Developing a Circular Business Model for Machinery Life Cycle Extension by Exploiting Tools for Digitalization

Abstract

:1. Introduction

- What Life Cycle Extension Strategy (LCES) is suitable for digital CBM adoption?

- How does the digitalization of machines enable OEMs to innovate their BMs?

2. Background

2.1. Digital CBMs for Machine Life-Cycle Extension

2.2. Success Stories

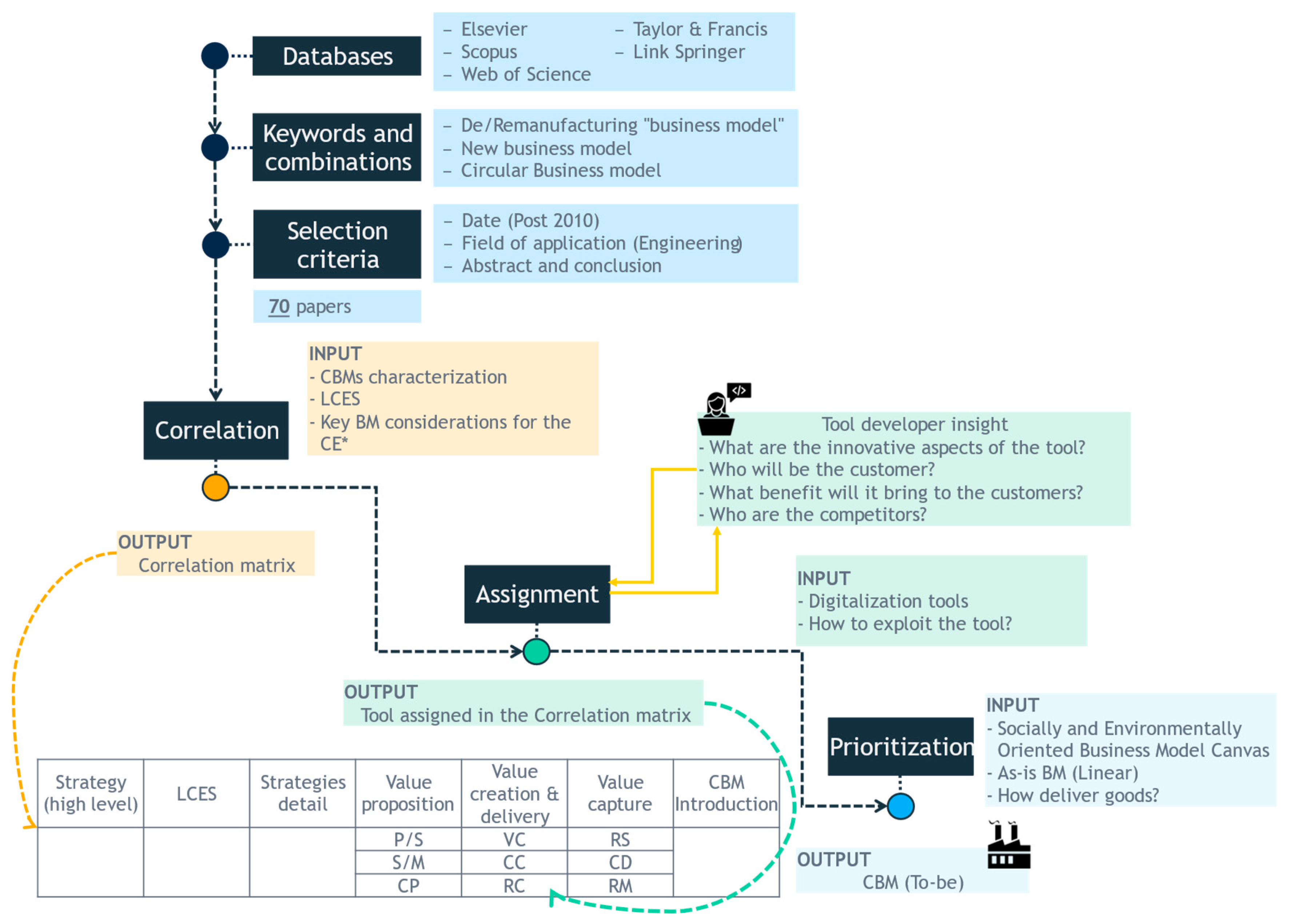

3. Materials and Methods

3.1. CBMs’ Characterization

3.2. Correlation

3.3. Assignment

3.4. Prioritization

4. Results

4.1. Correlation Matrix

4.1.1. Reuse-Resell

4.1.2. Pay per Use

4.1.3. Repair or Corrective Maintenance

4.1.4. Predictive Maintenance

4.1.5. Time-Based Maintenance

4.1.6. Remanufacturing

4.1.7. Recondition

4.1.8. Refurbishment

4.1.9. Recycle and Cannibalization

4.2. Business Cases

- Segmenting the complex metamorphosis process from linear to CBMs

- Simplifying the transformation by tackling difficulties and changes little by little.

5. Discussion and Conclusions

- It supports the exploitation of digitalization tools; with the advent of the fourth and fifth industrial revolutions [87] companies equip their products and processes with innovative tools. Their potentialities can be exploited more deeply and enlarged to a wider perspective with the support of the proposed approach. The correlation matrix as it has been developed in its general form, stands as a base to be specified for the single organization, and thus digitalizing tools can be inserted between the core resources.

- It is based on qualitative evaluations, as it is designed to support the very first decision-making steps.

- It is widely applicable in enterprises of different sectors, as the correlation matrix can be customized according to the peculiar needs and features of the involved organization.

- -

- Clearly rationalize the tools available, focusing on their entire functionalities, not just the ones most used on a daily basis. This will help in having minor influences on daily routines and actions.

- -

- Involve people with different roles in the company in the last phase, as they can contribute to building a more detailed description of the actual state.

- -

- When defining roadmaps for new CBMs, prioritize the shift from actual (linear) to future (circular) business models, by picking those more like the present business model.

