Truck-Drone Pickup and Delivery Problem with Drone Weight-Related Cost

Abstract

:1. Introduction

- (i)

- To the best of our knowledge, it is the first study to introduce drone weight-related cost into the truck-drone pickup and delivery problem, and the corresponding problem is called the truck-drone pickup and delivery problem with drone weight-related cost. Based on minimizing the sum of the drone weight-related cost, the fixed vehicle cost, and the travel distance cost, a mixed-integer programming model is proposed.

- (ii)

- To tackle the problem, an improved ALNS algorithm is designed. In this algorithm, several effective destroy operators and repair operators are designed, based on the characteristics of the problem, to explore the solution space, and the simulated annealing acceptance criterion is introduced to improve the algorithm performance by preventing the solution falling into local optima.

- (iii)

- Extensive computational experiments demonstrate the effectiveness of the model and algorithm and the necessity to consider the drone weight-related cost constraints.

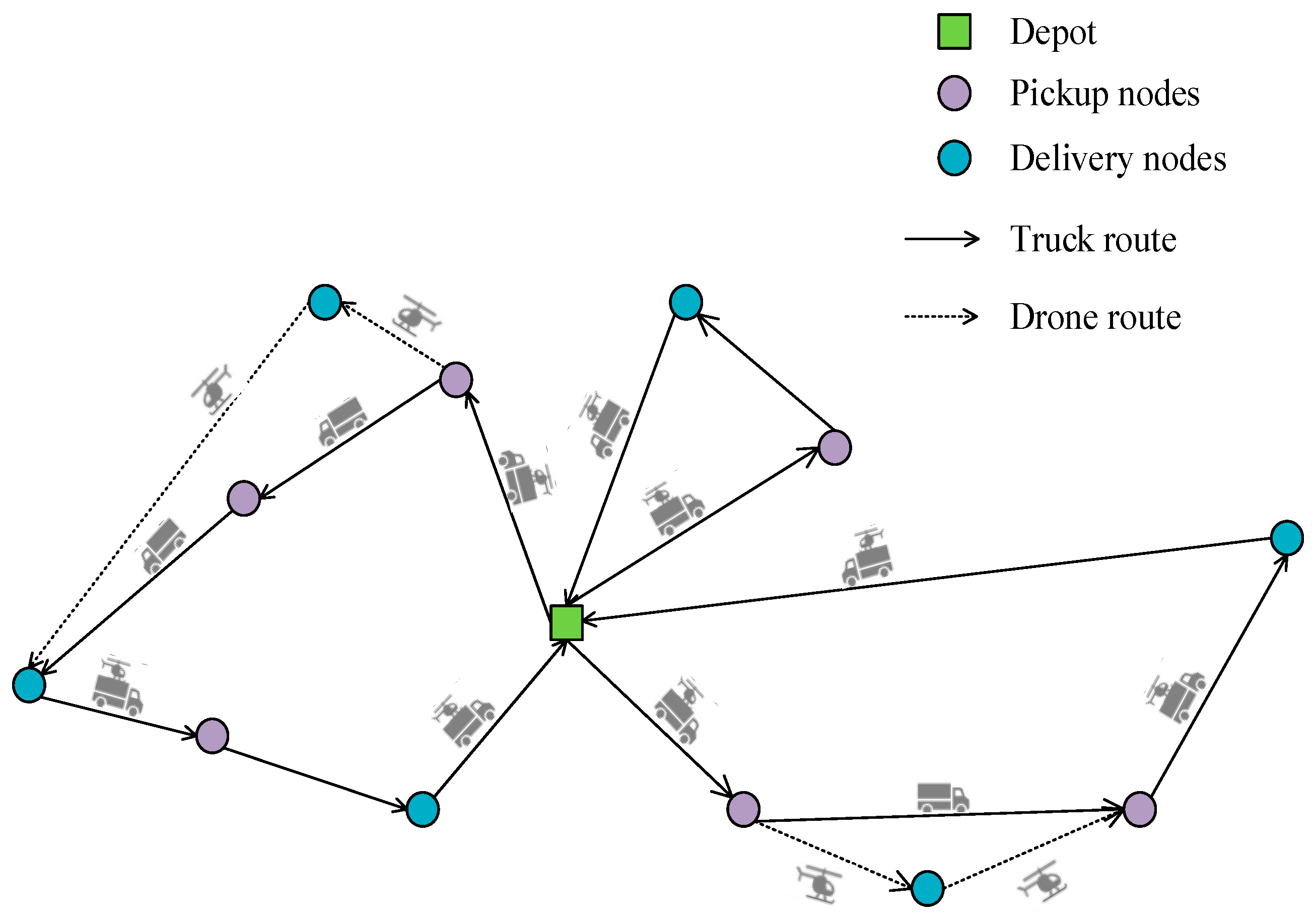

2. Problem Definition and Mathematical Model

- (i)

- A fleet of identical truck-drone pairs K will begin at 0 and return to 2n + 1 while fulfilling demands for pickup or delivery goods at different locations within specified time windows. The truck’s cargo load must not exceed Q and the drone’s cargo load must not exceed Q’.

- (ii)

- Customers should be serviced by either a truck or drone. Each customer’s demand qi corresponds to a pickup node and delivery node. The pickup and delivery nodes need to be serviced by trucks and drones within their time windows.

- (iii)

- The trucks TR first pick up the goods at the pickup nodes P and then deliver the goods to the corresponding delivery nodes D. The drone can only service delivery nodes D’ that meet the constraints of cargo capacity Q’ and power range e; it departs from the truck and then meets up with the truck after completing the delivery service. While a drone delivers, the truck moves to another node to fulfill further demands. To ensure sufficient power for future flights, drone batteries are swiftly switched out upon docking with the truck. Both trucks and drones travel at consistent speeds throughout pickup and delivery.

