Power Cost and CO2 Emissions for a Microgrid with Hydrogen Storage and Electric Vehicles

Abstract

:1. Introduction

2. Literature Review

- The microgrid comprises PV power plants and micro-hydro sources in comparison to other studies, where wind turbines and PV power plants were used;

- The analysis is presented for different scenarios (electric and fuel cell vehicles are connected or not to the system) and seasons (spring, summer, autumn and winter);

- It is determined how much hydrogen can be produced and later used to cover power demand and if it is enough, considering the variable power demand during the seasons; three energy carriers are present (power, hydrogen and natural gas);

- The power cost and CO2 emissions are analysed.

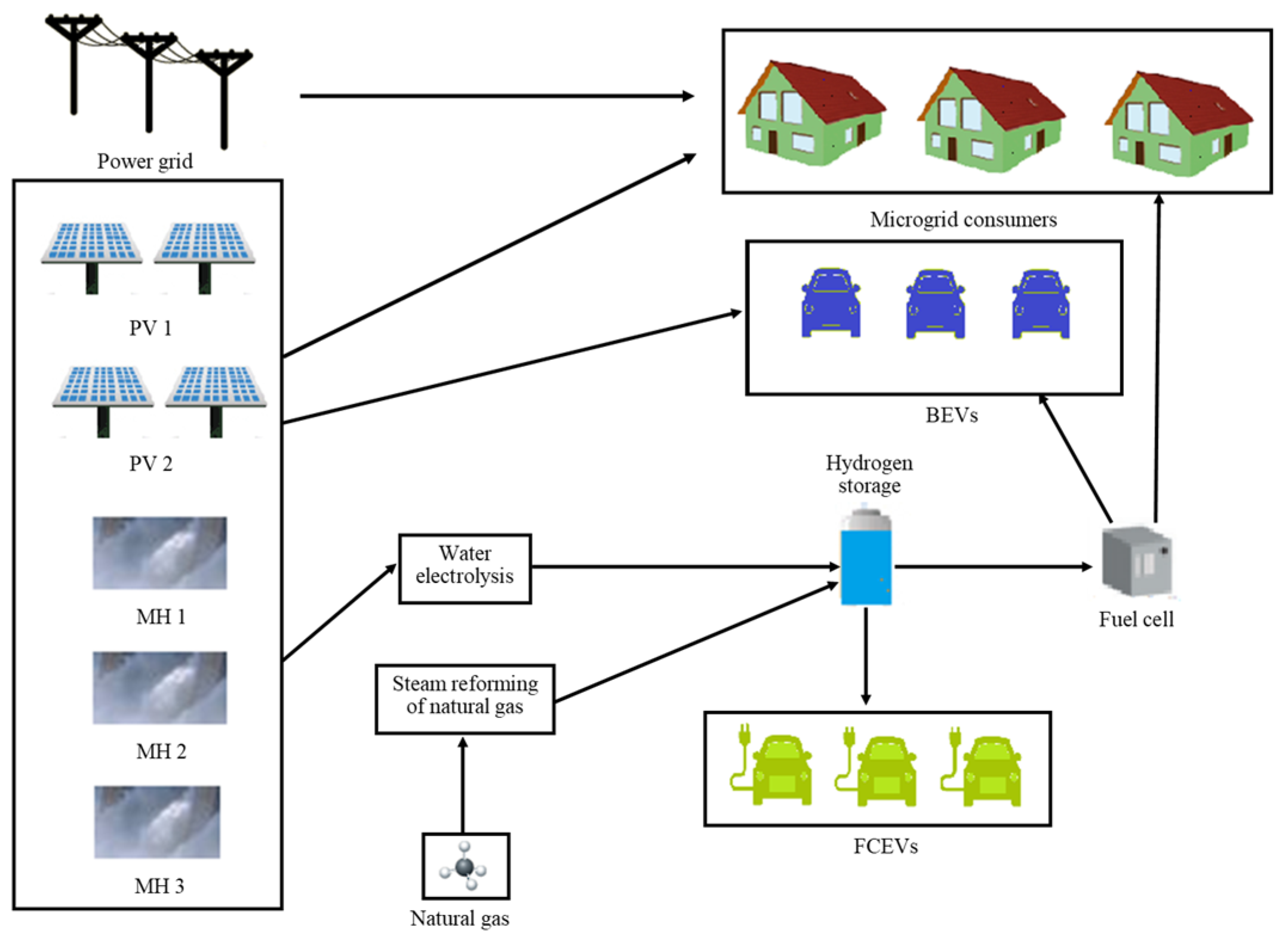

3. Materials and Methods

4. Results and Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tarhan, C.; Çil, M.A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J. Energy Storage 2021, 40, 102676. [Google Scholar] [CrossRef]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An Overview of Hydrogen Production: Current Status, Potential, and Challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Rasul, M.G.; Hazrat, M.A.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Sazali, N. Emerging technologies by hydrogen: A review. Int. J. Hydrogen Energy 2020, 45, 18753–18771. [Google Scholar] [CrossRef]

- Liu, W.; Zuo, H.; Wang, J.; Xue, Q.; Ren, B.; Yang, F. The production and application of hydrogen in steel industry. Int. J. Hydrogen Energy 2021, 46, 10548–10569. [Google Scholar] [CrossRef]

- Ajanovic, A.; Sayer, M.; Haas, R. The economics and the environmental benignity of different colors of hydrogen. Int. J. Hydrogen Energy 2022, 47, 24136–24154. [Google Scholar] [CrossRef]

- Panchenko, V.A.; Daus, Y.V.; Kovalev, A.A.; Yudaev, I.V.; Litti, Y.V. Prospects for the production of green hydrogen: Review of countries with high potential. Int. J. Hydrogen Energy 2023, 48, 4551–4571. [Google Scholar] [CrossRef]

- Felseghi, R.A.; Carcadea, E.; Raboaca, M.S.; Trufin, C.N.; Filote, C. Hydrogen Fuel Cell Technology for the Sustainable Future of Stationary Applications. Energies 2019, 12, 4593. [Google Scholar] [CrossRef]

- Sharma, S.; Agarwal, S.; Jain, A. Significance of Hydrogen as Economic and Environmentally Friendly Fuel. Energies 2021, 14, 7389. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef] [PubMed]

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Noussan, M.; Raimondi, P.P.; Scita, R.; Hafner, M. The Role of Green and Blue Hydrogen in the Energy Transition—A Technological and Geopolitical Perspective. Sustainability 2021, 13, 298. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Hefny, M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Hydrogen production, storage, utilisation and environmental impacts: A review. Environ. Chem. Lett. 2022, 20, 153–188. [Google Scholar] [CrossRef]

- Sun, X.; Cao, X.; Zeng, B.; Zhai, Q.; Guan, X. Multistage Dynamic Planning of Integrated Hydrogen-Electrical Microgrids under Multiscale Uncertainties. IEEE Trans. Smart Grid 2022, 14, 3482–3498. [Google Scholar] [CrossRef]

- Zhang, R.; Li, X.; Wang, X.; Wang, Q.; Qi, Z. Optimal Scheduling for Hydrogen-electric Hybrid Microgrid with Vehicle to Grid Technology. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; pp. 6296–6300. [Google Scholar] [CrossRef]

- Alluraiah, N.C.; Vijayapriya, P. Optimization, Design, and Feasibility Analysis of a Grid-Integrated Hybrid AC/DC Microgrid System for Rural Electrification. IEEE Access 2023, 11, 67013–67029. [Google Scholar] [CrossRef]

- Zhong, Z.; Huang, D.; Hu, K.; Ai, X.; Fang, J. Real-time Optimal Operation of Microgrid with Power-to-hydrogen. In Proceedings of the 2020 IEEE Sustainable Power and Energy Conference (iSPEC), Chengdu, China, 23–25 November 2020; pp. 2275–2280. [Google Scholar] [CrossRef]

- Ghezelbash, A.; Khaligh, V.; Liu, J.; Ryu, J.H. Scheduling of a Multi-energy Microgrid Enhanced with Hydrogen Storage. In Proceedings of the 2022 IEEE PES 14th Asia-Pacific Power and Energy Engineering Conference (APPEEC), Melbourne, Australia, 20–23 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Villa Londono, J.E.; Mazza, A.; Pons, E.; Lok, H.; Bompard, E. Modelling and Control of a Grid-Connected RES-Hydrogen Hybrid Microgrid. Energies 2021, 14, 1540. [Google Scholar] [CrossRef]

- Sahri, Y.; Belkhier, Y.; Tamalouzt, S.; Ullah, N.; Shaw, R.N.; Chowdhury, M.S.; Techato, K. Energy Management System for Hybrid PV/Wind/Battery/Fuel Cell in Microgrid-Based Hydrogen and Economical Hybrid Battery/Super Capacitor Energy Storage. Energies 2021, 14, 5722. [Google Scholar] [CrossRef]

- Arsalis, A.; Georghiou, G.E.; Papanastasiou, P. Recent Research Progress in Hybrid Photovoltaic–Regenerative Hydrogen Fuel Cell Microgrid Systems. Energies 2022, 15, 3512. [Google Scholar] [CrossRef]

- Abdelsalam, R.A.; Abdallah, Y.S.; Shabar, N.M.; Afifi, O.A.; Fouda, M.H.; El-Deib, A.A. Energy Management and Techno-Economic Optimization of an Isolated Hybrid AC/DC Microgrid with Green Hydrogen Storage System. In Proceedings of the 2023 IEEE Conference on Power Electronics and Renewable Energy (CPERE), Luxor, Egypt, 19–21 February 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Cao, X.; Sun, X.; Xu, Z.; Zeng, B.; Guan, X. Hydrogen-Based Networked Microgrids Planning Through Two-Stage Stochastic Programming with Mixed-Integer Conic Recourse. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3672–3685. [Google Scholar] [CrossRef]

- Wang, J.; Li, D.; Lv, X.; Meng, X.; Zhang, J.; Ma, T.; Pei, W.; Xiao, H. Two-Stage Energy Management Strategies of Sustainable Wind-PV-Hydrogen-Storage Microgrid Based on Receding Horizon Optimization. Energies 2022, 15, 2861. [Google Scholar] [CrossRef]

