Digital Technique-Enabled Container Logistics Supply Chain Sustainability Achievement

Abstract

:1. Introduction

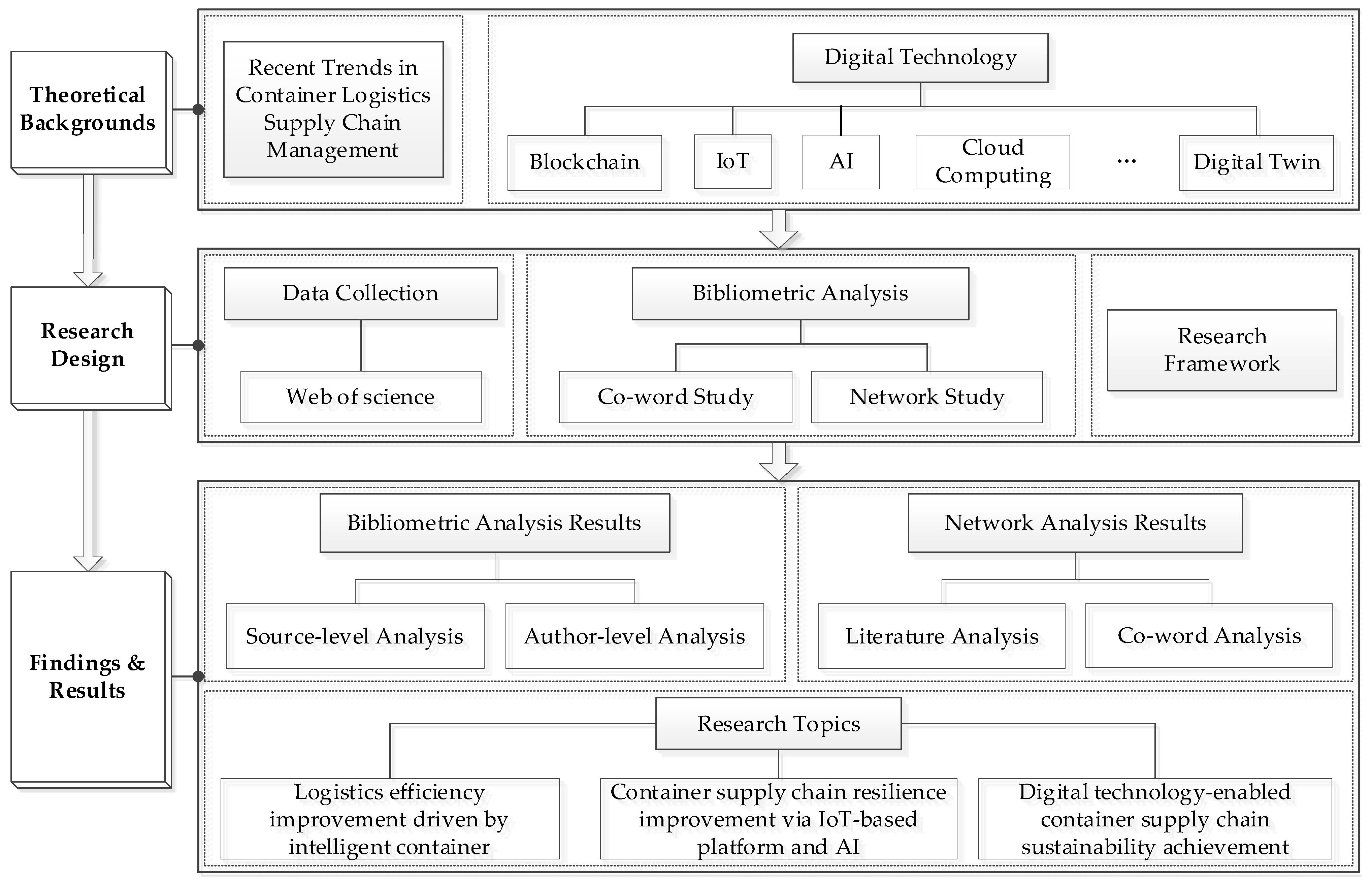

2. Theoretical Backgrounds

2.1. IoT-Based Container Logistics 4.0

2.2. Container Supply Chain Management

2.3. Digital Technology

3. Research Design

3.1. Data Sources and Reference Collection

- Step 1

- Initial keyword selection. Based on the research title “digital technique-enabled container logistics supply chain”, we found that “digital technique”, “container logistics”, and “container supply chain” could be regarded as the initial selection words for literature retrieval.

- Step 2

- Expand the range of keyword indexing. We needed to make sure that the main journals and references related to the research topic occurred in the indexing results. In addition, the textual words that clearly describe the research topic could be the extended keywords based on the title, abstract, chapter names, and professional terminology that initially occurred in indexing results, such as “green container supply chain”, “sustainable port”, “Blockchain”, “IoT”, and “maritime transportation”.

- Step 3

- Remove irrelevant keyword search terms. The irrelevant research items and publications should be removed based on the indexing results through the expanded keywords searching. In this stage, the irrelevant expanded keywords needed to be identified and removed, such as “telecommunications”, “automated control”, and “container manufacturing”.

- Step 4

- Repeat Step 2 and Step 3 until the searching results fully meet the review study requirements of the objective research topic. In other words, the comprehensive literature samples could be retrieved in the research data sample.