3. Improved Adaptive Large Neighborhood Search Algorithm

| Algorithm 1: IALNS Algorithm Framework | ||

| Inputs: initial temperature Tinit, current solution S, cooling rate a. | ||

| Sbest = S, T = Tinit; destruct operator = {1,…, 1}, repair operator = {1,…, 1}; | ||

| While not meet the stopping criteria do | ||

| Select destroy operator d based on the operators’ weight using the roulette method; Select repair operator r based on the operators’ weight using the roulette method; | ||

| S’ = r(d(S)); | ||

| if f(S’) < f(Sbest) then | ||

| Sbest; | ||

| else if f(S’) < f(S) then | ||

| S; | ||

| else | ||

| Accept or not S’ based on simulated annealing criterion | ||

| end if | ||

| T = T × a; | ||

| end while | ||

| return Sbest | ||

3.1. Destroy Operators

3.1.1. Correlation Destroy Operator

| Algorithm 2: Correlation Destroy Operator | |

| Inputs: current routes S, generate random number q: = number of demands to be destroyed; | |

| A randomly selected demand r from S is placed in the array D, D = {r}; | |

| while |D| < q | |

| A randomly selected demand r from the array D; Store the remaining demands in S in the array L; Arrange the array L according to the formula, i < j if R(r, L|i|) < R(r, L|j|); Randomly select a number y from [0,1); D = D ∪ {L[yp|L|]}; | |

| end while Remove all demands in D; | |

| return D, Undestroyed demands constitutes routes S. | |

3.1.2. Random Destroy Operator

| Algorithm 3: Random Destroy Operator | |

| Inputs: current routes S, generate random number q: = number of demands to be destroyed, m = 0; | |

| while m < q | |

| x = S.randomChoose(S); | |

| Insert demand x into D; | |

| m ++; | |

| end while | |

| Remove all demands in D; | |

| return D, Undestroyed demands constitute routes S. | |

3.2. Repair Operators

3.2.1. Truck-First Greedy Repair Operator

| Algorithm 4: Truck-first greedy repair operator | ||||||

| Inputs: current routes S; uninserted demands D. | ||||||

| while D ≠ φ do | ||||||

| Randomly select a demand i in D, D = D\{i}; | ||||||

| Insert pickup node and delivery node of demand i according to min ci, ci = mink∈K{Δfik}; | ||||||

