Abstract

This article examines the issues in assessment of the energy efficiency of industrial facilities, which have not yet been scientifically resolved, in contrast to the widely used approaches to assessing residential buildings, which are similar in many countries of the world. The sequence of the study was determined in combination with the characteristics of the methods used, the leading of which was the expert survey method. Based on the analysis of the collected statistical information, the significance of energy efficiency indicators was agreed upon and assessed for three groups: first—industrial building, second—technological processes, and third—ensuring the environmental friendliness and energy efficiency of an industrial facility. The weight of each group was also determined based on an expert survey. This made it possible to calculate the specific weights of the indicators and formulate a rating scale. The principle of assigning points for each indicator is determined depending on the deviation of actual values from standard values for quantitative indicators and according to the characteristics of the object of analysis for qualitative indicators. The result of the study was the positioning of classes on the scale of energy efficiency within the established boundaries based on experimental data.

1. Introduction

Modern conditions for the economic development of enterprises engaged in production and economic activities in the industrial sectors of the economy determine the relevance of the tasks of resource conservation [1,2]. This issue is of particular importance in the presence of budgetary constraints and inflationary processes that affect the growth of tariffs on energy resources [3,4,5]. Difficult environmental, epidemiological, and geopolitical conditions that destabilize the world economy have a negative impact on the investment climate and orient the management of enterprises toward saving on all types of costs, including fuel and energy. Digital monitoring and energy management (EnM) tools are of great importance in this regard [6,7,8,9]. This research topic has remained relevant for a long time and is consistently developing in accordance with the emerging problems of national and global economies, as well as new technological opportunities.

A study of the experience of energy saving and ensuring the energy efficiency (EnEff) of facilities showed that one of the turning points in the formation of an obvious global need for the conservation of natural resources was the oil crisis of 1973. During this period, national and international approaches to solving energy problems began to be developed.

Among them, one can single out a general direction in solving the problems of energy saving and ensuring EnEff—the formation at the state level of a legislative framework and programs to stimulate activities to save energy resources, the development of standards in the field of EnEff, energy certification (certification), and labeling of buildings. In global practice, most of the current standards and the legislative frameworks as a whole relate to residential and public buildings, but there are practically no system solutions in the field of energy saving and energy efficiency for industrial facilities (EnEffIF). This fact is confirmed by official intergovernmental documents. According to the “Draft Action Plan for Energy Efficiency in Industry and Assessment of the Role of the United Nations Economic Commission for Europe in its Implementation” the objectives of the Task Force on Energy Efficiency in Industry are: “to articulate clearly and intelligibly what exactly is meant by energy efficiency in industry…”. Thus, at the theoretical level and in the practice of enterprises engaged in production and economic activities in the industrial sectors of the economy, there is no unified system for assessing the EEffIF recognized by authoritative organizations of international status. Moreover, there is no certainty regarding the principles for choosing an approach to assessing EnEff in industry. These unresolved issues and the disunity of opinions among scientists is creating new directions for discussion among both government authorities and intergovernmental organizations, as well as the scientific community. The reports of intergovernmental organizations and those of representatives of the authorities responsible for EnEff issues are of the most importance, taking into account the level of elaboration of the material. Among the authors of scientific works on the topic of this study, it should be noted: Karasek A. et al. evaluate the EnEff of the countries of the European Union (EU) using data coverage analysis (DEA) [10]; Patterson M. et al. analyze the practice of assessing industrial energy and discuss the need to take into account decarbonization trends through electrification and renewable energy in industry [11]; Richter B. et al. offer a model for assessing EnEff and setting priorities in industry based on the PROMETHEE multi-criteria method [12]; Wang Y. et al. conduct research compiling data on environmental friendliness and EnEff in the context of “green” design and the construction of facilities [13,14,15]; Luo S. et al. analyze the relationship between the energy consumption of enterprises and greenhouse emissions [16,17].

Attempts to form approaches to assessing EnEff in industry are reflected in scientists’ works: Lyakhomsky A.V. et al. propose to evaluate the level of EnEff of technological processes by determining the specific energy costs per unit of output in natural units [18]; Romankova T.V. et al. offer to evaluate the level of EnEff of industrial products, proposing the use of the following indicators: the energy intensity of products, the “energy component of the cost of manufactured (sold) products”, and “energy return” (inverse indicator of energy intensity) [19]; Osipov V.A. et al. in the monograph “Energy Efficiency of Industrial Production”, propose to calculate the EnEff of a production system, taking into account the labor productivity and energy intensity of production [20]. The issues of the energy characteristics of building and engineering networks are considered in the works of the representatives of NP “AVOK”, Shilkin N.V. and Tabunshchikov Y.A. [21,22]. The architecture of an energy-efficient industrial building, taking into account “green” standards, is considered by Fisenko A.A. and Basse M.E. [23]. Proposals for a rating system for assessing the EnEff of industrial enterprises are presented in the scientific works of Myatishkin G.V. and Filinov A.S. [24]. Based on the study of these works, the authors came to the conclusion that in existing assessments of EnEff in industry, different objects were considered: technological processes, industrial products, industrial production, and industrial building. There are no scientific works and guidelines that would allow us to combine all the above issues while taking into account current trends in the field of sustainable development in a unified system of indicators.

Reports and the programs of international organizations present various approaches to classifying buildings according to their EnEff level [25,26]. When assessing the EnEff of a property in Finland, water consumption, electricity consumption and the energy required for ventilation of the building are analyzed. In the USA, the assessment of the EnEff class of buildings is carried out according to the specific consumption of primary energy in kWh/m2 per year (RESNET standard); in the EU countries, assessment concerns the value of the specific annual consumption of primary energy per 1 m2 of the total building area (standard EN 15217) [27]; in Russia the class of the EnEff (CEnEff) of a residential building is determined by the value of the specific consumption of thermal energy for heating during the heating period; in Belarus assessment concerns the indicator of specific consumption of thermal energy for heating and ventilation [25,26]. At the same time, a distinctive feature of the classification of buildings by EnEff is both the assessment indicator itself and the billing period; in most countries it is one year, however, in some countries a monthly calculation mode is established.

