Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber

Abstract

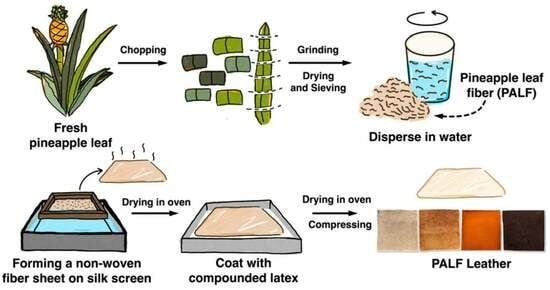

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Natural Rubber Latex Compound Preparation

2.3. Fiber Preparation

2.4. Preparation of Non-Woven Fiber Sheets

2.5. Preparation of PALF Leather

2.6. Characterization

2.6.1. Fiber Chemical Composition Analysis

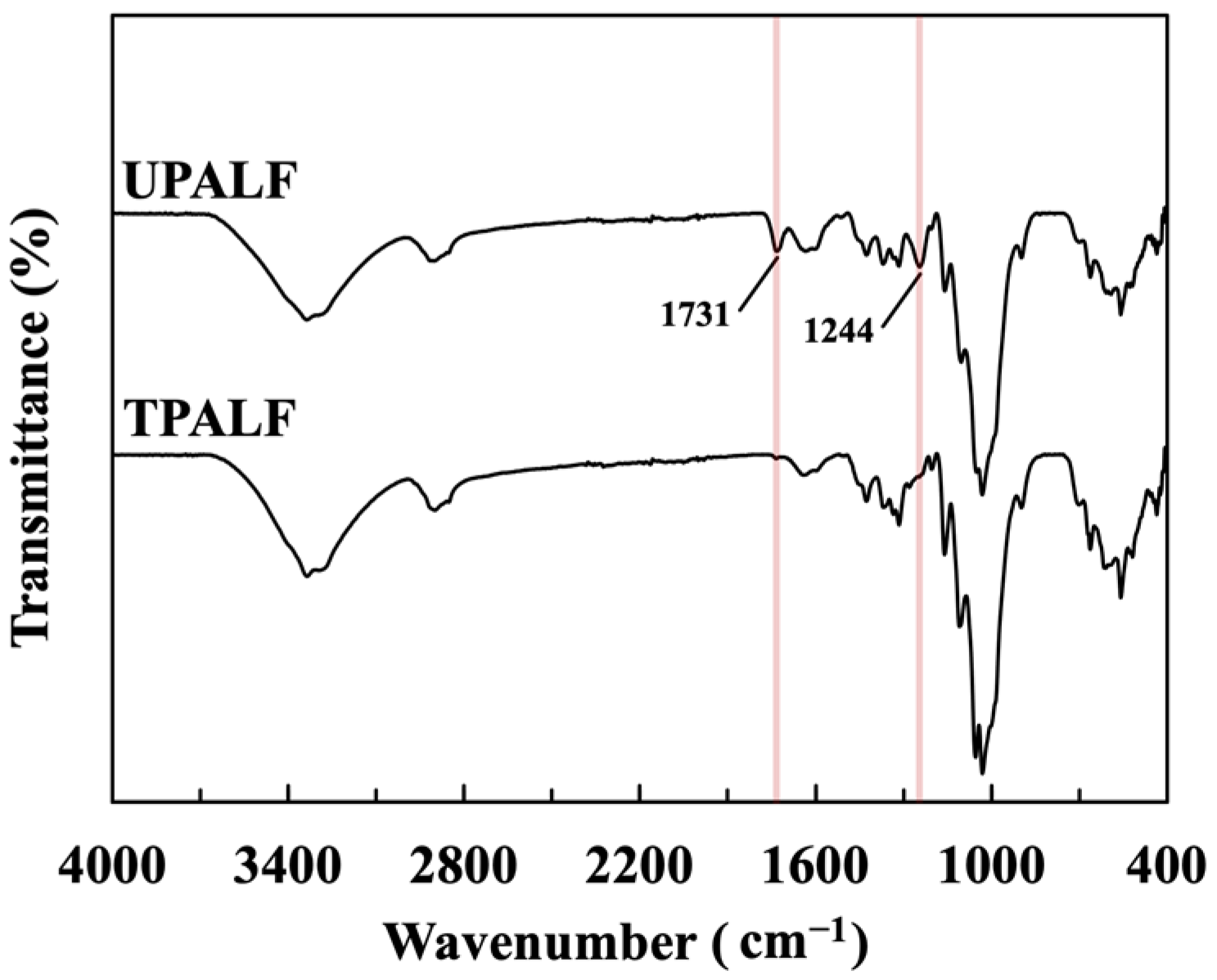

2.6.2. Fourier-Transform Infrared Spectroscopy (FTIR) Analysis

2.6.3. Thermogravimetric Analysis (TGA)

2.6.4. Morphological Properties Analysis

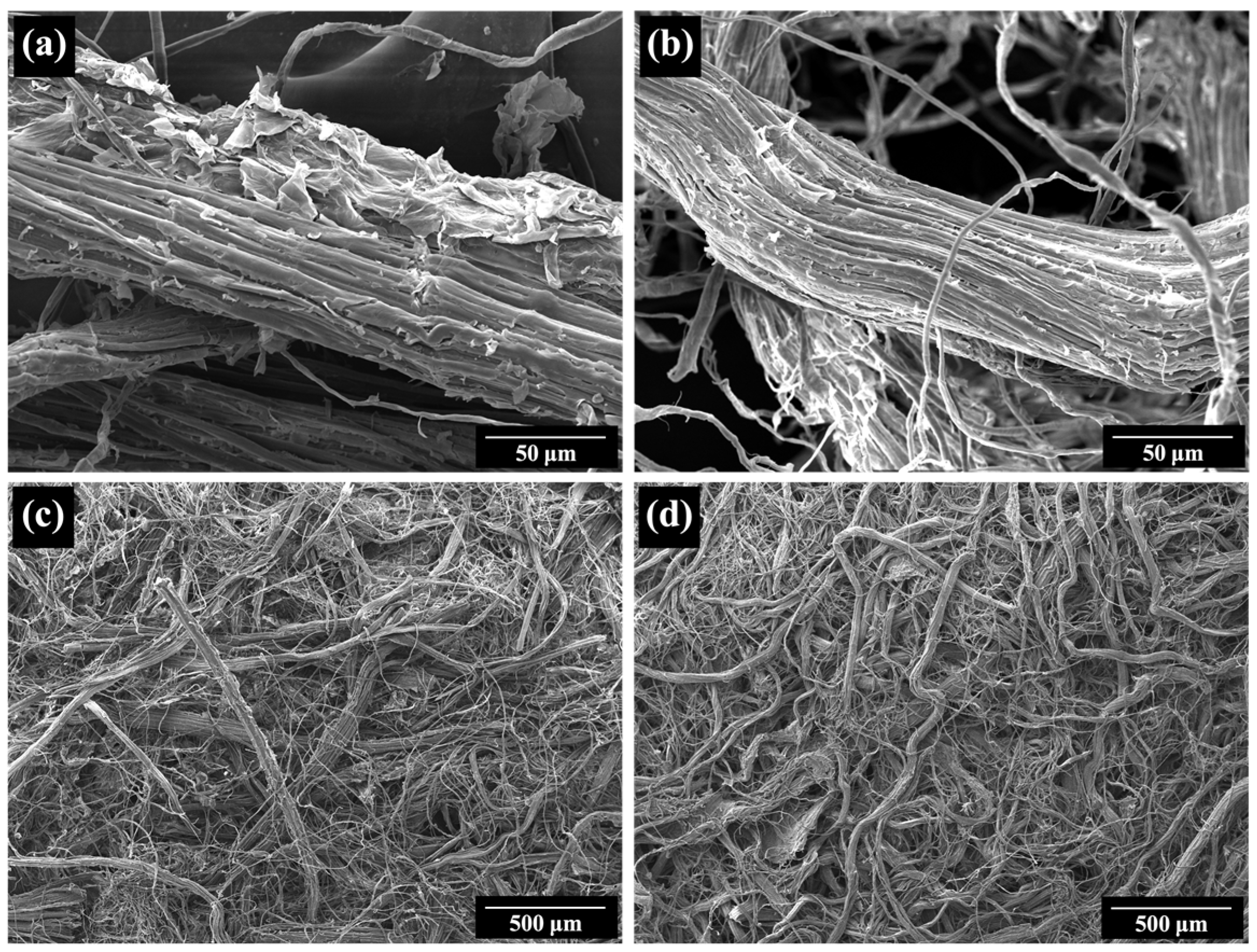

2.6.5. Mechanical Properties Analysis

2.6.6. Color Measurement

3. Results

3.1. Fiber and Non-Woven Sheet Characteristics

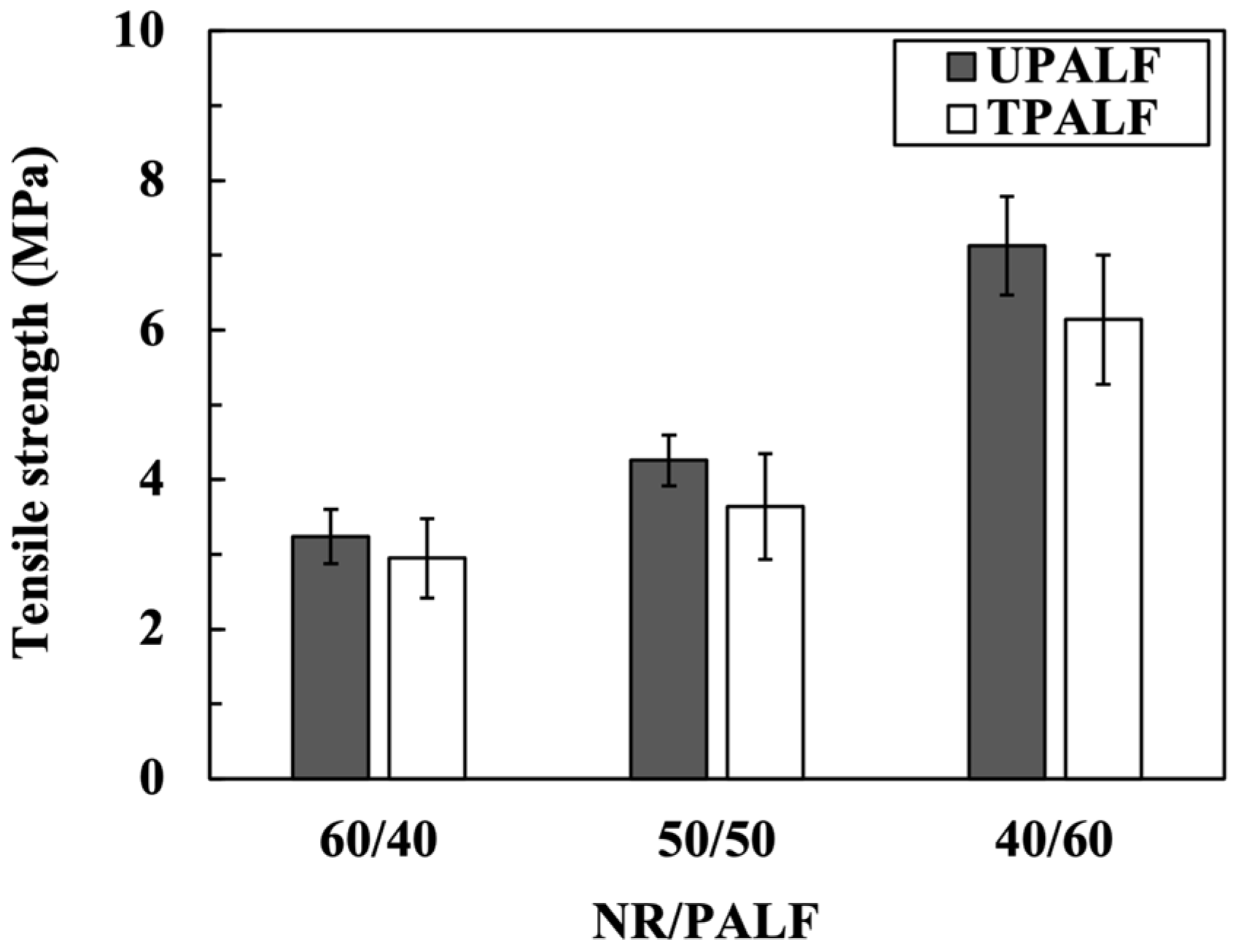