3.2. Bibliometric Review Study

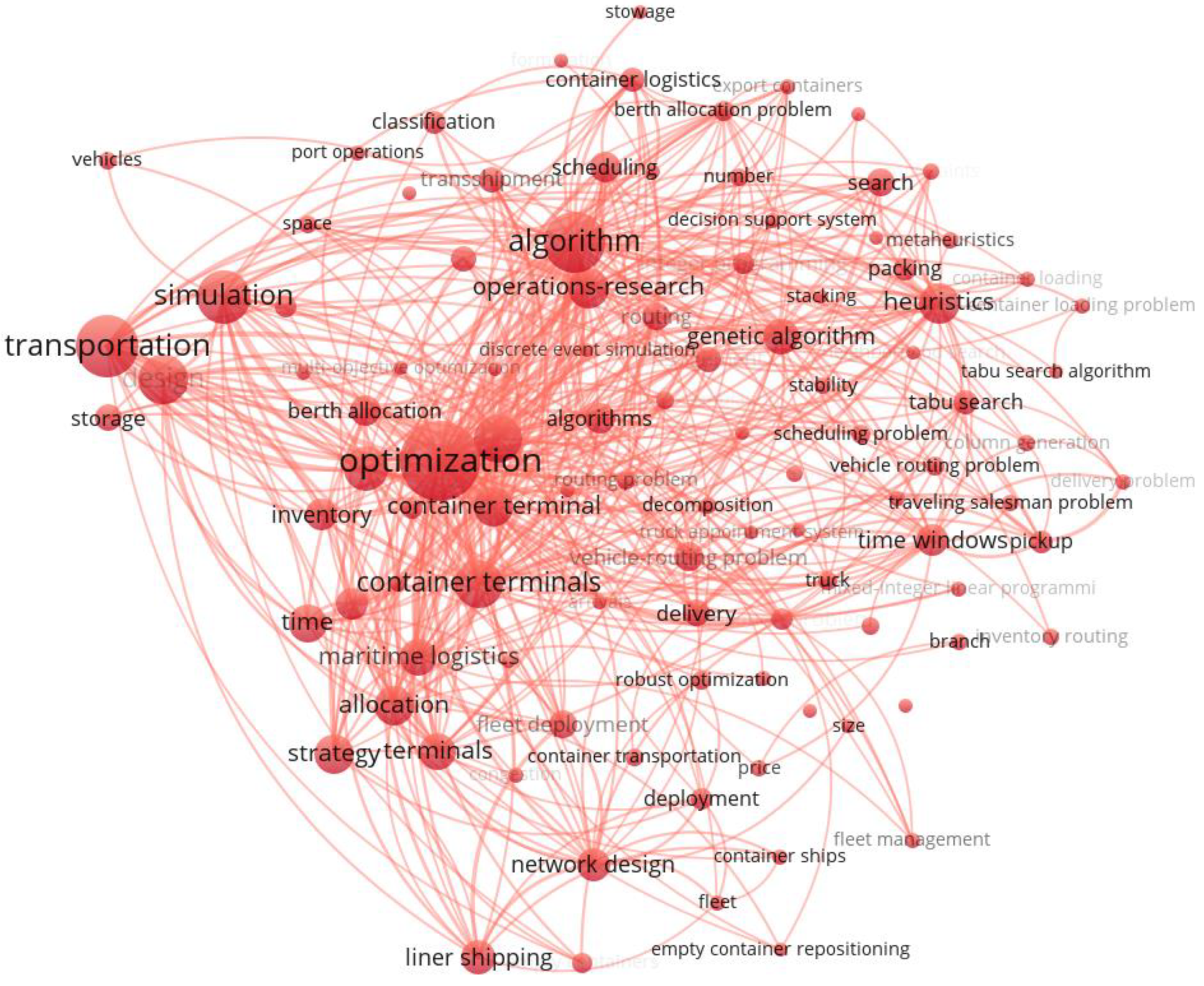

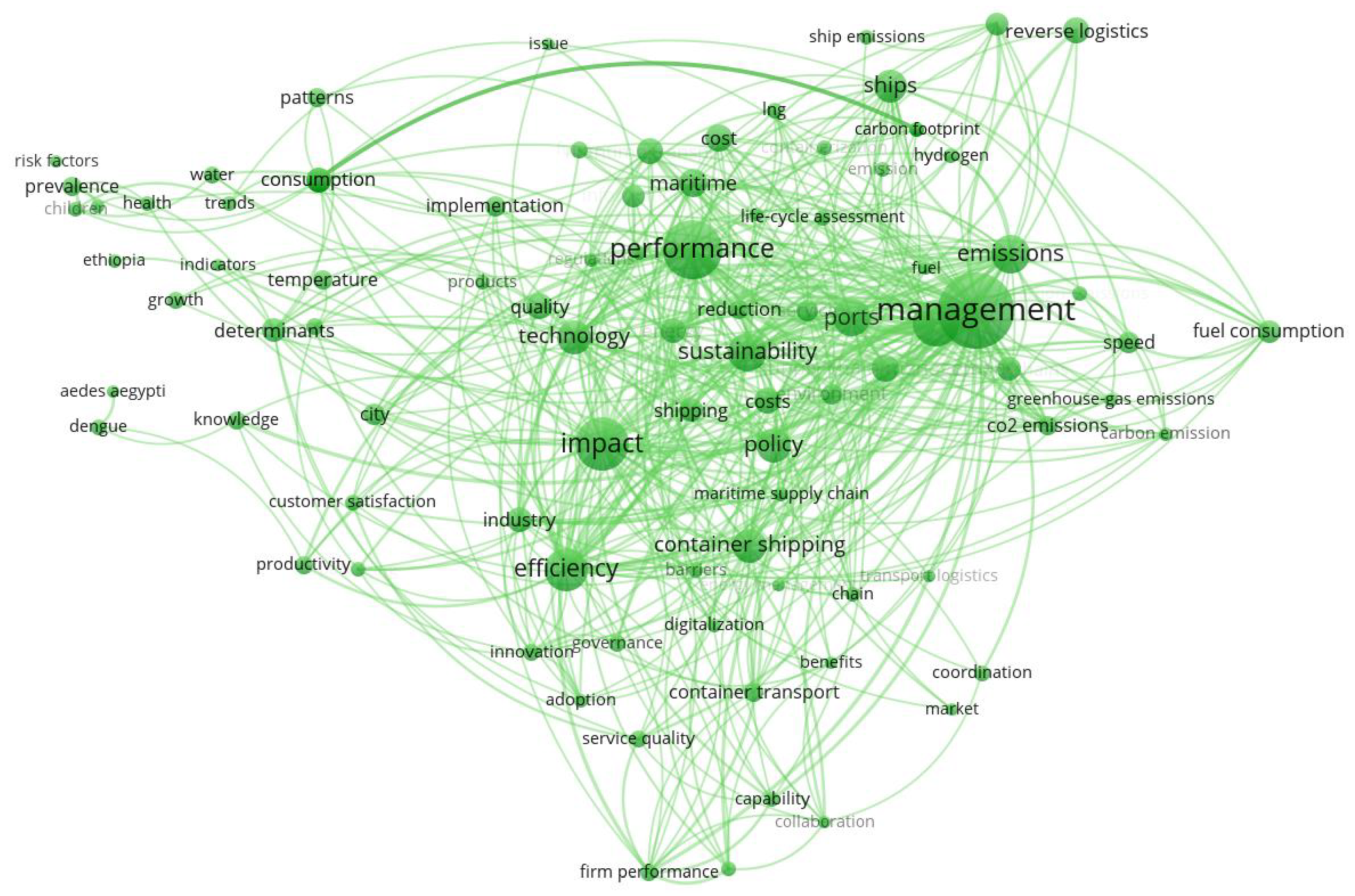

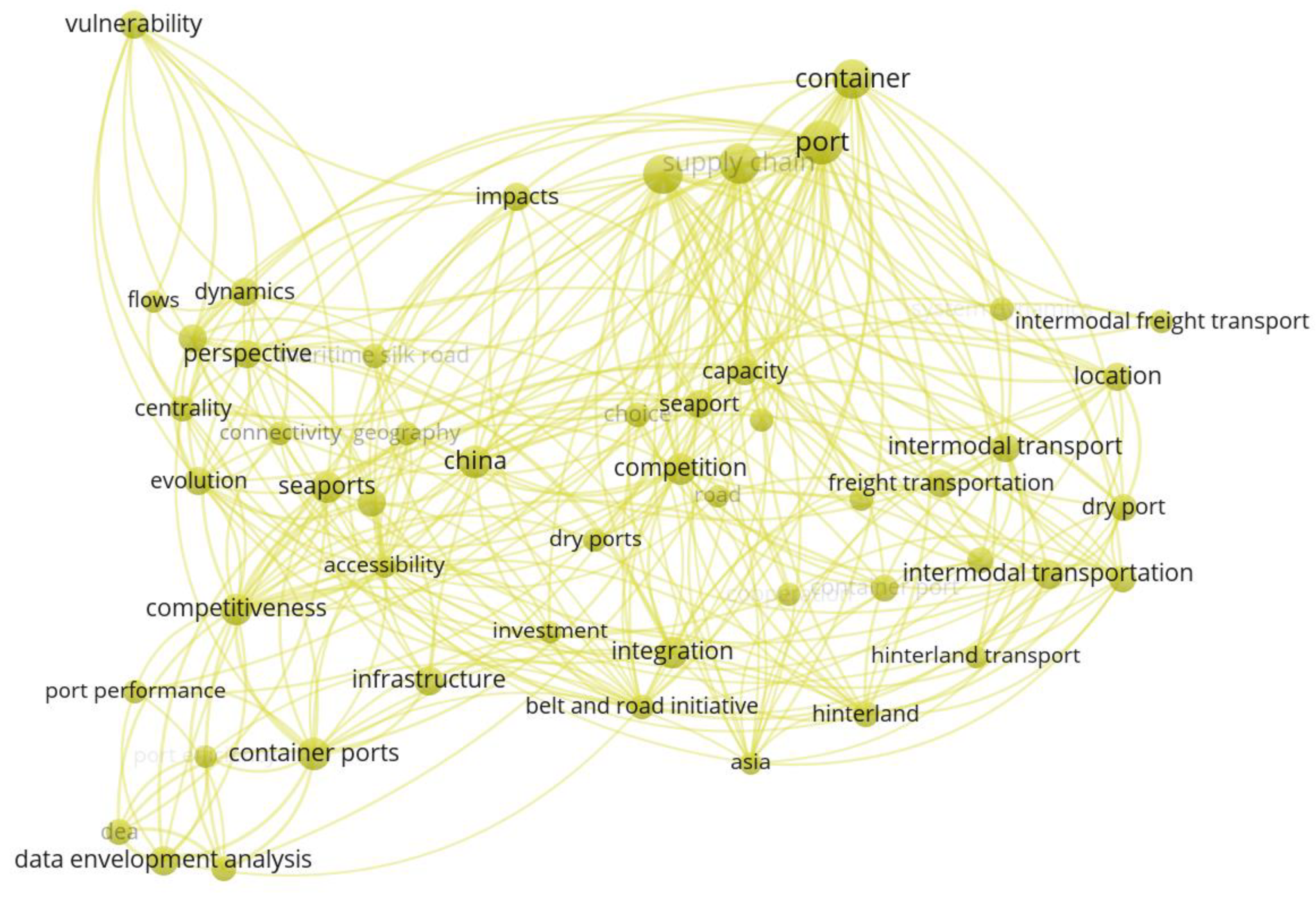

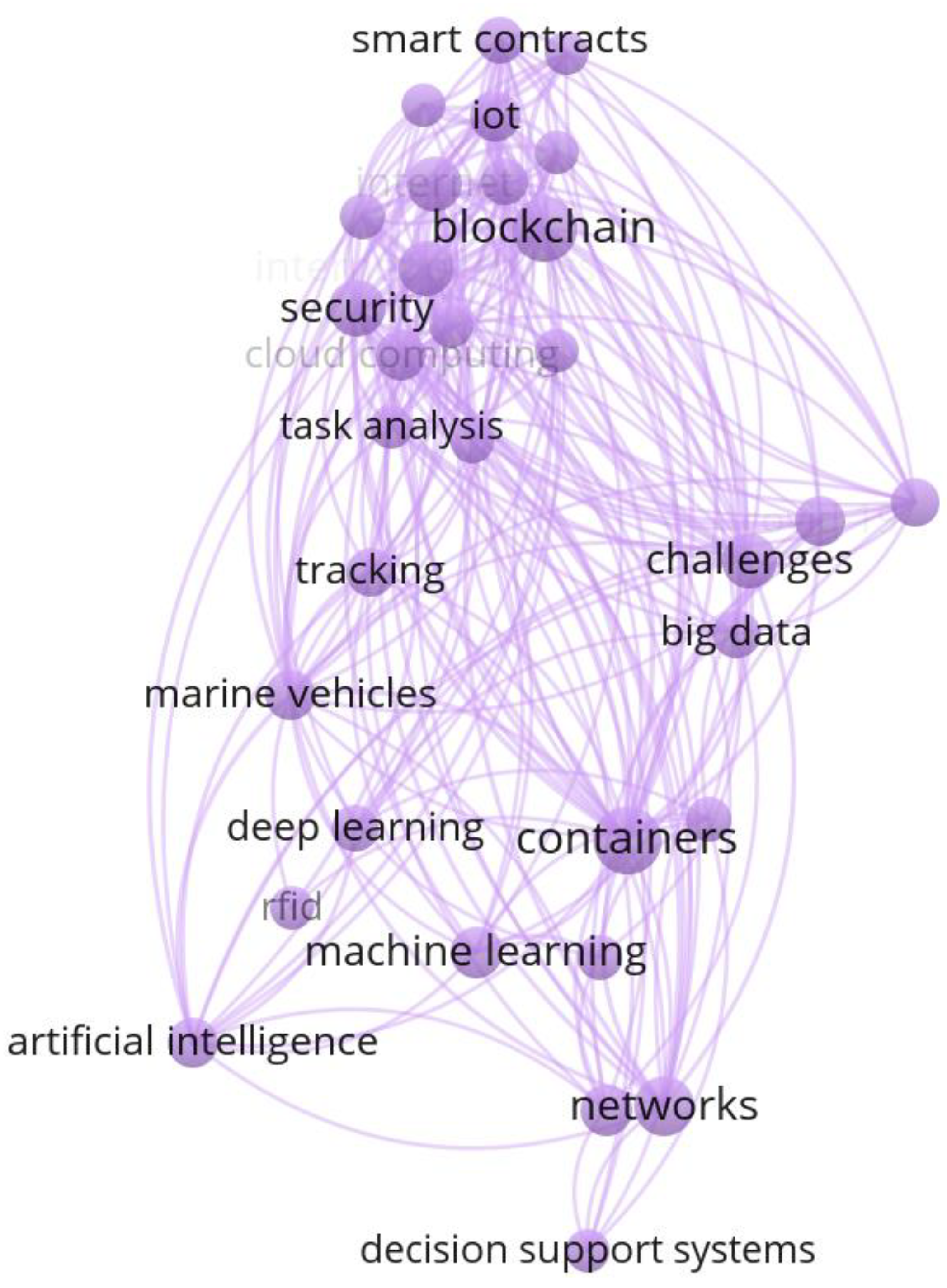

3.2.1. Co-Word Analysis

3.2.2. Network Analysis

3.3. The Proposed Research Framework

4. Research Findings

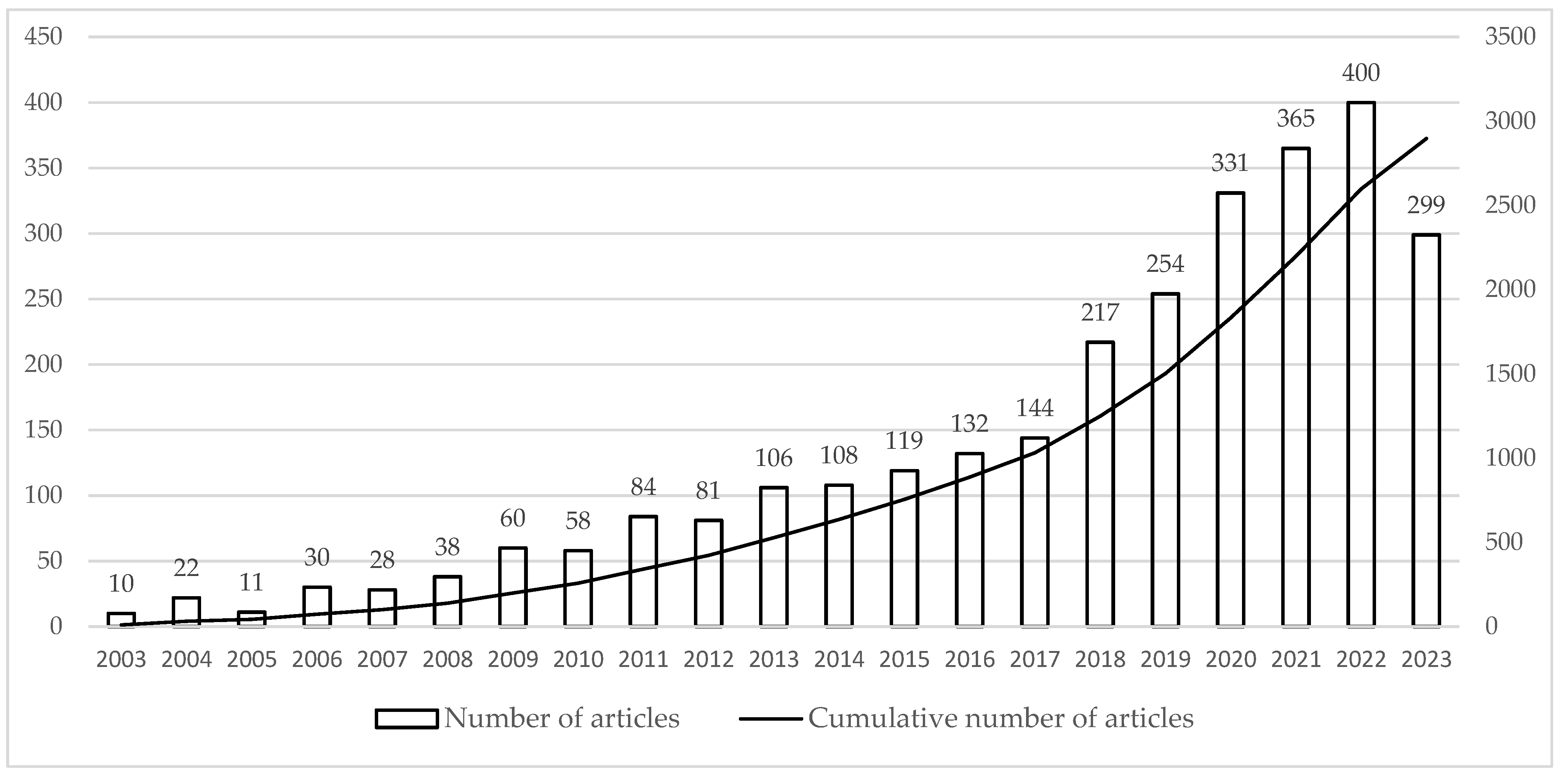

4.1. Overview Analysis Results

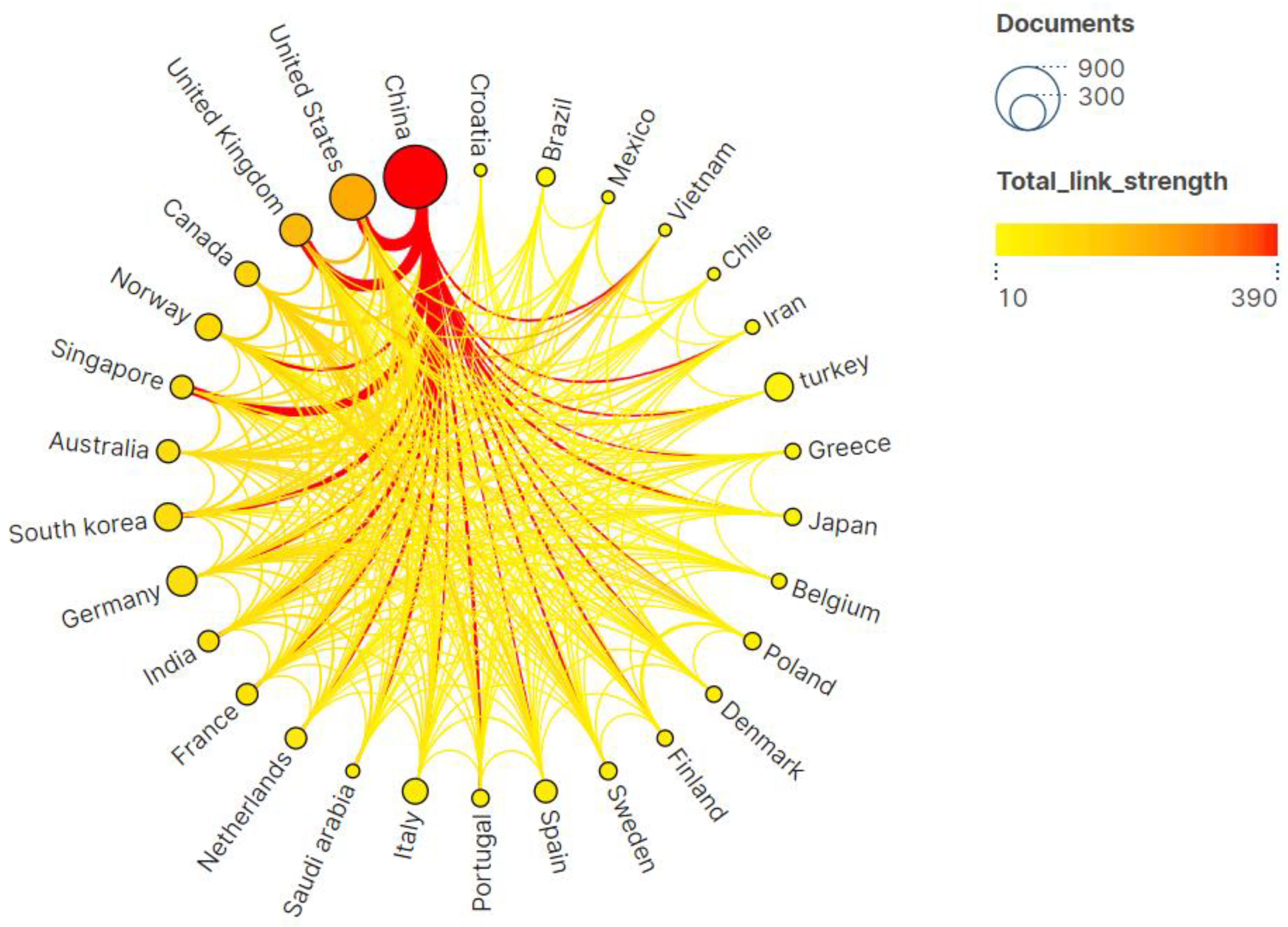

4.1.1. Source-Level Analysis

4.1.2. Author-Level Analysis

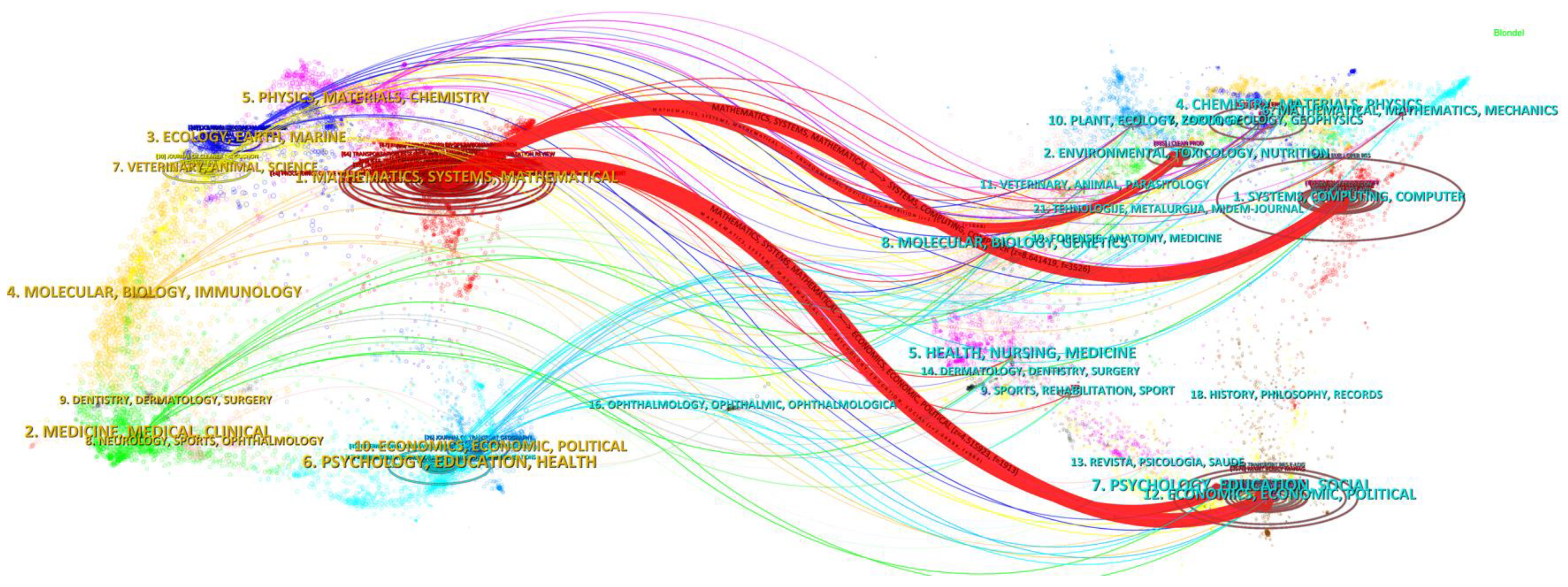

4.2. Network Analysis Results

4.2.1. Literature Analysis

4.2.2. Co-Word Analysis

4.3. Container Supply Chain Promotion by Digital Technology

4.3.1. Intelligent Container-Driven Efficiency Improvement of Logistics Operations

- (1)

- Innovative management of intelligent container stacking mode

- (2)

- Intelligent Container IoT System Empowered by Digital Technology

- (3)

- Intelligent Container Defect Monitoring System Based on Video AI Algorithm

- (4)

- Intelligent container transportation relying on modern transportation systems

4.3.2. Container Supply Chain Resilience Improvement via IoT-Based Platform and AI

- (1)

- The container intelligence achievement driven by IoT

- (2)

- Intelligent container terminals driven by AI technology

- (3)

- Multimodal transportation network optimization considering carbon emission

- (4)

- Construction of an intelligent container transportation system

4.3.3. Digital Technology-Empowered Container Supply Chain Sustainability Achievement

- (1)

