A Semi-Analytical Model of Contaminant Transport in Barrier Systems with Arbitrary Numbers of Layers

Abstract

:1. Introduction

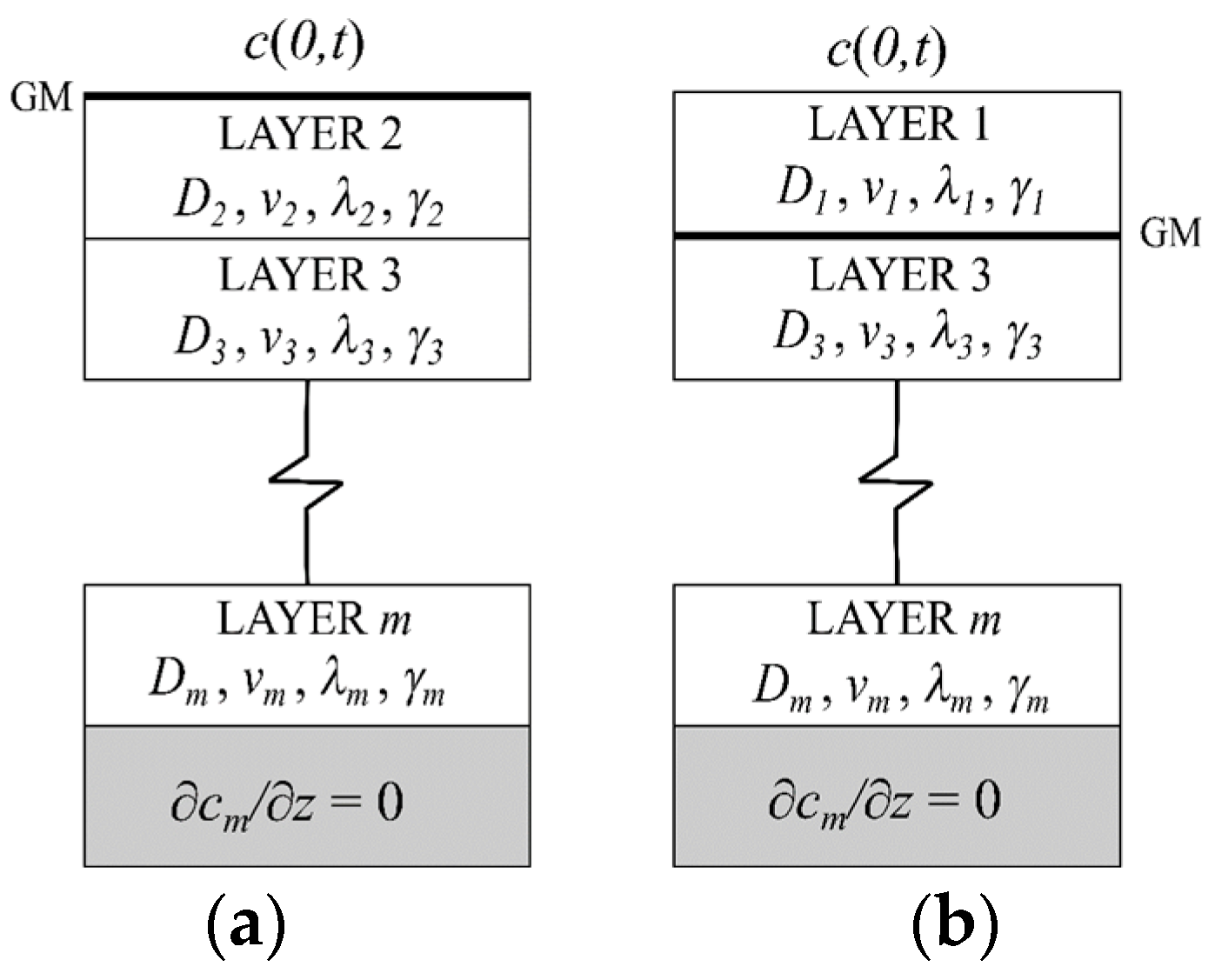

2. Mathematical Modeling

3. Results

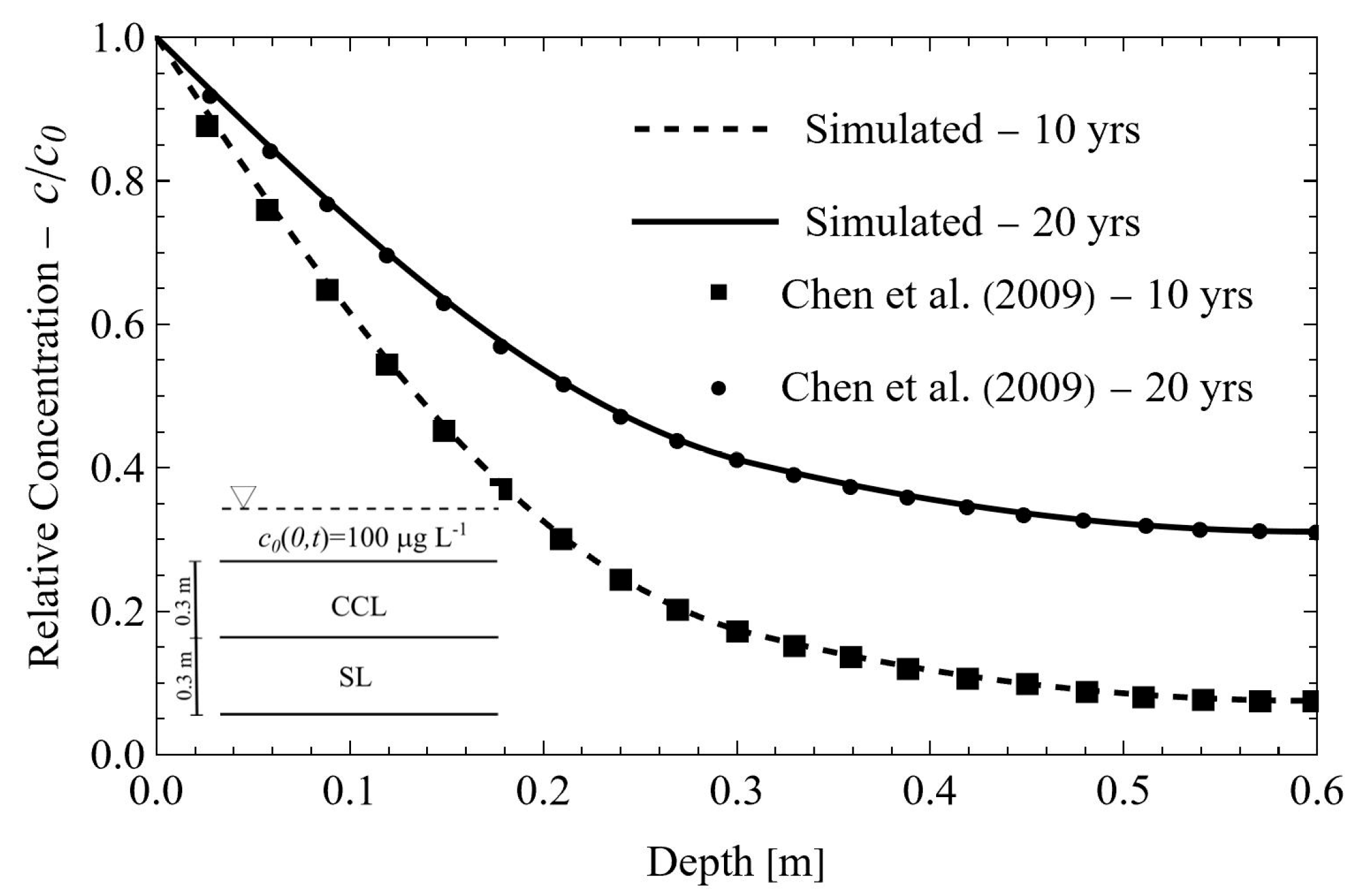

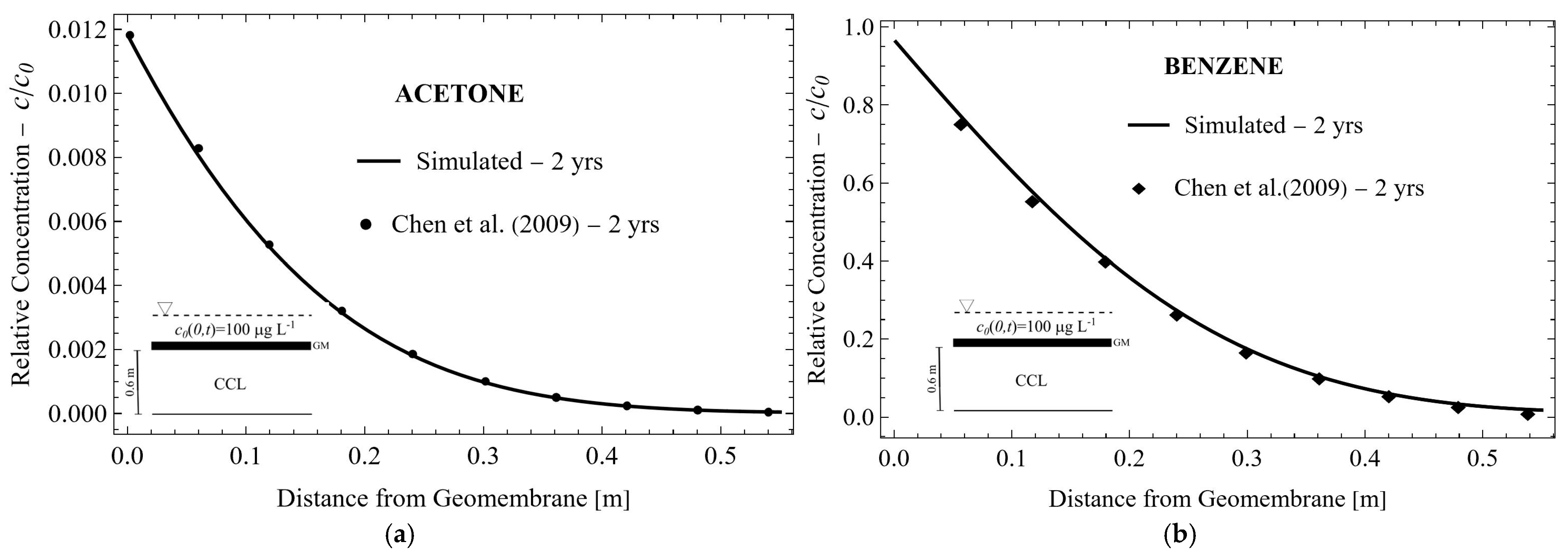

3.1. Model Validation

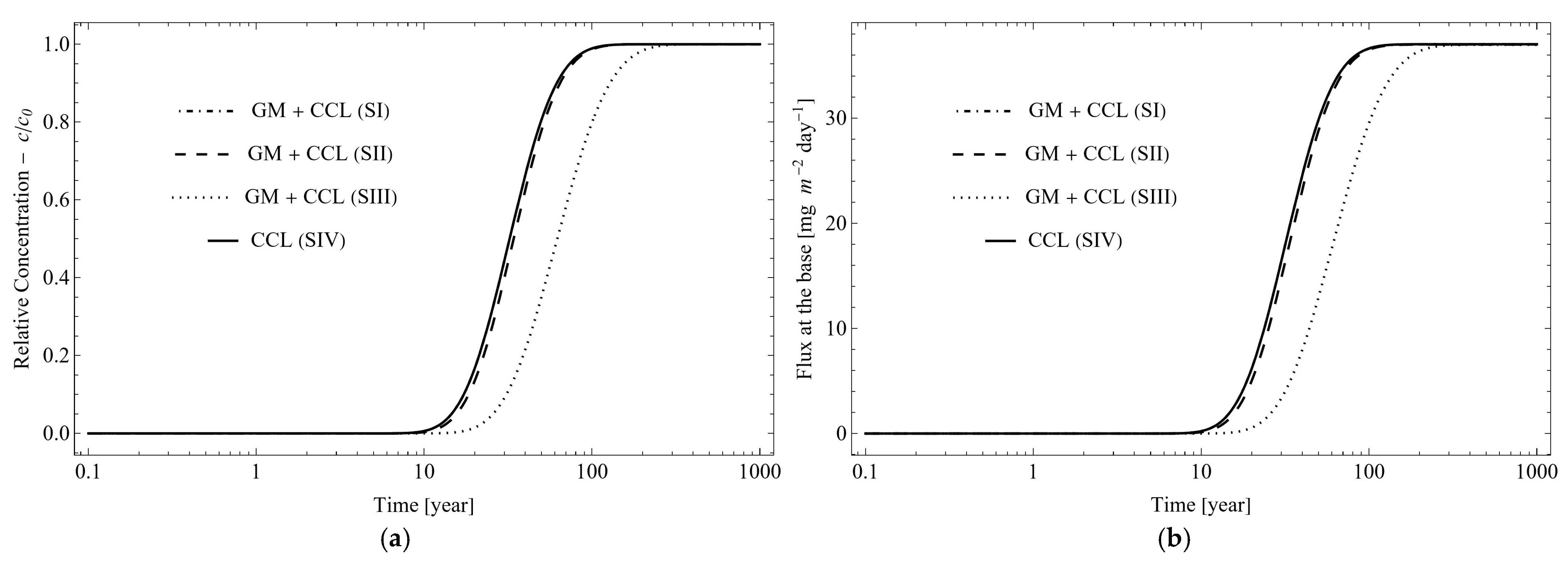

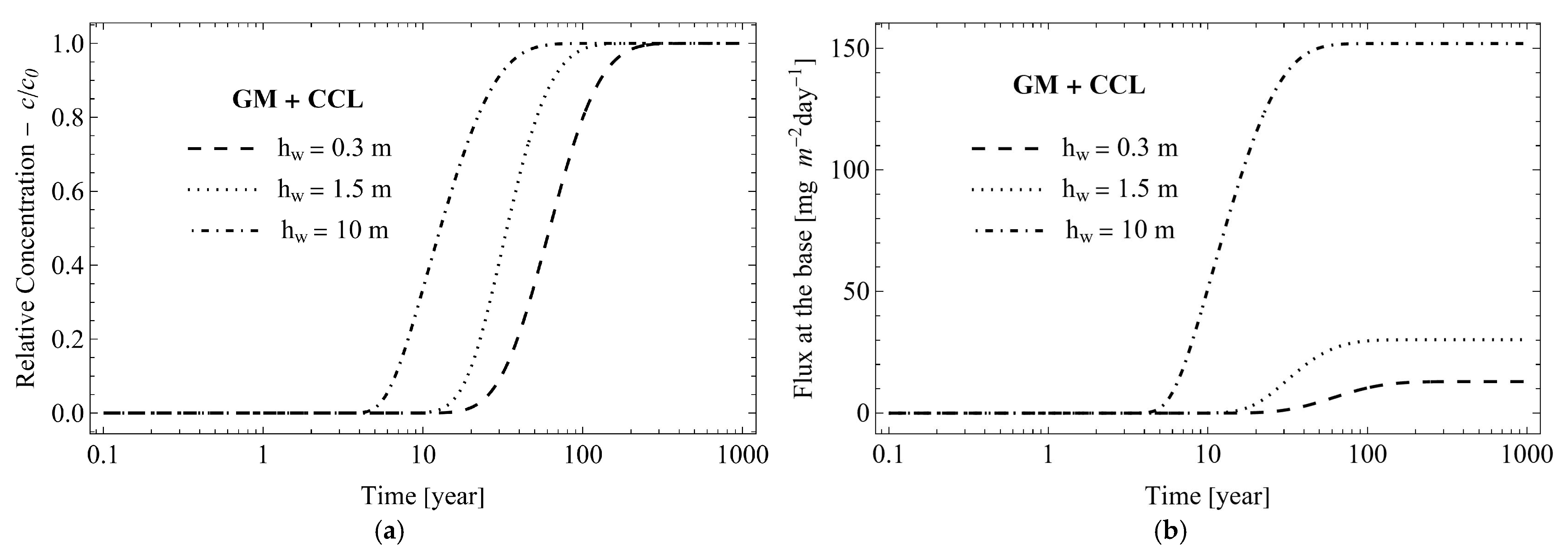

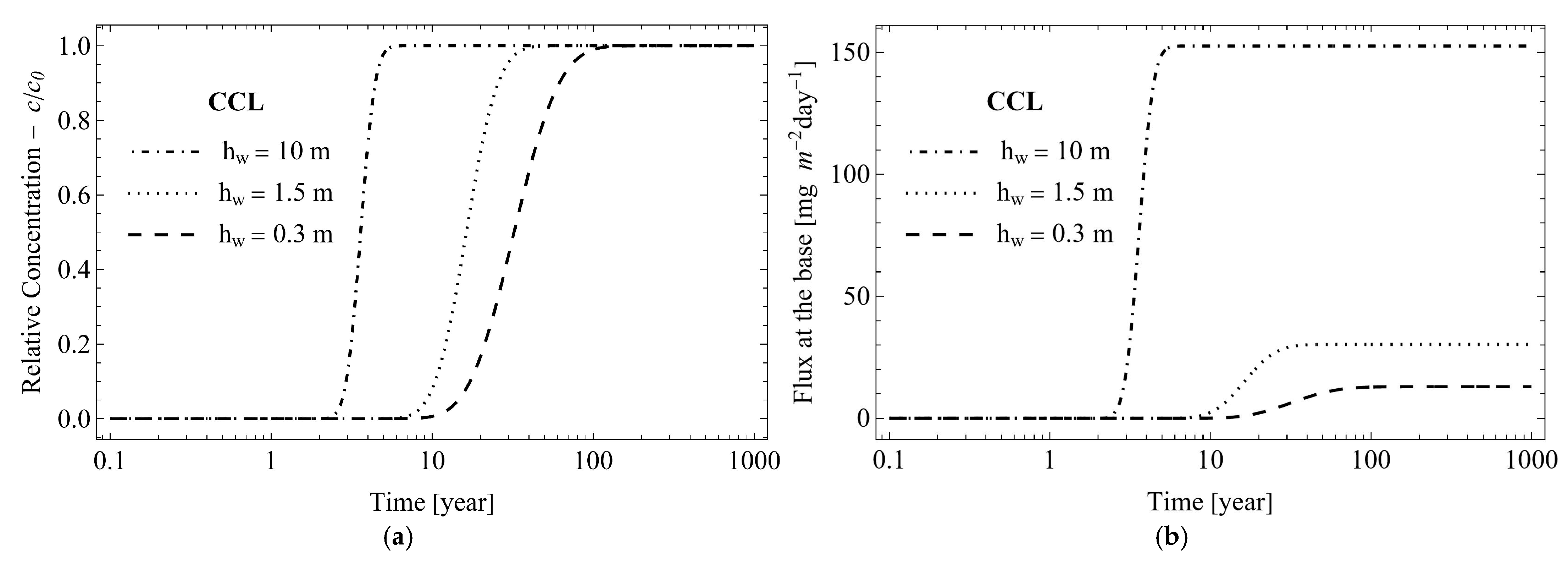

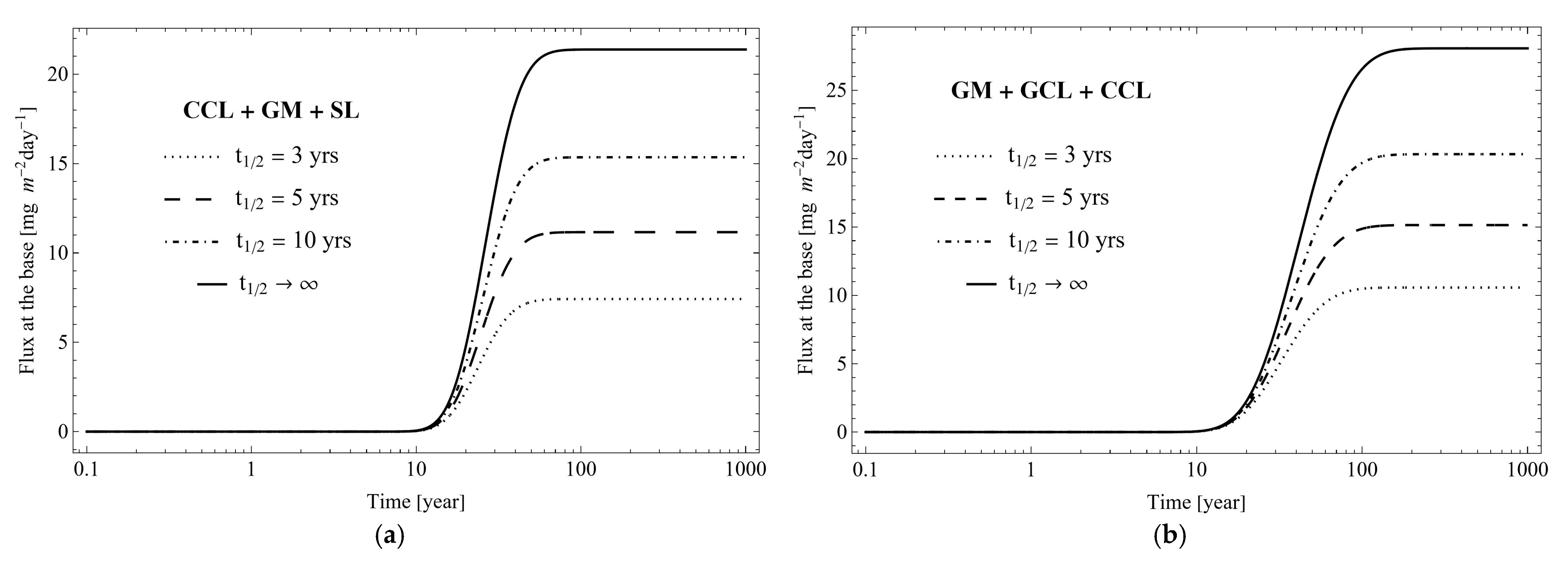

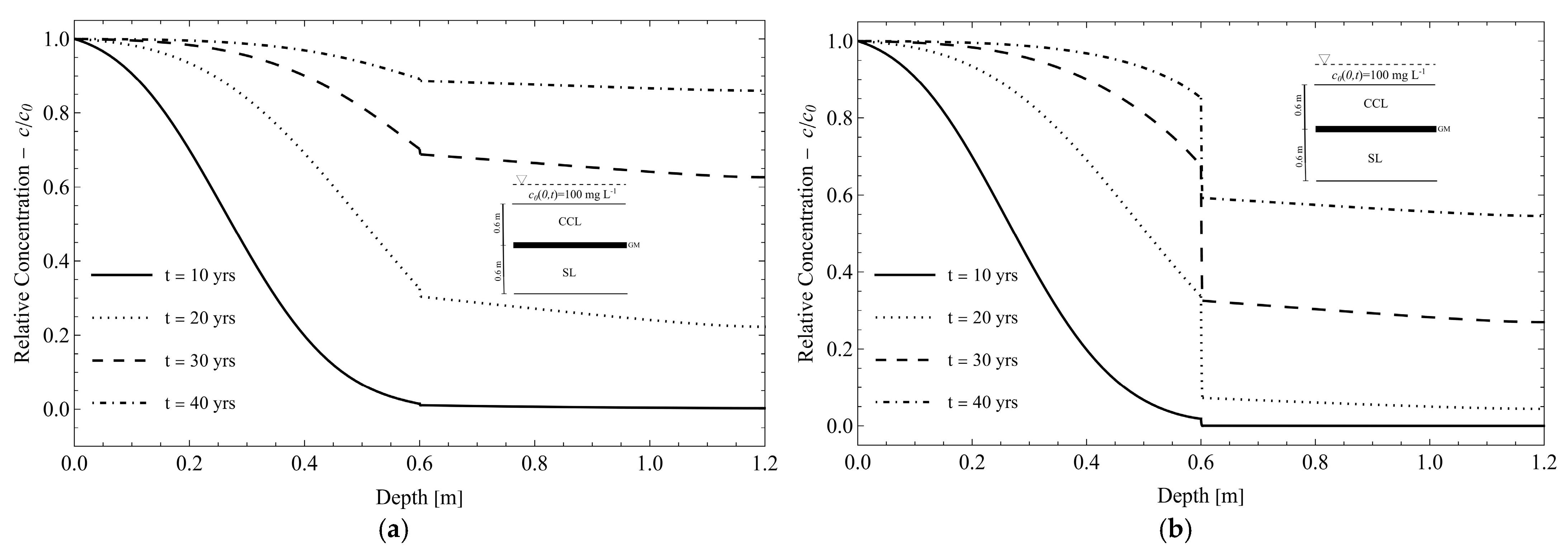

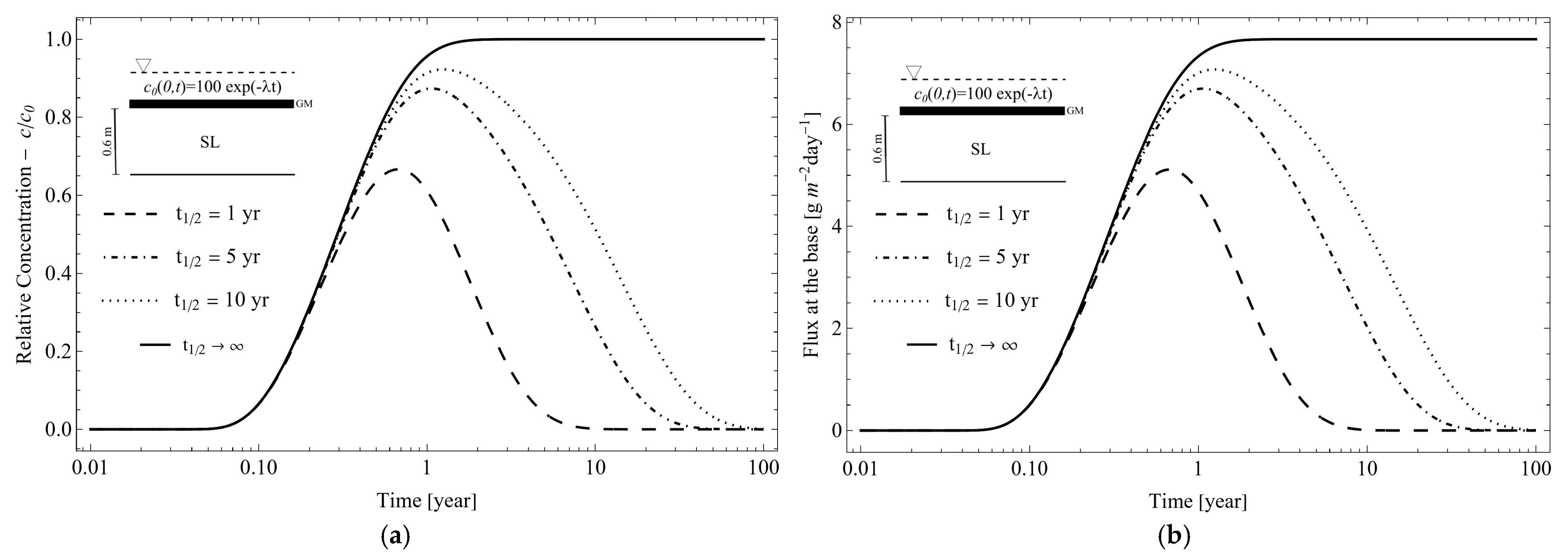

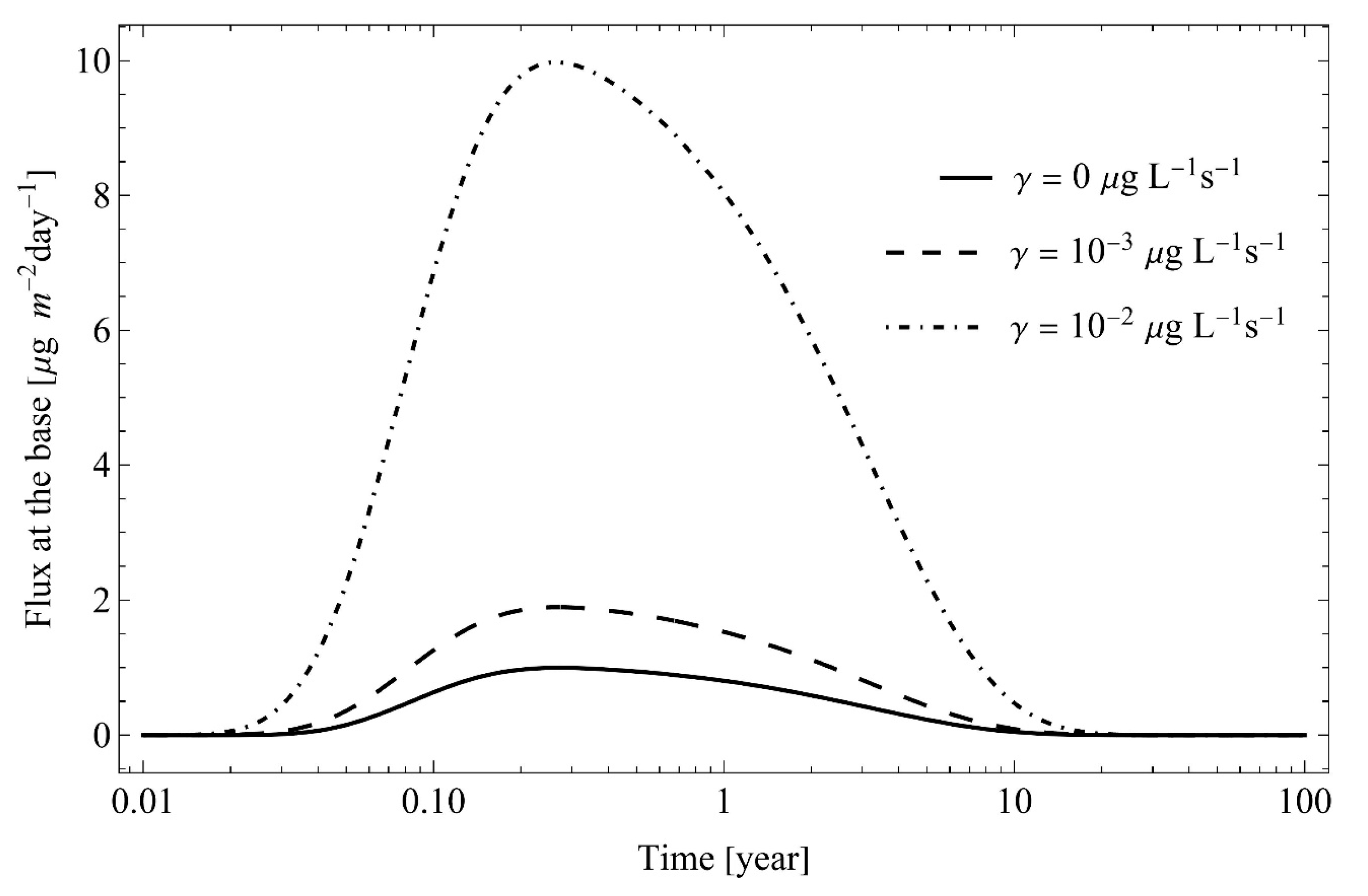