| end while return S | ||||||

| C = All delivery nodes that meet drone capacity; while C ≠ 0 do | ||||||

| Randomly select a node in C, C = C\{c}; if Both node c and its corresponding pickup node c’ satisfy the time window and other constraints then | ||||||

| S’ = S, S = S\{c, c’}, f(S1) = INF; for each route in S do | ||||||

| if satisfy the current route capacity constraint then | ||||||

| for the positions of all consecutive nodes along routes do | ||||||

| Let truck and drone visit c’, let drone visit c, and the position of node c is after node c’. | ||||||

| if newly constructed routes costs f(S2) < f(S1) then | ||||||

| S1 = S2; | ||||||

| end if | ||||||

| end for | ||||||

| end if | ||||||

| end for | ||||||

| return S1; | ||||||

| S = S1; | ||||||

| end if | ||||||

| end while return Sbest | ||||||

3.2.2. Truck-First Regret Value Repair Operator

3.3. Adaptive Strategy

3.4. Acceptance Criteria

4. Experiment Results

- (1)

- A comparison of the solution results between CPLEX and IALNS algorithm for 18 small-scale instances is employed to demonstrate the effectiveness of the model and algorithm;

- (2)

- A comparison of the solution results for 54 large-scale instances of the model with or without drone weight-related cost under the same constraints is to verify that the stability of the algorithm and the model with drone weight-related cost can effectively reduce the total route transportation cost.

4.1. Test Environment and Parameter Settings

4.2. Results for Small-Scale Instances

4.3. Results for Large-Scale Instances

5. Conclusions and Outlook

- (i)

- Comparing the results with the optimal solutions by CPLEX, ALNS basically outperforms CPLEX in terms of solution time and solution results by solving small-scale instances, and the effectiveness of the model and algorithm is validated.

- (ii)

- Comparing the results of TDPDP and TDPDP-DW, ignoring the drone weight constraints leads to an average underestimation of the total travel cost by 12.61% by solving large-scale instances. The stability of the algorithm and the necessity of incorporating drone weight cost into the problem is demonstrated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Sets | |

| P | Set of pickup nodes; P = {1, 2,…, n} |

| D | Set of delivery nodes; D = {n + 1,…, 2n} |

| N | N = P ∪ D |

| 0, 2n + 1 | 0 represents the starting node, 2n+1 is the ending node |

| V | V = N ∪ {0, 2n + 1} |

| P’ | P’ ⊆ P, set of corresponding pickup nodes that can be serviced by drone |

| D’ | D’ ⊆ D, set of corresponding delivery nodes that can be serviced by drone |

| K | Set of vehicles, where each vehicle consists of one truck and one drone; K = {1, 2,…, k} |

| TR | Set of trucks; TR = {1, 2,…, tr}; tr = k |

| DR | Set of drones; DR = {1, 2,…, dr}; dr = k |

| Parameters | |

| qi | Demand of customer i |

| Q | Maximum capacity of truck |

| Q’ | Maximum capacity of drone |

| B0 | Fixed cost of dispatching a vehicle, where each vehicle consists of one truck and one drone |

| B1 | Fixed cost per unit distance travelled by truck |

| B2 | Fixed cost per unit distance travelled by drone |

| a | Distance–weight cost ratio for drone delivery |

| b | Distance cost ratio for drone delivery |

| e | Maximum duration of drone battery |

| dij | |

| [ei, li] | |

| L | Time taken to launch a drone |

| R | Time taken to recover a drone |

| si | |

| M | A large number |

| Decision Variables | |

| xijk | |

| xijtr | |

| yijdr | |

| titr | |

| tdidr | |

| wij | |

References

- Zheng, Y.; Xu, Y. Optimizing green strategy for retired electric vehicle battery recycling: An evolutionary game theory approach. Sustainability 2023, 15, 15464. [Google Scholar] [CrossRef]

