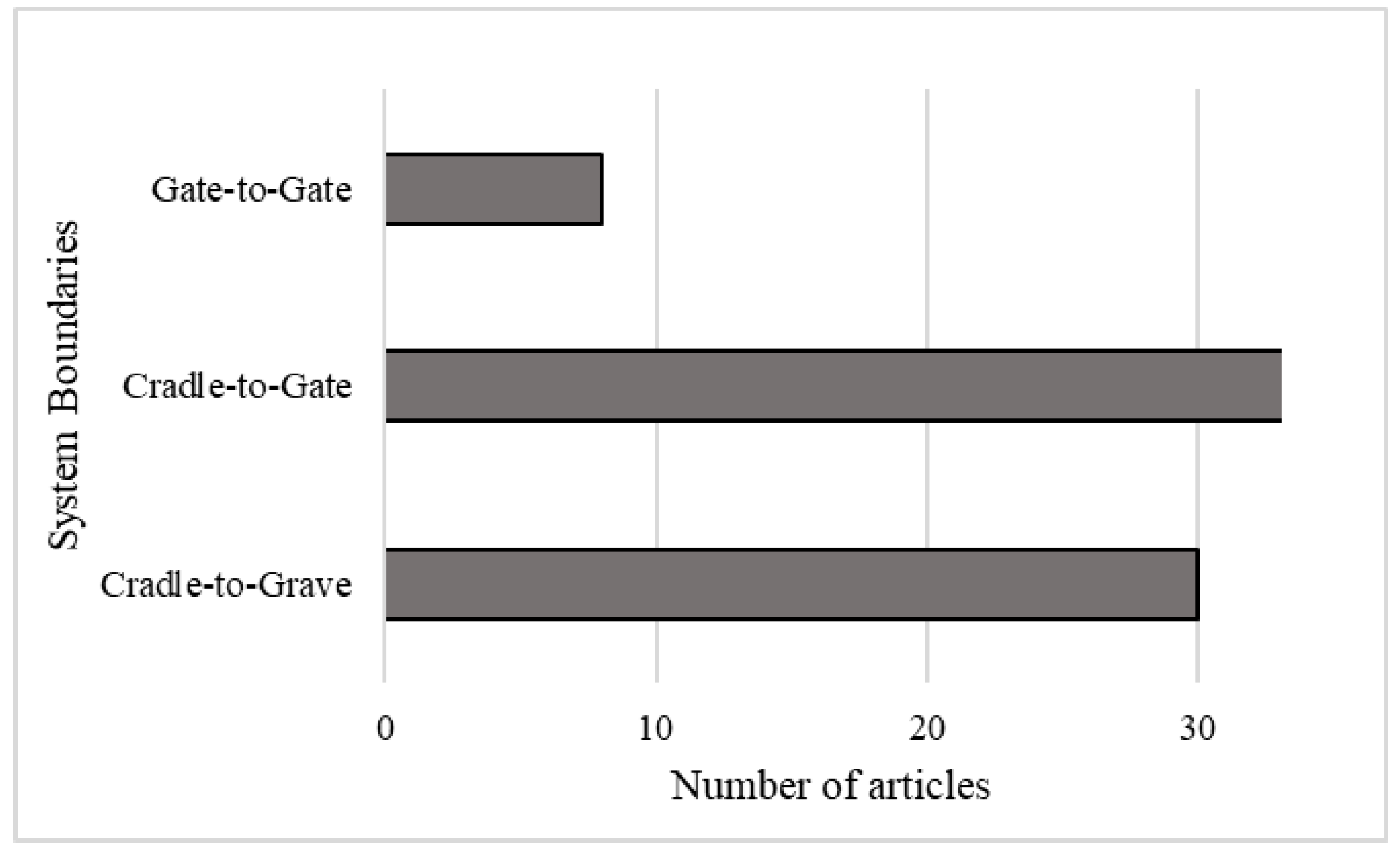

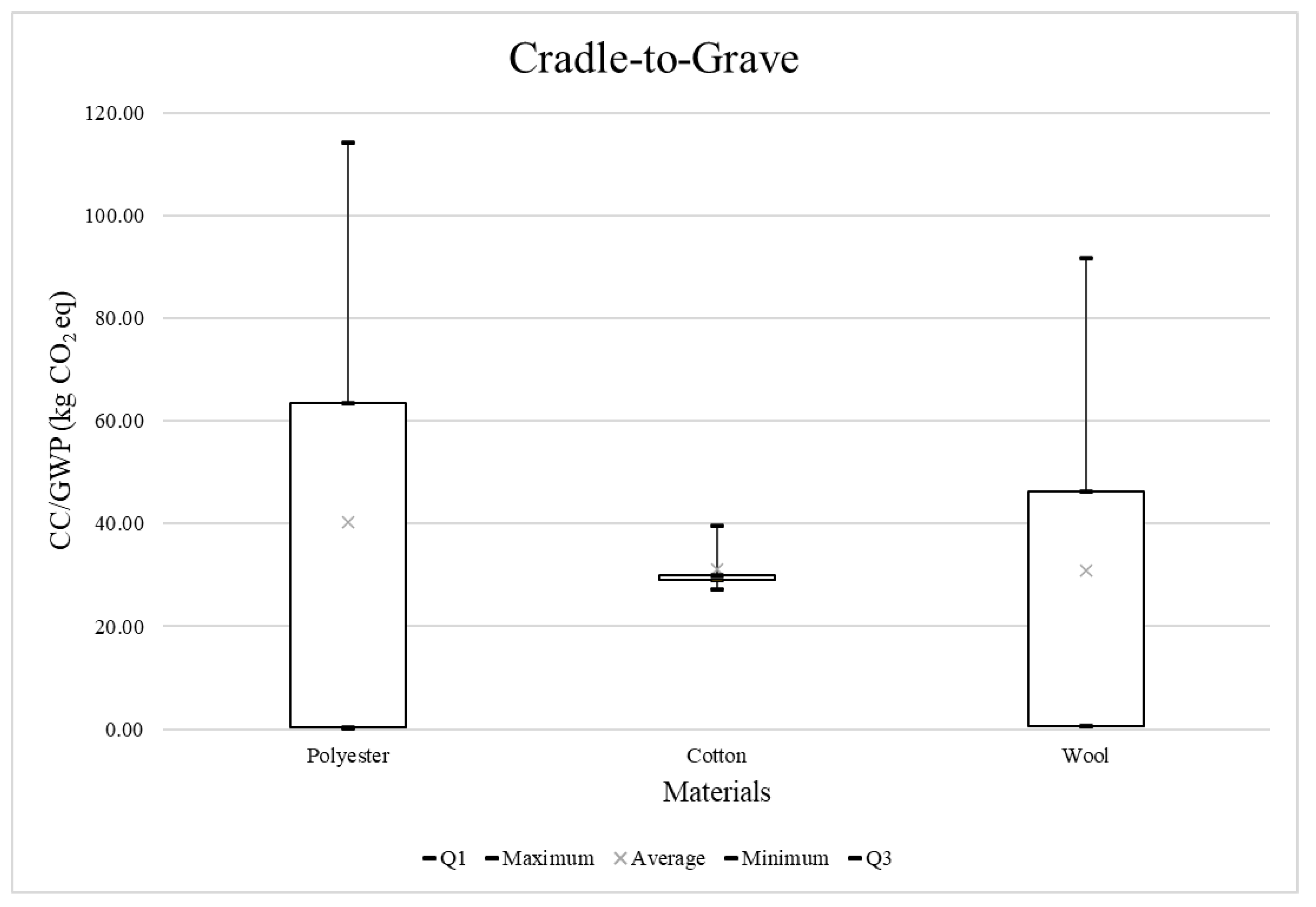

3.4.1. Impact Assessment According to System Boundaries

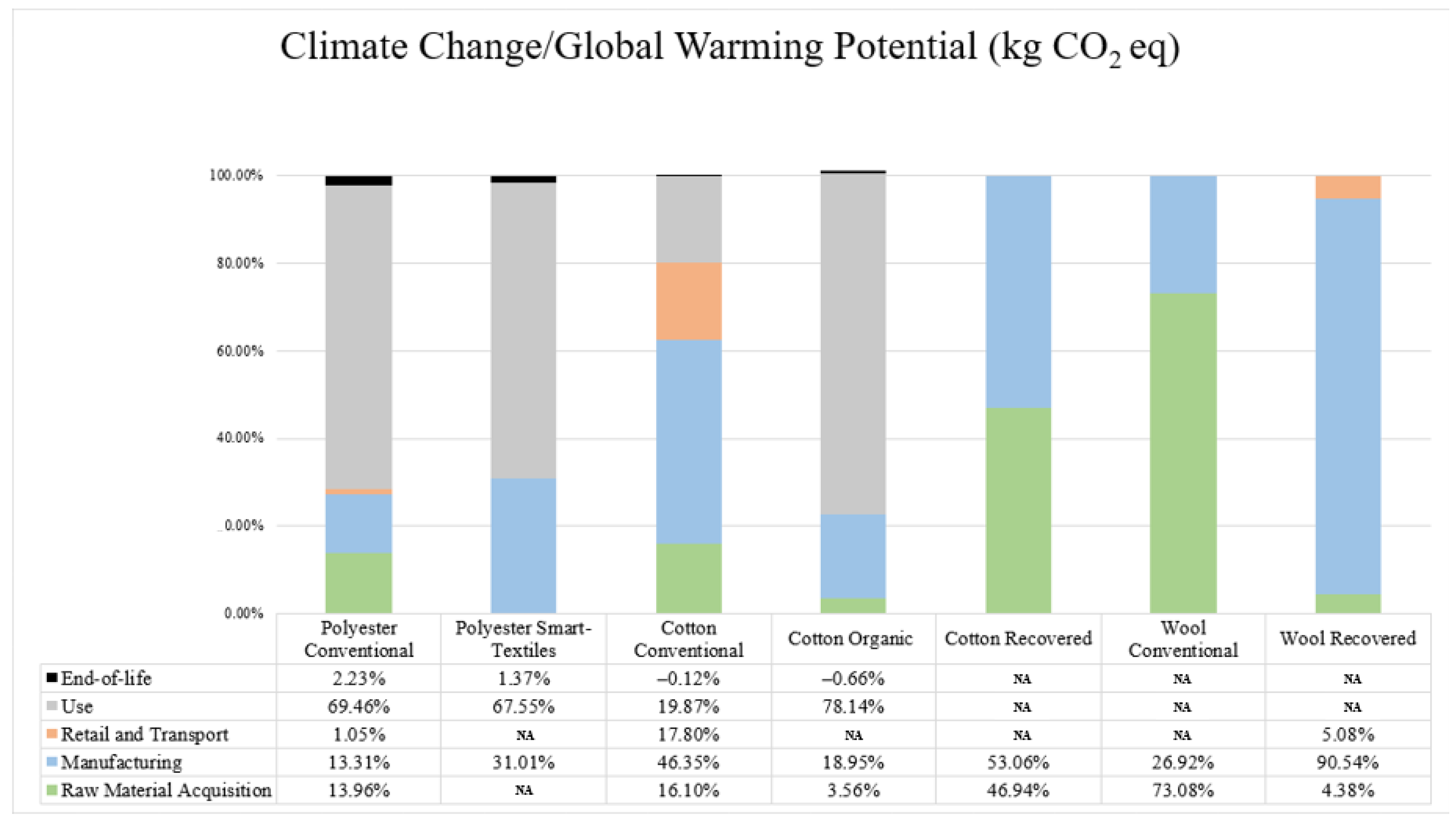

3.4.2. Impact Assessment According to Life Cycle Phases

4. Discussion

Limitations of the Study and Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Costa, C.; Azoia, N.G.; Silva, C.; Marques, E.F. Textile Industry in a Changing World: Challenges of Sustainable Development. Univ. Porto J. Eng. 2020, 6, 86–97. [Google Scholar] [CrossRef]

- Duhoux, T.; Le Blévennec, K.; Arnold, M.; Mortensen, L.F. Textiles and the Environment the Role of Design in Europe’s Circular Economy; ECT CE: Brussels, Belgium, 2022. [Google Scholar]

- Smith, P.; Baille, J.; McHattie, L.S. Sustainable Design Futures: An Open Design Vision for the Circular Economy in Fashion and Textiles. Des. J. 2017, 20, S1938–S1947. [Google Scholar] [CrossRef]

- Nikolina, Š. Environmental Impact of the Textile and Clothing Industry. What Consumers Need to Know. Eur. Parliam. Res. Serv. 2019. Available online: https://policycommons.net/artifacts/1335345/enviro (accessed on 7 July 2023).