- Alzahrani, A.; Ramu, S.K.; Devarajan, G.; Vairavasundaram, I.; Vairavasundaram, S. A Review on Hydrogen-Based Hybrid Microgrid System: Topologies for Hydrogen Energy Storage, Integration, and Energy Management with Solar and Wind Energy. Energies 2022, 15, 7979. [Google Scholar] [CrossRef]

- Hou, H.; Chen, Y.; Liu, P.; Xie, C.; Huang, L.; Zhang, R.; Zhang, Q. Multisource Energy Storage System Optimal Dispatch Among Electricity Hydrogen and Heat Networks from the Energy Storage Operator Prospect. IEEE Trans. Ind. Appl. 2022, 58, 2825–2835. [Google Scholar] [CrossRef]

- Ganeshan, A.; Holmes, D.G.; Meegahapola, L.; McGrath, B.P. Enhanced control of a hydrogen energy storage system in a microgrid. In Proceedings of the 2017 Australasian Universities Power Engineering Conference (AUPEC), Melbourne, Australia, 19–22 November 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Oliveira, A.M.; Beswick, R.R.; Yan, Y. A green hydrogen economy for a renewable energy society. Curr. Opin. Chem. Eng. 2021, 33, 100701. [Google Scholar] [CrossRef]

- Behera, M.K.; Saikia, L.C. A Novel Resilient Control of Grid-Integrated Solar PV-Hybrid Energy Storage Microgrid for Power Smoothing and Pulse Power Load Accommodation. IEEE Trans. Power Electron. 2023, 36, 3965–3980. [Google Scholar] [CrossRef]

- Shanbog, N.S.; Agalgaonkar, Y.; Rajarathnam, U. A Financial Feasibility Analysis of Hydrogen in Microgrids. In Proceedings of the 2019 2nd International Conference on Power and Embedded Drive Control (ICPEDC), Chennai, India, 21–23 August 2019; pp. 58–63. [Google Scholar] [CrossRef]

- Gong, X.; Dong, F.; Mohamed, M.A.; Abdalla, O.M.; Ali, Z.M. A Secured Energy Management Architecture for Smart Hybrid Microgrids Considering PEM-Fuel Cell and Electric Vehicles. IEEE Access 2020, 8, 47807–47823. [Google Scholar] [CrossRef]

- Li, B. Build 100% renewable energy based power station and microgrid clusters through hydrogen-centric storage systems. In Proceedings of the 2020 4th International Conference on HVDC (HVDC), Xi’an, China, 6–9 November 2020; pp. 1253–1257. [Google Scholar] [CrossRef]

- Fan, F.; Zhang, R.; Xu, Y.; Ren, S. Robustly Coordinated Operation of an Emission-free Microgrid with Hybrid Hydrogen-battery Energy Storage. CSEE J. Power Energy Syst. 2022, 8, 369–379. [Google Scholar] [CrossRef]

- Serra, F.; Petrollese, M.; Lucariello, M.; Cau, G. Assessment of a hydrogen production, storage and utilization system in a demonstrative microgrid. In Proceedings of the 2020 2nd IEEE International Conference on Industrial Electronics for Sustainable Energy Systems (IESES), Cagliari, Italy, 1–3 September 2020; pp. 157–162. [Google Scholar] [CrossRef]

- Khaligh, V.; Ghezelbash, A.; Liu, J.; Ryu, J.H. Cooperative Energy Management of a Microgrid with Bidirectional Electricity-Hydrogen Energy Conversion. In Proceedings of the 2022 IEEE PES 14th Asia-Pacific Power and Energy Engineering Conference (APPEEC), Melbourne, Australia, 20–23 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Valverde, L.; Rosa, F.; Bordons, C. Design, Planning and Management of a Hydrogen-Based Microgrid. IEEE Trans. Ind. Inform. 2013, 9, 1398–1404. [Google Scholar] [CrossRef]

- Cecilia, A.; Carroquino, J.; Roda, V.; Costa-Castelló, R.; Barreras, F. Optimal Energy Management in a Standalone Microgrid, with Photovoltaic Generation, Short-Term Storage, and Hydrogen Production. Energies 2020, 13, 1454. [Google Scholar] [CrossRef]

- Naseri, N.; El Hani, S.; El Harouri, K.; Mediouni, H. Primary and secondary control of an autonomous solar microgrid based power-to-X: Renewable hydrogen conversion. Int. J. Hydrogen Energy 2022, 47, 24421–24438. [Google Scholar] [CrossRef]

- Hossain, B.; Islam, R.; Muttaqi, K.M.; Sutanto, D.; Agalgaonkar, A.P. Modeling and performance analysis of renewable hydrogen energy hub connected to an ac/dc hybrid microgrid. Int. J. Hydrogen Energy 2022, 47, 28626–28644. [Google Scholar] [CrossRef]

- Bovo, A.; Poli, N.; Trovò, A.; Marini, G.; Guarnieri, M. Hydrogen energy storage system in a Multi–Technology Microgrid:technical features and performance. Int. J. Hydrogen Energy 2023, 48, 12072–12088. [Google Scholar] [CrossRef]

- Van, L.P.; Chi, K.D.; Duc, T.N. Review of hydrogen technologies based microgrid: Energy management systems, challenges and future recommendations. Int. J. Hydrogen Energy 2023, 48, 14127–14148. [Google Scholar] [CrossRef]

- Califano, M.; Califano, G.; Sorrentino, M.; Rosen, M.A.; Pianese, C. Hydrogen-based microgrid: Development of medium level controls in a multilevel algorithm framework. Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Mah, A.X.Y.; Ho, W.S.; Hassim, M.H.; Hashim, H.; Ling, G.H.T.; Ho, C.S.; Muis, Z.A. Optimization of a standalone photovoltaic-based microgrid with electrical and hydrogen loads. Energy 2021, 235, 121218. [Google Scholar] [CrossRef]

- Mansour-Saatloo, A.; Mirzaei, M.A.; Mohammadi-Ivatloo, B.; Zare, K. A Risk-Averse Hybrid Approach for Optimal Participation of Power-to-Hydrogen Technology-Based Multi-Energy Microgrid in Multi-Energy Markets. Sustain. Cities Soc. 2020, 63, 102421. [Google Scholar] [CrossRef]

- Alam, M.; Kumar, K.; Verma, S.; Dutta, V. Renewable sources based DC microgrid using hydrogen energy storage: Modelling and experimental analysis. Sustain. Energy Technol. Assess. 2020, 42, 100840. [Google Scholar] [CrossRef]

- Hafsi, O.; Abdelkhalek, O.; Mekhilef, S.; Soumeur, M.A.; Hartani, M.A.; Chakar, A. Integration of hydrogen technology and energy management comparison for DC-Microgrid including renewable energies and energy storage system. Sustain. Energy Technol. Assess. 2022, 52, 102121. [Google Scholar] [CrossRef]

- Yang, H.; Li, Q.; Zhao, S.; Chen, W.; Liu, H. A Hierarchical Self-Regulation Control for Economic Operation of AC/DC Hybrid Microgrid with Hydrogen Energy Storage System. IEEE Access 2019, 7, 89330–89341. [Google Scholar] [CrossRef]

- Gugulothu, R.; Nagu, B.; Pullaguram, D. Energy management strategy for standalone DC microgrid system with photovoltaic/fuel cell/battery storage. J. Energy Storage 2023, 57, 106274. [Google Scholar] [CrossRef]

- Förster, R.; Kaiser, M.; Wenninger, S. Future vehicle energy supply-sustainable design and operation of hybrid hydrogen and electric microgrids. Appl. Energy 2023, 334, 120653. [Google Scholar] [CrossRef]

- Abo-Elyousr, F.K.; Guerrero, J.M.; Ramadan, H.S. Prospective hydrogen-based microgrid systems for optimal leverage via metaheuristic approaches. Appl. Energy 2021, 300, 117384. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, W.; Mei, C.; Deng, W.; Tan, J.; Zhang, Q. Transform from gasoline stations to electric-hydrogen hybrid refueling stations: An islanding DC microgrid with electric-hydrogen hybrid energy storage system and its control strategy. Int. J. Electr. Power Energy Syst. 2022, 136, 107684. [Google Scholar] [CrossRef]

- Tostado-Véliz, M.; Arévalo, P.; Jurado, F. A comprehensive electrical-gas-hydrogen Microgrid model for energy management applications. Energy Convers. Manag. 2021, 228, 113726. [Google Scholar] [CrossRef]

- Navas, S.J.; Cabello González, G.M.; Pino, F.J. Hybrid power-heat microgrid solution using hydrogen as an energy vector for residential houses in Spain. A case study. Energy Convers. Manag. 2022, 263, 115724. [Google Scholar] [CrossRef]

- Yousri, D.; Farag, H.E.Z.; Zeineldin, H.; El-Saadany, E.F. Integrated model for optimal energy management and demand response of microgrids considering hybrid hydrogen-battery storage systems. Energy Convers. Manag. 2023, 280, 116809. [Google Scholar] [CrossRef]

- K/bidi, F.; Damour, C.; Grondin, D.; Hilairet, M.; Benne, M. Multistage power and energy management strategy for hybrid microgrid with photovoltaic production and hydrogen storage. Appl. Energy 2022, 280, 119549. [Google Scholar] [CrossRef]

- Fang, X.; Dong, W.; Wang, Y.; Yang, Q. Multiple time-scale energy management strategy for a hydrogen-based multi-energy microgrid. Appl. Energy 2022, 328, 120195. [Google Scholar] [CrossRef]

- Heidary, H.; El-Kharouf, A.; Steinberger-Wilckens, R.; Bozorgmehri, S.; Salimi, M.; Golmohammad, M. Life cycle assessment of solid oxide fuel cell vehicles in a natural gas producing country; comparison with proton electrolyte fuel cell, battery and gasoline vehicles. Sustain. Energy Technol. Assess. 2023, 59, 103396. [Google Scholar] [CrossRef]

- Robledo, C.B.; Oldenbroek, V.; Abbruzzese, A.; van Wijk, A.J.M. Integrating a hydrogen fuel cell electric vehicle with vehicle-to-grid technology, photovoltaic power and a residential building. Appl. Energy 2018, 215, 615–629. [Google Scholar] [CrossRef]

- Mukherjee, U.; Maroufmashat, A.; Ranisau, J.; Barbouti, M.; Trainor, A.; Juthani, N.; El-Shayeb, H.; Fowler, M. Techno-economic, environmental, and safety assessment of hydrogen powered community microgrids; case study in Canada. Int. J. Hydrogen Energy 2017, 40, 14333–14349. [Google Scholar] [CrossRef]

- Sánchez-Sáinz, H.; García-Vázquez, C.-A.; Llorens Iborra, F.; Fernández-Ramírez, L.M. Methodology for the Optimal Design of a Hybrid Charging Station of Electric and Fuel Cell Vehicles Supplied by Renewable Energies and an Energy Storage System. Sustainability 2019, 11, 5743. [Google Scholar] [CrossRef]

- Dulău, L.I.; Abrudean, M.; Bică, D. Distributed Generation Technologies and Optimization. Procedia Technol. 2014, 12, 687–692. [Google Scholar] [CrossRef]

- U.S. Department of Energy, Hydrogen and Fuel Cell Technologies Office. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-and-fuel-cell-technologies-office (accessed on 23 October 2023).

