Life Cycle-Based Carbon Emission Reduction Benefit Assessment of Centralized Photovoltaic Power Plants in China

Abstract

:1. Introduction

2. Materials and Methods

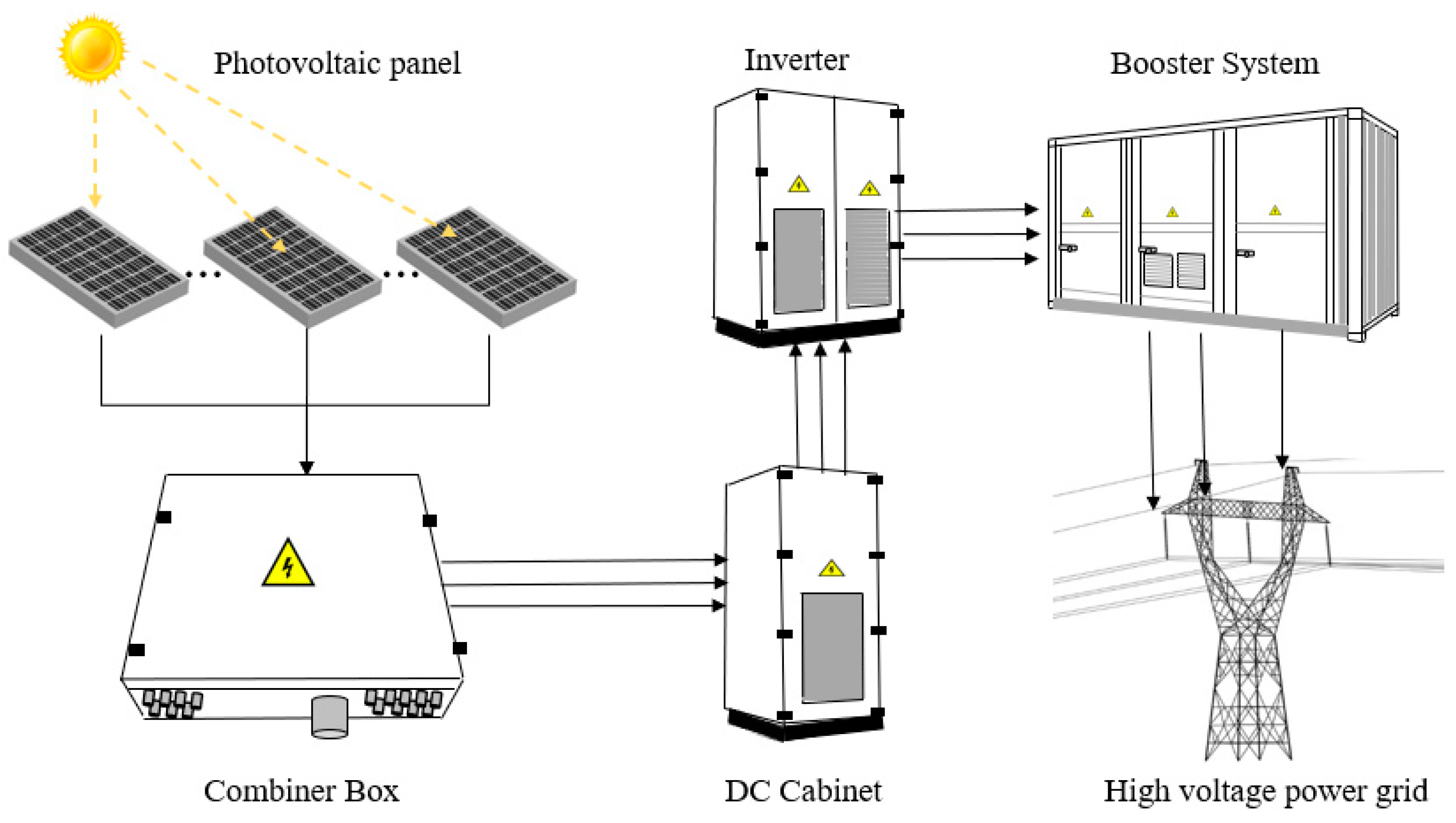

2.1. Scope of Carbon Emission Accounting for the Whole Life Cycle of Centralized PV Power Plants

2.2. Carbon Emission Accounting Methods for Centralized Photovoltaic Power Plants

- (1)

- Accounting model of the carbon emissions during the raw materials production stage.