- The operational status could be dynamically monitored due to the adoption of sensors and IoT technology, such as the location, temperature, humidity, and other environmental conditions of goods in real-time. In addition, effective data mining under the IoT scenario could help to predict the arrival time of goods and potential problems during transportation, facilitating an improvement in sustainability by reducing cargo detention and damage.

- (2)

- The container supply chain network could be optimized to minimize the cost and carbon emission by adopting a big data-driven optimization technique, as well as the distribution routes and transportation mode. In addition, digital technology can also provide real-time traffic information, contributing to dynamic route adjustment and congestion avoidance.

- (3)

- Information sharing and resource coordination will also be achieved among different container supply chain participants relying on digital techniques, which helps to improve resource utilization. For instance, empty containers can be quickly found through digital platforms to avoid empty or prolonged stays.

- (4)

- Blockchain technology has proved to be effective in establishing the transparency and traceability of the container supply chain by disclosing the source, production process, and delivery of goods [55]. This helps to prevent counterfeit products and illegal activities and improve the quality and security of the supply chain.

5. Discussions

5.1. Theoretical Contributions

5.2. Practical Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, D. A Literature Review, Container Shipping Supply Chain: Planning Problems and Research Opportunities. Logistics 2021, 5, 41. [Google Scholar] [CrossRef]