- Yang, W.; Ke, L.; Wang, D.Z.W.; Lam, J.S.L. A branch-price-and-cut algorithm for the vehicle routing problem with release and due dates. Transp. Res. Part E Logist. Transp. Rev. 2021, 145, 102167. [Google Scholar] [CrossRef]

- Euchi, J.; Sadok, A. Hybrid genetic-sweep algorithm to solve the vehicle routing problem with drones. Phys. Commun. 2021, 44, 101236. [Google Scholar] [CrossRef]

- Otto, A.; Agatz, N.; Campbell, J.; Golden, B.; Pesch, E. Optimization approaches for civil applications of unmanned aerial vehicles (UAVs) or aerial drones: A survey. Networks 2018, 72, 411–458. [Google Scholar] [CrossRef]

- Ren, X.; Huang, H.; Yu, S.; Feng, S.; Liang, G. Review on vehicle-UAV combined delivery problem. Control Decis. 2021, 36, 2313–2327. [Google Scholar] [CrossRef]

- Murray, C.C.; Chu, A.G. The flying sidekick traveling salesman problem: Optimization of drone-assisted parcel delivery. Transp. Res. Part C Emerg. Technol. 2015, 54, 86–109. [Google Scholar] [CrossRef]

- Bouman, P.; Agatz, N.; Schmidt, M. Dynamic programming approaches for the traveling salesman problem with drone. Networks 2018, 72, 528–542. [Google Scholar] [CrossRef]

- Wang, X.; Poikonen, S.; Golden, B. The vehicle routing problem with drones: Several worst-case results. Optim. Lett. 2016, 11, 679–697. [Google Scholar] [CrossRef]

- Sacramento, D.; Pisinger, D.; Ropke, S. An adaptive large neighborhood search metaheuristic for the vehicle routing problem with drones. Transp. Res. Part C Emerg. Technol. 2019, 102, 289–315. [Google Scholar] [CrossRef]

- El-Adle, A.M.; Ghoniem, A.; Haouari, M. Parcel delivery by vehicle and drone. J. Oper. Res. Soc. 2019, 72, 398–416. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Guan, X.; Fan, J.; Xu, M.; Wang, H. Collaborative multi-depot pickup and delivery vehicle routing problem with split loads and time windows. Knowl. Based Syst. 2021, 231, 107412. [Google Scholar] [CrossRef]

- Alyasiry, A.M.; Forbes, M.; Bulmer, M. An exact algorithm for the pickup and delivery problem with time windows and last-in-first-out loading. Transp. Sci. 2019, 53, 1695–1705. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.-l.; Lao, Y.-t.; Yu, H.-y.; Liu, Y. A two-stage heuristic method for vehicle routing problem with split deliveries and pickups. J. Zhejiang Univ. Sci. C 2014, 15, 200–210. [Google Scholar] [CrossRef]

- Ropke, S.; Pisinger, D. An adaptive large neighborhood search heuristic for the pickup and delivery problem with time windows. Transp. Sci. 2006, 40, 455–472. [Google Scholar] [CrossRef]

- Sartori, C.S.; Buriol, L.S. A study on the pickup and delivery problem with time windows: Matheuristics and new instances. Comput. Oper. Res. 2020, 124, 105065. [Google Scholar] [CrossRef]

- Naccache, S.; Côté, J.-F.; Coelho, L.C. The multi-pickup and delivery problem with time windows. Eur. J. Oper. Res. 2018, 269, 353–362. [Google Scholar] [CrossRef]

- Goeke, D. Granular tabu search for the pickup and delivery problem with time windows and electric vehicles. Eur. J. Oper. Res. 2019, 278, 821–836. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Liu, J. An improved genetic algorithm for the granularity-based split vehicle routing problem with simultaneous delivery and pickup. Mathematics 2023, 11, 3328. [Google Scholar] [CrossRef]

- Hornstra, R.P.; Silva, A.; Roodbergen, K.J.; Coelho, L.C. The vehicle routing problem with simultaneous pickup and delivery and handling costs. Comput. Oper. Res. 2020, 115, 104858. [Google Scholar] [CrossRef]