3.2. Parametric Evaluation

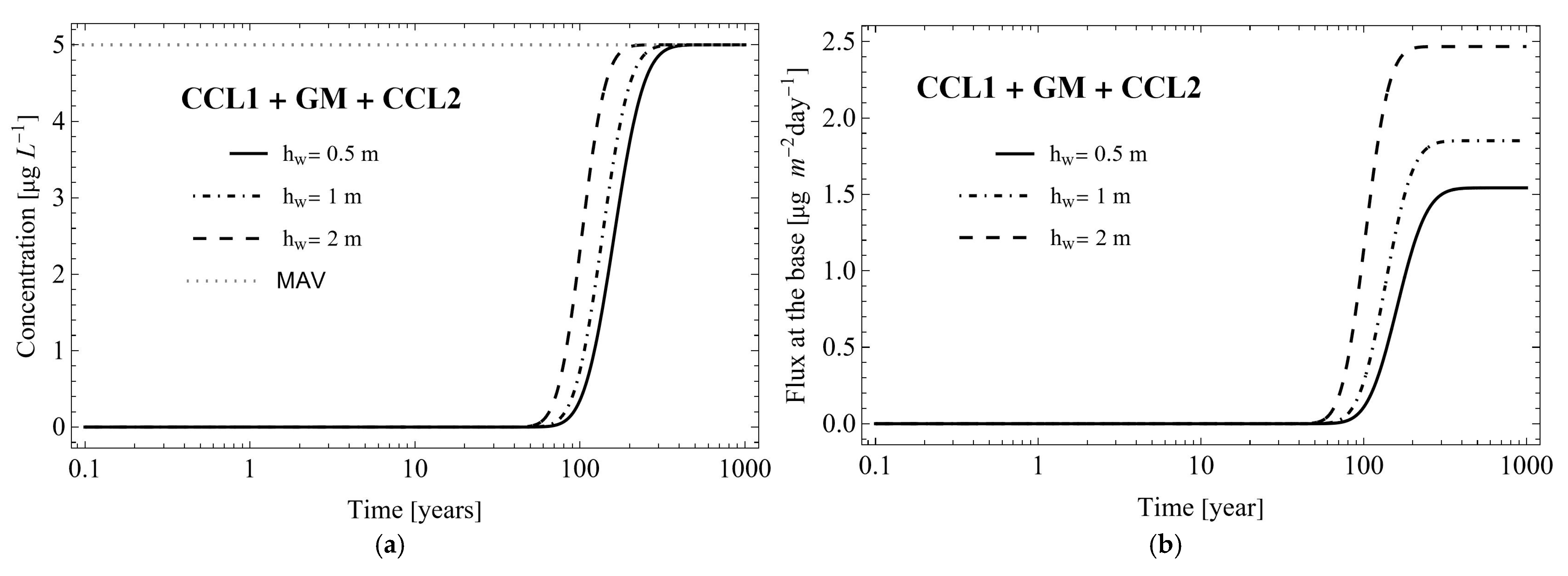

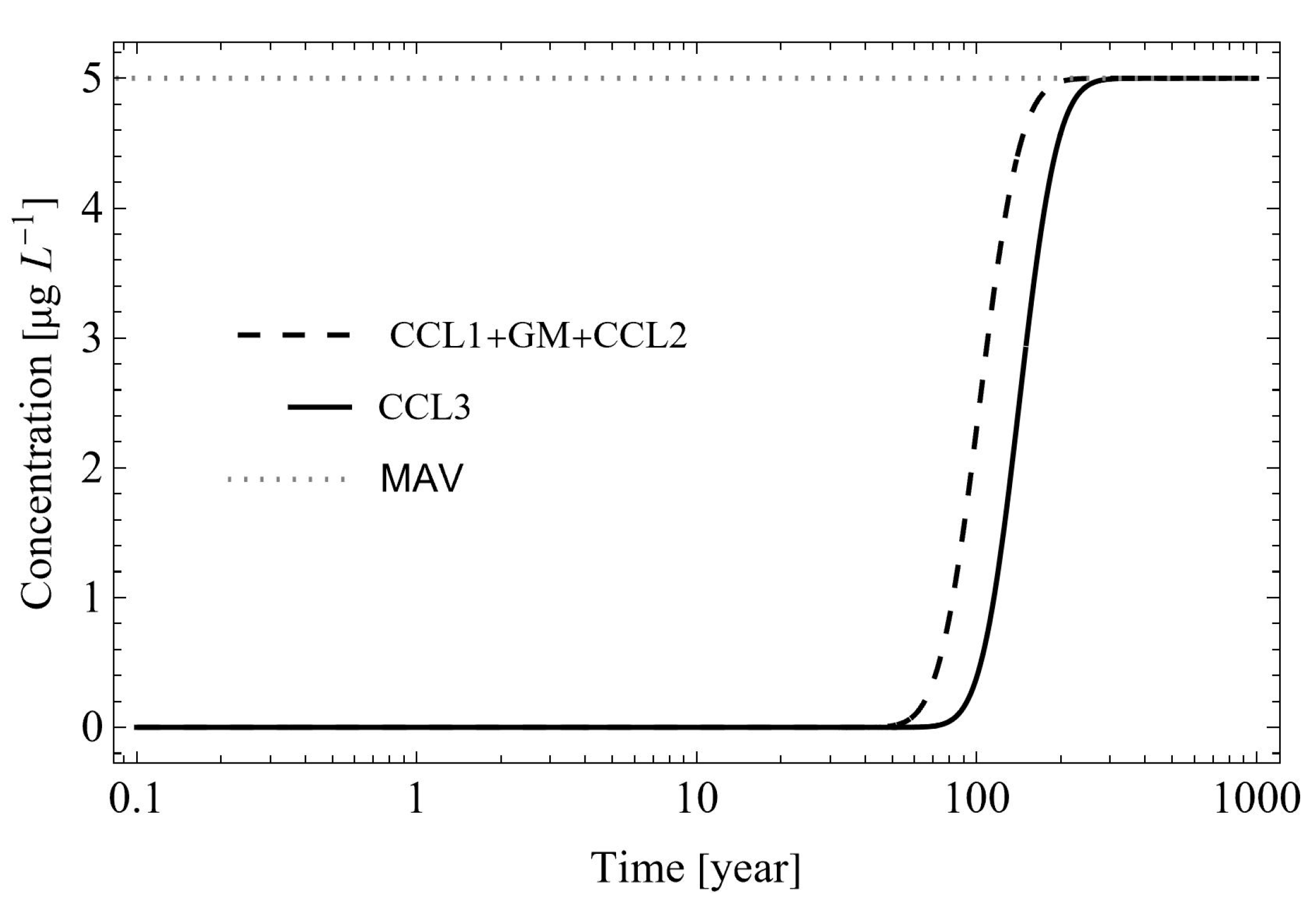

3.3. Application to Real Sanitary Landfill

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. General Solution for m Layers in Laplace Space

Appendix A.2. Flux of Contaminant of an Arbitrary Layer

References

- Wijekoon, P.; Koliyabandara, P.A.; Cooray, A.T.; Lam, S.S.; Athapattu, B.C.L.; Vithanage, M. Progress and prospects in mitigation of landfill leachate pollution: Risk, pollution potential, treatment and challenges. J. Hazard. Mater. 2022, 421, 126627. [Google Scholar] [CrossRef]