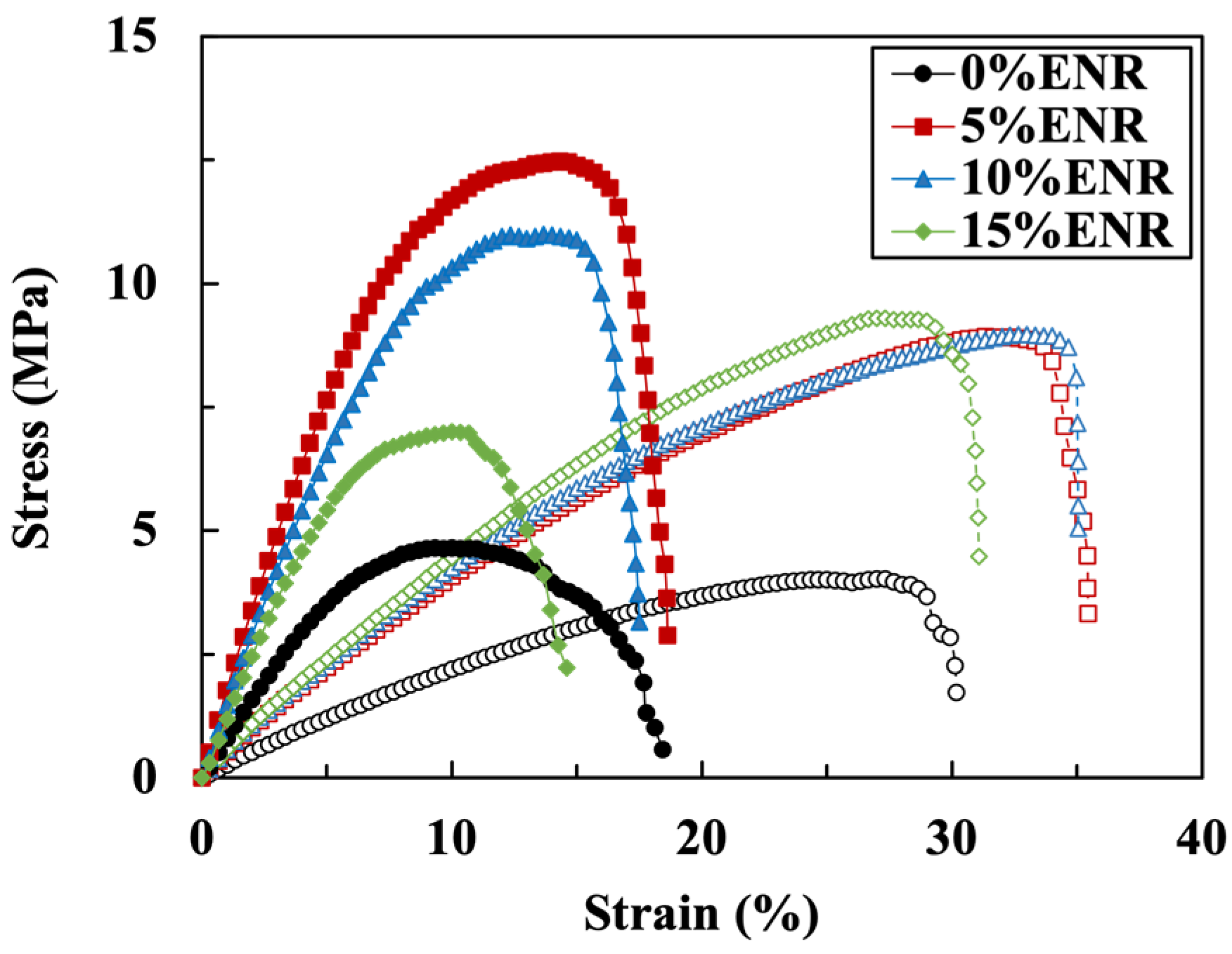

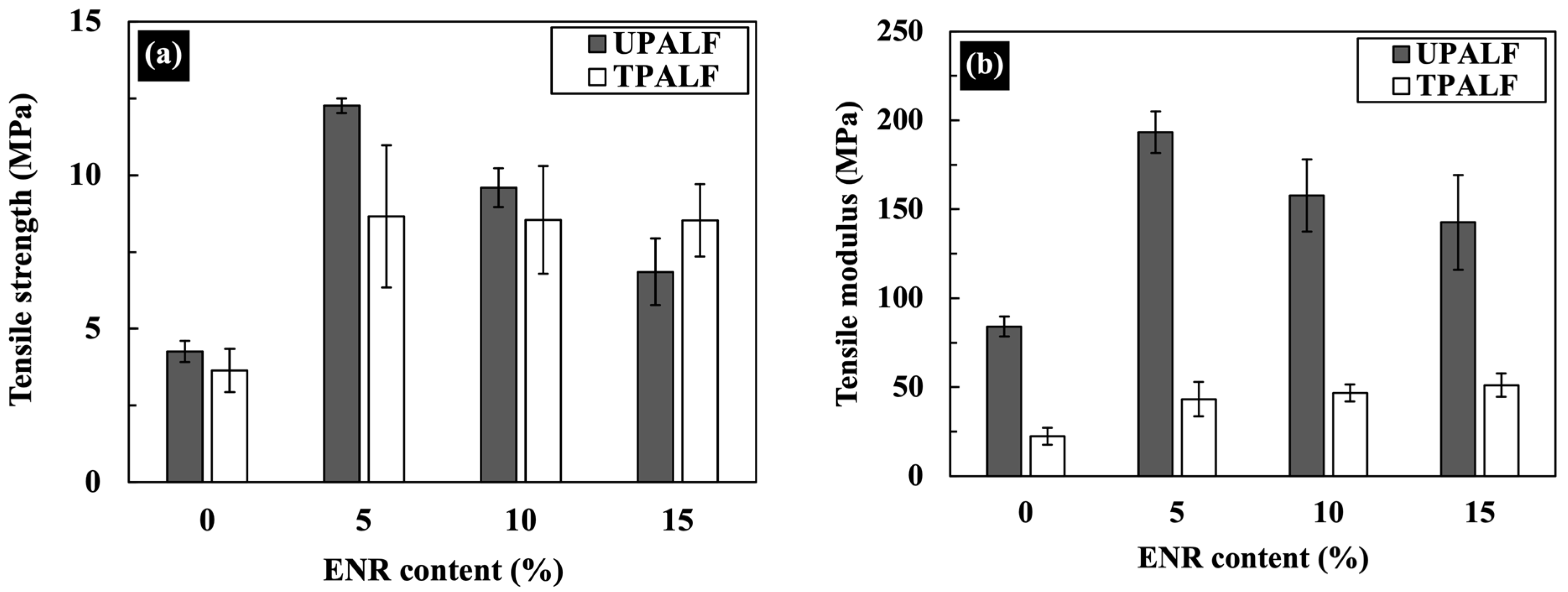

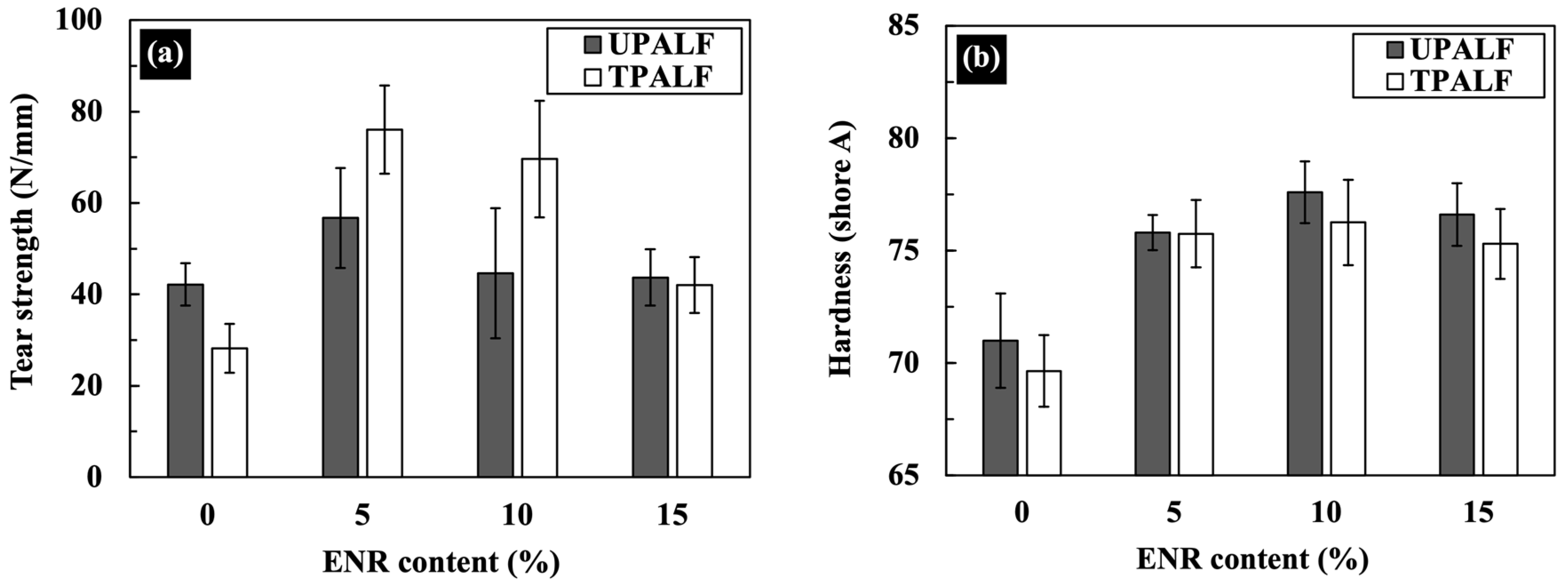

3.2. Mechanical Properties

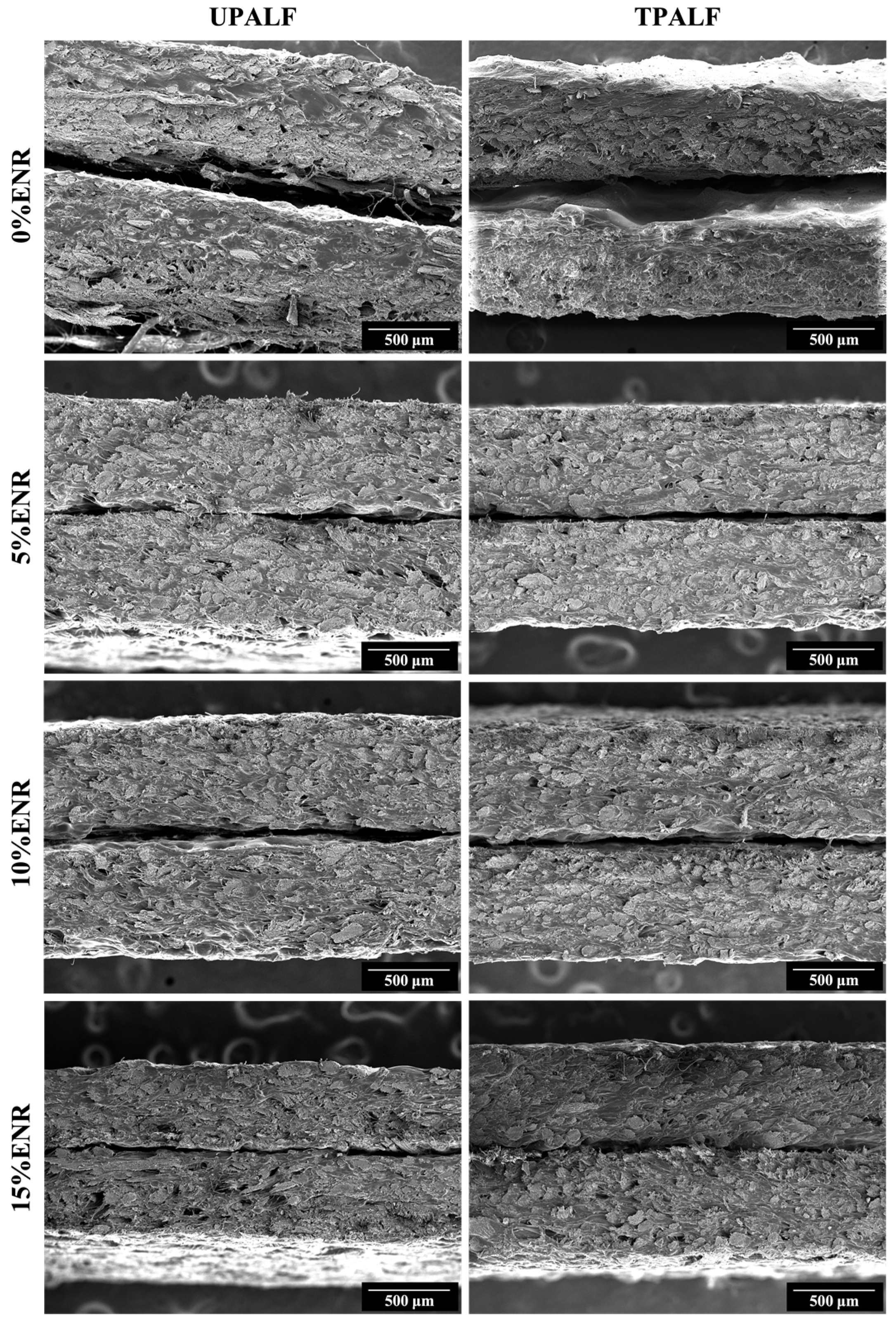

3.3. Morphology of PALF Leather

3.4. Colors of the PALF Leather

3.5. Comparison of PALF Leather Properties with Commercial Alternatives

3.6. Application Example of PALF Leather

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, Y.-H.; Lee, K.-H. Ethical Consumers’ Awareness of Vegan Materials: Focused on Fake Fur and Fake Leather. Sustainability 2021, 13, 436. [Google Scholar] [CrossRef]

- Ramchandani, M.; Coste-Manière, I. Leather and Footwear Sustainability; Springer: London, UK, 2020; pp. 11–22. [Google Scholar]

- Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives. Coatings 2021, 11, 226. [Google Scholar] [CrossRef]

- Gandia, A.; van den Brandhof, J.G.; Appels, F.V.W.; Jones, M.P. Flexible Fungal Materials: Shaping the Future. Trends Biotechnol. 2021, 39, 1321–1331. [Google Scholar] [CrossRef]

- Raman, J.; Kim, D.S.; Kim, H.S.; Oh, D.S.; Shin, H.J. Mycofabrication of Mycelium-Based Leather from Brown-Rot Fungi. J. Fungi 2022, 8, 317. [Google Scholar] [CrossRef] [PubMed]

- Wijayarathna, E.R.K.B.; Mohammadkhani, G.; Soufiani, A.M.; Adolfsson, K.H.; Ferreira, J.A.; Hakkarainen, M.; Berglund, L.; Heinmaa, I.; Root, A.; Zamani, A. Fungal textile alternatives from bread waste with leather-like properties. Resour. Conserv. Recycl. 2022, 179, 106041. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, F.; An, Z.; Shi, W.; Li, H. Novel bio-based filler: Hyperbranched polymer modified leather buffing dust and its influence on the porous structure and mechanical properties of polyurethane film. RSC Adv. 2021, 11, 27183–27192. [Google Scholar] [CrossRef]

- Gong, D.; Han, Y.; Zhang, Q.; Xu, B.; Zhang, C.; Li, K.; Tan, L. Development of Leather Fiber/Polyurethane Composite with Antibacterial, Wet Management, and Temperature-Adaptive Flexibility for Foot Care. ACS Biomater. Sci. Eng. 2022, 8, 4557–4565. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, J.; Zheng, S.; He, X.; Liu, X. Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development. Sustainability 2022, 14, 13971. [Google Scholar] [CrossRef]