- Lurkin, V.; Schyns, M. The airline container loading problem with pickup and delivery. Eur. J. Oper. Res. 2015, 244, 955–965. [Google Scholar] [CrossRef]

- Hochstenbach, M.; Notteboom, C.; Theys, B.; De Schutter, J. Design and control of an unmanned aerial vehicle for autonomous parcel delivery with transition from vertical take-off to forward flight—VertiKUL, a Quadcopter tailsitter. Int. J. Micro Air Veh. 2015, 7, 395–405. [Google Scholar] [CrossRef]

- Luo, Z.; Qin, H.; Zhang, D.; Lim, A. Adaptive large neighborhood search heuristics for the vehicle routing problem with stochastic demands and weight-related cost. Transp. Res. Part E Logist. Transp. Rev. 2016, 85, 69–89. [Google Scholar] [CrossRef]

- Kuo, Y. Using simulated annealing to minimize fuel consumption for the time-dependent vehicle routing problem. Comput. Ind. Eng. 2010, 59, 157–165. [Google Scholar] [CrossRef]

- Zhang, J.U.N.; Tang, J.; Fung, R.Y.K. A scatter search for multi-depot vehicle routing problem with weight-related cost. Asia-Pac. J. Oper. Res. 2011, 28, 323–348. [Google Scholar] [CrossRef]

- Luo, Z.; Qin, H.; Zhu, W.; Lim, A. Branch and price and cut for the split-delivery vehicle routing problem with time windows and linear weight-related cost. Transp. Sci. 2017, 51, 668–687. [Google Scholar] [CrossRef]

- Mulati, M.H.; Fukasawa, R.; Miyazawa, F.K. The arc-item-load and related formulations for the cumulative vehicle routing problem. Discret. Optim. 2022, 45, 100710. [Google Scholar] [CrossRef]

- Pan, X.; Wu, Y.; Chong, G.; Khan, M.A. Multipoint distribution vehicle routing optimization problem considering random demand and changing load. Secur. Commun. Netw. 2022, 2022, 8199991. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Song, B.D.; Lee, S. Truck-drone hybrid delivery routing: Payload-energy dependency and no-fly zones. Int. J. Prod. Econ. 2019, 214, 220–233. [Google Scholar] [CrossRef]

- Shaw, P. A New Local Search Algorithm Providing High Quality Solutions to Vehicle Routing Problems; APES Group, Deptartment of Computer Science, University of Strathclyde: Glasgow, UK, 1997; Volume 46. [Google Scholar]

- Li, H.; Lim, A. A Metaheuristic for the pickup and delivery problem with time windows. Int. J. Artif. Intell. Tools 2011, 12, 173–186. [Google Scholar] [CrossRef]