- Lu, S.-F.; Xiong, J.-H.; Feng, S.-J.; Chen, H.-X.; Bai, Z.-B.; Fu, W.-D.; Lü, F. A finite-volume numerical model for bio-hydro-mechanical behaviors of municipal solid waste in landfills. Comput. Geotech. 2019, 109, 204–219. [Google Scholar] [CrossRef]

- Rowe, R.K.; Quigley, R.M.; Brachman, R.W.I.; Booker, J.R. Barrier Systems for Waste Disposal Facilities; Taylor & Francis: London, UK, 2004. [Google Scholar]

- Bernardo, B.; Candeias, C.; Rocha, F. Characterization of the Dynamics of Leachate Contamination Plumes in the Surroundings of the Hulene-BWaste Dump in Maputo, Mozambique. Environments 2022, 9, 19. [Google Scholar] [CrossRef]

- Christensen, T.H.; Kjeldsen, P.; Bjerg, P.L.; Jensen, D.L.; Christensen, J.B.; Baun, A.; Albrechtsen, H.J.; Heron, C. Biogeochemistry of landfill leachate plumes. Appl. Geochem. 2001, 16, 659–718. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, R.; Yang, Y.; Yu, M.; Xi, B.; Li, M.; Xu, Z.; Gao, S.; Yang, C. Migration and evolution of dissolved organic matter in landfill leachate-contaminated groundwater plume. Resour. Conserv. Recycl. 2019, 151, 104463. [Google Scholar] [CrossRef]