- Nadeem, F.; Hussain, S.M.S.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Comparative Review of Energy Storage Systems, Their Roles, and Impacts on Future Power Systems. IEEE Access 2019, 7, 4555–4585. [Google Scholar] [CrossRef]

- Elio, J.; Phelan, P.; Villalobos, R. A Review of Energy Storage Technologies for Demand-Side Management in Industrial Facilities. J. Clean. Prod. 2021, 307, 127322. [Google Scholar] [CrossRef]

- Mongird, K.; Viswanathan, V.; Alam, J. 2020 Grid Energy Storage Technology Cost and Performance Assessment; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2020.

- Taylor, M.; Ralon, P.; Al-Zoghoul, S. Renewable Power Generation Costs in 2021; Technical Report; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- Mongird, K.; Fotedar, V.; Viswanathan, V. Energy Storage Technology and Cost Characterization Report; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2019.

- Faria, R.; Moura, P.; Delgado, J.; de Almeida, A.T. A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Ramachandran, S.; Stimming, U. Well to wheel analysis of low carbon alternatives for road traffic. Energy Environ. Sci. 2015, 8, 3313–3324. [Google Scholar] [CrossRef]

- Longden, T.; Beck, F.J.; Jotzo, F.; Andrews, R.; Prasad, M. ‘Clean’ hydrogen?—Comparing the emissions and costs of fossil fuel versus renewable electricity based hydrogen. Appl. Energy 2022, 306, 118145. [Google Scholar] [CrossRef]

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687. [Google Scholar] [CrossRef]

- Dulău, L.I. CO2 Emissions of Battery Electric Vehicles and Hydrogen Fuel Cell Vehicles. Clean Technol. 2023, 5, 696–712. [Google Scholar] [CrossRef]

- Tong, F.; Michalek, J.; Azevedo, I.L. A review of hydrogen production pathways, cost and decarbonization potential. In Proceedings of the 35th USAEE/IAEE North American Conference, Houston, TX, USA, 12–15 November 2017. [Google Scholar]

- Tenhumberg, N.; Büker, K. Ecological and Economic Evaluation of Hydrogen Production by Different Water Electrolysis Technologies. Chem. Ing. Tech. 2020, 92, 1586–1595. [Google Scholar] [CrossRef]

- MATLAB R2023b. Available online: https://www.mathworks.com/products/matlab.html (accessed on 1 September 2023).

| Hour (h) | Power Demand [kw] | |||

|---|---|---|---|---|

| Spring | Summer | Autumn | Winter | |

| 1 | 90.59 | 86.52 | 91.33 | 105.5 |

| 2 | 91.74 | 85.99 | 93.66 | 106.38 |

| 3 | 94.43 | 87.25 | 99.28 | 109.86 |

| 4 | 102.11 | 93.48 | 109.28 | 119.44 |

| 5 | 109.87 | 100.65 | 117.79 | 131.54 |

| 6 | 113.62 | 103.73 | 121.98 | 140.23 |

| 7 | 113.66 | 105.18 | 122.27 | 144.08 |

| 8 | 112.08 | 105.77 | 120.8 | 144.23 |

| 9 | 111.43 | 107.12 | 119.89 | 142.5 |

| 10 | 111.37 | 108.42 | 119.57 | 141.43 |

| 11 | 110.23 | 107.28 | 118.65 | 140.76 |

| 12 | 109.27 | 106.75 | 117.5 | 138.35 |

| 13 | 109.48 | 106.83 | 117.18 | 137.52 |

| 14 | 109.58 | 106.92 | 118.18 | 139.25 |

| 15 | 110.89 | 106.56 | 122.27 | 145.27 |

| 16 | 115 | 106.78 | 129.03 | 147.42 |

| 17 | 122.61 | 108.34 | 131.07 | 146.1 |

| 18 | 123.96 | 112.55 | 126.05 | 141.28 |

| 19 | 115.23 | 107.5 | 116.42 | 132.6 |

| 20 | 104.68 | 98.87 | 106.83 | 116.06 |

| 21 | 97.39 | 92.15 | 99.73 | 117.45 |

| 22 | 93.95 | 88.38 | 96.31 | 111.17 |

| 23 | 91.62 | 85.94 | 93.93 | 107.87 |

| 24 | 90.3 | 86.13 | 91.24 | 105.33 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 50 | 0 | 70 | 80 |

| 2 | 0 | 50 | 0 | 70 | 80 |

| 3 | 0 | 50 | 0 | 70 | 80 |

| 4 | 0 | 50 | 0 | 70 | 80 |

| 5 | 0 | 50 | 0 | 70 | 80 |

| 6 | 0 | 50 | 0 | 70 | 80 |

| 7 | 14 | 50 | 12 | 70 | 80 |

| 8 | 24 | 50 | 20 | 70 | 80 |

| 9 | 36 | 50 | 30 | 70 | 80 |

| 10 | 50 | 50 | 40 | 70 | 80 |

| 11 | 70 | 50 | 52 | 70 | 80 |

| 12 | 84 | 50 | 66 | 70 | 80 |

| 13 | 66 | 50 | 48 | 70 | 80 |

| 14 | 56 | 50 | 40 | 70 | 80 |

| 15 | 42 | 50 | 32 | 70 | 80 |

| 16 | 28 | 50 | 22 | 70 | 80 |

| 17 | 16 | 50 | 10 | 70 | 80 |

| 18 | 0 | 50 | 0 | 70 | 80 |

| 19 | 0 | 50 | 0 | 70 | 80 |

| 20 | 0 | 50 | 0 | 70 | 80 |

| 21 | 0 | 50 | 0 | 70 | 80 |

| 22 | 0 | 50 | 0 | 70 | 80 |

| 23 | 0 | 50 | 0 | 70 | 80 |

| 24 | 0 | 50 | 0 | 70 | 80 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 25 | 0 | 35 | 45 |

| 2 | 0 | 25 | 0 | 35 | 45 |

| 3 | 0 | 25 | 0 | 35 | 45 |

| 4 | 0 | 25 | 0 | 35 | 45 |

| 5 | 0 | 25 | 0 | 35 | 45 |

| 6 | 10 | 25 | 6 | 35 | 45 |

| 7 | 22 | 25 | 16 | 35 | 45 |

| 8 | 38 | 25 | 24 | 35 | 45 |

| 9 | 54 | 25 | 36 | 35 | 45 |

| 10 | 68 | 25 | 50 | 35 | 45 |

| 11 | 82 | 25 | 64 | 35 | 45 |

| 12 | 100 | 25 | 80 | 35 | 45 |

| 13 | 84 | 25 | 66 | 35 | 45 |

| 14 | 72 | 25 | 52 | 35 | 45 |

| 15 | 58 | 25 | 38 | 35 | 45 |

| 16 | 42 | 25 | 30 | 35 | 45 |

| 17 | 26 | 25 | 20 | 35 | 45 |

| 18 | 14 | 25 | 8 | 35 | 45 |

| 19 | 0 | 25 | 0 | 35 | 45 |

| 20 | 0 | 25 | 0 | 35 | 45 |

| 21 | 0 | 25 | 0 | 35 | 45 |

| 22 | 0 | 25 | 0 | 35 | 45 |

| 23 | 0 | 25 | 0 | 35 | 45 |

| 24 | 0 | 25 | 0 | 35 | 45 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 28 | 0 | 38 | 48 |

| 2 | 0 | 28 | 0 | 38 | 48 |

| 3 | 0 | 28 | 0 | 38 | 48 |

| 4 | 0 | 28 | 0 | 38 | 48 |

| 5 | 0 | 28 | 0 | 38 | 48 |

| 6 | 0 | 28 | 0 | 38 | 48 |

| 7 | 10 | 28 | 6 | 38 | 48 |

| 8 | 18 | 28 | 10 | 38 | 48 |

| 9 | 32 | 28 | 16 | 38 | 48 |

| 10 | 42 | 28 | 24 | 38 | 48 |

| 11 | 56 | 28 | 34 | 38 | 48 |

| 12 | 68 | 28 | 46 | 38 | 48 |

| 13 | 58 | 28 | 36 | 38 | 48 |

| 14 | 44 | 28 | 26 | 38 | 48 |

| 15 | 36 | 28 | 18 | 38 | 48 |

| 16 | 22 | 28 | 12 | 38 | 48 |

| 17 | 12 | 28 | 8 | 38 | 48 |

| 18 | 0 | 28 | 0 | 38 | 48 |

| 19 | 0 | 28 | 0 | 38 | 48 |

| 20 | 0 | 28 | 0 | 38 | 48 |

| 21 | 0 | 28 | 0 | 38 | 48 |

| 22 | 0 | 28 | 0 | 38 | 48 |

| 23 | 0 | 28 | 0 | 38 | 48 |

| 24 | 0 | 28 | 0 | 38 | 48 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 30 | 0 | 40 | 50 |