The study also showed that the InterfaxERA environmental and energy rating agency attempted to create an EnEff rating at three levels: one for business (rating of enterprises in Russia and Kazakhstan), one for industry groups of enterprises, and one for regions [28,29]. Ranking is carried out according to five criteria: energy and resource efficiency (energy and resource costs per unit of output), technological efficiency (resource consumption and waste generation per unit of work done), ecosystem efficiency (the level of pollution and environmental impacts coming from the company’s enterprises, which can be assimilated by natural ecosystems in the areas where these enterprises are located), efficiency dynamics (change in efficiency since 2005), and transparency (the level of disclosure of reporting on energy and resource consumption and environmental impacts). InterfaxERA experts compare sixteen industry groups: oil and gas production and pumping; extraction of other types of raw materials; agricultural production; transport; construction; capital infrastructure; management and distribution networks; food and medicine; non-food retail goods; woodworking; mechanical engineering and metalworking; casting and heavy engineering; thermal processing of raw materials; chemical production; utilities; and power generation and distribution. Companies are ranked according to the value of each criterion. The final place in the ranking is determined by the sum of the places in the five ranking lists.

The authors concluded that when conducting an assessment, it is necessary to take into account the current conditions and factors of sustainable development of industrial enterprises that directly or indirectly affect the EnEffIF. First of all, such factors include the environmental aspects of the enterprise, which determine its impact on the environment. Therefore, in the context of the development of “green” standards in construction and the introduction of mandatory carbon reporting for individual enterprises, these factors should be taken into account when assessing the EnEffIF. In addition, the reviewed materials do not include an assessment of the aspects of EnEff management (management activities in the field of EnEff), and it determines a significant potential for energy saving and increasing the EnEffIF.

The results of a review of publications and the regulatory frameworks of various countries enable us to draw the conclusion that there is no methodology for assessing EnEff classes.

The study identified key issues that determine the research agenda:

- -

- industrial facilities were not previously considered as an object of study;

- -

- assessment methods and indicators of EnEffIF (production systems are considered), which are proposed by scientists in scientific articles, are based on the determination of a single specific indicator of EnEff, reflecting only the energy intensity per product;

- -

- the proposed approaches to assessing EnEff in industry do not allow addressing only current individual development trends without taking into account in the overarching trends: the “environmental agenda”, carbon reporting, energy intensity, etc.;

- -

- none of the proposed assessment systems take aspects of enterprise EnM into account.

There are universal point-rating assessment systems used to assess the level of buildings’ “environmental friendliness” (sustainability), known as “green standards”. Despite their environmental focus, they account for the efficiency of energy resource management but not the fixed assets that correspond to technological processes for industrial facilities.

Considering the urgent need to develop a methodology for assessing and classifying industrial facilities according to EnEff, the scientific team of the National Research University Moscow State University of Civil Engineering conducted a three-year (from 2020–2022) study with the support of the Russian Foundation for Basic Research on the topic “Development of a methodology for assessing energy efficiency classes of industrial facilities”. Interim results of the study were published in rating journals and received positive reviews from foreign experts [30,31]. In particular, the results of a study of various approaches to assessing the EnEff of enterprises and other facilities (for example, residential and public) allowed the authors to conclude that it is advisable to use an assessment based on a point-rating system, the methodological prototype of which can be defined as “green standards”. Such a system makes it possible to take into account many quantitative and qualitative indicators of EnEff in a wide range of estimates (interval values), and on this basis, we propose a system of indicators [30].

All the above arguments made it possible to formulate the goal of this study: the development of a universal point-rating system for assessing the EnEff of an industrial facility (IF). The object of the study is an IF (a category previously introduced by the authors of the study to specify the diagnostic object). This category should not be confused with an industrial building; in most cases, the building is part of an IF.

To achieve the goal, the following tasks were identified:

- Determination of the boundaries of the scale of EnEff classes for industrial facilities.

- Determination of classes on the EnEff scale of IF.

- Approbation of a point-rating system through assessment of the EnEffIF using the example of an operating enterprise.

The research stages, materials, and methods are described in more detail in the next section. To make decisions on conceptual controversial issues, international expert surveys were conducted (for example, when choosing the composition of indicators, the number of classes, the scale of rating ranges, etc.).

The results obtained make it possible to identify industrial facilities by class (from A++ to G), which can become a reference tool for realizing the potential for sustainable development of an enterprise by increasing the EnEffIF. The assessment approach and scaling system were tested at an IF for the production of concrete transport equipment.

2. Materials and Methods

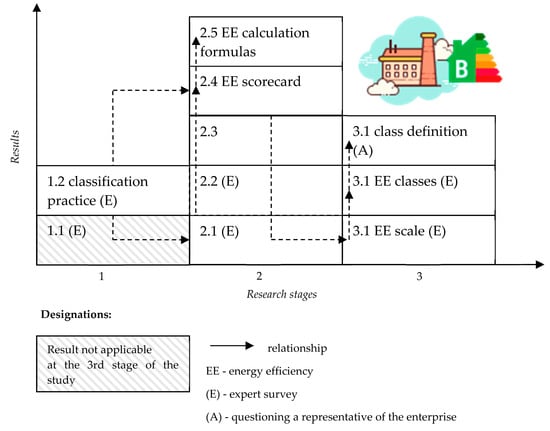

This study covers the final stage of work on a scientific project that has been carried out over a period of three years. Intermediate results for two stages of the study have been published, and some of them form the informational basis of this stage of work [30,31] (Figure 1).

Figure 1.

Results of the study that determine the information basis of the final stage of the project.

The results of the study, indicating their significance for the third stage:

Results of the first stage:

(1.1)—A form was developed for obtaining and processing information on industrial enterprises and the general and energy characteristics of industrial facilities in their composition, known as the Unified Information Statistical Database on Industrial Facilities (UISB), in accordance with the register of the All-Russian Classifier of Economic Activities (OKVED) and the open data of the Information Service “Catalog of enterprises” of the State Information Systems of Industry (GISP), containing the following information: the name of the enterprise, the name of the IF, the actual address, and the OKVED code. This result is of great practical importance, provided that it is applied in the practical activities of industrial enterprises, regardless of their country of origin. Data can be used to consolidate information on industrial facilities on a national scale and determine their EnEff classes on this statistical basis [30].