- Hilmola, O.-P.; Li, W.; Panova, Y. Development status and future trends for Eurasian container land bridge transport. Logistics 2021, 5, 18. [Google Scholar] [CrossRef]

- Ding, Y.; Jin, M.; Li, S.; Feng, D. Smart logistics based on the internet of things technology: An overview. Int. J. Logist. Res. Appl. 2021, 24, 323–345. [Google Scholar] [CrossRef]

- de Andres Gonzalez, O.; Koivisto, H.; Mustonen, J.M.; Keinänen-Toivola, M.M. Digitalization in just-in-time approach as a sustainable solution for maritime logistics in the baltic sea region. Sustainability 2021, 13, 1173. [Google Scholar] [CrossRef]

- Yang, Y.; Zhong, M.; Yao, H.; Yu, F.; Fu, X.; Postolache, O. Internet of things for smart ports: Technologies and challenges. IEEE Instrum. Meas. Mag. 2018, 21, 34–43. [Google Scholar] [CrossRef]

- Bonina, C.; Koskinen, K.; Eaton, B.; Gawer, A. Digital platforms for development: Foundations and research agenda. Inform. Syst. J. 2021, 31, 869–902. [Google Scholar] [CrossRef]

- Nguyen, S.; Chen, P.S.-L.; Du, Y. Container shipping operational risks: An overview of assessment and analysis. Marit. Policy Manag. 2022, 49, 279–299. [Google Scholar] [CrossRef]

- Zhou, F.; Chen, T.; Tiwari, S.; Si, D.; Pratap, S.; Mahto, R.V. Pricing and Quality Improvement Decisions in the End-of-Life Vehicle Closed-Loop Supply Chain Considering Collection Quality. IEEE Trans. Eng. Manag. 2023, 1–15. [Google Scholar] [CrossRef]

- Martínez-Jurado, P.J.; Moyano-Fuentes, J. Lean management, supply chain management and sustainability: A literature review. J. Clean. Prod. 2014, 85, 134–150. [Google Scholar] [CrossRef]