- The economic sphere: only when a new practice expected by the exploited step is well-established and economically advantageous can the company move to the following one; economical KPIs should not only observe the total revenues or incomes derived from a certain LCES, rather they might also evaluate the quantities of goods handled within that LCES. Specific KPIs should be defined for each LCES, as different strategies lay behind each LCES.

- The environmental and social sphere: each step of the roadmap should be sustainable within all the pillars of sustainability, and benefits involving proper management of the resources (i.e., materials, EoL processes, waste reduction) and the impact of the organization on its employees and the surrounding citizenship should be quantified and identified, prior to facing new challenges. For these two pillars of sustainability, the indicators should be defined as well for calculating methods for each.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ertz, M.; Leblanc-Proulx, S.; Sarigöllü, E.; Morin, V. Made to break? A taxonomy of business models on product lifetime extension. J. Clean. Prod. 2019, 234, 867–880. [Google Scholar] [CrossRef]

- Yang, S.; Raghavendra, M.R.A.; Kaminski, J.; Pepin, H. Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery, and Amending Directive 95/16/EC. 2006. Available online: http://data.europa.eu/eli/dir/2006/42/oj (accessed on 27 June 2023).

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Ruggerio, C.A. Sustainability and sustainable development: A review of principles and definitions. Sci. Total Environ. 2021, 786, 147481. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, B.; Zhu, L. Digital technology usage, strategic flexibility, and business model innovation in traditional manufacturing firms: The moderating role of the institutional environment. Technol. Forecast. Soc. Chang. 2023, 194, 122726. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef]

- Roci, M.; Rashid, A. Economic and environmental impact of circular business models: A case study of White Goods-as-a-Service using multi-method simulation modelling. J. Clean. Prod. 2023, 407, 137147. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Commission of the European Communities; International Monetary Fund; Organisation for Economic Cooperation and Development; United Nations and World Bank. System of National Accounts 2008; United Nations: New York, NY, USA, 2009; Available online: https://unstats.un.org/unsd/nationalaccount/docs/sna2008.pdf (accessed on 27 June 2023).