- Basak, S.; Shakyawar, D.B.; Samanta, K.K.; Debnath, S.; Bhowmick, M.; Kumar, N. Development of natural fibre based flexural composite: A sustainable mimic of natural leather. Mater. Today Commun. 2022, 32, 103976. [Google Scholar] [CrossRef]

- Sourprae, K.; Kalkornsurapranee, E.; Lehman, N.; Chuaybamrung, A.; Tuljittraporn, A.; Nakaramontri, Y.; Krainoi, A.; Johns, J.; Songtipya, L.; Uthaipan, N. Leather-Like Material Based on Natural Rubber Composites. J. Phys. Sci. 2022, 33, 65–82. [Google Scholar] [CrossRef]

- What Is Apple Leather? (And 8 Fashion Brands Using It). Available online: https://www.sustainablychic.com/blog/what-is-apple-leather (accessed on 24 November 2022).

- AppleSkin™: Vegan Leather Made in Italy. Available online: https://staiy.com/blogs/staiy-edit/appleskin™-vegan-leather-made-in-italy?article=articlepage (accessed on 24 November 2022).

- Desserto, a Highly Sustainable Plant-Based Vegan Leather Made from Cactus. Available online: https://www.designboom.com/design/desserto-cactus-vegan-leather-06-26-2020/ (accessed on 24 November 2022).

- Pinatex—Pineapple Leather the Fabric of the Future. Available online: https://danandmez.com/blog/pinatex/ (accessed on 24 November 2022).

- The Truth about Piñatex Pineapple Leather. Available online: https://www.panaprium.com/blogs/i/pinatex-pineapple-leather (accessed on 24 November 2022).

- Replacing Animal Leather Is Possible. Muskin Is an Eco-Friendly Alternative Entirely Made from Natural Raw Materials, Including the Cap of a Special Mushroom. Available online: https://www.lifegate.com/muskin-leather-mushrooms (accessed on 24 November 2022).