- Guan, C.; Xie, H.J.; Wang, Y.Z.; Chen, Y.M.; Jiang, Y.S.; Tang, X.W. An analytical model for solute transport through a GCL-based two-layered liner considering biodegradation. Sci. Total Environ. 2014, 466–467, 221–231. [Google Scholar] [CrossRef]

- Southen, J.M.; Rowe, R.K. Evaluation of the water retention curve for geosynthetic clay liners. Geotext. Geomembr. 2007, 25, 2–9. [Google Scholar] [CrossRef]

- Özçoban, M.S.; Acarer, S.; Tüfekci, N. Effect of solid waste landfill leachate contaminants on hydraulic conductivity of landfill liners. Water Sci. Technol. 2022, 85, 1581–1599. [Google Scholar] [CrossRef]

- McWatters, R.S.; Rutter, A.; Rowe, R.K. Geomembrane applications for controlling diffusive migration of petroleum hydrocarbons in cold region environments. J. Environ. Manag. 2016, 181, 80–94. [Google Scholar] [CrossRef]

- Rowe, R.K. Long-term performance of contaminant barrier systems. Géotechnique 2005, 55, 631–678. [Google Scholar] [CrossRef]

- Shackelford, C.D. The ISSMGE Kerry Rowe Lecture: The role of diffusion in environmental geotechnics. Can. Geotech. J. 2014, 51, 1219–1242. [Google Scholar] [CrossRef]

- EPA625-4-89-022; Requirements for Hazardous Waste Landfill Design, Construction, and Closure. U.S. EPA: Washington, DC, USA, 1989.