- Fordal, J.M.; Schjølberg, P.; Helgetun, H.; Skjermo, T.; Wang, Y.; Wang, C. Application of sensor data based predictive maintenance and artificial neural networks to enable Industry 4.0. Adv. Manuf. 2023, 11, 248–263. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Rusch, M.; Stumpf, L.; Baumgartner, R.J. Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector. Sustain. Prod. Consum. 2023, 35, 401–420. [Google Scholar] [CrossRef]

- Cappelletti, F.; Rossi, M.; Germani, M. How de-manufacturing supports circular economy linking design and EoL—A literature review. J. Manuf. Syst. 2022, 63, 118–133. [Google Scholar] [CrossRef]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Design for remanufacture: A literature review and future research needs. J. Clean. Prod. 2011, 19, 2004–2014. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D.; Zwolinski, P. The strategy for implementing remanufacturing process in a commercial enterprise, the case study of a French company. Proc. CIRP 2019, 80, 554–559. [Google Scholar] [CrossRef]

- Henry, M.; Bauwens, T.; Hekkert, M.; Kirchherr, J. A Typology of Circular Start-Ups: Analysis of 128 Circular Business Models. J. Clean. Prod. 2019, 245, 118528. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular Economy Performance Assessment Methods: A Systematic Literature Review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Rojas Luiz, J.V.; Rojas Luiz, O.; Jabbour, C.J.C.; Ndubisi, N.O.; Caldeira de Oliveira, J.H.; Junior, F.H. Circular economy business models and operations management. J. Clean. Prod. 2019, 235, 1525–1539. [Google Scholar] [CrossRef]

- Fontana, A.; Barni, A.; Leone, D.; Spirito, M.; Tringale, A.; Ferraris, M.; Reis, J.; Goncalves, G. Circular Economy Strategies for Equipment Lifetime Extension: A Systematic Review. Sustainability 2021, 13, 1117. [Google Scholar] [CrossRef]

- Martin, P.; Guide, V.D.R., Jr.; Craighead, C.W. Supply Chain Sourcing in Remanufacturing Operations: An Empirical Investigation of Remake Versus Buy. Decis. Sci. 2010, 41, 301–324. [Google Scholar] [CrossRef]

- Steinhilper, R.; Weiland, F. Exploring New Horizons for Remanufacturing an Up-to-date Overview of Industries, Products and Technologies. Procedia CIRP 2015, 29, 769–773. [Google Scholar] [CrossRef]

- Dassisti, M.; Florio, G.; Maddalena, F. Cryogenic Delamination and Sustainability: Analysis of an Innovative Recycling Process for Photovoltaic Crystalline Modules. In Sustainable Design and Manufacturing, Smart Innovation, Systems and Technologies; Campana, G., Howlett, R.J., Rossi, S., Cimatti, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; Volume 68. [Google Scholar] [CrossRef]

- Ghosh, S.; Hughes, M.; Hodgkinson, I.; Hughes, P. Digital transformation of industrial businesses: A dynamic capability approach. Technovation 2022, 113, 102414. [Google Scholar] [CrossRef]

- Ali, Z.H.; Ali, H.A.; Badawy, M.M. Internet of Things (IoT): Definitions, Challenges and Recent Research Directions. Int. J. Comput. Appl. 2015, 128, 37–47. [Google Scholar] [CrossRef]

- Baines, T.W.; Lightfoot, H. Servitization of the manufacturing firm. Exploring the operations practices and technologies that deliver advanced services. Int. J. Oper. Prod. Manag. 2013, 34, 2–35. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Liebherr, Rental Services for Construction Machines. Available online: https://www.liebherr.com/en/usa/about-liebherr/service-services/service-services.html (accessed on 16 December 2022).

- Hilti. Our Fleet Management Service. Available online: https://www.hilti.group/content/hilti/CP/XX/en/services/tool-services/fleet-management.html#nav/close (accessed on 15 December 2022).