- (2)

- Accounting model of the carbon emissions during the components production stage.

- (3)

- Accounting model of the carbon emissions during the transportation phase.

- (4)

- Accounting model of the carbon emissions during the PV power plant waste disposal phase.

2.3. Data Collection

3. Calculation Results of the Carbon Emissions of PV Power Generation

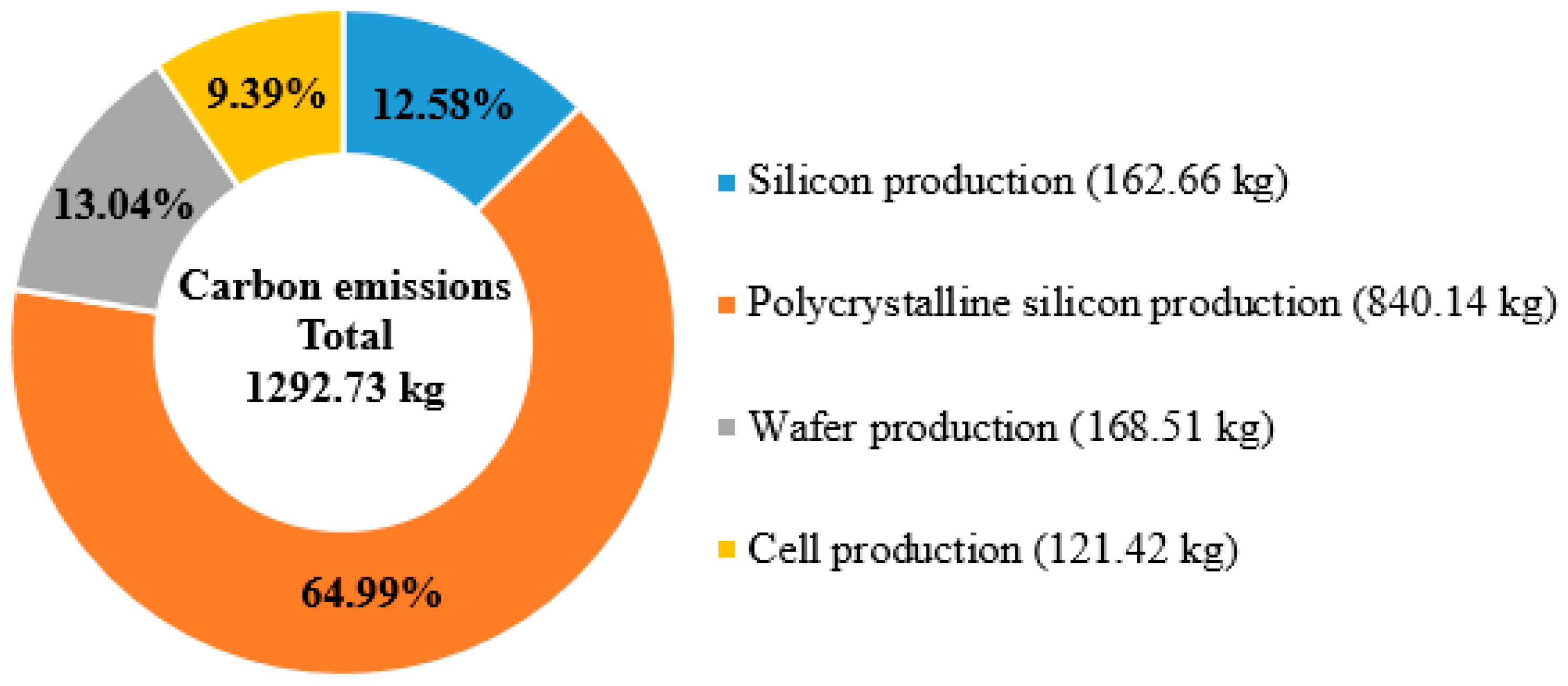

3.1. Carbon Emissions during the Raw Materials Production Stage

3.2. Carbon Emissions during the Modules Production Stage

3.3. Carbon Emissions during the Transportation Phase

3.4. Carbon Emissions during the Waste Disposal Phase

4. Discussion and Evaluation of the Carbon Emissions Reduction Effects of Centralized PV Power Generation

4.1. Calculation of Carbon Benefits of Photovoltaic Systems