- Saha, N.; Fahanwi, A.N.; Nguyen, H.; Saha, P. Environmentally friendly and animal free leather: Fabrication and characterization. AIP Conf. Proc. 2020, 2289, 020049. [Google Scholar]

- Bustillos, J.; Loganathan, A.; Agrawal, R.; Gonzalez, B.A.; Perez, M.G.; Ramaswamy, S.; Boesl, B.; Agarwal, A. Uncovering the Mechanical, Thermal, and Chemical Characteristics of Biodegradable Mushroom Leather with Intrinsic Antifungal and Antibacterial Properties. ACS Appl. Bio Mater. 2020, 3, 3145–3156. [Google Scholar] [CrossRef] [PubMed]

- Kengkhetkit, N.; Amornsakchai, T. A new approach to “Greening” plastic composites using pineapple leaf waste for performance and cost effectiveness. Mater. Des. 2014, 55, 292–299. [Google Scholar] [CrossRef]

- Anm, M.R.; Khan, R.A. Influence of UV radiation on mechanical properties of PVC composites reinforced with pineapple fiber. J. Mod. Text. Sci. Eng. 2018, 8, 1–5. [Google Scholar]

- Kengkhetkit, N.; Amornsakchai, T. Utilisation of pineapple leaf waste for plastic reinforcement: 1. A novel extraction method for short pineapple leaf fiber. Ind. Crops Prod. 2012, 40, 55–61. [Google Scholar] [CrossRef]

- Shih, Y.F.; Chang, W.C.; Liu, W.C.; Lee, C.C.; Kuan, C.S.; Yu, Y.H. Pineapple leaf/recycled disposable chopstick hybrid fiber reinforced biodegradable composites. J. Taiwan. Inst. Chem. Eng. 2014, 45, 2039–2046. [Google Scholar] [CrossRef]

- Surajarusarn, B.; Hajjar-Garreau, S.; Schrodj, G.; Mougin, K.; Amornsakchai, T. Comparative study of pineapple leaf microfiber and aramid fiber reinforced natural rubbers using dynamic mechanical analysis. Polym. Test. 2020, 82, 106289. [Google Scholar] [CrossRef]

- Hariwongsanupab, N.; Thanawan, S.; Amornsakchai, T.; Vallat, M.; Mougin, K. Improving the mechanical properties of short pineapple leaf fiber reinforced natural rubber by blending with acrylonitrile butadiene rubber. Polym. Test. 2017, 57, 94–100. [Google Scholar] [CrossRef]

- Chawalitsakunchai, W.; Dittanet, P.; Loykulnant, S.; Sae-oui, P.; Tanpichai, S.; Seubsai, A.; Prapainainar, P. Properties of natural rubber reinforced with nano cellulose from pineapple leaf agricultural waste. Mater. Today Commun. 2021, 28, 2352–4928. [Google Scholar]

- Tessanan, W.; Chanthateyanonth, R.; Yamaguchi, M.; Phinyocheep, P. Improvement of mechanical and impact performance of poly(lactic acid) by renewable modified natural rubber. J. Clean. Prod. 2020, 276, 123800. [Google Scholar] [CrossRef]

- Updegraff, D.M. Semimicro determination of cellulose inbiological materials. Anal. Biochem. 1969, 32, 420–424. [Google Scholar] [CrossRef] [PubMed]

- Wise, L.E.; Murphy, M.; Adieco, A.A.D. A chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- TAPPI UM 250; Acid-Soluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 1991.

- TAPPI T 222; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 2002.

- ISO 3376:2020; Leather-Physical and Mechanical Tests-Determination of Tensile Strength and Percentage Elongation. ISO: Geneva, Switzerland, 2020.

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibres and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 131–135. [Google Scholar] [CrossRef]

- Ra, S.; Karayil, J.; Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J. A review on the extraction of pineapple, sisal and abaca fibers and their use as reinforcement in polymer matrix. Express Polym. Lett. 2020, 14, 309–335. [Google Scholar]

- Tanpichai, S.; Witayakran, S. All-cellulose composite laminates prepared from pineapple leaf fibers treated with steam explosion and alkaline treatment. J. Reinf. Plast. Compos. 2017, 36, 073168441770492. [Google Scholar] [CrossRef]

- Huda, M.; Drzal, L.; Mohanty, A.; Misra, M. Effect of Chemical Modifications of the Pineapple Leaf Fiber Surfaces on the Interfacial and Mechanical Properties of Laminated Biocomposite. Compos. Interfaces 2008, 15, 169–191. [Google Scholar] [CrossRef]

- Gaba, E.W.; Asimeng, B.O.; Kaufmann, E.E.; Katu, S.K.; Foster, E.J.; Tiburu, E.K. Mechanical and Structural Characterization of Pineapple Leaf Fiber. Fibers 2021, 9, 51. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, W.; Xuehua, W.; Wang, H.; Wu, Y.; Zhong, T.; Fei, B. Effect of alkali treatment on wettability and thermal stability of individual bamboo fibers. J. Wood. Sci. 2018, 64, 398–405. [Google Scholar] [CrossRef]

- Sakuri, S.; Surojo, E.; Ariawan, D. Thermogravimetry and Interfacial Characterization of Alkaline Treated Cantala fiber/Microcrystalline Cellulose-Composite. Procedia. Struct. 2020, 27, 85–92. [Google Scholar] [CrossRef]