- Cat Reman. Available online: https://www.caterpillar.com/en/brands/cat-reman.html (accessed on 16 December 2022).

- Aston Business School, Case Studies. Available online: https://www.advancedservicesgroup.co.uk/research/publications/case-studies (accessed on 16 December 2022).

- Goodyear. Available online: https://news.goodyear.eu/goodyear-launches-digital-innovations-to-reduce-otr-costs/ (accessed on 16 December 2022).

- Bosch eXchange. Available online: https://www.boschaftermarket.com/xrm/media/images/country_specific/it/xx_pdfs_28/parts_5/gamma_bosch_exchange.pdf (accessed on 16 December 2022).

- Volvo. Available online: https://www.volvotrucks.com/en-en/news-stories/magazine-online/2018/may/remanufacturing-engines.html (accessed on 16 December 2022).

- Schneider Electric. Available online: https://www.se.com/uk/en/ (accessed on 16 December 2022).

- Valtra. Parts and Services. Available online: https://www.valtra.co.uk/service/services-and-repair/spare-parts.html (accessed on 16 December 2022).

- Tarmac. Available online: https://www.tarmacaerosave.aero/about-us (accessed on 16 December 2022).

- Fairphone. Available online: https://www.fairphone.com/it/impact/ (accessed on 16 December 2022).

- Hyla Mobile. Available online: https://www.hylamobile.com/#content3 (accessed on 16 December 2022).

- Taitonetti. Available online: https://taitonetti.fi/index.php?route=blog/article&path=2&article_id=15 (accessed on 16 December 2022).

- CCL North. Company Publication. Available online: https://www.cclnorth.com/ (accessed on 16 December 2022).

- Apple. Liam, an Innovation Story. Available online: https://www.apple.com/environment/pdf/Liam_white_paper_Sept2016.pdf (accessed on 16 December 2022).

- Vonk, L. Paying Attention to Waste: Apple’s Circular Economy. Continuum 2018, 32, 745–757. [Google Scholar] [CrossRef]

- Cheung, W.M.; Marsh, R.; Griffin, P.W.; Newnes, L.B.; Mileham, A.R.; Lanham, J.D. Towards cleaner production: A roadmap for predicting product end-of-life costs at early design concept. J. Clean. Prod. 2015, 87, 431–441. [Google Scholar] [CrossRef]

- Philips Decoupling Growth from Resource Consumption. Available online: https://www.philips.com/a-w/about/sustainability/circular-economy (accessed on 16 December 2022).

- Hp. Sustainable Impact Report. Available online: https://www8.hp.com/h20195/v2/GetPDF.aspx/c05179523.pdf#page=1 (accessed on 16 December 2022).

- Dell. Design for Environment. 2018. Available online: https://i.dell.com/sites/content/corporate/corp-comm/en/Documents/design-for-environment.pdf (accessed on 16 December 2022).

- Motorola. Corporate Responsibility. Available online: https://www.motorola.com/us/about/corporate-responsibility-recycling (accessed on 16 December 2022).

- Lowe, G.; Bogue, R. Design for disassembly: A critical twenty-first century discipline. Assem. Autom. 2007, 27, 285–289. [Google Scholar] [CrossRef]

- Kodak. Corporate Responsibility Report. Available online: https://www.kodak.com/content/products-brochures/Company/Kodak-2017-Corporate-Responsibility-Report.pdf (accessed on 16 December 2022).

- Xerox. Prevent and Manage Waste. Available online: https://www.xerox.com/en-us/about/ehs/reduce-waste (accessed on 16 December 2022).

- Canon. Environmental Circulation. Available online: https://global.canon/en/environment/circulation.html (accessed on 16 December 2022).

- Opresnik, D.; Taisch, M. The manufacturer’s value chain as a service—The case of remanufacturing. J. Remanufacturing 2015, 5, 2. [Google Scholar] [CrossRef]

- Enerkem. Carbon Recycling. Available online: https://enerkem.com/process-technology/carbon-recycling/ (accessed on 16 December 2022).