4.1.1. Calculation of the Carbon Payback Period for Centralized PV Power Generation

4.1.2. Calculation of the Carbon Dioxide Reduction by the Centralized PV Power Plants

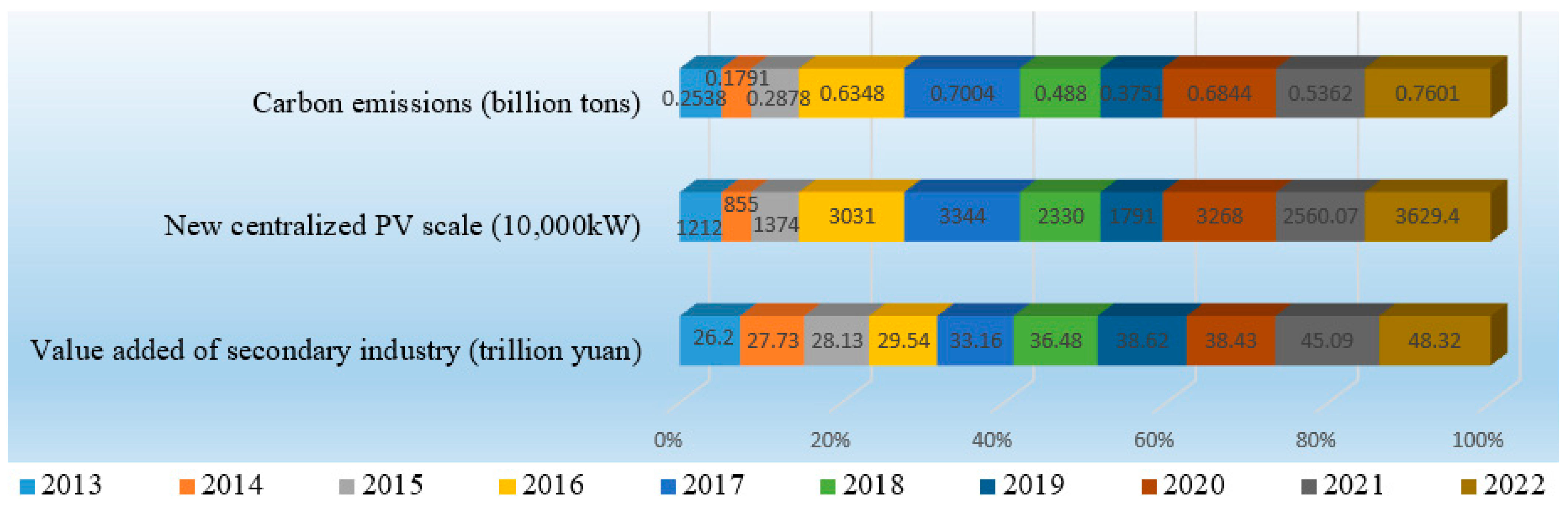

4.1.3. Comparison between the Carbon Emissions Caused by the Newly Constructed Centralized PV Power Plants in 2013 and 2022

4.2. Assumption of the Economic Cost of Centralized PV Power Generation

4.3. Evaluation of the Relationship between the Carbon Emissions of PV Power Generation and the Development of the Economy

4.4. Policy Recommendations

4.5. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, L.; Li, X.; Zhao, H.; Ma, W.; Jiang, P. System dynamic modeling of urban carbon emissions based on the regional National Economy and Social Development Plan: A case study of Shanghai city. J. Clean. Prod. 2018, 172, 1501–1513. [Google Scholar] [CrossRef]