| AC | CPLEX | IALNS | GAP (%) | ||||

|---|---|---|---|---|---|---|---|

| RN | TC | RT | RN | TC | RT | ||

| lc10-1 | 2 | 192.24 | 10.81 | 2 | 192.24 | 0.43 | 0 |

| lc10-2 | 2 | 172.01 | 19.98 | 2 | 172.01 | 0.40 | 0 |

| lr10-1 | 3 | 258.56 | 101.32 | 3 | 258.56 | 1.72 | 0 |

| lr10-2 | 2 | 310.55 | 3041.43 | 2 | 310.55 | 1.96 | 0 |

| lrc10-1 | 4 | 545.33 | 3600 | 4 | 515.39 | 1.94 | −5.49 |

| lrc10-2 | 4 | 428.10 | 3600 | 4 | 378.12 | 3.80 | −11.67 |

| lc15-1 | 2 | 281.19 | 3600 | 2 | 286.31 | 4.18 | 1.82 |

| lc15-2 | 2 | 514.25 | 3600 | 2 | 498.43 | 2.01 | −3.08 |

| lr15-1 | 3 | 421.32 | 3600 | 4 | 335.47 | 6.48 | −20.38 |

| lr15-2 | 4 | 386.30 | 3600 | 4 | 343.32 | 10.74 | −11.13 |

| lrc15-1 | 4 | 472.65 | 3600 | 4 | 420.99 | 15.08 | −10.93 |

| lrc15-2 | 5 | 578.38 | 3600 | 5 | 535.49 | 8.18 | −7.42 |

| lc20-1 | 2 | 496.13 | 3600 | 2 | 464.43 | 3.52 | −6.39 |

| lc20-2 | 2 | 453.21 | 3600 | 2 | 435.52 | 7.27 | −3.90 |

| lr20-1 | 5 | 689.12 | 3600 | 5 | 559.16 | 5.87 | −18.86 |

| lr20-2 | 4 | 601.32 | 3600 | 5 | 472.41 | 5.36 | −21.44 |

| lrc20-1 | 7 | 1044.34 | 3600 | 7 | 849.37 | 8.54 | −18.67 |

| lrc20-2 | 7 | 956.86 | 3600 | 7 | 782.24 | 14.36 | −18.25 |

| C | TDPDP | TDPDP-DW | GAPW (%) | GAPV | ||

|---|---|---|---|---|---|---|

| ZD | VD | ZDW | VDW | |||

| lc100-10-1 | 349.42 | 8 | 321.17 | 8 | 8.08 | 0 |

| lc100-10-2 | 439.31 | 8 | 384.58 | 8 | 12.46 | 0 |

| lc100-10-3 | 413.05 | 8 | 369.09 | 8 | 10.46 | 0 |

| lc100-10-4 | 398.82 | 8 | 355.5 | 8 | 10.86 | 0 |

| lc100-10-5 | 482.47 | 8 | 424.06 | 8 | 12.11 | 0 |

| lc100-10-6 | 413.15 | 8 | 378.65 | 7 | 8.35 | 1 |

| lc100-20-1 | 664.52 | 8 | 539.21 | 8 | 18.86 | 0 |

| lc100-20-2 | 597.19 | 8 | 532.04 | 8 | 10.91 | 0 |

| lc100-20-3 | 754.07 | 8 | 617.08 | 8 | 11.01 | 0 |

| lc100-20-4 | 774.52 | 8 | 698.56 | 8 | 9.81 | 0 |

| lc100-20-5 | 910.17 | 8 | 746.33 | 8 | 18.00 | 0 |

| lc100-20-6 | 1108.03 | 9 | 993.84 | 9 | 10.31 | 0 |

| lc100-30-1 | 1083.62 | 8 | 948.99 | 8 | 12.42 | 0 |

| lc100-30-2 | 1259.71 | 8 | 1130.59 | 9 | 10.25 | 0 |

| lc100-30-3 | 1399.03 | 10 | 1173.86 | 10 | 16.09 | 0 |

| lc100-30-4 | 1182.73 | 10 | 1074.26 | 9 | 9.17 | 1 |

| lc100-30-5 | 1474.01 | 8 | 1277.5 | 8 | 13.33 | 0 |

| lc100-30-6 | 1439.08 | 9 | 1203.28 | 9 | 16.39 | 0 |

| AC | TDPDP | TDPDP-DW | GAPW (%) | GAPV | ||

|---|---|---|---|---|---|---|

| ZD | VD | ZDW | VDW | |||

| lr100-10-1 | 468.78 | 9 | 413.42 | 9 | 11.81 | 0 |

| lr100-10-2 | 521.11 | 9 | 445.52 | 9 | 14.51 | 0 |

| lr100-10-3 | 443.03 | 9 | 412.41 | 8 | 6.91 | 1 |

| lr100-10-4 | 529.31 | 9 | 478.57 | 9 | 9.59 | 0 |

| lr100-10-5 | 537.4 | 10 | 464.92 | 10 | 13.49 | 0 |