- Bouazza, A.; Bowders, J.J. Geosynthetic Clay Liners for Waste Containment Facilities; Taylor & Francis Group: London, UK, 2010. [Google Scholar]

- Shan, H.-Y.; Lai, Y.-J. Effect of hydrating liquid on the hydraulic properties of geosynthetic clay liner. Geotext. Geomembr. 2002, 20, 19–38. [Google Scholar] [CrossRef]

- Uma Shankar, M.; Muthukumar, M. Comprehensive review of geosynthetic clay liner and compacted clay liner. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032026. [Google Scholar] [CrossRef]

- Visentin, C.; Zanella, P.; Kronhardt, B.K.; Da Silva Trentin, A.W.; Braun, A.B.; Thomé, A. Use of geosynthetic clay liner as a waterproofing barrier in sanitary landfills. J. Urban Environ. Eng. 2019, 13, 115–124. [Google Scholar] [CrossRef]

- Giroud, J.; Badu-Tweneboah, K.; Soderman, K.L. Comparison of leachate flow through compacted clay liners and geosynthetic clay liners in landfill liner systems. Geosynth. Int. 1997, 4, 391–431. [Google Scholar] [CrossRef]

- EPA530-F-97-002; Geosynthetic Clay Liners Used in Municipal Solid Waste Landfills. U.S. EPA: Washington, DC, USA, 2001.

- Cleall, P.J.; Li, Y.C. Analytical solution for diffusion of VOCs through composite landfill liners. J. Geotech. Geoenviron. Eng. 2011, 137, 850–854. [Google Scholar] [CrossRef]

- Foose, G.J. Transit-time design for diffusion through composite liners. J. Geotech. Geoenviron. Eng. 2002, 128, 590–601. [Google Scholar] [CrossRef]

- Carr, E.J. New Semi-Analytical Solutions for Advection–Dispersion Equations in Multilayer Porous Media. Transp. Porous Medium 2020, 135, 39–58. [Google Scholar] [CrossRef]

- Xie, H.; Zhang, C.; Sedighi, M.; Thomas, H.R.; Chen, Y. An analytical model for diffusion of chemicals under thermal effects in semi-infinite porous media. Comput. Geotech. 2015, 69, 329–337. [Google Scholar] [CrossRef]

- Xie, H.; Chen, Y.; Lou, Z. An analytical solution to contaminant transport through composite liners with geomembrane defects. Sci. China Technol. Sci. 2010, 53, 1424–1433. [Google Scholar] [CrossRef]

- Ozelim, L.C.S.M.; Paz, Y.P.L.; Cunha, L.S.; Cavalcante, A.L.B. Enhanced landfill’s characterization by using an alternative analytical model for diffusion tests. Environ. Monit. Assess. 2021, 193, 739. [Google Scholar] [CrossRef]

- Xie, H.J.; Thomas, H.R.; Chen, Y.M.; Sedighi, M.; Tang, X.W. Diffusion of organic contaminants in triple-layer composite liners—An analytical modelling approach. Acta Geotech. 2015, 10, 255–262. [Google Scholar] [CrossRef]

- Peng, M.-Q.; Feng, S.-J.; Chen, H.-X.; Chen, Z.-L. An analytical solution for organic pollutant diffusion in a triple-layer composite liner considering the coupling influence of thermal diffusion. Comput. Geotech. 2021, 137, 104283. [Google Scholar] [CrossRef]

- Qiu, J.; He, Y.; Song, D.; Tong, J. Analytical solution for solute transport in a triple liner under non-isothermal condition. Geosynth. Int. 2022, 30, 364–381. [Google Scholar] [CrossRef]

- Lin, H.; Huang, W.; Wang, L.; Liu, Z. Transport of Organic Contaminants in Composite Vertical Cut-Off Wall with Defective HDPE Geomembrane. Polymers 2023, 15, 3031. [Google Scholar] [CrossRef] [PubMed]

- Davis, G.B.; Patterson, B.M.; Johnston, C.D. Aerobic bioremediation of 1, 2 dichloromethane and vinyl chloride at field scale. J. Contam. Hydrol. 2009, 107, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Wiedemeier, T.H.; Rifai, H.S.; Newell, C.J.; Wilson, J.T. Natural Attenuation of Fuels and Chlorinated Solvents in the Subsurface; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Ogata, A.; Banks, R.B. A Solution of the Differential Equation of Longitudinal Dispersion in Porous Media; U.S. Government Printing Office: Washington, DC, USA, 1961.

- Van Genuchten, M.T.; Alves, W.J. Analytical Solutions of the One-Dimensional Convective-Dispersive Solute Transport Equation; U.S. Department of Agriculture, Agricultural Research Service: Washington, DC, USA, 1982.

- Leij, F.J.; Van Genuchten, M.T. Approximate analytical solutions for solute transport in two-layer porous media. Transp. Porous Med. 1995, 18, 65–85. [Google Scholar] [CrossRef]

- Liu, C.; Ball, W.P.; Ellis, J.H. An analytical solution to the one-dimensional solute advection-dispersion equation in multi-layer porous media. Transp. Porous Med. 1998, 30, 25–43. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, H.; Ke, H.; Chen, R. An analytical solution for one-dimensional contaminant diffusion through multi-layered system and its applications. Environ. Geol. 2009, 58, 1083–1094. [Google Scholar] [CrossRef]

- Rowe, R.K.; Booker, J.R. The analysis of pollutant migration in a non-homogeneous soil. Geotechnique 1984, 34, 601–612. [Google Scholar] [CrossRef]

- Vieira, G.M.D.; Lemos, M.A.C.; Cavalcante, A.L.B.; Casagrande, M.D.T. Effectiveness of Polyvinylidene Fluoride Fibers (PVDF) in the Diffusion and Adsorption Processes of Atrazine in a Sandy Soil. Sustainability 2023, 15, 11729. [Google Scholar] [CrossRef]