- Kugler, M.; Brandenburg, M.; Limant, S. Automizing the manual link in maritime supply chains? An analysis of twistlock handling automation in container terminals. Marit. Transp. Res. 2021, 2, 100017. [Google Scholar] [CrossRef]

- Xu, B.; Liu, W.; Li, J.; Yang, Y.; Wen, F.; Song, H. Resilience measurement and dynamic optimization of container logistics supply chain under adverse events. Comput. Ind. Eng. 2023, 180, 109202. [Google Scholar] [CrossRef]

- Raza, Z.; Woxenius, J.; Vural, C.A.; Lind, M. Digital transformation of maritime logistics: Exploring trends in the liner shipping segment. Comput. Ind. 2023, 145, 103811. [Google Scholar] [CrossRef]

- Liu, S.; Park, S.-H.; Choi, Y.-S.; Yeo, G.-T. Efficiency evaluation of major container terminals in the top three cities of the Pearl River Delta using SBM-DEA and undesirable DEA. Asian J. Shipp. Logist. 2022, 38, 99–106. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, C.; Chen, T.; Lim, M.K. An evolutionary game analysis on blockchain technology adoption in cross-border e-commerce. Oper. Manag. Res. 2023. [Google Scholar] [CrossRef]

- Ahmad, R.W.; Hasan, H.; Jayaraman, R.; Salah, K.; Omar, M. Blockchain applications and architectures for port operations and logistics management. Res. Transp. Bus. Manag. 2021, 41, 100620. [Google Scholar] [CrossRef]

- Heikkilä, M.; Saarni, J.; Saurama, A. Innovation in Smart Ports: Future Directions of Digitalization in Container Ports. J. Mar. Sci. Eng. 2022, 10, 1925. [Google Scholar] [CrossRef]

- Chen, J.; Zhuang, C.; Xu, H.; Xu, L.; Ye, S.; Rangel-Buitrago, N. Collaborative management evaluation of container shipping alliance in maritime logistics industry: CKYHE case analysis. Ocean. Coast. Manag. 2022, 225, 106176. [Google Scholar] [CrossRef]