- Beylot, A.; Ardente, F.; Marques, A.; Mathieux, F.; Pant, R.; Sala, S.; Zampori, L.; European Commission Joint Research Centre. Abiotic and Biotic Resources Impact Categories in LCA: Development of New Approaches: Accounting for Abiotic Resources Dissipation and Biotic Resources; Publications Office of the European Union: Luxembourg, 2020; ISBN 9789276172277. [Google Scholar]

- Panda, S.K.B.C.; Sen, K.; Mukhopadhyay, S. Sustainable Pretreatments in Textile Wet Processing. J. Clean. Prod. 2021, 329, 129725. [Google Scholar] [CrossRef]

- Konwar, M. Textile Industry and Its Environmental Impacts: A Review. Indian J. Pure Appl. Biosci. 2020, 8, 134–139. [Google Scholar] [CrossRef]

- Broega, A.C.; Jordão, C.; Martins, S.B. Textile Sustainability: Reuse of Clean Waste from the Textile and Apparel Industry. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 192006. [Google Scholar] [CrossRef]

- European Commission. EU Strategy for Sustainable and Circular Textiles. Commun. Comm. Eur. Parliam. Counc. Eur. Econ. Soc. Comm. Comm. Reg. 2022, 1, 5–24. [Google Scholar]

- Salo, H.H.; Suikkanen, J.; Nissinen, A. Eco-Innovation Motivations and Ecodesign Tool Implementation in Companies in the Nordic Textile and Information Technology Sectors. Bus. Strateg. Environ. 2020, 29, 2654–2667. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Nguyen, Q.V.; Clarke, S.J. Using LCA and Circularity Indicators to Measure the Sustainability of Textiles—Examples of Renewable and Non-Renewable Fibres. Sustainability 2022, 14, 16683. [Google Scholar] [CrossRef]