- Filippov, S. New Technological Revolution and Energy Requirements. Foresight STI Gov. 2018, 12, 20–33. [Google Scholar] [CrossRef]

- Yan, Z.; Ding, Y.; Zhai, P.; Song, L.; Cao, L.; Li, Z. Re-Assessing Climatic Warming in China since 1900. J. Meteorol. Res. 2020, 34, 243–251. [Google Scholar] [CrossRef]

- Pacifici, M.; Foden, W.B.; Visconti, P.; Watson, J.E.M.; Butchart, S.H.M.; Kovacs, K.M.; Scheffers, B.R.; Hole, D.G.; Martin, T.G.; Akçakaya, H.R.; et al. Assessing species vulnerability to climate change. Nat. Clim. Change 2015, 5, 215–224. [Google Scholar] [CrossRef]

- Manabe, S. Role of greenhouse gas in climate change. Tellus A Dyn. Meteorol. Oceanogr. 2019, 71, 1620078. [Google Scholar] [CrossRef]

- Gillingham, K.; Stock, J.H. The Cost of Reducing Greenhouse Gas Emissions. J. Econ. Perspect. 2018, 32, 53–72. [Google Scholar] [CrossRef]

- Oertel, C.; Matschullat, J.; Zurba, K.; Zimmermann, F.; Erasmi, S. Greenhouse gas emissions from soils—A review. Geochemistry 2016, 76, 327–352. [Google Scholar] [CrossRef]

- Lv, W.; Hong, X.; Fang, K. Chinese regional energy efficiency change and its determinants analysis: Malmquist index and Tobit model. Ann. Oper. Res. 2012, 228, 9–22. [Google Scholar] [CrossRef]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G.; et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef]

- Zheng, J.; Mi, Z.; Coffman, D.M.; Milcheva, S.; Shan, Y.; Guan, D.; Wang, S. Regional development and carbon emissions in China. Energy Econ. 2019, 81, 25–36. [Google Scholar] [CrossRef]

- Tang, R.; Zhao, J.; Liu, Y.; Huang, X.; Zhang, Y.; Zhou, D.; Ding, A.; Nielsen, C.P.; Wang, H. Air quality and health co-benefits of China’s carbon dioxide emissions peaking before 2030. Nat. Commun. 2022, 13, 1008. [Google Scholar] [CrossRef] [PubMed]

- Du, D.; Lu, Y.; Li, Q.; Zhou, Y.; Cao, T.; Cui, H.; Han, G. Estimating industrial process emission and assessing carbon dioxide equivalent of perfluorooctanoic acid (PFOA) and its salts in China. Sci Total Environ. 2023, 867, 161507. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Geng, L. Carbon emissions calculation from municipal solid waste and the influencing factors analysis in China. J. Clean. Prod. 2015, 104, 177–184. [Google Scholar] [CrossRef]

- Lai, S.; Lu, J.; Luo, X.; Ge, J. Carbon emission evaluation model and carbon reduction strategies for newly urbanized areas. Sustain. Prod. Consum. 2022, 31, 13–25. [Google Scholar] [CrossRef]

- Dudley, B.; Pureprint Group Limited, UK. BP Statistical Review of World Energy 2016. 2019. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/news-and-insights/speeches/bp-statistical-review-of-world-energy-2016-bob-dudley-speech.pdf (accessed on 1 December 2022).

- Wu, J.; Tang, G.; Wang, R.; Yanwei, S. Multi-Objective Optimization for China’s Power Carbon Emission Reduction by 2035. J. Therm. Sci. 2019, 28, 184–194. [Google Scholar] [CrossRef]

- Wen, L.; Diao, P. Simulation study on carbon emission of China’s electricity supply and demand under the dual-carbon target. J. Clean. Prod. 2022, 379, 134654. [Google Scholar] [CrossRef]

- Lin, B.; Wang, Y. Does energy poverty really exist in China? From the perspective of residential electricity consumption. Energy Policy 2020, 143, 111557. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. National Data. 2020. Available online: http://www.stats.gov.cn/english/ (accessed on 1 December 2022).