- Tian, G.; Lu, W.; Zhang, X.; Zhan, M.; Dulebenets, M.A.; Aleksandrov, A.; Fathollahi-Fard, A.M.; Ivanov, M. A survey of multi-criteria decision-making techniques for green logistics and low-carbon transportation systems. Environ. Sci. Pollut. Res. 2023, 30, 57279–57301. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Papaefthimiou, S.; Korfiatis, N. Towards AI driven environmental sustainability: An application of automated logistics in container port terminals. Int. J. Prod. Res. 2022, 60, 4508–4528. [Google Scholar] [CrossRef]

- Kuźmicz, K.A. Impact of the COVID-19 pandemic disruptions on container transport. Eng. Manag. Prod. Serv. 2022, 14, 106–115. [Google Scholar] [CrossRef]

- Li, Q.; Yan, R.; Zhang, L.; Yan, B. Empirical study on improving international dry port competitiveness based on logistics supply chain integration: Evidence from China. Int. J. Logist. Manag. 2022, 33, 1040–1068. [Google Scholar] [CrossRef]

- Chen, X. Reconnecting Eurasia: A new logistics state, the China–Europe freight train, and the resurging ancient city of Xi’an. Eurasian Geogr. Econ. 2023, 64, 60–88. [Google Scholar] [CrossRef]

- Giuffrida, N.; Fajardo-Calderin, J.; Masegosa, A.D.; Werner, F.; Steudter, M.; Pilla, F. Optimization and machine learning applied to last-mile logistics: A review. Sustainability 2022, 14, 5329. [Google Scholar] [CrossRef]

- Fruth, M.; Teuteberg, F. Digitization in maritime logistics—What is there and what is missing? Cogent Bus. Manag. 2017, 4, 1411066. [Google Scholar] [CrossRef]

- Ahmady, M.; Eftekhari Yeghaneh, Y. Optimizing the cargo flows in multi-modal freight transportation network under disruptions. Iran. J. Sci. Trans. Civ. Eng. 2022, 46, 453–472. [Google Scholar] [CrossRef]

- Jiang, Z.; Lei, L.; Zhang, J.; Wang, C.; Ye, S. Spatio-temporal evolution and location factors of port and shipping service enterprises: A case study of the Yangtze River Delta. J. Transp. Geogr. 2023, 106, 103515. [Google Scholar] [CrossRef]

- Li, Q.; Cao, X.; Xu, H. In-transit Status perception of freight containers logistics based on multi-sensor information. In Proceedings of the Internet and Distributed Computing Systems: 9th International Conference, IDCS 2016, Wuhan, China, 28–30 September 2016; Proceedings 9. pp. 503–512. [Google Scholar]

- Nguyen, S.; Chen, P.S.-L.; Du, Y. Risk assessment of maritime container shipping blockchain-integrated systems: An analysis of multi-event scenarios. Transp. Res. Part E Logist. Transp. Rev. 2022, 163, 102764. [Google Scholar] [CrossRef]

- Abdelshafie, A.; Salah, M.; Kramberger, T.; Dragan, D. Repositioning and optimal Re-allocation of empty containers: A review of methods, models, and applications. Sustainability 2022, 14, 6655. [Google Scholar] [CrossRef]

- Pratap, S.; Jauhar, S.K.; Paul, S.K.; Zhou, F.L. Stochastic optimization approach for green routing and planning in perishable food production. J. Clean. Prod. 2022, 333, 130063. [Google Scholar] [CrossRef]

- Kosuge, N.; Shibasaki, R.; Sanui, K.; Okubo, K. Impact of Cambodian international logistics policies on container cargo flow in a comprehensive intermodal transport network. Int. J. Logist. Res. Appl. 2021, 1–25. [Google Scholar] [CrossRef]

- Lee, C.K.; Lv, Y.; Ng, K.; Ho, W.; Choy, K.L. Design and application of Internet of things-based warehouse management system for smart logistics. Int. J. Prod. Res. 2018, 56, 2753–2768. [Google Scholar] [CrossRef]

- Aslanzade, R. Methodological approaches to assessing the social responsibility level in the field of supply chain management. Access J.—Access Sci. Bus. Innov. Digit. Econ. 2021, 2, 162–174. [Google Scholar] [CrossRef]

- Jeong, Y.; Kim, G.; Moon, I. Reliable container supply chain under disruption. Ann. Oper. Res. 2022. [Google Scholar] [CrossRef]

- Kumawat, G.L.; Roy, D.; De Koster, R.; Adan, I. Stochastic modeling of parallel process flows in intra-logistics systems: Applications in container terminals and compact storage systems. Eur. J. Oper. Res. 2021, 290, 159–176. [Google Scholar] [CrossRef]

- Sugimura, Y.; Wakashima, H.; Liang, Z.; Shibasaki, R. Logistics strategy simulation of second-ranked ports on the basis of Japan’s port reforms: A case study of Hakata Port. Marit. Policy Manag. 2023, 50, 707–723. [Google Scholar] [CrossRef]

- Jović, M.; Tijan, E.; Žgaljić, D.; Aksentijević, S. Improving maritime transport sustainability using blockchain-based information exchange. Sustainability 2020, 12, 8866. [Google Scholar] [CrossRef]

- Zhou, F.; He, Y.; Ma, P.; Mahto, R.V. Knowledge management practice of medical cloud logistics industry: Transportation resource semantic discovery based on ontology modelling. J. Intellect. Cap. 2020, 22, 360–383. [Google Scholar] [CrossRef]

- Zhou, F.; He, Y.; Chan, F.T.; Ma, P.; Schiavone, F. Joint Distribution Promotion by Interactive Factor Analysis using an Interpretive Structural Modeling Approach. SAGE Open 2022, 12, 21582440221079903. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Das, A.; Sokolov, B. Digital supply chain twins: Managing the ripple effect, resilience, and disruption risks by data-driven optimization, simulation, and visibility. In Handbook of Ripple Effects in the Supply Chain; Springer: Cham, Switzerland, 2019; pp. 309–332. [Google Scholar]

- Wang, J.; Liu, J.; Wang, F.; Yue, X. Blockchain technology for port logistics capability: Exclusive or sharing. Transp. Res. Part B Methodol. 2021, 149, 347–392. [Google Scholar] [CrossRef]

- Sternberg, H.S.; Denizel, M. Toward the physical internet—Logistics service modularity and design implications. J. Bus. Logist. 2021, 42, 144–166. [Google Scholar] [CrossRef]

- Ahmedov, I. The impact of digital economy on international trade. Eur. J. Bus. Manag. Res. 2020, 5. [Google Scholar] [CrossRef]

- Nanyam, V.N.; Jha, K.N. Operational performance model for Indian container terminals using qualitative comparative analysis. Asian J. Shipp. Logist. 2022, 38, 197–206. [Google Scholar] [CrossRef]

- Petrova, M.; Popova, P.; Popov, V.; Shishmanov, K.; Marinova, K. Digital Ecosystem: Nature, Types and Opportunities for Value Creation. In Innovations in Digital Economy; Springer: Cham, Switzerland, 2022; pp. 71–85. [Google Scholar]

- Attaran, M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum Int. J. 2020, 21, 158–172. [Google Scholar] [CrossRef]

- Ye, Z.G.; Cai, Z.Q.; Yang, H.; Si, S.B.; Zhou, F.L. Joint optimization of maintenance and quality inspection for manufacturing networks based on deep reinforcement learning. Reliab. Eng. Syst. Saf. 2023, 236, 109290. [Google Scholar] [CrossRef]