(1.2)—A comparative description of the practice of dividing industrial facilities into certain groups based on EnEff-indicators was carried out, the results of which were: the systematization of EnEff-indicators and labeling systems and EnEff scales for assessment objects in the USA, EU countries, and CIS countries. The practices of individual countries are noted, in which there are methods for classifying “buildings”, including industrial ones, as energy efficient. At the same time, the absence of a unified approach to the definition of the concept of “IF” was revealed.

Results of the second stage:

(2.1)—The object of research was specified (“production facility”). It is important to consider here that this is not only a building (as in most sustainability or EnEff classification systems), but also a single engineering infrastructure. In addition, there are aspects that should be encouraged, such as a level of management that ensures energy efficient policy. These areas of assessment determined the grouping of EnEff-indicators, which differed from those previously used in the direction of a wider coverage of the assessed factors [29].

(2.2)—EnEff factors (preliminary) that affect the EnEffIF were identified. This takes into account both the traditional efficiency policy, which focuses on reducing the energy intensity of finished products, and modern trends in the development of non-traditional technologies and the environmental friendliness of processes and industrial resources [29].

(2.3)—The basic principles of forming systems of EnEff-indicators for industrial enterprises were formulated, enabling evaluations of approaches for any industry or direction and at any scale of use of enterprises and corresponding industrial complexes. An important principle is compliance with the requirements of regulations, mandatory standards, and legal documents governing the construction and industrial industries of the country where the assessment of industrial facilities is carried out [29].

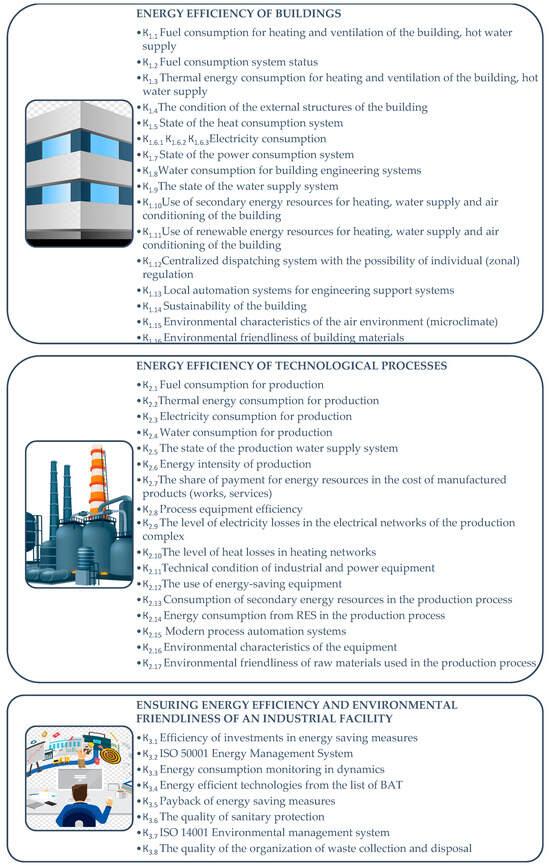

(2.4)—The names and composition of EnEff-indicators, which include quantitative and qualitative indicators, were clarified. These indicators integrated the best methodological developments in the field of assessing the EnEff and environmental friendliness of buildings, which are largely reflected in the rating average indicators of “sustainability” or “green” standards, where one of the mandatory thematic sections is “EnEff” (Figure 2).

Figure 2.

Composition of EnEff-indicators for an IF.

In this study, groups of indicators were determined in more detail and the weight of each indicator was assessed and sequentially weighted in the group share.

(2.5)—Algorithms and formulas for assessing EnEffIF based on the determination of quantitative and qualitative assessments, applicable to various industries and allowing comparison with the criterion (normative) values of EnEff-indicators, and, in further research, applicable to the determination of the EnEff classes of industrial facilities.

To solve the theoretical first and second tasks of the final stage of the study, which are related to determining the conditions for using the scale to assess the EnEff classes of industrial facilities, empirical methods of expert analysis were applied, as well as methods on the theoretical level of research (analysis and synthesis) which enable the systematization of the data obtained and the identification of non-random dependencies, for example, when evaluating the quality of responses. The expert analysis was carried out on the basis of a survey of specialists in EnEff (representatives of enterprises, experts, members of scientific and academic communities) in several directions: the assessment of the system of EnEff-indicators formed in the study, the determination of the weight values of indicators in the total set of assessment indicators, and the principles of the classification of industrial facilities’ levels of EnEff.

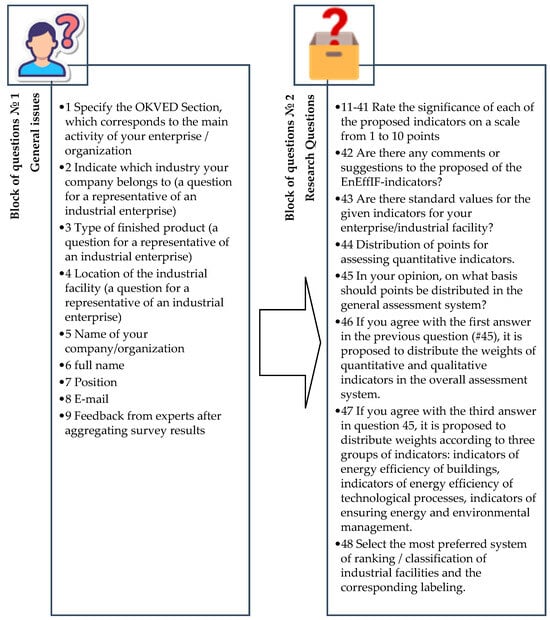

The survey questionnaire included two blocks of questions: general questions (reflecting the characteristics of the respondent and the sectoral affiliation of the enterprise he represents) and special questions on the topic of the study (information necessary for the analysis of the proposals of the authors of the study) (Figure 3):

Figure 3.