- Jinping, X.J.; Ministry of Foreign Affairs of the People’s Republic of China. Statement by HE Xi Jinping President of the People’s Republic of China at the General Debate of the 75th Session of The United Nations General Assembly. 2020. Available online: https://www.gov.cn/xinwen/2020-09/22/content_5546168.htm (accessed on 1 December 2022).

- Wu, Y.; Xu, B. When will China’s carbon emissions peak? Evidence from judgment criteria and emissions reduction paths. Energy Rep. 2022, 8, 8722–8735. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Adu, F.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Nigeria’s energy review: Focusing on solar energy potential and penetration. Environ. Dev. Sustain. 2022, 25, 5755–5796. [Google Scholar] [CrossRef]

- Imaaduddiin, M.H.; Utama, W.; Jasikur, C.; Lestari, W.; Aini, A.N. Potential for Renewable Energy Generation from Water Sources in the Batang River Area. Environ. Res. Eng. Manag. 2023, 79, 80–89. [Google Scholar] [CrossRef]

- Zhou, X.; Lin, J.; Wang, L.; Huang, H.; Zhao, X. Wind power resources and China’s sustainable development roadmap: Evidence from China. Resour. Policy 2022, 79, 103015. [Google Scholar] [CrossRef]

- Yu, G.; Liu, C.; Tang, B.; Chen, R.; Lu, L.; Cui, C.; Hu, Y.; Shen, L.; Muyeen, S.M. Short term wind power prediction for regional wind farms based on spatial-temporal characteristic distribution. Renew. Energy 2022, 199, 599–612. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Guo, X.; Dong, Y.; Ren, D.J.E. CO2 emission reduction effect of photovoltaic industry through 2060 in China. Energy 2023, 269, 126692. [Google Scholar] [CrossRef]

- Qiu, T.; Wang, L.; Lu, Y.; Zhang, M.; Qin, W.; Wang, S.; Wang, L. Potential assessment of photovoltaic power generation in China. Renew. Sustain. Energy Rev. 2022, 154, 111900. [Google Scholar] [CrossRef]

- Song, D.; Pei, H.; Liu, Y.; Wei, H.; Yang, S.; Hu, S. Review on Legislative System of Photovoltaic Industry Development in China. Energies 2022, 15, 306. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, Q.; Tan, T. An ensemble learning framework for rooftop photovoltaic project site selection. Energy 2023, 285, 128919. [Google Scholar] [CrossRef]

- Morey, M.; Gupta, N.; Garg, M.M.; Kumar, A. A comprehensive review of grid-connected solar photovoltaic system: Architecture, control, and ancillary services. Renew. Energy Focus 2023, 45, 307–330. [Google Scholar] [CrossRef]

- He, B.; Qian, S.; Li, T. Modeling product carbon footprint for manufacturing process. J. Clean. Prod. 2023, 402, 136805. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, C.; Lu, Q.; Tian, C.; Xiao, Z. Feature-based carbon emission quantitation strategy for the part machining process. Int. J. Comput. Integr. Manuf. 2017, 31, 406–425. [Google Scholar] [CrossRef]

- Wiedmann, T.; Minx, J. A Definition of ‘Carbon Footprint’. In Ecological Economics Research Trends; Nova Science Publishers: Hauppauge, NY, USA, 2008; pp. 1–11. [Google Scholar]

- Barthelmie, R.J.; Morris, S.D.; Schechter, P. Carbon neutral Biggar: Calculating the community carbon footprint and renewable energy options for footprint reduction. Sustain. Sci. 2008, 3, 267–282. [Google Scholar] [CrossRef]

- Larsen, H.N.; Hertwich, E.G. The case for consumption-based accounting of greenhouse gas emissions to promote local climate action. Environ. Sci. Policy 2009, 12, 791–798. [Google Scholar] [CrossRef]