- Cicconi, P. Eco-Design and Eco-Materials: An Interactive and Collaborative Approach. Sustain. Mater. Technol. 2020, 23, e00135. [Google Scholar] [CrossRef]

- Msahli, S.; Faouzi, S.; Taieb, A.H.; Sakly, F. An Eco-Design Approach for the Functional Textile. In Proceedings of the 6th International Conference on the Future Technical Textile Conference (FTT 2014), Istanbul, Turkey, 15–17 October 2014. [Google Scholar]

- Niinimäki, K. Ecodesign and Textiles. Res. J. Text. Appar. 2006, 10, 67–75. [Google Scholar] [CrossRef]

- Cimatti, B.; Campana, G.; Carluccio, L. Eco Design and Sustainable Manufacturing in Fashion: A Case Study in the Luxury Personal Accessories Industry. Procedia Manuf. 2017, 8, 393–400. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, H.; Hou, H.; Shao, S.; Sun, X.; Qin, C.; Zhang, S. Improved Design for Textile Production Process Based on Life Cycle Assessment. Clean Technol. Environ. Policy 2018, 20, 1355–1365. [Google Scholar] [CrossRef]

- Standard ISO 14006; Environmental Management Systems—Guidelines for Incorporating Ecodesign. 2nd ed. International Standard Organization: Geneva, Switzerland, 2020.