Questions of the questionnaire of specialists in EnEff.

Questions 10–41 identified qualitative and quantitative data for further research, reflecting the need to take each indicator and its significance in points into account. Respondents assessed the significance of indicators on a scale from one to ten for assessing the level of EnEffIF, where one point is the least significant indicator and ten points is the most significant indicator. If, in the opinion of the expert, the indicator required exclusion from the assessment system, then it was necessary to put zero points. Thus, the significance of the indicator was assessed, which affects its weight in the overall system for assessing the EnEffIF.

The indicators are structured by groups and assessment approaches:

First Group—EnEff of buildings:

1.1—Quantitative indicators of EnEff of buildings (eight indicators);

1.2—Qualitative indicators of EnEff of buildings (ten indicators).

Second Group—EnEff of technological processes:

2.1—Quantitative indicators of EnEff of technological processes (eleven indicators);

2.2—Qualitative indicators of EnEff of technological processes (six indicators).

Third Group—Ensuring the energy and environmental management of the enterprise:

3.1—Quantitative indicators and characteristics of the management of EnEff and environmental friendliness of an IF (one indicator);

3.2—Qualitative indicators and characteristics of the management of EnEff and environmental friendliness of an IF (seven indicators).

The significance of each EnEff indicator was determined as the arithmetic mean of the scores given by the respondents. The obtained values were the basis for determining the specific weights of indicators in the general system of indicators of the EnEffIF. At the same time, the weight of a group of indicators was taken into account based on the answers of the respondents. The specific weights of EnEff-indicators, as well as the maximum and minimum evaluation scores for each indicator, using the Excel program, made it possible to calculate the maximum and minimum values of the final EnEff-indicator, which were used to calibrate the scale for assessing the EnEff classes of an IF.

Questions 42 and 44–48 determined the qualitative information basis of the study. This encompasses the proposals of the respondents on the proposed indicators, the coordination of the distribution of points for assessing quantitative indicators (below the standard value—zero points; above the standard by 0–5%—two points; above the standard by 5–10%—four points; above the norm by 10–20%—six points; above the norm by 20–30%—eight points; above the norm by more than 30%—ten points), and the principle of the distribution of points in the general system assessment, comparing the significance of quantitative and qualitative indicators, all indicators among themselves, or groups of indicators. This is the most preferred system of ranking/classification of industrial facilities and the corresponding labeling in the general assessment system (similar to the MKD or STO NOSTROY 2.35.4-2011 [32]). Question 43 determined quantitative data, namely, standard values for the given indicators (if any).

The questionnaire, which is the main tool of the empirical research method, was distributed to the official e-mail addresses of industrial enterprises in Russia and also posted on the portal of the State Information Systems “Energy Efficiency” (GIS “Energy Efficiency”) page. The publicity of the questionnaire made it possible to ensure maximum coverage of stakeholders.

When solving the empirical problem of determining the EnEff class of an IF using the example of an operating enterprise, the method of questioning a representative of an industrial enterprise developed by the authors was used (Table 1).

Table 1.

Fragment of the questionnaire for a representative of the enterprise for an IF.

Materials describing the indicators and instructions for filling out the questionnaire were attached to the questionnaire for the enterprise of the IF. It is recommended to compare the obtained data with project documentation and energy passports. The score values of the indicators were processed taking into account their specific weights and compared with the description of the criteria for assessing the EnEff of an IF. This allows you to determine the EnEff class of an IF and draw conclusions about the current situation at the facility and in the EnM system, as well as the possibilities for increasing the EnEff class.

3. Results

Let us present the main results of the development of the scale of EnEff classes of an IF obtained in the study to ensure the practical use of the system of indicators for assessing the EnEff of an IF, which are universal. They can be used for any industry in various countries around the world. As noted above, the system of indicators for assessing an IF includes three groups of indicators (the “EnEff of buildings”, the “EnEff of technological processes”, and “Ensuring EnEff and environmental friendliness of an IF”) which have a scoring measurement. The first two groups include quantitative and qualitative indicators reflecting the consumption of energy resources and water. The third group includes indicators for managing the EnEff and environmental friendliness of an IF. The presented features of the system of indicators for assessing the EnEff of an IF, which provide the possibility of applying a new approach to its provision, are of fundamental importance for the formation of a scale of EnEff classes for industrial facilities.

According to the author’s approach, the definition of the boundaries of the scale of EnEff classes of industrial facilities was carried out, taking into account the specific weight and significance of an individual indicator included in the system of indicators of the EnEffIF. Based on the conducted expert survey, a significant result was obtained, which determines the principles for taking into account the specific weight of each of the groups and individual indicators as part of the final assessment of the EnEffIF.

As a result of the study, the specific weight of each group of indicators for assessing the EnEffIF was determined. For the first group, “EnEff of buildings”, it was 30%; for the second group, “EnEff of technological processes”, it was 50%; and for the third group, “Ensuring EnEff and environmental friendliness of an IF”, it was 20%.

The significance of individual indicators of the EnEff in points as part of the final assessment of the EnEffIF was also determined on the basis of a questionnaire survey. In accordance with the author’s approach, the assessment of the significance of a particular EnEff indicator was determined by experts using the formula developed by the authors:

where:

—the share of a separate -th indicator in the final assessment of the EnEffIF, %;

—a separate i-th indicator of EnEff in the j-th group;

j—group of EnEff-indicators (j = 1,2,3), j1—group “EnEff of buildings”, j2—group “EnEff of technological processes”, j3—group “Ensuring EnEff and environmental friendliness of an IF”;

i—indicator number in the j-th group;

—the significance score of a separate Kji-th EnEff indicator in the j-th group;

—the share of the j-th group of EnEff-indicators in the final value of the indicator, %; (for = 30%; = 50%; = 20%);

—overall significance score of the -th indicators.