- Zheng, L.; Li, Y.; Qian, C.; Du, Y. Carbon Emission Evaluation of Roadway Construction at Contaminated Sites Based on Life Cycle Assessment Method. Sustainability 2023, 15, 2642. [Google Scholar] [CrossRef]

- Lei, B.; Yu, L.; Chen, Z.; Yang, W.; Deng, C.; Tang, Z. Carbon Emission Evaluation of Recycled Fine Aggregate Concrete Based on Life Cycle Assessment. Sustainability 2022, 14, 4448. [Google Scholar] [CrossRef]

- Jia, H.; Liang, L.; Xie, J.; Zhang, J. Environmental Effects of Technological Improvements in Polysilicon Photovoltaic Systems in China—A Life Cycle Assessment. Sustainability 2022, 14, 8670. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Zhang, R.J.E.E. A review of the research methods on influencing factors of carbon emissions and carbon footprint. Environ. Eng. 2017, 35, 155–159. [Google Scholar]

- Hernández, H.; Ossio, F.; Silva, M. Assessment of Sustainability and Efficiency Metrics in Modern Methods of Construction: A Case Study Using a Life Cycle Assessment Approach. Sustainability 2023, 15, 6267. [Google Scholar] [CrossRef]

- Dong, H.; Geng, Y.J.R.S. Study on carbon footprint of the household consumption in Beijing based on input-output analysis. Resour. Sci. 2012, 34, 494–501. [Google Scholar]

- Perčić, M.; Ančić, I.; Vladimir, N. Life-cycle cost assessments of different power system configurations to reduce the carbon footprint in the Croatian short-sea shipping sector. Renew. Sustain. Energy Rev. 2020, 131, 110028. [Google Scholar] [CrossRef]

- Sharma, J.; Ravindranath, N.H. Applying IPCC 2014 framework for hazard-specific vulnerability assessment under climate change. Environ. Res. Commun. 2019, 1, 051004. [Google Scholar] [CrossRef]

- Farzaneh, F.; Jung, S. Lifecycle carbon footprint comparison between internal combustion engine versus electric transit vehicle: A case study in the U.S. J. Clean. Prod. 2023, 390, 136111. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Taborianski, V.M.; Prado, R.T.A. Methodology of CO2 emission evaluation in the life cycle of office building façades. Environ. Impact Assess. Rev. 2012, 33, 41–47. [Google Scholar] [CrossRef]

- Kellenberger, D.; Althaus, H.-J. Relevance of simplifications in LCA of building components. Build. Environ. 2009, 44, 818–825. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ramadan, M.; Naher, S.; Pullen, K.; Olabi, A.G. The impacts of different heating systems on the environment: A review. Sci Total Environ. 2021, 766, 142625. [Google Scholar] [CrossRef]

- Hanfang, L.; Lin, H.; Tan, Q.; Wu, P.; Wang, C.; Gejirifu, D.; Huang, L. Research on the policy route of China’s distributed photovoltaic power generation. Energy Rep. 2020, 6, 254–263. [Google Scholar] [CrossRef]

- ISO 14040; Life Cycle Assessment (LCA)–Principles And Guidelines; Waste Management for the Food Industries. Academic Press: Cambridge, MA, USA, 2008; pp. 97–132.

- ISO 14040:2006; Environmental Management: Life Cycle Assessment; Principles and Framework. International Organization for Standardization: Cham, Switzerland, 2006.