- Cao, L.; Huang, J.; Chen, Y. Dual Cross-linked Epoxidized Natural Rubber Reinforced by Tunicate Cellulose Nanocrystals with Improved Strength and Extensibility. ACS Sustain. Chem. Eng. 2018, 6, 14802–14811. [Google Scholar] [CrossRef]

- Surya, I.; Ismail, H. The silica-filled natural rubber in presence of epoxidized natural rubbers: Curing, swelling and tensile properties. J. Phys. Conf. Ser. 2020, 1501, 012024. [Google Scholar] [CrossRef]

- Sengloyluan, K.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W.M. Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur. Polym. J. 2014, 51, 69–79. [Google Scholar] [CrossRef]

- Sam, S.T.; Ismail, H. The Effect of Epoxidized Natural Rubber (ENR 50) as a Compatibilizer on Spear Grass Filled Low Density Polyethylene/ Soya Spent Powder. Sains. Malays. 2015, 44, 787–792. [Google Scholar] [CrossRef]

- Tessanan, W.; Daniel, P.; Phinyocheep, P. Development of Photosensitive Natural Rubber as a Mechanical Modifier for Ultraviolet-Curable Resin Applied in Digital Light Processing-Based Three-Dimensional Printing Technology. ACS Omega 2021, 6, 14838–14847. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Song, J.E.; Kim, H.R. Comparative study on the physical entrapment of soy and mushroom proteins on the durability of bacterial cellulose bio-leather. Cellulose 2021, 28, 3183–3200. [Google Scholar] [CrossRef]

- Shahid, M.A.; Miah, M.S.; Razzaq, M.A. Fabrication of ecofriendly jute fiber reinforced flexible planar composite as a potential alternative of leather. J. Eng. Fibers Fabr. 2023, 18, 15589250221144015. [Google Scholar] [CrossRef]

- Some Plant-Based Leathers Might Not Be So Eco-Friendly after All. Available online: https://www.howcork.com/blogs/news/some-plant-based-leathers-might-not-be-too-eco-friendly-after-all (accessed on 4 September 2023).

| Ingredients | Amount (phr *) |

|---|---|

| NR latex (10% DRC) | 100 |

| Sulfur | 1.2 |

| ZDEC | 1.5 |

| ZnO | 0.5 |

| CPL | 1.0 |

| Chemical Constituent (%) | UPALF | TPALF |

|---|---|---|

| Cellulose (%) | 57.19 | 88.73 |

| Holocellulose (%) | 85.49 | 95.37 |

| Lignin (acid soluble) | 2.61 | 0.87 |

| Lignin (acid insoluble) | 7.82 | 3.99 |

| Sample | ENR Content (wt.%) | L* | a* | b* |

|---|---|---|---|---|

| UPALF | 0 | 73.48 | 3.04 | 20.10 |

| 5 | 75.45 | 2.66 | 20.86 | |

| 10 | 76.04 | 2.48 | 20.29 | |

| 15 | 77.77 | 2.40 | 20.57 | |

| TPALF | 0 | 75.23 | 5.42 | 29.17 |

| 5 | 79.16 | 3.33 | 22.89 | |

| 10 | 81.24 | 2.52 | 21.01 | |

| 15 | 81.55 | 2.52 | 21.57 |

| Sample | Tensile Strength (MPa) | Tear Strength (N/mm) | Hardness (Shore A) | Ref. |

|---|---|---|---|---|

| PALF leather | 12.3 | 56.7 | 75.8 | This work |

| Real leather | 39.5 | 82.9 | not reported | [3] |

| Real leather * | 17.2 | 55.9 | 57.3 | * |

| Pinatex | 4.5 | 31.0 | not reported | [3] |

| Pinatex * | not measured | 30.4 | 40.9 | * |

| Muskin | 0.2 | 0.5 | not reported | [3] |

| Desserto | 20.8 | 37.2 | not reported | [3] |

| Appleskin | 14 | 18.4 | not reported | [3] |

| PU leather * | 10.6 | 34.4 | 45.7 | * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duangsuwan, S.; Junkong, P.; Phinyocheep, P.; Thanawan, S.; Amornsakchai, T. Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber. Sustainability 2023, 15, 15400. https://doi.org/10.3390/su152115400

Duangsuwan S, Junkong P, Phinyocheep P, Thanawan S, Amornsakchai T. Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber. Sustainability. 2023; 15(21):15400. https://doi.org/10.3390/su152115400

Chicago/Turabian StyleDuangsuwan, Sorn, Preeyanuch Junkong, Pranee Phinyocheep, Sombat Thanawan, and Taweechai Amornsakchai. 2023. "Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber" Sustainability 15, no. 21: 15400. https://doi.org/10.3390/su152115400

APA StyleDuangsuwan, S., Junkong, P., Phinyocheep, P., Thanawan, S., & Amornsakchai, T. (2023). Development of Green Leather Alternative from Natural Rubber and Pineapple Leaf Fiber. Sustainability, 15(21), 15400. https://doi.org/10.3390/su152115400