For the formation of their opinion, the experts were offered an interval for assessing the significance of individual indicators of the EnEffIF (-th) from one to ten points, with a focus on the approach set out in the rating system for assessing a sustainable environment. Experts assigned one point to the least significant indicator and ten points to the most significant indicator.

The score values and the specific weights of individual indicators of the EnEffIF as part of the final value of its EnEff indicator, obtained on the basis of a survey of experts and the formula developed by the authors, are presented in Table 2.

Table 2.

Point values and the share of individual indicators of the EnEffIF as part of the final value of the indicator of its EnEff.

A separate indicator of the EnEffIF refers to a certain range of indicator values (). To divide the scale for assessing the EnEff classes of an IF into classes, the following positions were formulated: quantitative indicators are distributed in the interval [−10;10] and qualitative indicators are distributed in the interval [−6;6]. When choosing the boundaries of the intervals, the authors took the intervals as a basis, taking into account all variants of deviations in the actual values of indicators from the normative (or required state) with a step of two points. It should be noted that a number of indicators can only have positive values; for example, quantitative indicators of the use of renewable and secondary energy resources for the heating, water supply, and air conditioning of a building and secondary energy resources and energy from renewable energy sources in the production process. These indicators are not mandatory requirements for improving EnEff, as regulating the consumption of energy resources and water is, but reflect only the initiative of the enterprise to reduce energy consumption. The values of the points assigned to them can be in the interval [0;10]. Similarly, the quality indicators of the application of ISO 14000 and 50000 series standards [33,34], namely, building environmental certificates, building materials, and equipment; use by the enterprise of a centralized dispatching system with the possibility of individual (zonal) regulation; a local automation system for engineering support systems; energy-saving equipment and modern systems of automation of technological processes; energy efficient technologies from the best available technology (BAT) list; assessment of the actual state of industrial and power equipment and the quality of sanitary protection; and monitoring of energy consumption and measures to optimize microclimate parameters in terms of temperature, humidity, and air exchange reflect the degree of their use and can take values in the range [0;6]. The distribution of EnEff-indicators within the accepted intervals is presented in Table 3.

Table 3.

Distribution of EnEff-indicators by interval values.

To form the lower (negative) and upper (positive) limits of the scale of EnEff classes of industrial facilities, the specific weight of an individual EnEff indicator (, Table 1) is multiplied by the points of the boundary value of the interval in which they fell as a result of an expert survey (, Table 2).

Thus, a separate () indicator is weighted according to its boundary negative and positive values.

The determination of the weighted score values of the boundaries of the interval of a separate indicator of the EnEffIF was carried out on the basis of the formula proposed by the authors:

where:

—weighted score value of the boundaries of the interval of a separate indicator of EnEffIF ;

q—symbol for demonstrating a negative or positive scale and is not a calculated indicator, for negative values q = 1, for positive values q = 2;

—boundary values of the interval of a separate -th EnEff indicator in points,

Table 4 presents the weighted score values of the boundaries of the range of EnEff-indicators of an IF.

Table 4.

Weighted score values of the boundaries of the interval of EnEff-indicators of an IF.

The extreme negative and positive values of the boundaries of the scale of EnEff classes of an IF are determined by summing the weighted negative and positive score values of the boundaries of the intervals of individual indicators (). First, the negative scores of the values of the interval of individual indicators are summed up ( at q = 1), and the extreme negative limit of the scale of EnEff classes of industrial facilities is determined. Then, the positive scores of the values of the interval of individual indicators are summed up ( at q = 2), and the extreme positive limit of the scale of EnEff classes of industrial facilities is determined. The formula proposed by the authors for the calculation is as follows:

where —the extreme weighted score value of the boundary indicator of the scale of EnEff classes of an IF; for a negative value of the boundary indicator, s = 1, for a positive value, s = 2.

The extreme negative value of the boundary of the scale of EnEff classes of industrial facilities () obtained as a result of the calculations was −466 points, and the extreme positive value (), respectively, was 788 points.

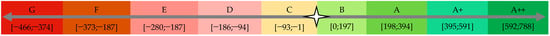

The study also resulted in the formation of classes for assessing the EnEffIF within the boundaries of the developed scale [−466;788]. The authors took as a basis the approach of letter designation of EnEff classes, which is adopted in the practice of evaluating the EnEff classes of apartment buildings. Within the boundaries of the developed scale, it is proposed to distinguish nine classes: five classes for industrial facilities with low EnEff and letter designations from G to C (G, F, E, D, C) and four classes for objects with sufficient and high EnEff, with designations from B to A++ (B, A, A+, A++). In the proposed approach, the B-class is the median. Its lower bound is set to zero. Points within the limits of negative and positive values of the indicators of the intervals of the developed scale of EnEff classes are distributed evenly. Taking into account the accepted number of classes, the interval step for negative values of EnEff-indicators is 93 (466/5) and for positive values it is 197 (788/4). The developed scale of EnEff classes of industrial facilities is shown in Figure 4.

Figure 4.

EnEff class scale for industrial facilities.

The study developed a detailed description of the EnEff classes of industrial facilities, which is shown in Table 5.

Table 5.

Characteristics of EnEff classes of industrial facilities.

Approbation of the developed rating scale at an operating industrial enterprise, which is one of the leading manufacturers of concrete transport equipment in Russia, showed that the results of assessing the EnEff class of an IF make it possible to form new directions for improving its EnEff, including through the use of reserves for creating industrial enterprise EnM systems. Using the questionnaire developed by the authors, a survey of specialists in an industrial enterprise was conducted.

The processing of the survey results made it possible to determine the EnEff class of an industrial enterprise producing concrete transport equipment. The final value of the EnEff index of this IF was 3.08, which, in accordance with the developed scale of EnEff classes of industrial facilities, classifies it as a B-class. The result obtained indicates the compliance of the IF with all regulatory requirements in the field of EnEff. An assessment of the EnEff of an industrial enterprise producing concrete transport equipment to determine its EnEff class is presented in Table 6.

Table 6.

Assessment of EnEff of an industrial enterprise producing concrete transport equipment.