- Salo, H.; Suikkanen, J.; Nissinen, A. Use of Ecodesign Tools and Expectations for Product Environmental Footprint: Case Study of Nordic Textile and IT Companies; Nordic Council of Ministers: Copenhagen, Denmark, 2019; ISBN 978-92-893-6254-2. [Google Scholar]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of Eco-Design and Life Cycle Assessment Standards for Environmental Impact Reduction of an Industrial Product. Sustainability 2017, 9, 1724. [Google Scholar] [CrossRef]

- Dekoninck, E.A.; Domingo, L.; O’Hare, J.A.; Pigosso, D.C.A.; Reyes, T.; Troussier, N. Defining the Challenges for Ecodesign Implementation in Companies: Development and Consolidation of a Framework. J. Clean. Prod. 2016, 135, 410–425. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. 2nd ed. International Standard Organization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. 1st ed. International Standard Organization: Geneva, Switzerland, 2006.

- Muthu, S.S. Textile and Clothing Sustainability: Recycled and Upcycled Textiles and Fashion; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-981-10-2146-6. [Google Scholar]

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549. [Google Scholar] [CrossRef]

- Munasinghe, P.; Druckman, A.; Dissanayake, D.G.K. A Systematic Review of the Life Cycle Inventory of Clothing. J. Clean. Prod. 2021, 320, 128852. [Google Scholar] [CrossRef]

- Roos, S.; Zamani, B.; Sandin, G.; Peters, G.M.; Svanström, M. A Life Cycle Assessment (LCA)-Based Approach to Guiding an Industry Sector towards Sustainability: The Case of the Swedish Apparel Sector. J. Clean. Prod. 2016, 133, 691–700. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Dash, A.K. Sustainable Polyester and Caprolactam Fibres; Elsevier Ltd.: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Laiblová, L.; Pešta, J.J.; Kumar, A.; Hájek, P.; Fiala, C.; Vlach, T.; Kocí, V. Environmental Impact of Textile Reinforced Concrete Facades Compared to Conventional Solutions-Lca Case Study. Materials 2019, 12, 3194. [Google Scholar] [CrossRef]

- Dahllöf, L.; Steen, B. A Statistical Approach for Estimation of Process Flow Data from Production of Chemicals of Fossil Origin. Int. J. Life Cycle Assess. 2007, 12, 103–108. [Google Scholar] [CrossRef]

- Ahangarnokolaei, M.A.; Attarian, P.; Ayati, B.; Ganjidoust, H.; Rizzo, L. Life Cycle Assessment of Sequential and Simultaneous Combination of Electrocoagulation and Ozonation for Textile Wastewater Treatment. J. Environ. Chem. Eng. 2021, 9, 106251. [Google Scholar] [CrossRef]

- Chen, F.; Ji, X.; Chu, J.; Xu, P.; Wang, L. A Review: Life Cycle Assessment of Cotton Textiles. Ind. Textila 2021, 72, 19–29. [Google Scholar] [CrossRef]

- Russell, I.M. Sustainable Wool Production and Processing. In Sustainable Textiles—Life Cycle and Environmental Impact; Woodhead Publishing: Sawston, UK, 2009; pp. 63–87. [Google Scholar] [CrossRef]

- Schrott, W.; Paul, R. Environmental Impacts of Denim Manufacture; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; ISBN 9780857098498. [Google Scholar]

- Bhatt, A.; Abbassi, B. Review of Environmental Performance of Sheep Farming Using Life Cycle Assessment. J. Clean. Prod. 2021, 293, 126192. [Google Scholar] [CrossRef]

- Devaraju, A.; Harikumar, R. Life Cycle Assessment of Sisal Fiber; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 1–5, ISBN 9780128131961. [Google Scholar]

- Muthu, S.S. (Ed.) Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780081001875. [Google Scholar]

- Jhanji, Y. Life Cycle Analysis of Textiles and Associated Carbon Emissions. In Sustainable Fibres for Fashion and Textile Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 403–431. ISBN 9780128240526. [Google Scholar]

- Watson, K.J.; Wiedemann, S.G. Review of Methodological Choices in LCA-Based Textile and Apparel Rating Tools: Key Issues and Recommendations Relating to Assessment of Fabrics Made from Natural Fibre Types. Sustainability 2019, 11, 3846. [Google Scholar] [CrossRef]

- Footprint, E.; Impacts, S. Looking for Sustainability Scoring in Apparel: A Review on Environmental Footprint, Social Impacts and Transparency. Energies 2021, 14, 3032. [Google Scholar]

- Moazzem, S.; Wang, L.; Daver, F.; Crossin, E. Environmental Impact of Discarded Apparel Landfilling and Recycling. Resour. Conserv. Recycl. 2021, 166, 105338. [Google Scholar] [CrossRef]

- Dahlbo, H.; Aalto, K.; Eskelinen, H.; Salmenperä, H. Increasing Textile Circulation—Consequences and Requirements. Sustain. Prod. Consum. 2017, 9, 44–57. [Google Scholar] [CrossRef]