- Clarios. The Clarios Difference. Available online: https://www.clarios.com/products (accessed on 16 December 2022).

- Renault. Renault Optimizes the Lifecycle of Its Electric Vehicle Batteries. Available online: https://group.renault.com/en/news-on-air/news/renault-optimizes-the-lifecycle-of-its-electric-vehicle-batteries/ (accessed on 16 December 2022).

- AB InBev. Driving Sustainable Packaging. Available online: https://www.ab-inbev.com/sustainability/circular-packaging/ (accessed on 16 December 2022).

- Re Pack. Upgrade Your Unpacking. Available online: https://www.originalrepack.com/ (accessed on 16 December 2022).

- Toner Plast. Cloose the Loop. Available online: https://www.closetheloop.com.au/tonerplas/ (accessed on 16 December 2022).

- Eldan Recycling. The Best of Tyre Recycling. Available online: https://eldan-recycling.com/tyre-recycling/ (accessed on 16 December 2022).

- Lehigh Technologies. Micronized Rubber Powders. Available online: https://lehightechnologies.com/what_we_do/the_business_we_are_in/#gallery (accessed on 16 December 2022).

- Timberland. Drive. Recycle. Wear. Available online: https://www.timberland.com/blog/archive/timberland-tires.html (accessed on 16 December 2022).

- Gulipac, S. Industrial Symbiosis: Building on Kalundborg’s waste management experience. Renew. Energy Focus 2017, 17, 25–27. [Google Scholar] [CrossRef]

- Ciccarelli, M.; Papetti, A.; Cappelletti, F.; Brunzini, A.; Germani, M. Combining World Class Manufacturing system and Industry 4.0 technologies to design ergonomic manufacturing equipment. Int. J. Interact. Des. Manuf. 2022, 16, 263–279. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Richardson, J. The business model: An integrative framework for strategy execution. Strat. Chang. 2008, 17, 133–144. [Google Scholar] [CrossRef]

- Schiavone, F.; Leone, D.; Caporuscio, A.; Lan, S. Digital servitization and new sustainable configurations of manufacturing systems. Technol. Forecast. Soc. Chang. 2022, 176, 121441. [Google Scholar] [CrossRef]

- Sparviero, S. The Case for a Socially Oriented Business Model Canvas: The Social Enterprise Model Canvas. J. Soc. Entrep. 2019, 10, 232–251. [Google Scholar] [CrossRef]

- Kin, S.T.M.; Ong, S.; Nee, A. Remanufacturing Process Planning. Procedia CIRP 2014, 15, 189–194. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, J.; Ahmad, R. A cost-driven process planning method for hybrid additive–subtractive remanufacturing. J. Manuf. Syst. 2020, 55, 248–263. [Google Scholar] [CrossRef]

- Poschmann, H.; Brüggemann, H.; Goldmann, D. Disassembly 4.0: A Review on Using Robotics in Disassembly Tasks as a Way of Automation. Chem. Ing. Tech. 2020, 92, 341–359. [Google Scholar] [CrossRef]

- Chierici, E.; Copani, G. Remanufacturing with Upgrade PSS for New Sustainable Business Models. Procedia CIRP 2016, 47, 531–536. [Google Scholar] [CrossRef]

- Kurilova-Palisaitiene, J.; Sundin, E. Toward Pull Remanufacturing: A Case Study on Material and Information Flow Uncertainties at a German Engine Remanufacturer. Procedia CIRP 2015, 26, 270–275. [Google Scholar] [CrossRef]

- Harivardhini, S.; Krishna, K.M.; Chakrabarti, A. An Integrated Framework for supporting decision making during early design stages on end-of-life disassembly. J. Clean. Prod. 2017, 168, 558–574. [Google Scholar] [CrossRef]