- Wang, K.; Hu, Q.; Zhou, M.; Zun, Z.; Qian, X. Multi-aspect applications and development challenges of digital twin-driven management in global smart ports. Case Stud. Transp. Policy 2021, 9, 1298–1312. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, R.Y.; Tian, Z.G.; Dai, H.-N.; Barenji, A.V.; Huang, G.Q. Industrial Blockchain: A state-of-the-art Survey. Robot. Comput.-Integr. Manuf. 2021, 70, 102124. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Bui, T.D.; Ali, M.H.; Tsai, F.M.; Iranmanesh, M.; Tseng, M.-L.; Lim, M.K. Challenges and trends in sustainable corporate finance: A bibliometric systematic review. J. Risk Financ. Manag. 2020, 13, 264. [Google Scholar] [CrossRef]

- Lim, M.K.; Xiong, W.; Lei, Z. Theory, supporting technology and application analysis of cloud manufacturing: A systematic and comprehensive literature review. Ind. Manag. Data Syst. 2020, 120, 1585–1614. [Google Scholar] [CrossRef]

- Christiansen, M.; Fagerholt, K.; Nygreen, B.; Ronen, D. Ship routing and scheduling in the new millennium. Eur. J. Oper. Res. 2013, 228, 467–483. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, Y. Blockchain-enabled cross-border e-commerce supply chain management: A bibliometric systematic review. Sustainability 2022, 14, 15918. [Google Scholar] [CrossRef]

- Neeraj, K.N.; Maurya, V. A review on machine learning (feature selection, classification and clustering) approaches of big data mining in different area of research. J. Crit. Rev. 2020, 7, 2610–2626. [Google Scholar]

- Muñoz-Leiva, F.; López, M.E.R.; Liebana-Cabanillas, F.; Moro, S. Past, present, and future research on self-service merchandising: A co-word and text mining approach. Eur. J. Mark. 2021, 55, 2269–2307. [Google Scholar] [CrossRef]

- Feng, Y.; Zhu, Q.; Lai, K.-H. Corporate social responsibility for supply chain management: A literature review and bibliometric analysis. J. Clean. Prod. 2017, 158, 296–307. [Google Scholar] [CrossRef]

- Yang, B.; Swe, T.; Chen, Y.; Zeng, C.; Shu, H.; Li, X.; Yu, T.; Zhang, X.; Sun, L. Energy cooperation between Myanmar and China under One Belt One Road: Current state, challenges and perspectives. Energy 2021, 215, 119130. [Google Scholar] [CrossRef]

- Liu, W.; Wei, W.; Yan, X.; Dong, D.; Chen, Z. Sustainability risk management in a smart logistics ecological chain: An evaluation framework based on social network analysis. J. Clean. Prod. 2020, 276, 124189. [Google Scholar] [CrossRef]

- Shi, D.P.; Zhou, J.C.; Wang, D.; Wu, X.P. Research Status, Hotspots, and Evolutionary Trends of Intelligent Education from the Perspective of Knowledge Graph. Sustainability 2022, 14, 10934. [Google Scholar] [CrossRef]

- Chen, C.M.; Leydesdorff, L. Patterns of Connections and Movements in Dual-Map Overlays: A New Method of Publication Portfolio Analysis. J. Assoc. Inf. Sci. Technol. 2014, 65, 334–351. [Google Scholar] [CrossRef]

- Steenken, D.; Voss, S.; Stahlbock, R. Container terminal operation and operations research—A classification and literature review. OR Spectr. 2004, 26, 3–49. [Google Scholar] [CrossRef]

- Stahlbock, R.; Voß, S. Operations research at container terminals: A literature update. OR Spectr. 2008, 30, 1–52. [Google Scholar] [CrossRef]

- Christiansen, M.; Fagerholt, K.; Ronen, D. Ship routing and scheduling: Status and perspectives. Transp. Sci. 2004, 38, 1–18. [Google Scholar] [CrossRef]

- Vis, I.F.A.; De Koster, R. Transshipment of containers at a container terminal: An overview. Eur. J. Oper. Res. 2003, 147, 1–16. [Google Scholar] [CrossRef]

- Trucco, P.; Cagno, E.; Ruggeri, F.; Grande, O. A Bayesian Belief Network modelling of organisational factors in risk analysis: A case study in maritime transportation. Reliab. Eng. Syst. Saf. 2008, 93, 845–856. [Google Scholar] [CrossRef]

- Psaraftis, H.N.; Kontovas, C.A. Speed models for energy-efficient maritime transportation: A taxonomy and survey. Transp. Res. Part C Emerg. Technol. 2013, 26, 331–351. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, S.; Andersson, H.; Thun, K. Containership routing and scheduling in liner shipping: Overview and future research directions. Transp. Sci. 2014, 48, 265–280. [Google Scholar] [CrossRef]

- Roso, V.; Woxenius, J.; Lumsden, K. The dry port concept: Connecting container seaports with the hinterland. J. Transp. Geogr. 2009, 17, 338–345. [Google Scholar] [CrossRef]

- Agarwal, R.; Ergun, Ö. Ship scheduling and network design for cargo routing in liner shipping. Transp. Sci. 2008, 42, 175–196. [Google Scholar] [CrossRef]

- Norstad, I.; Fagerholt, K.; Laporte, G. Tramp ship routing and scheduling with speed optimization. Transp. Res. Part C Emerg. Technol. 2011, 19, 853–865. [Google Scholar] [CrossRef]

- Goerlandt, F.; Montewka, J. Maritime transportation risk analysis: Review and analysis in light of some foundational issues. Reliab. Eng. Syst. Saf. 2015, 138, 115–134. [Google Scholar] [CrossRef]

- Montewka, J.; Ehlers, S.; Goerlandt, F.; Hinz, T.; Tabri, K.; Kujala, P. A framework for risk assessment for maritime transportation systems—A case study for open sea collisions involving RoPax vessels. Reliab. Eng. Syst. Saf. 2014, 124, 142–157. [Google Scholar] [CrossRef]

- Fagerholt, K.; Gausel, N.T.; Rakke, J.G.; Psaraftis, H.N. Maritime routing and speed optimization with emission control areas. Transp. Res. Part C Emerg. Technol. 2015, 52, 57–73. [Google Scholar] [CrossRef]

- Brouer, B.D.; Alvarez, J.F.; Plum, C.E.M.; Pisinger, D.; Sigurd, M.M. A base integer programming model and benchmark suite for liner-shipping network design. Transp. Sci. 2014, 48, 281–312. [Google Scholar] [CrossRef]

- Chen, X.; Chen, J.; Wu, D.; Xie, Y.; Li, J. Mapping the research trends by co-word analysis based on keywords from funded project. Procedia Comput. Sci. 2016, 91, 547–555. [Google Scholar] [CrossRef]

- Jonker, T.; Duinkerken, M.; Yorke-Smith, N.; de Waal, A.; Negenborn, R. Coordinated optimization of equipment operations in a container terminal. Flex. Serv. Manuf. J. 2021, 33, 281–311. [Google Scholar] [CrossRef]

- Yu, H.; Fang, Z.; Fu, X.; Liu, J.; Chen, J. Literature review on emission control-based ship voyage optimization. Transp. Res. Part D Transp. Environ. 2021, 93, 102768. [Google Scholar] [CrossRef]

- Ung, S.-T. Navigation Risk estimation using a modified Bayesian Network modeling-a case study in Taiwan. Reliab. Eng. Syst. Saf. 2021, 213, 107777. [Google Scholar] [CrossRef]

- Hamka, M.A. Safety risks assessment on container terminal using hazard identification and risk assessment and fault tree analysis methods. Procedia Eng. 2017, 194, 307–314. [Google Scholar]