| lr100-10-6 | 522.66 | 9 | 463.41 | 9 | 11.34 | 0 |

| lr100-20-1 | 861.02 | 8 | 783.90 | 8 | 8.96 | 0 |

| lr100-20-2 | 600.1 | 9 | 513.58 | 9 | 14.42 | 0 |

| lr100-20-3 | 951.09 | 8 | 763.72 | 8 | 19.70 | 0 |

| lr100-20-4 | 889.21 | 9 | 793.47 | 9 | 10.77 | 0 |

| lr100-20-5 | 1083.64 | 9 | 962.83 | 9 | 11.15 | 0 |

| lr100-20-6 | 1210.71 | 9 | 1121.93 | 8 | 7.33 | 1 |

| lr100-30-1 | 1139.64 | 9 | 961.35 | 9 | 15.64 | 0 |

| lr100-30-2 | 1291.91 | 10 | 1102.53 | 10 | 14.66 | 0 |

| lr100-30-3 | 1398.41 | 9 | 1261.01 | 9 | 13.04 | 0 |

| lr100-30-4 | 1498.56 | 8 | 1236.12 | 8 | 17.51 | 0 |

| lr100-30-5 | 1599.79 | 9 | 1372.82 | 9 | 14.19 | 0 |

| lr100-30-6 | 1302.61 | 9 | 1100.35 | 9 | 15.53 | 0 |

| AC | TDPDP | TDPDP-DW | GAPW (%) | GAPV | ||

|---|---|---|---|---|---|---|

| ZD | VD | ZDW | VDW | |||

| lrc100-10-1 | 456.38 | 9 | 423.45 | 9 | 7.22 | 0 |

| lrc100-10-2 | 492.07 | 8 | 431.42 | 8 | 12.33 | 0 |

| lrc100-10-3 | 484.32 | 9 | 414.31 | 9 | 14.46 | 0 |

| lrc100-10-4 | 457.21 | 9 | 411.03 | 9 | 10.10 | 0 |

| lrc100-10-5 | 432.58 | 9 | 383.56 | 9 | 11.33 | 0 |

| lrc100-10-6 | 396.15 | 9 | 352.67 | 9 | 10.98 | 0 |

| lrc100-20-1 | 656.23 | 8 | 552.89 | 8 | 15.75 | 0 |

| lrc100-20-2 | 854.09 | 8 | 735.85 | 8 | 13.84 | 0 |

| lrc100-20-3 | 971.06 | 8 | 792.41 | 8 | 18.40 | 0 |

| lrc100-20-4 | 816.89 | 8 | 725.10 | 8 | 11.24 | 0 |

| lrc100-20-5 | 665.19 | 8 | 555.78 | 8 | 16.45 | 0 |

| lrc100-20-6 | 909.87 | 8 | 802.57 | 8 | 11.79 | 0 |

| lrc100-30-1 | 1061.66 | 10 | 979.36 | 9 | 7.75 | 1 |

| lrc100-30-2 | 1217.47 | 8 | 1041.21 | 8 | 14.48 | 0 |

| lrc100-30-3 | 1379.26 | 9 | 1200.05 | 9 | 12.99 | 0 |

| lrc100-30-4 | 1586.09 | 9 | 1401.91 | 9 | 11.61 | 0 |

| lrc100-30-5 | 1639.58 | 9 | 1368.74 | 9 | 16.52 | 0 |

| lrc100-30-6 | 1296.86 | 9 | 1113.82 | 9 | 14.11 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Wu, T.; Xia, B.; Zhang, J. Truck-Drone Pickup and Delivery Problem with Drone Weight-Related Cost. Sustainability 2023, 15, 16342. https://doi.org/10.3390/su152316342

Xia Y, Wu T, Xia B, Zhang J. Truck-Drone Pickup and Delivery Problem with Drone Weight-Related Cost. Sustainability. 2023; 15(23):16342. https://doi.org/10.3390/su152316342

Chicago/Turabian StyleXia, Yang, Tingying Wu, Beixin Xia, and Junkang Zhang. 2023. "Truck-Drone Pickup and Delivery Problem with Drone Weight-Related Cost" Sustainability 15, no. 23: 16342. https://doi.org/10.3390/su152316342

APA StyleXia, Y., Wu, T., Xia, B., & Zhang, J. (2023). Truck-Drone Pickup and Delivery Problem with Drone Weight-Related Cost. Sustainability, 15(23), 16342. https://doi.org/10.3390/su152316342