- Sitcharangsie, S.; Ijomah, W.; Wong, T. Decision makings in key remanufacturing activities to optimise remanufacturing outcomes: A review. J. Clean. Prod. 2019, 232, 1465–1481. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Butzer, S.; Schötz, S.; Steinhilper, R. Remanufacturing Process Assessment—A Holistic Approach. Procedia CIRP 2016, 52, 234–238. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Makarevičius, V.; Lukošiūtė, S.-I.; Bendikiene, R.; Denafas, G. A strategy for synthesis of copper nanoparticles from recovered metal of waste printed circuit boards. J. Clean. Prod. 2018, 185, 653–664. [Google Scholar] [CrossRef]

- Peng, S.; Li, T.; Li, M.; Guo, Y.; Shi, J.; Tan, G.Z.; Zhang, H. An integrated decision model of restoring technologies selection for engine remanufacturing practice. J. Clean. Prod. 2019, 206, 598–610. [Google Scholar] [CrossRef]

- Hu, Z.; Qin, X.; Shao, T. Welding Thermal Simulation and Metallurgical Characteristics Analysis in WAAM for 5CrNiMo Hot Forging Die Remanufacturing. Procedia Eng. 2017, 207, 2203–2208. [Google Scholar] [CrossRef]

- Zhang, X.; Ao, X.; Cai, W.; Jiang, Z.; Zhang, H. A sustainability evaluation method integrating the energy, economic and environment in remanufacturing systems. J. Clean. Prod. 2019, 239, 118100. [Google Scholar] [CrossRef]

- Huang, W.; Jiang, Z.; Wang, T.; Wang, Y.; Hu, X. Remanufacturing Scheme Design for Used Parts Based on Incomplete Information Reconstruction. Chin. J. Mech. Eng. 2020, 33, 1–14. [Google Scholar] [CrossRef]

- Wu, Z.; Li, T.; Li, Q.; Shi, B.; Li, X.; Wang, X.; Lu, H.; Zhang, H.-C. Process optimization of laser cladding Ni60A alloy coating in remanufacturing. Opt. Laser Technol. 2019, 120, 105718. [Google Scholar] [CrossRef]

- Peng, H.; Wang, H.; Chen, D. Optimization of remanufacturing process routes oriented toward eco-efficiency. Front. Mech. Eng. 2019, 14, 422–433. [Google Scholar] [CrossRef]

- Cappelletti, F.; Rossi, M.; Marasca, S.; Germani, M. De-manufacturing: Identification of the best strategies through the environmental and economic evaluation. Int. J. Interact. Des. Manuf 2023, 17, 1589–1609. [Google Scholar] [CrossRef]

- Papetti, A.; Ciccarelli, M.; Scoccia, C.; Palmieri, G.; Germani, M. A human-oriented design process for collaborative robotics. Int. J. Comput. Integr. Manuf. 2022. [Google Scholar] [CrossRef]

| Strategy (High Level) | LCES | Value Proposition | CBM Introduction |

|---|---|---|---|

| Cycling | Resell–Reuse | Used machine take-back | Acquisition |

| Pay per use | Machine as a service (rent- subscription/pay per use) | ||

| Remanufactured machine as a service | |||

| Recondition | Reconditioned machine | ||

| Refurbish | Machine refurbishment | ||

| Back in box spare parts | Diversification | ||

| Cannibalization | Used machine take-back | Acquisition | |

| Recycle | Used machine take-back | ||

| Remanufacture | Remanufactured machines | ||

| Extending | Repair or Corrective Maintenance | Remote/automatic troubleshooting AR maintenance | Diversification |

| Spare parts/modules rent | |||

| Preventive Maintenance |

| Diversification | |

| Predictive Maintenance |

| Diversification | |

| Time-based Maintenance | Maintenance kit | Diversification |

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Sell used full products or parts of it | VC | RSC management operations (take back) | RS | Revenue models based on used parts of product sale |

| S/M | Segment of existing or new customers | CC | Capacity management (demand and supply of products) | CD |

|

| CP | Need machine but with lower initial investments | RC | Machine experts or specific tools able to understand the state of the part/product | RM | Sale |