- Lu, C.S.J.; Morrison, R.D.; Stearns, R.J. Leachate production and management from municipal landfills: Summary and assessment. Land disposal: Municipal solid waste. In Proceedings of the 7th Annual Research Symposium, Philadelphia, PA, USA, 16–18 March 1981. [Google Scholar]

- Xie, H.; Jiang, Y.; Zhang, C.; Feng, S. An analytical model for volatile organic compound transport through a composite liner consisting of a geomembrane, a GCL, and a soil liner. Environ. Sci. Pollut. Res. 2015, 22, 2824–2836. [Google Scholar] [CrossRef] [PubMed]

- Rowe, R.; Hrapovic, L.; Kosaric, N. Diffusion of Chloride and Dichloromethane through an HDPE Geomembrane. Geosynth. Int. 1995, 2, 507–536. [Google Scholar] [CrossRef]

- SLU—Municipal Cleaning Service of the Federal District. January–June 2023, Activity Report of the DF Municipal Cleaning Service; The DF Urban Cleaning Services (SLU): Brasília, Brazil, 2023; 139p. [Google Scholar]

- Baran, C.T. Modeling Contaminant Transport in Multi-Layer Compacted Clay Liners and Geomembrane Liners. Master’s Dissertation, University of Brasília, Brasília, Brazil, 2021. [Google Scholar]

- Brazil—National Environmental Council. Resolution No 396, April 3rd. Published in DOU no. 66, of 7 April 2008, Section 1, pages 64–68. Available online: https://www.mpf.mp.br/atuacao-tematica/ccr4/dados-da-atuacao/projetos/qualidade-da-agua/legislacao/resolucoes/resolucao-conama-no-396-de-3-de-abril-de-2008/view (accessed on 9 October 2023).

- Carr, E.J.; March, N.G. Semi-analytical solution of multilayer diffusion problems with time-varying boundary conditions and general interface conditions. Appl. Math. Comput. 2018, 333, 286–303. [Google Scholar] [CrossRef]

- Carr, E.J.; Turner, I.W. A semi-analytical solution for multilayer diffusion in a composite medium consisting of a large number of layers. Appl. Math. Model. 2016, 40, 7034–7050. [Google Scholar] [CrossRef]

- Trefethen, L.N.; Weideman, J.A.C.; Schmelzer, T. Talbot quadratures and rational approximations. BIT Numer. Math. 2006, 46, 653–670. [Google Scholar] [CrossRef]

| Material | Kd (mL g−1) | Dm (m2 s−1) | ρd (g cm−3) | n |

|---|---|---|---|---|

| CCL | 1 | 2.04 × 10−10 | 1.24 | 0.54 |

| SL | 0 | 3.17 × 10−10 | 1.60 | 0.40 |

| Layer | Property | Benzene | Acetone |

|---|---|---|---|

| GM | S0,GM | 36.4 | 0.02 |

| SL,GM | 36.4 | 0.03 | |

| DGM (m2 s−1) | 8.58 × 10−13 | 8.58 × 10−13 | |

| CCL | Kd (mL g−1) | 0.11 | 0 |

| Dm (m2 s−1) | 6.43 × 10−10 | 3.40 × 10−10 | |

| ρd (g cm−3) | 1.79 | 1.79 | |

| n | 0.35 | 0.35 |

| Parameters | GCL | SL | CCL |

|---|---|---|---|

| Thickness (m) | 0.01 | 0.60 | 0.60 |

| Porosity (n) | 0.70 | 0.30 | 0.35 |

| Dry density (g cm−3) | 0.79 | 1.62 | 1.66 |

| Dm (m2 s−1) | 3 × 10−10 | 8 × 10−10 | 4 × 10−10 |

| Kd (mL g−1) | 0 | 0 | 1.86 |

| Saturated hydraulic conductivity (m s−1) | 5 × 10−11 | 1 × 10−7 | 1 × 10−9 |

| Scenario | DGM (m2 s−1) | hw (m) | tGM (mm) | LCCL (m) | c0 (mg L−1) |

|---|---|---|---|---|---|

| SI | 10−11 | 0.3 | 0.75 | 0.6 | 100 |

| SII | 10−13 | 0.3 | 1.5 | 0.6 | 100 |

| SIII | 10−14 | 0.3 | 2.5 | 0.6 | 100 |

| SIV | - | 0.3 | - | 0.6 | 100 |

| Parameters | PL | DL | GM | CCL |

|---|---|---|---|---|

| Thickness (m) | 0.50 | 0.30 | 0.0015 | 0.40 |

| Porosity (n) | 0.47 | 0.38 | - | 0.51 |

| Dry density (g cm−3) | 1.50 | 1.59 | - | 1.25 |

| Effective diffusion coefficient (m2 s−1) | 1.58 × 10−6 | 3.47 × 10−6 | 3.50 × 10−13 | 1.58 × 10−6 |

| S0,GM = SL,GM | - | - | 150 | - |

| Retardation factor (Ri) | 5.6 | 15.2 | - | 16.2 |

| Parameters | CCL1 | GM | CCL2 | CCL3 |

|---|---|---|---|---|

| Thickness (m) | 0.50 | 0.002 | 1.50 | 2.5 |

| Porosity (n) | 0.35 | - | 0.35 | 0.35 |

| Dry density (g cm−3) | 1.66 | - | 1.66 | 1.66 |

| Effective diffusion coefficient (m2 s−1) | 4.10 × 10−10 | 1.90 × 10−13 | 4.10 × 10−10 | 4.10 × 10−10 |

| S0,GM = SL,GM | - | 36.4 | - | - |

| Kd (mL g−1) | 1.86 | - | 1.86 | 1.86 |

| Hydraulic conductivity (m s−1) | 1.0 × 10−9 | - | 1.0 × 10−9 | 1.0 × 10−9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemos, M.A.C.; Baran, C.T.; Cavalcante, A.L.B.; Palmeira, E.M. A Semi-Analytical Model of Contaminant Transport in Barrier Systems with Arbitrary Numbers of Layers. Sustainability 2023, 15, 16299. https://doi.org/10.3390/su152316299

Lemos MAC, Baran CT, Cavalcante ALB, Palmeira EM. A Semi-Analytical Model of Contaminant Transport in Barrier Systems with Arbitrary Numbers of Layers. Sustainability. 2023; 15(23):16299. https://doi.org/10.3390/su152316299

Chicago/Turabian StyleLemos, Moisés A. C., Camilla T. Baran, André L. B. Cavalcante, and Ennio M. Palmeira. 2023. "A Semi-Analytical Model of Contaminant Transport in Barrier Systems with Arbitrary Numbers of Layers" Sustainability 15, no. 23: 16299. https://doi.org/10.3390/su152316299

APA StyleLemos, M. A. C., Baran, C. T., Cavalcante, A. L. B., & Palmeira, E. M. (2023). A Semi-Analytical Model of Contaminant Transport in Barrier Systems with Arbitrary Numbers of Layers. Sustainability, 15(23), 16299. https://doi.org/10.3390/su152316299