- Lin, T.Y.; Shi, G.; Yang, C.; Zhang, Y.; Wang, J.; Jia, Z.; Guo, L.; Xiao, Y.; Wei, Z.; Lan, S. Efficient container virtualization-based digital twin simulation of smart industrial systems. J. Clean. Prod. 2021, 281, 124443. [Google Scholar] [CrossRef]

- Jakovlev, S.; Eglynas, T.; Voznak, M.; Partila, P.; Tovarek, J.; Jusis, M.; Pocevicius, E.; Purlaura, Z. Development of an intelligent digital twins framework for secure container terminal operations. In Proceedings of the 2021 62nd International Scientific Conference on Information Technology and Management Science of Riga Technical University (ITMS), Riga, Latvia, 14–15 October 2021; pp. 1–4. [Google Scholar]

- Xie, B.; Zhang, X.; Lu, J.; Liu, F.; Fan, Y. Research on ecological evaluation of Shanghai port logistics based on emergy ecological footprint models. Ecol. Indic. 2022, 139, 108916. [Google Scholar] [CrossRef]

- Zhuang, Z.; Zhang, Z.; Teng, H.; Qin, W.; Fang, H. Optimization for integrated scheduling of intelligent handling equipment with bidirectional flows and limited buffers at automated container terminals. Comput. Oper. Res. 2022, 145, 105863. [Google Scholar] [CrossRef]

- Song, Y.; Yu, F.R.; Zhou, L.; Yang, X.; He, Z. Applications of the Internet of Things (IoT) in smart logistics: A comprehensive survey. IEEE Internet Things J. 2020, 8, 4250–4274. [Google Scholar] [CrossRef]

- Choi, H.R.; Moon, Y.S.; Kim, J.J.; Lee, J.K.; Lee, K.B.; Shin, J.J. Development of an IoT-based container tracking system for China’s Belt and Road (B&R) initiative. Marit. Policy Manag. 2018, 45, 388–402. [Google Scholar] [CrossRef]

- Bahrami, Z.; Zhang, R.; Wang, T.; Liu, Z. An end-to-end framework for shipping container corrosion defect inspection. IEEE Trans. Instrum. Meas. 2022, 71, 1–14. [Google Scholar] [CrossRef]

- Young, R.R.; Gordon, G.A. Intermodal maritime supply chains: Assessing factors for resiliency and security. J. Transp. Secur. 2020, 13, 231–244. [Google Scholar] [CrossRef]

- Kurtuluş, E. Optimizing inland container logistics and dry port location-allocation from an environmental perspective. Res. Transp. Bus. Manag. 2023, 48, 100839. [Google Scholar] [CrossRef]

- Baygin, M.; Yaman, O.; Baygin, N.; Karakose, M. A blockchain-based approach to smart cargo transportation using UHF RFID. Expert Syst. Appl. 2022, 188, 116030. [Google Scholar] [CrossRef]

- Chung, S.-H. Applications of smart technologies in logistics and transport: A review. Transp. Res. Part E Logist. Transp. Rev. 2021, 153, 102455. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, X.; Li, X.Y.; Zhang, C. A Fuzzy Programming Method for Modeling Demand Uncertainty in the Capacitated Road-Rail Multimodal Routing Problem with Time Windows. Symmetry 2019, 11, 91. [Google Scholar] [CrossRef]

- Muthuramalingam, S.; Bharathi, A.; Rakesh Kumar, S.; Gayathri, N.; Sathiyaraj, R.; Balamurugan, B. IoT based intelligent transportation system (IoT-ITS) for global perspective: A case study. In Internet of Things and Big Data Analytics for Smart Generation; Springer: Berlin/Heidelberg, Germany, 2019; pp. 279–300. [Google Scholar]

- Seo, J.; Lee, B.K.; Jeon, Y. Digitalization strategies and evaluation of maritime container supply chains. Bus. Process Manag. J. 2023, 29, 1–21. [Google Scholar] [CrossRef]

- Park, J.; Lee, B.K.; Low, J.M. A two-stage parallel network DEA model for analyzing the operational capability of container terminals. Marit. Policy Manag. 2022, 49, 118–139. [Google Scholar] [CrossRef]

| Organization | Country | Papers |

|---|---|---|

| Shanghai Maritime University | China | 98 |

| Norwegian University of Science and Technology | Norway | 89 |

| The Hong Kong Polytechnic University | China | 78 |

| Dalian Maritime University | China | 75 |

| Wuhan University of Technology | China | 72 |

| Istanbul Technical University | Turkey | 56 |

| National University of Singapore | Singapore | 50 |

| Nanyang Technological University | Singapore | 37 |

| Liverpool John Moores University | UK | 33 |

| Aalto University | Finland | 31 |

| Country | Published Papers |

|---|---|

| China | 791 |

| USA | 413 |

| UK | 205 |

| Germany | 175 |

| South Korea | 151 |

| Norway | 139 |

| Italy | 128 |

| Canada | 120 |

| Singapore | 105 |

| Australia | 103 |

| Item | Journal Name | Theme | Source | Total Citations |

|---|---|---|---|---|

| 1 | OR Spectrum | Container terminal operation and operations research—a classification and literature review | [63] | 869 |

| 2 | OR Spectrum | Operations research at container terminals: a literature update | [64] | 722 |

| 3 | Transportation Science | Ship routing and scheduling: status and perspectives | [65] | 459 |

| 4 | European Journal of Operational Research | Transshipment of containers at a container terminal: an overview | [66] | 440 |

| 5 | European Journal of Operational Research | Ship routing and scheduling in the new millennium | [54] | 359 |

| 6 | Reliability Engineering & System Safety | A Bayesian belief network modelling of organizational factors in risk analysis: a case study in maritime transportation | [67] | 317 |

| 7 | Transportation Research Part C: Emerging Technologies | Speed models for energy-efficient maritime transportation: A taxonomy and survey | [68] | 311 |

| 8 | Transportation Science | Containership routing and scheduling in liner shipping: overview and future research directions | [69] | 293 |

| 9 | Journal of Transport Geography | The dry port concept: connecting container seaports with the hinterland | [70] | 281 |

| 10 | Transportation Science | Ship scheduling and network design for cargo routing in liner shipping | [71] | 275 |

| 11 | Transportation Research Part C: Emerging Technologies | Tramp ship routing and scheduling with speed optimization | [72] | 213 |

| 12 | Reliability Engineering & System Safety | Maritime transportation risk analysis: review and analysis in light of some foundational issues | [73] | 209 |

| 13 | Reliability Engineering & System Safety | A framework for risk assessment for maritime transportation systems—a case study for open sea collisions involving RoPax vessels | [74] | 172 |

| 14 | Transportation Research Part C: Emerging Technologies | Maritime routing and speed optimization with emission control areas | [75] | 164 |

| 15 | Transportation Science | A base integer programming model and benchmark suite for liner-shipping network design | [76] | 158 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, J.; Zhou, F.; He, Y. Digital Technique-Enabled Container Logistics Supply Chain Sustainability Achievement. Sustainability 2023, 15, 16014. https://doi.org/10.3390/su152216014

Lyu J, Zhou F, He Y. Digital Technique-Enabled Container Logistics Supply Chain Sustainability Achievement. Sustainability. 2023; 15(22):16014. https://doi.org/10.3390/su152216014

Chicago/Turabian StyleLyu, Jieyin, Fuli Zhou, and Yandong He. 2023. "Digital Technique-Enabled Container Logistics Supply Chain Sustainability Achievement" Sustainability 15, no. 22: 16014. https://doi.org/10.3390/su152216014

APA StyleLyu, J., Zhou, F., & He, Y. (2023). Digital Technique-Enabled Container Logistics Supply Chain Sustainability Achievement. Sustainability, 15(22), 16014. https://doi.org/10.3390/su152216014