| 2 | 0 | 30 | 0 | 40 | 50 |

| 3 | 0 | 30 | 0 | 40 | 50 |

| 4 | 0 | 30 | 0 | 40 | 50 |

| 5 | 0 | 30 | 0 | 40 | 50 |

| 6 | 0 | 30 | 0 | 40 | 50 |

| 7 | 0 | 30 | 0 | 40 | 50 |

| 8 | 10 | 30 | 6 | 40 | 50 |

| 9 | 24 | 30 | 14 | 40 | 50 |

| 10 | 32 | 30 | 22 | 40 | 50 |

| 11 | 42 | 30 | 28 | 40 | 50 |

| 12 | 50 | 30 | 34 | 40 | 50 |

| 13 | 38 | 30 | 30 | 40 | 50 |

| 14 | 26 | 30 | 24 | 40 | 50 |

| 15 | 16 | 30 | 12 | 40 | 50 |

| 16 | 0 | 30 | 0 | 40 | 50 |

| 17 | 0 | 30 | 0 | 40 | 50 |

| 18 | 0 | 30 | 0 | 40 | 50 |

| 19 | 0 | 30 | 0 | 40 | 50 |

| 20 | 0 | 30 | 0 | 40 | 50 |

| 21 | 0 | 30 | 0 | 40 | 50 |

| 22 | 0 | 30 | 0 | 40 | 50 |

| 23 | 0 | 30 | 0 | 40 | 50 |

| 24 | 0 | 30 | 0 | 40 | 50 |

| Source | gc (EUR/kWh) |

|---|---|

| PV 1 | 0.047 |

| PV 2 | 0.0473 |

| MH 1 | 0.0481 |

| MH 2 | 0.0478 |

| MH 3 | 0.0475 |

| Hydrogen fuel cell | 3.26 |

| Power grid | 0.08 |

| Power Plant Type | Carbon Dioxide Emissions |

|---|---|

| Hydro | 12 gCO2/kWh |

| Solar | 50 gCO2/kWh |

| Power grid | 203 gCO2/kWh |

| Hydro-powered electrolysis | 300 gCO2/kg |

| Solar-powered electrolysis | 1800 gCO2/kg |

| Steam reforming of natural gas | 9000 gCO2/kg |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 0 | 0 | 10.59 | 80 |

| 2 | 0 | 0 | 0 | 11.74 | 80 |

| 3 | 0 | 0 | 0 | 14.43 | 80 |

| 4 | 0 | 0 | 0 | 22.11 | 80 |

| 5 | 0 | 0 | 0 | 29.87 | 80 |

| 6 | 0 | 0 | 0 | 33.62 | 80 |

| 7 | 14 | 0 | 12 | 7.66 | 80 |

| 8 | 24 | 0 | 20 | 0 | 68.08 |

| 9 | 36 | 0 | 30 | 0 | 45.43 |

| 10 | 50 | 0 | 40 | 0 | 21.37 |

| 11 | 70 | 0 | 40.23 | 0 | 0 |

| 12 | 84 | 0 | 25.27 | 0 | 0 |

| 13 | 66 | 0 | 43.48 | 0 | 0 |

| 14 | 56 | 0 | 40 | 0 | 13.58 |

| 15 | 42 | 0 | 32 | 0 | 36.89 |

| 16 | 28 | 0 | 22 | 0 | 65 |

| 17 | 16 | 0 | 10 | 16.61 | 80 |

| 18 | 0 | 0 | 0 | 43.96 | 80 |

| 19 | 0 | 0 | 0 | 35.23 | 80 |

| 20 | 0 | 0 | 0 | 24.68 | 80 |

| 21 | 0 | 0 | 0 | 17.39 | 80 |

| 22 | 0 | 0 | 0 | 13.95 | 80 |

| 23 | 0 | 0 | 0 | 11.62 | 80 |

| 24 | 0 | 0 | 0 | 10.3 | 80 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 6.52 | 0 | 35 | 45 |

| 2 | 0 | 5.99 | 0 | 35 | 45 |

| 3 | 0 | 7.25 | 0 | 35 | 45 |

| 4 | 0 | 13.48 | 0 | 35 | 45 |

| 5 | 0 | 20.65 | 0 | 35 | 45 |

| 6 | 10 | 7.73 | 6 | 35 | 45 |

| 7 | 22 | 0 | 16 | 22.18 | 45 |

| 8 | 38 | 0 | 24 | 0 | 43.77 |

| 9 | 54 | 0 | 36 | 0 | 17.12 |

| 10 | 68 | 0 | 40.42 | 0 | 0 |

| 11 | 82 | 0 | 25.28 | 0 | 0 |

| 12 | 100 | 0 | 6.75 | 0 | 0 |

| 13 | 84 | 0 | 22.83 | 0 | 0 |

| 14 | 72 | 0 | 34.92 | 0 | 0 |

| 15 | 58 | 0 | 38 | 0 | 10.56 |

| 16 | 42 | 0 | 30 | 0 | 34.78 |

| 17 | 26 | 0 | 20 | 17.34 | 45 |

| 18 | 14 | 10.55 | 8 | 35 | 45 |

| 19 | 0 | 25 | 0 | 35 | 45 |

| 20 | 0 | 18.87 | 0 | 35 | 45 |

| 21 | 0 | 12.15 | 0 | 35 | 45 |

| 22 | 0 | 8.38 | 0 | 35 | 45 |

| 23 | 0 | 5.94 | 0 | 35 | 45 |

| 24 | 0 | 6.13 | 0 | 35 | 45 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 5.33 | 0 | 38 | 48 |