Negative values of the indicators were noted for such indicators as the water consumption of the engineering support systems of the building, which is included in the “EnEff of Buildings” group (−2 points) and the water consumption for the production of products included in the group “EnEff of technological processes” (−4 points).

The analysis of data from a survey of specialists of an industrial enterprise made it possible to identify factors that affect its EnEff. In the first group, “EnEff of buildings”, these factors include: the presence of a centralized dispatching system with the possibility of individual (zonal) regulation and the use of secondary energy resources and RES for the heating, water supply, and air conditioning of the building. In the second group, “EnEff of technological processes”, these factors include the use of automation systems and energy-saving equipment (such as LED lighting equipment and variable frequency drives (VFDs)) and the consumption of secondary energy resources and energy from RES in the production process. In the third group, “Ensuring EnEff and environmental friendliness of an IF”, these factors include effective investment in energy-saving measures, implementation of energy management principles by the enterprise, certification of the environmental management system in accordance with the requirements of the international standard ISO 14001, regular monitoring of energy consumption by the enterprise, implementation of energy-saving measures with a short payback period, and compliance with sanitary protection requirements (including the organization of sanitary protective zones) in accordance with the hazard class of industrial facilities and industries.

The obtained results will allow the enterprise to determine the main directions for improving the EnEffIF based on the development of measures to bring the level of negative values of indicators to positive values. Possible directions for improving the EnEffIF in accordance with the proposed approach, which is certainly new, should be related to the requirements of the ISO 50001 energy management system, monitoring of energy consumption dynamics, energy efficient technologies from the BAT list, the quality of sanitary protection, environmental management systems ISO 14001, and the quality of the organization of waste collection and disposal. In addition, the method enables accounting for the costs and results of ongoing energy saving measures and ensures the effectiveness of investments in improving the EnEffIF and assessments of the payback period of investments.

4. Discussion

The conducted research and development of a scale of EnEff classes for industrial facilities showed that the current practice is associated with two approaches. The first approach is related to the definition of the scale of EnEff classes of apartment buildings based on quantitative indicators. The second approach proceeds from the definitions of the scale of sustainable habitat classes for designed and operated residential and public buildings using scores of quantitative and qualitative indicators. In this approach, when determining quality indicators, the opinion of experts was taken into account.

In the author’s approach, when developing the scale of EnEffIF, the second approach was taken as a basis, but supplemented in the above aspects. A scale of EnEff classes was developed for a new facility: an industrial enterprise; The EnEff assessment indicators that are used in the development of the EnEff scale not only take the EnEff of the building into account, but also the EnEff of the technological process and steps to ensure the EnEff and environmental friendliness of the IF. This approach makes it possible to determine the EnEff class of an IF within the limits of the scale of EnEff classes, taking into account all areas of consumption of energy resources and water, and to form a set of measures to improve the EnEffIF. At the same time, all existing systems exclusively evaluate the efficiency of the use of energy carriers and do not reflect current trends in the field of sustainable development, including environmental and management aspects (management of EnEff and environmental friendliness). The use of qualitative indicators in determining EnEff-indicators for the formation of an EnEff scale has been extended to include buildings and technological processes. At the same time, the calculation of EnEff-indicators in points was taken as the foundation but supplemented with calculations to determine the significance of a separate indicator in the total set of EnEff-indicators. Approaches to the formation of EnEff object classes and stable environment classes for objects have been analyzed in detail and will be included in one of the following publications. The author’s approach, among other things, differs in that the scale of EnEff classes of industrial facilities also includes negative values of weighted EnEff-indicators, which expands the range of industrial enterprises for which an EnEff class can be defined.

An important contribution to the solution of the issue of developing a scale of EnEff classes of industrial facilities is the mathematical apparatus developed by the authors for the sequential calculation of intermediate values of indicators to determine the indicators of the boundaries of the scale of EnEff classes of an IF. At the same time, at each stage of calculating the intermediate values of the indicators, the significance of an individual indicator in their total population was confirmed on the basis of expert opinions obtained using the questionnaires developed by the authors. In addition to the above, the authors proposed to include in the calculation the specific weight of each group of IF EnEff indicators, which was supported by experts. The proposed solutions make it possible to determine the boundary values of the scale of the EnEff class of an IF, taking into account an extended number of factors. Considering the proposed approach to determining the boundaries of the scale of EnEff classes of industrial facilities as universal, the authors do not exclude the possibility of expanding the range of factors to be taken into account in assessing the EnEff of industrial facilities and determining the boundaries of the scale of their EnEff classes depending on the sectoral affiliation of the IF.

An assessment of the EnEffIF is proposed according to a universal rating scale in points, which is subsequently adjusted to take into account the specific weight of each indicator. In alternative assessment systems, there are no specific weights of indicators, and the assessment scale is more variable, i.e., the proposed scores for the respective criteria for assessing the indicators already take into account the significance of each of them. One subject for further discussion may be the approach proposed by the authors to determine the number of classes in the scale of EnEff classes of industrial facilities. The authors admit the possibility of reducing or increasing the number of EnEff classes of industrial facilities, depending on various factors, such as the size and composition of the property complex, natural and climatic conditions at the location of the IF, energy potential, the required degree of detail included in the calculations of EnEff-indicators, changes in regulations, etc.

This study is based on factors and their parametric values obtained as a result of processing an expert survey. It is clear that changes in global priorities, restrictions and shifts in focus, and more detailed analysis and in-depth expert assessments can change the composition of indicators and their weights. In view of this, it is necessary to create a survey methodology conducted by state authorities specialized in EnEff and ensure the collection of statistics through state information systems with the possibility of posting on state statistics portals (Rosstat, Eurostat, etc.). The quality and speed of making adjustments to the assessment system will be influenced by information tools for collecting and processing data.

5. Conclusions

This study, which was carried out by the authors over three years, revealed many problems that impede the development of a system for classifying IF according to EnEff. The key reason for the lack of practical developments in the research area is the uniqueness of the objects and the wide range of regulatory indicators affecting EnEff and, for certain areas and industries, their absence. Another important issue is the creation of a unified system for collecting information on objects that allows verification of scientific proposals.