- Sohn, J.; Nielsen, K.S.; Birkved, M.; Joanes, T.; Gwozdz, W. The Environmental Impacts of Clothing: Evidence from United States and Three European Countries. Sustain. Prod. Consum. 2021, 27, 2153–2164. [Google Scholar] [CrossRef]

- Abu-Qdais, H.A.; Abu-Dalo, M.A.; Hajeer, Y.Y. Impacts of Nanosilver-Based Textile Products Using a Life Cycle Assessment. Sustain. 2021, 13, 3436. [Google Scholar] [CrossRef]

- Agnhage, T.; Perwuelz, A.; Behary, N. Towards Sustainable Rubia Tinctorum L. Dyeing of Woven Fabric: How Life Cycle Assessment Can Contribute. J. Clean. Prod. 2017, 141, 1221–1230. [Google Scholar] [CrossRef]

- Astudillo, M.F.; Thalwitz, G.; Vollrath, F. Life Cycle Assessment of Indian Silk. J. Clean. Prod. 2014, 81, 158–167. [Google Scholar] [CrossRef]

- Avadí, A.; Marcin, M.; Biard, Y.; Renou, A.; Gourlot, J.P.; Basset-Mens, C. Life Cycle Assessment of Organic and Conventional Non-Bt Cotton Products from Mali. Int. J. Life Cycle Assess. 2020, 25, 678–697. [Google Scholar] [CrossRef]

- Barcelos, S.; Oiko, O.; Salvador, R. Basis for Conducting Life Cycle Assessment of Brazilian Silk Yarn Manufacturing. E3S Web Conf. 2022, 349, 08001. [Google Scholar] [CrossRef]

- Barnes, E.M.; Daystar, J.S.; Wallace, M.L. Challenges of Conducting a Life Cycle Assessment for Bio-Based Materials Using a Cotton Example. ASABE 2018 Annu. Int. Meet. 2018, 1800013. [Google Scholar] [CrossRef]

- Baydar, G.; Ciliz, N.; Mammadov, A. Life Cycle Assessment of Cotton Textile Products in Turkey. Resour. Conserv. Recycl. 2015, 104, 213–223. [Google Scholar] [CrossRef]

- Bech, N.M.; Birkved, M.; Charnley, F.; Kjaer, L.L.; Pigosso, D.C.A.; Hauschild, M.Z.; McAloone, T.C.; Moreno, M. Evaluating the Environmental Performance of a Product/Service-System Business Model for Merino Wool Next-to-Skin Garments: The Case of Armadillo Merino®. Sustainability 2019, 11, 5854. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental Analysis of a Cotton Yarn Supply Chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Bianco, I.; Gerboni, R.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of MWool® Recycled Wool Fibers. Resources 2022, 11, 41. [Google Scholar] [CrossRef]

- Biswas, W.K.; Graham, J.; Kelly, K.; John, M.B. Global Warming Contributions from Wheat, Sheep Meat and Wool Production in Victoria, Australia-a Life Cycle Assessment. J. Clean. Prod. 2010, 18, 1386–1392. [Google Scholar] [CrossRef]

- Busi, E.; Maranghi, S.; Corsi, L.; Basosi, R. Environmental Sustainability Evaluation of Innovative Self-Cleaning Textiles. J. Clean. Prod. 2016, 133, 439–450. [Google Scholar] [CrossRef]

- Costa, A.F.S.; Aragão, J.V.S.; Duarte, A.D.; Macêdo, J.S.; Galdino, C.J.S.; Milanez, V.F.A.; Silva, G.L.; Sarubbo, L.A. Analysis of the Environmental Life Cycle of Dyeing in Textiles. Chem. Eng. Trans. 2021, 86, 727–732. [Google Scholar] [CrossRef]

- De Saxce, M.; Pesnel, S.; Perwuelz, A. LCA of Bed Sheets—Some Relevant Parameters for Lifetime Assessment. J. Clean. Prod. 2012, 37, 221–228. [Google Scholar] [CrossRef]

- Esteve-Turrillas, F.A.; de la Guardia, M. Environmental Impact of Recover Cotton in Textile Industry. Resour. Conserv. Recycl. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Farrant, L.; Olsen, S.I.; Wangel, A. Environmental Benefits from Reusing Clothes. Int. J. Life Cycle Assess. 2010, 15, 726–736. [Google Scholar] [CrossRef]

- Fidan, F.; Aydoğan, E.K.; Uzal, N. An Integrated Life Cycle Assessment Approach for Denim Fabric Production Using Recycled Cotton Fibers and Combined Heat and Power Plant. J. Clean. Prod. 2021, 287, 125439. [Google Scholar] [CrossRef]

- González-García, S.; Hospido, A.; Feijoo, G.; Moreira, M.T. Life Cycle Assessment of Raw Materials for Non-Wood Pulp Mills: Hemp and Flax. Resour. Conserv. Recycl. 2010, 54, 923–930. [Google Scholar] [CrossRef]

- Gonzalez, V.; Lou, X.; Chi, T. Evaluating Environmental Impact of Natural and Synthetic Fibers: A Life Cycle Assessment Approach. Sustainability 2023, 15, 7670. [Google Scholar] [CrossRef]

- Horn, S.; Mölsä, K.M.; Sorvari, J.; Tuovila, H.; Heikkilä, P. Environmental Sustainability Assessment of a Polyester T-Shirt—Comparison of Circularity Strategies. Sci. Total Environ. 2023, 884, 163821. [Google Scholar] [CrossRef]