| 2 | 0 | 7.66 | 0 | 38 | 48 |

| 3 | 0 | 13.28 | 0 | 38 | 48 |

| 4 | 0 | 23.28 | 0 | 38 | 48 |

| 5 | 0 | 28 | 0 | 38 | 48 |

| 6 | 0 | 28 | 0 | 38 | 48 |

| 7 | 10 | 20.27 | 6 | 38 | 48 |

| 8 | 18 | 6.8 | 10 | 38 | 48 |

| 9 | 32 | 0 | 16 | 23.89 | 48 |

| 10 | 42 | 0 | 24 | 5.57 | 48 |

| 11 | 56 | 0 | 34 | 0 | 28.65 |

| 12 | 68 | 0 | 46 | 0 | 3.5 |

| 13 | 58 | 0 | 36 | 0 | 23.18 |

| 14 | 44 | 0 | 26 | 0.18 | 48 |

| 15 | 36 | 0 | 18 | 20.27 | 48 |

| 16 | 22 | 9.03 | 12 | 38 | 48 |

| 17 | 12 | 25.07 | 8 | 38 | 48 |

| 18 | 0 | 28 | 0 | 38 | 48 |

| 19 | 0 | 28 | 0 | 38 | 48 |

| 20 | 0 | 20.83 | 0 | 38 | 48 |

| 21 | 0 | 13.73 | 0 | 38 | 48 |

| 22 | 0 | 10.31 | 0 | 38 | 48 |

| 23 | 0 | 7.93 | 0 | 38 | 48 |

| 24 | 0 | 5.24 | 0 | 38 | 48 |

| Hour (h) | Power Supplied [kw] | ||||

|---|---|---|---|---|---|

| PV1 | MH1 | PV2 | MH2 | MH3 | |

| 1 | 0 | 15.5 | 0 | 40 | 50 |

| 2 | 0 | 16.38 | 0 | 40 | 50 |

| 3 | 0 | 19.86 | 0 | 40 | 50 |

| 4 | 0 | 29.44 | 0 | 40 | 50 |

| 5 | 0 | 30 | 0 | 40 | 50 |

| 6 | 0 | 30 | 0 | 40 | 50 |

| 7 | 0 | 30 | 0 | 40 | 50 |

| 8 | 10 | 30 | 6 | 40 | 50 |

| 9 | 24 | 14.5 | 14 | 40 | 50 |

| 10 | 32 | 0 | 22 | 37.43 | 50 |

| 11 | 42 | 0 | 28 | 20.76 | 50 |

| 12 | 50 | 0 | 34 | 4.35 | 50 |

| 13 | 38 | 0 | 30 | 19.52 | 50 |

| 14 | 26 | 0 | 24 | 39.25 | 50 |

| 15 | 16 | 27.27 | 12 | 40 | 50 |

| 16 | 0 | 30 | 0 | 40 | 50 |

| 17 | 0 | 30 | 0 | 40 | 50 |

| 18 | 0 | 30 | 0 | 40 | 50 |

| 19 | 0 | 30 | 0 | 40 | 50 |

| 20 | 0 | 26.06 | 0 | 40 | 50 |

| 21 | 0 | 27.45 | 0 | 40 | 50 |

| 22 | 0 | 21.17 | 0 | 40 | 50 |

| 23 | 0 | 17.87 | 0 | 40 | 50 |

| 24 | 0 | 15.33 | 0 | 40 | 50 |

| Hour (h) | Power Surplus [kw] | |||

|---|---|---|---|---|

| MH1 | PV2 | MH2 | MH3 | |

| 1 | 50 | 0 | 59.41 | 0 |

| 2 | 50 | 0 | 58.26 | 0 |

| 3 | 50 | 0 | 55.57 | 0 |

| 4 | 50 | 0 | 47.89 | 0 |

| 5 | 50 | 0 | 40.13 | 0 |

| 6 | 50 | 0 | 36.38 | 0 |

| 7 | 50 | 0 | 62.34 | 0 |

| 8 | 50 | 0 | 70 | 11.92 |

| 9 | 50 | 0 | 70 | 34.57 |

| 10 | 50 | 0 | 70 | 58.63 |

| 11 | 50 | 11.77 | 70 | 80 |

| 12 | 50 | 40.73 | 70 | 80 |

| 13 | 50 | 4.52 | 70 | 80 |

| 14 | 50 | 0 | 70 | 66.42 |

| 15 | 50 | 0 | 70 | 43.11 |

| 16 | 50 | 0 | 70 | 15 |

| 17 | 50 | 0 | 53.39 | 0 |

| 18 | 50 | 0 | 26.04 | 0 |

| 19 | 50 | 0 | 34.77 | 0 |

| 20 | 50 | 0 | 45.32 | 0 |

| 21 | 50 | 0 | 52.61 | 0 |

| 22 | 50 | 0 | 56.05 | 0 |

| 23 | 50 | 0 | 58.38 | 0 |

| 24 | 50 | 0 | 59.7 | 0 |

| Hour (h) | Power Surplus [kw] | |||

|---|---|---|---|---|

| MH1 | PV2 | MH2 | MH3 | |

| 1 | 18.48 | 0 | 0 | 0 |

| 2 | 19.01 | 0 | 0 | 0 |

| 3 | 17.75 | 0 | 0 | 0 |

| 4 | 11.52 | 0 | 0 | 0 |

| 5 | 4.35 | 0 | 0 | 0 |

| 6 | 17.27 | 0 | 0 | 0 |

| 7 | 25 | 0 | 12.82 | 0 |

| 8 | 25 | 0 | 35 | 1.23 |

| 9 | 25 | 0 | 35 | 27.88 |

| 10 | 25 | 9.58 | 35 | 45 |

| 11 | 25 | 24.72 | 35 | 45 |

| 12 | 25 | 73.25 | 35 | 45 |

| 13 | 25 | 43.17 | 35 | 45 |

| 14 | 25 | 17.08 | 35 | 45 |

| 15 | 25 | 0 | 35 | 34.44 |

| 16 | 25 | 0 | 35 | 10.22 |

| 17 | 25 | 0 | 17.66 | 0 |

| 18 | 14.45 | 0 | 0 | 0 |

| 19 | 0 | 0 | 0 | 0 |

| 20 | 6.13 | 0 | 0 | 0 |

| 21 | 12.85 | 0 | 0 | 0 |

| 22 | 16.62 | 0 | 0 | 0 |

| 23 | 19.06 | 0 | 0 | 0 |

| 24 | 18.87 | 0 | 0 | 0 |

| Hour (h) | Power Surplus [kw] | ||

|---|---|---|---|

| MH1 | MH2 | MH3 | |

| 1 | 22.67 | 0 | 0 |

| 2 | 20.34 | 0 | 0 |

| 3 | 14.72 | 0 | 0 |

| 4 | 4.72 | 0 | 0 |

| 5 | 0 | 0 | 0 |

| 6 | 0 | 0 | 0 |

| 7 | 7.73 | 0 | 0 |

| 8 | 21.2 | 0 | 0 |

| 9 | 28 | 14.11 | 0 |

| 10 | 28 | 32.43 | 0 |

| 11 | 28 | 38 | 19.35 |

| 12 | 28 | 38 | 44.5 |

| 13 | 28 | 38 | 24.82 |

| 14 | 28 | 37.82 | 0 |

| 15 | 28 | 17.73 | 0 |

| 16 | 18.97 | 0 | 0 |

| 17 | 2.93 | 0 | 0 |

| 18 | 0 | 0 | 0 |

| 19 | 0 | 0 | 0 |

| 20 | 7.17 | 0 | 0 |

| 21 | 14.27 | 0 | 0 |

| 22 | 17.69 | 0 | 0 |

| 23 | 20.07 | 0 | 0 |

| 24 | 22.76 | 0 | 0 |

| Hour (h) | Power Surplus [kw] | |

|---|---|---|

| MH1 | MH2 | |

| 1 | 14.5 | 0 |

| 2 | 13.62 | 0 |

| 3 | 10.14 | 0 |

| 4 | 0.56 | 0 |

| 5 | 0 | 0 |

| 6 | 0 | 0 |

| 7 | 0 | 0 |

| 8 | 0 | 0 |

| 9 | 15.5 | 0 |

| 10 | 30 | 2.57 |

| 11 | 30 | 19.24 |

| 12 | 30 | 35.65 |

| 13 | 30 | 20.48 |

| 14 | 30 | 0.75 |

| 15 | 2.73 | 0 |

| 16 | 0 | 0 |

| 17 | 0 | 0 |

| 18 | 0 | 0 |

| 19 | 0 | 0 |

| 20 | 3.94 | 0 |

| 21 | 2.55 | 0 |

| 22 | 8.83 | 0 |

| 23 | 12.13 | 0 |

| 24 | 14.67 | 0 |

| Hour (h) | Hydrogen Produced (Spring) (kg) | Hydrogen Produced (Summer) (kg) | Hydrogen Produced (Autumn) (kg) | Hydrogen Produced (Winter) (kg) |