The final results presented in this article provided the definition of the boundaries of the EnEff class scale of industrial facilities, the identification of classes within the boundaries of this scale, and operation on the example of an operating enterprise. The results obtained were achieved through the use of a set of research methods based on the materials of previous results reflected in the author’s articles [30,31] and supplemented by the results of an expert survey.

The solution of the first task set by the authors is related to determining the specific weight of a separate EnEff indicator of an IF as part of the final value of its EnEff indicator, which includes three groups of EnEff-indicators, which was determined by the authors as the result of an expert survey (for the first group of indicators (EnEff of buildings), the totality of all indicators is 30%; for the second group of indicators (EnEff of technological processes), the aggregate of all indicators is 50%; for the third group of indicators (Ensuring EnEff and environmental friendliness of an IF), the aggregate of all indicators is 20%).

The most important result of the study was the developed scale of EnEff classes for industrial facilities. The proposed scale of EnEff classes takes into account the experience of developing rating scales for buildings according to “green standards”. At the same time, it is distinguished by the author’s approach, which makes it possible to take into account in the assessment of the EnEffIF not only positive values of indicators, but also negative ones, as well as the differentiation of industrial facilities in terms of EnEff. To this end, the authors proposed to allocate four classes of industrial facilities with a positive assessment of EnEff (A++, A+, A, B) and five classes with a negative assessment of EnEff (C, D, E, F, G). Based on these provisions, it is possible to distribute industrial facilities by EnEff classes in a certain sequence built by the authors. It is assumed that the developed scale of EnEff classes can be used in the development of national systems for assessing the EnEffIF in different countries. If the point-rating system for classifying industrial facilities by EnEff is distributed in a private format in the form of voluntary certification systems, the results of the analysis and the formation of industry ratings will form a benchmarking system and become a market tool for increasing the competitiveness of enterprises.

The applied significance of the solutions developed by the authors is confirmed by the practical use of the scale of classes of EnEffIF at a particular industrial enterprise. As a result of the analysis of the survey data of a representative of an enterprise and the assignment of an IF to a specific EnEff class, conclusions were drawn regarding the factors affecting the EnEff of an object, which makes it possible to determine the main directions for increasing the EnEffIF.

At the same time, the issues of concretizing the composition of the indicators of each group, which require taking into account the industry specifics of industrial facilities, remain debatable, which will certainly affect the limits of the scale and interval values of each class. At the same time, the principle of forming the scale of EnEff classes and the boundaries of class intervals, as well as the number of classes, will remain the same.

If the state or interstate organizations approve the draft methodology for assessing the EnEffIF, it is necessary to provide mathematical testing of the results of calculating the weights of EnEff-indicators from big data that will be collected by industry for its adjustment.

Author Contributions

Conceptualization, N.V. and T.M.; methodology, N.V., T.M. and N.S. (Natalia Shchepkina); formal analysis, N.V., N.T. and T.M.; investigation, N.S. (Natalia Shchepkina); data curation, N.S. (Natalia Solopova); writing—original draft, N.T., T.M. and N.S. (Natalia Shchepkina); Writing—review & editing, N.S. (Natalia Solopova), N.T., T.M. and N.S. (Natalia Shchepkina); visualization, T.M.; supervision, N.S. (Natalia Solopova); project administration, N.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bahr, M.T.; Immonen, J.; Billings, B.W.; Powell, K.M. Intelligent Control of Thermal Energy Storage in the Manufacturing Sector for Plant-Level Grid Response. Processes 2023, 11, 2202. [Google Scholar] [CrossRef]

- Chen, Y.; Billings, B.; Partridge, S.; Pruneau, B.; Powell, K.M. Grid-Responsive Smart Manufacturing: Can the Manufacturing Sector Help Incorporate Renewables? IFAC 2022, 55, 637–642. [Google Scholar] [CrossRef]

- Knez, S.; Šimić, G.; Milovanović, A.; Starikova, S.; Zupanic, F.Z. Prices of conventional and renewable energy as determinants of sustainable and secure energy development: Regression model analysis. Energy Sustain. Soc. 2022, 12, 6. [Google Scholar] [CrossRef]

- Shi, H.; Zheng, H. Spillover connection between oil prices, energy risk exposure, and financial stability: Implications for the COVID-19 pandemic. Environ. Sci. Pollut. Res. 2022, 29, 78683–78697. [Google Scholar] [CrossRef]

- Ren, H.; Zhou, W.; Wang, H.; Zhang, B.; Ma, T. An energy system optimization model accounting for the interrelations of multiple stochastic energy prices. Ann. Oper. Res. 2022, 316, 555–579. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Wu, X.; Sun, K.; Du, X.; Wang, H.; Zhao, J. Economic Optimization Scheduling Based on Load Demand in Microgrids Considering Source Network Load Storage. Electronics 2023, 12, 2721. [Google Scholar] [CrossRef]

- Jasim, A.M.; Jasim, B.H.; Mohseni, S.; Brent, A.C. Energy Internet-Based Load Shifting in Smart Microgrids: An Experimental Study. Energies 2023, 16, 4957. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Elsayed, H.; Savio, G. Multi-Material Additive Manufacturing: Creating IN718-AISI 316L Bimetallic Parts by 3D Printing, Debinding, and Sintering. Sustainability 2023, 15, 11911. [Google Scholar] [CrossRef]

- Condon, F.; Franco, P.; Martínez, J.M.; Eltamaly, A.M.; Kim, Y.-C.; Ahmed, M.A. EnergyAuction: IoT-Blockchain Architecture for Local Peer-to-Peer Energy Trading in a Microgrid. Sustainability 2023, 15, 13203. [Google Scholar] [CrossRef]

- Karasek, A.; Fura, B.; Zajaczkowska, M. The Assessment of the Energy Efficiency in the European Union Countries in 2013 and 2020. Sustainability 2023, 15, 3414. [Google Scholar] [CrossRef]