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Machine as a service | VC |

| RS |

|

| Remanufactured machine as a service | |||||

| S/M | Segment of existing or new customers | CC |

| CD |

|

| |||||

| CP |

| RC |

| RM |

|

| |||||

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Troubleshooting AR maintenance | VC | Support maintenance phase/service operations | RS | Revenue models based on service packages |

| Spare parts/modules rent | Revenues from storing services | ||||

| S/M |

| CC | Knowledge of machine and failure cases | CD | Service maintenance costs |

| Cost for warehousing and maintaining spare modules in good condition | |||||

| CP | Willing to accelerate/make maintenance simpler | RC |

| RM |

|

| Suppliers’ management | |||||

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S |

| VC | Avoid physical interventions | RS | Revenues models based on service packages and/or tailored contracts |

| S/M |

| CC | Knowledge of machine and failure cases | CD | Service maintenance costs |

| CP | Need to avoid unexpected failures | RC |

| RM |

|

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Maintenance kit | VC | Periodical shipment of maintenance kits to the customers | RS | Revenue models based on maintenance kit fee |

| S/M |

| CC |

| CD | Maintenance kit logistics |

| CP | Need to avoid unexpected failures | RC |

| RM | Revenue from providing maintenance kit (time-based) |

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Remanufactured machines | VC |

| RS |

|

| S/M | Segment of existing or new customers | CC |

| CD |

|

| CP |

| RC |

| RM | Revenue from high-quality products at lower prices |

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Reconditioned machines | VC | RSC management (take back) and remanufacture operations | RS |

|

| S/M | Segment of existing or new customers | CC |

| CD |

|

| CP |

| RC |

| RM | Revenue from reconditioned products sold at lower prices |

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Machine refurbishment | VC | Refurbish machines as in pilot cases | RS | Additional revenue through upgrade service |

| Back-in-box spare parts |

| Remanufactured spare part selling | |||

| S/M | Segment of existing customers that want their machines to be upgrade | CC | Supply chain management (if upgrades occur outside the shopfloor where the machine is installed) | CD | Refurbishment cost + machine analysis status costs (+ reverse supply chain cost) |

| Segment of existing customers that did not buy original spare parts before | Spare parts refurbishment |

| |||

| CP | Wish to have a keeping-up to times machine without investing a lot | RC |

| RM | Payment of refurbishment service |

| Wish to pay less for maintenance but want guaranteed well-functioning spare parts |

| Bosch Exchange—back in box | |||

| Value Proposition | Value Creation and Delivery | Value Capture | |||

|---|---|---|---|---|---|

| P/S | Used machine take-back | VC |

| RS |

|

| S/M | Segment of customers who bought machines years ago and are replacing/dismantling the machine | CC |

| CD | Costs related to machine taking back (RSC) and preparing for recycle |

| CP |

| RC |

| RM | Revenue model based on direct sales or trade of resources |

| Step | Tools | Resources Involved |

|---|---|---|

| Structured interviews BM canvas | Innovation manager R&D manager |

| Correlation matrix | R&D manager |

| Correlation matrix BM canvas | Innovation manager R&D manager |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappelletti, F.; Menato, S. Developing a Circular Business Model for Machinery Life Cycle Extension by Exploiting Tools for Digitalization. Sustainability 2023, 15, 15500. https://doi.org/10.3390/su152115500

Cappelletti F, Menato S. Developing a Circular Business Model for Machinery Life Cycle Extension by Exploiting Tools for Digitalization. Sustainability. 2023; 15(21):15500. https://doi.org/10.3390/su152115500

Chicago/Turabian StyleCappelletti, Federica, and Silvia Menato. 2023. "Developing a Circular Business Model for Machinery Life Cycle Extension by Exploiting Tools for Digitalization" Sustainability 15, no. 21: 15500. https://doi.org/10.3390/su152115500

APA StyleCappelletti, F., & Menato, S. (2023). Developing a Circular Business Model for Machinery Life Cycle Extension by Exploiting Tools for Digitalization. Sustainability, 15(21), 15500. https://doi.org/10.3390/su152115500