- van Sark, W.; Reich, N.; Alsema, E.; Nieuwlaar, E.; Willeke, G.; Ossenbrink, H.; Helm, P. CO2 Emissions of PV in the perspective of a Renewable Energy Economy. In Proceedings of the 22nd European Photovoltaic Solar Energy Conference, Milan, Italy, 3–7 September 2007; pp. 3538–3542. [Google Scholar]

- Mi, Y.; Liu, C.; Yang, J.; Zhang, H.; Wu, Q. Low-carbon generation expansion planning considering uncertainty of renewable energy at multi-time scales. Glob. Energy Interconnect. 2021, 4, 261–272. [Google Scholar] [CrossRef]

- Pinto, M.A.; Frate, C.A.; Rodrigues, T.O.; Caldeira-Pires, A. Sensitivity analysis of the carbon payback time for a Brazilian photovoltaic power plant. Util. Policy 2020, 63, 101014. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Laclau, B.; Garnesson, T.; Yang, X.; Tukker, A. Energy-carbon-investment payback analysis of prefabricated envelope-cladding system for building energy renovation: Cases in Spain, the Netherlands, and Sweden. Renew. Sustain. Energy Rev. 2021, 145, 111077. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Wu, Y.; Wang, Q.; Liu, X.; Qi, L.; Lu, X.; Gao, L. How to make better use of intermittent and variable energy? A review of wind and photovoltaic power consumption in China. Renew. Sustain. Energy Rev. 2021, 137, 110626. [Google Scholar] [CrossRef]

- Shubbak, M.H. The technological system of production and innovation: The case of photovoltaic technology in China. Res. Policy 2019, 48, 993–1015. [Google Scholar] [CrossRef]

- Haghpour, B.; Sahabeh, E.; Halvari, H. Opportunity cost in consumer behavior: Definitions, operationalizations, and ambiguities. Int. J. Consum. Stud. 2022, 46, 1942–1959. [Google Scholar] [CrossRef]

- de Figueiredo Silva, F.; Fulginiti, L.E.; Perrin, R.K.; Braga, M.J. The increasing opportunity cost of sequestering CO2 in the Brazilian Amazon forest. Empir. Econ. 2021, 62, 439–460. [Google Scholar] [CrossRef]

- Emirmahmutoglu, F.; Kose, N. Testing for Granger causality in heterogeneous mixed panels. Econ. Model. 2011, 28, 870–876. [Google Scholar] [CrossRef]

- Troster, V. Testing for Granger-causality in quantiles. Econom. Rev. 2016, 37, 850–866. [Google Scholar] [CrossRef]

| Production Stage | Direct Carbon Emissions | Electricity Consumption |

|---|---|---|

| Silicon production | 4.721 kg CO2/kg | 11.69 kWh/kg |

| Polycrystalline silicon production | / | 95 kWh/kg |

| Wafer production | / | 0.73 kWh/pieces |

| Cell production | / | 124 kWh/kWp |

| Power Consumption | Imports | Exports | |||

|---|---|---|---|---|---|

| Material | Energy | Material | Quantities | Material | Quantities |

| Power consumption | 58.5 kWh | Photovoltaic cell | 1.02 kWp | Battery component | 1 kWp |

| Reinforced glass | 62.22 kg | Solid waste | 132 g | ||

| Aluminum frame | 13.12 kg | TVOC | 3.24 g | ||

| EVA film | 7.06 kg | Welding fume | 1.04 g | ||

| Organic Silicone Gel | 40 kg | ||||

| Parameters | Parameter Value |

|---|---|

| Transportation distance | 84.3 km |

| Total transport mass | 4 t |

| Fuel consumption | 0.20 L/km |

| Origin and destination of transportation | Hangzhou-Jiaxing |

| Installed photovoltaic capacity | 1 kWp |

| Power Consumption | Import | Export | |||

|---|---|---|---|---|---|

| Material | Energy | Material | Energy | Material | Energy |

| Electricity consumption | 128.24 kWh | Waste battery pack | 1 kWp | Silicon chip | 217 pieces |