|---|---|---|---|---|

| 1 | 2.1882 | 0.3696 | 0.4534 | 0.29 |

| 2 | 2.1652 | 0.3802 | 0.4068 | 0.2724 |

| 3 | 2.1114 | 0.355 | 0.2944 | 0.2028 |

| 4 | 1.9578 | 0.2304 | 0.0944 | 0.0112 |

| 5 | 1.8026 | 0.087 | 0 | 0 |

| 6 | 1.7276 | 0.3454 | 0 | 0 |

| 7 | 2.2468 | 0.7564 | 0.1546 | 0 |

| 8 | 2.6384 | 1.2246 | 0.424 | 0 |

| 9 | 3.0914 | 1.7576 | 0.8422 | 0.31 |

| 10 | 3.5726 | 2.2916 | 1.2086 | 0.6514 |

| 11 | 4.2354 | 2.5944 | 1.707 | 0.9848 |

| 12 | 4.8146 | 3.565 | 2.21 | 1.313 |

| 13 | 4.0904 | 2.9634 | 1.8164 | 1.0096 |

| 14 | 3.7284 | 2.4416 | 1.3164 | 0.615 |

| 15 | 3.2622 | 1.8888 | 0.9146 | 0.0546 |

| 16 | 2.7 | 1.4044 | 0.3794 | 0 |

| 17 | 2.0678 | 0.8532 | 0.0586 | 0 |

| 18 | 1.5208 | 0.289 | 0 | 0 |

| 19 | 1.6954 | 0 | 0 | 0 |

| 20 | 1.9064 | 0.1226 | 0.1434 | 0.0788 |

| 21 | 2.0522 | 0.257 | 0.2854 | 0.051 |

| 22 | 2.121 | 0.3324 | 0.3538 | 0.1766 |

| 23 | 2.1676 | 0.3812 | 0.4014 | 0.2426 |

| 24 | 2.194 | 0.3774 | 0.4552 | 0.2934 |

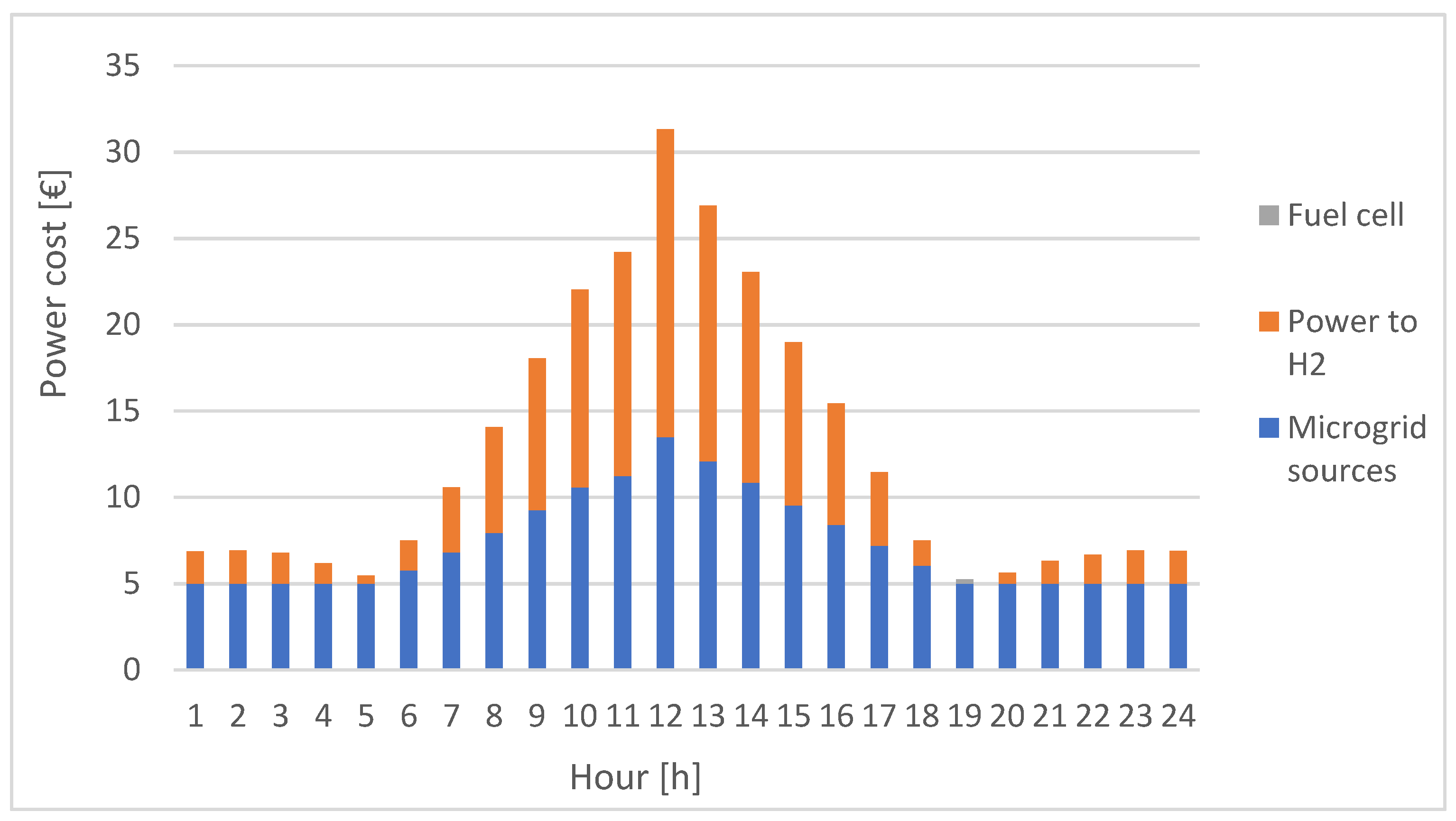

| Hour (h) | Power Cost [EUR] | |

|---|---|---|

| Microgrid Sources | Power to H2 | |

| 1 | 9.551 | 10.941 |

| 2 | 9.551 | 10.826 |

| 3 | 9.551 | 10.557 |

| 4 | 9.551 | 9.789 |

| 5 | 9.551 | 9.013 |

| 6 | 9.551 | 8.638 |

| 7 | 10.7766 | 11.234 |

| 8 | 11.625 | 13.192 |

| 9 | 12.662 | 15.457 |

| 10 | 13.793 | 17.863 |

| 11 | 15.3006 | 21.177 |

| 12 | 16.6208 | 24.073 |

| 13 | 14.9234 | 20.452 |

| 14 | 14.075 | 18.642 |

| 15 | 13.0386 | 16.311 |

| 16 | 11.9076 | 13.5 |

| 17 | 10.776 | 10.339 |

| 18 | 9.551 | 7.604 |

| 19 | 9.551 | 8.477 |

| 20 | 9.551 | 9.532 |

| 21 | 9.551 | 10.261 |

| 22 | 9.551 | 10.605 |

| 23 | 9.551 | 10.838 |

| 24 | 9.551 | 10.97 |

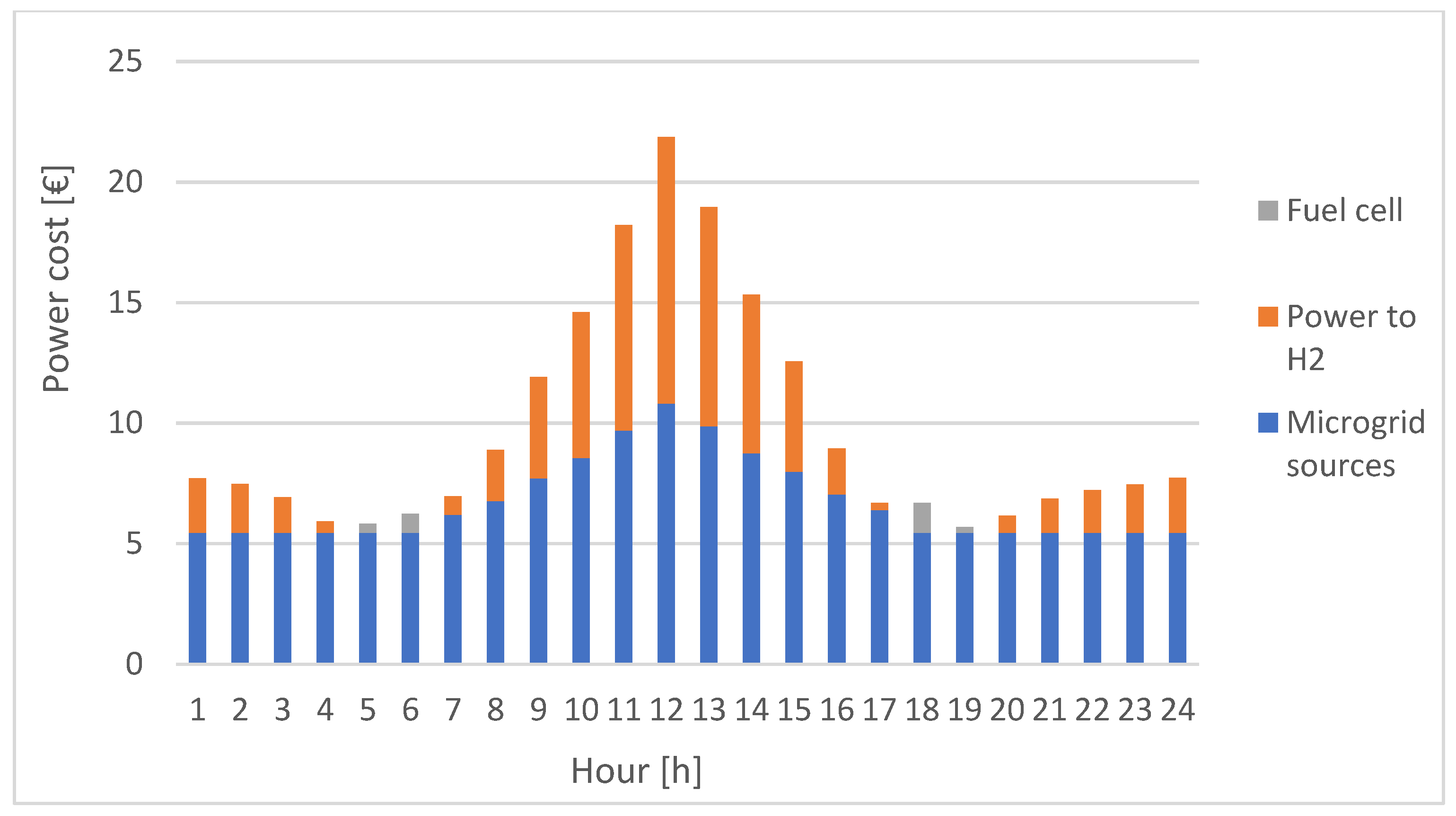

| Hour (h) | Power Cost [EUR] | ||

|---|---|---|---|

| Microgrid Sources | Power to H2 | Fuel Cell | |

| 1 | 5.013 | 1.848 | 0 |

| 2 | 5.013 | 1.901 | 0 |

| 3 | 5.013 | 1.775 | 0 |

| 4 | 5.013 | 1.152 | 0 |

| 5 | 5.013 | 0.435 | 0 |

| 6 | 5.7668 | 1.727 | 0 |

| 7 | 6.8038 | 3.782 | 0 |

| 8 | 7.9342 | 6.123 | 0 |

| 9 | 9.2538 | 8.788 | 0 |

| 10 | 10.574 | 11.458 | 0 |

| 11 | 11.232 | 12.972 | 0 |

| 12 | 13.497 | 17.825 | 0 |

| 13 | 12.0828 | 14.817 | 0 |

| 14 | 10.8566 | 12.208 | 0 |

| 15 | 9.5364 | 9.444 | 0 |

| 16 | 8.406 | 7.022 | 0 |

| 17 | 7.181 | 4.266 | 0 |

| 18 | 6.0494 | 1.445 | 0 |

| 19 | 5.013 | 0 | 0.24776 |

| 20 | 5.013 | 0.613 | 0 |

| 21 | 5.013 | 1.285 | 0 |

| 22 | 5.013 | 1.662 | 0 |

| 23 | 5.013 | 1.906 | 0 |

| 24 | 5.013 | 1.887 | 0 |

| Hour (h) | Power Cost [EUR] | ||