- Kazan, H.; Akgul, D.; Kerc, A. Life Cycle Assessment of Cotton Woven Shirts and Alternative Manufacturing Techniques. Clean Technol. Environ. Policy 2020, 22, 849–864. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Grammatikos, S.A. Comparative Life Cycle Assessment of Cotton and Other Natural Fibers for Textile Applications. Fibers 2019, 7, 101. [Google Scholar] [CrossRef]

- L’Abbate, P.; Dassisti, M.; Cappelletti, G.M.; Nicoletti, G.M.; Russo, C.; Ioppolo, G. Environmental Analysis of Polyester Fabric for Ticking. J. Clean. Prod. 2018, 172, 735–742. [Google Scholar] [CrossRef]

- Lenzo, P.; Traverso, M.; Mondello, G.; Salomone, R.; Ioppolo, G. Sustainability Performance of an Italian Textile Product. Economies 2018, 6, 17. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, H.; Zhu, L.; Zhang, C.; Ren, F.; Liu, Z. Could the Recycled Yarns Substitute for the Virgin Cotton Yarns: A Comparative LCA. Int. J. Life Cycle Assess. 2020, 25, 2050–2062. [Google Scholar] [CrossRef]

- Mahiat, T.; Alam, M.A.A.; Argho, M.; Corlett, J.; Chowdhury, R.B.; Biswas, K.F.; Hossain, M.M.; Sujauddin, M. Modeling the Environmental and Social Impacts of the Handloom Industry in Bangladesh through Life Cycle Assessment. Model. Earth Syst. Environ. 2023, 9, 239–252. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Worrell, E.; Patel, M.K. Prospective Life Cycle Assessment of an Antibacterial T-Shirt and Supporting Business Decisions to Create Value. Resour. Conserv. Recycl. 2015, 103, 47–57. [Google Scholar] [CrossRef]

- Martin, M.; Herlaar, S. Environmental and Social Performance of Valorizing Waste Wool for Sweater Production. Sustain. Prod. Consum. 2021, 25, 425–438. [Google Scholar] [CrossRef]

- Meyer, D.E.; Curran, M.A.; Gonzalez, M.A. An Examination of Silver Nanoparticles in Socks Using Screening-Level Life Cycle Assessment. J. Nanoparticle Res. 2011, 13, 147–156. [Google Scholar] [CrossRef]

- Moazzem, S.; Daver, F.; Crossin, E.; Wang, L. Assessing Environmental Impact of Textile Supply Chain Using Life Cycle Assessment Methodology. J. Text. Inst. 2018, 109, 1574–1585. [Google Scholar] [CrossRef]

- Moazzem, S.; Crossin, E.; Daver, F.; Wang, L. Baseline Scenario of Carbon Footprint of Polyester T-Shirt. J. Fiber Bioeng. Inform. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Moazzem, S.; Crossin, E.; Daver, F.; Wang, L. Life Cycle Assessment of Apparel Consumption in Australia. Environ. Clim. Technol. 2021, 25, 71–111. [Google Scholar] [CrossRef]

- Morita, A.M.; Moore, C.C.S.; Nogueira, A.R.; Kulay, L.; da Silva Sá Ravagnani, M.A. Assessment of Potential Alternatives for Improving Environmental Trouser Jeans Manufacturing Performance in Brazil. J. Clean. Prod. 2020, 247, 119156. [Google Scholar] [CrossRef]

- Muthu, S.S.K.; Li, Y.; Hu, J.Y.; Ze, L. Carbon Footprint Reduction in the Textile Process Chain: Recycling of Textile Materials. Fibers Polym. 2012, 13, 1065–1070. [Google Scholar] [CrossRef]

- Muthukumarana, T.T.; Karunathilake, H.P.; Punchihewa, H.K.G.; Manthilake, M.M.I.D.; Hewage, K.N. Life Cycle Environmental Impacts of the Apparel Industry in Sri Lanka: Analysis of the Energy Sources. J. Clean. Prod. 2018, 172, 1346–1357. [Google Scholar] [CrossRef]

- Parisi, M.L.; Fatarella, E.; Spinelli, D.; Pogni, R.; Basosi, R. Environmental Impact Assessment of an Eco-Efficient Production for Coloured Textiles. J. Clean. Prod. 2015, 108, 514–524. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Wiener, J.; Militky, J. Life-Cycle Assessment of Denim; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081020449. [Google Scholar]

- Piontek, F.M.; Rapaport, M.; Müller, M. One Year of Clothing Consumption of a German Female Consumer. Procedia CIRP 2019, 80, 417–421. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Moving down the Cause-Effect Chain of Water and Land Use Impacts: An LCA Case Study of Textile Fibres. Resour. Conserv. Recycl. 2013, 73, 104–113. [Google Scholar] [CrossRef]

- Şener Fidan, F.; Kızılkaya Aydoğan, E.; Uzal, N. The Impact of Organic Cotton Use and Consumer Habits in the Sustainability of Jean Production Using the LCA Approach. Environ. Sci. Pollut. Res. 2023, 30, 8853–8867. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental Impact Assessment of Man-Made Cellulose Fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Shou, M.; Domenech, T. Integrating LCA and Blockchain Technology to Promote Circular Fashion—A Case Study of Leather Handbags. J. Clean. Prod. 2022, 373, 133557. [Google Scholar] [CrossRef]