| Toluene | 26.66 kg | Steel | 0.229 kg | ||

| HNO3 | 15.00 kg | Silver | 0.328 kg | ||

| HF | 10.35 kg | Aluminum | 13.55 kg | ||

| CH3COOH | 9.00 kg | Plastics | 0.776 kg | ||

| EVA | 4.26 kg | ||||

| Glass | 48.98 kg | ||||

| TPT | 3.26 kg | ||||

| Sealing silicone | 0.265 kg | ||||

| Production Stage | Emission | Proportion |

|---|---|---|

| Battery assembly production | 405.82 kg | 40.54% |

| Balanced component production | 595.20 kg | 59.46% |

| Total: 1001.02 kg | ||

| Type of Greenhouse Gas | GWP Value |

|---|---|

| CO2 | 1 |

| CH4 | 23 |

| N2O | 296 |

| Type of Greenhouse Gas | Emission Factors (kg/L) |

|---|---|

| CO2 | 2.73 |

| CH4 | 1.44 × 10−4 |

| N2O | 1.44 × 10−4 |

| Type of Emission | Emission | Proportion |

|---|---|---|

| Energy consumption | 123.11 kg | 79.99% |

| Depletion of resources | 30.796 kg | 20.01% |

| Resource recycle | −400.06 kg | / |

| Total: −246.15 kg | ||

| Life Cycle Stage | Emission | Proportion |

|---|---|---|

| Raw material production stage | 1292.73 kg | 61.72% |

| Module production stage | 1001.02 kg | 47.79% |

| Transportation and maintenance phase | 46.80 kg | 2.23% |

| Waste disposal phase | −246.15 kg | −11.75% |

| Total: 2094.40 kg | ||

| Life Cycle Stage | Emission | Proportion | Magnitude of Change | |

|---|---|---|---|---|

| Raw material production stage | Silicon production | 162.28 | 5.16% | +0.23% |

| Polycrystalline silicon production | 1110.72 | 35.35% | −24.36% | |

| Wafer production | 336.42 | 10.71% | −49.91% | |

| Well production | 219.79 | 6.99% | −44.75% | |

| module production stage | Battery assembly production | 684.94 | 21.80% | −40.75% |

| Balanced component production | 827.70 | 26.34% | −28.09% | |

| Transportation and Maintenance phase | / | 46.8 | 1.49% | 0% |

| Waste disposal phase | / | −246.151 | −7.83% | 0% |

| Total: 3142.51 kg | Magnitude of change: −33.35% | |||

| Crop Type | Unit Net Profit (yuan/m2) | Acreage (m2) | Profitability of Planting (yuan/kWp) |

|---|---|---|---|

| Paddy | 0.090 | 169.86 | R1 = 15.287 |

| Maize | 0.194 | R2 = 32.953 | |

| Corn | 0.243 | R3 = 41.276 |

| Variable Relationship | Hysteresis | p-Value | Conclusions |

|---|---|---|---|

| Carbon emissions → secondary sector | Phase 1 | 0.021 | Granger |

| Secondary sector → carbon emissions | 0.277 | Not Granger |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Wu, J.; Yang, Q.; Chen, W.; Li, P.; Huang, C.; Deng, J.; Ji, B.; Xie, L. Life Cycle-Based Carbon Emission Reduction Benefit Assessment of Centralized Photovoltaic Power Plants in China. Sustainability 2023, 15, 16323. https://doi.org/10.3390/su152316323

Deng Y, Wu J, Yang Q, Chen W, Li P, Huang C, Deng J, Ji B, Xie L. Life Cycle-Based Carbon Emission Reduction Benefit Assessment of Centralized Photovoltaic Power Plants in China. Sustainability. 2023; 15(23):16323. https://doi.org/10.3390/su152316323

Chicago/Turabian StyleDeng, Yanhua, Jiji Wu, Qian Yang, Weizhen Chen, Penghan Li, Chenhao Huang, Jinsong Deng, Biyong Ji, and Lijian Xie. 2023. "Life Cycle-Based Carbon Emission Reduction Benefit Assessment of Centralized Photovoltaic Power Plants in China" Sustainability 15, no. 23: 16323. https://doi.org/10.3390/su152316323

APA StyleDeng, Y., Wu, J., Yang, Q., Chen, W., Li, P., Huang, C., Deng, J., Ji, B., & Xie, L. (2023). Life Cycle-Based Carbon Emission Reduction Benefit Assessment of Centralized Photovoltaic Power Plants in China. Sustainability, 15(23), 16323. https://doi.org/10.3390/su152316323