|---|---|---|---|

| Microgrid Sources | Power to H2 | Fuel Cell | |

| 1 | 5.4432 | 2.267 | 0 |

| 2 | 5.4432 | 2.034 | 0 |

| 3 | 5.4432 | 1.472 | 0 |

| 4 | 5.4432 | 0.472 | 0 |

| 5 | 5.4432 | 0 | 0.374574 |

| 6 | 5.4432 | 0 | 0.788594 |

| 7 | 6.197 | 0.773 | 0 |

| 8 | 6.7622 | 2.12 | 0 |

| 9 | 7.704 | 4.211 | 0 |

| 10 | 8.5524 | 6.043 | 0 |

| 11 | 9.6834 | 8.535 | 0 |

| 12 | 10.815 | 11.05 | 0 |

| 13 | 9.872 | 9.082 | 0 |

| 14 | 8.741 | 6.582 | 0 |

| 15 | 7.9866 | 4.573 | 0 |

| 16 | 7.0448 | 1.897 | 0 |

| 17 | 6.3856 | 0.293 | 0 |

| 18 | 5.4432 | 0 | 1.234888 |

| 19 | 5.4432 | 0 | 0.239284 |

| 20 | 5.4432 | 0.717 | 0 |

| 21 | 5.4432 | 1.427 | 0 |

| 22 | 5.4432 | 1.769 | 0 |

| 23 | 5.4432 | 2.007 | 0 |

| 24 | 5.4432 | 2.276 | 0 |

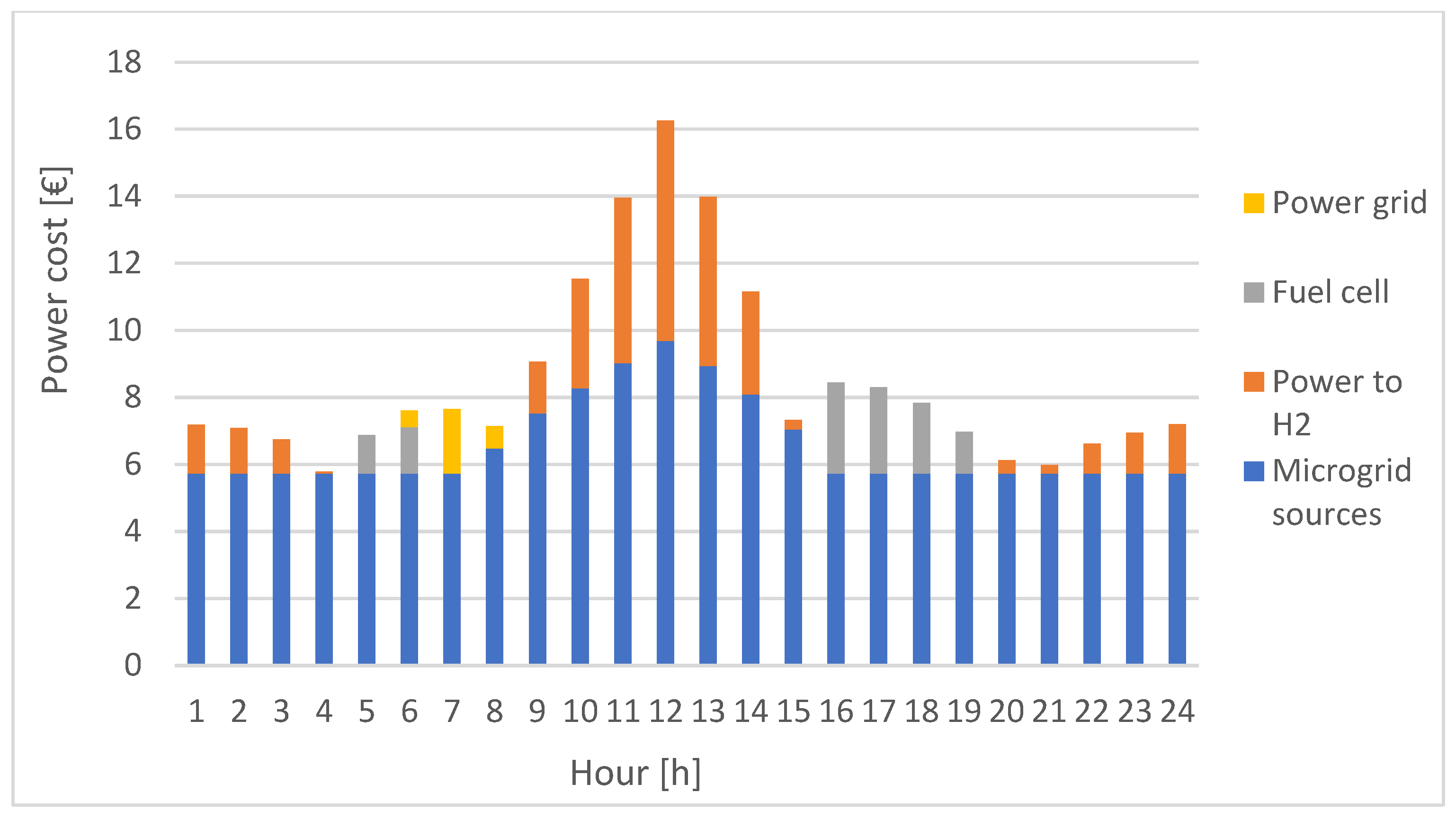

| Hour (h) | Power Cost [EUR] | |||

|---|---|---|---|---|

| Microgrid Sources | Power to H2 | Fuel Cell | Power Grid | |

| 1 | 5.73 | 1.45 | 0 | 0 |

| 2 | 5.73 | 1.362 | 0 | 0 |

| 3 | 5.73 | 1.014 | 0 | 0 |

| 4 | 5.73 | 0.056 | 0 | 0 |

| 5 | 5.73 | 0 | 1.140022 | 0 |

| 6 | 5.73 | 0 | 1.391042 | 0.492 |

| 7 | 5.73 | 0 | 0 | 1.9264 |

| 8 | 6.4838 | 0 | 0 | 0.6584 |

| 9 | 7.5202 | 1.55 | 0 | 0 |

| 10 | 8.2746 | 3.257 | 0 | 0 |

| 11 | 9.0284 | 4.924 | 0 | 0 |

| 12 | 9.6882 | 6.565 | 0 | 0 |

| 13 | 8.935 | 5.048 | 0 | 0 |

| 14 | 8.0872 | 3.075 | 0 | 0 |

| 15 | 7.0496 | 0.273 | 0 | 0 |

| 16 | 5.73 | 0 | 2.70906 | 0 |

| 17 | 5.73 | 0 | 2.57866 | 0 |

| 18 | 5.73 | 0 | 2.102374 | 0 |

| 19 | 5.73 | 0 | 1.244994 | 0 |

| 20 | 5.73 | 0.394 | 0 | 0 |

| 21 | 5.73 | 0.255 | 0 | 0 |

| 22 | 5.73 | 0.883 | 0 | 0 |

| 23 | 5.73 | 1.213 | 0 | 0 |

| 24 | 5.73 | 1.467 | 0 | 0 |

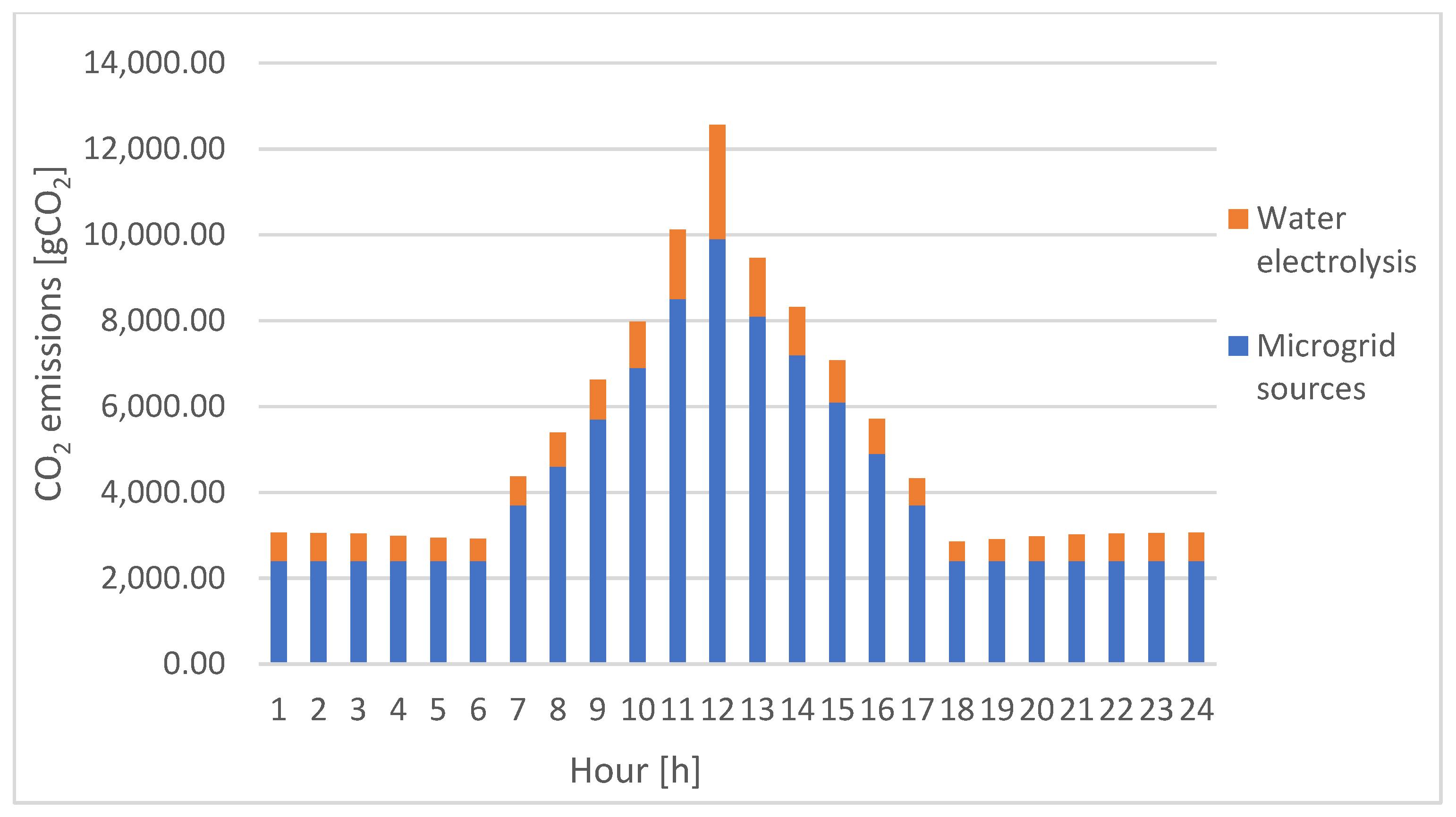

| Hour (h) | CO2 Emissions [gCO2] | |

|---|---|---|

| Microgrid Sources | Water Electrolysis | |

| 1 | 2400 | 656.46 |

| 2 | 2400 | 649.56 |

| 3 | 2400 | 633.42 |

| 4 | 2400 | 587.34 |

| 5 | 2400 | 540.78 |

| 6 | 2400 | 518.28 |

| 7 | 3700 | 674.04 |

| 8 | 4600 | 791.52 |

| 9 | 5700 | 927.42 |

| 10 | 6900 | 1071.78 |

| 11 | 8500 | 1623.72 |

| 12 | 9900 | 2666.28 |

| 13 | 8100 | 1362.72 |

| 14 | 7200 | 1118.52 |

| 15 | 6100 | 978.66 |

| 16 | 4900 | 810 |

| 17 | 3700 | 620.34 |

| 18 | 2400 | 456.24 |

| 19 | 2400 | 508.62 |

| 20 | 2400 | 571.92 |

| 21 | 2400 | 615.66 |

| 22 | 2400 | 636.3 |

| 23 | 2400 | 650.28 |

| 24 | 2400 | 658.2 |

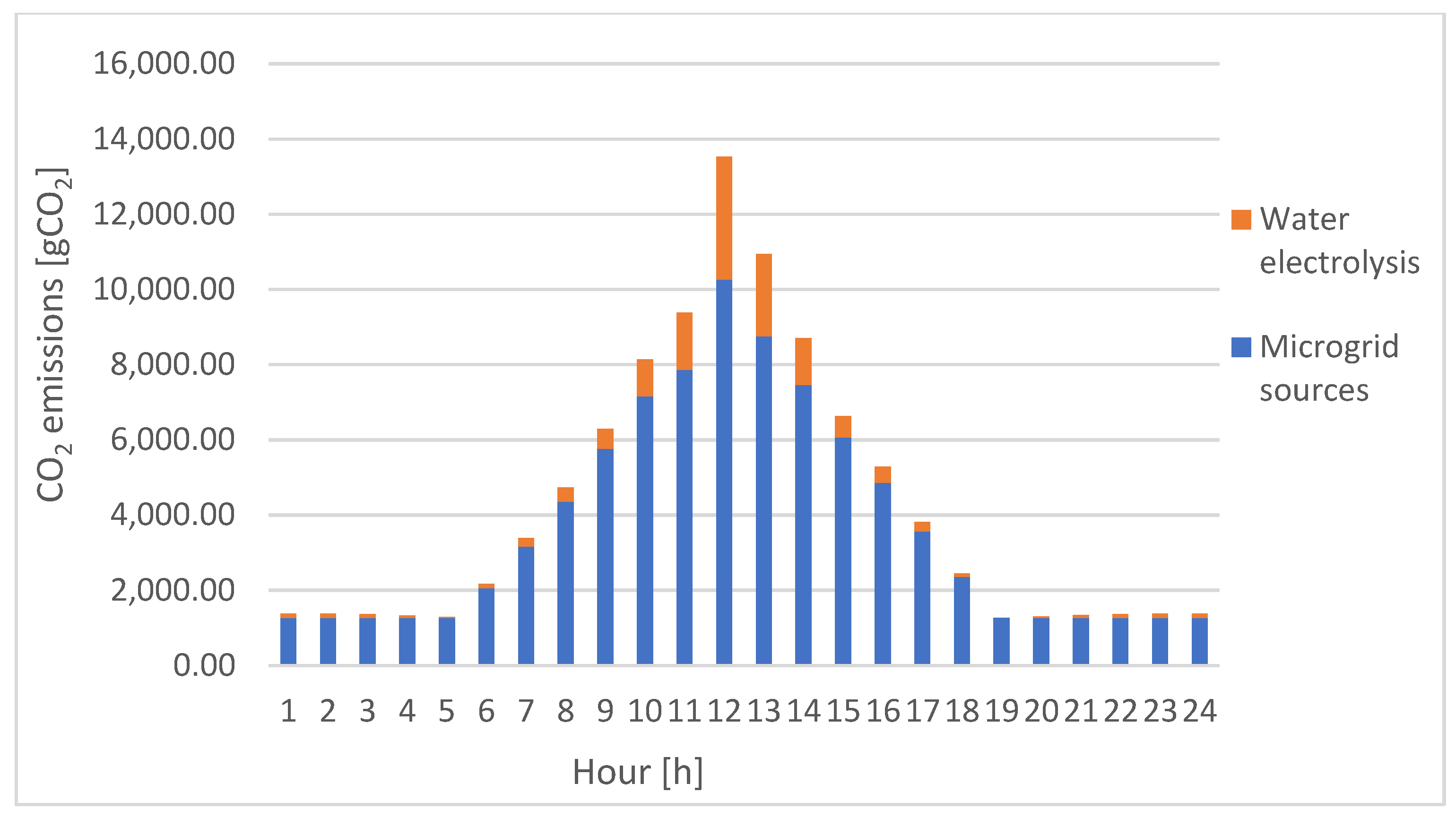

| Hour (h) | CO2 Emissions [gCO2] | |

|---|---|---|

| Microgrid Sources | Water Electrolysis | |