- Sim, J.; Prabhu, V. The Life Cycle Assessment of Energy and Carbon Emissions on Wool and Nylon Carpets in the United States. J. Clean. Prod. 2018, 170, 1231–1243. [Google Scholar] [CrossRef]

- Temizel-Sekeryan, S.; Hicks, A.L. Cradle-to-Grave Environmental Impact Assessment of Silver Enabled t-Shirts: Do Nano-Specific Impacts Exceed Non Nano-Specific Emissions? NanoImpact 2021, 22, 100319. [Google Scholar] [CrossRef]

- Terinte, N.; Manda, B.M.K.; Taylor, J.; Schuster, K.C.; Patel, M.K. Environmental Assessment of Coloured Fabrics and Opportunities for Value Creation: Spin-Dyeing versus Conventional Dyeing of Modal Fabrics. J. Clean. Prod. 2014, 72, 127–138. [Google Scholar] [CrossRef]

- van der Velden, N.M.; Kuusk, K.; Köhler, A.R. Life Cycle Assessment and Eco-Design of Smart Textiles: The Importance of Material Selection Demonstrated through e-Textile Product Redesign. Mater. Des. 2015, 84, 313–324. [Google Scholar] [CrossRef]

- Van Der Velden, N.M.; Patel, M.K.; Vogtländer, J.G. LCA Benchmarking Study on Textiles Made of Cotton, Polyester, Nylon, Acryl, or Elastane. Int. J. Life Cycle Assess. 2014, 19, 331–356. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Turunen, L. The Environmental Impacts of the Production of Hemp and Flax Textile Yarn. Ind. Crop. Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective Environmental Life Cycle Assessment of Nanosilver T-Shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, L.; Liu, X.; Du, C.; Ding, D.; Jia, J.; Yan, Y.; Wu, G. Carbon Footprint of Textile throughout Its Life Cycle: A Case Study of Chinese Cotton Shirts. J. Clean. Prod. 2015, 108, 464–475. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Yan, M.J.; Henry, B.K.; Murphy, C.M. Resource Use and Greenhouse Gas Emissions from Three Wool Production Regions in Australia. J. Clean. Prod. 2016, 122, 121–132. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Simmons, A.; Watson, K.J.L.; Biggs, L. Effect of Methodological Choice on the Estimated Impacts of Wool Production and the Significance for LCA-Based Rating Systems. Int. J. Life Cycle Assess. 2019, 24, 848–855. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Ledgard, S.F.; Henry, B.K.; Yan, M.J.; Mao, N.; Russell, S.J. Application of Life Cycle Assessment to Sheep Production Systems: Investigating Co-Production of Wool and Meat Using Case Studies from Major Global Producers. Int. J. Life Cycle Assess. 2015, 20, 463–476. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.G.; Swan, P.G.; Watson, K. Environmental Impacts Associated with the Production, Use, and End-of-Life of a Woollen Garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Clarke, S.J.; Russell, S.J. Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater. Sustainability 2022, 14, 1081. [Google Scholar] [CrossRef]

- Wu, Z. Haode Evaluating the Life-Cycle Environmental Impacts of Polyester Sports T-Shirts. IOP Conf. Ser. Earth Environ. Sci. 2020, 474, 022017. [Google Scholar] [CrossRef]

- Yacout, D.M.M.; Abd El-Kawi, M.A.; Hassouna, M.S. Cradle to Gate Environmental Impact Assessment of Acrylic Fiber Manufacturing. Int. J. Life Cycle Assess. 2016, 21, 326–336. [Google Scholar] [CrossRef]

- Yang, Y.; He, W.; Chen, F.; Wang, L. Water Footprint Assessment of Silk Apparel in China. J. Clean. Prod. 2020, 260, 121050. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, L.; Zhang, C.; Ren, F.; Huang, H.; Liu, Z. Life Cycle Assessment of Melange Yarns from the Manufacturer Perspective. Int. J. Life Cycle Assess. 2020, 25, 588–599. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, C.; Xie, R.; Yu, H.; Sun, M.; Li, F. Environmental Assessment of Fabric Wet Processing from Gate-to-Gate Perspective: Comparative Study of Weaving and Materials. Sci. Total Environ. 2023, 857, 159495. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xiao, R.; Yuan, Z. Life Cycle Assessment of Cotton T-Shirts in China. Int. J. Life Cycle Assess. 2015, 20, 994–1004. [Google Scholar] [CrossRef]

- Bhalla, K.; Kumar, T.; Rangaswamy, J. An Integrated Rural Development Model Based on Comprehensive Life-Cycle Assessment (LCA) of Khadi-Handloom Industry in Rural India. Procedia CIRP 2018, 69, 493–498. [Google Scholar] [CrossRef]

- Braun, G.; Som, C.; Schmutz, M.; Hischier, R. Environmental Consequences of Closing the Textile Loop-Life Cycle Assessment of a Circular Polyester Jacket. Appl. Sci. 2021, 11, 2964. [Google Scholar] [CrossRef]