- Patterson, M.; Singh, P.; Cho, H. The current state of the industrial energy assessment and its impacts on the manufacturing industry. Energy Rep. 2022, 8, 7297–7311. [Google Scholar] [CrossRef]

- Richter, B.; Marcondes, G.; Monteiro, N.; Costa, S.E.; Loures, E.; Deschamps, F.; Lima, E. Industrial energy efficiency assessment and prioritization model—An approach based on multi-criteria method PROMETHEE. Int. J. Sustain. Energy Plan. Manag. 2023, 37, 41–60. [Google Scholar] [CrossRef]

- Wang, Y.; Lv, L.; Geng, X.; Ren, L.; Sun, R. Research on Cooperative Evolutionary Game of Design and Construction Consortium of Green Building Project under Design Change. Buildings 2023, 13, 1146. [Google Scholar] [CrossRef]

- Li, Q.; Yang, W.; Kohler, N.; Yang, L.; Li, J.; Sun, Z.; Yu, H.; Liu, L.; Ren, J. A BIM–LCA Approach for the Whole Design Process of Green Buildings in the Chinese Context. Sustainability 2023, 15, 3629. [Google Scholar] [CrossRef]

- Rodrigues, L.; Delgado, J.M.P.Q.; Mendes, A.; Lima, A.G.B.; Guimarães, A.S. Sustainability Assessment of Buildings Indicators. Sustainability 2023, 15, 3403. [Google Scholar] [CrossRef]

- Luo, S.; Yuan, Y. The Path to Low Carbon: The Impact of Network Infrastructure Construction on Energy Conservation and Emission Reduction. Sustainability 2023, 15, 3683. [Google Scholar] [CrossRef]

- Huang, S.; Chen, L. The Impact of the Digital Economy on the Urban Total-Factor Energy Efficiency: Evidence from 275 Cities in China. Sustainability 2023, 15, 3195. [Google Scholar] [CrossRef]

- Lyakhomsky, A.V.; Pichuev, A.V.; Perfilyeva, E.N. Energy indicators and indicators of energy efficiency of technological processes in mining. Min. Inf. Anal. Bull. Sci. Tech. J. 2014, S1, 450–460. [Google Scholar]

- Romankova, T.V.; Grinevich, M.N.; Golushkov, O.V. Energy Efficiency of the Enterprise: Indicators, Factors and Mechanism of Improvement: Monograph; Belarusian-Russian University: Mogilev, Belarus, 2013; 148p, ISBN 978-985-492-129-7. [Google Scholar]

- Osipov, E.A.; Embulaev, V.N.; Osipov, A.V. Energy Efficiency of Industrial Production [Text]: Monograph; Publishing House VGUES: Vladivostok, Russia, 2016; 176p. [Google Scholar]

- Shilkin, N.V.; Brodach, M.M. Universal standards for assessing the energy performance of buildings. Energy Sav. 2020, 1, S33–S39. [Google Scholar]

- Tabunshchikov, Y.A.; Shilkin, N.V. Calculation of the air pressure difference on the outer and inner surfaces of the building envelopes of high-rise buildings. ABOK Vent. Heat. Air Cond. Heat Supply Build. Therm. Phys. 2021, 3, S14–S19. [Google Scholar]

- Fisenko, A.A.; Basse, M.E. Energy Efficiency of Industrial Architecture: Modern Theory and Practice. AMIT 2013, 2, 23. Available online: https://marhi.ru/AMIT/2013/2kvart13/basse/basse.pdf (accessed on 14 August 2023).

- Myatishkin, G.V.; Filinova, A.S. Using indicators for efficient energy consumption. Izvestiya Samara Sci. Cent. Russ. Acad. Sci. 2017, 19, S76–S79. Available online: http://www.ssc.smr.ru/media/journals/izvestia/2017/2017_6_76_79.pdf (accessed on 14 August 2023).

- Comparative Overview of Building Energy Efficiency Standards and Technologies in the United Nations Economic Commission for Europe Region. Geneva. 2018. Available online: http://energoeffekt.gov.by/downloads/cooperation/20190318_obzor_stand.pdf (accessed on 14 August 2023).

- UNDP/GEF Project “Improving Energy Efficiency in the Housing Construction Sector of Turkmenistan”. 2016. Available online: https://www.undp.org/sites/g/files/zskgke326/files/migration/tm/WEB_systems-of-energy-certificates-of-buildings-_-Final.pdf (accessed on 14 August 2023).

- DIN EN 15217-2007-09. Energy Performance of Buildings—Methods for Expressing Energy Performance and for Energy Certification of Buildings. Available online: https://infostore.saiglobal.com/en-gb/standards/din-en-15217-2007-09-448384_saig_din_din_1011215/ (accessed on 14 August 2023).

- ITS 48-2017 “Improving the Efficiency of the Assessment of Economic and (or) Other Activities”. Available online: https://files.stroyinf.ru/Data2/1/4293743/4293743156.pdf (accessed on 14 August 2023).

- Martynov, A.S. Disclosure of environmental reporting as a tool to improve business efficiency. Econ. Strateg. 2018, 20, S88–S93. [Google Scholar]

- Verstina, N.; Solopova, N.; Taskaeva, N.; Meshcheryakova, T.; Shchepkina, N. A New Approach to Assessing the Energy Efficiency of Industrial Facilities. Buildings 2022, 12, 191. [Google Scholar] [CrossRef]

- Taskaeva, N.; Meshcheryakova, T.; Shchepkina, N. Unified informational statistical base as a tool for monitoring energy efficiency of industrial facilities. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 062047. [Google Scholar] [CrossRef]

- National Association of Builders. Available online: https://nostroy.ru/department/metodolog/otdel_tehniceskogo_regulir/sto/СТО%20НОСТРОЙ%202.35.4-2011.pdf (accessed on 14 August 2023).

- ISO 14000; Environmental Management Systems. Available online: https://www.iso.org/ru/iso-14001-environmental-management.html (accessed on 14 August 2023).

- ISO 50000; Energy Management Systems. Requirements with Guidance for Use. Available online: https://www.iso.org/ru/iso-50001-energy-management.html (accessed on 14 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).