| 1 | 1260 | 110.88 |

| 2 | 1260 | 114.06 |

| 3 | 1260 | 106.5 |

| 4 | 1260 | 69.12 |

| 5 | 1260 | 26.1 |

| 6 | 2060 | 103.62 |

| 7 | 3160 | 226.92 |

| 8 | 4360 | 367.38 |

| 9 | 5760 | 527.28 |

| 10 | 7160 | 974.88 |

| 11 | 7860 | 1519.92 |

| 12 | 10,260 | 3267 |

| 13 | 8760 | 2184.12 |

| 14 | 7460 | 1244.88 |

| 15 | 6060 | 566.64 |

| 16 | 4860 | 421.32 |

| 17 | 3560 | 255.96 |

| 18 | 2360 | 86.7 |

| 19 | 1260 | 0 |

| 20 | 1260 | 36.78 |

| 21 | 1260 | 77.1 |

| 22 | 1260 | 99.72 |

| 23 | 1260 | 114.36 |

| 24 | 1260 | 113.22 |

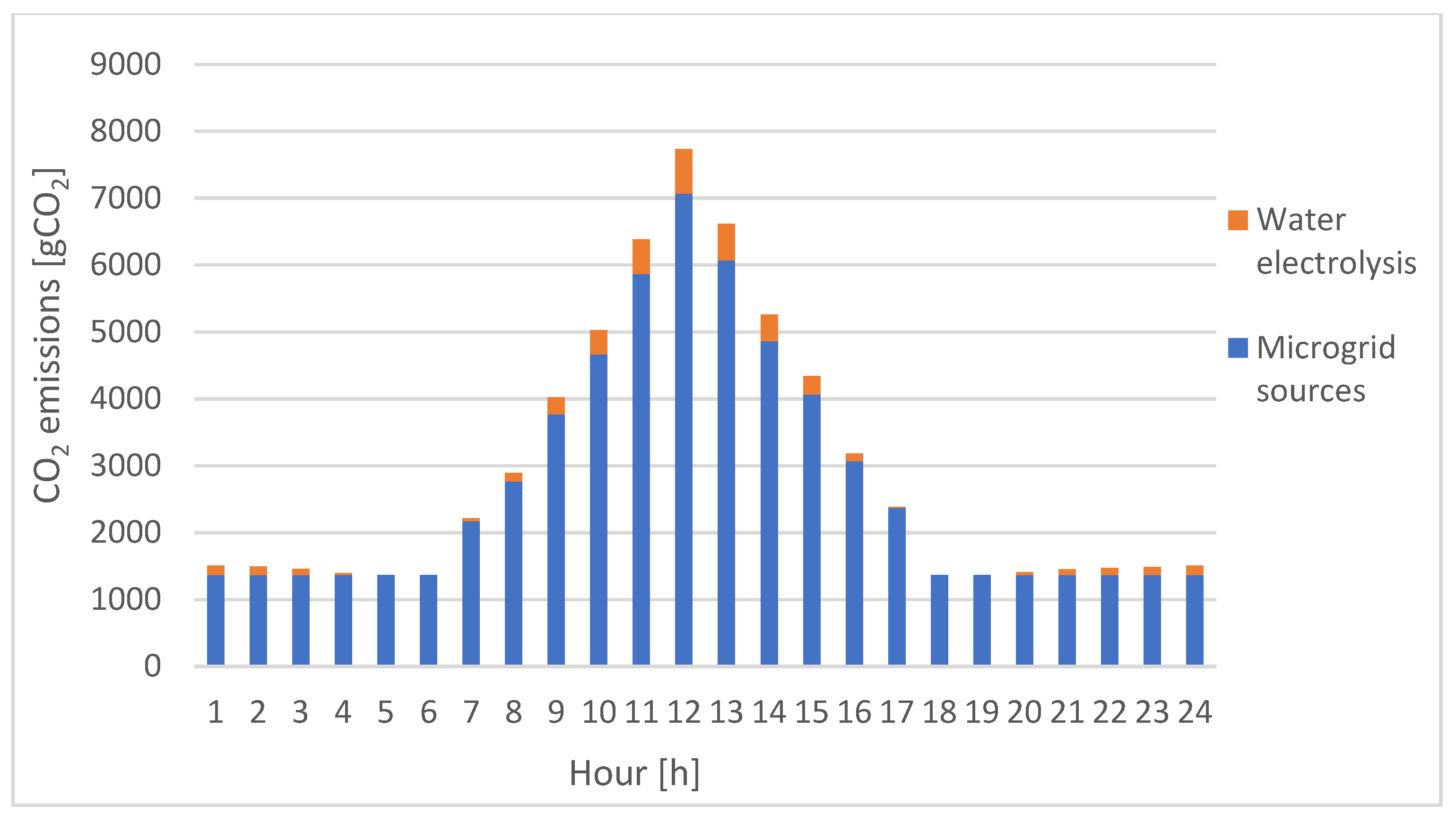

| Hour (h) | CO2 Emissions [gCO2] | |

|---|---|---|

| Microgrid Sources | Water Electrolysis | |

| 1 | 1368 | 136.02 |

| 2 | 1368 | 122.04 |

| 3 | 1368 | 88.32 |

| 4 | 1368 | 28.32 |

| 5 | 1368 | 0 |

| 6 | 1368 | 0 |

| 7 | 2168 | 46.38 |

| 8 | 2768 | 127.2 |

| 9 | 3768 | 252.66 |

| 10 | 4668 | 362.58 |

| 11 | 5868 | 512.1 |

| 12 | 7068 | 663 |

| 13 | 6068 | 544.92 |

| 14 | 4868 | 394.92 |

| 15 | 4068 | 274.38 |

| 16 | 3068 | 113.82 |

| 17 | 2368 | 17.58 |

| 18 | 1368 | 0 |

| 19 | 1368 | 0 |

| 20 | 1368 | 43.02 |

| 21 | 1368 | 85.62 |

| 22 | 1368 | 106.14 |

| 23 | 1368 | 120.42 |

| 24 | 1368 | 136.56 |

| Hour (h) | CO2 Emissions [gCO2] | ||

|---|---|---|---|

| Microgrid Sources | Water Electrolysis | Power Grid | |

| 1 | 1440 | 87 | 0 |

| 2 | 1440 | 81.72 | 0 |

| 3 | 1440 | 60.84 | 0 |

| 4 | 1440 | 3.36 | 0 |

| 5 | 1440 | 0 | 0 |

| 6 | 1440 | 0 | 1248.45 |

| 7 | 1440 | 0 | 4888.24 |

| 8 | 2240 | 0 | 1670.69 |

| 9 | 3340 | 93 | 0 |

| 10 | 4140 | 195.42 | 0 |

| 11 | 4940 | 295.44 | 0 |

| 12 | 5640 | 393.9 | 0 |

| 13 | 4840 | 302.88 | 0 |

| 14 | 3940 | 184.5 | 0 |

| 15 | 2840 | 16.38 | 0 |

| 16 | 1440 | 0 | 0 |

| 17 | 1440 | 0 | 0 |

| 18 | 1440 | 0 | 0 |

| 19 | 1440 | 0 | 0 |

| 20 | 1440 | 23.64 | 0 |

| 21 | 1440 | 15.3 | 0 |

| 22 | 1440 | 52.98 | 0 |

| 23 | 1440 | 72.78 | 0 |

| 24 | 1440 | 88.02 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dulău, L.-I. Power Cost and CO2 Emissions for a Microgrid with Hydrogen Storage and Electric Vehicles. Sustainability 2023, 15, 15750. https://doi.org/10.3390/su152215750

Dulău L-I. Power Cost and CO2 Emissions for a Microgrid with Hydrogen Storage and Electric Vehicles. Sustainability. 2023; 15(22):15750. https://doi.org/10.3390/su152215750

Chicago/Turabian StyleDulău, Lucian-Ioan. 2023. "Power Cost and CO2 Emissions for a Microgrid with Hydrogen Storage and Electric Vehicles" Sustainability 15, no. 22: 15750. https://doi.org/10.3390/su152215750