- Hicks, A.L.; Theis, T.L. A Comparative Life Cycle Assessment of Commercially Available Household Silver-Enabled Polyester Textiles. Int. J. Life Cycle Assess. 2017, 22, 256–265. [Google Scholar] [CrossRef]

- Rana, S.; Karunamoorthy, S.; Parveen, S.; Fangueiro, R. Life Cycle Assessment of Cotton Textiles and Clothing. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 195–216. [Google Scholar]

- Zhao, M.; Zhou, Y.; Meng, J.; Zheng, H.; Cai, Y.; Shan, Y.; Guan, D.; Yang, Z. Virtual Carbon and Water Flows Embodied in Global Fashion Trade—A Case Study of Denim Products. J. Clean. Prod. 2021, 303, 127080. [Google Scholar] [CrossRef]

- Bianco, I.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of Worsted and Woollen Processing in Wool Production: ReviWool® Noils and Other Wool Co-Products. J. Clean. Prod. 2023, 415, 137877. [Google Scholar] [CrossRef]

- Mölsä, K.M.; Horn, S.; Dahlbo, H.; Rissanen, M. Linear, Reuse or Recycling? An Environmental Comparison of Different Life Cycle Options for Cotton Roller Towels. J. Clean. Prod. 2022, 374, 133976. [Google Scholar] [CrossRef]

- Selli, F.; Kornhan, S.; Kaya, A.; Erdogan, U.H. Effect of Reprocess on the Sustainability of T-Shirt Production. J. Text. Eng. 2022, 1, 254–259. [Google Scholar]

- Siagian, Y.Y.; Sinaga, R.; Sinaga, C.; Manik, Y. Life Cycle Assessment and Eco-Efficiency Indicator for Ulos Weaving Using Loom Machine in Toba Samosir Regency of North Sumatra. E3S Web Conf. 2018, 74, 05002. [Google Scholar] [CrossRef]

- Parker, G. Measuring the Environmental Performance of Food Packaging: Life Cycle Assessment; Woodhead Publishing Limited: Sawston, UK, 2008; ISBN 9781845691943. [Google Scholar]

- Steinberger, J.K.; Friot, D.; Jolliet, O.; Erkman, S. A Spatially Explicit Life Cycle Inventory of the Global Textile Chain. Int. J. Life Cycle Assess. 2009, 14, 443–455. [Google Scholar] [CrossRef]

- Textile Exchange. Preferred Fiber & Materials: Market Report 2022; Textile Exchange: Lamesa, TX, USA, 2022; pp. 1–118. [Google Scholar]

- Al-Ghussain, L. Global Warming: Review on Driving Forces and Mitigation. Environ. Prog. Sustain. Energy 2019, 38, 13–21. [Google Scholar] [CrossRef]

- Barcelos, S.M.B.D.; Salvador, R.; Barros, M.V.; de Francisco, A.C.; Guedes, G. Circularity of Brazilian Silk: Promoting a Circular Bioeconomy in the Production of Silk Cocoons. J. Environ. Manag. 2021, 296, 113373. [Google Scholar] [CrossRef]

- Hernandez, E.; Nowack, B.; Mitrano, D.M. Polyester Textiles as a Source of Microplastics from Households: A Mechanistic Study to Understand Microfiber Release during Washing. Environ. Sci. Technol. 2017, 51, 7036–7046. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R.; Nadeem, S.P.; Riccio, E. Sustainability Trends and Gaps in the Textile, Apparel and Fashion Industries. In Environment, Development and Sustainability; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M. Environmental Impact of Textile Reuse and Recycling—A Review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Van Eynde, H. Comparative Life Cycle Assessment of Hemp and Cotton Fibres Used in Chinese Textile Manufacturing. Master’s Thesis, KU Leuven, Leuven, Belgium, 2015; 158p. [Google Scholar]

- Yukseler, H.; Uzal, N.; Sahinkaya, E.; Kitis, M.; Dilek, F.B.; Yetis, U. Analysis of the Best Available Techniques for Wastewaters from a Denim Manufacturing Textile Mill. J. Environ. Manag. 2017, 203, 1118–1125. [Google Scholar] [CrossRef] [PubMed]

- Patti, A.; Cicala, G.; Acierno, D. Eco-Sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World. Polymers 2021, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Rashid, M.E.; Khan, M.R.; Haque, R.U.; Hasanuzzaman, M. Challenges of Textile Waste Composite Products and Its Prospects of Recycling. J. Mater. Cycles Waste Manag. 2023, 25, 1267–1287. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonseca, A.; Ramalho, E.; Gouveia, A.; Henriques, R.; Figueiredo, F.; Nunes, J. Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability 2023, 15, 15267. https://doi.org/10.3390/su152115267

Fonseca A, Ramalho E, Gouveia A, Henriques R, Figueiredo F, Nunes J. Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability. 2023; 15(21):15267. https://doi.org/10.3390/su152115267

Chicago/Turabian StyleFonseca, Ana, Edgar Ramalho, Ana Gouveia, Rita Henriques, Filipa Figueiredo, and João Nunes. 2023. "Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design" Sustainability 15, no. 21: 15267. https://doi.org/10.3390/su152115267

APA StyleFonseca, A., Ramalho, E., Gouveia, A., Henriques, R., Figueiredo, F., & Nunes, J. (2023). Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability, 15(21), 15267. https://doi.org/10.3390/su152115267